diagram NISSAN TEANA 2008 Owners Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2008, Model line: TEANA, Model: NISSAN TEANA 2008Pages: 5121, PDF Size: 69.03 MB

Page 1462 of 5121

EC-1

ENGINE

C

DE

F

G H

I

J

K L

M

SECTION EC

A

EC

N

O P

CONTENTS

ENGINE CONTROL SYSTEM

VQ25DE, VQ35DE

BASIC INSPECTION ....... .............................

7

DIAGNOSIS AND REPAIR WORKFLOW ..... .....7

Work Flow ........................................................... ......7

Diagnostic Work Sheet ............................................10

INSPECTION AND ADJUSTMENT ....................11

BASIC INSPECTION ......... ........................................11

BASIC INSPECTION : Special Repair Require-

ment .................................................................... ....

11

ADDITIONAL SERVICE WHEN REPLACING

CONTROL UNIT .................................................... ....

14

ADDITIONAL SERVICE WHEN REPLACING

CONTROL UNIT : Description ................................

14

ADDITIONAL SERVICE WHEN REPLACING

CONTROL UNIT : Special Repair Requirement .....

14

IDLE SPEED .......................................................... ....14

IDLE SPEED : Description ........................ ..............14

IDLE SPEED : Special R epair Requirement ...........14

IGNITION TIMING .................................................. ....15

IGNITION TIMING : Description ..............................15

IGNITION TIMING : Special Repair Requirement ....15

ACCELERATOR PEDAL RELEASED POSITION

LEARNING ............................................................ ....

15

ACCELERATOR PEDAL RELEASED POSITION

LEARNING : Description .........................................

15

ACCELERATOR PEDAL RELEASED POSITION

LEARNING : Special Repair Requirement ..............

15

THROTTLE VALVE CLOSED POSITION LEARN-

ING ......................................................................... ....

16

THROTTLE VALVE CLOSED POSITION

LEARNING : Description .........................................

16

THROTTLE VALVE CLOSED POSITION

LEARNING : Special Repair Requirement ..............

16

IDLE AIR VOLUME LEARNING ............................ ....16

IDLE AIR VOLUME LEARNING : Description .........16

IDLE AIR VOLUME LEARNI NG : Special Repair

Requirement ........................................................ ....

16

MIXTURE RATIO SELF-LEARNING VALUE

CLEAR ................................................................... ....

18

MIXTURE RATIO SELF-LEARNING VALUE

CLEAR : Description ................................................

18

MIXTURE RATIO SELF-LEARNING VALUE

CLEAR : Special Repair Requirement .....................

18

FUNCTION DIAGNOSIS ..............................19

ENGINE CONTRO L SYSTEM ..........................19

System Diagram ................................................. ....19

System Description ..................................................20

Component Parts Location ....................................20

Component Description ...........................................25

MULTIPORT FUEL INJECTION SYSTEM .......27

System Diagram .....................................................27

System Description ..................................................27

Component Parts Location ....................................31

Component Description ...........................................36

ELECTRIC IGNITION SYSTEM ........................37

System Diagram .....................................................37

System Description ..................................................37

Component Parts Location ....................................38

Component Description ...........................................43

AIR CONDITIONING CUT CONTROL ..............44

System Diagram ......................................................44

System Description ..................................................44

Component Parts Location ....................................45

Component Description ...........................................50

AUTOMATIC SPEED CONTROL DEVICE

(ASCD) ..............................................................

51

System Diagram ......................................................51

System Description ..................................................51

Page 1463 of 5121

EC-2

Component Parts Location ...................................53

Component Description .........................................58

CAN COMMUNICATION ...................................59

System Description .................................................59

COOLING FAN CONTROL ...............................60

System Diagram .....................................................60

System Description .................................................60

Component Parts Location ...................................62

Component Description ..........................................67

ELECTRONIC CONTROLLED ENGINE

MOUNT ..............................................................

68

System Diagram .....................................................68

System Description .................................................69

Component Parts Location ...................................70

Component Description .........................................75

EVAPORATIVE EMISSION SYSTEM ...............76

System Diagram .....................................................76

System Description .................................................76

Component Parts Location ...................................80

Component Description .........................................85

INTAKE VALVE TIMING CONTROL .................86

System Diagram .....................................................86

System Description .................................................86

Component Parts Location ...................................87

Component Description ..........................................92

VARIABLE INDUCTION AIR SYSTEM .............93

System Diagram .....................................................93

System Description .................................................93

Component Parts Location ...................................96

Component Description ........................................101

ON BOARD DIAGNOSTIC (OBD) SYSTEM ...102

Diagnosis Description ............................................102

CONSULT-III Function ..........................................113

Diagnosis Tool Function ......................................122

COMPONENT DIAGNOSIS .......................124

TROUBLE DIAGNOSIS - SPECIFICATION

VALUE .............................................................

