Pro pressure NISSAN TEANA 2014 Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2014, Model line: TEANA, Model: NISSAN TEANA 2014Pages: 4801, PDF Size: 51.2 MB

Page 2624 of 4801

HA-18

< SYMPTOM DIAGNOSIS >

REFRIGERATION SYSTEM SYMPTOMS

REFRIGERATION SYSTEM SYMPTOMS

Trouble Diagnosis For Unusual PressureINFOID:0000000009463923

Diagnose using a manifold gauge whenever system’s high and/or low side pressure(s) is/are unusual. The

marker above the gauge scale in the following tables indicates the standard (usual) pressure range. Refer to

above table (Ambient air temperature-to-operating pres sure table) since the standard (usual) pressure, how-

ever, differs from vehicle to vehicle.

Symptom TableINFOID:0000000009463924

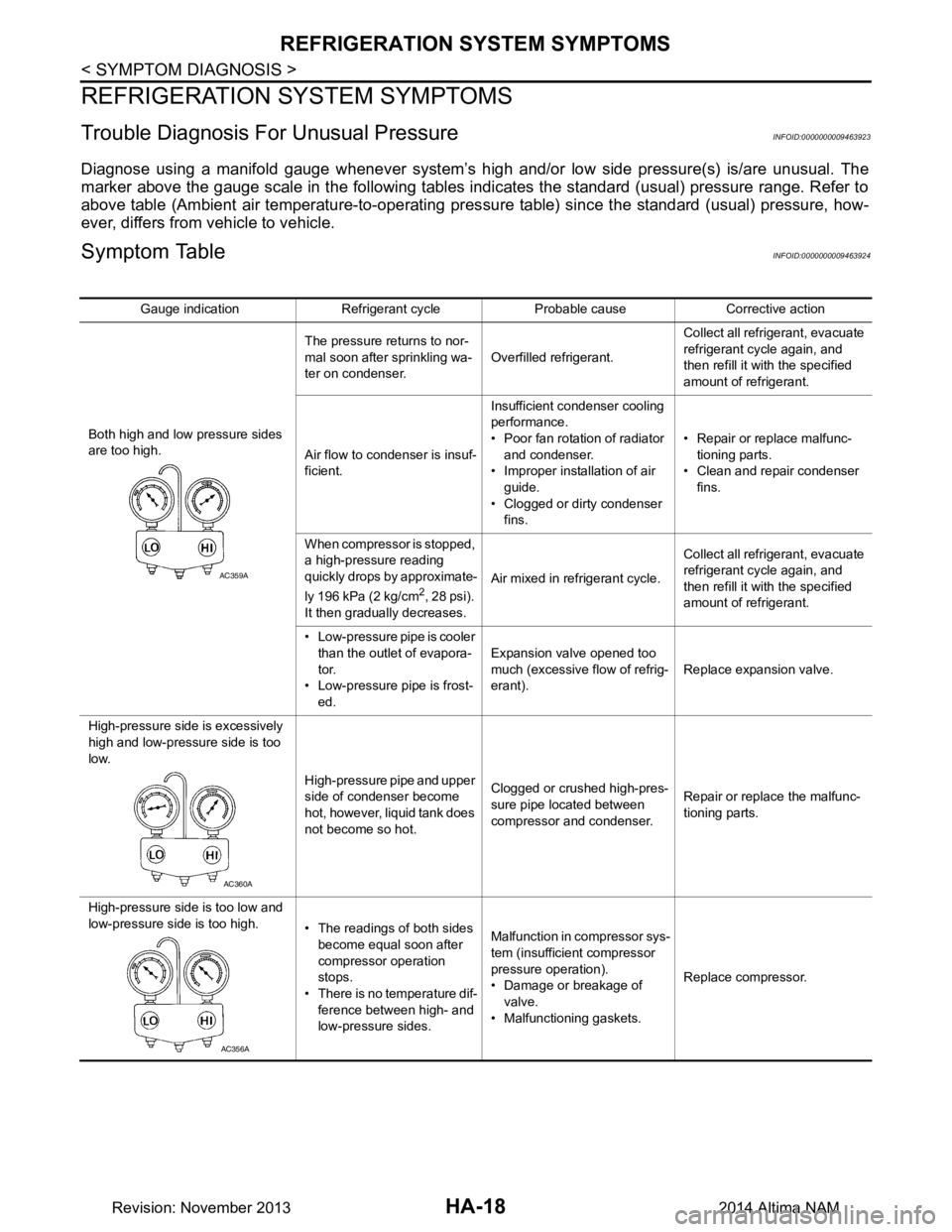

Gauge indication Refrigerant cycle Probable cause Corrective action

Both high and low pressure sides

are too high. The pressure returns to nor-

mal soon after sprinkling wa-

ter on condenser. Overfilled refrigerant. Collect all refrigerant, evacuate

refrigerant cycle again, and

then refill it with the specified

amount of refrigerant.

Air flow to condenser is insuf-

ficient. Insufficient condenser cooling

performance.

• Poor fan rotation of radiator and condenser.

• Improper installation of air

guide.

• Clogged or dirty condenser fins. • Repair or replace malfunc-

tioning parts.

• Clean and repair condenser

fins.

When compressor is stopped,

a high-pressure reading

quickly drops by approximate-

ly 196 kPa (2 kg/cm

2, 28 psi).

It then gradually decreases. Air mixed in refrigerant cycle.

Collect all refrigerant, evacuate

refrigerant cycle again, and

then refill it with the specified

amount of refrigerant.

• Low-pressure pipe is cooler than the outlet of evapora-

tor.

• Low-pressure pipe is frost- ed. Expansion valve opened too

much (excessive flow of refrig-

erant). Replace expansion valve.

High-pressure side is excessively

high and low-pressure side is too

low.

High-pressure pipe and upper

side of condenser become

hot, however, liquid tank does

not become so hot. Clogged or crushed high-pres-

sure pipe located between

compressor and condenser. Repair or replace the malfunc-

tioning parts.

High-pressure side is too low and

low-pressure side is too high. • The readings of both sides

become equal soon after

compressor operation

stops.

• There is no temperature dif- ference between high- and

low-pressure sides. Malfunction in compressor sys-

tem (insufficient compressor

pressure operation).

• Damage or breakage of

valve.

• Malfunctioning gaskets. Replace compressor.

AC359A

AC360A

AC356A

Revision: November 20132014 Altima NAM

Page 2625 of 4801

REFRIGERATION SYSTEM SYMPTOMSHA-19

< SYMPTOM DIAGNOSIS >

C

D E

F

G H

J

K L

M A

B

HA

N

O P

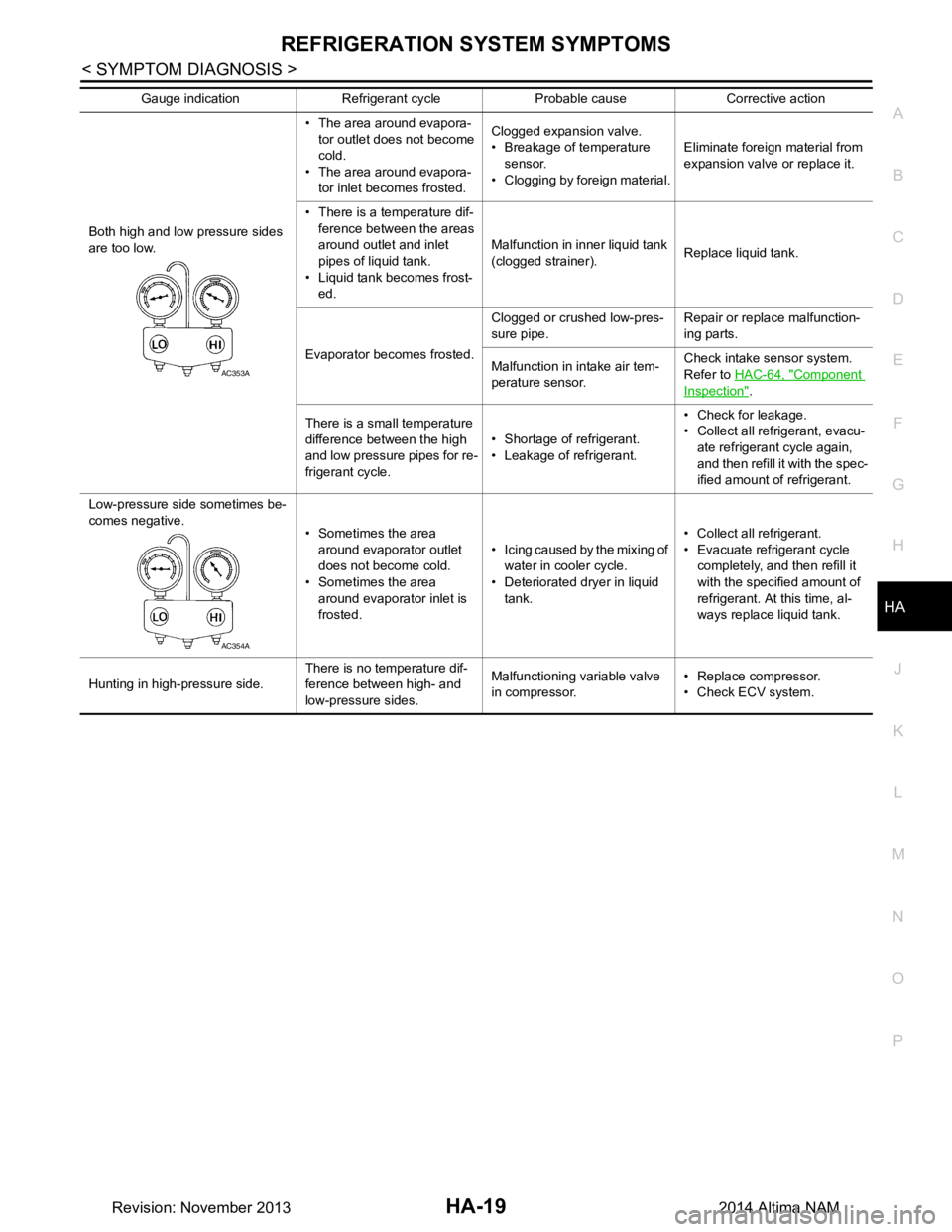

Both high and low pressure sides

are too low. • The area around evapora-

tor outlet does not become

cold.

• The area around evapora- tor inlet becomes frosted. Clogged expansion valve.

• Breakage of temperature sensor.

• Clogging by foreign material. Eliminate foreign material from

expansion valve or replace it.

• There is a temperature dif- ference between the areas

around outlet and inlet

pipes of liquid tank.

• Liquid tank becomes frost- ed. Malfunction in inner liquid tank

(clogged strainer). Replace liquid tank.

Evaporator becomes frosted. Clogged or crushed low-pres-

sure pipe. Repair or replace malfunction-

ing parts.

Malfunction in intake air tem-

perature sensor. Check intake sensor system.

Refer to HAC-64, "Component

Inspection".

There is a small temperature

difference between the high

and low pressure pipes for re-

frigerant cycle. • Shortage of refrigerant.

• Leakage of refrigerant. • Check for leakage.

• Collect all refrigerant, evacu-

ate refrigerant cycle again,

and then refill it with the spec-

ified amount of refrigerant.

Low-pressure side sometimes be-

comes negative. • Sometimes the area

around evaporator outlet

does not become cold.

• Sometimes the area

around evaporator inlet is

frosted. • Icing caused by the mixing of

water in cooler cycle.

• Deteriorated dryer in liquid

tank. • Collect all refrigerant.

• Evacuate refrigerant cycle completely, and then refill it

with the specified amount of

refrigerant. At this time, al-

ways replace liquid tank.

Hunting in high-pressure side. There is no temperature dif-

ference between high- and

low-pressure sides. Malfunctioning variable valve

in compressor. • Replace compressor.

• Check ECV system.

Gauge indication Refrigerant cycle Probable cause Corrective action

AC353A

AC354A

Revision: November 20132014 Altima NAM

Page 2628 of 4801

HA-22

< PERIODIC MAINTENANCE >

REFRIGERANT

4. Press UV lamp switch (5) and check A/C system for refrigerant leakage. (Where refrigerant leakage

occurs, fluorescent leak detec tion dye appears in green color.)

WARNING:

Do not look directly into UV lamp light source.

NOTE:

• For continuous operating time of UV lamp, follow the manufacturer operating instructions.

• Illuminate piping joints from different angles using UV lamp and check that there is no leakage.

• Use a mirror in area that is difficult to see to check refrigerant leakage.

• Refrigerant leakage from evaporator can be detected by soaking cotton swab or a similar material with

drain hose water and illuminating it using UV lamp.

• Dust, dirt and packing materials adhesive used for condenser, evaporator, and other locations may fluo- resce. Be careful not to misidentify leakage.

5. Repair or replace parts where refrigerant leakage occurs and wipe off fluorescent leak detection dye. NOTE:

Completely wipe off fluorescent leak detection dy e from gaps between parts, screw threads, and others

using a cotton swab or similar materials.

6. Use a UV lamp to check that no fluorescent leak detection dye remains after finishing work.

WARNING:

Do not look directly into UV lamp light source.

NOTE:

• For continuous operating time of UV lamp, follow the manufacturer operating instructions.

• Dust, dirt, and packing materials adhesive used for condenser, evaporator, and other locations may flu-

oresce. Be careful not to misidentify leakage.

CHECK REFRIGERANT LEAKAGE USING ELECTRICAL LEAK DETECTOR

WARNING:

Do not check refrigerant leakage while the engine is running.

CAUTION:

Be careful of the following it ems so that inaccurate checks or misidentifications are avoided.

• Do not allow refrigerant vapor, shop chemical vapor s, cigarette smoke or others around the vehicle.

• Always check refrigerant leakage in a low air flow en vironment so that refrigerant may not disperse

when leakage occurs.

1. Stop the engine.

2. Connect recovery/recycling/recharging equipment or manifold gauge set (J-39183-C) to A/C service

valve.

3. Check that A/C refrigerant pressure is 345 kPa (3.52 kg/cm

2, 50 psi) or more when temperature is 16 °C

(61 °F) or more. When pressure is lower than the specif ied value, recycle refrigerant completely and fill

refrigerant to the specified level.

NOTE:

Leakages may not be detected if A/C refrigerant pressure is 345 kPa (3.52 kg/cm

2, 50 psi) or less when

temperature is less than 16 °C (61 °F).

4. Clean area where refrigerant leakage check is performed and check refrigerant leakage along all surfaces of pipe connections and A/C system components us ing electrical leak detector (J-41995) probe.

CAUTION:

• Continue checking when a leakag e is found. Always continue and complete checking along all

pipe connections and A/C system components for additional leakage.

• When a leakage is detected, clean leakage area using compressed air and check again.

• When checking leakage of cooling unit inside, always clean inside of drain hose so that the

probe surface may not be exposed to water or dirt.

NOTE:

• Always check leakage starting from high-pressure side and continue to low-pressure side.

• When checking leakage of cooling unit inside, operate bl ower fan motor for 15 minutes or more at the

maximum fan speed while the engine is stopped, and then in sert electrical leak detector probe into drain

hose and hold for 10 minutes or more.

• When disconnecting shut-off valve that is connected to A/C service valve, always evacuate remaining

refrigerant so that misidentification can be avoided.

5. Repair or replace parts where refrigerant leak age is detected. (Leakage is detected but leakage area is

unknown.)

Revision: November 20132014 Altima NAM

Page 2629 of 4801

REFRIGERANTHA-23

< PERIODIC MAINTENANCE >

C

D E

F

G H

J

K L

M A

B

HA

N

O P

6. Start the engine and set A/C control in the following conditions. • A/C switch ON

• Air flow: VENT (ventilation)

• Intake door position: Recirculation

• Temperature setting: Full cold

• Fan (blower) speed: Maximum speed set

7. Run the engine at approximately 1,500 rpm for 2 minutes or more.

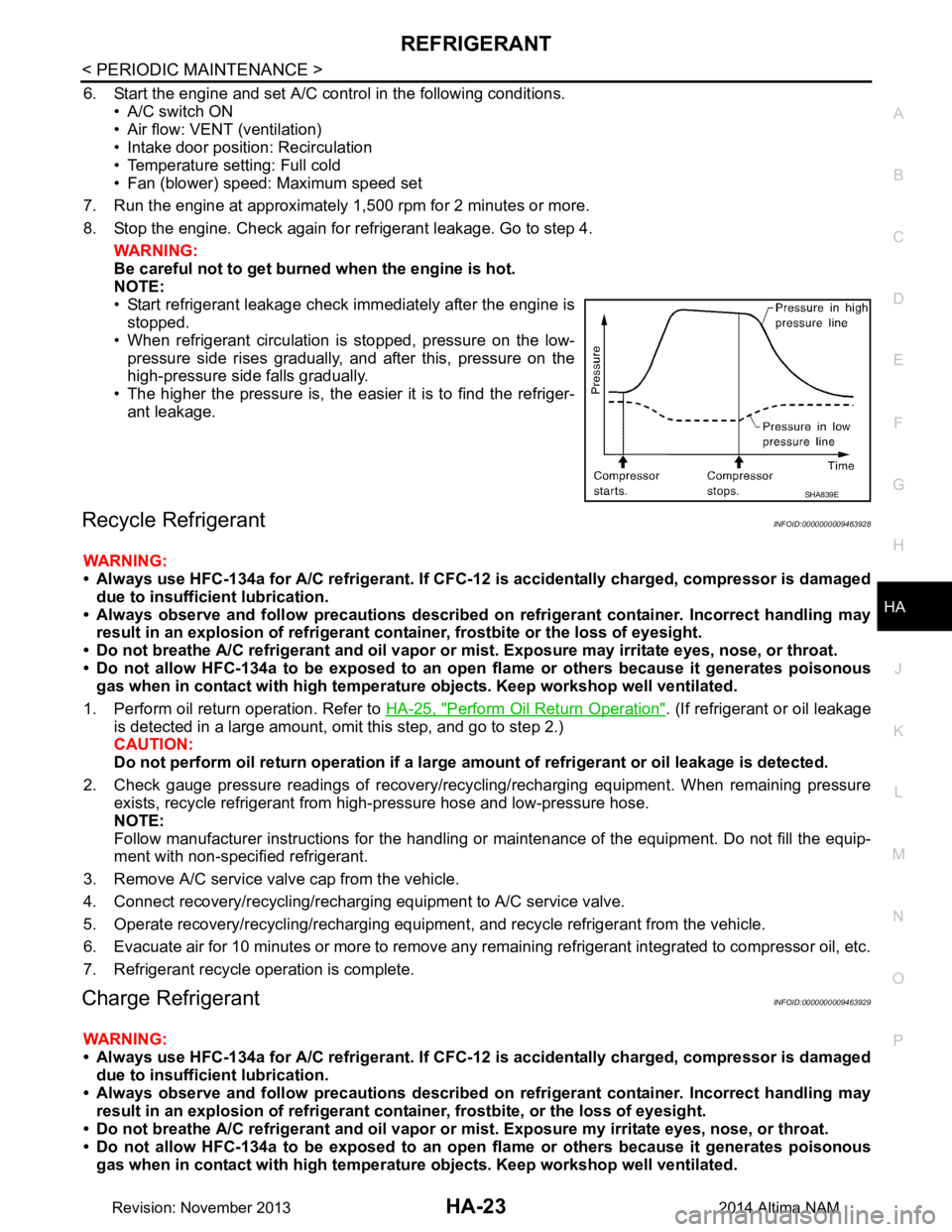

8. Stop the engine. Check again for refrigerant leakage. Go to step 4. WARNING:

Be careful not to get burned when the engine is hot.

NOTE:

• Start refrigerant leakage check immediately after the engine is stopped.

• When refrigerant circulation is stopped, pressure on the low- pressure side rises gradually, and after this, pressure on the

high-pressure side falls gradually.

• The higher the pressure is, the easier it is to find the refriger-

ant leakage.

Recycle RefrigerantINFOID:0000000009463928

WARNING:

• Always use HFC-134a for A/C refrigerant. If CFC-12 is accidentally charged, compressor is damaged

due to insufficient lubrication.

• Always observe and follow precaution s described on refrigerant container. Incorrect handling may

result in an explosion of refrigerant co ntainer, frostbite or the loss of eyesight.

• Do not breathe A/C refrigerant and oil vapor or mi st. Exposure may irritate eyes, nose, or throat.

• Do not allow HFC-134a to be exposed to an open flame or others because it generates poisonous

gas when in contact with high temperatur e objects. Keep workshop well ventilated.

1. Perform oil return operation. Refer to HA-25, "Perform Oil Return Operation"

. (If refrigerant or oil leakage

is detected in a large amount, omit this step, and go to step 2.)

CAUTION:

Do not perform oil return operation if a large am ount of refrigerant or oil leakage is detected.

2. Check gauge pressure readings of recovery/recyc ling/recharging equipment. When remaining pressure

exists, recycle refrigerant from high-pressure hose and low-pressure hose.

NOTE:

Follow manufacturer instructions for the handling or maintenance of the equipment. Do not fill the equip-

ment with non-specified refrigerant.

3. Remove A/C service valve cap from the vehicle.

4. Connect recovery/recycling/recharging equipment to A/C service valve.

5. Operate recovery/recycling/recharging equipment , and recycle refrigerant from the vehicle.

6. Evacuate air for 10 minutes or more to remove any remaining refrigerant integrated to compressor oil, etc.

7. Refrigerant recycle operation is complete.

Charge RefrigerantINFOID:0000000009463929

WARNING:

• Always use HFC-134a for A/C refrigerant. If CFC-12 is accidentally charged, compressor is damaged

due to insufficient lubrication.

• Always observe and follow precaution s described on refrigerant container. Incorrect handling may

result in an explosion of refrigerant co ntainer, frostbite, or the loss of eyesight.

• Do not breathe A/C refrigerant and oil vapor or mi st. Exposure my irritate eyes, nose, or throat.

• Do not allow HFC-134a to be exposed to an open flame or others because it generates poisonous

gas when in contact with high temperatur e objects. Keep workshop well ventilated.

SHA839E

Revision: November 20132014 Altima NAM

Page 2630 of 4801

HA-24

< PERIODIC MAINTENANCE >

REFRIGERANT

1. Connect recovery/recycling/recharging equipment to the A/C service valve.

2. Operate recovery/recycling/recharging equipment, and evacuate air from A/C system for 25 minutes or

more.

CAUTION:

Evacuate air for 15 minutes or more if the parts are replaced.

3. Check the airtightness of A/C system for 25 minutes or more. If pressure raises more than the specified

level, charge A/C system with approximately 200g refriger ant and check that there is no refrigerant leak-

age. Refer to HA-21, "Leak Test"

.

CAUTION:

Check the airtightness for 15 minutes or more if the parts are replaced.

4. If parts other than compressor are replaced, fill co mpressor oil according to parts that are replaced.

5. Charge the specified amount of refrigerant to A/C system.

6. Check that A/C system operates normally.

7. Disconnect recovery/recycling/recharging equipment. (Col lect the refrigerant from the high-pressure hose

and low-pressure hose of recovery/recycling/recharging equipment.)

8. Install A/C service valve cap.

9. Refrigerant charge is complete.

Revision: November 20132014 Altima NAM

Page 2632 of 4801

HA-26

< PERIODIC MAINTENANCE >

OIL

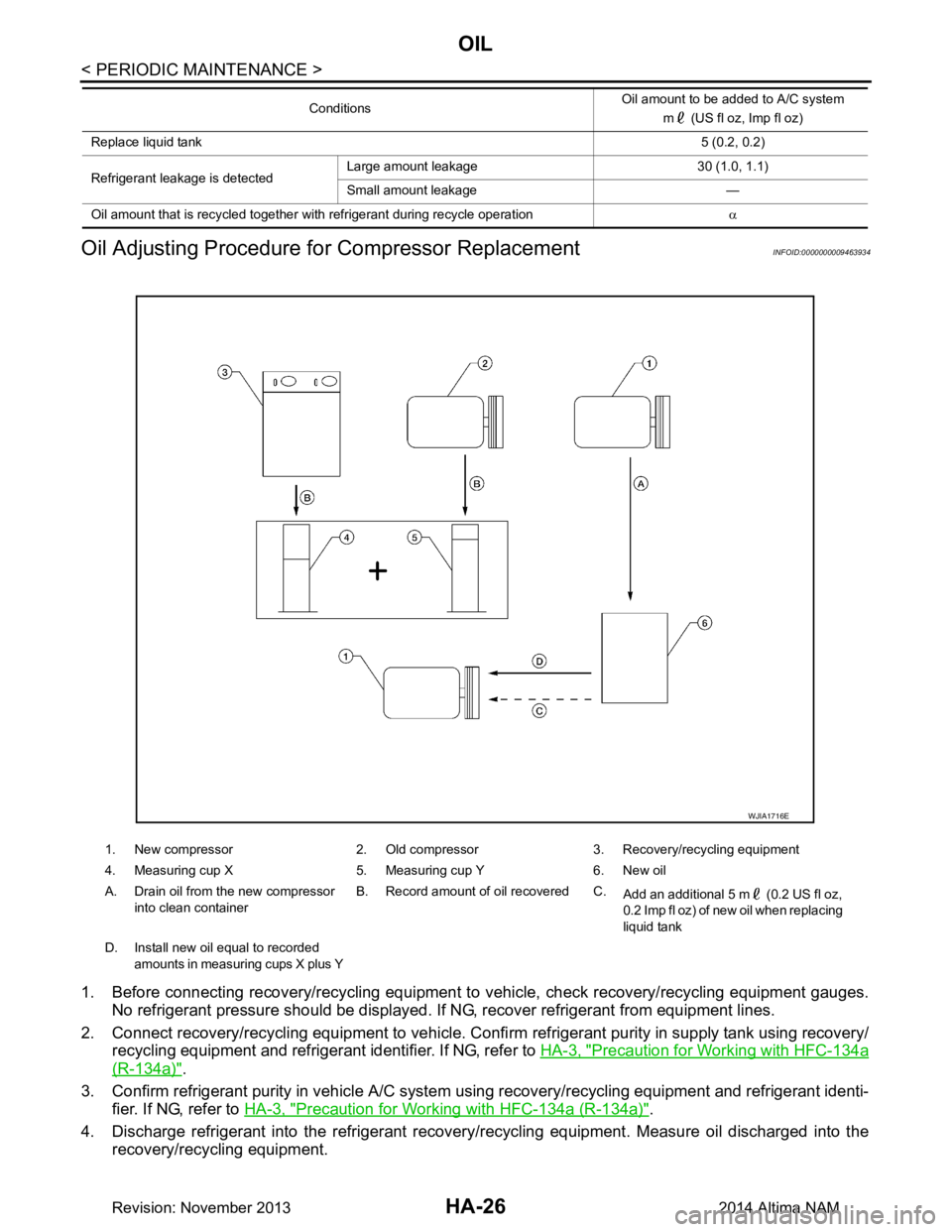

Oil Adjusting Procedure fo r Compressor Replacement

INFOID:0000000009463934

1. Before connecting recovery/recycling equipment to vehicle, check recovery/recycling equipment gauges.

No refrigerant pressure should be displayed. If NG, recover refrigerant from equipment lines.

2. Connect recovery/recycling equipment to vehicle. Confi rm refrigerant purity in supply tank using recovery/

recycling equipment and refrigerant identifier. If NG, refer to HA-3, "Precaution for Working with HFC-134a

(R-134a)".

3. Confirm refrigerant purity in vehi cle A/C system using recovery/recycling equipment and refrigerant identi-

fier. If NG, refer to HA-3, "Precaution for Working with HFC-134a (R-134a)"

.

4. Discharge refrigerant into the refrigerant recove ry/recycling equipment. Measure oil discharged into the

recovery/recycling equipment.

Replace liquid tank 5 (0.2, 0.2)

Refrigerant leakage is detected Large amount leakage 30 (1.0, 1.1)

Small amount leakage —

Oil amount that is recycled together with refrigerant during recycle operation α

Conditions

Oil amount to be added to A/C system

m (US fl oz, Imp fl oz)

1. New compressor 2. Old compressor 3. Recovery/recycling equipment

4. Measuring cup X 5. Measuring cup Y 6. New oil

A. Drain oil from the new compressor into clean container B. Record amount of oil recovered C.

Add an additional 5 m (0.2 US fl oz,

0.2 Imp fl oz) of new oil when replacing

liquid tank

D. Install new oil equal to recorded amounts in measuring cups X plus Y

WJIA1716E

Revision: November 20132014 Altima NAM

Page 2634 of 4801

HA-28

< PERIODIC MAINTENANCE >

PERFORMANCE TEST

PERFORMANCE TEST

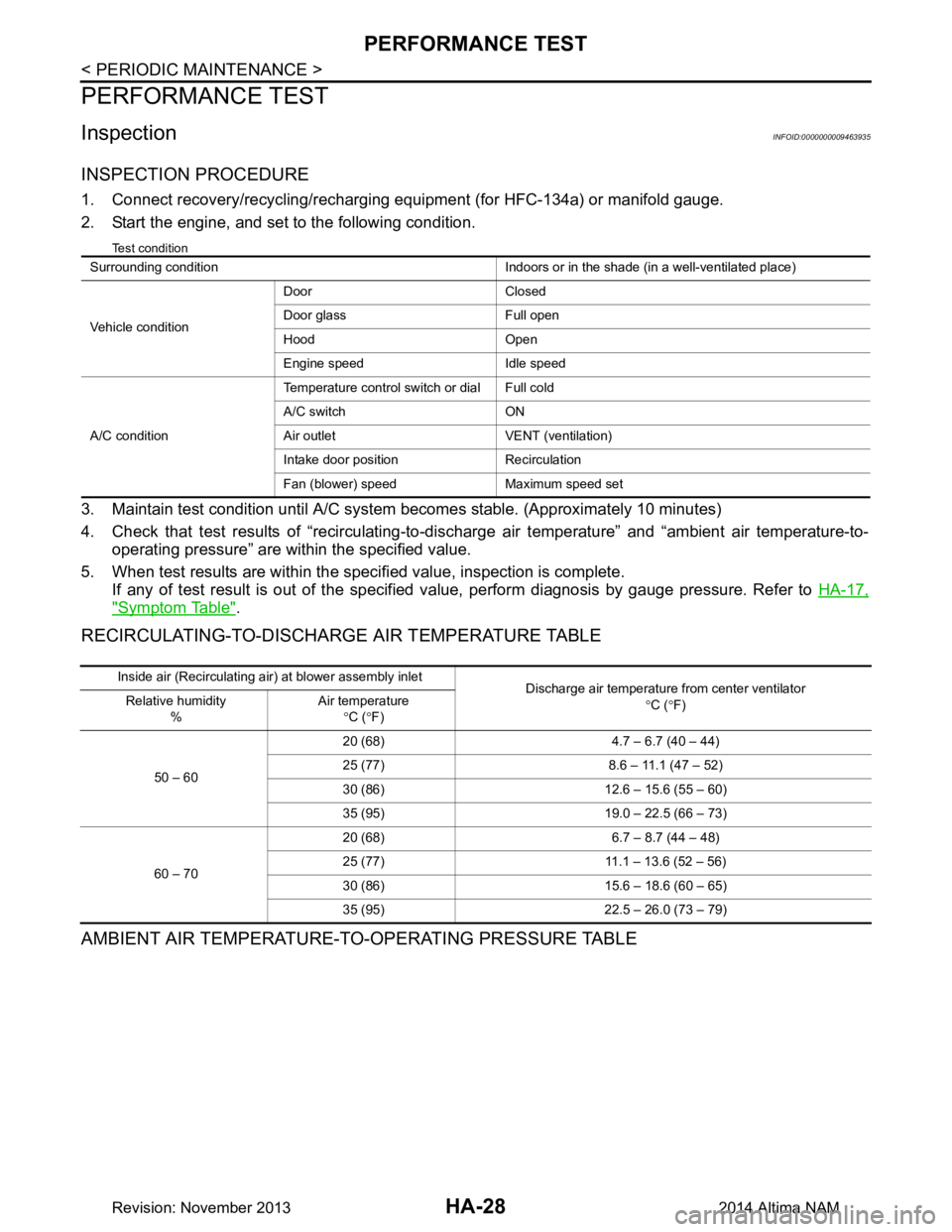

InspectionINFOID:0000000009463935

INSPECTION PROCEDURE

1. Connect recovery/recycling/recharging equipment (for HFC-134a) or manifold gauge.

2. Start the engine, and set to the following condition.

Test condition

3. Maintain test condition until A/C system becomes stable. (Approximately 10 minutes)

4. Check that test results of “recirculating-to-disc harge air temperature” and “ambient air temperature-to-

operating pressure” are within the specified value.

5. When test results are within the spec ified value, inspection is complete.

If any of test result is out of the specifi ed value, perform diagnosis by gauge pressure. Refer to HA-17,

"Symptom Table".

RECIRCULATING-TO-DISCHARGE AIR TEMPERATURE TABLE

AMBIENT AIR TEMPERATURE-TO-OPERATING PRESSURE TABLE

Surrounding condition Indoors or in the shade (in a well-ventilated place)

Vehicle condition Door Closed

Door glass Full open

Hood Open

Engine speed Idle speed

A/C condition Temperature control switch or dial Full cold

A/C switch ON

Air outlet VENT (ventilation)

Intake door position Recirculation

Fan (blower) speed Maximum speed set

Inside air (Recirculating air) at blower assembly inlet Discharge air temperature from center ventilator

°C ( °F)

Relative humidity

% Air temperature

°C ( °F)

50 – 60 20 (68) 4.7 – 6.7 (40 – 44)

25 (77) 8.6 – 11.1 (47 – 52)

30 (86) 12.6 – 15.6 (55 – 60)

35 (95) 19.0 – 22.5 (66 – 73)

60 – 70 20 (68) 6.7 – 8.7 (44 – 48)

25 (77) 11.1 – 13.6 (52 – 56)

30 (86) 15.6 – 18.6 (60 – 65)

35 (95) 22.5 – 26.0 (73 – 79)

Revision: November 20132014 Altima NAM

Page 2652 of 4801

HAC-3

C

D E

F

G H

J

K L

M A

B

HAC

N

O P

AMBIENT SENSOR ....................................... ..103

Removal and Installation .......................................103

IN-VEHICLE SENSOR ................................... ..104

Removal and Installation .......................................104

SUNLOAD SENSOR ...................................... ..105

Removal and Installation .......................................105

INTAKE SENSOR .......................................... ..106

Removal and Installation .......................................106

REFRIGERANT PRESSURE SENSOR ......... ..107

Removal and Installation .......................................107

DOOR MOTOR ............................................... ..108

Exploded View .................................................... ..108

INTAKE DOOR MOTOR ........................................ ..109

INTAKE DOOR MOTOR : Removal and Installa-

tion ...................................................................... ..

109

MODE DOOR MOTOR .......................................... ..109

MODE DOOR MOTOR : Removal and Installation ..109

AIR MIX DOOR MOTOR ....................................... ..109

AIR MIX DOOR MOTOR : Removal and Installa-

tion - Air Mix Door Motor (RH) ............................. ..

109

AIR MIX DOOR MOTOR : Removal and Installa-

tion - Air Mix Door Motor (LH) ............................. ..

109

MANUAL AIR CONDITIONER

PRECAUTION ................ ............................

110

PRECAUTIONS .............................................. ..110

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ..

110

Precaution for Work ..............................................110

Working with HFC-134a (R-134a) .........................110

Precaution for Service Equipment .........................111

PREPARATION .........................................113

PREPARATION .............................................. ..113

Special Service Tool ........................................... ..113

Commercial Service Tool ......................................113

SYSTEM DESCRIPTION ...........................114

COMPONENT PARTS ................................... ..114

Component Part Location ................................... ..114

Component Description .........................................115

SYSTEM ...........................................................117

System Diagram .................................................. ..117

System Description ...............................................117

Air Flow Control .....................................................118

Air Inlet Control .....................................................118

Air Outlet Control ...................................................118

Compressor Control ..............................................118

Door Control ..........................................................119

Temperature Control ........................................... ..121

OPERATION ...................................................122

Switch Name and Function ....................................122

DIAGNOSIS SYSTEM (BCM) .........................124

CONSULT Function (BCM - COMMON ITEM) ......124

CONSULT Function (BCM - AIR CONDITIONER) ..125

DIAGNOSIS SYSTEM (IPDM E/R) .................126

CONSULT Function (IPDM E/R) ...........................126

ECU DIAGNOSIS INFORMATION ............128

FRONT AIR CONTROL ..................................128

Reference Value .................................................. ..128

ECM, IPDM E/R, BCM .....................................129

List of ECU Reference ...........................................129

WIRING DIAGRAM ....................................130

AIR CONDITIONER CONTROL ......................130

Wiring Diagram .................................................... ..130

BASIC INSPECTION .................................139

DIAGNOSIS AND REPAIR WORKFLOW ......139

Work Flow ............................................................ ..139

OPERATION INSPECTION ............................140

Work Procedure .....................................................140

DTC/CIRCUIT DIAGNOSIS .......................142

MODE DOOR MOTOR ....................................142

Diagnosis Procedure ........................................... ..142

AIR MIX DOOR MOTOR .................................144

Diagnosis Procedure .............................................144

INTAKE DOOR MOTOR .................................146

Diagnosis Procedure .............................................146

BLOWER MOTOR ..........................................148

Diagnosis Procedure .............................................148

Component Inspection (Blower Motor) ..................149

Component Inspection (Front Blower Motor Re-

lay) ....................................................................... ..

149

MAGNET CLUTCH .........................................151

Component Function Check ..................................151

Diagnosis Procedure .............................................151

POWER SUPPLY AND GROUND CIRCUIT

FOR FRONT AIR CONTROL ..........................

152

Description ........................................................... ..152

Component Function Check ..................................152

Diagnosis Procedure .............................................152

SYMPTOM DIAGNOSIS ............................154

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 2653 of 4801

HAC-4

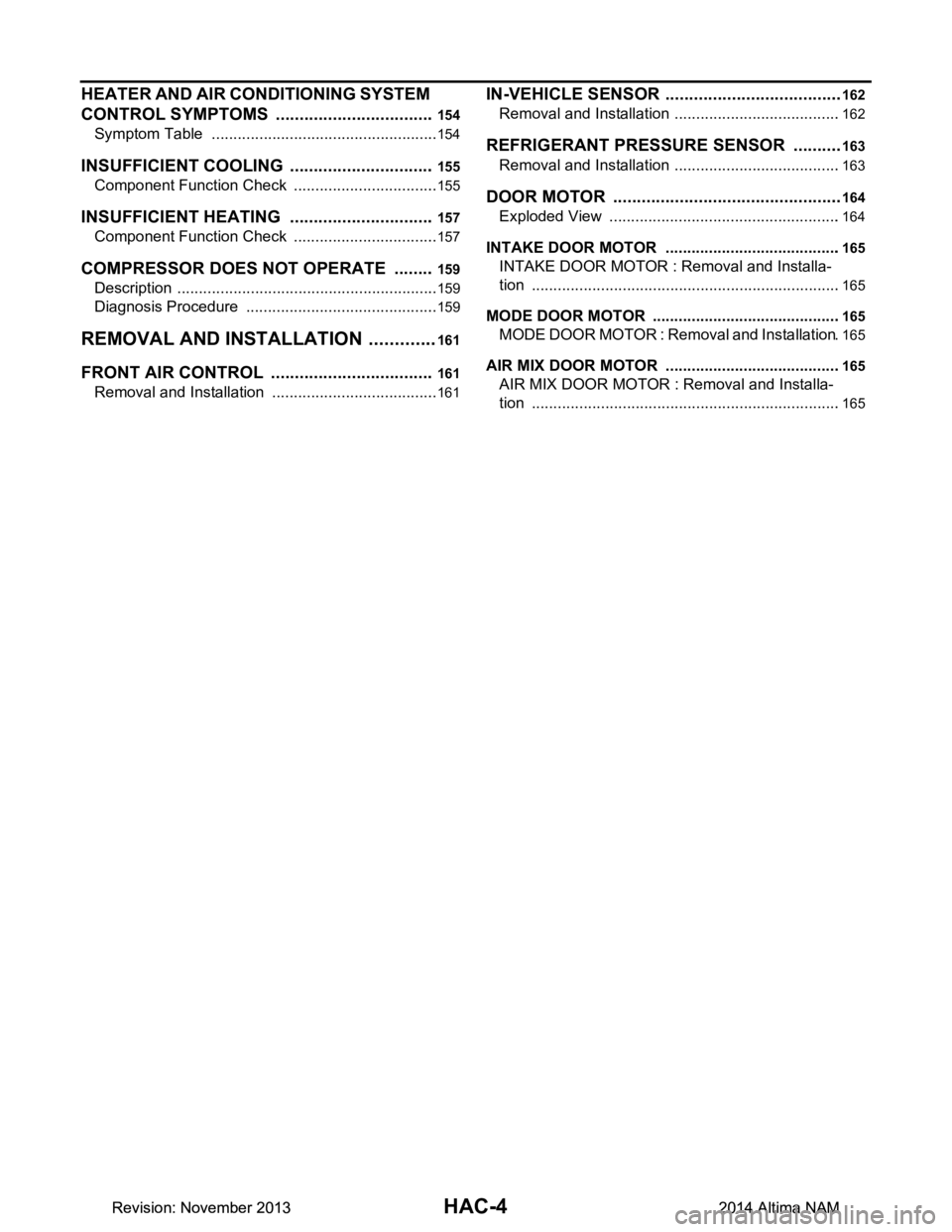

HEATER AND AIR CONDITIONING SYSTEM

CONTROL SYMPTOMS ................................. .

154

Symptom Table ................................................... ..154

INSUFFICIENT COOLING ...............................155

Component Function Check ................................ ..155

INSUFFICIENT HEATING ...............................157

Component Function Check ................................ ..157

COMPRESSOR DOES NOT OPERATE .........159

Description ........................................................... ..159

Diagnosis Procedure .............................................159

REMOVAL AND INSTALLATION ..............161

FRONT AIR CONTROL .................................. .161

Removal and Installation ..................................... ..161

IN-VEHICLE SENSOR ......................................162

Removal and Installation .......................................162

REFRIGERANT PRESSURE SENSOR ......... ..163

Removal and Installation .......................................163

DOOR MOTOR ............................................... ..164

Exploded View ..................................................... .164

INTAKE DOOR MOTOR ........................................ .165

INTAKE DOOR MOTOR : Removal and Installa-

tion ....................................................................... .

165

MODE DOOR MOTOR ........................................... .165

MODE DOOR MOTOR : Removal and Installation .165

AIR MIX DOOR MOTOR ........................................ .165

AIR MIX DOOR MOTOR : Removal and Installa-

tion ....................................................................... .

165

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 2665 of 4801

![NISSAN TEANA 2014 Service Manual

HAC-16

< SYSTEM DESCRIPTION >[AUTOMATIC AIR CONDITIONER]

SYSTEM

Air Outlet Control

INFOID:0000000009463097

• While air outlet is in automatic control, A/C auto amp. selects the mode door position d NISSAN TEANA 2014 Service Manual

HAC-16

< SYSTEM DESCRIPTION >[AUTOMATIC AIR CONDITIONER]

SYSTEM

Air Outlet Control

INFOID:0000000009463097

• While air outlet is in automatic control, A/C auto amp. selects the mode door position d](/img/5/57390/w960_57390-2664.png)

HAC-16

< SYSTEM DESCRIPTION >[AUTOMATIC AIR CONDITIONER]

SYSTEM

Air Outlet Control

INFOID:0000000009463097

• While air outlet is in automatic control, A/C auto amp. selects the mode door position depending on a target air mix door angle and

outlet air temperature calculated from sunload.

• If ambient temperature is excessively low, D/F is selected to pre- vent windshield fogging when air outlet is set to FOOT.

Compressor ControlINFOID:0000000009463098

DESCRIPTION

• When the compressor activation condition is satisfied whil e blower motor is activated, A/C auto amp. trans-

mits A/C ON signal and blower fan ON signal to ECM via CAN communication.

• ECM judges that the compressor can be activated depending on the state of each sensor (refrigerant pres-

sure sensor signal and others) and transmits A/C comp ressor request signal to IPDM E/R via CAN commu-

nication.

• IPDM E/R turns A/C relay ON and activate s the compressor depending on request from ECM.

COMPRESSOR PROTECTION CONTROL AT PRESSURE MALFUNCTION

When high-pressure side value that is detected by refrigerant pressure sensor is as per the following state,

ECM requests IPDM E/R to turn A/C relay OFF and stops the compressor.

• 3.12 MPa (31.82 kg/cm

2, 452.4 psi) or more (When the engine speed is less than 1,500 rpm)

• 2.74 MPa (27.95 kg/cm

2, 397.3 psi) or more (When the engine speed is 1,500 rpm or more)

• 0.14 MPa (1.43 kg/cm

2, 20.3 psi) or less

COMPRESSOR OIL CIRCULATION CONTROL

When the engine starts while the engine coolant temperature is 56 °C (133 °F) or less, ECM activates the com-

pressor for approximately 6 seconds and circulates the compressor lubricant once.

LOW TEMPERATURE PROTECTION CONTROL

• When intake sensor detects that front evaporator fin temperature is 2.5 °C (37 °F) or less, A/C auto amp. requests ECM to turn com-

pressor OFF, and stops the compressor.

• When the front evaporator fin temperature returns to 5.0 °C (41 °F)

or more, the compressor is activated.

OPERATING RATE CONTROL

When set temperature is other than fully cold or air out let is “VENT”, “B/L” or “FOOT” A/C auto amp. controls

the compressor activation depending on ambient temperature.

AIR CONDITIONING CUT CONTROL

When set engine is running is excessively high load conditi on, ECM requests IPDM E/R to turn A/C relay OFF,

and stops the compressor. Refer to EC-56, "AIR CONDITIONING CUT CONT ROL : System Description (with

automatic air conditioner)" (QR25DE) or EC-573, "AIR CONDITIONING CUT CONTROL : System Descrip-

tion" (VQ35DE) for details.

JMIIA0730GB

JMIIA0742GB

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM