Connector NISSAN TEANA 2003 Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2003, Model line: TEANA, Model: NISSAN TEANA 2003Pages: 3502, PDF Size: 74.56 MB

Page 1252 of 3502

DI-46

WARNING LAMPS

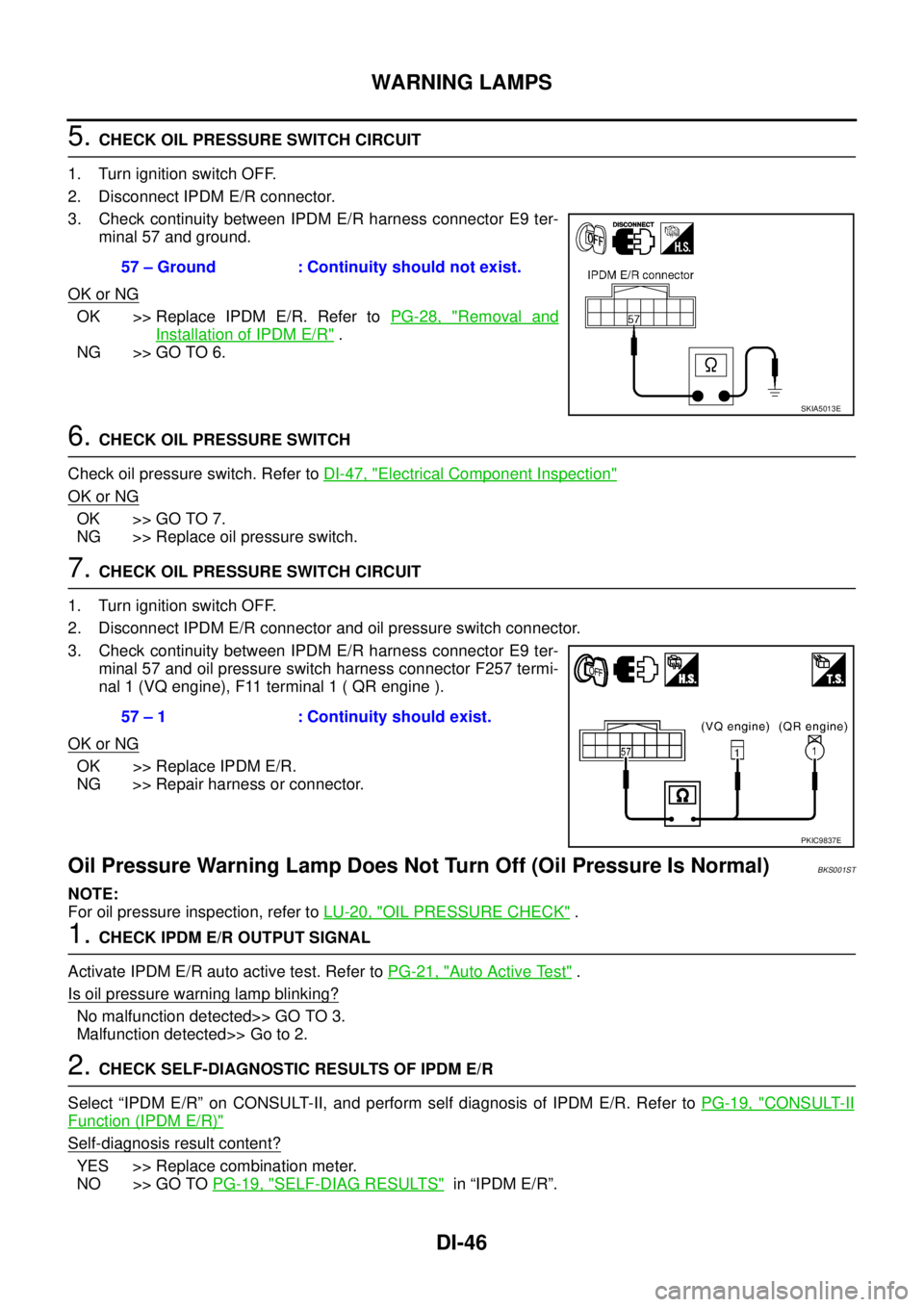

5. CHECK OIL PRESSURE SWITCH CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect IPDM E/R connector.

3. Check continuity between IPDM E/R harness connector E9 ter-

minal 57 and ground.

OK or NG

OK >> Replace IPDM E/R. Refer to PG-28, "Removal and

Installation of IPDM E/R" .

NG >> GO TO 6.

6. CHECK OIL PRESSURE SWITCH

Check oil pressure switch. Refer to DI-47, "

Electrical Component Inspection"

OK or NG

OK >> GO TO 7.

NG >> Replace oil pressure switch.

