NISSAN SERENA 1993 Service Repair Manual

SERENA 1993

NISSAN

NISSAN

https://www.carmanualsonline.info/img/5/57387/w960_57387-0.png

NISSAN SERENA 1993 Service Repair Manual

Trending: tow, jump start, radiator, USB, light, low beam, fuse diagram

Page 691 of 1254

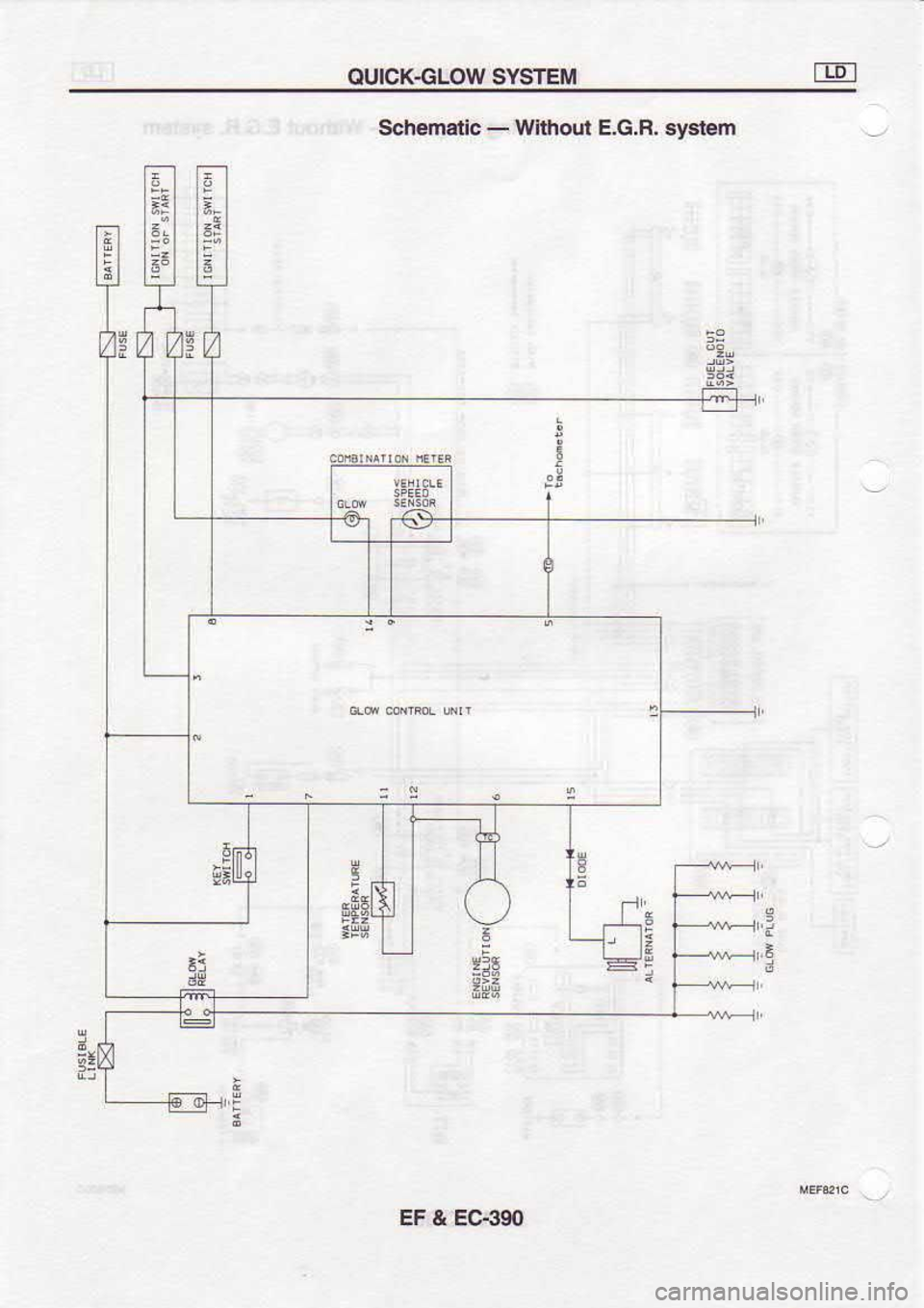

OUICKGLOW

SYSTEiI

;F 6e

a

:tltFrE

Schem€tlc

-

Wllfiout E.G.R. sysr€m

!

c ,i

'E

a

|dt

3=

EF & EC:('SO

Page 692 of 1254

OUICK€LOW

SYSTEM

Description

IL

] lJL

11- .-

i tj.

--[-

H" J--

jI

JL|L

-I-i;L

ftdr>T" ri!__

liii ru

^'lr

I

L,-.1

Wh€nlhsig.irion k6y i6 ns€nedtntothe

key cyti.d6r, th6.on-

trcl lnit luhs on

lhe elay and 'high

levol" 6ler c curcnt llo$

lhrcuqh lh€

Alow pluqs

and heats $€m up quickly.

When the

ign lion 6wilch is tlmed o., th€ onrrclunl luhs

on the indie-

lor. Atler T1 seconds have pssd

lrom k€y in, the codot unit

ions oll lh6 indi€tor. whil€

chnklng, the €lay rcma n5

on.

Th€ rc ay aulomalica

ly tums olt an€r T. s€6nd.

hav€ p4sed

EF & EC€91

Page 693 of 1254

OUICKGLOW

SYSTEM

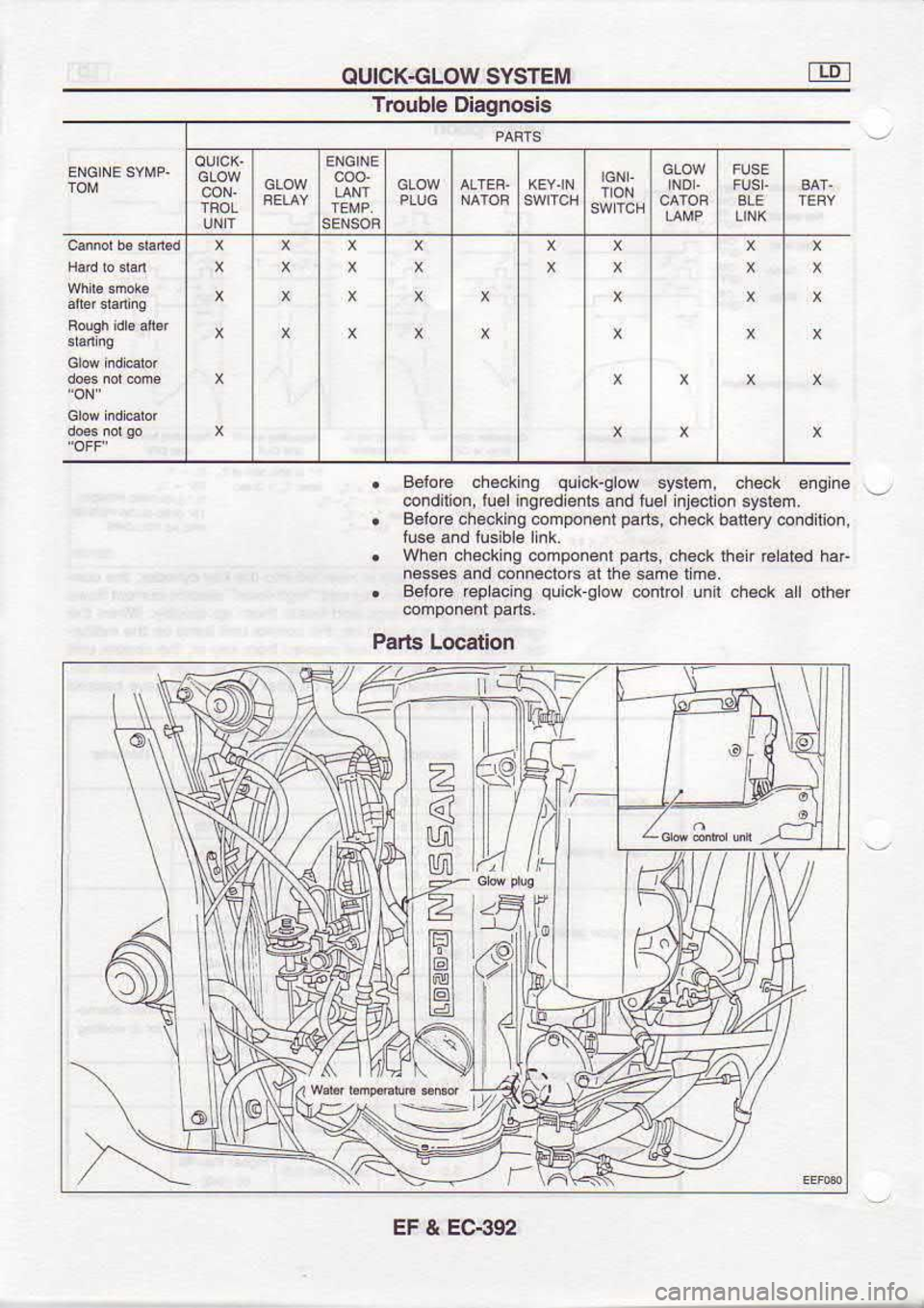

Trouble Diagnosis

. Belo€

.h€cking qlick-glow

system, check engn6

@ndilion, luel ing€dients and luel lnt€clion

sy6t€m.

. BoloG

checking component pans,

chek baliery co.dition,

tlse and lusible

link.

. Whe. checkinq @mponenl pans,

ch€ck rher crst€d haF

ne$6 and connedoA at lhe sam€ rm€.

. Setore rcplacing quick

g ow @nlrc unl ch6ck al

other

Pgrts Location

\-

EF & EC€92

Page 694 of 1254

OUICK€LOW

SYSTEM

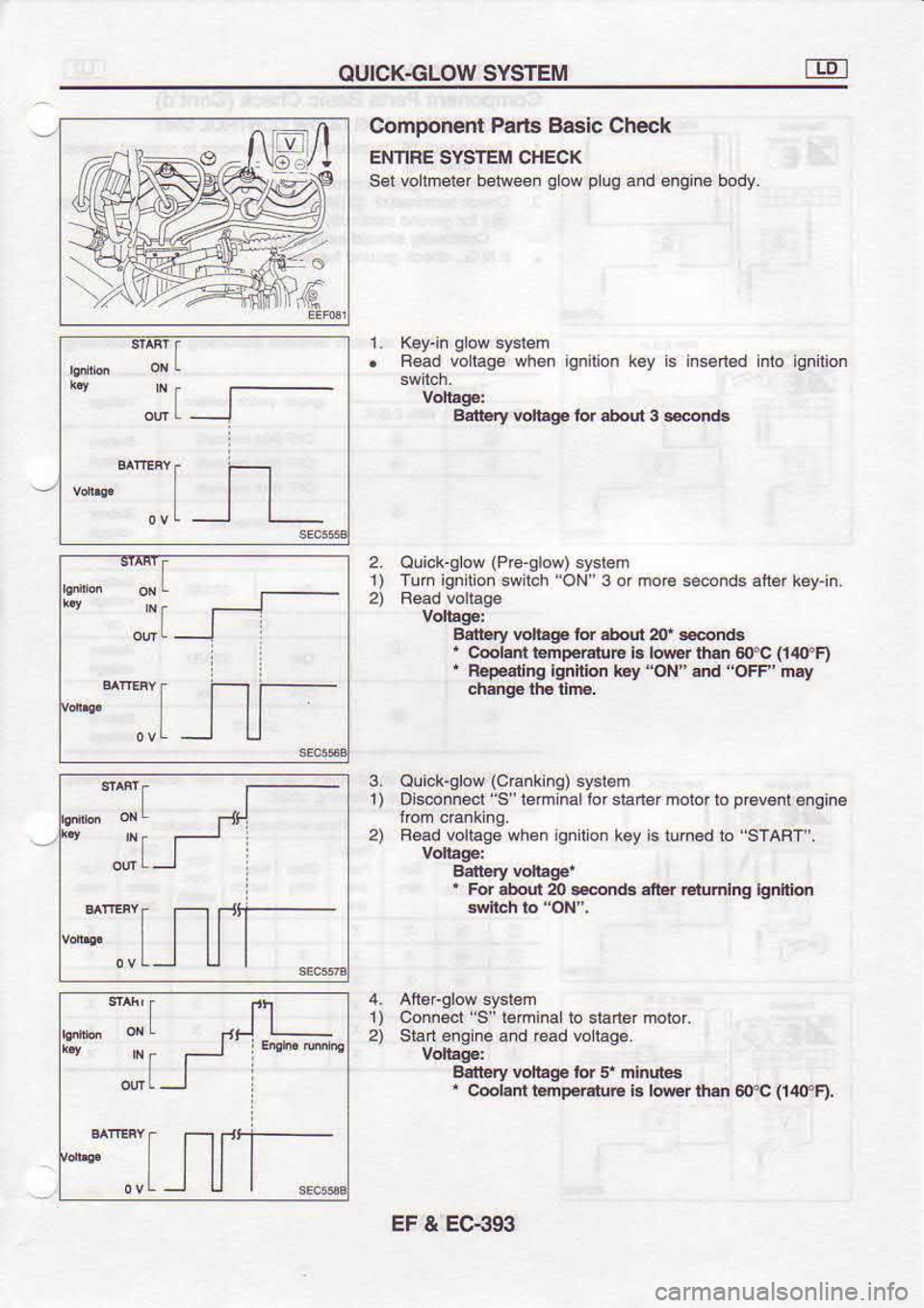

Comoonent Parts Baslc Ch€ck

ENNFE SYSTEM CHECK

ser vortmeier bellleen grow

plug

and engine body.

. Read voLiag6 when ieniton ksy is i.sd€d into ignilion

Ern6ry v!{agp ior abolt 3 6n.rs

2. ouick-glow (Pre-slow)

syslem

1) Iuh ignihon swtch 'ON

3 or mor6 sconds ai1* k€y-in.

Adbry v!t!g. for .hqit 2lf

snd8

' c@|am r.mp.r.ruF b low $.n 6{rc (i4cn

' R.p.6dnq lgdnon i6y oN"sd oFF'nly

chlngE th. tim,

n

^f

{rjllT *"s-

Ouick-slow (c€nkind

.ysr€m

1) Oisconnecl

"9 lemlnal

lor sianef moior lo prev€nl

6nain6

2) F€d vollage when igniroi k6y is rum€d to "STABT .

Balt ry hltag.'

, For .bod m snd. aner Ermhg

lgddm

1) Connecl

"S" l€minalto

daner motor.

2) Start engine and €ad voltagB.

Barbry rcnag. id 5r mhur€s

, Cdrani t6np.€t!b b rtur

ihs 6fC (14OF).

*Tt

TIJI

T:I

EF & EC€gi'