124

Description .............................................................124

Component Function Check ..................................124

Diagnosis Procedure .............................................125

POWER SUPPLY AND GROUND CIRCUIT ...132

Diagnosis Procedure .............................................132

U1000, U1001 CAN COMM CIRCUIT .............135

Description .............................................................135

DTC Logic ..............................................................135

Diagnosis Procedure .............................................135

P0011, P0021 IVT CONTROL .........................136

DTC Logic ..............................................................136

Diagnosis Procedure .............................................137

Component Inspection ..........................................138

P0031, P0032, P0051, P0052 A/F SENSOR 1

HEATER ...........................................................

140

Description ............................................................140

DTC Logic .............................................................140

Diagnosis Procedure .............................................140

Component Inspection ..........................................142

P0037, P0038, P0057, P0058 HO2S2 HEAT-

ER .....................................................................

143

Description ............................................................143

DTC Logic .............................................................143

Diagnosis Procedure .............................................144

Component Inspection ..........................................145

P0075, P0081 IVT CONTROL SOLENOID

VALVE ..............................................................

146

Description ............................................................146

DTC Logic .............................................................146

Diagnosis Procedure .............................................146

Component Inspection ..........................................147

P0102, P0103 MAF SENSOR ..........................149

Description ............................................................149

DTC Logic .............................................................149

Diagnosis Procedure .............................................150

Component Inspection ..........................................151

P0112, P0113 IAT SENSOR ............................154

Description ............................................................154

DTC Logic .............................................................154

Diagnosis Procedure .............................................155

Component Inspection ..........................................155

P0117, P0118 ECT SENSOR ...........................157

Description ............................................................157

DTC Logic .............................................................157

Diagnosis Procedure .............................................158

Component Inspection ..........................................158

P0122, P0123 TP SENSOR ..............................160

Description ............................................................160

DTC Logic .............................................................160

Diagnosis Procedure .............................................160

Component Inspection ..........................................162

Special Repair Requirement .................................162

P0130, P0150 A/F SENSOR 1 .........................163

Description ............................................................163

DTC Logic .............................................................163

Component Function Check .................................165

Diagnosis Procedure .............................................165

P0131, P0151 A/F SENSOR 1 .........................167

Description ............................................................167

DTC Logic .............................................................167

Diagnosis Procedure .............................................168

P0132, P0152 A/F SENSOR 1 .........................170

Description ............................................................170

Page 1466 of 5121

EC-5

C

D

E

F

G

H

I

J

K

L

M

ECA

N

O

P

P2122, P2123 APP SENSOR ...........................304

Description ............................................................304

DTC Logic .............................................................304

Diagnosis Procedure .............................................304

Component Inspection ..........................................306

Special Repair Requirement .................................306

P2127, P2128 APP SENSOR ...........................307

Description ............................................................307

DTC Logic .............................................................307

Diagnosis Procedure .............................................307

Component Inspection ..........................................309

Special Repair Requirement .................................310

P2135 TP SENSOR ..........................................311

Description ............................................................311

DTC Logic .............................................................311

Diagnosis Procedure .............................................311

Component Inspection ..........................................313

Special Repair Requirement .................................313

P2138 APP SENSOR .......................................314

Description ............................................................314

DTC Logic .............................................................314

Diagnosis Procedure .............................................314

Component Inspection ..........................................316

Special Repair Requirement .................................317

P2A00, P2A03 A/F SENSOR 1 ........................318

Description ............................................................318

DTC Logic .............................................................318

Diagnosis Procedure .............................................319

ASCD BRAKE SWITCH ...................................321

Description ............................................................321

Component Function Check ..................................321

Diagnosis Procedure .............................................321

Component Inspection (ASCD Brake Switch) .......322

ASCD INDICATOR ...........................................323

Description ............................................................323

Component Function Check ..................................323

Diagnosis Procedure .............................................323

COOLING FAN .................................................324

Description ............................................................324

Component Function Check ..................................324

Diagnosis Procedure .............................................324

Component Inspection (Cooling Fan Motor) .........327

Component Inspection (Cooling Fan Relay) .........328

ELECTRICAL LOAD SIGNAL .........................329

Description ............................................................329

Component Function Check ..................................329

Diagnosis Procedure .............................................329

ELECTRONIC CONTROLLED ENGINE

MOUNT .............................................................

