battery NISSAN TEANA 2014 Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2014, Model line: TEANA, Model: NISSAN TEANA 2014Pages: 4801, PDF Size: 51.2 MB

Page 2835 of 4801

![NISSAN TEANA 2014 Service Manual

INL-14

< SYSTEM DESCRIPTION >

DIAGNOSIS SYSTEM (BCM)

SELF DIAGNOSTIC RESULT

Refer to BCS-52, "DTC Index".

DATA MONITOR

Monitor Item [Unit] Main Description

REQ SW -DR [On/Off] ×Indicates condition o NISSAN TEANA 2014 Service Manual

INL-14

< SYSTEM DESCRIPTION >

DIAGNOSIS SYSTEM (BCM)

SELF DIAGNOSTIC RESULT

Refer to BCS-52, "DTC Index".

DATA MONITOR

Monitor Item [Unit] Main Description

REQ SW -DR [On/Off] ×Indicates condition o](/img/5/57390/w960_57390-2834.png)

INL-14

< SYSTEM DESCRIPTION >

DIAGNOSIS SYSTEM (BCM)

SELF DIAGNOSTIC RESULT

Refer to BCS-52, "DTC Index".

DATA MONITOR

Monitor Item [Unit] Main Description

REQ SW -DR [On/Off] ×Indicates condition of door request switch LH.

REQ SW -AS [On/Off] ×Indicates condition of door request switch RH.

REQ SW -BD/TR [On/Off] ×Indicates condition of trunk opener request switch.

PUSH SW [On/Off] Indicates condition of push-button ignition switch.

SHFTLCK SLNID PER SPLY [On/Off] ×Indicates condition of power supply to shiftlock solenoid.

BRAKE SW 1 [On/Off] ×Indicates condition of brake switch.

BRAKE SW 2 [On/Off] Indicates condition of brake switch.

DETE/CANCL SW [On/Off] ×Indicates condition of P (park) position.

SFT PN/N SW [On/Off] ×Indicates condition of P (park) or N (neutral) position.

UNLK SEN -DR [On/Off] ×Indicates condition of door unlock sensor.

PUSH SW -IPDM [On/Off] Indicates condition of push-button ignition switch received from IPDM E/R

on CAN communication line.

IGN RLY1 -F/B [On/Off] Indicates condition of ignition relay 1 received from IPDM E/R on CAN

communication line.

DETE SW -IPDM [On/Off] Indicates condition of detent switch received from TCM on CAN communi-

cation line.

SFT PN -IPDM [On/Off] Indicates condition of P (park) or N (neutral) position from TCM on CAN

communication line.

SFT P -MET [On/Off] Indicates condition of P (park) position from TCM on CAN communication

line.

SFT N -MET [On/Off] Indicates condition of N (neutral) position from IPDM E/R on CAN commu-

nication line.

ENGINE STATE [STOP/START/CRANK/RUN] ×Indicates condition of engine state from ECM on CAN communication line.

VEH SPEED 1 [mph/km/h] ×Indicates condition of vehicle speed signal received from ABS on CAN

communication line.

VEH SPEED 2 [mph/km/h] ×Indicates condition of vehicle speed signal received from combination

meter on CAN communication line.

DOOR STAT -DR [LOCK/READY/UNLK] ×Indicates condition of driver side door status.

DOOR STAT -AS [LOCK/READY/UNLK] ×Indicates condition of passenger side door status.

DOOR STAT -RR [LOCK/READY/UNLK] ×Indicates condition of rear right side door status.

DOOR STAT -RL [LOCK/READY/UNLK] ×Indicates condition of rear left side door status.

ID OK FLAG [Set/Reset] Indicates condition of Intelligent Key ID.

PRMT ENG STRT [Set/Reset] Indicates condition of engine start possibility.

PRMT RKE STRT [Set/Reset] Indicates condition of engine start possibility from Intelligent Key.

I-KEY OK FLAG [Key ON/Key OFF] ×Indicates condition of Intelligent Key OK flag.

PRBT ENG STRT [Set/Reset] Indicates condition of engine start prohibit.

ID AUTHENT CANCEL TIMER [STOP] Indicates condition of Intelligent Key ID authentication.

ACC BATTERY SAVER [STOP] Indicate s condition of battery saver.

CRNK PRBT TMR [On/Off] Indicates co ndition of crank prohibit timer.

AUT CRNK TMR [On/Off] Indicates co ndition of automatic engine crank timer fr om Intelligent Key.

CRNK PRBT TME [sec] Indicat es condition of engine crank prohibit time.

AUTO CRNK TME [sec] Indicates co ndition of automatic engine crank time from Intelligent Key.

CRANKING TME [sec] Indicates condition of engine cranking time from Intelligent Key.

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 2836 of 4801

![NISSAN TEANA 2014 Service Manual

DIAGNOSIS SYSTEM (BCM)INL-15

< SYSTEM DESCRIPTION >

C

D E

F

G H

I

J

K

M A

B

INL

N

O P

ACTIVE TEST

WORK SUPPORT

DETE SW PWR [On/Off] Indicates condition of detent switch voltage.

ACC RLY -REQ [On/ NISSAN TEANA 2014 Service Manual

DIAGNOSIS SYSTEM (BCM)INL-15

< SYSTEM DESCRIPTION >

C

D E

F

G H

I

J

K

M A

B

INL

N

O P

ACTIVE TEST

WORK SUPPORT

DETE SW PWR [On/Off] Indicates condition of detent switch voltage.

ACC RLY -REQ [On/](/img/5/57390/w960_57390-2835.png)

DIAGNOSIS SYSTEM (BCM)INL-15

< SYSTEM DESCRIPTION >

C

D E

F

G H

I

J

K

M A

B

INL

N

O P

ACTIVE TEST

WORK SUPPORT

DETE SW PWR [On/Off] Indicates condition of detent switch voltage.

ACC RLY -REQ [On/Off] Indicates condition of accessory relay control request.

RKE OPE COUN1 [0-19] ×When remote keyless entry receiver receives the signal transmitted while

operating on Intelligent Key, the numerical value start changing.

RKE OPE COUN2 [0-19] ×When remote keyless entry receiver receives the signal transmitted while

operating on Intelligent Key, the numerical value start changing.

TRNK/HAT MNTR [On/Off] Indicates condition of trunk room lamp switch.

RKE-LOCK [On/Off] Indicates condition of lock signal from Intelligent Key.

RKE-UNLOCK [On/Off] Indicates condition of unlock signal from Intelligent Key.

RKE-TR/BD [On/Off] Indicates condition of trunk open signal from Intelligent Key.

RKE-PANIC [On/Off] Indicates condition of panic signal from Intelligent Key.

