service interval NISSAN TEANA 2008 Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2008, Model line: TEANA, Model: NISSAN TEANA 2008Pages: 5121, PDF Size: 69.03 MB

Page 3194 of 5121

MA-6

< ON-VEHICLE MAINTENANCE >

PERIODIC MAINTENANCE

PERIODIC MAINTENANCE

Periodic MaintenanceINFOID:0000000003858222

The following tables show the normal maintenance schedule. Depending upon weather and atmospheric con-

ditions, varying road surfaces, individual driving habits and vehicle usage, additional or more frequent mainte-

nance may be required.

Periodic maintenance beyond the last period shown on the tables requires similar maintenance.

ENGINE AND EMISSION CONTROL MAINTENANCE

(Annual Mileage < 30,000 km/year)

Abbreviations: I = Inspect and correct or replace as necessary, R = Replace,[ ] = At the specified mileage only.

NOTE:

Maintenance items with “ ” should be performed more frequently according to “Maintenance Under Severe Driving Condi-

tions”.

(1) Periodic maintenance is not required. However, if valve noise increases, check valve clearance.

(2) Replace the drive belt if found damaged or if the auto belt tensioner reading reaches the maximum limit.

(3) Use Genuine NISSAN Engine Coolant or equivalent in its quality, in order to avoid possible aluminum corrosion within

the engine cooling system caused by the use of non-genuine engine coolant.

First replace at 90,000 Km (54,000 miles)/60 months, then every 60,000 km (36,000 miles)/48 months. Perform "I" (Checking

the mixture ratio and correcting the mixture ratio if necessary) at the middle of replacement interval.

(4) Fuel filter is maintenance-free. For service procedures, refer to FL section. MAINTENANCE OPERATIONMAINTENANCE INTERVAL

Refer-

ence

page Perform at a kilometer (mile) interval or

month interval, whichever comes first.km x

1,000

(Miles x

1,000)

Months15

(9)

1230

(18)

2445

(27)

3660

(36)

4875

(45)

6090

(54)

72105

(63)

84120

(72)

96

Engine compartment and under vehicle

Intake and exhaust valve clearanceSee

NOTE

(1)EM-17

Drive beltSee

NOTE

(2)I I IIIIIIMA-13

Engine oil (Use recommended oil.)R R RRRRRRMA-18

Engine oil filter (Use genuine NISSAN

engine oil filter or equivalent)R R RRRRRRMA-19

Engine coolant (Use Genuine NISSAN

Engine Coolant or equivalent in its quali-

ty.)See

NOTE

(3)IMA-14

Cooling system I I IIIIIIMA-13

,

MA-17

,

MA-17

Fuel and EVAP vapor lines I I I IMA-18,

MA-22

Air cleaner filterRRMA-18

Positive crankcase ventilation (PSV)

systemIIIIMA-21

Fuel filter (In-tank type)See

NOTE

(4)—

Spark plugs (Iridium-tipped type)See

NOTE

(5)[R] [R] [R] [R] [R] [R] [R] [R]MA-20

Page 3197 of 5121

PERIODIC MAINTENANCE

MA-9

< ON-VEHICLE MAINTENANCE >

C

D

E

F

G

H

I

J

K

L

MB

MAN

OA

NOTE:

Maintenance items with “ ” should be performed more frequently according to “Maintenance Under Severe Driving Condi-

tions”.

(1) Periodic maintenance is not required. However, if valve noise increases, check valve clearance.

(2) Replace the drive belt if found damaged or if the auto belt tensioner reading reaches the maximum limit.

(3) Use Genuine NISSAN Engine Coolant or equivalent in its quality, in order to avoid possible aluminum corrosion within

the engine cooling system caused by the use of non-genuine coolant.

First replace at 90,000 km (54,000 miles), then every 60,000 km (36,000 miles). Perform "I" (Checking the mixture ratio and

correcting the mixture ratio if necessary) at the middle of replacement interval.

(4) Fuel filter is maintenance-free. For service procedures, refer to FL section.

(5) Replace spark plug when the spark plug gap exceeds 1.4 mm (0.055 in) even if within specified periodic replacement

mileage.

CHASSIS AND BODY MAINTENANCE

(Annual Mileage > 30,000 km/year)

Abbreviations: I = Inspect and correct or replace as necessary, R = Replace, L = Lubricate.

Fuel and EVAP vapor lines I IMA-18,

MA-22

Air cleaner filterRRMA-18

Fuel filter (In-tank type)See

NOTE (4)—

Positive crankcase ventilation (PCV) system I I I IMA-21

Spark-plugs (Iridium-tipped type)See

NOTE (5)R R RRRRRRMA-20

MAINTENANCE OPERATIONMAINTENANCE INTERVAL

Refer-

ence

page Perform at number of kilometers (miles) basis

only.km x

1,000

(Miles x

1,000)15

(9)30

(18)45

(27)60

(36)75

(45)90

(54)105

(63)120

(72)

MAINTENANCE OPERATIONMAINTENANCE INTERVAL

Reference

page Perform at number of kilometers (miles)

basis only.km x 1,000

(Miles x

1,000)15

(9)30

(18)45

(27)60

(36)75

(45)90

(54)105

(63)120

(72)

Underhood and under vehicle

Headlamp aiming I I I IMA-23

,

MA-27

Brake system and fluid (For level &

leaks)IIIIMA-38,

MA-37

Brake fluidRRMA-38

Brake booster vacuum hoses, connec-

tions & check valveIIBR-12

Power steering fluid & lines (For level &

leaks)IIIIMA-40

CVT fluid (For level & leaks)See

NOTE (1)IIIIMA-32,

MA-34

Steering gear & linkage, axle & suspen-

sion parts, & front drive shafts IIMA-39,

MA-40

,

MA-41

Exhaust systemIIMA-32

Brake pads, rotors & other brake com-

ponentsIIIIMA-38,

BR-13

,

BR-15

Foot brake & parking brake (For free

play, stroke & operation)IIIIBR-6,

PB-2

Page 3225 of 5121

CHASSIS MAINTENANCE

MA-37

< ON-VEHICLE MAINTENANCE >

C

D

E

F

G

H

I

J

K

L

MB

MAN

OA

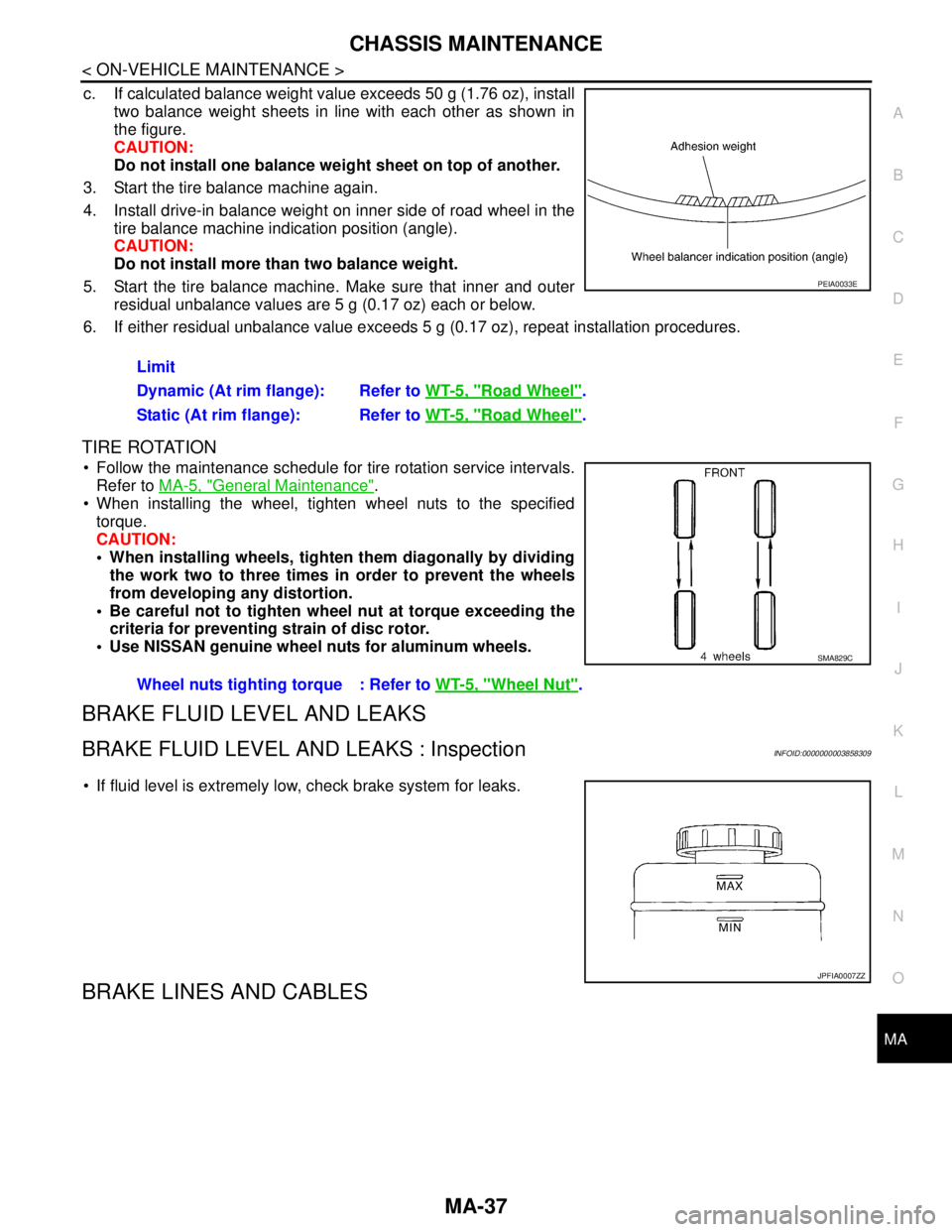

c. If calculated balance weight value exceeds 50 g (1.76 oz), install

two balance weight sheets in line with each other as shown in

the figure.

CAUTION:

Do not install one balance weight sheet on top of another.

3. Start the tire balance machine again.

4. Install drive-in balance weight on inner side of road wheel in the

tire balance machine indication position (angle).

CAUTION:

Do not install more than two balance weight.

5. Start the tire balance machine. Make sure that inner and outer

residual unbalance values are 5 g (0.17 oz) each or below.

6. If either residual unbalance value exceeds 5 g (0.17 oz), repeat installation procedures.

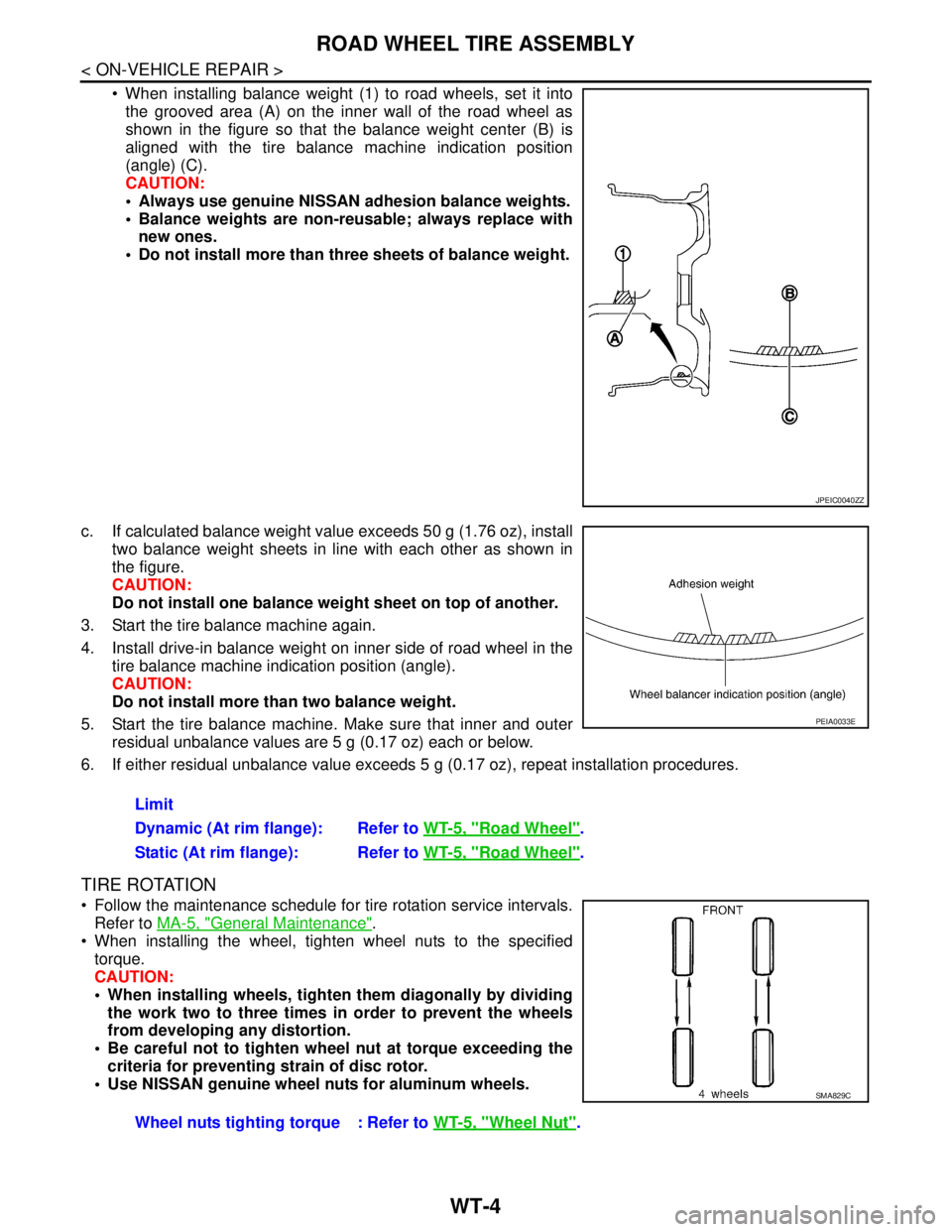

TIRE ROTATION

Follow the maintenance schedule for tire rotation service intervals.

Refer to MA-5, "

General Maintenance".

When installing the wheel, tighten wheel nuts to the specified

torque.

CAUTION:

When installing wheels, tighten them diagonally by dividing

the work two to three times in order to prevent the wheels

from developing any distortion.

Be careful not to tighten wheel nut at torque exceeding the

criteria for preventing strain of disc rotor.

Use NISSAN genuine wheel nuts for aluminum wheels.

BRAKE FLUID LEVEL AND LEAKS

BRAKE FLUID LEVEL AND LEAKS : InspectionINFOID:0000000003858309

If fluid level is extremely low, check brake system for leaks.

BRAKE LINES AND CABLES

Limit

Dynamic (At rim flange): Refer to WT-5, "

Road Wheel".

Static (At rim flange): Refer to WT-5, "

Road Wheel".

PEIA0033E

Wheel nuts tighting torque : Refer to WT-5, "Wheel Nut".

SMA829C

JPFIA0007ZZ

Page 5011 of 5121

WT-4

< ON-VEHICLE REPAIR >

ROAD WHEEL TIRE ASSEMBLY

When installing balance weight (1) to road wheels, set it into

the grooved area (A) on the inner wall of the road wheel as

shown in the figure so that the balance weight center (B) is

aligned with the tire balance machine indication position

(angle) (C).

CAUTION:

Always use genuine NISSAN adhesion balance weights.

Balance weights are non-reusable; always replace with

new ones.

Do not install more than three sheets of balance weight.

c. If calculated balance weight value exceeds 50 g (1.76 oz), install

two balance weight sheets in line with each other as shown in

the figure.

CAUTION:

Do not install one balance weight sheet on top of another.

3. Start the tire balance machine again.

4. Install drive-in balance weight on inner side of road wheel in the

tire balance machine indication position (angle).

CAUTION:

Do not install more than two balance weight.

5. Start the tire balance machine. Make sure that inner and outer

residual unbalance values are 5 g (0.17 oz) each or below.

6. If either residual unbalance value exceeds 5 g (0.17 oz), repeat installation procedures.

TIRE ROTATION

Follow the maintenance schedule for tire rotation service intervals.

Refer to MA-5, "

General Maintenance".

When installing the wheel, tighten wheel nuts to the specified

torque.

CAUTION:

When installing wheels, tighten them diagonally by dividing

the work two to three times in order to prevent the wheels

from developing any distortion.

Be careful not to tighten wheel nut at torque exceeding the

criteria for preventing strain of disc rotor.

Use NISSAN genuine wheel nuts for aluminum wheels.

JPEIC0040ZZ

Limit

Dynamic (At rim flange): Refer to WT-5, "

Road Wheel".

Static (At rim flange): Refer to WT-5, "

Road Wheel".

PEIA0033E

Wheel nuts tighting torque : Refer to WT-5, "Wheel Nut".

SMA829C