331

Description ............................................................331

Component Function Check ..................................331

Diagnosis Procedure .............................................331

Component Inspection ...........................................332

FUEL INJECTOR ............................................334

Description .............................................................334

Component Function Check ..................................334

Diagnosis Procedure .............................................334

Component Inspection ...........................................336

FUEL PUMP ....................................................337

Description .............................................................337

Component Function Check ..................................337

Diagnosis Procedure .............................................337

Component Inspection (Fuel Pump) ......................340

Component Inspection (Condenser) ......................340

IGNITION SIGNAL ..........................................341

Description .............................................................341

Component Function Check ..................................341

Diagnosis Procedure .............................................341

Component Inspection (Ignition Coil with Power

Transistor) .............................................................

344

Component Inspection (Condenser) ......................345

MALFUNCTION INDICATOR .........................346

Description .............................................................346

Component Function Check ..................................346

Diagnosis Procedure .............................................346

POSITIVE CRANKCASE VENTILATION .......347

Description .............................................................347

Component Inspection ...........................................347

REFRIGERANT PRESSURE SENSOR ..........348

Description .............................................................348

Component Function Check ..................................348

Diagnosis Procedure .............................................348

VARIABLE INDUCTION AIR SYSTEM ..........351

Description .............................................................351

Component Function Check (VQ35DE engine) .....351

Component Function Check (VQ25DE engine) .....353

Diagnosis Procedure (VQ35DE engine) ................353

Diagnosis Procedure (VQ25DE engine) ................355

ECU DIAGNOSIS .......................................357

ECM .................................................................357

Reference Value ....................................................357

Wiring Diagram—ENGINE CONTROL SYS-

TEM— ...................................................................

371

Fail safe .................................................................386

DTC Inspection Priority Chart .............................388

DTC Index .............................................................389

How to Set SRT Code ........................................392

Test Value and Test Limit ...................................394

SYMPTOM DIAGNOSIS ............................400

ENGINE CONTROL SYSTEM SYMPTOMS ...400

Symptom Table .....................................................400

NORMAL OPERATING CONDITION .............404

Page 1480 of 5121

![NISSAN TEANA 2008 Owners Manual ENGINE CONTROL SYSTEM

EC-19

< FUNCTION DIAGNOSIS >[VQ25DE, VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