Page 695 of 1254

OUICK€LOW

SYSTEM

Et6

ffi l__

I aol

u*

Idg:rud:le

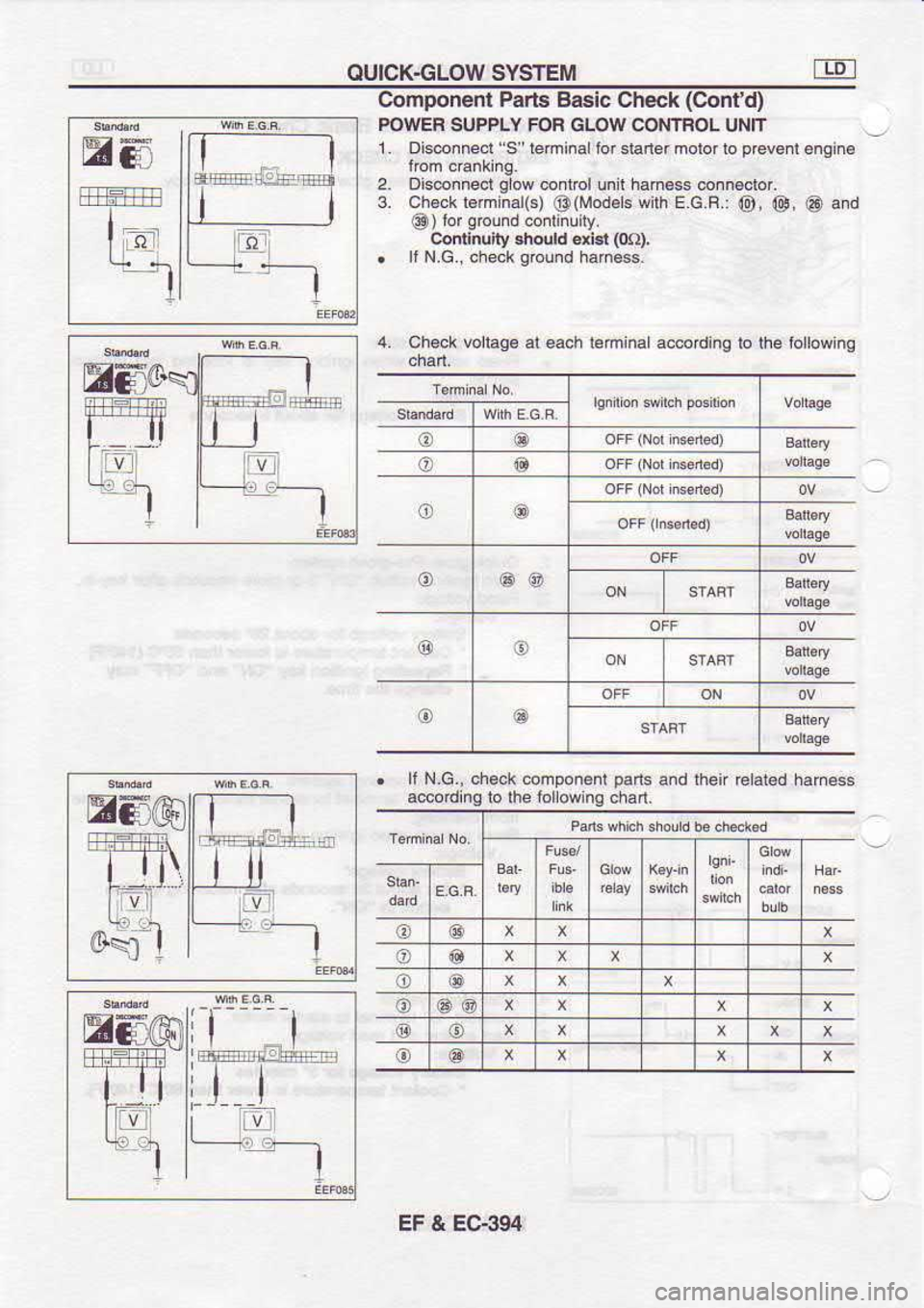

Componenl

Pads Basic Check (Cont'd)

POWER SUPPLY FOF

GLOW CONTFOL UNIT

1. Ois@nnecl S"temiia tor $aner molor lo prcverl

engine

2. [email protected]| glow

conl@l un t hah€ss enneclof.

3. ch6ck l6m nal(s)

@(Mod6ls wilh

E.G.R.:

@, @, @ and

@) lor

grolnd

conlinuily.

condnuhy 3h@rd dj3t (m),

. It N.G., checkgound hane$.

li 4.

ch6ck vollage

al each leminal accodinq to the lonowing

o o

o (e

o o

o @@

@ o

o @

. ll

N.G-, check

@mponenl Dans and

then re|at€d h.m€ss

a@odinglo lhe lonowing chan.

@ @

o o

o @

@ 6@

@ o

o @

@at

EF & EC-394

Page 696 of 1254

OUICK€LOW

SYSTEM

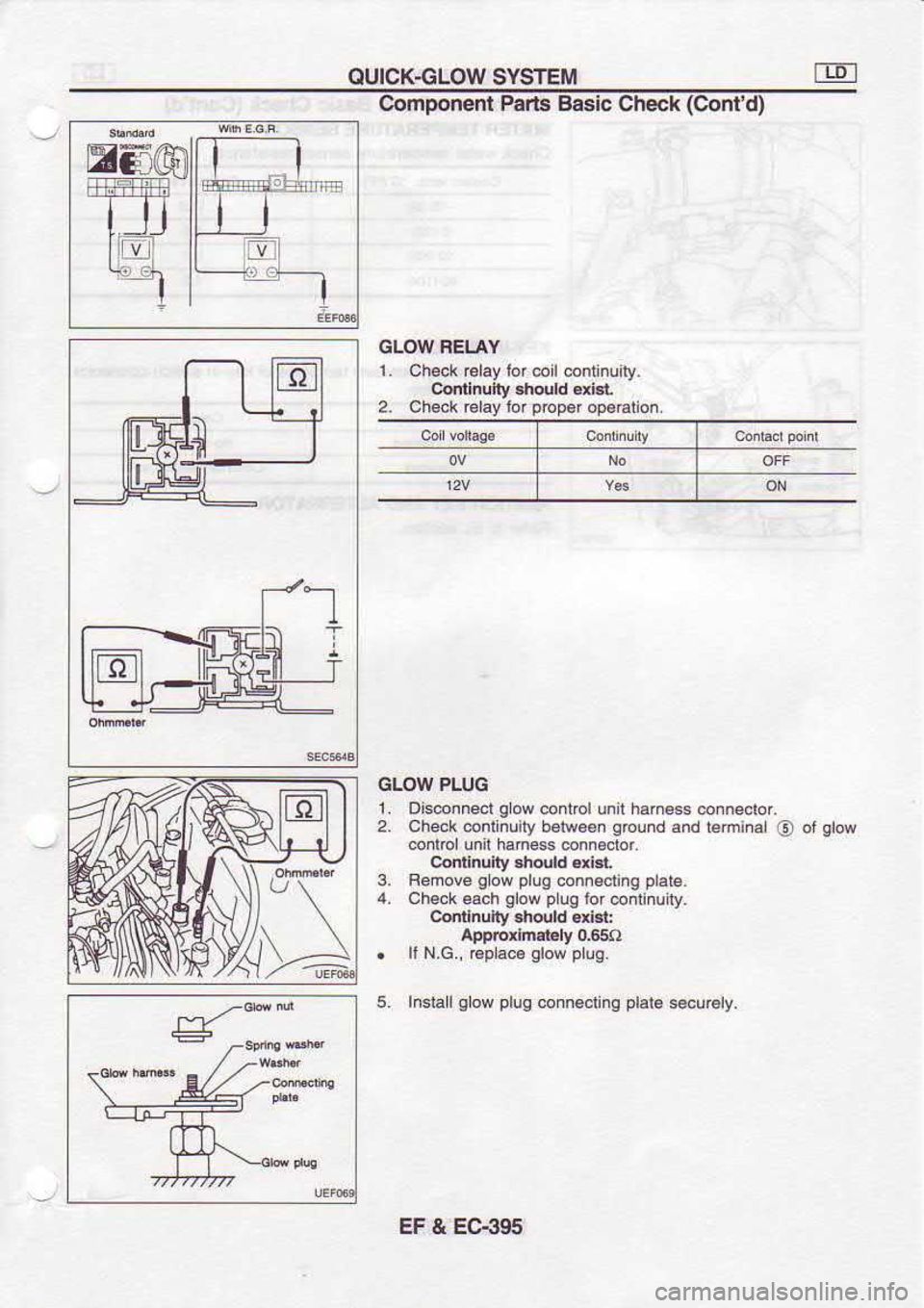

Component Paris Basic

Check (Confd)

GLOW FEI.AY

1. Check @lay lor coil .onrinuily.

Cqnh!fty .,hould €ri8t

2. Check relay lor prcp$

op.alion.

GLOW PLUG

2.

3. Ois@nneol

glow

coni@l unt h.h€.s onnector

Check @nlinuily b6tw6..

Ablnd and

teminal

@

co rol unit ham6s conndctor.

confinuit shdld 6xi3r

Remov6 gow

plug

conn€clinq plale.

Chek 6ach glow

plug

tor @ inuity_

Contlnualy 3hould oxlsl:

appbrh.tdy 0.65f)

ll N.G., Gp ace glow

plug.

5. In$allglow plug

conn€cling plata.ecurely,

EF & EC-395

Page 697 of 1254

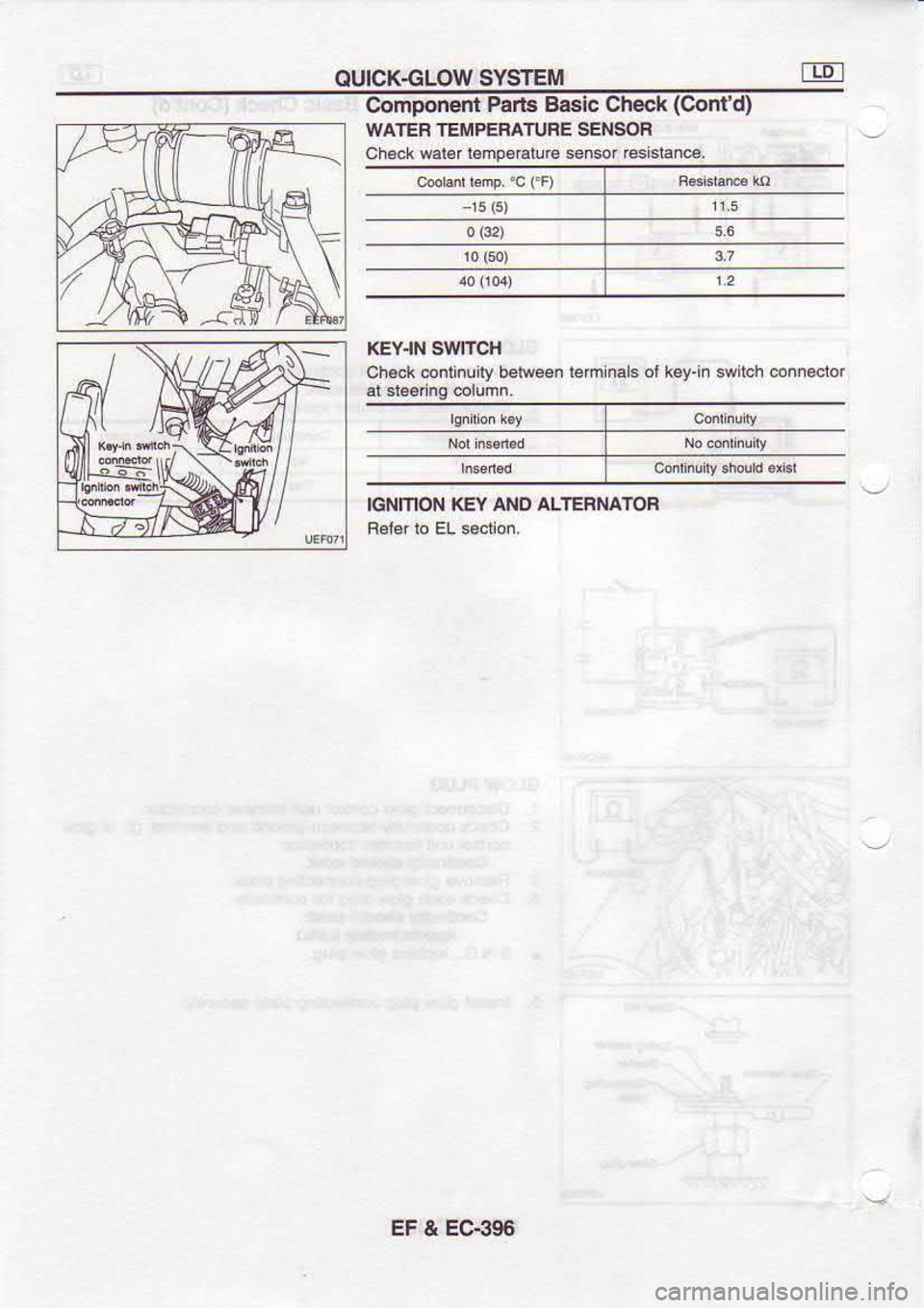

OUICK.GLOW

SYSTEM E

C,omponent Parta

Basic Check (Cont'd)

WATEB TEMPEBATURE SENSOF

Check warer

lBmp.€turc sensor rcsistance,

KEY.IN SIVITCH

ch€ck @ntinully belween leminals ot key.i. swilch 6n..ctor

IGNITION KEY ANO ALTEBNATOF

EC€96

Page 698 of 1254

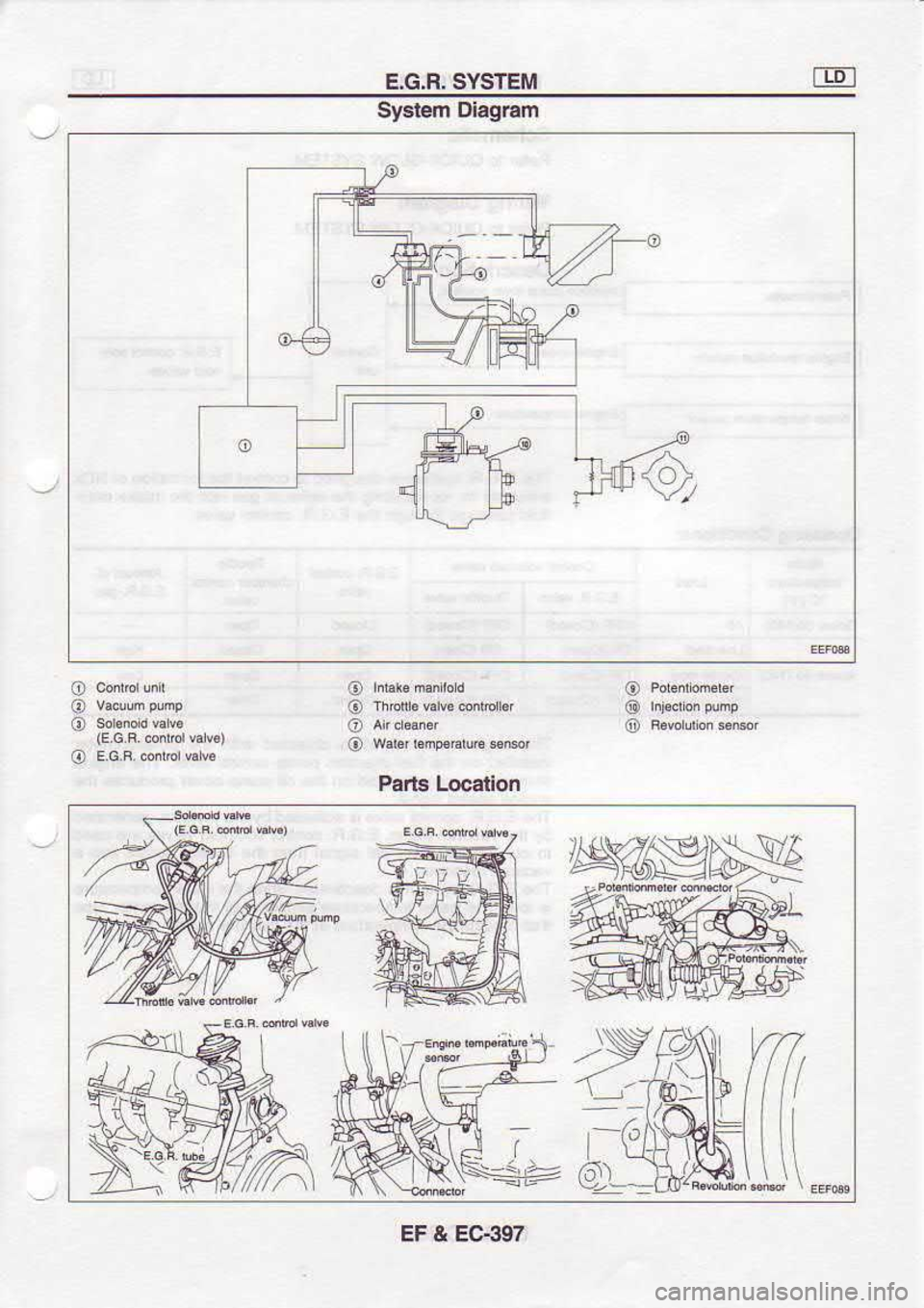

E.G.B.

SYSTEM

Syatem Dlagram

o

@

@

o

o

o

o

o

o

o

o Pans Locatlon

--/ EF & EC-397

Page 699 of 1254

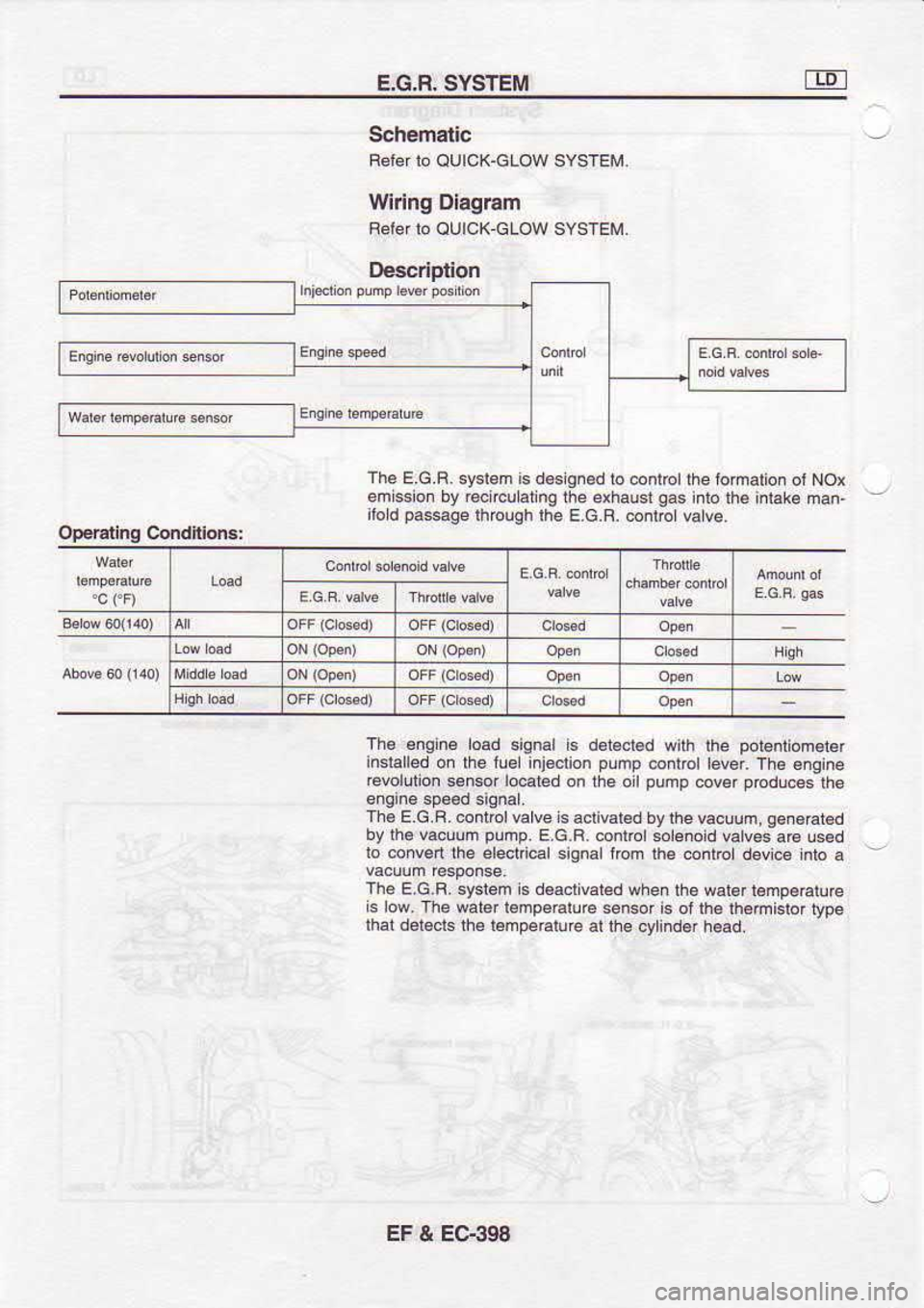

E.G,R,

SYSTEM

Sch6malic Feler to outcK-GLow sYsTEir.

Wiring Diagram

Felef to olJtcK GLow sYsTEM.

De€crlplion

The F

G F

sysrem is d€srgnod ro

contrcr l.e .omation

o, NOr

emission by €circulalng

the exhaust gas

into th6 i.taka

man-

ilod psege

through lhe E.c.B. onrrot valve.

The enqne load

signal is

dot€ci€o wirh

lhe pol6ntion€r€r

insr.ned o. lhe '!el

ijecrion p-mp

cori@l laer. Tre e.g'ne

€eoluiion s€nsof lo€ted

on the oil pump

cov* pod!@s

the

Th€ E.G.R.

contol valve is aclivar€d by

lh€ vacuuh, g.n.€t€d

by rh€ vacuum pump.

E.G.R. @nrrclslenold

vatves aG us6d

lo conv€rl

lhe elecl @l signal fbm rha

contrcl devicg inlo a -

The E,G,B. syst6m is d€acrivated

when ihe wal6r lempeaturc

is low. The w.t€r lempehlue

sensor is oJ lh€ th6mi6tor

type

lhat d6l€cls lh€ r€mDeElure

ai th€ qlind€r

head.

EF & EC-398

Page 700 of 1254

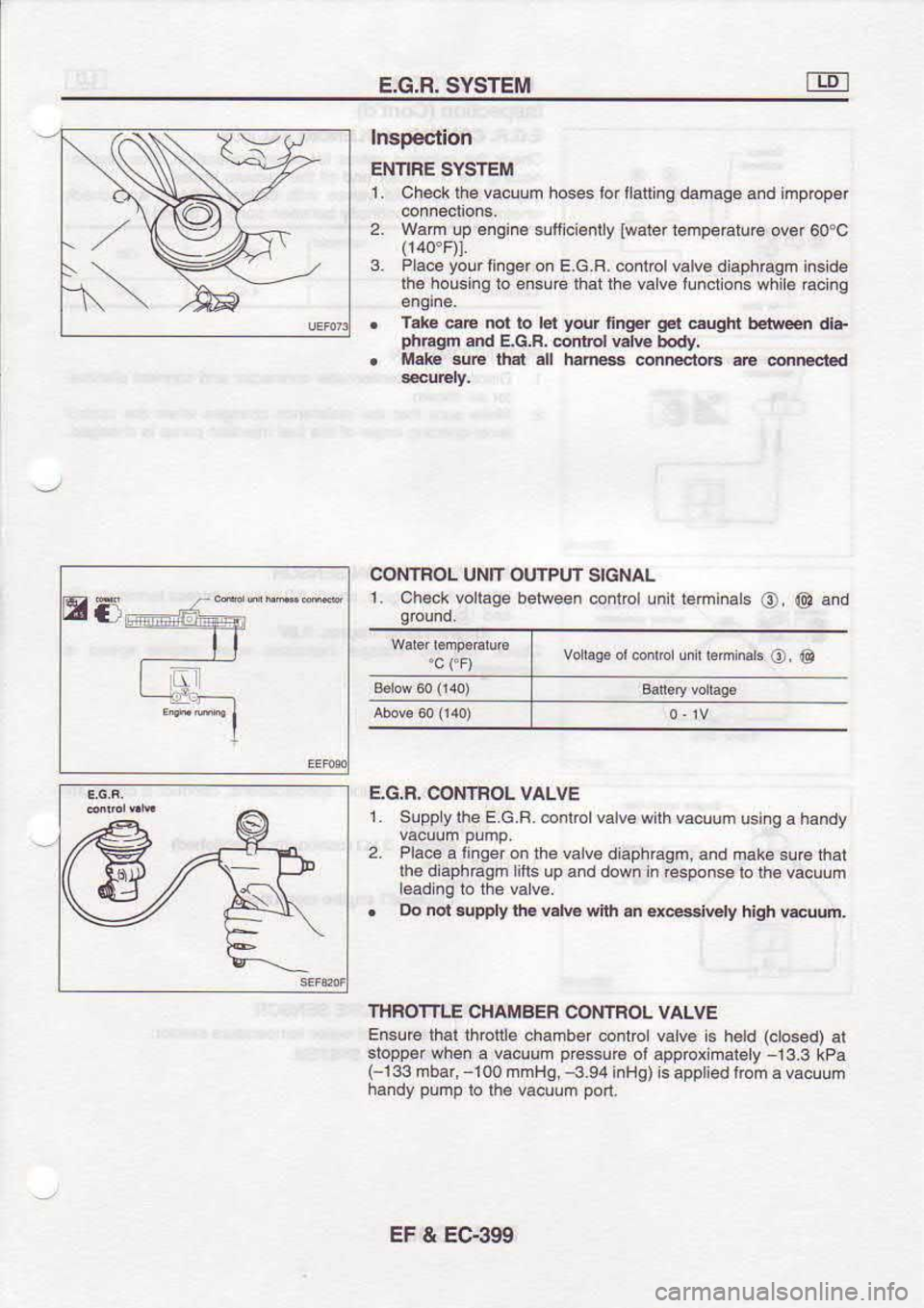

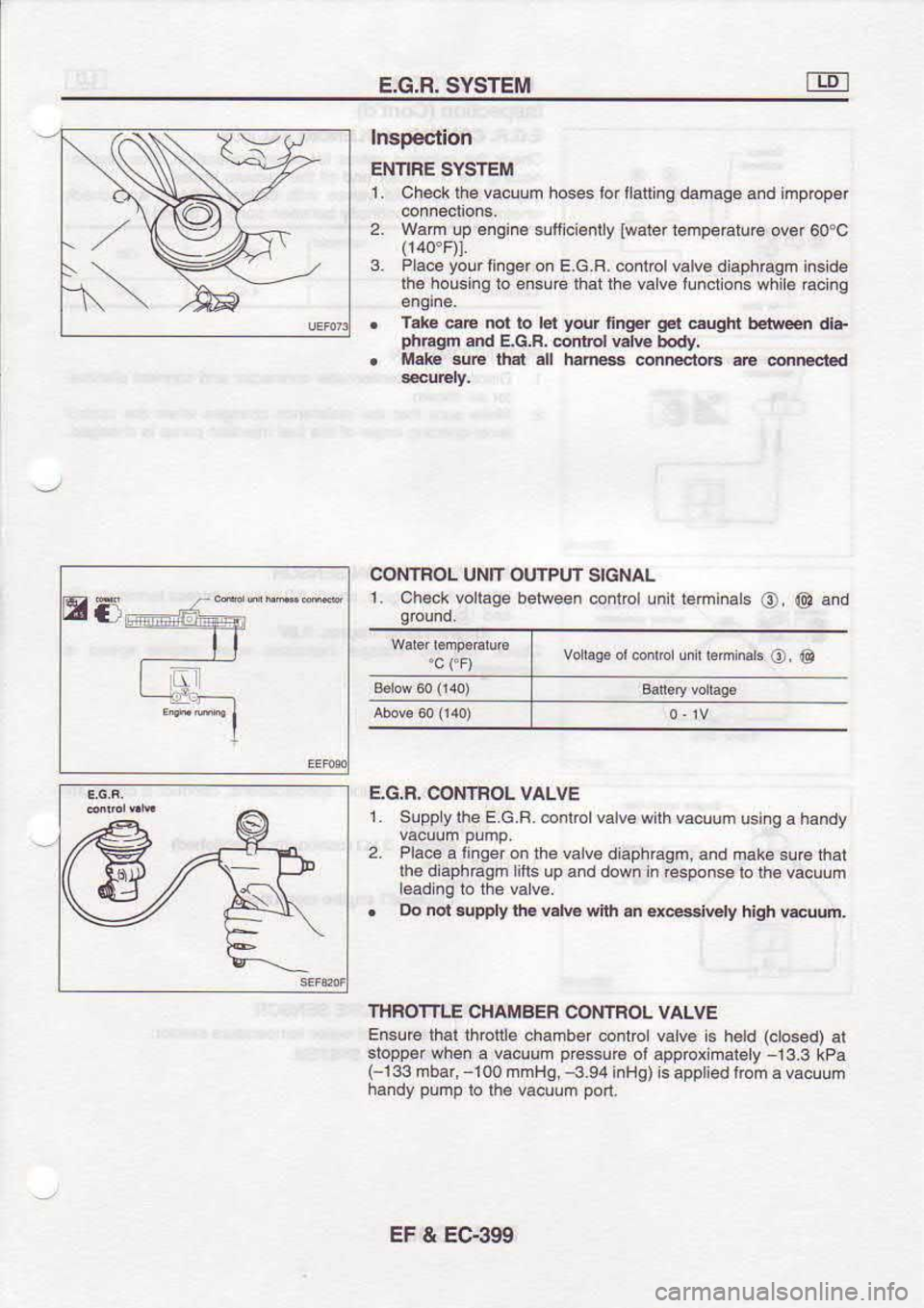

E.G.R.

SYSTEM

Inspeclion

ENNFE SYSTEM

1. C h€ck lhe vacuum hoses Io r llatting damaqe snd m prop6r

2. w.m up €ngine

s!fiici€nlly

lwatertenperatu.6 ovor

60oc

3. Placa yow

tinger on E.G.B. co.l@l valve diaphEAm i..ide

lh€ houshg

lo e.sJre lhsl lhe vav€ fLncro-s while

acng

Take @E not lo ld your

fingE q€r

eugh betweei

dla

PftElm and

E.G.R,onlrol vdE

body,

Mek &E ih.l all