RKE-MODE CHG [On/Off] Indicates condition of mode change signal from Intelligent Key. Monitor Item [Unit] Main Description

Test Item Description

INTELLIGENT KEY LINK (CAN) This test is able to check Intelligent Key iden

tification number [Off/ID No1/ID N02/ID No3/ID

No4/ID No5].

INT LAMP This test is able to check interior room lamp operation [On/Off].

FLASHER This test is able to check hazard lamp operation [LH/RH/Off].

HORN This test is able to check horn operation [On].

BATTERY SAVER This test is able to check battery saver operation [On/Off].

TRUNK/BACK DOOR This test is able to check trunk actuator operation [Open].

OUTSIDE BUZZER This test is able to check In telligent Key warning buzzer operation [On/Off].

INSIDE BUZZER This test is able to check combination meter warning chime operation [Take Out/Knob/Key/

Off].

INDICATOR This test is able to check combination meter warning lamp operation [KEY ON/KEY IND/Off].

IGN CONT2 This test is able to check ignition relay-2 control operation [On/Off].

ENGINE SW ILLUMI This test is able to check push-bu tton ignition switch START indicator operation [On/Off].

PUSH SWITCH INDICATOR This test is able to check push-button ignition switch indicator operation [On/Off].

ACC CONT This test is able to check ac cessory relay control operation [On/Off].

IGN CONT1 This test is able to check ignition relay-1 control operation [On/Off].

ST CONT LOW This test is able to check starter control relay operation [On/Off].

IGNITION RELAY This test is able to ignition relay operation [On/Off].

REVERSE LAMP TEST This test is able to check reverse lamp illuminatio n operation [On/Off].

TRUNK/LUGGAGE LAMP TEST This test is able to check cargo lamp illumination operation [On/Off].

KEYFOB PW TEST This test is able to check power window operation using the Inte lligent Key [Off/DOWN/UP].

SHIFTLOCK SOLENOID TEST This te st is able to check shift lock solenoid operation [On/Off].

Support Item Setting Description

IGN/ACC BATTERY SAVER On* Battery saver function ON.

Off Battery saver function OFF.

REMOTE ENGINE STARTER On* Remote engine start function ON.

Off Remote engine start function OFF.

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 2839 of 4801

INL-18

< SYSTEM DESCRIPTION >

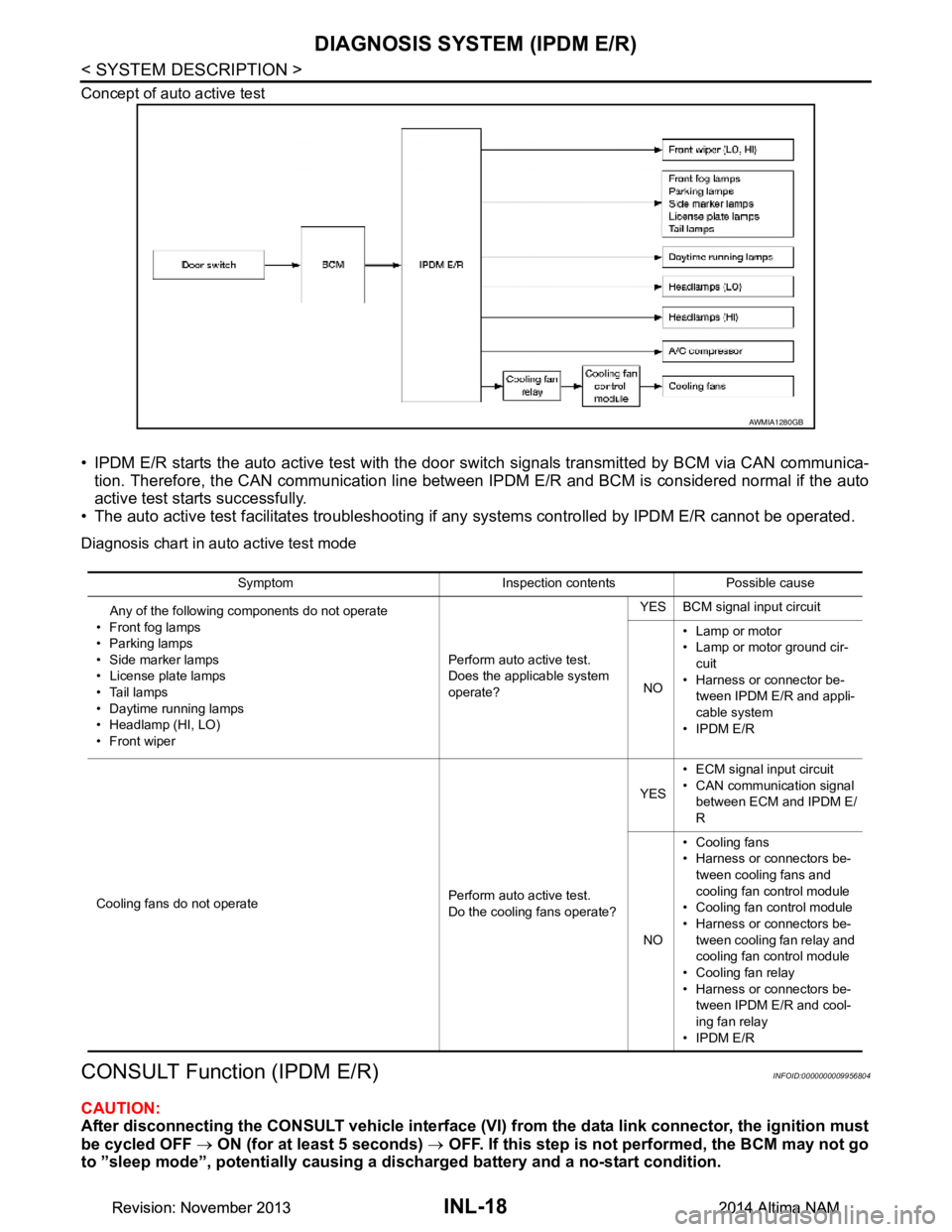

DIAGNOSIS SYSTEM (IPDM E/R)

Concept of auto active test

• IPDM E/R starts the auto active test with the door switch signals transmitted by BCM via CAN communica-

tion. Therefore, the CAN communication line between IPDM E/R and BCM is considered normal if the auto

active test starts successfully.

• The auto active test facilitates troubleshooting if any systems controlled by IPDM E/R cannot be operated.

Diagnosis chart in auto active test mode

CONSULT Function (IPDM E/R)INFOID:0000000009956804

CAUTION:

After disconnecting the CONSULT vehicle interface (VI) from the data link connector, the ignition must

be cycled OFF → ON (for at least 5 seconds) → OFF. If this step is not performed, the BCM may not go

to ”sleep mode”, potentially causing a di scharged battery and a no-start condition.