FUNCTION DIAGNOSIS

ENGINE CONTROL SYSTEM

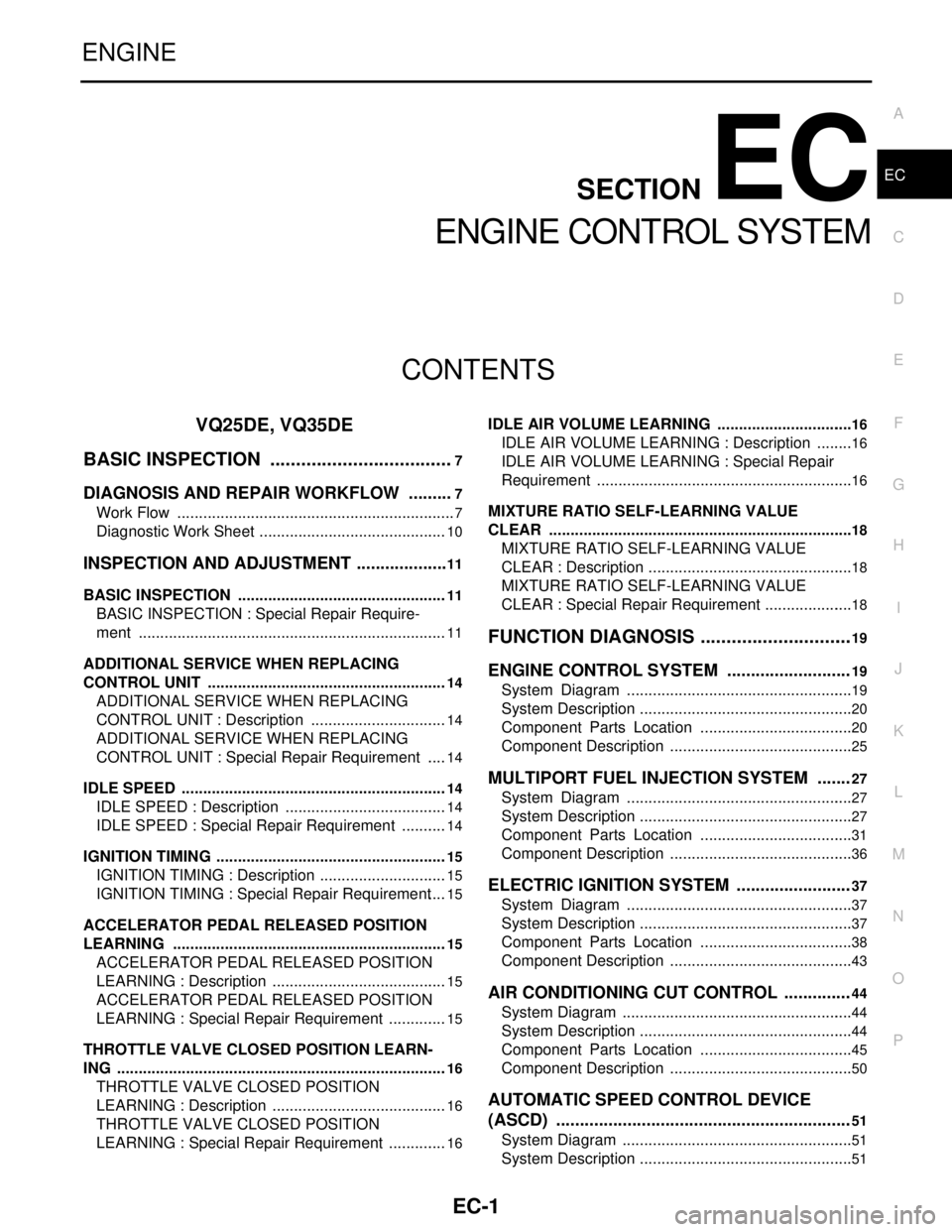

System DiagramINFOID:0000000003856461

JMBIA1465GB NISSAN TEANA 2008 Owners Manual ENGINE CONTROL SYSTEM

EC-19

< FUNCTION DIAGNOSIS >[VQ25DE, VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

FUNCTION DIAGNOSIS

ENGINE CONTROL SYSTEM

System DiagramINFOID:0000000003856461

JMBIA1465GB](/img/5/57391/w960_57391-1479.png)

ENGINE CONTROL SYSTEM

EC-19

< FUNCTION DIAGNOSIS >[VQ25DE, VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

FUNCTION DIAGNOSIS

ENGINE CONTROL SYSTEM

System DiagramINFOID:0000000003856461

JMBIA1465GB

Page 1488 of 5121

![NISSAN TEANA 2008 Owners Manual MULTIPORT FUEL INJECTION SYSTEM

EC-27

< FUNCTION DIAGNOSIS >[VQ25DE, VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

