engine oil NISSAN SERENA 1993 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1993, Model line: SERENA, Model: NISSAN SERENA 1993Pages: 1254, PDF Size: 89.68 MB

Page 644 of 1254

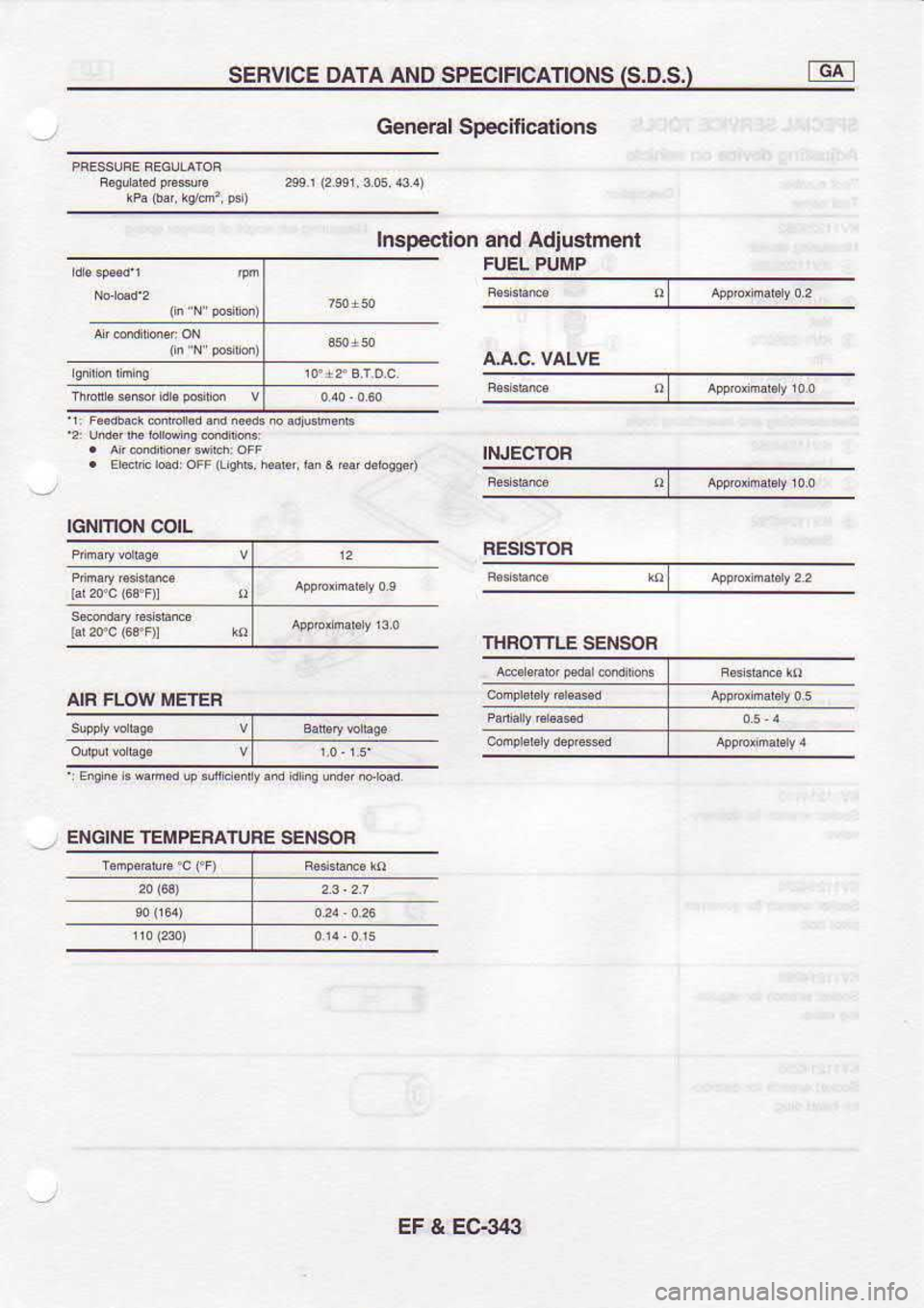

SERVTCE

DATA AND SPECTFTCATTONS (S.D.S.)

General SDecitications

Inspeclion and Adiustment

INJECTOF RESISTOF

THROTTLE SENSOF

AIF FLOW METER

ENGINE TEMPEHATUFE

IGNITION

COIL

SENSOB

EF & EG34:}

Page 885 of 1254

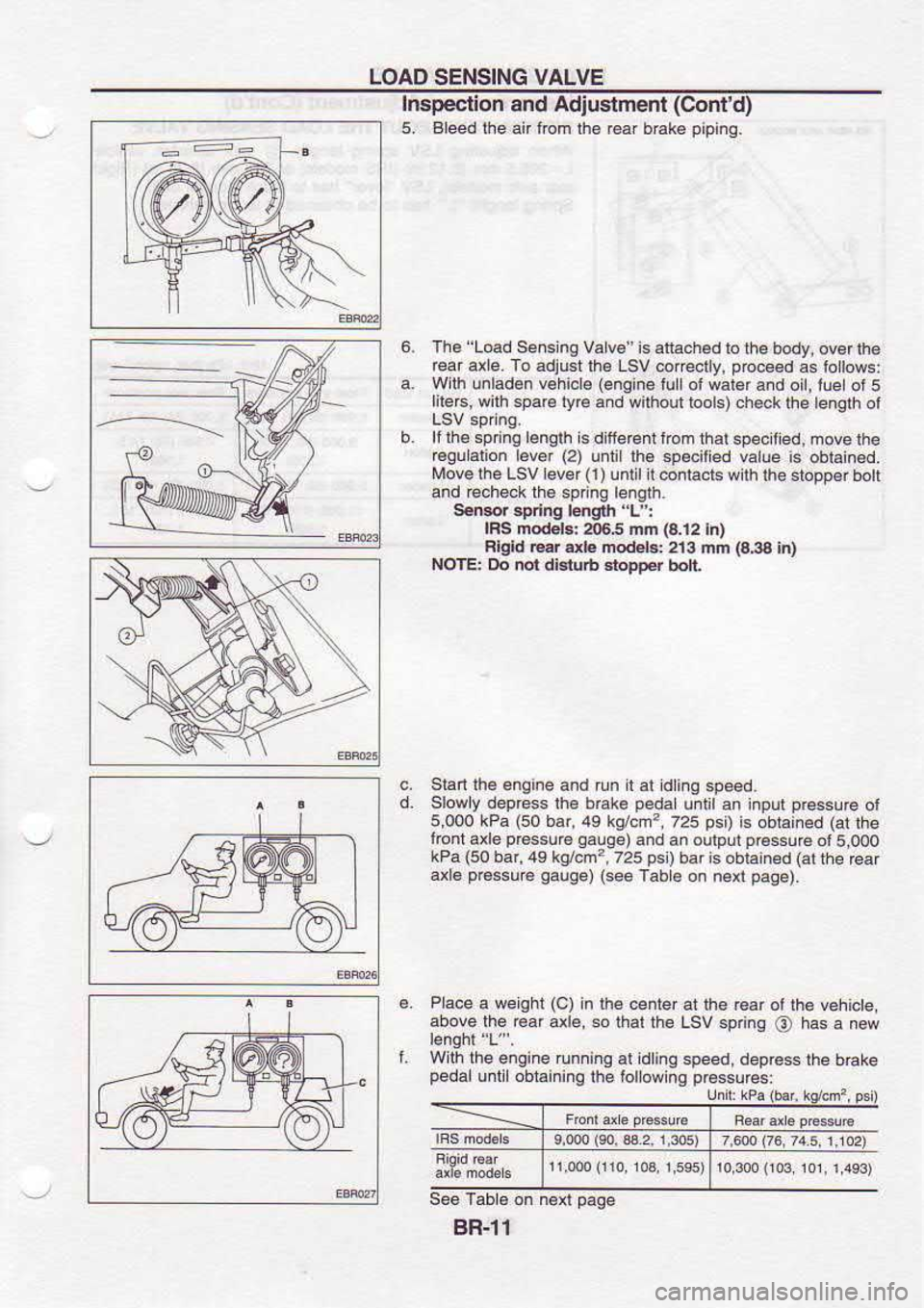

LOAD

SENSING VALVE

Inspeclion and Adius:menl(Cont'd)

5, Bleedlhe anlom lhe r6af brake pipinq.

The 'Load

Se.s ng Valv€ is attachad

to the body, ovor lh€

reai axle. To adjust lh€ Lsv

@irectly, p@ce€d

as iollows:

With unladen v€hicl€ (engine

lullol wal€r and oil,lle

of5

lilerc, wilh sparc lyr6

and wilhoul lools) ch€ck lhe lenath

ot

lf rh6 spnna bnalh

is d llercnt trom rhal sp& lied.

move lhe

€qu.lion lever (2)

unlillh6 specilied value

is oblan6d.

Move lhe LSVlever(l)un

n @ntacts w ih fie sbDD€r bol

and @check lh6 spnng

bnglh.

SeMr spd.g

|mgrh 'L':

lRs modob: a)6,5 mn la.12lnl

Flgld @r db modeGi 213

mfr (a3a

in)

NOTE: Do nol dialub Etopper

bolt

Stan lhe

enqine and run I al dinq

speed.

Slowly deprcss lh€ bEke peda

uitit an inpur pr6ssu@

ot

5,000 kPa (50

bar,49 kg/.m?,

725 psi)

is obrained (at

lhe

loni axle p€ssu€

Oalge)and an

oulputpressu€

o15.000

kPa (50

bar,49 kg/cm?,725 psl)baris

obiain€d (at

lhe €ar

axl6 p€ssu€

qauge)(seeTabe

on ne{ paae).

6. Pace

a weghr (c)

in rhe

center at lhe Gar oi

tha vehicte,

above the Gaf axl€, so

thal the Lsv sp nq

\6) has

a new

L Wth

lhe engine runninq al idlinq

speed, deprcss the

brake

pedal u|li obtainino

lhe followins prcssures:

gR-l1

Page 951 of 1254

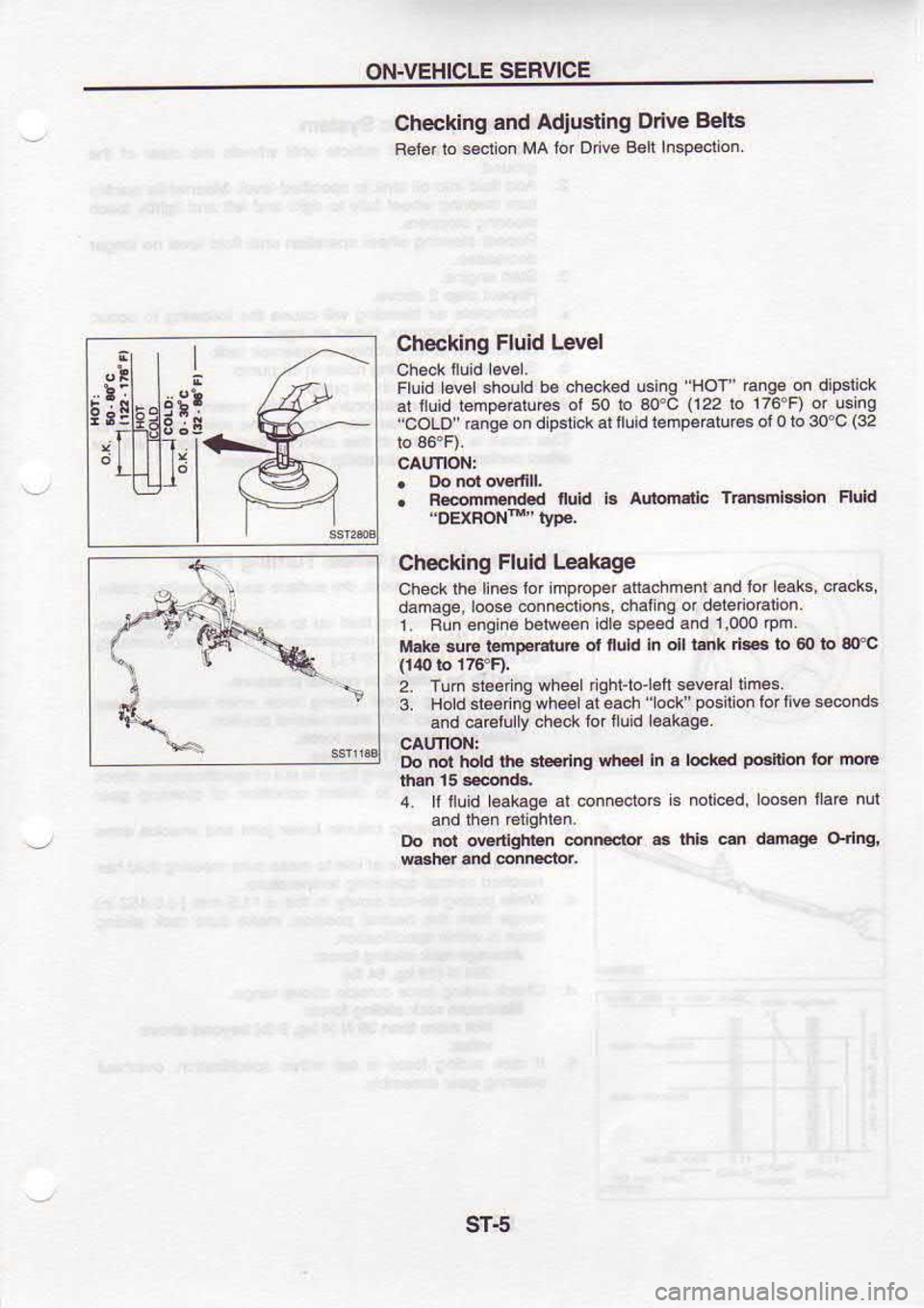

ON.VEHICLE

SEBVICE

f4 s- Checkidg

and

Adjusting Ddve B€lts

Beler lo secl

on MA ior

Drve Belt Inspecton

Checking Fluid

Level

Fluid Levershoud be

cheoked usinq HoT

Enge on

dipslrck

at iluid lenoeratur€s ol

50 b ao'C (122

lo 176'F) ot

usmg

'coLo" Gnoe on

d pstck

allluidlempeEtures ol0

to 30'c (32

. Rdnrended fuid

b adomsiic Transmlslon Fluid

Checking Fluid

Leakage

Check lhe

linos lof mproper allachmenl

and lor

l6aks, c6cks,

damage,loose conneclions chal

ng or deleio€lion.

i Bun engine b€ftveen

idLe speed and

1,000 .pm

M.k€ suE lentEr.tuE ot

fluld ln oil

l.nk des to 60lo 30Pc

2. Turn

s1€efne wheel rqhl-to'etl

seve6 limes.