hffi conn6io6 .6 drFcted

E5 @NIROL

UNIT OUTPUT SIGNAL

1. Chek vollage

between conlol unir reminals

O, @ and

vo6F ormdre lirh'hn*

o @

E.G.8. CONIAOL VALVE

1. Slpplylhe E.G.B. @nlrolvalv€ with vacuud

using a handy

2. Pla€

a linger

on the valv6 diaphraqm,

and mak€ surc lhat

lhe diaphEgm litls up and down in

€6ponse b lh€ vacuum

. Do

nol {pply lh. v.lv. with

an q6slvely

high wum.

ITIFOTTLE CHAMBEF

CONTBOL

EnsuE lhar rhbrile

chamber conrrcl

slopper wh€.

a vacuum p.€ssu6

ol

(-133mbar, 100 mmHs. -3.9r

inHg)

handy pump

to the vacuum pon. valv€

i. held (clced)

al

approximaiely 13.3 kPa

ls appliedlrcm

a vacuum

EF & EC.39S

Trending: set clock, wiring diagram, check oil, sunroof, change time, fuel filter, Engine mount

![NISSAN SERENA 1993 Service Repair Manual OUICK€LOW

SYSTEM

Description

IL

] lJL

11- .-

i tj.

--[-

H" J--

jI

JL|L

-I-i;L

ftdr>T" ri!__

liii ru

^lr

I

L,-.1

Wh€nlhsig.irion k6y i6 ns€nedtntothe

key cyti.d6r, th6.on-

trcl lnit lu NISSAN SERENA 1993 Service Repair Manual OUICK€LOW

SYSTEM

Description

IL

] lJL

11- .-

i tj.

--[-

H" J--

jI

JL|L

-I-i;L

ftdr>T" ri!__

liii ru

^lr

I

L,-.1

Wh€nlhsig.irion k6y i6 ns€nedtntothe

key cyti.d6r, th6.on-

trcl lnit lu](/img/5/57387/w960_57387-691.png)