air condition NISSAN TEANA 2008 Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2008, Model line: TEANA, Model: NISSAN TEANA 2008Pages: 5121, PDF Size: 69.03 MB

Page 1 of 5121

MODEL J32 SERIES

© 2008 NISSAN INTERNATIONAL SA

Allrightsreserved.NopartofthisElectronicServiceManualmaybereproducedorstoredinaretrievalsystem,ortransmittedinanyform,or by any means, electronic, mechanical, photocopying, recording or otherwise, without the prior written permission of Nissan InternationalSA, Switzerland.

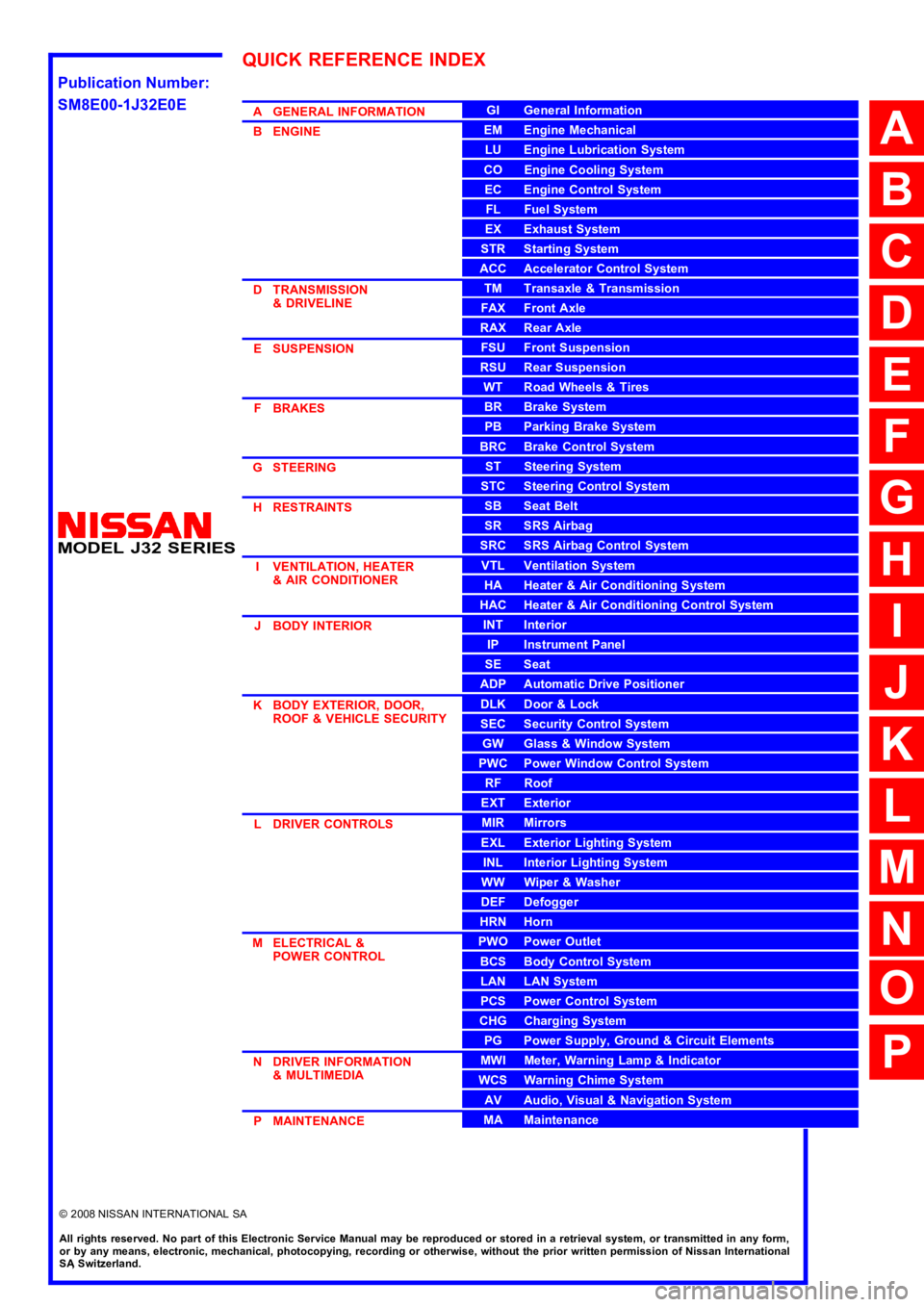

AGENERALINFORMATION

BENGINE

DTRANSMISSION&DRIVELINE

ESUSPENSION

FBRAKES

GSTEERING

HRESTRAINTS

IVENTILATION,HEATER&AIRCONDITIONER

JBODYINTERIOR

KBODYEXTERIOR,DOOR,ROOF&VEHICLESECURITY

LDRIVERCONTROLS

MELECTRICAL&POWERCONTROL

NDRIVERINFORMATION&MULTIMEDIA

PMAINTENANCE

GIGeneralInformation

EMEngineMechanical

LUEngineLubricationSystem

COEngineCoolingSystem

ECEngineControlSystem

FLFuelSystem

EXExhaustSystem

STRStartingSystem

ACCAcceleratorControlSystem

TMTransaxle &Transmission

FAXFrontAxle

RAXRearAxle

FSUFrontSuspension

RSURearSuspension

WTRoadWheels &Tires

BRBrakeSystem

PBParkingBrakeSystem

BRCBrakeControlSystem

STSteeringSystem

STCSteeringControlSystem

SBSeatBelt

SRSRSAirbag

SRCSRSAirbagControlSystem

VTLVentilationSystem

HAHeater &AirConditioningSystem

HACHeater &AirConditioningControlSystem

INTInterior

IPInstrumentPanel

SESeat

ADPAutomaticDrivePositioner

DLKDoor &Lock

SECSecurityControlSystem

GWGlass &WindowSystem

PWCPowerWindowControlSystem

RFRoof

EXTExterior

MIRMirrors

EXLExteriorLightingSystem

INLInteriorLightingSystem

WWWiper &Washer

DEFDefogger

HRNHorn

PWOPowerOutlet

BCSBodyControlSystem

LANLANSystem

PCSPowerControlSystem

CHGChargingSystem

PGPowerSupply,Ground&CircuitElements

MWIMeter,WarningLamp&Indicator

WCSWarningChimeSystem

AVAudio,Visual&NavigationSystem

MAMaintenance

QUICKREFERENCEINDEX

A

B

C

D

E

F

G

H

I

J

K

L

M

N

O

P

M

Publication Number:

SM8E00-1J32E0E

Page 9 of 5121

ADP-3

C

D

E

F

G

H

I

K

L

MA

B

ADP

N

O

P Diagnosis Procedure ..............................................

74

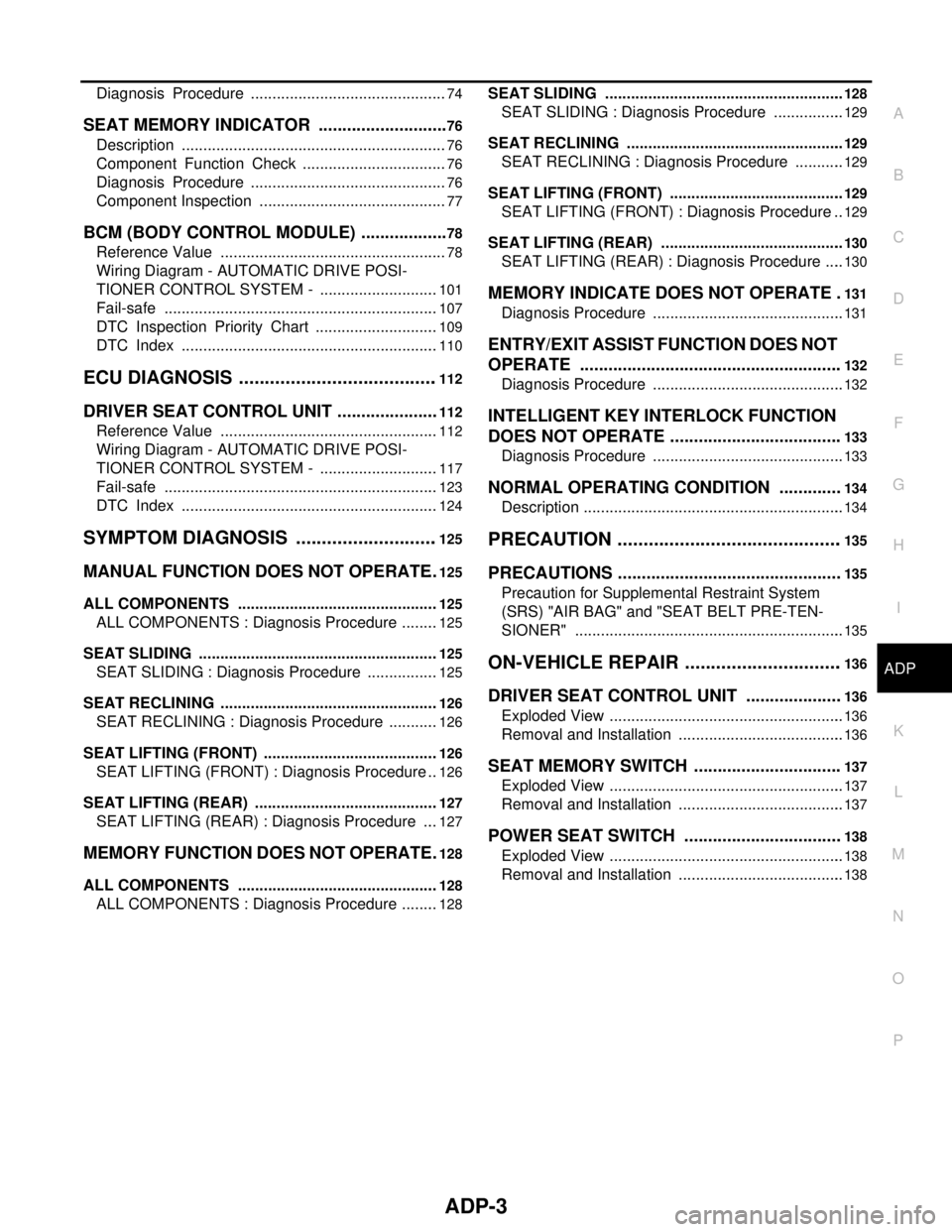

SEAT MEMORY INDICATOR ............................76

Description ..............................................................76

Component Function Check ..................................76

Diagnosis Procedure ..............................................76

Component Inspection ............................................77

BCM (BODY CONTROL MODULE) ...................78

Reference Value .....................................................78

Wiring Diagram - AUTOMATIC DRIVE POSI-

TIONER CONTROL SYSTEM - ............................

101

Fail-safe ................................................................107

DTC Inspection Priority Chart .............................109

DTC Index ............................................................110

ECU DIAGNOSIS .......................................112

DRIVER SEAT CONTROL UNIT ......................112

Reference Value ...................................................112

Wiring Diagram - AUTOMATIC DRIVE POSI-

TIONER CONTROL SYSTEM - ............................

117

Fail-safe ................................................................123

DTC Index ............................................................124

SYMPTOM DIAGNOSIS ............................125

MANUAL FUNCTION DOES NOT OPERATE ..125

ALL COMPONENTS ...............................................125

ALL COMPONENTS : Diagnosis Procedure .........125

SEAT SLIDING ........................................................125

SEAT SLIDING : Diagnosis Procedure .................125

SEAT RECLINING ...................................................126

SEAT RECLINING : Diagnosis Procedure ............126

SEAT LIFTING (FRONT) .........................................126

SEAT LIFTING (FRONT) : Diagnosis Procedure ..126

SEAT LIFTING (REAR) ...........................................127

SEAT LIFTING (REAR) : Diagnosis Procedure ....127

MEMORY FUNCTION DOES NOT OPERATE ..128

ALL COMPONENTS ...............................................128

ALL COMPONENTS : Diagnosis Procedure .........128

SEAT SLIDING ........................................................128

SEAT SLIDING : Diagnosis Procedure .................129

SEAT RECLINING ...................................................129

SEAT RECLINING : Diagnosis Procedure ............129

SEAT LIFTING (FRONT) .........................................129

SEAT LIFTING (FRONT) : Diagnosis Procedure ..129

SEAT LIFTING (REAR) ...........................................130

SEAT LIFTING (REAR) : Diagnosis Procedure .....130

MEMORY INDICATE DOES NOT OPERATE .131

Diagnosis Procedure .............................................131

ENTRY/EXIT ASSIST FUNCTION DOES NOT

OPERATE .......................................................

132

Diagnosis Procedure .............................................132

INTELLIGENT KEY INTERLOCK FUNCTION

DOES NOT OPERATE ....................................

133

Diagnosis Procedure .............................................133

NORMAL OPERATING CONDITION .............134

Description .............................................................134

PRECAUTION ............................................135

PRECAUTIONS ...............................................135

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ...............................................................

135

ON-VEHICLE REPAIR ...............................136

DRIVER SEAT CONTROL UNIT ....................136

Exploded View .......................................................136

Removal and Installation .......................................136

SEAT MEMORY SWITCH ...............................137

Exploded View .......................................................137

Removal and Installation .......................................137

POWER SEAT SWITCH .................................138

Exploded View .......................................................138

Removal and Installation .......................................138

Page 11 of 5121

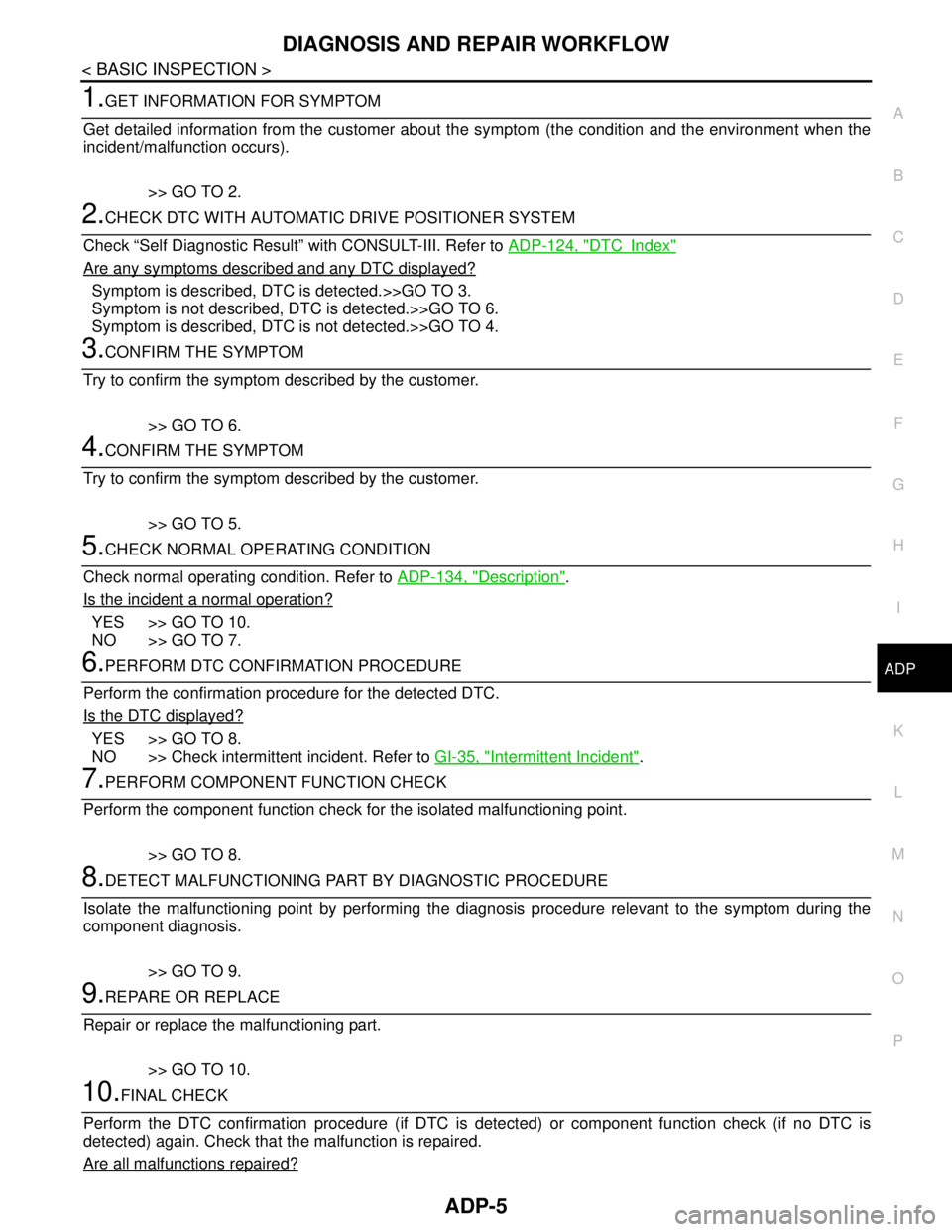

DIAGNOSIS AND REPAIR WORKFLOW

ADP-5

< BASIC INSPECTION >

C

D

E

F

G

H

I

K

L

MA

B

ADP

N

O

P

1.GET INFORMATION FOR SYMPTOM

Get detailed information from the customer about the symptom (the condition and the environment when the

incident/malfunction occurs).

>> GO TO 2.

2.CHECK DTC WITH AUTOMATIC DRIVE POSITIONER SYSTEM

Check “Self Diagnostic Result” with CONSULT-III. Refer to ADP-124, "

DTCIndex"

Are any symptoms described and any DTC displayed?

Symptom is described, DTC is detected.>>GO TO 3.

Symptom is not described, DTC is detected.>>GO TO 6.

Symptom is described, DTC is not detected.>>GO TO 4.

3.CONFIRM THE SYMPTOM

Try to confirm the symptom described by the customer.

>> GO TO 6.

4.CONFIRM THE SYMPTOM

Try to confirm the symptom described by the customer.

>> GO TO 5.

5.CHECK NORMAL OPERATING CONDITION

Check normal operating condition. Refer to ADP-134, "

Description".

Is the incident a normal operation?

YES >> GO TO 10.

NO >> GO TO 7.

6.PERFORM DTC CONFIRMATION PROCEDURE

Perform the confirmation procedure for the detected DTC.

Is the DTC displayed?

YES >> GO TO 8.

NO >> Check intermittent incident. Refer to GI-35, "

Intermittent Incident".

7.PERFORM COMPONENT FUNCTION CHECK

Perform the component function check for the isolated malfunctioning point.

>> GO TO 8.

8.DETECT MALFUNCTIONING PART BY DIAGNOSTIC PROCEDURE

Isolate the malfunctioning point by performing the diagnosis procedure relevant to the symptom during the

component diagnosis.

>> GO TO 9.

9.REPARE OR REPLACE

Repair or replace the malfunctioning part.

>> GO TO 10.

10.FINAL CHECK

Perform the DTC confirmation procedure (if DTC is detected) or component function check (if no DTC is

detected) again. Check that the malfunction is repaired.

Are all malfunctions repaired?

Page 13 of 5121

INSPECTION AND ADJUSTMENT

ADP-7

< BASIC INSPECTION >

C

D

E

F

G

H

I

K

L

MA

B

ADP

N

O

P

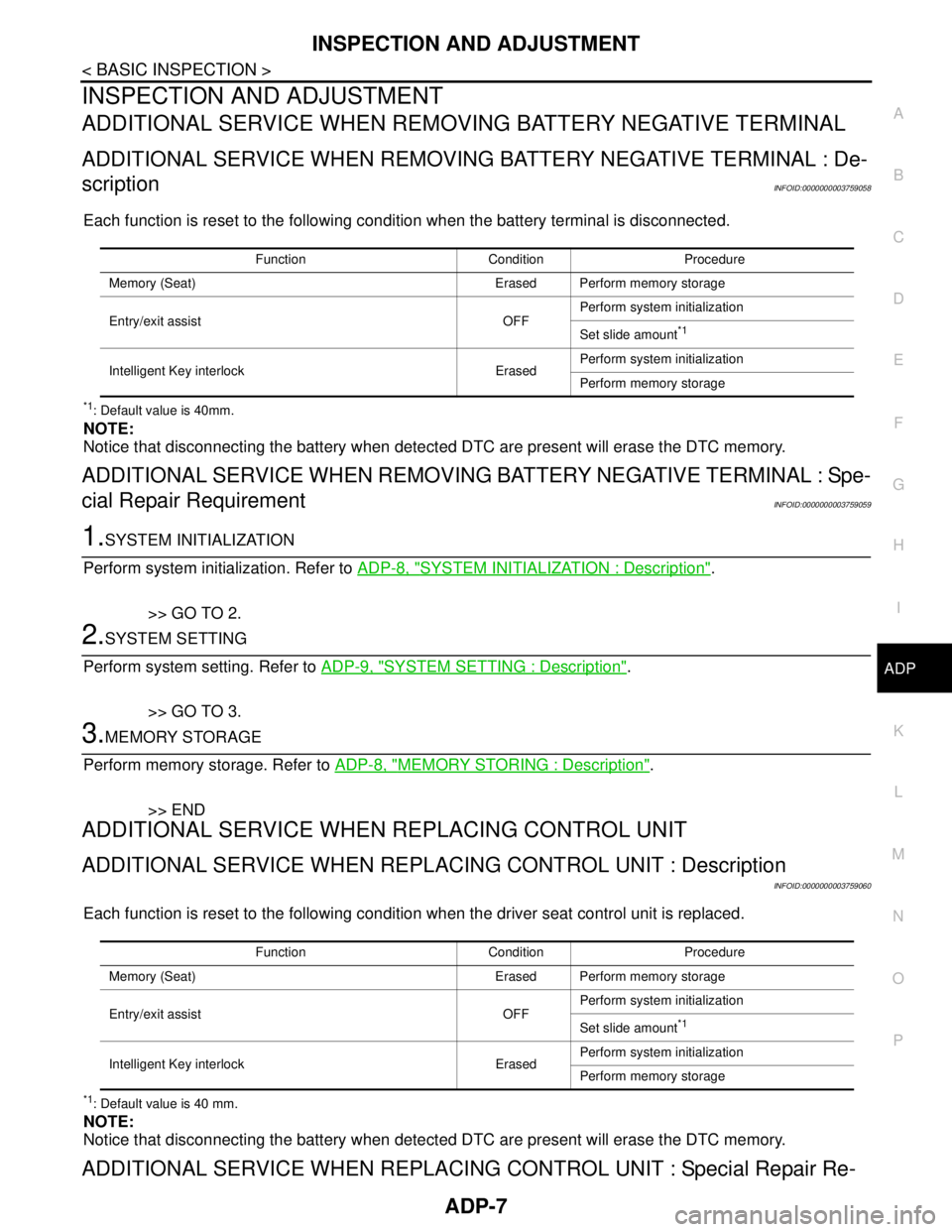

INSPECTION AND ADJUSTMENT

ADDITIONAL SERVICE WHEN REMOVING BATTERY NEGATIVE TERMINAL

ADDITIONAL SERVICE WHEN REMOVING BATTERY NEGATIVE TERMINAL : De-

scription

INFOID:0000000003759058

Each function is reset to the following condition when the battery terminal is disconnected.

*1: Default value is 40mm.

NOTE:

Notice that disconnecting the battery when detected DTC are present will erase the DTC memory.

ADDITIONAL SERVICE WHEN REMOVING BATTERY NEGATIVE TERMINAL : Spe-

cial Repair Requirement

INFOID:0000000003759059

1.SYSTEM INITIALIZATION

Perform system initialization. Refer to ADP-8, "

SYSTEM INITIALIZATION : Description".

>> GO TO 2.

2.SYSTEM SETTING

Perform system setting. Refer to ADP-9, "

SYSTEM SETTING : Description".

>> GO TO 3.

3.MEMORY STORAGE

Perform memory storage. Refer to ADP-8, "

MEMORY STORING : Description".

>> END

ADDITIONAL SERVICE WHEN REPLACING CONTROL UNIT

ADDITIONAL SERVICE WHEN REPLACING CONTROL UNIT : Description

INFOID:0000000003759060

Each function is reset to the following condition when the driver seat control unit is replaced.

*1: Default value is 40 mm.

NOTE:

Notice that disconnecting the battery when detected DTC are present will erase the DTC memory.

ADDITIONAL SERVICE WHEN REPLACING CONTROL UNIT : Special Repair Re-

Function Condition Procedure

Memory (Seat) Erased Perform memory storage

Entry/exit assist OFFPerform system initialization

Set slide amount

*1

Intelligent Key interlock ErasedPerform system initialization

Perform memory storage

Function Condition Procedure

Memory (Seat) Erased Perform memory storage

Entry/exit assist OFFPerform system initialization

Set slide amount

*1

Intelligent Key interlock ErasedPerform system initialization

Perform memory storage

Page 44 of 5121

ADP-38

< COMPONENT DIAGNOSIS >

U1000 CAN COMM CIRCUIT

COMPONENT DIAGNOSIS

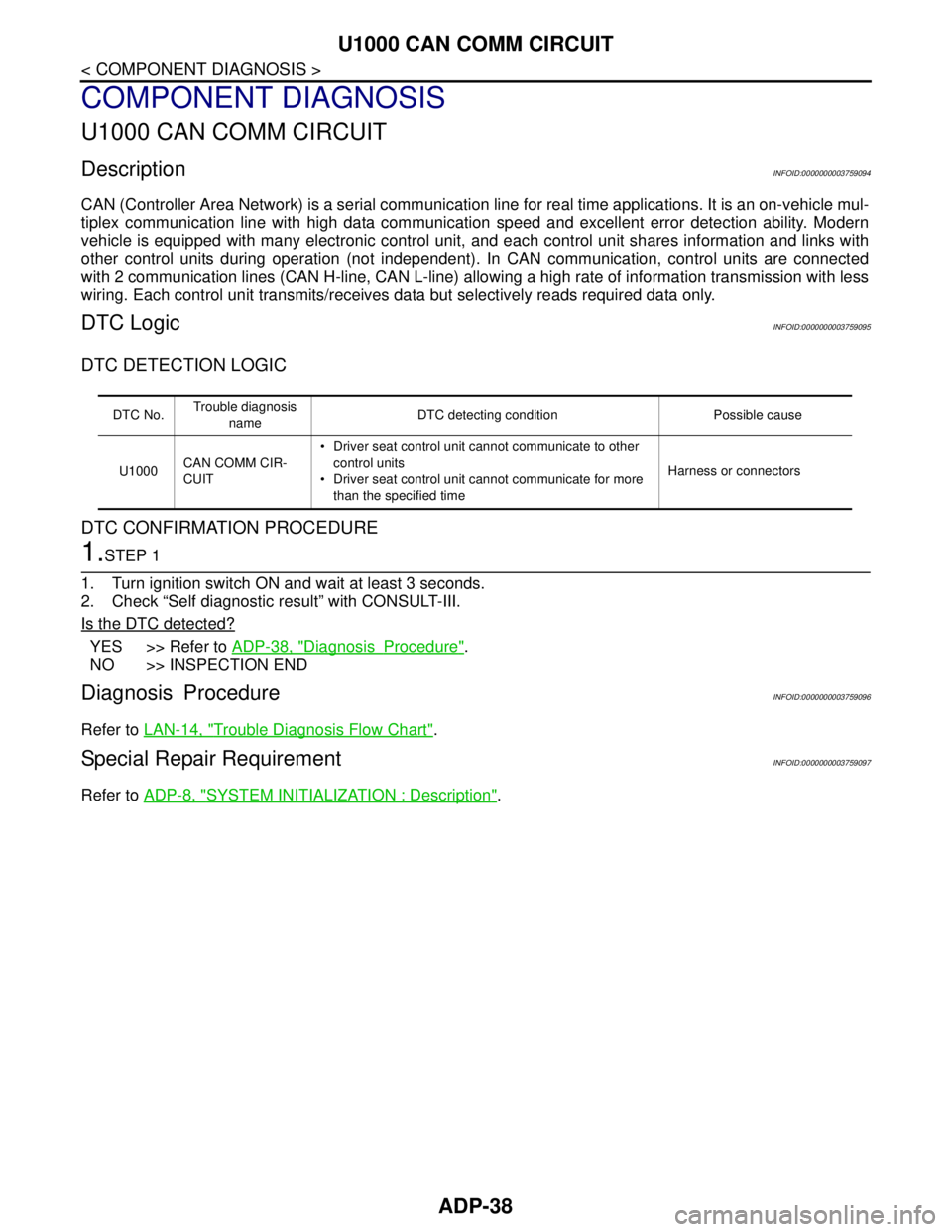

U1000 CAN COMM CIRCUIT

DescriptionINFOID:0000000003759094

CAN (Controller Area Network) is a serial communication line for real time applications. It is an on-vehicle mul-

tiplex communication line with high data communication speed and excellent error detection ability. Modern

vehicle is equipped with many electronic control unit, and each control unit shares information and links with

other control units during operation (not independent). In CAN communication, control units are connected

with 2 communication lines (CAN H-line, CAN L-line) allowing a high rate of information transmission with less

wiring. Each control unit transmits/receives data but selectively reads required data only.

DTC LogicINFOID:0000000003759095

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.STEP 1

1. Turn ignition switch ON and wait at least 3 seconds.

2. Check “Self diagnostic result” with CONSULT-III.

Is the DTC detected?

YES >> Refer to ADP-38, "DiagnosisProcedure".

NO >> INSPECTION END

Diagnosis ProcedureINFOID:0000000003759096

Refer to LAN-14, "Trouble Diagnosis Flow Chart".

Special Repair RequirementINFOID:0000000003759097

Refer to ADP-8, "SYSTEM INITIALIZATION : Description".

DTC No.Trouble diagnosis

nameDTC detecting condition Possible cause

U1000CAN COMM CIR-

CUIT Driver seat control unit cannot communicate to other

control units

Driver seat control unit cannot communicate for more

than the specified timeHarness or connectors

Page 47 of 5121

B2112 SLIDING MOTOR

ADP-41

< COMPONENT DIAGNOSIS >

C

D

E

F

G

H

I

K

L

MA

B

ADP

N

O

P

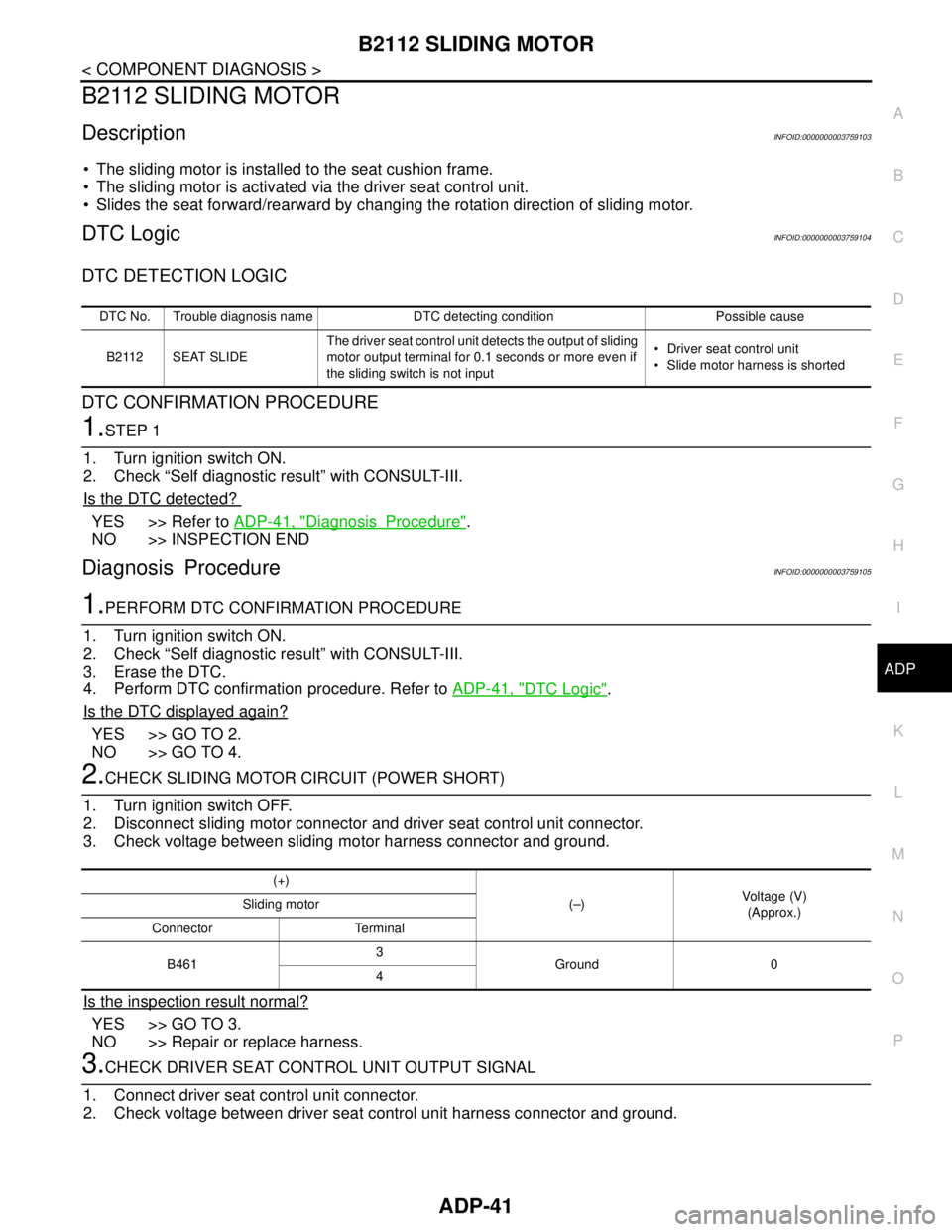

B2112 SLIDING MOTOR

DescriptionINFOID:0000000003759103

The sliding motor is installed to the seat cushion frame.

The sliding motor is activated via the driver seat control unit.

Slides the seat forward/rearward by changing the rotation direction of sliding motor.

DTC LogicINFOID:0000000003759104

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.STEP 1

1. Turn ignition switch ON.

2. Check “Self diagnostic result” with CONSULT-III.

Is the DTC detected?

YES >> Refer to ADP-41, "DiagnosisProcedure".

NO >> INSPECTION END

Diagnosis ProcedureINFOID:0000000003759105

1.PERFORM DTC CONFIRMATION PROCEDURE

1. Turn ignition switch ON.

2. Check “Self diagnostic result” with CONSULT-III.

3. Erase the DTC.

4. Perform DTC confirmation procedure. Refer to ADP-41, "

DTC Logic".

Is the DTC displayed again?

YES >> GO TO 2.

NO >> GO TO 4.

2.CHECK SLIDING MOTOR CIRCUIT (POWER SHORT)

1. Turn ignition switch OFF.

2. Disconnect sliding motor connector and driver seat control unit connector.

3. Check voltage between sliding motor harness connector and ground.

Is the inspection result normal?

YES >> GO TO 3.

NO >> Repair or replace harness.

3.CHECK DRIVER SEAT CONTROL UNIT OUTPUT SIGNAL

1. Connect driver seat control unit connector.

2. Check voltage between driver seat control unit harness connector and ground.

DTC No. Trouble diagnosis name DTC detecting condition Possible cause

B2112 SEAT SLIDEThe driver seat control unit detects the output of sliding

motor output terminal for 0.1 seconds or more even if

the sliding switch is not input Driver seat control unit

Slide motor harness is shorted

(+)

(–)Voltage (V)

(Approx.) Sliding motor

Connector Terminal

B4613

Ground 0

4

Page 49 of 5121

B2113 RECLINING MOTOR

ADP-43

< COMPONENT DIAGNOSIS >

C

D

E

F

G

H

I

K

L

MA

B

ADP

N

O

P

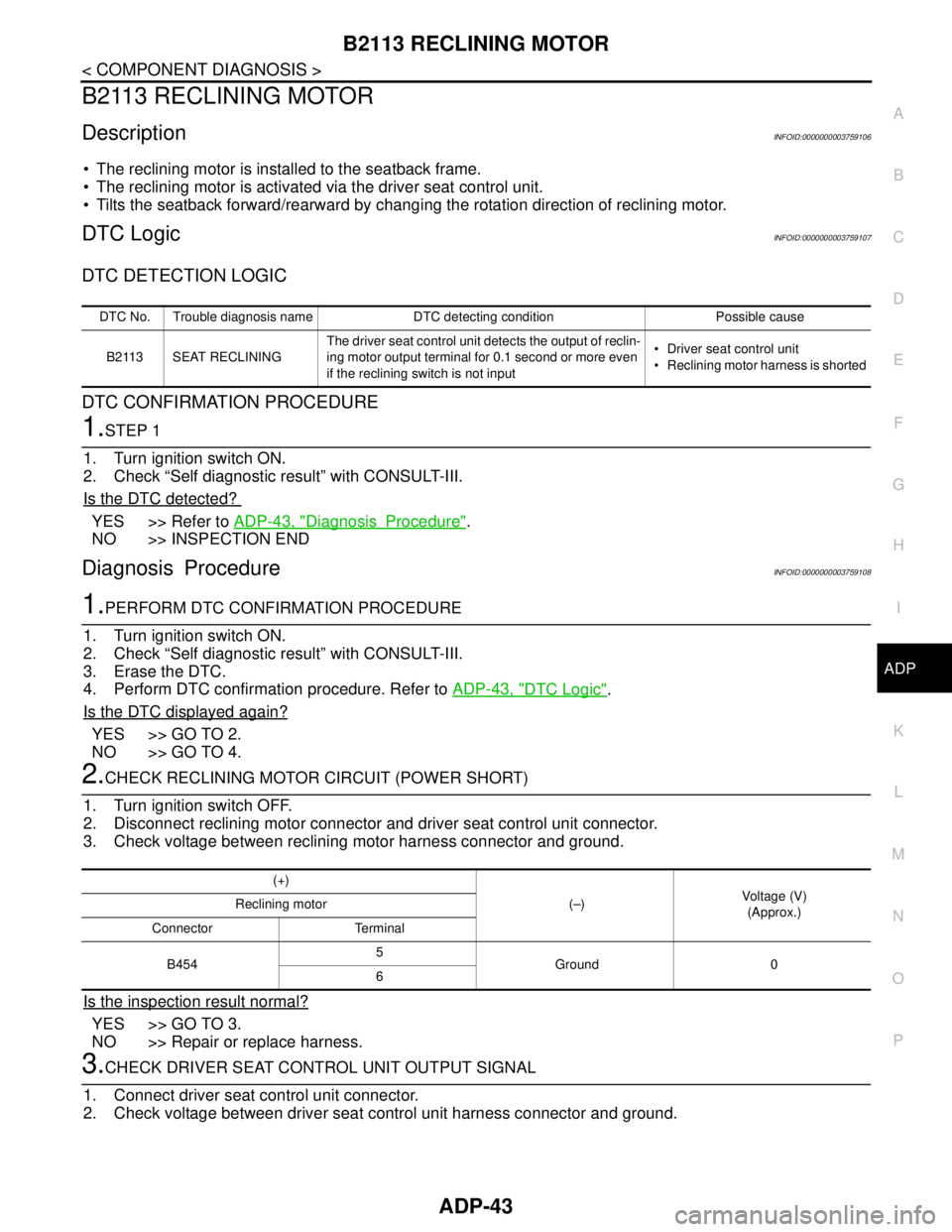

B2113 RECLINING MOTOR

DescriptionINFOID:0000000003759106

The reclining motor is installed to the seatback frame.

The reclining motor is activated via the driver seat control unit.

Tilts the seatback forward/rearward by changing the rotation direction of reclining motor.

DTC LogicINFOID:0000000003759107

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.STEP 1

1. Turn ignition switch ON.

2. Check “Self diagnostic result” with CONSULT-III.

Is the DTC detected?

YES >> Refer to ADP-43, "DiagnosisProcedure".

NO >> INSPECTION END

Diagnosis ProcedureINFOID:0000000003759108

1.PERFORM DTC CONFIRMATION PROCEDURE

1. Turn ignition switch ON.

2. Check “Self diagnostic result” with CONSULT-III.

3. Erase the DTC.

4. Perform DTC confirmation procedure. Refer to ADP-43, "

DTC Logic".

Is the DTC displayed again?

YES >> GO TO 2.

NO >> GO TO 4.

2.CHECK RECLINING MOTOR CIRCUIT (POWER SHORT)

1. Turn ignition switch OFF.

2. Disconnect reclining motor connector and driver seat control unit connector.

3. Check voltage between reclining motor harness connector and ground.

Is the inspection result normal?

YES >> GO TO 3.

NO >> Repair or replace harness.

3.CHECK DRIVER SEAT CONTROL UNIT OUTPUT SIGNAL

1. Connect driver seat control unit connector.

2. Check voltage between driver seat control unit harness connector and ground.

DTC No. Trouble diagnosis name DTC detecting condition Possible cause

B2113 SEAT RECLININGThe driver seat control unit detects the output of reclin-

ing motor output terminal for 0.1 second or more even

if the reclining switch is not input Driver seat control unit

Reclining motor harness is shorted

(+)

(–)Voltage (V)

(Approx.) Reclining motor

Connector Terminal

B4545

Ground 0

6

Page 53 of 5121

SLIDING SWITCH

ADP-47

< COMPONENT DIAGNOSIS >

C

D

E

F

G

H

I

K

L

MA

B

ADP

N

O

P

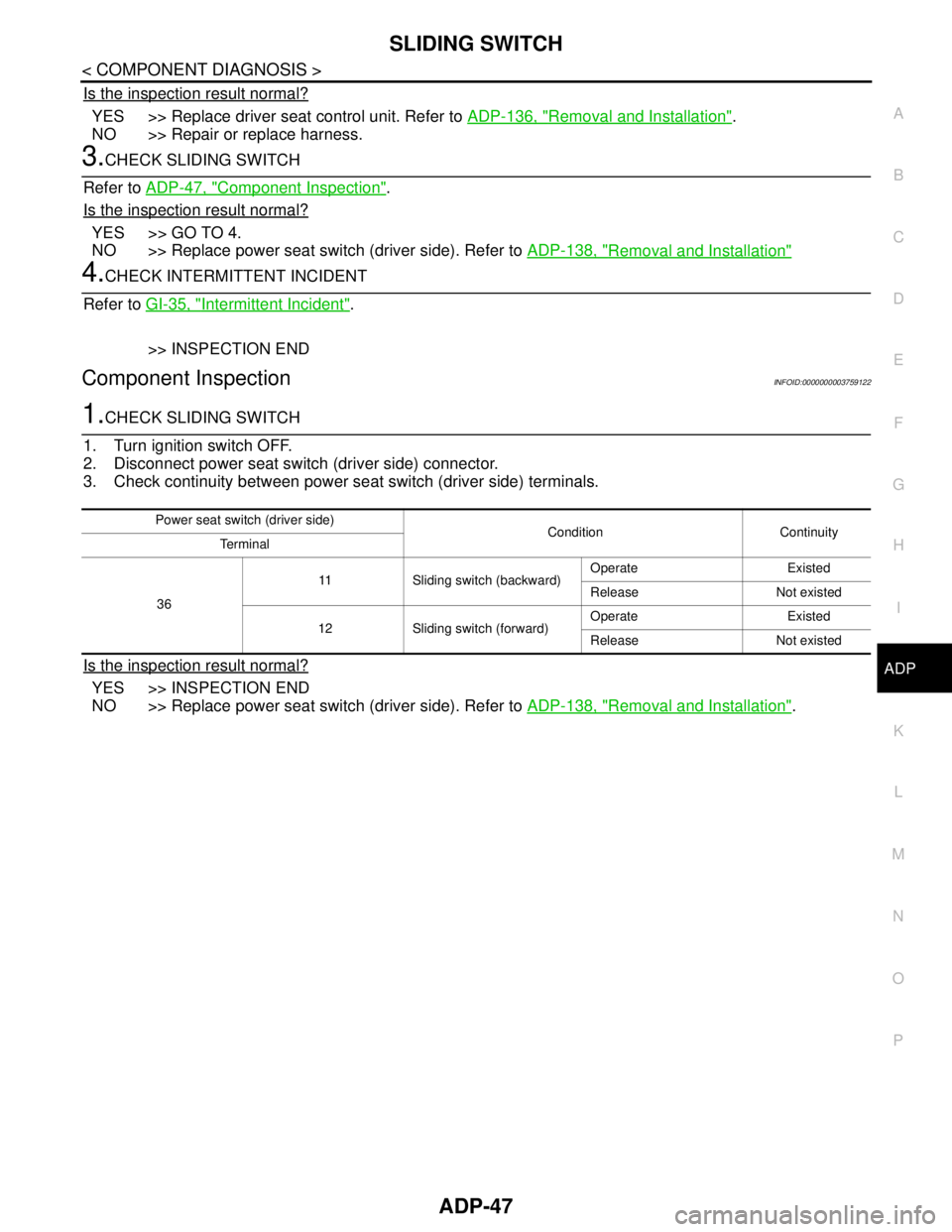

Is the inspection result normal?

YES >> Replace driver seat control unit. Refer to ADP-136, "Removal and Installation".

NO >> Repair or replace harness.

3.CHECK SLIDING SWITCH

Refer to ADP-47, "

Component Inspection".

Is the inspection result normal?

YES >> GO TO 4.

NO >> Replace power seat switch (driver side). Refer to ADP-138, "

Removal and Installation"

4.CHECK INTERMITTENT INCIDENT

Refer to GI-35, "

Intermittent Incident".

>> INSPECTION END

Component InspectionINFOID:0000000003759122

1.CHECK SLIDING SWITCH

1. Turn ignition switch OFF.

2. Disconnect power seat switch (driver side) connector.

3. Check continuity between power seat switch (driver side) terminals.

Is the inspection result normal?

YES >> INSPECTION END

NO >> Replace power seat switch (driver side). Refer to ADP-138, "

Removal and Installation".

Power seat switch (driver side)

Condition Continuity

Te r m i n a l

3611 Sliding switch (backward)Operate Existed

Release Not existed

12 Sliding switch (forward)Operate Existed

Release Not existed

Page 55 of 5121

RECLINING SWITCH

ADP-49

< COMPONENT DIAGNOSIS >

C

D

E

F

G

H

I

K

L

MA

B

ADP

N

O

P

Is the inspection result normal?

YES >> Replace driver seat control unit. Refer to ADP-136, "Removal and Installation".

NO >> Repair or replace harness.

3.CHECK RECLINING SWITCH

Refer to ADP-49, "

Component Inspection".

Is the inspection result normal?

YES >> GO TO 4.

NO >> Replace power seat switch (driver side). Refer to ADP-138, "

Removal and Installation".

4.CHECK INTERMITTENT INCIDENT

Refer to GI-35, "

Intermittent Incident".

>> INSPECTION END

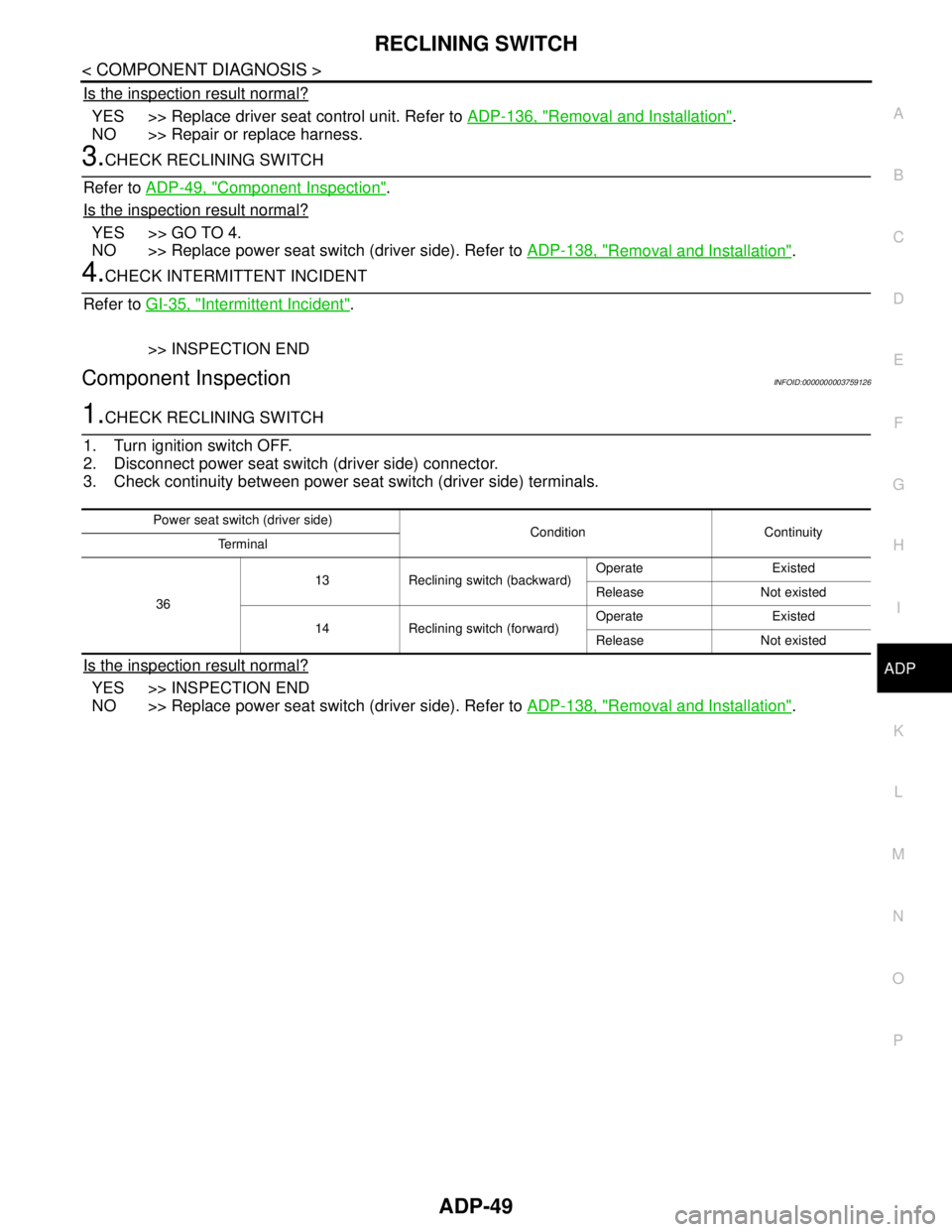

Component InspectionINFOID:0000000003759126

1.CHECK RECLINING SWITCH

1. Turn ignition switch OFF.

2. Disconnect power seat switch (driver side) connector.

3. Check continuity between power seat switch (driver side) terminals.

Is the inspection result normal?

YES >> INSPECTION END

NO >> Replace power seat switch (driver side). Refer to ADP-138, "

Removal and Installation".

Power seat switch (driver side)

Condition Continuity

Te r m i n a l

3613 Reclining switch (backward)Operate Existed

Release Not existed

14 Reclining switch (forward)Operate Existed

Release Not existed

Page 57 of 5121

LIFTING SWITCH (FRONT)

ADP-51

< COMPONENT DIAGNOSIS >

C

D

E

F

G

H

I

K

L

MA

B

ADP

N

O

P

Is the inspection result normal?

YES >> Replace driver seat control unit. Refer to ADP-136, "Removal and Installation".

NO >> Repair or replace harness.

3.CHECK LIFTING SWITCH (FRONT)

Refer to ADP-51, "

Component Inspection".

Is the inspection result normal?

YES >> GO TO 4.

NO >> Replace power seat switch (driver side). Refer to ADP-138, "

Removal and Installation".

4.CHECK INTERMITTENT INCIDENT

Refer to GI-35, "

Intermittent Incident".

>> INSPECTION END

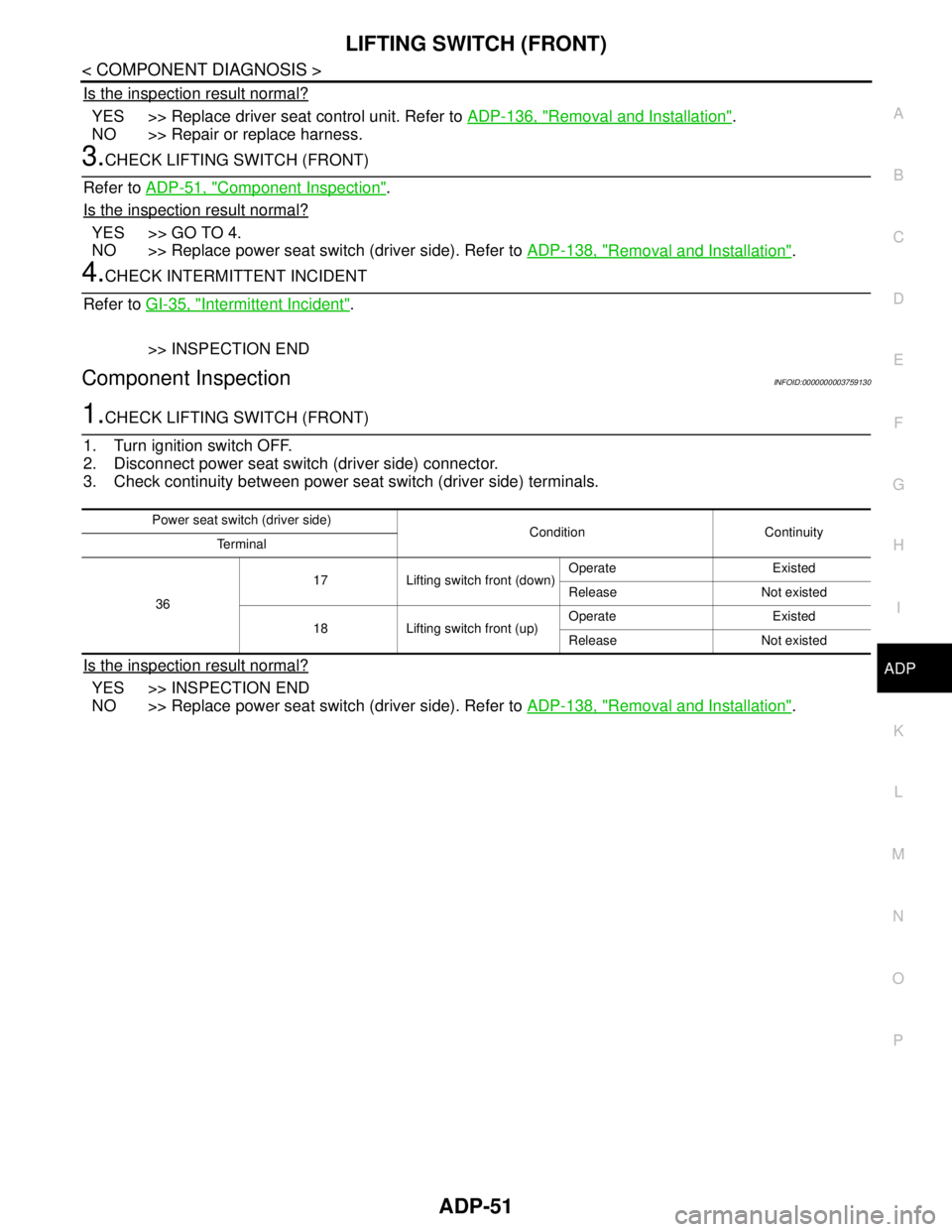

Component InspectionINFOID:0000000003759130

1.CHECK LIFTING SWITCH (FRONT)

1. Turn ignition switch OFF.

2. Disconnect power seat switch (driver side) connector.

3. Check continuity between power seat switch (driver side) terminals.

Is the inspection result normal?

YES >> INSPECTION END

NO >> Replace power seat switch (driver side). Refer to ADP-138, "

Removal and Installation".

Power seat switch (driver side)

Condition Continuity

Te r m i n a l

3617 Lifting switch front (down)Operate Existed

Release Not existed

18 Lifting switch front (up)Operate Existed

Release Not existed