AWMIA1280GB

Symptom Inspection contents Possible cause

Any of the following components do not operate

•Front fog lamps

• Parking lamps

• Side marker lamps

• License plate lamps

•Tail lamps

• Daytime running lamps

• Headlamp (HI, LO)

• Front wiper Perform auto active test.

Does the applicable system

operate? YES BCM signal input circuit

NO • Lamp or motor

• Lamp or motor ground cir-

cuit

• Harness or connector be- tween IPDM E/R and appli-

cable system

•IPDM E/R

Cooling fans do not operate Perform auto active test.

Do the cooling fans operate? YES

• ECM signal input circuit

• CAN communication signal between ECM and IPDM E/

R

NO • Cooling fans

• Harness or connectors be-

tween cooling fans and

cooling fan control module

• Cooling fan control module

• Harness or connectors be- tween cooling fan relay and

cooling fan control module

• Cooling fan relay

• Harness or connectors be- tween IPDM E/R and cool-

ing fan relay

•IPDM E/R

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 2871 of 4801

INL-50

< DTC/CIRCUIT DIAGNOSIS >

POWER SUPPLY AND GROUND CIRCUIT

DTC/CIRCUIT DIAGNOSIS

POWER SUPPLY AND GROUND CIRCUIT

BCM

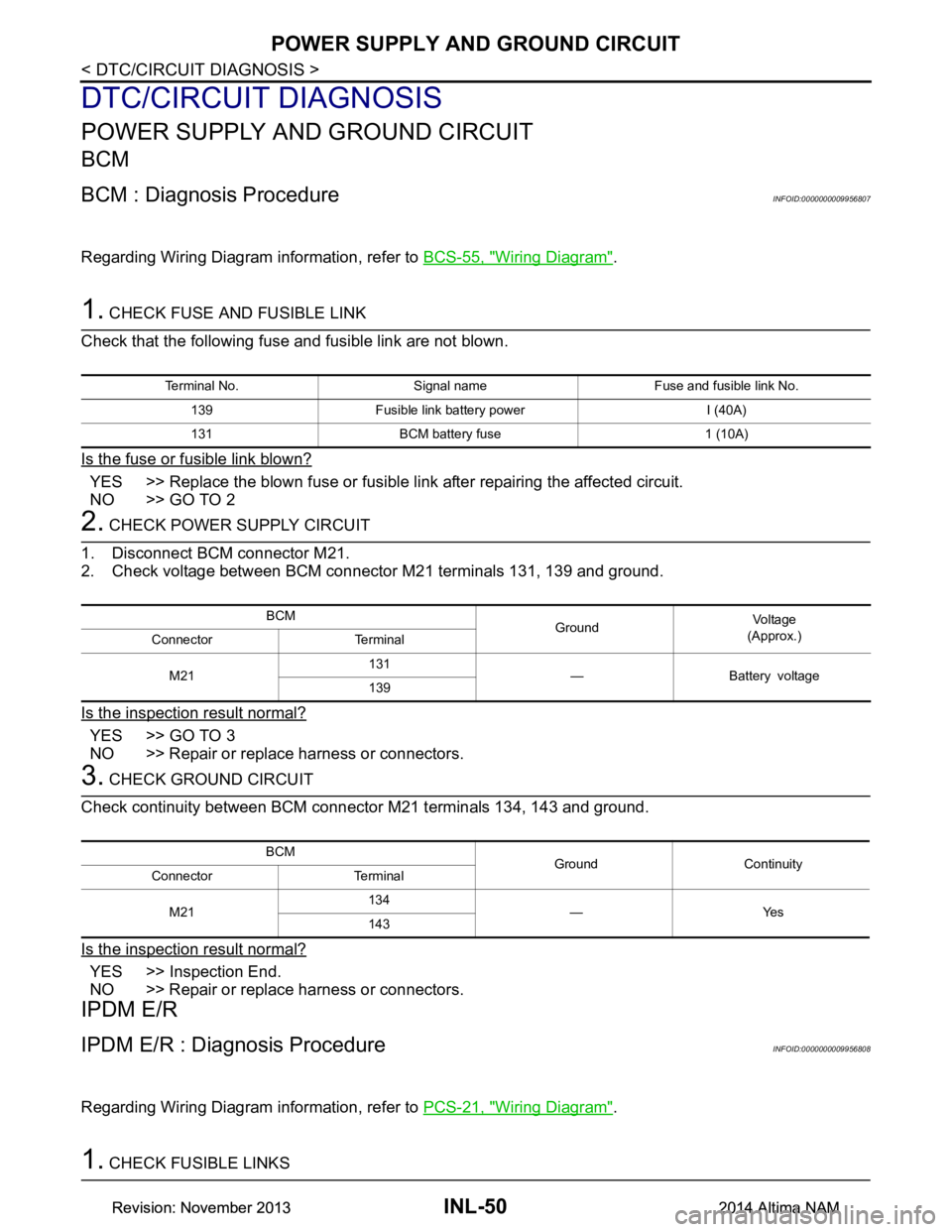

BCM : Diagnosis ProcedureINFOID:0000000009956807

Regarding Wiring Diagram information, refer to BCS-55, "Wiring Diagram".

1. CHECK FUSE AND FUSIBLE LINK

Check that the following fuse and fusible link are not blown.

Is the fuse or fusible link blown?

YES >> Replace the blown fuse or fusible link after repairing the affected circuit.

NO >> GO TO 2

2. CHECK POWER SUPPLY CIRCUIT

1. Disconnect BCM connector M21.

2. Check voltage between BCM connector M21 terminals 131, 139 and ground.

Is the inspection result normal?

YES >> GO TO 3

NO >> Repair or replace harness or connectors.

3. CHECK GROUND CIRCUIT

Check continuity between BCM connector M21 terminals 134, 143 and ground.

Is the inspection result normal?

YES >> Inspection End.

NO >> Repair or replace harness or connectors.

IPDM E/R

IPDM E/R : Diagnosis ProcedureINFOID:0000000009956808

Regarding Wiring Diagram information, refer to PCS-21, "Wiring Diagram".

1. CHECK FUSIBLE LINKS

Terminal No. Signal name Fuse and fusible link No.

139 Fusible link battery power I (40A)

131 BCM battery fuse 1 (10A)

BCM GroundVo l ta g e

(Approx.)