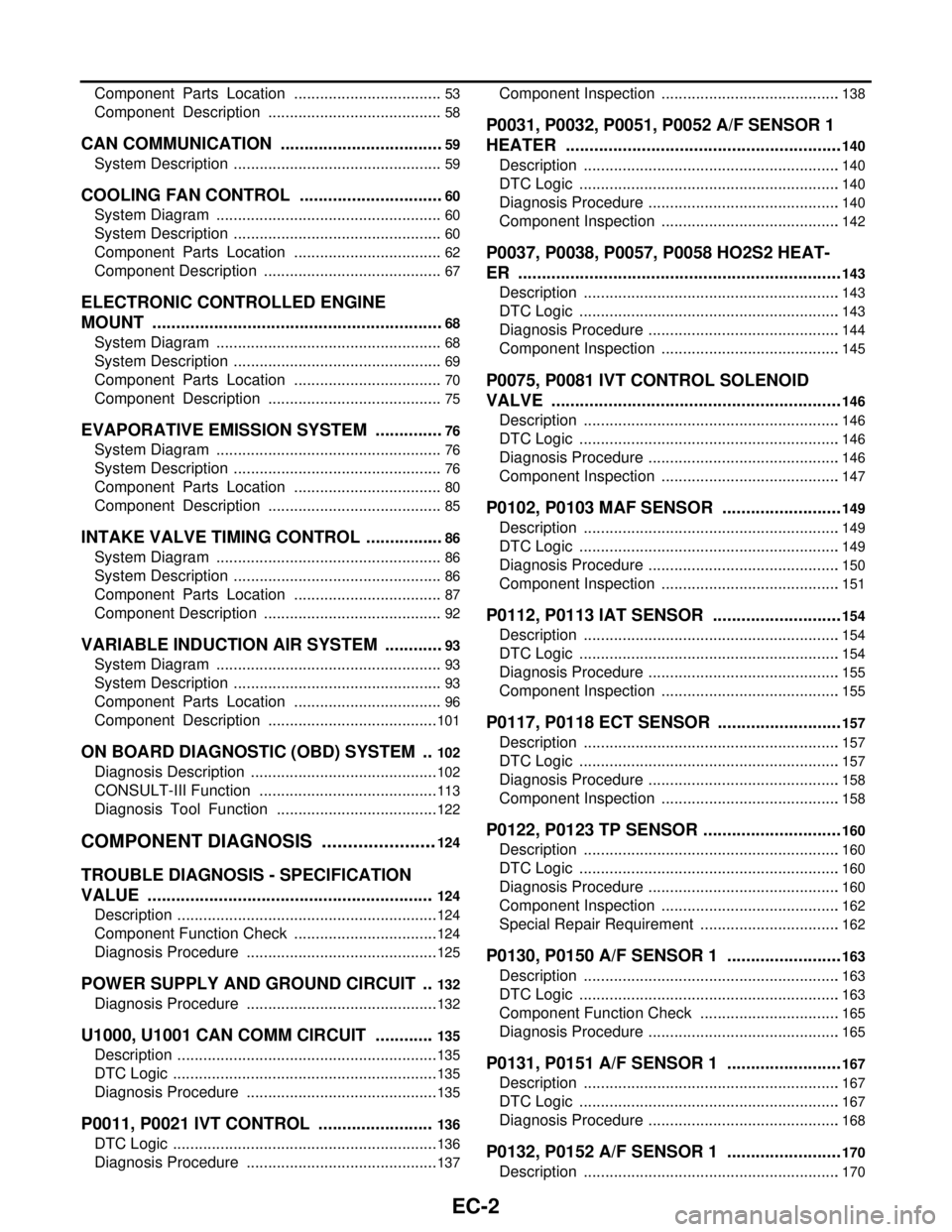

MULTIPORT FUEL INJECTION SYSTEM

System DiagramINFOID:0000000003856465

System DescriptionINF NISSAN TEANA 2008 Owners Manual MULTIPORT FUEL INJECTION SYSTEM

EC-27

< FUNCTION DIAGNOSIS >[VQ25DE, VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

MULTIPORT FUEL INJECTION SYSTEM

System DiagramINFOID:0000000003856465

System DescriptionINF](/img/5/57391/w960_57391-1487.png)

MULTIPORT FUEL INJECTION SYSTEM

EC-27

< FUNCTION DIAGNOSIS >[VQ25DE, VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

MULTIPORT FUEL INJECTION SYSTEM

System DiagramINFOID:0000000003856465

System DescriptionINFOID:0000000003856466

INPUT/OUTPUT SIGNAL CHART

JMBIA1492GB

Page 1498 of 5121

![NISSAN TEANA 2008 Owners Manual ELECTRIC IGNITION SYSTEM

EC-37

< FUNCTION DIAGNOSIS >[VQ25DE, VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

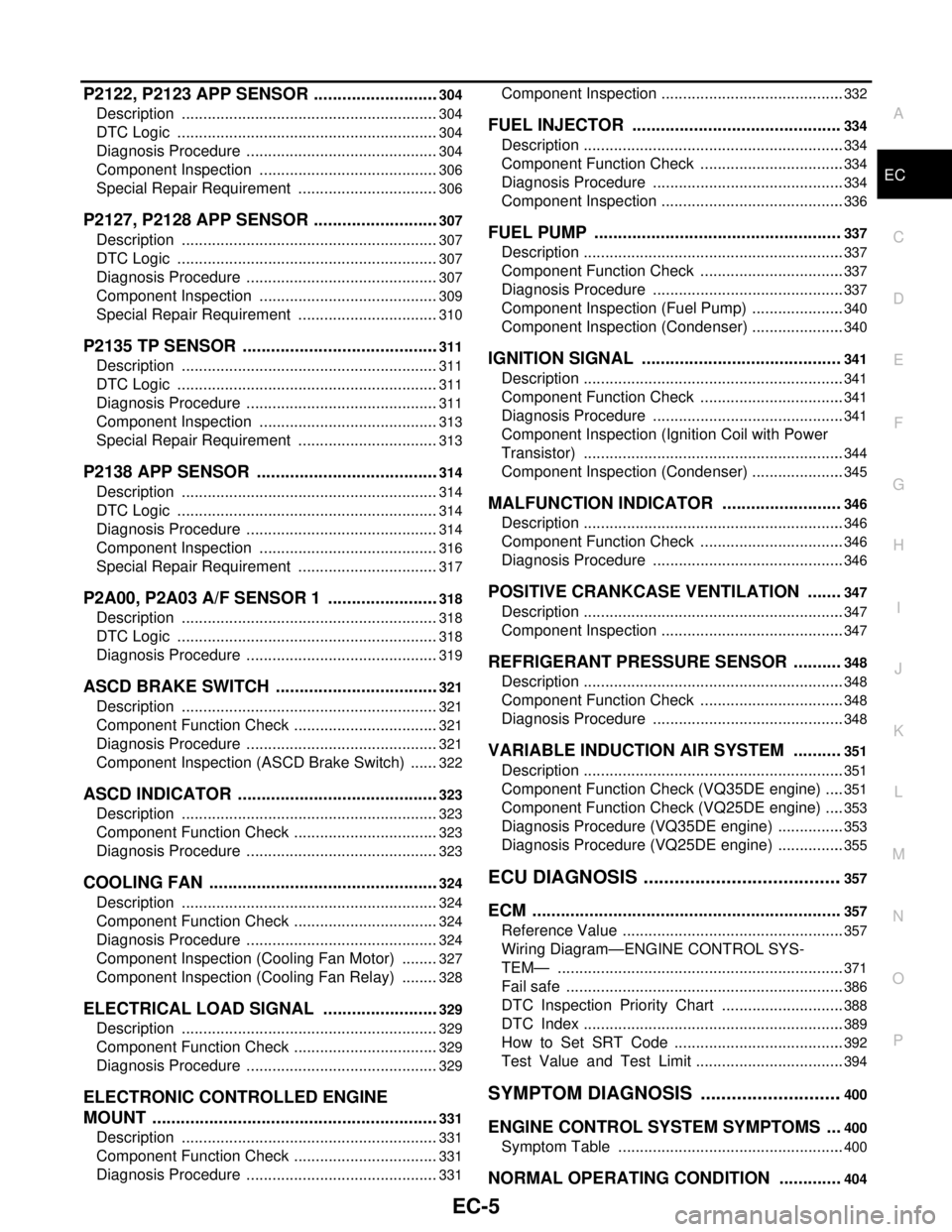

ELECTRIC IGNITION SYSTEM

System DiagramINFOID:0000000003856469

System DescriptionINFOID:0000000003 NISSAN TEANA 2008 Owners Manual ELECTRIC IGNITION SYSTEM

EC-37

< FUNCTION DIAGNOSIS >[VQ25DE, VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

ELECTRIC IGNITION SYSTEM

System DiagramINFOID:0000000003856469

System DescriptionINFOID:0000000003](/img/5/57391/w960_57391-1497.png)

ELECTRIC IGNITION SYSTEM

EC-37

< FUNCTION DIAGNOSIS >[VQ25DE, VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

ELECTRIC IGNITION SYSTEM

System DiagramINFOID:0000000003856469

System DescriptionINFOID:0000000003856470

INPUT/OUTPUT SIGNAL CHART

*1: This signal is sent to the ECM through CAN communication line.

*2: ECM determines the start signal status by the signals of engine speed and battery voltage.

SYSTEM DESCRIPTION

Ignition order: 1 - 2 - 3 - 4 - 5 - 6

The ignition timing is controlled by the ECM to maintain the best air-fuel ratio for every running condition of the

engine. The ignition timing data is stored in the ECM.

The ECM receives information such as the injection pulse width and camshaft position sensor (PHASE) sig-

nal. Computing this information, ignition signals are transmitted to the power transistor.

During the following conditions, the ignition timing is revised by the ECM according to the other data stored in

the ECM.

At starting

During warm-up

At idle

At low battery voltage

During acceleration

The knock sensor retard system is designed only for emergencies. The basic ignition timing is programmed

within the anti-knocking zone, if recommended fuel is used under dry conditions. The retard system does not

JMBIA1493GB

Sensor Input Signal to ECM ECM function Actuator

Crankshaft position sensor (POS)

Engine speed*

2

Piston position

Ignition timing

controlIgnition coil

(with power transistor) Camshaft position sensor (PHASE)

Mass air flow sensor Amount of intake air

Engine coolant temperature sensor Engine coolant temperature

Throttle position sensor Throttle position

Accelerator pedal position sensor Accelerator pedal position

Battery

Battery voltage*

2

Knock sensor Engine knocking

TCM (VQ35DE engine)

Park/neutral position (PNP) switch (VQ25DE engine)Gear position

ABS actuator and electric unit (control unit)

Vehicle speed*

1

Page 1505 of 5121

![NISSAN TEANA 2008 Owners Manual EC-44

< FUNCTION DIAGNOSIS >[VQ25DE, VQ35DE]

AIR CONDITIONING CUT CONTROL

AIR CONDITIONING CUT CONTROL

System DiagramINFOID:0000000003856473

System DescriptionINFOID:0000000003856474

INPUT/OUTPUT SIGN NISSAN TEANA 2008 Owners Manual EC-44

< FUNCTION DIAGNOSIS >[VQ25DE, VQ35DE]

AIR CONDITIONING CUT CONTROL

AIR CONDITIONING CUT CONTROL

System DiagramINFOID:0000000003856473

System DescriptionINFOID:0000000003856474

INPUT/OUTPUT SIGN](/img/5/57391/w960_57391-1504.png)

EC-44

< FUNCTION DIAGNOSIS >[VQ25DE, VQ35DE]

AIR CONDITIONING CUT CONTROL

AIR CONDITIONING CUT CONTROL

System DiagramINFOID:0000000003856473

System DescriptionINFOID:0000000003856474

INPUT/OUTPUT SIGNAL CHART

*1: This signal is sent to the ECM through CAN communication line.

*2: ECM determines the start signal status by the signals of engine speed and battery voltage.

SYSTEM DESCRIPTION

This system improves engine operation when the air conditioner is used.

Under the following conditions, the air conditioner is turned OFF.

When the accelerator pedal is fully depressed.

When cranking the engine.

At high engine speeds.

When the engine coolant temperature becomes excessively high.

When operating power steering during low engine speed or low vehicle speed.

When engine speed is excessively low.

When refrigerant pressure is excessively low or high.

JMBIA1414GB

Sensor Input Signal to ECM ECM function Actuator

BCM

Air conditioner ON signal*

1

Air conditioner

cut controlAir conditioner relay Accelerator pedal position sensor Accelerator pedal position

Crankshaft position sensor (POS)

Camshaft position sensor (PHASE)Engine speed*

2

Engine coolant temperature sensor Engine coolant temperature

Battery

Battery voltage*

2

Refrigerant pressure sensor Refrigerant pressure

Power steering pressure sensor Power steering operation

ABS actuator and electric unit (control unit)

Vehicle speed*

1

Page 1512 of 5121

![NISSAN TEANA 2008 Owners Manual AUTOMATIC SPEED CONTROL DEVICE (ASCD)

EC-51

< FUNCTION DIAGNOSIS >[VQ25DE, VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

AUTOMATIC SPEED CONTROL DEVICE (ASCD)

System DiagramINFOID:0000000003856477

System De NISSAN TEANA 2008 Owners Manual AUTOMATIC SPEED CONTROL DEVICE (ASCD)

EC-51

< FUNCTION DIAGNOSIS >[VQ25DE, VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

AUTOMATIC SPEED CONTROL DEVICE (ASCD)

System DiagramINFOID:0000000003856477

System De](/img/5/57391/w960_57391-1511.png)

AUTOMATIC SPEED CONTROL DEVICE (ASCD)

EC-51

< FUNCTION DIAGNOSIS >[VQ25DE, VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

AUTOMATIC SPEED CONTROL DEVICE (ASCD)

System DiagramINFOID:0000000003856477

System DescriptionINFOID:0000000003856478

INPUT/OUTPUT SIGNAL CHART

*: This signal is sent to the ECM through CAN communication line

BASIC ASCD SYSTEM

Refer to Owner's Manual for ASCD operating instructions.

Automatic Speed Control Device (ASCD) allows a driver to keep vehicle at predetermined constant speed

without depressing accelerator pedal. Driver can set vehicle speed in advance between approximately 40 km/

h (25 MPH) and 144 km/h (89 MPH).

ECM controls throttle angle of electric throttle control actuator to regulate engine speed.

Operation status of ASCD is indicated by CRUISE lamp and SET lamp in combination meter. If any malfunc-

tion occurs in the ASCD system, it automatically deactivates control.

NOTE:

Always drive vehicle in a safe manner according to traffic conditions and obey all traffic laws.

SET OPERATION

Press MAIN switch. (The CRUISE lamp in combination meter illuminates.)

When vehicle speed reaches a desired speed between approximately 40 km/h (25 MPH) and 144 km/h (89

MPH), press SET/COAST switch. (Then SET lamp in combination meter illuminates.)

ACCELERATE OPERATION

If the RESUME/ACCELERATE switch is pressed during cruise control driving, increase the vehicle speed until

the switch is released or vehicle speed reaches maximum speed controlled by the system.

And then ASCD will maintain the new set speed.

CANCEL OPERATION

When any of following conditions exist, cruise operation will be canceled.

CANCEL switch is pressed

More than 2 switches at ASCD steering switch are pressed at the same time (Set speed will be cleared)

JMBIA1494GB

Sensor Input signal to ECM ECM function Actuator

ASCD brake switch Brake pedal operation

ASCD vehicle speed

controlElectric throttle control

actuator Stop lamp switch Brake pedal operation

ASCD steering switch ASCD steering switch operation

TCM (VQ35DE engine)

Park/neutral position (PNP) switch (VQ25DE

engine)Gear position

Powertrain revolution*

ABS actuator and electric unit (control unit) Vehicle speed*

Page 1521 of 5121

![NISSAN TEANA 2008 Owners Manual EC-60

< FUNCTION DIAGNOSIS >[VQ25DE, VQ35DE]

COOLING FAN CONTROL

COOLING FAN CONTROL

System DiagramINFOID:0000000003856482

System DescriptionINFOID:0000000003856483

INPUT/OUTPUT SIGNAL CHART

*1: The E NISSAN TEANA 2008 Owners Manual EC-60

< FUNCTION DIAGNOSIS >[VQ25DE, VQ35DE]

COOLING FAN CONTROL

COOLING FAN CONTROL

System DiagramINFOID:0000000003856482

System DescriptionINFOID:0000000003856483

INPUT/OUTPUT SIGNAL CHART

*1: The E](/img/5/57391/w960_57391-1520.png)

EC-60

< FUNCTION DIAGNOSIS >[VQ25DE, VQ35DE]

COOLING FAN CONTROL

COOLING FAN CONTROL

System DiagramINFOID:0000000003856482

System DescriptionINFOID:0000000003856483

INPUT/OUTPUT SIGNAL CHART

*1: The ECM determines the start signal status by the signals of engine speed and battery voltage.

*2: This signal is sent to ECM through CAN communication line.

SYSTEM DESCRIPTION

The ECM controls the cooling fan corresponding to the vehicle speed, engine coolant temperature, refrigerant

pressure, and air conditioner ON signal. The control system has 4-step control [HIGH/MIDDLE/LOW/OFF].

JMBIA1324GB

Sensor Input signal to ECM ECM function Actuator

Crankshaft position sensor (POS)

Camshaft position sensor (PHASE)Engine speed*

1

Cooling fan

controlIPDM E/R

↓

Cooling fan relay

↓

Cooling fan motor Battery

Battery voltage*

1

ABS actuator and electric unit (control unit)

Vehicle speed*2

Engine coolant temperature sensor Engine coolant temperature

BCM

Air conditioner ON signal*

2

Refrigerant pressure sensor Refrigerant pressure

Page 1529 of 5121

![NISSAN TEANA 2008 Owners Manual EC-68

< FUNCTION DIAGNOSIS >[VQ25DE, VQ35DE]

ELECTRONIC CONTROLLED ENGINE MOUNT

ELECTRONIC CONTROLLED ENGINE MOUNT

System DiagramINFOID:0000000003856486

1. Power valve actuator 1 2. VIAS control solen NISSAN TEANA 2008 Owners Manual EC-68

< FUNCTION DIAGNOSIS >[VQ25DE, VQ35DE]

ELECTRONIC CONTROLLED ENGINE MOUNT

ELECTRONIC CONTROLLED ENGINE MOUNT

System DiagramINFOID:0000000003856486

1. Power valve actuator 1 2. VIAS control solen](/img/5/57391/w960_57391-1528.png)

EC-68

< FUNCTION DIAGNOSIS >[VQ25DE, VQ35DE]

ELECTRONIC CONTROLLED ENGINE MOUNT

ELECTRONIC CONTROLLED ENGINE MOUNT

System DiagramINFOID:0000000003856486

1. Power valve actuator 1 2. VIAS control solenoid valve 1 3. VIAS control solenoid valve 2

4. Power valve actuator 2 5. Intake manifold collector

: From next figure

JMBIA0182ZZ