3. Hold sl€ernq

wheelal each 'ock'poslio.lorr

ve s.conds

and carelully check

lor fu d eak.ge

Do not hold the 3teeting sh.€l

in a lek d pGiton

lor moE

4. ll tluid l€akace al

conneclo6 s

noliced, loosen rar€

nll

tro not ovedlgtn n

connectd as lhiB

c.. damage Orlng.

t

i

i

!

t

i

Y3 ri

l:

E

Page 1131 of 1254

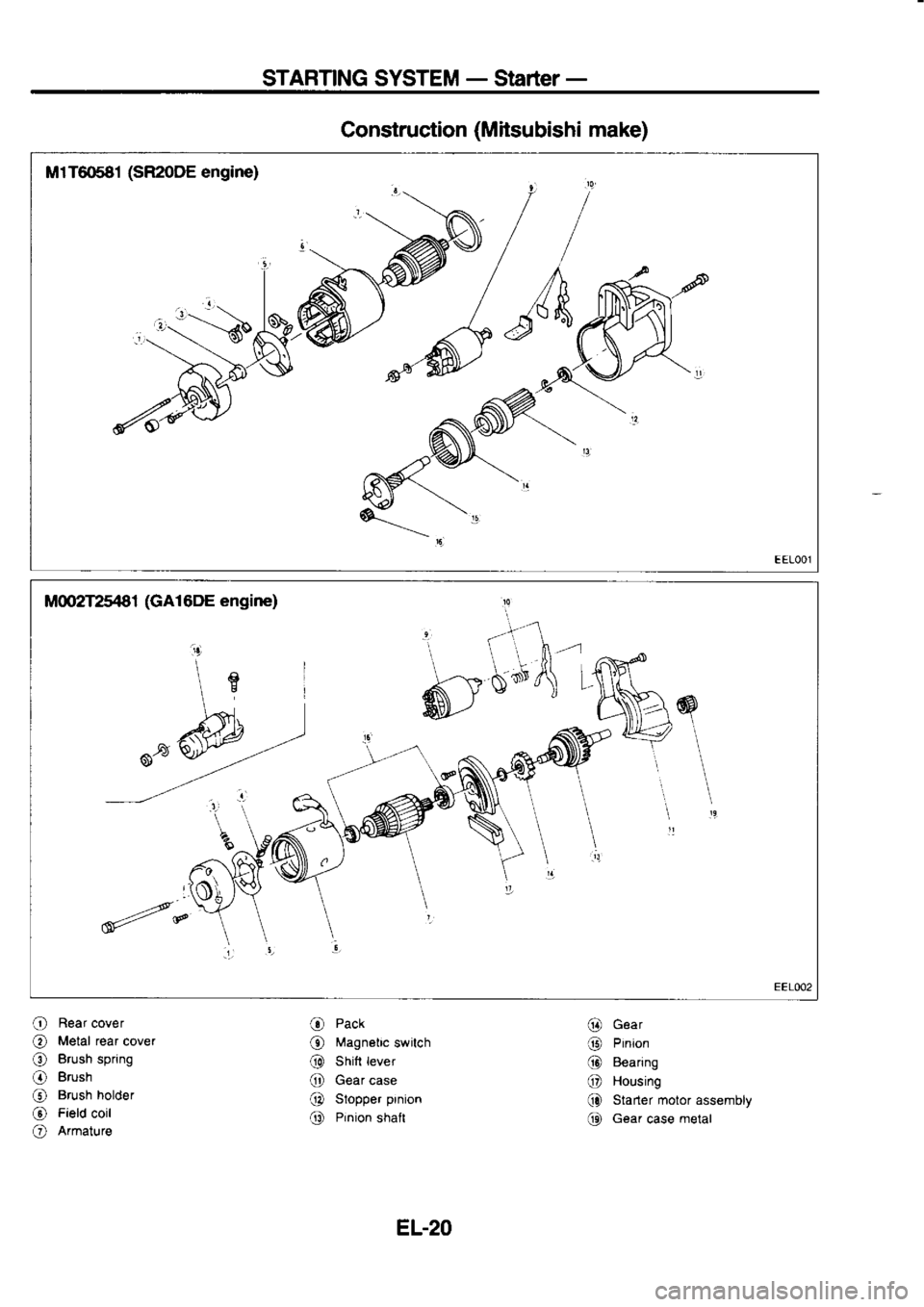

STARTING

SYSTEM -

Starter -

Construction (Mitsubishi

make)

M1T6681 (SR2oDE

engine)

O Rear

cover

O Metal

rear

cover

O Brush

spring

O Brush

@ Brush

holder

@ Field

coil

O Armature O

Pack

@ Magnetic

switch

@ Shitt

lever

@ Gear

case

@ Stopper

prnion

@ Pinion

shalt @

Gear

'rt Hrnron

@ Bearing

@ Housing

(} Starter motor

assembly

(t Gear case metal

EL-20

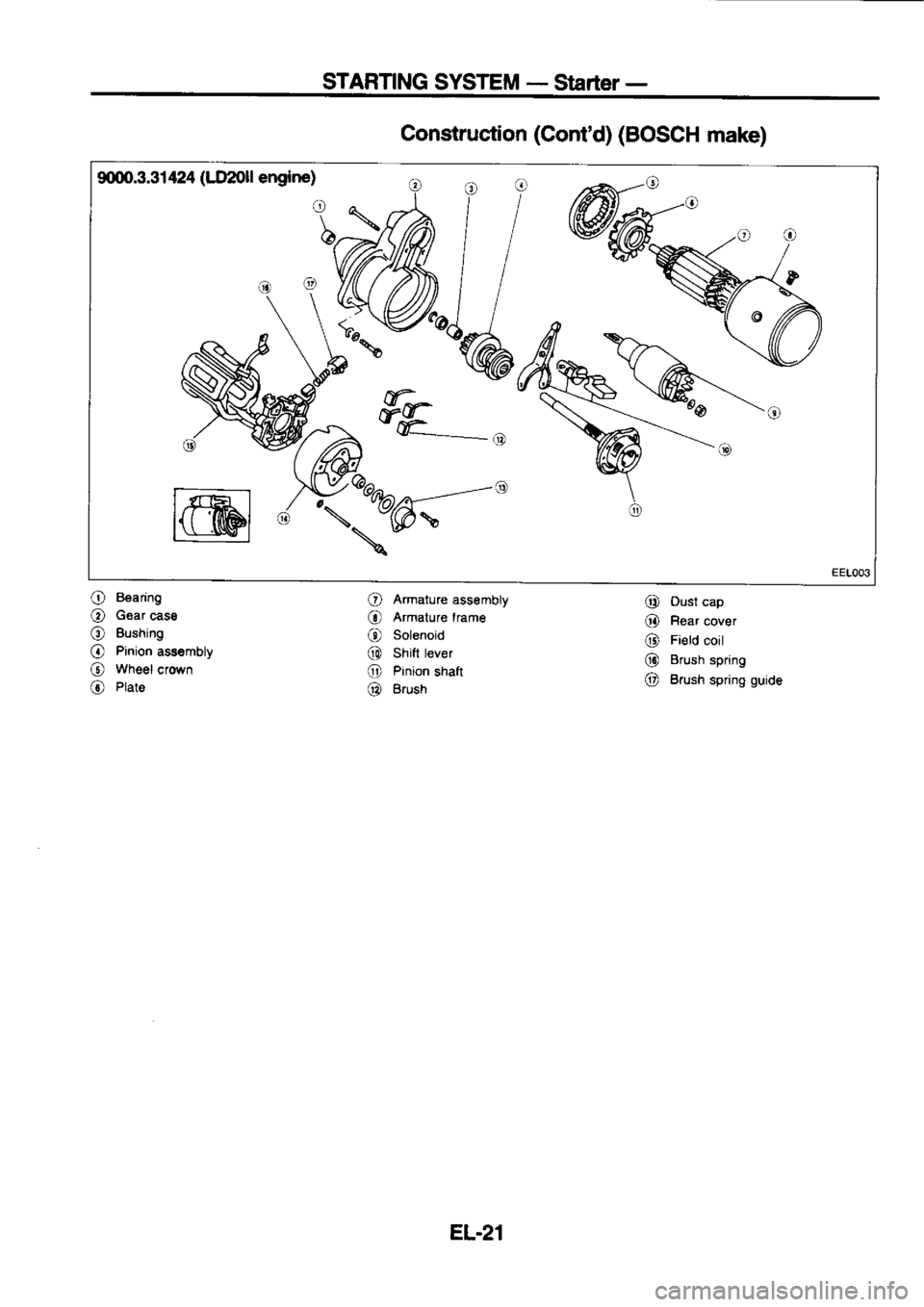

Page 1132 of 1254

STARTING

SYSTEM -

Stader-

9q)0.3.31 424 (LlI2Oll

engine)

wk

w$ FF.-,

@ /K:b@;-" I@----.*

Construction

(Cont'd)

(BOSCH

make)

O Armature

assembly

@ Dust

cap

O Bearing

O Gear

cass

O Bushing

O Pinion

ass€mbty

@ wheel

crown

O Plate @

Armature

lrame

@ Solenoid

@ shitt

tever

O Pinion

shatt

@ Brush @

Rear

cover

@ Field

coil

@ Brush

spring

O Brush

spring guide

EL.21

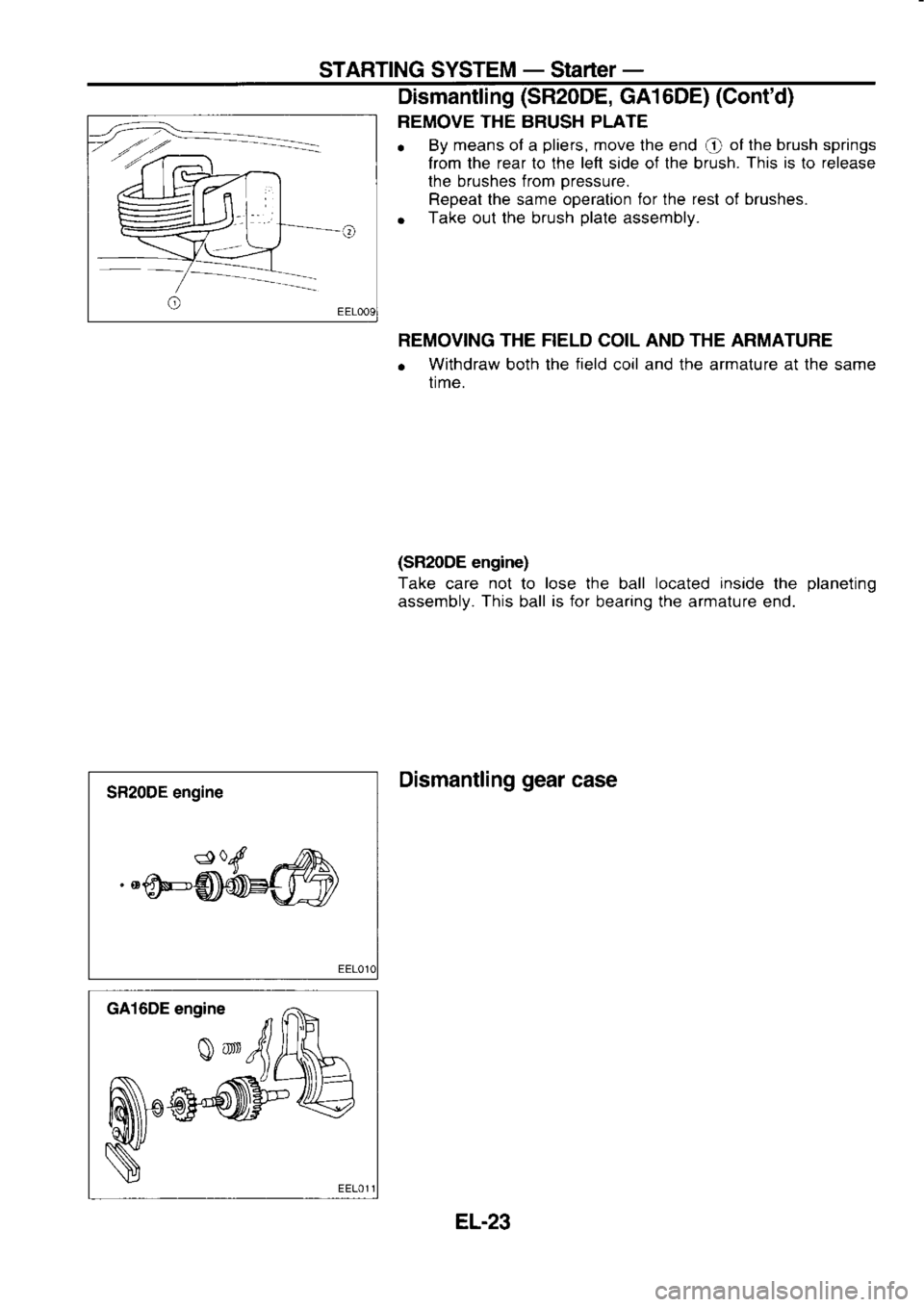

Page 1134 of 1254

STARTING

SYSTEM _

Starter _

Dismantling (SR20DE,

GA1 6DE) (Cont'd)

REMOVE THE BRUSH PLATE

o By

means of a pliers,

move the end

@ of

the brush springs

Irom the rear lo the left side of the brush. This

is

to release

the brushes from pressure.

Repeat the same operation for

the rest

of brushes.

o Take

out the brush plate

assembly.

REMOVING THE FIELD COIL AND THE ARMATURE

o Withdraw

both the field

coil and the armature at the same

time.

(SMODE engine)

Take care not

to lose

the ball located

inside

the planeting

assembly. This ball is

for

bearing the armature end.

Dismantling gear

case

SR20DE engine

EL-23

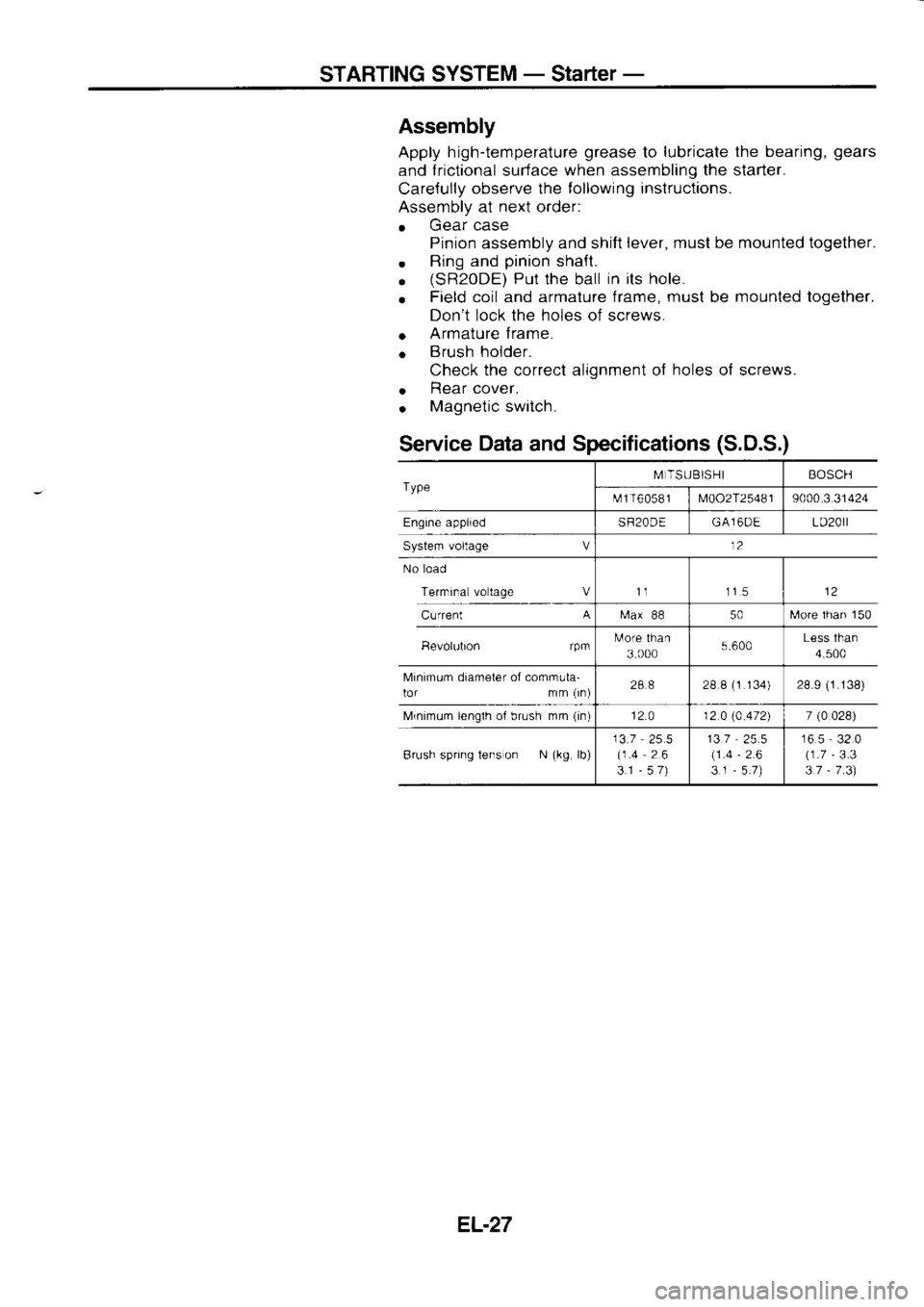

Page 1138 of 1254

STARTING

SYSTEM -

Starter -

Assembly

Apply h igh-temperature grease

to lubricate

the bearing, gears

and frictional

surface when

assembling the starter.

Care{ully observe

the following inslructions.

Assembly at next

order:

. Gear

case

Pinion assembly and shift lever,

musl be mounted together.

. Ring

and pinion

shaft.

. (sR20DE)

Put the ball in

its hole.

o Field

coil and armature frame, must

be mounted

together.

Don't lock the holes of screws.

o Armature

f rame.

o Brush

holder.

Check the correct alignment of holes

of screws.

o Rear

cover.

. Magnetic

switch.

Service Data

and Specifications (S.D.S.)

Type M

TSUBISHI BOSCH

t\.rf 1 T6

05 8 I

M002T25481 9000.3

31424

Engine applied SR20DEGA16DE LD20rl

System voltage V 12

No load

Terrnrna voltage Vt1 115

Current A

[ra.x

88 50[,,lore

lhan 150

Bevolubon rpmtulore

than

3 000 5.600Less

than

4,500

Minimum diameter of comrnula-

lor mm (rn) 288

28 8 (1

134) 28.9 (1.138)

Mrnimum lenglh of brush mm (in)

12.0 12 0 (4.472)

7 (0

028)

Brush spring tens on N (kg,

lb) 13.7

25.5

(1.4 26

3.1 -57) 137

(1 .4

3.1 -

2.6 16.5

32.0

(1.7 -

3.3

3.7 -

7 .3)

EL.27

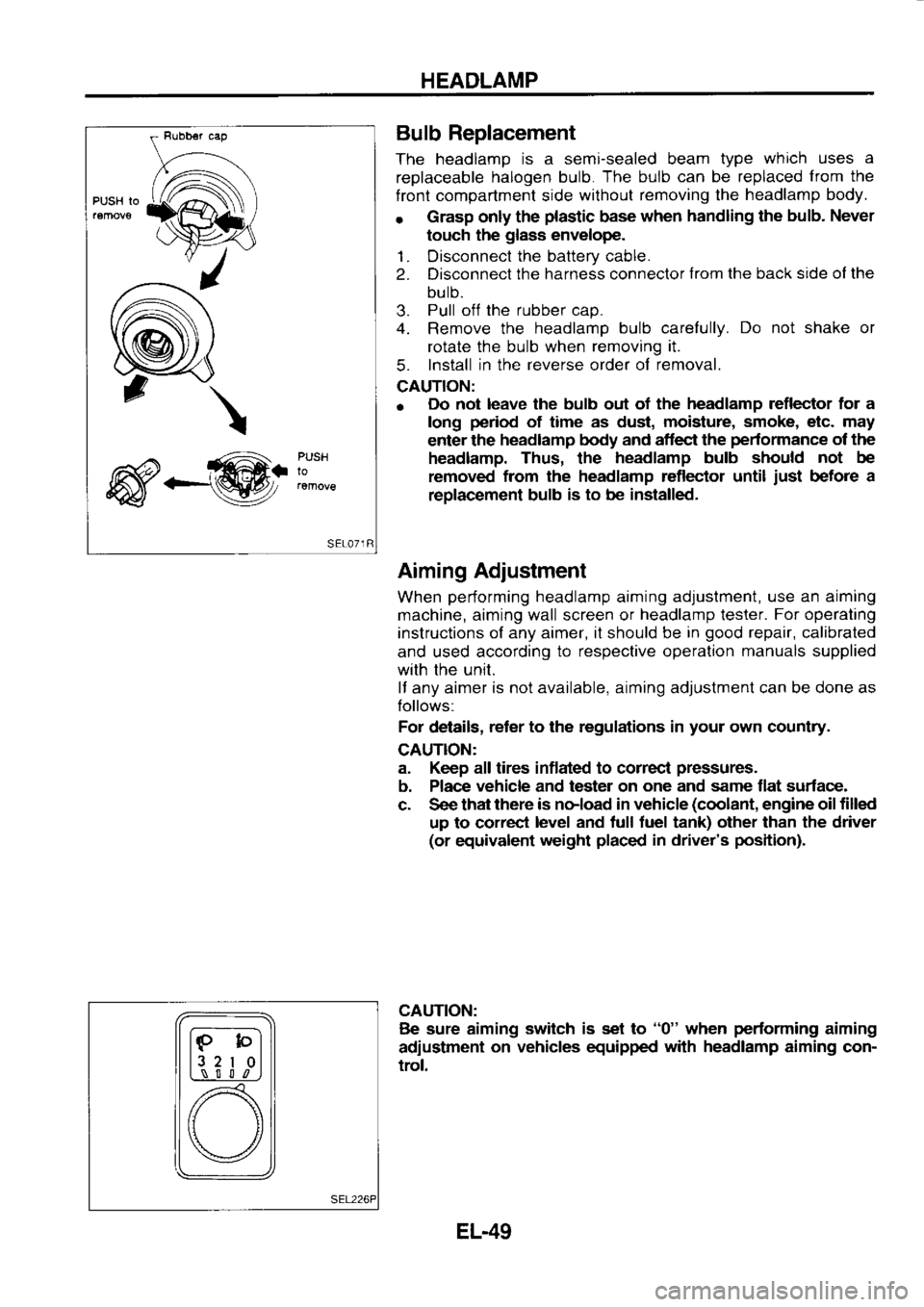

Page 1160 of 1254

HEADLAMP

PUSH Io

\

_@. PUSH

lo Bulb

Replacement

The headlamp is

a semi-sealed beam type which

uses a

replaceable halogen

bulb. The

bulb can

be replaced from

the

f ront compartment side without

removing the headlamp

body.

r Grasp

only the plastic

base when

handling the bulb.

Never

touch the glass

envelope.

1. Disconnect the

battery cable.

2. Disconnect the

harness connector from

the back side ol the

bulb.

3. Pull

off the

rubber cap.

4. Remove the headlamp

bulb carefully. Do

not shake or

rotate the bulb when removing it.

5. Install

in the reverse

order of removal.

CAUTION:

o Do

not leave the bulb out of the headlamp

reflector for a

long period

of time as dust, moisture,

smoke, etc. may

enter the headlamp

body and aflect the pedormance

of the

headlamp. Thus, the headlamp

bulb should not

be

removed from

the headlamp reflector until just

before a

replac€ment bulb is

to be installed.

Aiming Adjustment

When performing

headlamp aiming adjustment, use

an aiming

machine, aiming wall screen or headlamp

lester. For

operating

instructions of any aimer, it should be in good

repair, calibrated

and used according to

respective operation manuals

supplied

with the unit.

lf any aimer is

not available, aiming adjustment can be done as

Iollows:

For details, reter

to the regulations in your

own country.

CAUTION:

a. Keep all tires inflated to correcl pressures.

b. Place vehicle

and tester on one

and same flat surface-

c. See that there

is noload in vehicle (coolant,

engine oil filled

up to correct level

and tull tuel tank) other than the driver

(or equivalent weight placed

in driver's position).

CAUTION: Be sure aiming switch

is set to "0"

when performing

aiming

adiustment on

vehicles equipped with

headlamp

aiming con-

trol.

lF-bl

l3 2

I 0l

L,\_-! S l l

,n

[) \/

EL-49

Page 1190 of 1254

WARNING

LAMPS AND

BUZZER

----](-

Continuity

Bsnery Diode

Check

o Check

continuity using an ohmmeter.

o Diode

is functioning properly

il test results are as shown in

the f

ioure

at left.

o Diodes

for warning lamps are built into the combination

meter orinted circuit.

Refer to "Combination

Meter".

Engine Oil Level Unit

Check

1 . Connect as shown in the figure at left.

2. lf test lamp comes on when disconnecting terminal

O from

battery ground,

engine oil level

unit is

normal.

Warning Buzer

Check

F \zz

fi*ffi=l

| | r:

rL----rr l

#/\

EL-79