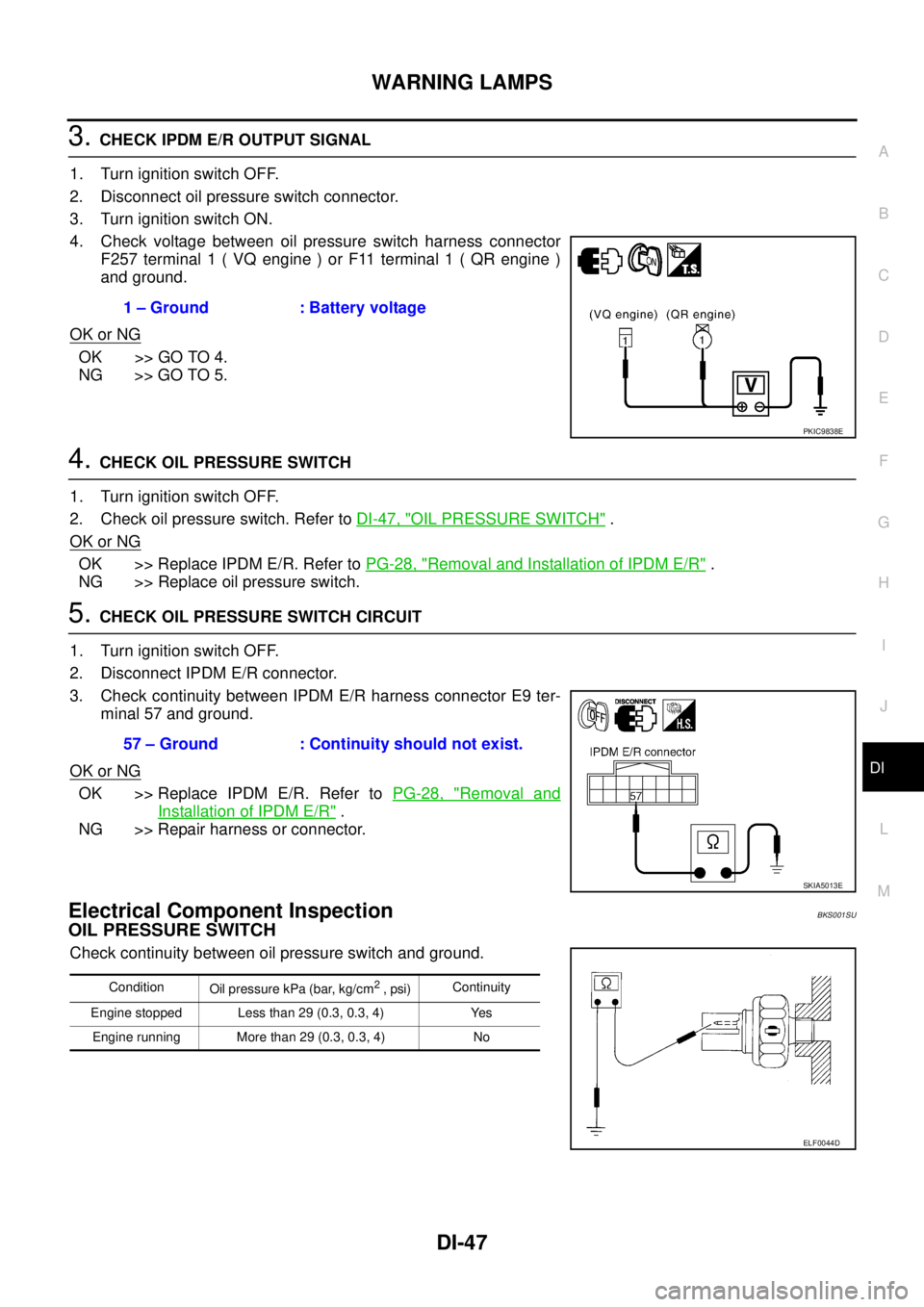

7. CHECK OIL PRESSURE SWITCH CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect IPDM E/R connector and oil pressure switch connector.

3. Check continuity between IPDM E/R harness connector E9 ter-

minal 57 and oil pressure switch harness connector F257 termi-

nal 1 (VQ engine), F11 terminal 1 ( QR engine ).

OK or NG

OK >> Replace IPDM E/R.

NG >> Repair harness or connector.

Oil Pressure Warning Lamp Does Not Turn Off (Oil Pressure Is Normal)BKS001ST

NOTE:

For oil pressure inspection, refer to LU-20, "

OIL PRESSURE CHECK" .

1. CHECK IPDM E/R OUTPUT SIGNAL

Activate IPDM E/R auto active test. Refer to PG-21, "

Auto Active Test" .

Is oil pressure warning lamp blinking?

No malfunction detected>> GO TO 3.

Malfunction detected>> Go to 2.

2. CHECK SELF-DIAGNOSTIC RESULTS OF IPDM E/R

Select “IPDM E/R” on CONSULT-II, and perform self diagnosis of IPDM E/R. Refer to PG-19, "

CONSULT-II

Function (IPDM E/R)"

Self-diagnosis result content?

YES >> Replace combination meter.

NO >> GO TO PG-19, "

SELF-DIAG RESULTS" in “IPDM E/R”. 57 – Ground : Continuity should not exist.

SKIA5013E

57 – 1 : Continuity should exist.

PKIC9837E

Page 1253 of 3502

WARNING LAMPS

DI-47

C

D

E

F

G

H

I

J

L

MA

B

DI

3. CHECK IPDM E/R OUTPUT SIGNAL

1. Turn ignition switch OFF.

2. Disconnect oil pressure switch connector.

3. Turn ignition switch ON.

4. Check voltage between oil pressure switch harness connector

F257 terminal 1 ( VQ engine ) or F11 terminal 1 ( QR engine )

and ground.

OK or NG

OK >> GO TO 4.

NG >> GO TO 5.

4. CHECK OIL PRESSURE SWITCH

1. Turn ignition switch OFF.

2. Check oil pressure switch. Refer to DI-47, "

OIL PRESSURE SWITCH" .

OK or NG

OK >> Replace IPDM E/R. Refer to PG-28, "Removal and Installation of IPDM E/R" .

NG >> Replace oil pressure switch.

5. CHECK OIL PRESSURE SWITCH CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect IPDM E/R connector.

3. Check continuity between IPDM E/R harness connector E9 ter-

minal 57 and ground.

OK or NG

OK >> Replace IPDM E/R. Refer to PG-28, "Removal and

Installation of IPDM E/R" .

NG >> Repair harness or connector.

Electrical Component InspectionBKS001SU

OIL PRESSURE SWITCH

Check continuity between oil pressure switch and ground.1 – Ground : Battery voltage

PKIC9838E

57 – Ground : Continuity should not exist.

SKIA5013E

Condition

Oil pressure kPa (bar, kg/cm2 , psi) Continuity

Engine stopped Less than 29 (0.3, 0.3, 4) Yes

Engine running More than 29 (0.3, 0.3, 4) No

ELF0044D

Page 1264 of 3502

DI-58

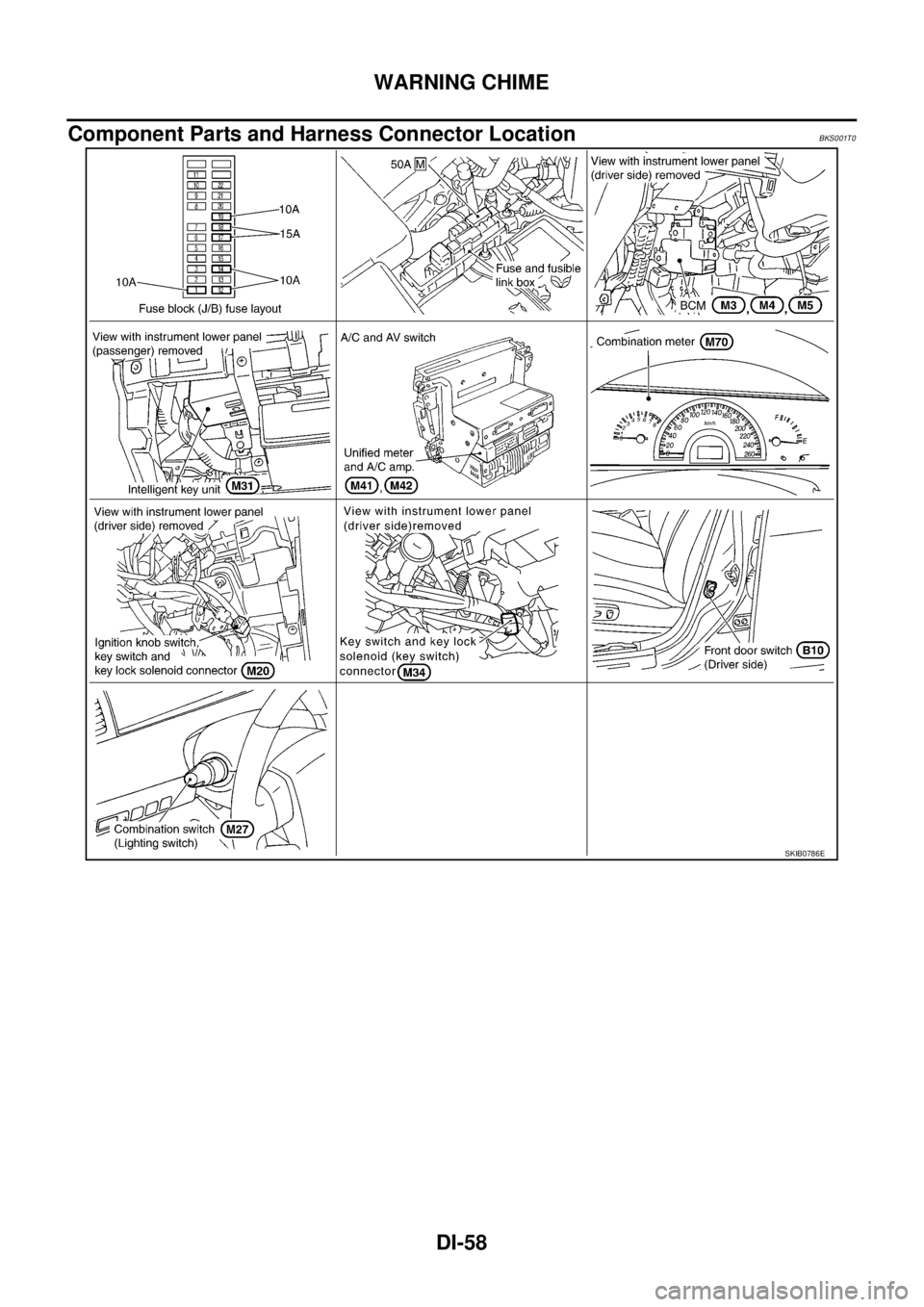

WARNING CHIME

Component Parts and Harness Connector LocationBKS001T0

SKIB0786E

Page 1273 of 3502

WARNING CHIME

DI-67

C

D

E

F

G

H

I

J

L

MA

B

DI

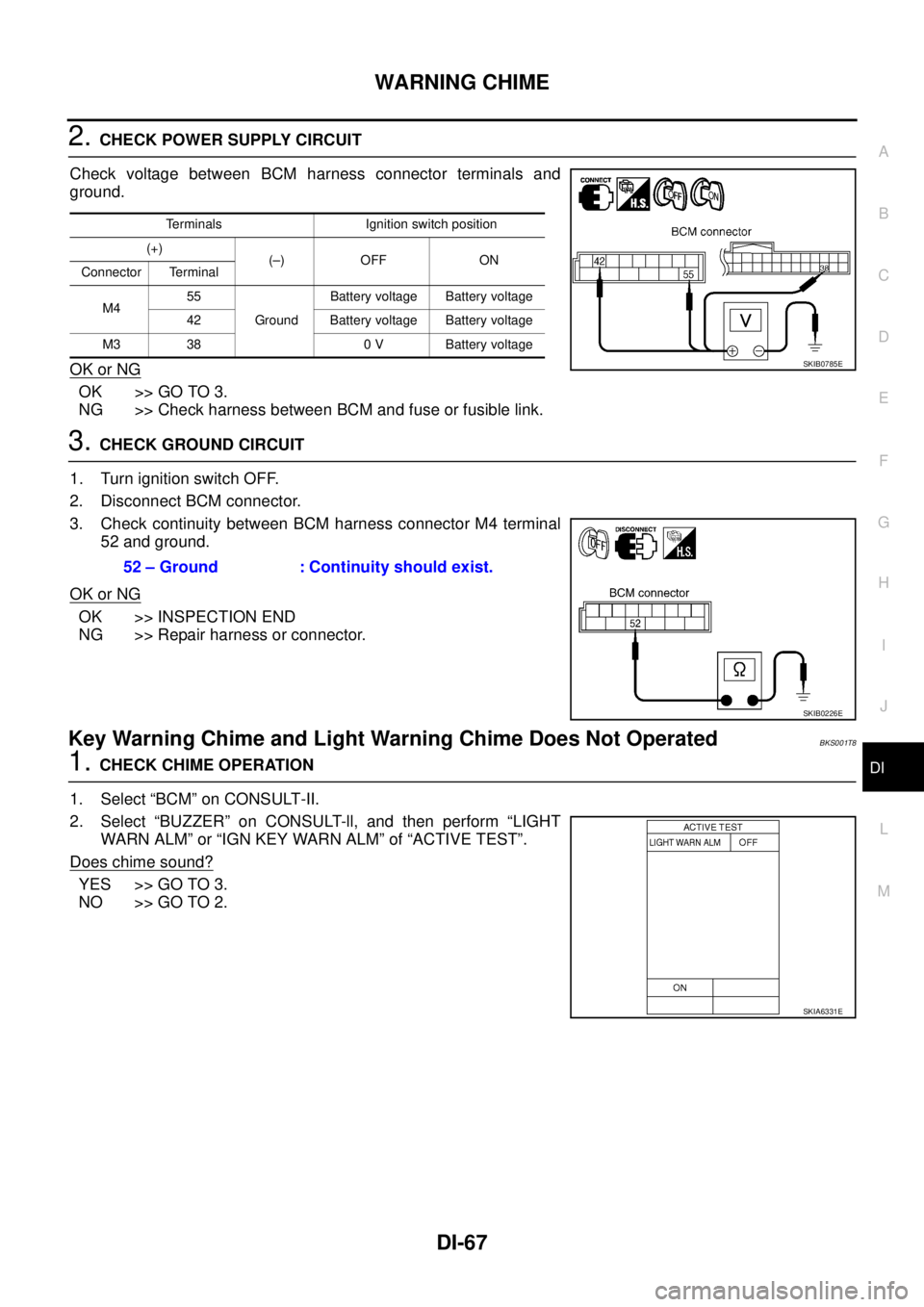

2. CHECK POWER SUPPLY CIRCUIT

Check voltage between BCM harness connector terminals and

ground.

OK or NG

OK >> GO TO 3.

NG >> Check harness between BCM and fuse or fusible link.

3. CHECK GROUND CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect BCM connector.

3. Check continuity between BCM harness connector M4 terminal

52 and ground.

OK or NG

OK >> INSPECTION END

NG >> Repair harness or connector.

Key Warning Chime and Light Warning Chime Does Not OperatedBKS001T8

1. CHECK CHIME OPERATION

1. Select “BCM” on CONSULT-II.

2. Select “BUZZER” on CONSULT-ll, and then perform “LIGHT

WARN ALM” or “IGN KEY WARN ALM” of “ACTIVE TEST”.

Does chime sound?

YES >> GO TO 3.

NO >> GO TO 2.

Terminals Ignition switch position

(+)

(–) OFF ON

Connector Terminal

M455

GroundBattery voltage Battery voltage

42 Battery voltage Battery voltage

M3 38 0 V Battery voltage

SKIB0785E

52 – Ground : Continuity should exist.

SKIB0226E

SKIA6331E

Page 1274 of 3502

DI-68

WARNING CHIME

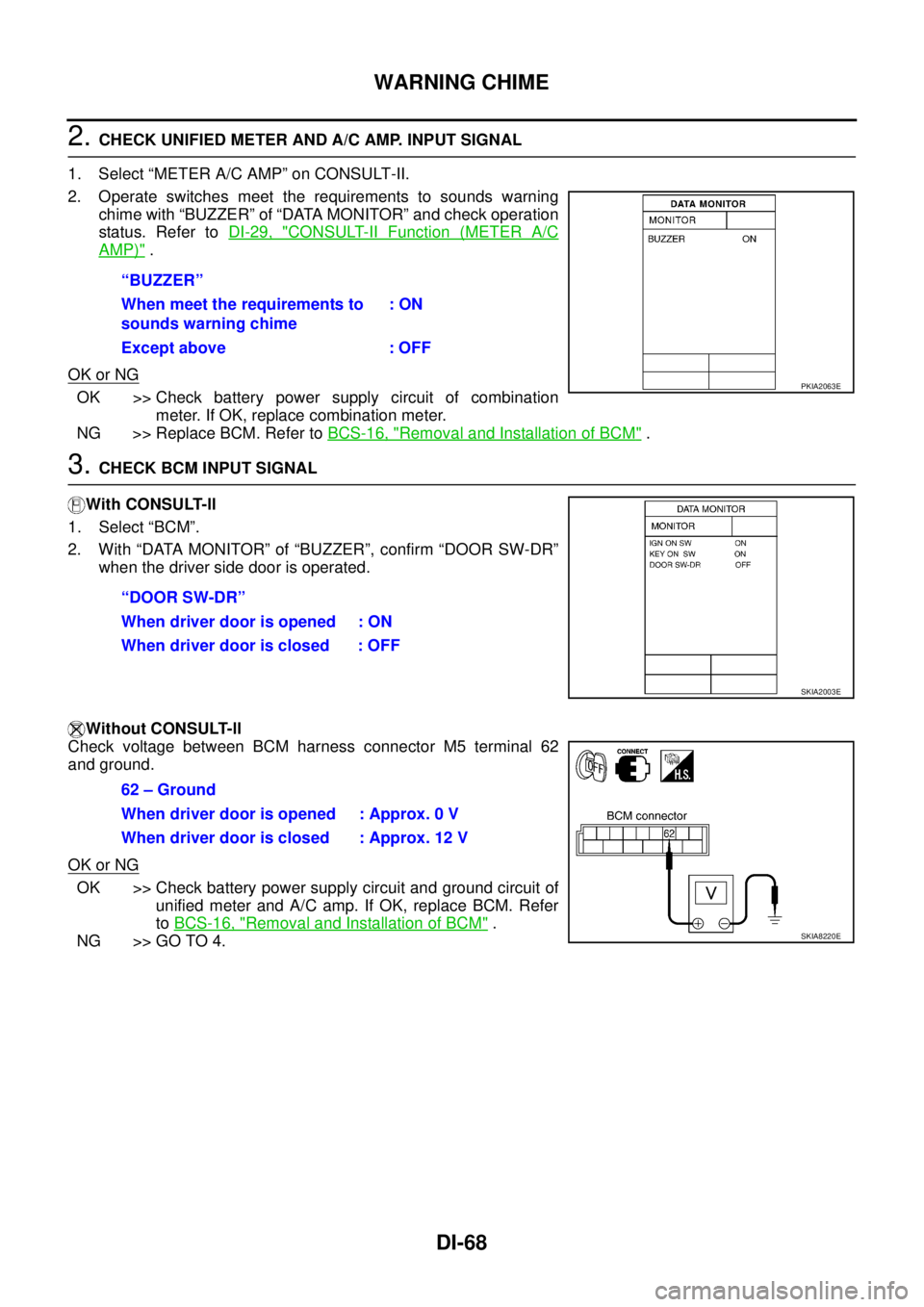

2. CHECK UNIFIED METER AND A/C AMP. INPUT SIGNAL

1. Select “METER A/C AMP” on CONSULT-II.

2. Operate switches meet the requirements to sounds warning

chime with “BUZZER” of “DATA MONITOR” and check operation

status. Refer to DI-29, "

CONSULT-II Function (METER A/C

AMP)" .

OK or NG

OK >> Check battery power supply circuit of combination

meter. If OK, replace combination meter.

NG >> Replace BCM. Refer to BCS-16, "

Removal and Installation of BCM" .

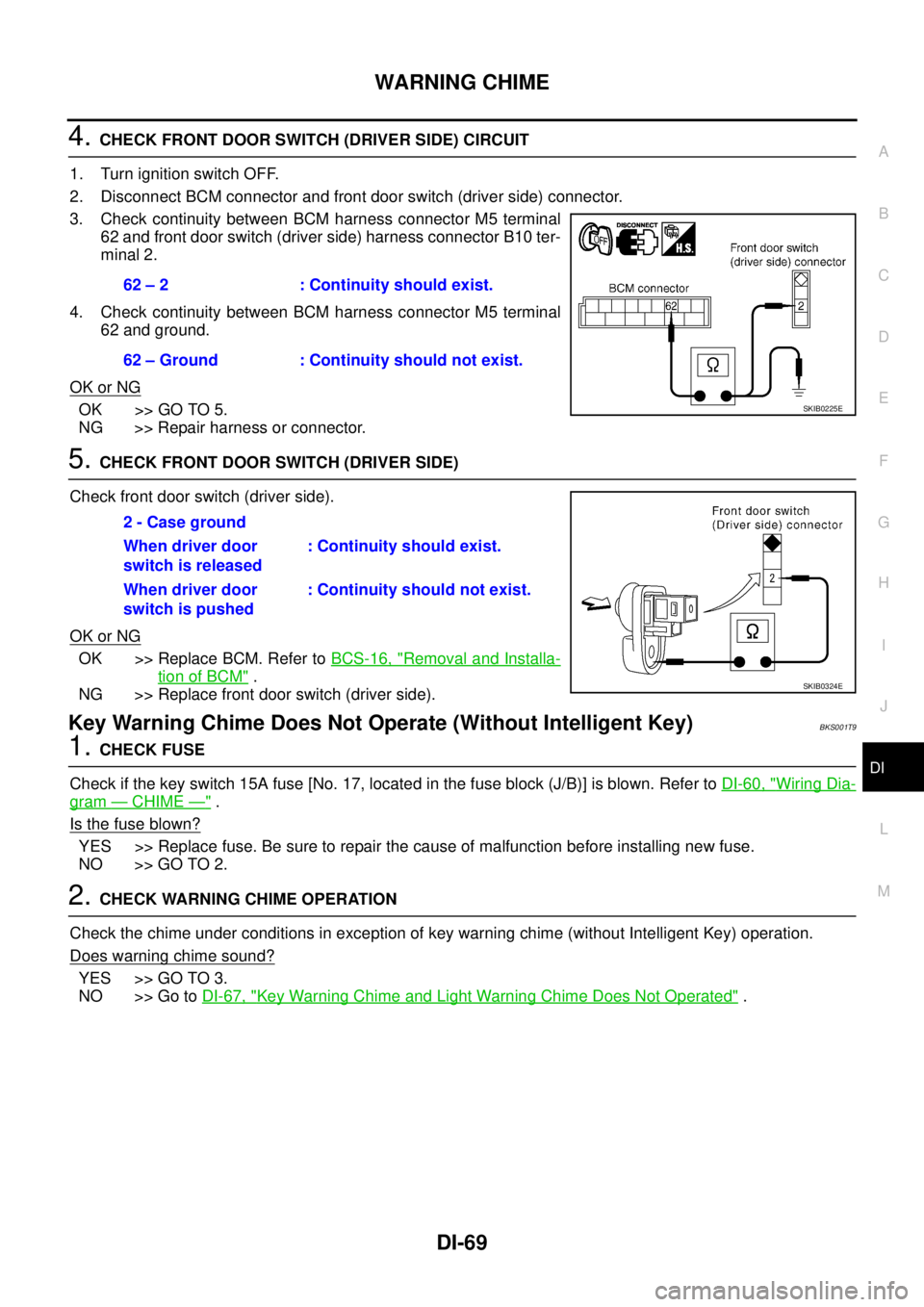

3. CHECK BCM INPUT SIGNAL

With CONSULT-ll

1. Select “BCM”.

2. With “DATA MONITOR” of “BUZZER”, confirm “DOOR SW-DR”

when the driver side door is operated.

Without CONSULT-ll

Check voltage between BCM harness connector M5 terminal 62

and ground.

OK or NG

OK >> Check battery power supply circuit and ground circuit of

unified meter and A/C amp. If OK, replace BCM. Refer

to BCS-16, "

Removal and Installation of BCM" .

NG >> GO TO 4.“BUZZER”

When meet the requirements to

sounds warning chime: ON

Except above : OFF

PKIA2063E

“DOOR SW-DR”

When driver door is opened : ON

When driver door is closed : OFF

SKIA2003E

62 – Ground

When driver door is opened : Approx. 0 V

When driver door is closed : Approx. 12 V

SKIA8220E

Page 1275 of 3502

WARNING CHIME

DI-69

C

D

E

F

G

H

I

J

L

MA

B

DI

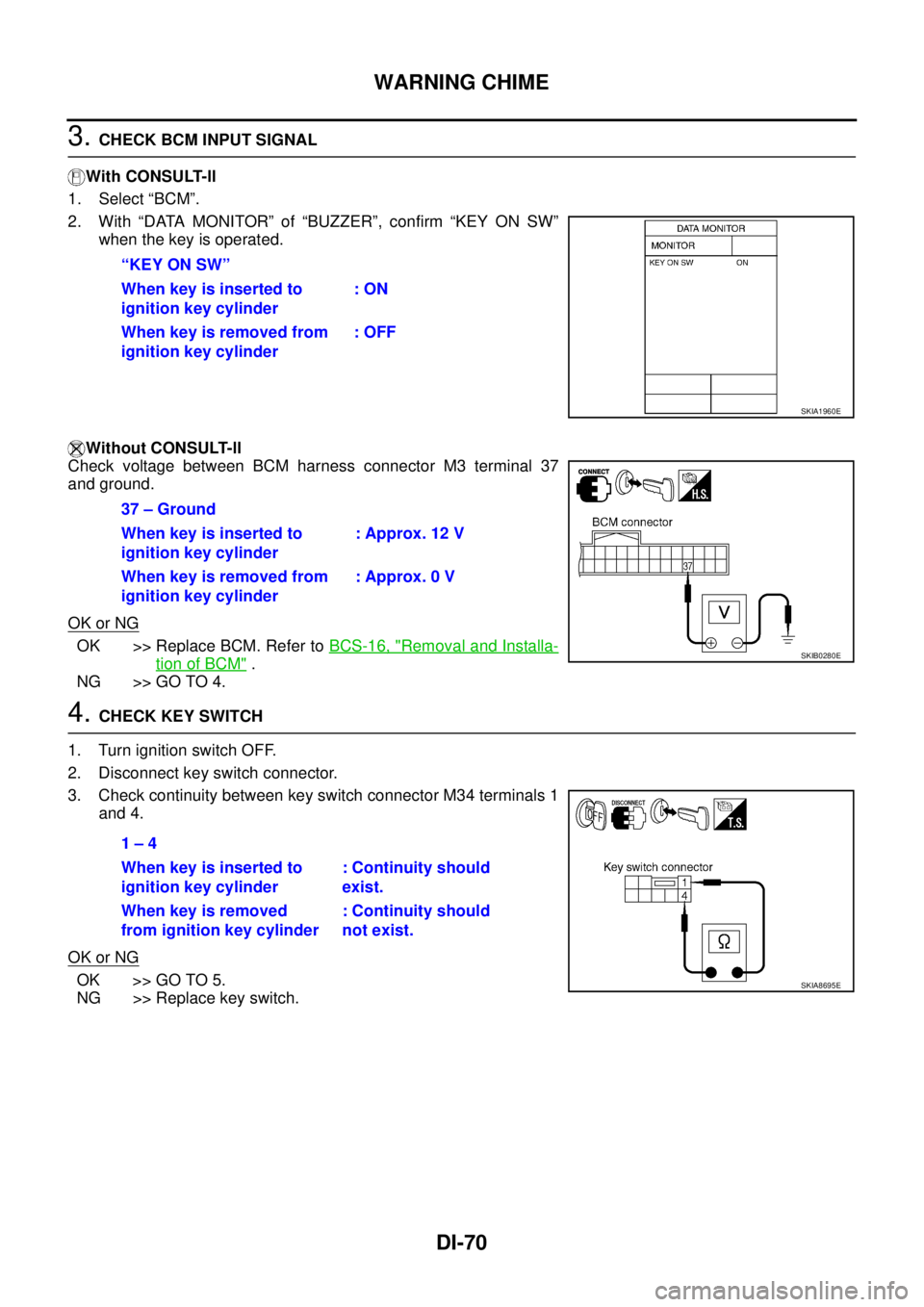

4. CHECK FRONT DOOR SWITCH (DRIVER SIDE) CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect BCM connector and front door switch (driver side) connector.

3. Check continuity between BCM harness connector M5 terminal

62 and front door switch (driver side) harness connector B10 ter-

minal 2.

4. Check continuity between BCM harness connector M5 terminal

62 and ground.

OK or NG

OK >> GO TO 5.

NG >> Repair harness or connector.

5. CHECK FRONT DOOR SWITCH (DRIVER SIDE)

Check front door switch (driver side).

OK or NG

OK >> Replace BCM. Refer to BCS-16, "Removal and Installa-

tion of BCM" .

NG >> Replace front door switch (driver side).

Key Warning Chime Does Not Operate (Without Intelligent Key)BKS001T9

1. CHECK FUSE

Check if the key switch 15A fuse [No. 17, located in the fuse block (J/B)] is blown. Refer to DI-60, "

Wiring Dia-

gram — CHIME —" .

Is the fuse blown?

YES >> Replace fuse. Be sure to repair the cause of malfunction before installing new fuse.

NO >> GO TO 2.

2. CHECK WARNING CHIME OPERATION

Check the chime under conditions in exception of key warning chime (without Intelligent Key) operation.

Does warning chime sound?

YES >> GO TO 3.

NO >> Go to DI-67, "

Key Warning Chime and Light Warning Chime Does Not Operated" . 62 – 2 : Continuity should exist.

62 – Ground : Continuity should not exist.

SKIB0225E

2 - Case ground

When driver door

switch is released: Continuity should exist.

When driver door

switch is pushed: Continuity should not exist.

SKIB0324E

Page 1276 of 3502

DI-70

WARNING CHIME

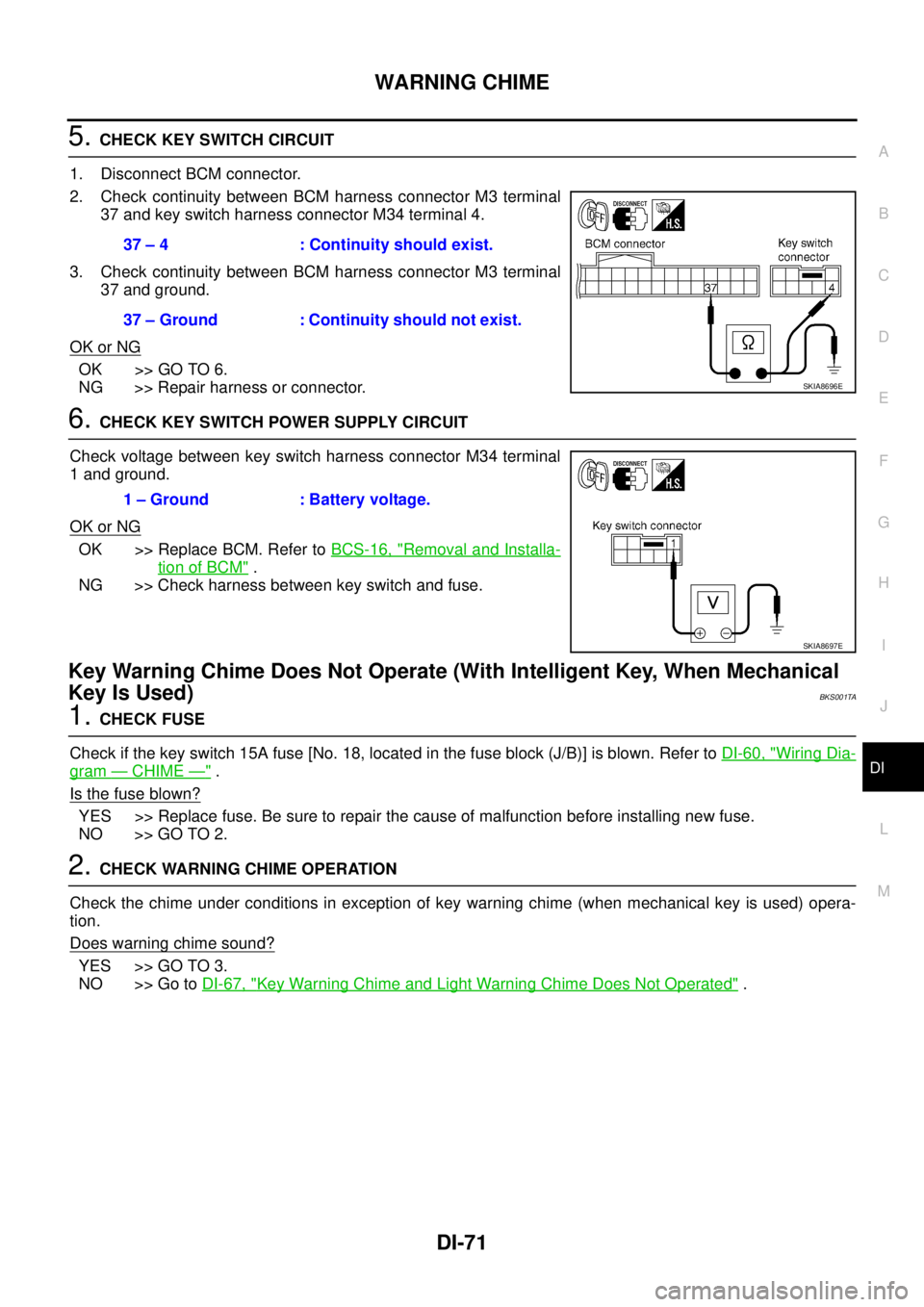

3. CHECK BCM INPUT SIGNAL

With CONSULT-ll

1. Select “BCM”.

2. With “DATA MONITOR” of “BUZZER”, confirm “KEY ON SW”

when the key is operated.

Without CONSULT-ll

Check voltage between BCM harness connector M3 terminal 37

and ground.

OK or NG

OK >> Replace BCM. Refer to BCS-16, "Removal and Installa-

tion of BCM" .

NG >> GO TO 4.

4. CHECK KEY SWITCH

1. Turn ignition switch OFF.

2. Disconnect key switch connector.

3. Check continuity between key switch connector M34 terminals 1

and 4.

OK or NG

OK >> GO TO 5.

NG >> Replace key switch.“KEY ON SW”

When key is inserted to

ignition key cylinder: ON

When key is removed from

ignition key cylinder: OFF

SKIA1960E

37 – Ground

When key is inserted to

ignition key cylinder: Approx. 12 V

When key is removed from

ignition key cylinder: Approx. 0 V

SKIB0280E

1 – 4

When key is inserted to

ignition key cylinder: Continuity should

exist.

When key is removed

from ignition key cylinder: Continuity should

not exist.

SKIA8695E

Page 1277 of 3502

WARNING CHIME

DI-71

C

D

E

F

G

H

I

J

L

MA

B

DI

5. CHECK KEY SWITCH CIRCUIT

1. Disconnect BCM connector.

2. Check continuity between BCM harness connector M3 terminal

37 and key switch harness connector M34 terminal 4.

3. Check continuity between BCM harness connector M3 terminal

37 and ground.

OK or NG

OK >> GO TO 6.

NG >> Repair harness or connector.

6. CHECK KEY SWITCH POWER SUPPLY CIRCUIT

Check voltage between key switch harness connector M34 terminal

1 and ground.

OK or NG

OK >> Replace BCM. Refer to BCS-16, "Removal and Installa-

tion of BCM" .

NG >> Check harness between key switch and fuse.

Key Warning Chime Does Not Operate (With Intelligent Key, When Mechanical

Key Is Used)

BKS001TA

1. CHECK FUSE

Check if the key switch 15A fuse [No. 18, located in the fuse block (J/B)] is blown. Refer to DI-60, "

Wiring Dia-

gram — CHIME —" .

Is the fuse blown?

YES >> Replace fuse. Be sure to repair the cause of malfunction before installing new fuse.

NO >> GO TO 2.

2. CHECK WARNING CHIME OPERATION

Check the chime under conditions in exception of key warning chime (when mechanical key is used) opera-

tion.

Does warning chime sound?

YES >> GO TO 3.

NO >> Go to DI-67, "

Key Warning Chime and Light Warning Chime Does Not Operated" . 37 – 4 : Continuity should exist.

37 – Ground : Continuity should not exist.

SKIA8696E

1 – Ground : Battery voltage.

SKIA8697E

Page 1278 of 3502

DI-72

WARNING CHIME

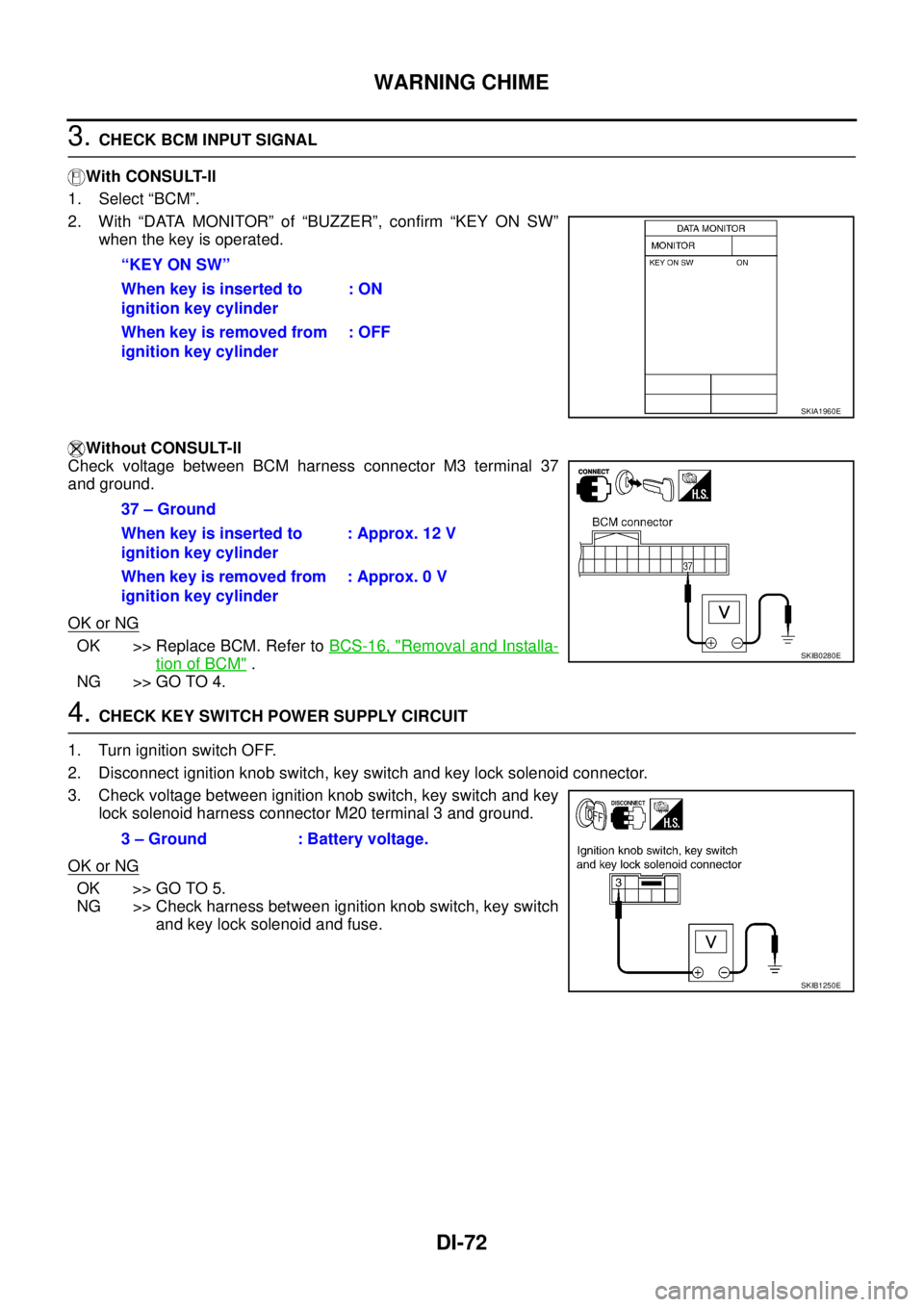

3. CHECK BCM INPUT SIGNAL

With CONSULT-ll

1. Select “BCM”.

2. With “DATA MONITOR” of “BUZZER”, confirm “KEY ON SW”

when the key is operated.

Without CONSULT-ll

Check voltage between BCM harness connector M3 terminal 37

and ground.

OK or NG

OK >> Replace BCM. Refer to BCS-16, "Removal and Installa-

tion of BCM" .

NG >> GO TO 4.

4. CHECK KEY SWITCH POWER SUPPLY CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect ignition knob switch, key switch and key lock solenoid connector.

3. Check voltage between ignition knob switch, key switch and key

lock solenoid harness connector M20 terminal 3 and ground.

OK or NG

OK >> GO TO 5.

NG >> Check harness between ignition knob switch, key switch

and key lock solenoid and fuse. “KEY ON SW”

When key is inserted to

ignition key cylinder: ON

When key is removed from

ignition key cylinder: OFF

SKIA1960E

37 – Ground

When key is inserted to

ignition key cylinder: Approx. 12 V

When key is removed from

ignition key cylinder: Approx. 0 V

SKIB0280E

3 – Ground : Battery voltage.

SKIB1250E

Page 1279 of 3502

WARNING CHIME

DI-73

C

D

E

F

G

H

I

J

L

MA

B

DI

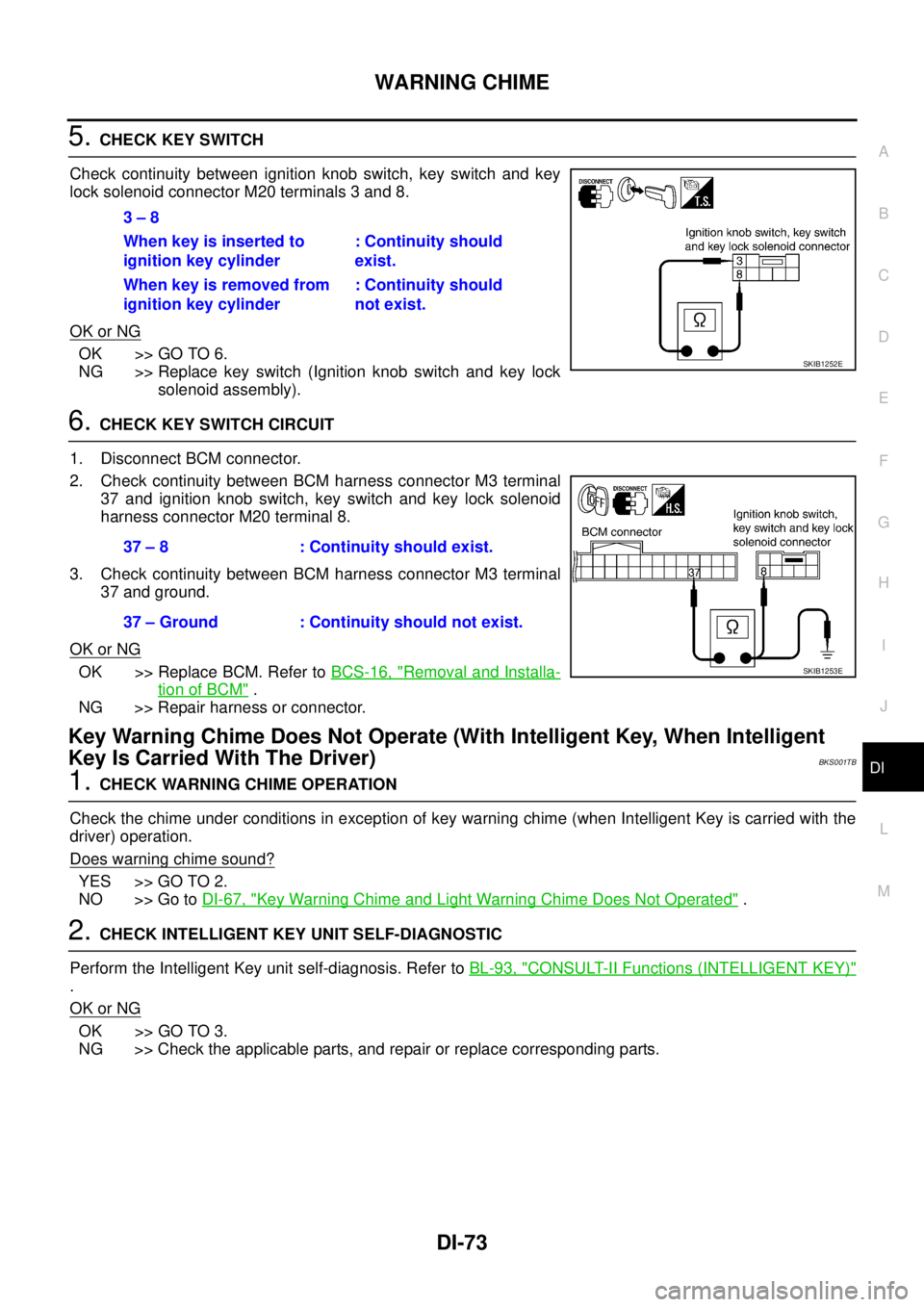

5. CHECK KEY SWITCH

Check continuity between ignition knob switch, key switch and key

lock solenoid connector M20 terminals 3 and 8.

OK or NG

OK >> GO TO 6.

NG >> Replace key switch (Ignition knob switch and key lock

solenoid assembly).

6. CHECK KEY SWITCH CIRCUIT

1. Disconnect BCM connector.

2. Check continuity between BCM harness connector M3 terminal

37 and ignition knob switch, key switch and key lock solenoid

harness connector M20 terminal 8.

3. Check continuity between BCM harness connector M3 terminal

37 and ground.

OK or NG

OK >> Replace BCM. Refer to BCS-16, "Removal and Installa-

tion of BCM" .

NG >> Repair harness or connector.

Key Warning Chime Does Not Operate (With Intelligent Key, When Intelligent

Key Is Carried With The Driver)

BKS001TB

1. CHECK WARNING CHIME OPERATION

Check the chime under conditions in exception of key warning chime (when Intelligent Key is carried with the

driver) operation.

Does warning chime sound?

YES >> GO TO 2.

NO >> Go to DI-67, "

Key Warning Chime and Light Warning Chime Does Not Operated" .

2. CHECK INTELLIGENT KEY UNIT SELF-DIAGNOSTIC

Perform the Intelligent Key unit self-diagnosis. Refer to BL-93, "

CONSULT-II Functions (INTELLIGENT KEY)"

.

OK or NG

OK >> GO TO 3.

NG >> Check the applicable parts, and repair or replace corresponding parts.3 – 8

When key is inserted to

ignition key cylinder: Continuity should

exist.

When key is removed from

ignition key cylinder: Continuity should

not exist.

SKIB1252E

37 – 8 : Continuity should exist.

37 – Ground : Continuity should not exist.

SKIB1253E