Connector Terminal

M21 131

— Battery voltage

139

BCM Ground Continuity

Connector Terminal

M21 134

—Yes

143

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 2872 of 4801

POWER SUPPLY AND GROUND CIRCUITINL-51

< DTC/CIRCUIT DIAGNOSIS >

C

D E

F

G H

I

J

K

M A

B

INL

N

O P

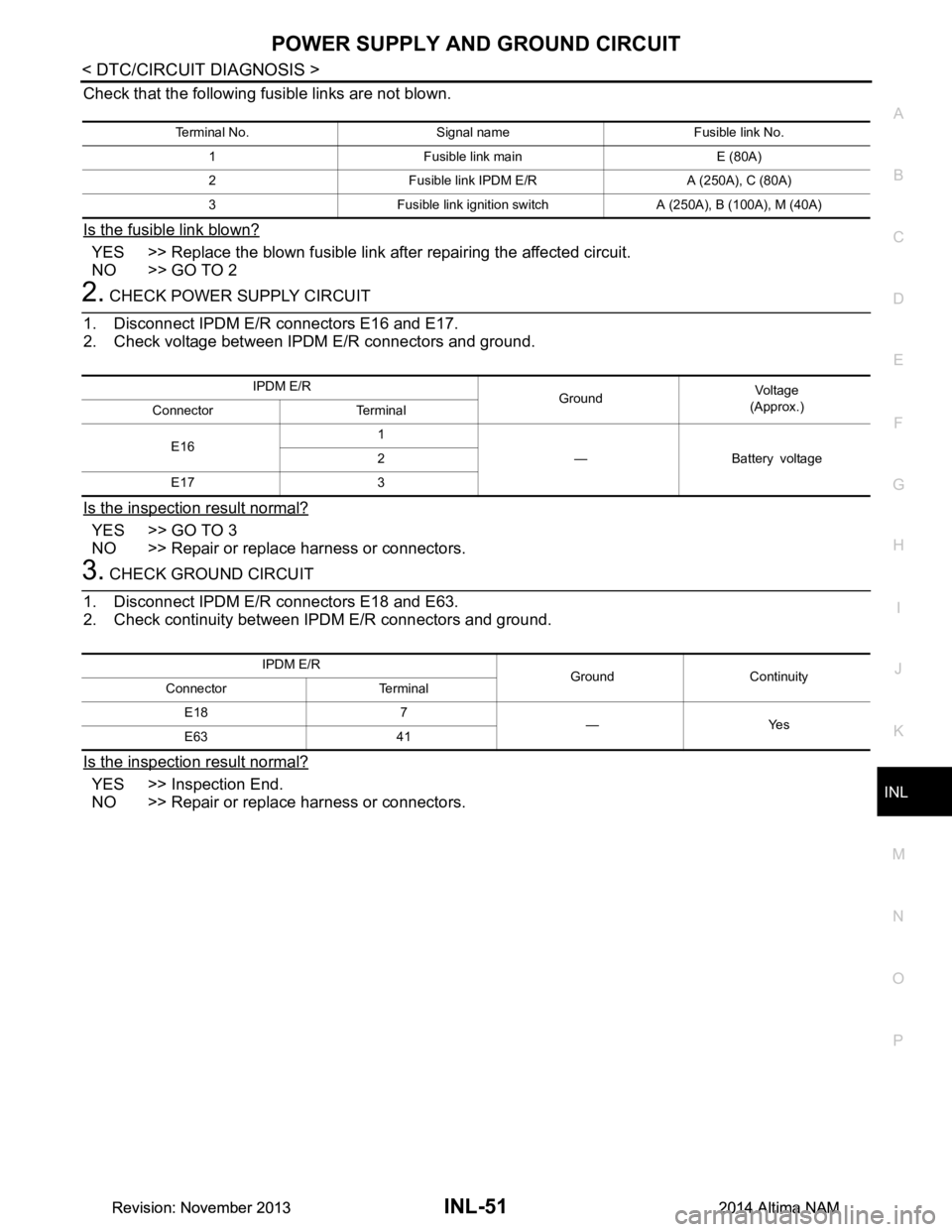

Check that the following fusible links are not blown.

Is the fusible link blown?

YES >> Replace the blown fusible link after repairing the affected circuit.

NO >> GO TO 2

2. CHECK POWER SUPPLY CIRCUIT

1. Disconnect IPDM E/R connectors E16 and E17.

2. Check voltage between IPDM E/R connectors and ground.

Is the inspection result normal?

YES >> GO TO 3

NO >> Repair or replace harness or connectors.

3. CHECK GROUND CIRCUIT

1. Disconnect IPDM E/R connectors E18 and E63.

2. Check continuity between IPDM E/R connectors and ground.

Is the inspection result normal?

YES >> Inspection End.

NO >> Repair or replace harness or connectors.

Terminal No. Signal name Fusible link No.

1 Fusible link main E (80A)

2 Fusible link IPDM E/R A (250A), C (80A)

3 Fusible link ignition switch A (250A), B (100A), M (40A)

IPDM E/R GroundVol tag e

(Approx.)

Connector Terminal

E16 1

— Battery voltage

2

E17 3

IPDM E/R Ground Continuity

Connector Terminal

E18 7 —Yes

E63 41

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 2873 of 4801

INL-52

< DTC/CIRCUIT DIAGNOSIS >

BATTERY SAVER OUTPUT/POWER SUPPLY CIRCUIT

BATTERY SAVER OUTPUT/POWER SUPPLY CIRCUIT

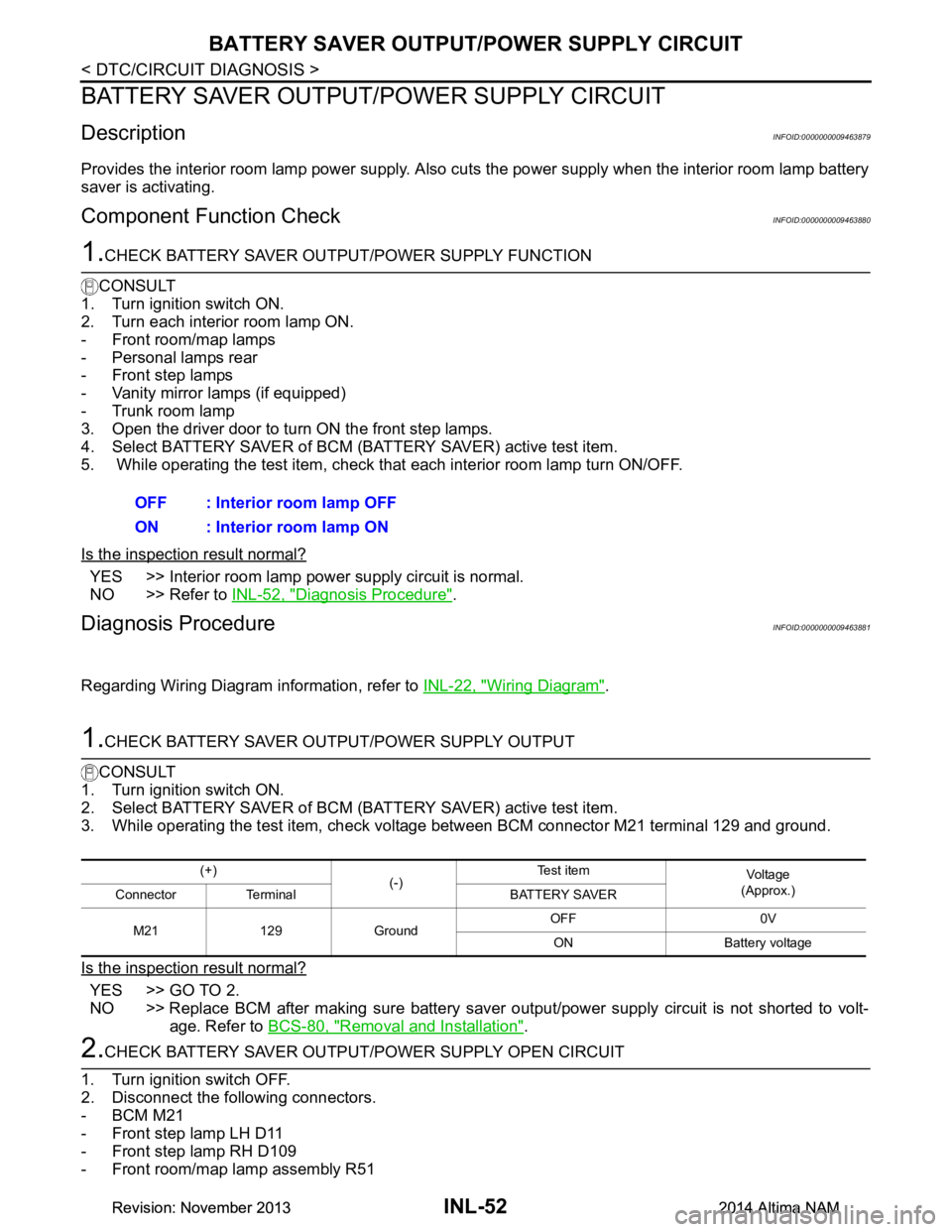

DescriptionINFOID:0000000009463879

Provides the interior room lamp power supply. Also cuts the power supply when the interior room lamp battery

saver is activating.

Component Function CheckINFOID:0000000009463880

1.CHECK BATTERY SAVER OUTPUT /POWER SUPPLY FUNCTION

CONSULT

1. Turn ignition switch ON.

2. Turn each interior room lamp ON.

- Front room/map lamps

- Personal lamps rear

- Front step lamps

- Vanity mirror lamps (if equipped)

- Trunk room lamp

3. Open the driver door to turn ON the front step lamps.

4. Select BATTERY SAVER of BCM (BATTERY SAVER) active test item.

5. While operating the test item, check that each interior room lamp turn ON/OFF.

Is the inspection result normal?

YES >> Interior room lamp power supply circuit is normal.

NO >> Refer to INL-52, "Diagnosis Procedure"

.

Diagnosis ProcedureINFOID:0000000009463881

Regarding Wiring Diagram information, refer to INL-22, "Wiring Diagram".

1.CHECK BATTERY SAVER OUTPUT/POWER SUPPLY OUTPUT

CONSULT

1. Turn ignition switch ON.

2. Select BATTERY SAVER of BCM (BATTERY SAVER) active test item.

3. While operating the test item, check voltage between BCM connector M21 terminal 129 and ground.

Is the inspection result normal?

YES >> GO TO 2.

NO >> Replace BCM after making sure battery saver out put/power supply circuit is not shorted to volt-

age. Refer to BCS-80, "Removal and Installation"

.

2.CHECK BATTERY SAVER OUTPUT/P OWER SUPPLY OPEN CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect the following connectors.

-BCM M21

- Front step lamp LH D11

- Front step lamp RH D109

- Front room/map lamp assembly R51 OFF : Interior room lamp OFF

ON : Interior room lamp ON

(+) (-)Te s t i t e m

Vo l ta g e

(Approx.)

Connector Terminal BATTERY SAVER

M21 129 Ground OFF 0V

ON Battery voltage

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 2874 of 4801

BATTERY SAVER OUTPUT/POWER SUPPLY CIRCUITINL-53

< DTC/CIRCUIT DIAGNOSIS >

C

D E

F

G H

I

J

K

M A

B

INL

N

O P

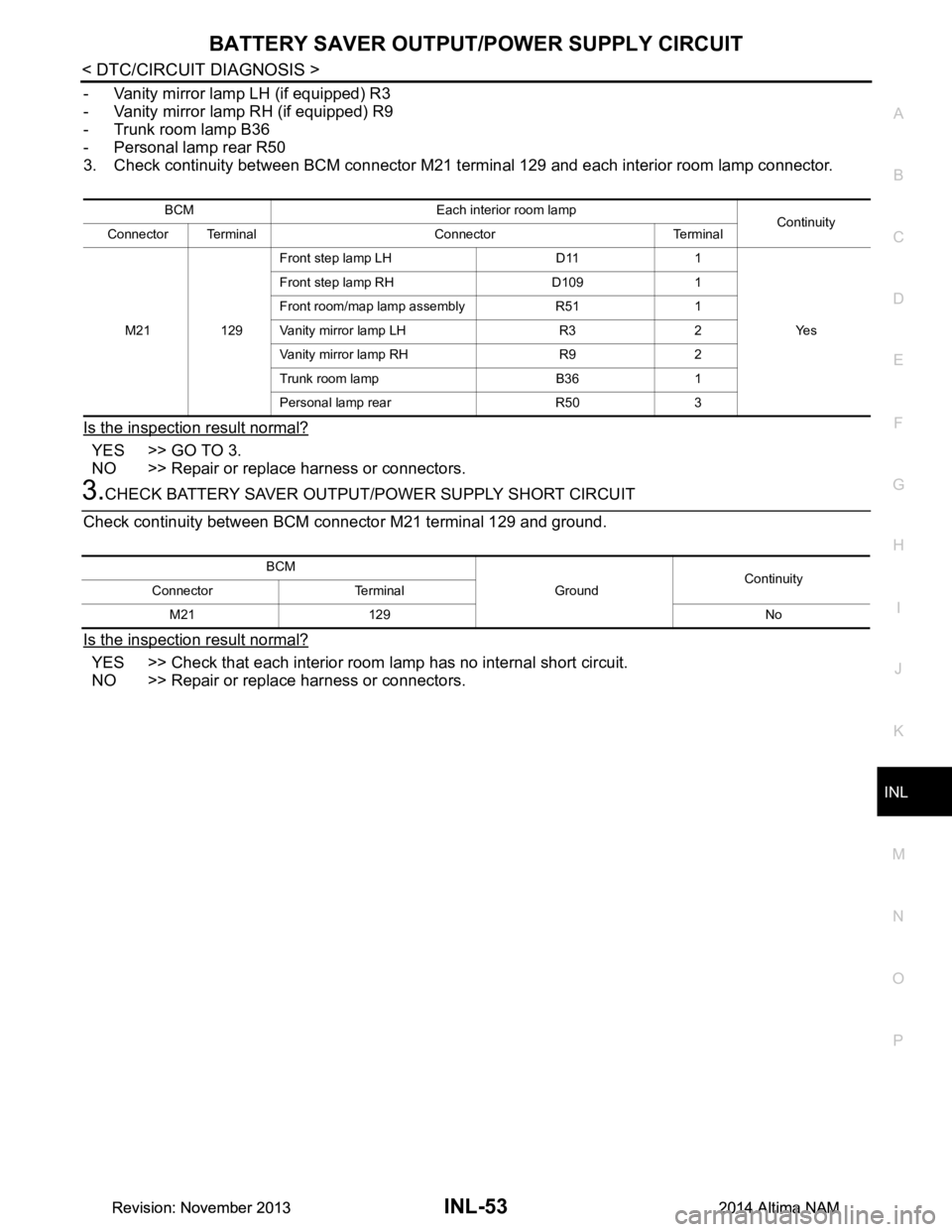

- Vanity mirror lamp LH (if equipped) R3

- Vanity mirror lamp RH (if equipped) R9

- Trunk room lamp B36

- Personal lamp rear R50

3. Check continuity between BCM connector M21 terminal 129 and each interior room lamp connector.

Is the inspection result normal?

YES >> GO TO 3.

NO >> Repair or replace harness or connectors.

3.CHECK BATTERY SAVER OUTPUT/POWER SUPPLY SHORT CIRCUIT

Check continuity between BCM connector M21 terminal 129 and ground.

Is the inspection result normal?

YES >> Check that each interior room lamp has no internal short circuit.

NO >> Repair or replace harness or connectors.

BCM Each interior room lamp Continuity

Connector Terminal Connector Terminal

M21 129 Front step lamp LH D11 1

Ye s

Front step lamp RH D109 1

Front room/map lamp assembly R51 1

Vanity mirror lamp LH R3 2

Vanity mirror lamp RH R9 2

Trunk room lamp B36 1

Personal lamp rear R50 3

BCM GroundContinuity

Connector Terminal

M21 129 No

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 2875 of 4801

INL-54

< DTC/CIRCUIT DIAGNOSIS >

INTERIOR ROOM LAMP CONTROL CIRCUIT

INTERIOR ROOM LAMP CONTROL CIRCUIT

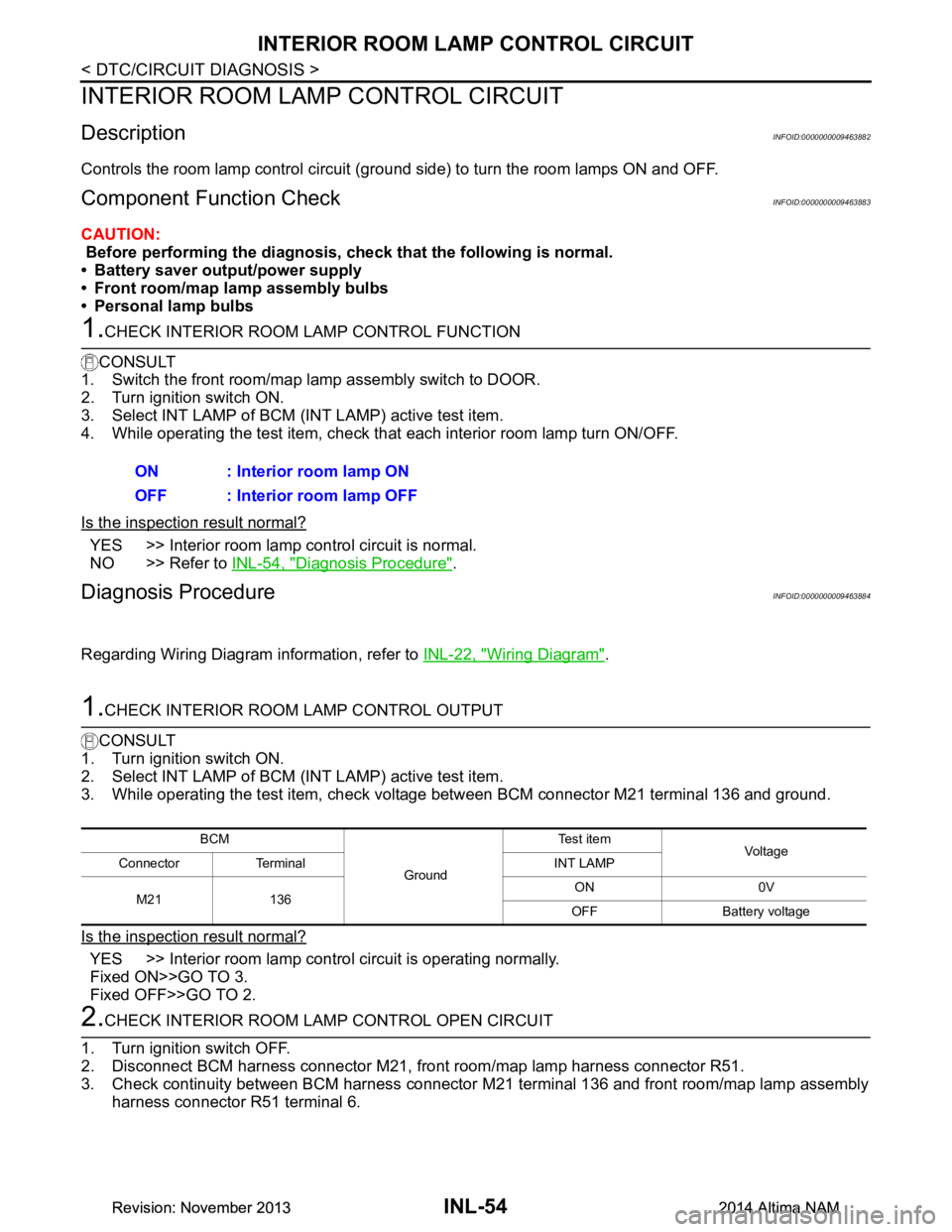

DescriptionINFOID:0000000009463882

Controls the room lamp control circuit (ground side) to turn the room lamps ON and OFF.

Component Function CheckINFOID:0000000009463883

CAUTION:

Before performing the diagnosis, check that the following is normal.

• Battery saver output/power supply

• Front room/map lamp assembly bulbs

• Personal lamp bulbs

1.CHECK INTERIOR ROOM LAMP CONTROL FUNCTION

CONSULT

1. Switch the front room/map lamp assembly switch to DOOR.

2. Turn ignition switch ON.

3. Select INT LAMP of BCM (INT LAMP) active test item.

4. While operating the test item, check that each interior room lamp turn ON/OFF.

Is the inspection result normal?

YES >> Interior room lamp control circuit is normal.

NO >> Refer to INL-54, "Diagnosis Procedure"

.

Diagnosis ProcedureINFOID:0000000009463884

Regarding Wiring Diagram information, refer to INL-22, "Wiring Diagram".

1.CHECK INTERIOR ROOM LAMP CONTROL OUTPUT

CONSULT

1. Turn ignition switch ON.

2. Select INT LAMP of BCM (INT LAMP) active test item.

3. While operating the test item, check voltage between BCM connector M21 terminal 136 and ground.

Is the inspection result normal?

YES >> Interior room lamp control circuit is operating normally.

Fixed ON>>GO TO 3.

Fixed OFF>>GO TO 2.

2.CHECK INTERIOR ROOM LA MP CONTROL OPEN CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect BCM harness connector M21, front room/map lamp harness connector R51.

3. Check continuity between BCM harness connector M21 terminal 136 and front room/map lamp assembly

harness connector R51 terminal 6.ON : Interior room lamp ON

OFF : Interior room lamp OFF

BCM

GroundTe s t i t e m

Voltag e

Connector Terminal INT LAMP

M21 136 ON 0V

OFF Battery voltage

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 2877 of 4801

INL-56

< DTC/CIRCUIT DIAGNOSIS >

STEP LAMP CIRCUIT

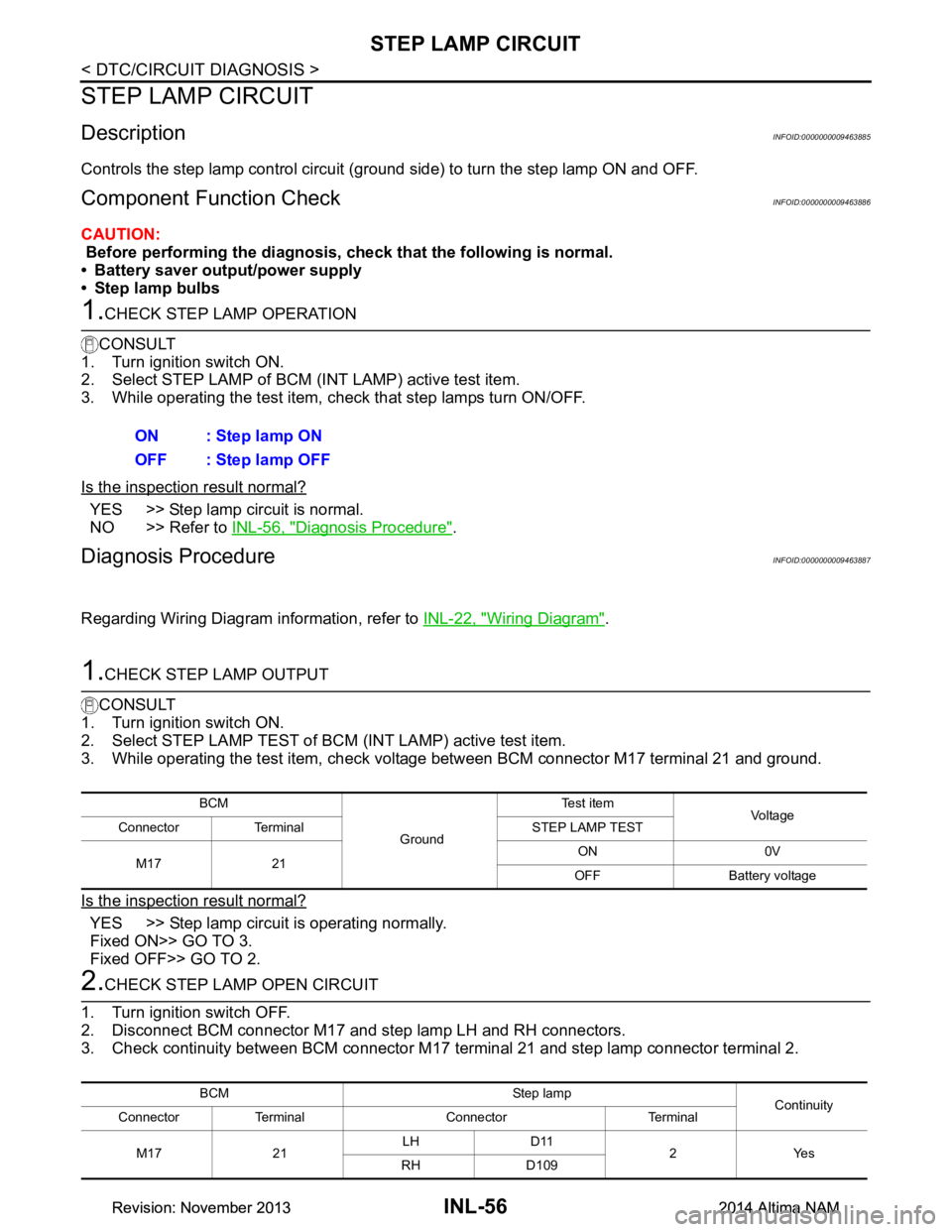

STEP LAMP CIRCUIT

DescriptionINFOID:0000000009463885

Controls the step lamp control circuit (ground side) to turn the step lamp ON and OFF.

Component Function CheckINFOID:0000000009463886

CAUTION:

Before performing the diagnosis, check that the following is normal.

• Battery saver output/power supply

• Step lamp bulbs

1.CHECK STEP LAMP OPERATION

CONSULT

1. Turn ignition switch ON.

2. Select STEP LAMP of BCM (I NT LAMP) active test item.

3. While operating the test item, c heck that step lamps turn ON/OFF.

Is the inspection result normal?

YES >> Step lamp circuit is normal.

NO >> Refer to INL-56, "Diagnosis Procedure"

.

Diagnosis ProcedureINFOID:0000000009463887

Regarding Wiring Diagram information, refer to INL-22, "Wiring Diagram".

1.CHECK STEP LAMP OUTPUT

CONSULT

1. Turn ignition switch ON.

2. Select STEP LAMP TEST of BC M (INT LAMP) active test item.

3. While operating the test item, check voltage between BCM connector M17 terminal 21 and ground.

Is the inspection result normal?

YES >> Step lamp circuit is operating normally.

Fixed ON>> GO TO 3.

Fixed OFF>> GO TO 2.

2.CHECK STEP LAMP OPEN CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect BCM connector M17 and step lamp LH and RH connectors.

3. Check continuity between BCM connector M17 terminal 21 and step lamp connector terminal 2.

ON : Step lamp ON

OFF : Step lamp OFF

BCM

GroundTe s t i t e m

Vo l ta g e

Connector Terminal STEP LAMP TEST

M17 21 ON 0V

OFF Battery voltage

BCM Step lamp Continuity

Connector Terminal Connector Terminal

M17 21 LH D11

2Yes

RH D109

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 2879 of 4801

INL-58

< DTC/CIRCUIT DIAGNOSIS >

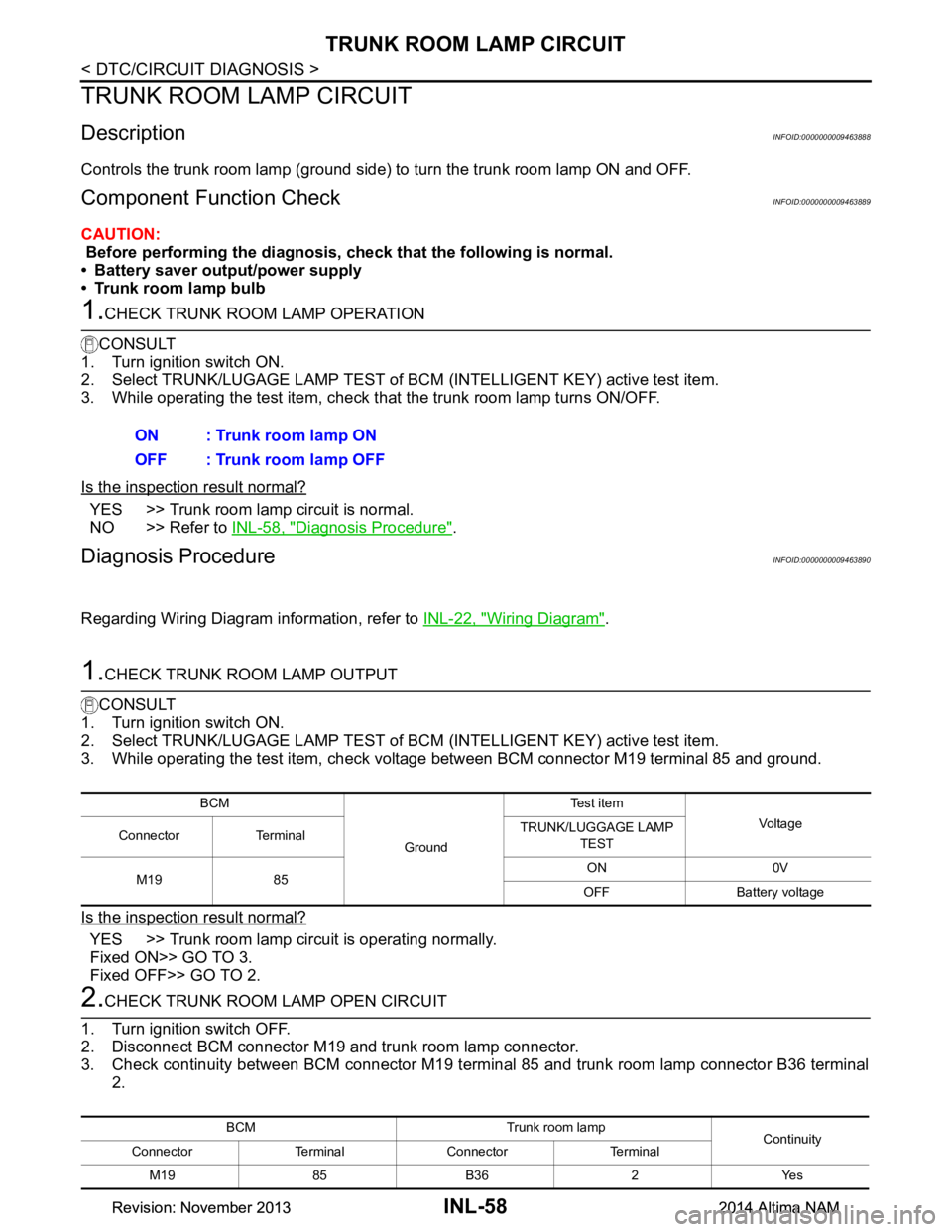

TRUNK ROOM LAMP CIRCUIT

TRUNK ROOM LAMP CIRCUIT

DescriptionINFOID:0000000009463888

Controls the trunk room lamp (ground side) to turn the trunk room lamp ON and OFF.

Component Function CheckINFOID:0000000009463889

CAUTION:

Before performing the diagnosis, check that the following is normal.

• Battery saver output/power supply

• Trunk room lamp bulb

1.CHECK TRUNK ROOM LAMP OPERATION

CONSULT

1. Turn ignition switch ON.

2. Select TRUNK/LUGAGE LAMP TEST of BC M (INTELLIGENT KEY) active test item.

3. While operating the test item, check t hat the trunk room lamp turns ON/OFF.

Is the inspection result normal?

YES >> Trunk room lamp circuit is normal.

NO >> Refer to INL-58, "Diagnosis Procedure"

.

Diagnosis ProcedureINFOID:0000000009463890

Regarding Wiring Diagram information, refer to INL-22, "Wiring Diagram".

1.CHECK TRUNK ROOM LAMP OUTPUT

CONSULT

1. Turn ignition switch ON.

2. Select TRUNK/LUGAGE LAMP TEST of BC M (INTELLIGENT KEY) active test item.

3. While operating the test item, check voltage between BCM connector M19 terminal 85 and ground.

Is the inspection result normal?

YES >> Trunk room lamp circuit is operating normally.

Fixed ON>> GO TO 3.

Fixed OFF>> GO TO 2.

2.CHECK TRUNK ROOM LAMP OPEN CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect BCM connector M19 and trunk room lamp connector.

3. Check continuity between BCM connector M19 terminal 85 and trunk room lamp connector B36 terminal 2.ON : Trunk room lamp ON

OFF : Trunk room lamp OFF

BCM

GroundTe s t i t e m

Vol tag e

Connector Terminal TRUNK/LUGGAGE LAMP

TEST

M19 85 ON 0V

OFF Battery voltage

BCM Trunk room lamp Continuity

Connector Terminal Connector Terminal

M19 85 B36 2 Yes

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM