dimensions NISSAN TEANA 2014 User Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2014, Model line: TEANA, Model: NISSAN TEANA 2014Pages: 4801, PDF Size: 51.2 MB

Page 2100 of 4801

![NISSAN TEANA 2014 User Guide

EM-102

< UNIT DISASSEMBLY AND ASSEMBLY >[QR25DE]

CYLINDER BLOCK

• Calculate by outer diameter of piston skirt and i

nner diameter of cylinder (direction X, position B).

(Clearance) = (Inner diamete NISSAN TEANA 2014 User Guide

EM-102

< UNIT DISASSEMBLY AND ASSEMBLY >[QR25DE]

CYLINDER BLOCK

• Calculate by outer diameter of piston skirt and i

nner diameter of cylinder (direction X, position B).

(Clearance) = (Inner diamete](/img/5/57390/w960_57390-2099.png)

EM-102

< UNIT DISASSEMBLY AND ASSEMBLY >[QR25DE]

CYLINDER BLOCK

• Calculate by outer diameter of piston skirt and i

nner diameter of cylinder (direction X, position B).

(Clearance) = (Inner diameter of cylinde r) – (Outer diameter of piston skirt).

• If it exceeds the limit, replace piston/piston pin assembly.

Reboring Cylinder Bore

1. Cylinder bore size is determined by adding pi ston-to-bore clearance to piston diameter (A).

2. Install lower cylinder block, and tighten to the specif ied torque. Otherwise, cylinder bores may be distorted

in final assembly.

3. Cut cylinder bores.

• When any cylinder needs boring, all ot her cylinders must also be bored.

• Do not cut too much out of cylinder bore at a time . Cut only 0.05 mm (0.0020 in) or so in diameter at

a time.

4. Hone cylinders to obtain specified piston-to-bore clearance.

5. Measure finished cylinder bore for out-of-round and taper.

• Measurement should be done af ter cylinder bore cools down.

OUTER DIAMETER OF CRANKSHAFT JOURNAL

• Measure outer diameter of crankshaft journals using suitable tool

(A).

OUTER DIAMETER OF CRANKSHAFT PIN

• Measure outer diameter of crankshaft pin using a suitable tool.

OUT-OF-ROUND AND TAPER OF CRANKSHAFT

• Measure the dimensions at four different points as shown on eachjournal and pin using a micrometer.

• Out-of-round is indicated by the difference in dimensions between

(X) and (Y) at (A) and (B).

• Taper is indicated by the difference in dimension between (A) and (B) at (X) and (Y). Standard : 0.010 - 0.030 mm (0.0004 - 0.0012 in)

Limit : 0.08 mm (0.0031 in)

Rebored size calculation: D = A + B - C

(D): Bored diameter

(A): Piston diameter as measured

(B): Piston-to-bore clearance (standard value)

(C): Honing allowance 0.02 mm (0.0008 in)

Standard : 54.955 - 54.979 mm (2.1636 - 2.1645 in)

AWBIA1331GB

Standard : 44.956 - 44.974 mm (1.7699 - 1.7706 in)

Standard

Out-of-round (X - Y) : 0.005 mm (0.0002 in)

Taper (A - B) : 0.005 mm (0.0002 in)

AWBIA1368ZZ

Revision: November 20132014 Altima NAM

Page 2102 of 4801

![NISSAN TEANA 2014 User Guide

EM-104

< UNIT DISASSEMBLY AND ASSEMBLY >[QR25DE]

CYLINDER BLOCK

Method of Using Plastigage

• Remove oil and dust on the crankshaft journal and the surfaces of

each bearing completely.

• Cut the NISSAN TEANA 2014 User Guide

EM-104

< UNIT DISASSEMBLY AND ASSEMBLY >[QR25DE]

CYLINDER BLOCK

Method of Using Plastigage

• Remove oil and dust on the crankshaft journal and the surfaces of

each bearing completely.

• Cut the](/img/5/57390/w960_57390-2101.png)

EM-104

< UNIT DISASSEMBLY AND ASSEMBLY >[QR25DE]

CYLINDER BLOCK

Method of Using Plastigage

• Remove oil and dust on the crankshaft journal and the surfaces of

each bearing completely.

• Cut the Plastigage slightly shorter than the bearing width, and

place it in crankshaft axial direction, avoiding oil holes.

• Tighten the main bearing bolts to the specified torque. CAUTION:

Do not rotate the crankshaft.

• Remove the bearing cap and bearings, and using the scale on the Plastigage bag, measure the Plastigage width.

NOTE:

The procedure when the measured value exceeds the limit is

same as that described in the "Method by Calculation".

CRUSH HEIGHT OF MAIN BEARING

• When the bearing cap is removed after being tightened to the specified torque with main bearings installed, the tip end of bearing

must protrude.

• If the standard is not met, replace main bearings.

OUTER DIAMETER OF LOWER CYLINDER BLOCK BOLT

• Perform only with M10 (0.39 in) bolts.

• Measure outer diameters (d1, d2) at two positions as shown.

• Measure d2 at a point within area (A) as shown.

• When the value of d1- d2 exceeds the limit (a large difference in dimensions), replace the bolt with a new one.

OUTER DIAMETER OF CONNECTING ROD BOLT

• Measure outer diameter (d) at position as shown.

• When (d) exceeds the limit (when it becomes thinner), replace the

bolt with a new one.

EM142

Standard : There must be crush height.

SEM502G

Limit : 0.13 mm (0.0051 in)

PBIC0272E

Limit : 7.75 mm (0.3051 in) or less

PBIC0273E

Revision: November 20132014 Altima NAM

Page 2104 of 4801

![NISSAN TEANA 2014 User Guide

EM-106

< UNIT DISASSEMBLY AND ASSEMBLY >[QR25DE]

HOW TO SELECT PISTON AND BEARING

When a Cylinder Block is Reused:

1. Measure the cylinder block bore inner diameter.

2. Determine the bore grade by c NISSAN TEANA 2014 User Guide

EM-106

< UNIT DISASSEMBLY AND ASSEMBLY >[QR25DE]

HOW TO SELECT PISTON AND BEARING

When a Cylinder Block is Reused:

1. Measure the cylinder block bore inner diameter.

2. Determine the bore grade by c](/img/5/57390/w960_57390-2103.png)

EM-106

< UNIT DISASSEMBLY AND ASSEMBLY >[QR25DE]

HOW TO SELECT PISTON AND BEARING

When a Cylinder Block is Reused:

1. Measure the cylinder block bore inner diameter.

2. Determine the bore grade by comparing the measur ement with the values under the cylinder bore inner

diameter of the "Piston Selection Tabl e". Select the piston of the same grade.

Piston Selection Table

• For the piston selection table, refer to EM-111, "Standard and Limit".

NOTE:

• The piston is available together with piston pin as an assembly.

• The piston pin (piston pin bore) grade is provided only for the parts installed at the plant. For service parts, no grades can be selected. Only 0 grade is available.

HOW TO SELECT A CONNECTING ROD BEARING

When New Connecting Rod and Crankshaft are Used:

1. Apply big end inside diameter grade stamped on connecting rod side face to the row in the "Connecting Rod Bearing Selection

Table".

2. Apply pin diameter grade (B) stamped on crankshaft front side to the column in the "Connecting Rod Bearing Selection Table".

• Journal diameter grade (A)

3. Read the symbol at the cross point of selected row and column in the "Connecting Rod Bearing Selection Table".

4. Apply the symbol obtained to connecting rod bearing grade table to select.

When Crankshaft and Connecting Rod are Reused:

1. Measure dimensions of the big end inner diameter of connecting rod and outer diameter of crankshaft pin

individually.

2. Apply the dimension measured to the "Connec ting Rod Bearing Selection Table" below.

(A) : Oil splash

(B) : Small end diameter grade

(C) : Reference code

(D) : Bearing stopper groove

(E) : Reference code

(F) : Cylinder No.

(G) : Big end diameter grade

AWBIA1279GB

AWBIA0017ZZ

Revision: November 20132014 Altima NAM

Page 2110 of 4801

![NISSAN TEANA 2014 User Guide

EM-112

< SERVICE DATA AND SPECIFICATIONS (SDS) [QR25DE]

SERVICE DATA AND SPECIFICATIONS (SDS)

*2: When the intake or exhaust valve opening angle is at the maximum.

*3: When starting the engine with e NISSAN TEANA 2014 User Guide

EM-112

< SERVICE DATA AND SPECIFICATIONS (SDS) [QR25DE]

SERVICE DATA AND SPECIFICATIONS (SDS)

*2: When the intake or exhaust valve opening angle is at the maximum.

*3: When starting the engine with e](/img/5/57390/w960_57390-2109.png)

EM-112

< SERVICE DATA AND SPECIFICATIONS (SDS) [QR25DE]

SERVICE DATA AND SPECIFICATIONS (SDS)

*2: When the intake or exhaust valve opening angle is at the maximum.

*3: When starting the engine with engine coolant temperature 60

°C (140 °F) or less.

DRIVE BELTS

EXHAUST MANIFOLD

Unit: mm (in)

SPARK PLUG

Unit: mm (in)

*: Always check with the Parts Department for the latest parts information.

CYLINDER HEAD

Unit: mm (in)

VA LV E

Valve Dimensions

Unit: mm (in)

Tension of drive belts Auto adjustment by drive belt auto-tensioner

Surface distortion Description Limit

Exhaust manifold 0.3 (0.012)

Make DENSO

Type* Standard FXE20HE11C

Gap (nominal) 1.1 (0.043)

Description Limit

Head surface distortion 0.1 (0.004)

Description Standard

Spark plug tube installation height 41.7 (1.642)

PBIC0283E

Valve head diameter (D) Intake 35.5 - 35.8 (1.398 - 1.409)

Exhaust 30.3 - 30.6 (1.193 - 1.205)

SEM188

Revision: November 20132014 Altima NAM

Page 2126 of 4801

![NISSAN TEANA 2014 User Guide

EM -128

< PREPARATION >[VQ35DE]

PREPARATION

Tool name

Description

Power tool Loosening nuts, screws and bolts

Pulley holder Removing and installing crankshaft pulley

(Holding crankshaft pulley)

a: NISSAN TEANA 2014 User Guide

EM -128

< PREPARATION >[VQ35DE]

PREPARATION

Tool name

Description

Power tool Loosening nuts, screws and bolts

Pulley holder Removing and installing crankshaft pulley

(Holding crankshaft pulley)

a:](/img/5/57390/w960_57390-2125.png)

EM -128

< PREPARATION >[VQ35DE]

PREPARATION

Tool name

Description

Power tool Loosening nuts, screws and bolts

Pulley holder Removing and installing crankshaft pulley

(Holding crankshaft pulley)

a: 68 mm (2.68 in) dia.

b: 8 mm (0.31 in) dia.

Spark plug wrench Removing and installing spark plug

Valve seat cutter set Finishing valve seat dimensions

Piston ring expander Removing and installing piston ring

Valve guide drift Removing and installing valve guide Intake & Exhaust:

a: 9.5 mm (0.374 in) dia.

b: 5.5 mm (0.217 in) dia.

Valve guide reamer Reaming valve guide 1 or hole for oversize valve guide 2

Intake & Exhaust:

d

1: 6.0 mm (0.236 in) dia.

d

2: 10.2 mm (0.402 in) dia.

PIIB1407E

NT628

PBIC2982E

NT048

NT030

NT015

NT016

Revision: November 20132014 Altima NAM

Page 2212 of 4801

![NISSAN TEANA 2014 User Guide

EM-214

< REMOVAL AND INSTALLATION >[VQ35DE]

CYLINDER HEAD

1. To remove valve guide, heat cylinder head to 110

° to 130 °C

(230 ° to 266 °F) by soaking in heated oil.

WARNING:

Cylinder head conta NISSAN TEANA 2014 User Guide

EM-214

< REMOVAL AND INSTALLATION >[VQ35DE]

CYLINDER HEAD

1. To remove valve guide, heat cylinder head to 110

° to 130 °C

(230 ° to 266 °F) by soaking in heated oil.

WARNING:

Cylinder head conta](/img/5/57390/w960_57390-2211.png)

EM-214

< REMOVAL AND INSTALLATION >[VQ35DE]

CYLINDER HEAD

1. To remove valve guide, heat cylinder head to 110

° to 130 °C

(230 ° to 266 °F) by soaking in heated oil.

WARNING:

Cylinder head contains heat. When working, wear protective

equipment to avoid getting burned.

2. Drive out the valve guide with a press [under a 20 kN (2.2 US ton) pressure] or hammer and suitable tool.

3. Ream cylinder head valve guide hole.

4. Heat cylinder head to 110 ° to 130 °C (230 ° to 266 °F) by soaking

in heated oil and press new valve guide from camshaft side into

the cylinder head to the dimensions as shown.

WARNING:

Cylinder head contains heat . When working, wear protec-

tive equipment to avo id getting burned.

SEM008A

SEM931C

Valve guide hole diameter

(for service parts), intake

and exhaust : 10.175 - 10.196 mm

(0.4006 - 0.4014 in)

SEM932C

Projection (L) : 12.6 - 12.8 mm (0.496 - 0.504 in)

SEM950E

Revision: November 20132014 Altima NAM

Page 2213 of 4801

![NISSAN TEANA 2014 User Guide

CYLINDER HEADEM-215

< REMOVAL AND INSTALLATION > [VQ35DE]

C

D E

F

G H

I

J

K L

M A

EM

NP

O

5. Using a valve guide reamer, apply a reamer finish to the valve

guide.

VALVE SEAT CONTACT

• After confir NISSAN TEANA 2014 User Guide

CYLINDER HEADEM-215

< REMOVAL AND INSTALLATION > [VQ35DE]

C

D E

F

G H

I

J

K L

M A

EM

NP

O

5. Using a valve guide reamer, apply a reamer finish to the valve

guide.

VALVE SEAT CONTACT

• After confir](/img/5/57390/w960_57390-2212.png)

CYLINDER HEADEM-215

< REMOVAL AND INSTALLATION > [VQ35DE]

C

D E

F

G H

I

J

K L

M A

EM

NP

O

5. Using a valve guide reamer, apply a reamer finish to the valve

guide.

VALVE SEAT CONTACT

• After confirming that the dimensions of valve guides and valves are

within specifications, perform this procedure.

• Apply prussian blue onto contacting surface of valve seat to check the condition of the valve contact on the surface.

• Check if the contact area band is continuous all around the circum- ference.

• If not, grind to adjust valve fitti ng and check again. If the contacting

surface still has NG conditions even after the re-check, replace

valve seat.

VALVE SEAT REPLACEMENT

1. Bore out old seat until it collapses. Boring should not continue beyond the bottom face of the seat recess in cylinder head. Set

the machine depth stop to ensure this.

2. Ream cylinder head recess for service valve seat.

Be sure to ream in circles co ncentric to the valve guide cen-

ter.

This will enable valve seat to fit correctly.

3. Heat cylinder head to 110 ° to 130 °C (230 ° to 266 °F) by soaking

in heated oil.

WARNING:

Cylinder head contains heat . When working, wear protec-

tive equipment to avo id getting burned.

4. Press fit valve seat until it seats on the bottom.

5. Cut or grind valve seat using suitable t ool to the specified dimensions. Refer to EM-249, "Cylinder Head"

.

6. After cutting, lap valve seat with abrasive compound.

7. Check valve seating condition. Intake and exhaust

finished size : 6.000 - 6.018 mm

(0.2362 - 0.2369 in)

SEM932C

SBIA0322E

Oversize : 0.5 mm (0.020 in)

Intake : 38.500 - 38.516 mm (1.5157 - 1.5164 in)

Exhaust : 32.100 - 32.116 mm (1.2638 - 1.2644 in)

SEM795A

SEM008A

Revision: November 20132014 Altima NAM

Page 2214 of 4801

![NISSAN TEANA 2014 User Guide

EM-216

< REMOVAL AND INSTALLATION >[VQ35DE]

CYLINDER HEAD

8. Use a depth gauge to measure the distance between the mount-

ing surface of the cylinder head spring seat and the valve stem

end. If the NISSAN TEANA 2014 User Guide

EM-216

< REMOVAL AND INSTALLATION >[VQ35DE]

CYLINDER HEAD

8. Use a depth gauge to measure the distance between the mount-

ing surface of the cylinder head spring seat and the valve stem

end. If the](/img/5/57390/w960_57390-2213.png)

EM-216

< REMOVAL AND INSTALLATION >[VQ35DE]

CYLINDER HEAD

8. Use a depth gauge to measure the distance between the mount-

ing surface of the cylinder head spring seat and the valve stem

end. If the distance is shorter than specified, repeat step 5 to

adjust it. If it is longer, replace the valve seat with a new one.

VALVE SPRING SQUARENESS

Set try square along the side of valve spring and rotate the spring.

Measure the maximum clearance between the top face of spring and

try square.

VALVE SPRING DIMENSIONS AND VALVE SPRING PRESSURE LOAD

Check valve spring pressure at specified spring height.

If it is not within specif ications, replace the spring.

Seat face angle

α : 45° 15' - 45 ° 45' de-

grees/minutes

Contacting width (W) fo r intake : 1.18 - 1.22 mm

(0.0465 - 0.0480 in)

Contacting width (W) fo r exhaust : 1.38 - 1.42 mm

(0.0543 - 0.0559 in)

SEM892B

Valve seat resurface limit (L)

intake : 41.16 - 41.76 mm

(1.6205 - 1.6441 in)

Valve seat resurface limit (L)

exhaust : 41.09 - 41.69 mm

(1.6177 - 1.6413 in)

SEM621F

Out-of-square limit : L ess than 2.0 mm (0.079 in)

PBIC0080E

Standard : 166 - 188 N (16.9 - 19.2 kg, 37.3 - 42.3 lb) at

height 37.0 mm (1.457 in)

Limit : 373 - 421 N (38.0 - 42.9 kg, 84 - 95 lb) at height 27.2 mm (1.071 in)

SEM113

Revision: November 20132014 Altima NAM

Page 2247 of 4801

![NISSAN TEANA 2014 User Guide

SERVICE DATA AND SPECIFICATIONS (SDS)EM-249

< SERVICE DATA AND SPECIFICATIONS (SDS) [VQ35DE]

C

D E

F

G H

I

J

K L

M A

EM

NP

O

*: Always check with the Parts Department for the latest parts informati NISSAN TEANA 2014 User Guide

SERVICE DATA AND SPECIFICATIONS (SDS)EM-249

< SERVICE DATA AND SPECIFICATIONS (SDS) [VQ35DE]

C

D E

F

G H

I

J

K L

M A

EM

NP

O

*: Always check with the Parts Department for the latest parts informati](/img/5/57390/w960_57390-2246.png)

SERVICE DATA AND SPECIFICATIONS (SDS)EM-249

< SERVICE DATA AND SPECIFICATIONS (SDS) [VQ35DE]

C

D E

F

G H

I

J

K L

M A

EM

NP

O

*: Always check with the Parts Department for the latest parts information.

Cylinder HeadINFOID:0000000009460590

CYLINDER HEAD

Unit: mm (in)

VALVE DIMENSIONS

820C 8.20 (0.3228)

822C 8.22 (0.3236)

824C 8.24 (0.3244)

826C 8.26 (0.3252)

828C 8.28 (0.3260)

830C 8.30 (0.3268)

832C 8.32 (0.3276)

834C 8.34 (0.3283)

836C 8.36 (0.3291)

838C 8.38 (0.3299)

840C 8.40 (0.3307)

Identification (stamped) mark* Thickness

SEM758G

Items Standard Limit

Head surface distortion Less than 0.03 (0.0012) 0.1 (0.004)

Normal cylinder head height (H) 126.3 - 126.5 (4.972 - 4.980) —

Spark plug tube installation height 37.7 - 39.1 (1.484 - 1.539) —

PBIC0924E

Revision: November 20132014 Altima NAM

Page 2529 of 4801

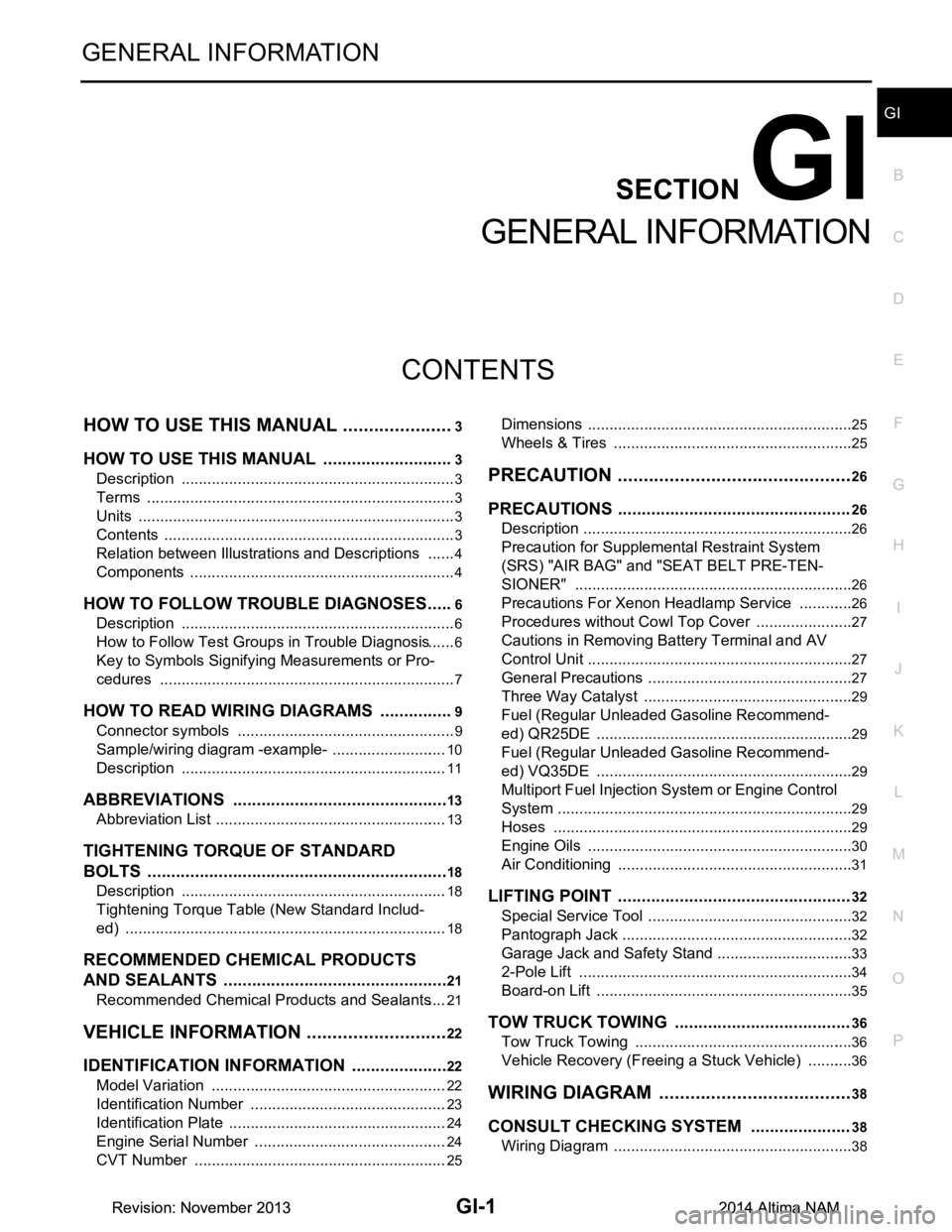

GI-1

GENERAL INFORMATION

C

D E

F

G H

I

J

K L

M B

GI

SECTION GI

N

O P

CONTENTS

GENERAL INFORMATION

HOW TO USE THIS MANU AL ......................3

HOW TO USE THIS MANUAL ....................... .....3

Description .......................................................... ......3

Terms ........................................................................3

Units ..........................................................................3

Contents ....................................................................3

Relation between Illustrations and Descriptions .......4

Components ..............................................................4

HOW TO FOLLOW TROUBLE DIAGNOSES .....6

Description ................................................................6

How to Follow Test Groups in Trouble Diagnosis ......6

Key to Symbols Signifying Measurements or Pro-

cedures ............................................................... ......

7

HOW TO READ WIRING DIAGRAMS ................9

Connector symbols ............................................. ......9

Sample/wiring diagram -example- ...........................10

Description ..............................................................11

ABBREVIATIONS .......................................... ....13

Abbreviation List .................................................. ....13

TIGHTENING TORQUE OF STANDARD

BOLTS ............................................................ ....

18

Description .......................................................... ....18

Tightening Torque Table (New Standard Includ-

ed) ....................................................................... ....

18

RECOMMENDED CHEMICAL PRODUCTS

AND SEALANTS ............................................ ....

21

Recommended Chemical Products and Sealants ....21

VEHICLE INFORMATION ............................22

IDENTIFICATION INFORMATION ................. ....22

Model Variation ................................................... ....22

Identification Number ..............................................23

Identification Plate ...................................................24

Engine Serial Number .............................................24

CVT Number ...........................................................25

Dimensions .......................................................... ....25

Wheels & Tires ........................................................25

PRECAUTION ..............................................26

PRECAUTIONS .................................................26

Description ........................................................... ....26

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ....

26

Precautions For Xenon Headlamp Service .............26

Procedures without Cowl Top Cover .......................27

Cautions in Removing Battery Terminal and AV

Control Unit .......................................................... ....

27

General Precautions ................................................27

Three Way Catalyst .................................................29

Fuel (Regular Unleaded Gasoline Recommend-

ed) QR25DE ........................................................ ....

29

Fuel (Regular Unleaded Gasoline Recommend-

ed) VQ35DE ........................................................ ....

29

Multiport Fuel Injection System or Engine Control

System ................................................................. ....

29

Hoses ......................................................................29

Engine Oils ..............................................................30

Air Conditioning .......................................................31

LIFTING POINT .................................................32

Special Service Tool ................................................32

Pantograph Jack ......................................................32

Garage Jack and Safety Stand ................................33

2-Pole Lift ................................................................34

Board-on Lift ............................................................35

TOW TRUCK TOWING .....................................36

Tow Truck Towing ...................................................36

Vehicle Recovery (Freeing a Stuck Vehicle) ...........36

WIRING DIAGRAM ......................................38

CONSULT CHECKING SYSTEM .....................38

Wiring Diagram .................................................... ....38

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM