sensor NISSAN TEANA 2014 Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2014, Model line: TEANA, Model: NISSAN TEANA 2014Pages: 4801, PDF Size: 51.2 MB

Page 3210 of 4801

MA-26

< PERIODIC MAINTENANCE >

ENGINE MAINTENANCE (VQ35DE)

AIR CLEANER FILTER : Removal and Installation

INFOID:0000000009464558

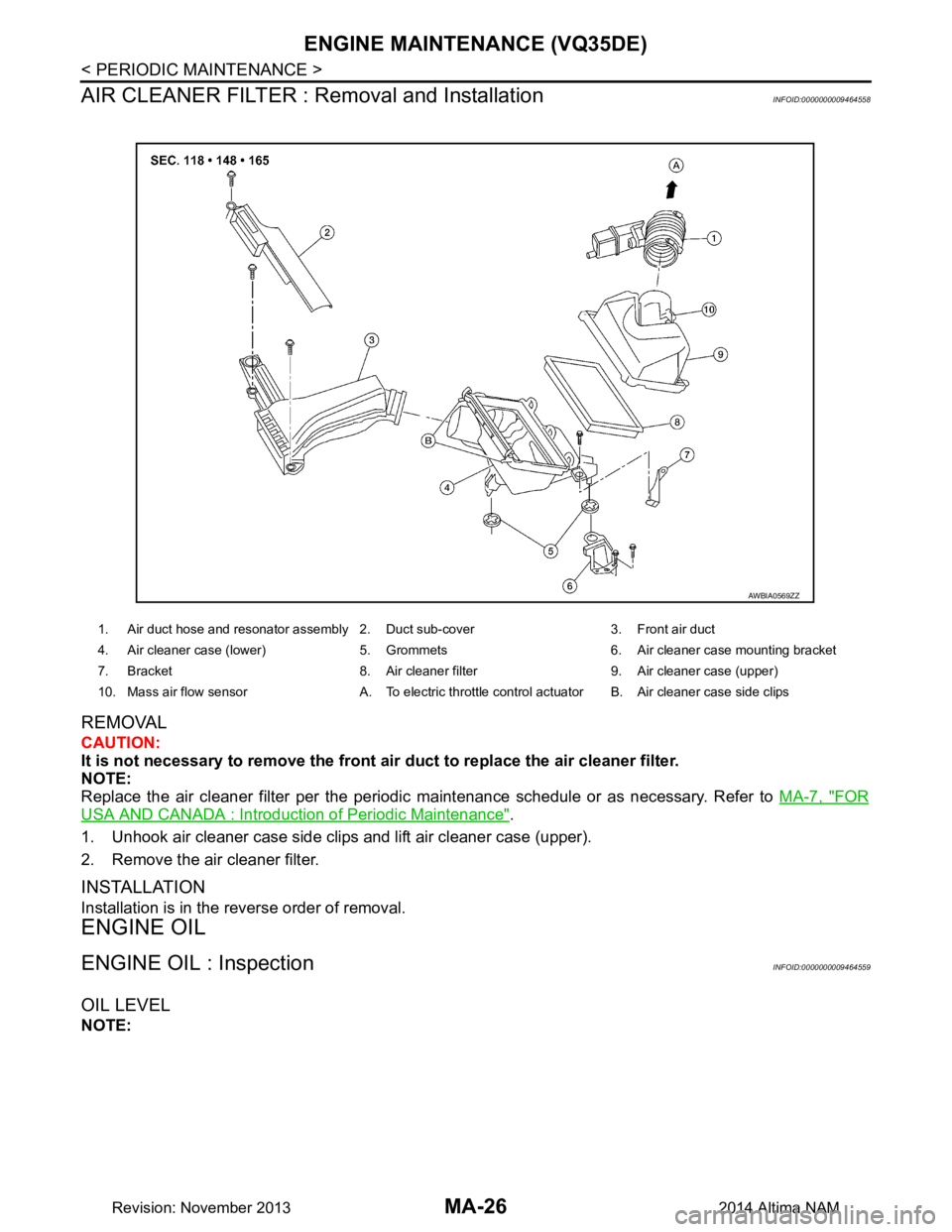

REMOVAL

CAUTION:

It is not necessary to remove the front air duct to replace the air cleaner filter.

NOTE:

Replace the air cleaner filter per the periodic maintenance schedule or as necessary. Refer to MA-7, "FOR

USA AND CANADA : Introduction of Periodic Maintenance".

1. Unhook air cleaner case side clips and lift air cleaner case (upper).

2. Remove the air cleaner filter.

INSTALLATION

Installation is in the reverse order of removal.

ENGINE OIL

ENGINE OIL : InspectionINFOID:0000000009464559

OIL LEVEL

NOTE:

1. Air duct hose and resonator assembly 2. Duct sub-cover 3. Front air duct

4. Air cleaner case (lower) 5. Grommets 6. Air cleaner case mounting bracket

7. Bracket 8. Air cleaner filter 9. Air cleaner case (upper)

10. Mass air flow sensor A. To electric throttle control actuator B. Air cleaner case side clips

AWBIA0569ZZ

Revision: November 20132014 Altima NAM

Page 3232 of 4801

MIR-2

< PRECAUTION >

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000009951574

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severi ty of injury to the driver and front passenger for certain

types of collision. Information necessary to service the system safely is included in the SR and SB section of

this Service Manual.

WARNING:

• To avoid rendering the SRS inopera tive, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISS AN/INFINITI dealer.

• Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintent ional activation of the system. For re moval of Spiral Cable and Air Bag

Module, see the SR section.

• Do not use electrical test equipmen t on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harn esses can be identified by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Unit or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or electri c power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers , always switch the Ignition OFF, disconnect the

battery and wait at least three minutes before performing any service.

Precaution for WorkINFOID:0000000009463520

• When removing or disassembling each component, be careful not to damage or deform it. If a component may be subject to interference, be sure to protect it with a shop cloth.

• When removing (disengaging) components with a screwdriver or similar tool, be sure to wrap the component with a shop cloth or vinyl tape to protect it.

• Protect the removed parts with a s hop cloth and prevent them from being dropped.

• Replace a deformed or damaged clip.

• If a part is specified as a non-reusable part, always replace it with a new one.

• Be sure to tighten bolts and nuts securely to the specified torque.

• After installation is complete, be sure to check that each part works properly.

• Follow the steps below to clean components:

- Water soluble dirt:

• Dip a soft cloth into lukewarm water, wring the water out of the cloth and wipe the dirty area.

• Then rub with a soft, dry cloth.

- Oily dirt:

• Dip a soft cloth into lukewarm water with mild detergent (concentration: within 2 to 3%) and wipe the dirty area.

• Then dip a cloth into fresh water, wring the water out of the cloth and wipe the detergent off.

• Then rub with a soft, dry cloth.

- Do not use organic solvent such as thinner, benzene, alcohol or gasoline.

- For genuine leather seats, use a genuine leather seat cleaner.

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 3257 of 4801

MWI-2

Wiring Diagram .......................................................30

METER ...............................................................32

Wiring Diagram .................................................... ...32

BASIC INSPECTION ...................................51

DIAGNOSIS AND REPAIR WORKFLOW ...... ...51

Work flow ............................................................. ...51

DTC/CIRCUIT DIAGNOSIS ...................... ...53

U1000 CAN COMM CIRCUIT ......................... ...53

DTC Logic ............................................................ ...53

Diagnosis Procedure .............................................53

U1010 CONTROL UNIT (CAN) .........................54

Description ........................................................... ...54

DTC Logic ...............................................................54

Diagnosis Procedure ..............................................54

B2205 VEHICLE SPEED ...................................55

Description ........................................................... ...55

DTC Logic ...............................................................55

Diagnosis Procedure .............................................55

B2267 ENGINE SPEED .....................................56

Description ........................................................... ...56

DTC Logic ...............................................................56

Diagnosis Procedure ..............................................56

B2268 WATER TEMP ........................................57

Description ........................................................... ...57

DTC Logic ...............................................................57

Diagnosis Procedure ..............................................57

POWER SUPPLY AND GROUND CIRCUIT .....58

COMBINATION METER ........................................ ...58

COMBINATION METER : Diagnosis Procedure ....58

BCM (BODY CONTROL MODULE) ...................... ...58

BCM (BODY CONTROL MODULE) : Diagnosis

Procedure ............................................................ ...

58

IPDM E/R (INTELLIGENT POWER DISTRIBU-

TION MODULE ENGINE ROOM) .......................... ...

59

IPDM E/R (INTELLIGENT POWER DISTRIBU-

TION MODULE ENGINE ROOM) : Diagnosis Pro-

cedure .................................................................. ...

59

FUEL LEVEL SENSOR SIGNAL CIRCUIT .......61

Description ........................................................... ...61

Component Function Check ...................................61

Diagnosis Procedure .............................................61

Component Inspection ............................................62

PARKING BRAKE SWITCH SIGNAL CIR-

CUIT ................................................................ ...

63

Description ........................................................... ...63

Component Function Check ...................................63

Diagnosis Procedure ..............................................63

Component Inspection ......................................... ...63

WASHER FLUID LEVEL SWITCH CIRCUIT ....64

Description ........................................................... ...64

Diagnosis Procedure ...............................................64

Component Inspection ............................................64

AMBIENT SENSOR SIGNAL CIRCUIT ............66

Description ........................................................... ...66

Component Function Check ...................................66

Diagnosis Procedure ...............................................66

Component Inspection ............................................67

METER CONTROL SWITCH SIGNAL CIR-

CUIT ................................................................ ...

68

Diagnosis Procedure ............................................ ...68

Component Inspection ............................................69

STEERING SWITCH ..........................................70

Description ........................................................... ...70

Diagnosis Procedure ...............................................70

Component Inspection ............................................70

SYMPTOM DIAGNOSIS ............................72

THE FUEL GAUGE INDICATOR DOES NOT

OPERATE ....................................................... ...

72

Description ........................................................... ...72

Diagnosis Procedure ...............................................72

THE METER CONTROL SWITCH IS INOPER-

ATIVE .............................................................. ...

73

Description ........................................................... ...73

Diagnosis Procedure ...............................................73

THE OIL PRESSURE WARNING CONTIN-

UES DISPLAYING, OR DOES NOT DISPLAY ...

74

Description ........................................................... ...74

Diagnosis Procedure ...............................................74

THE PARKING BRAKE RELEASE WARNING

CONTINUES DISPLAYING, OR DOES NOT

DISPLAY ......................................................... ...

75

Description ........................................................... ...75

Diagnosis Procedure ...............................................75

THE LOW WASHER FLUID WARNING CON-

TINUES DISPLAYING, or DOES NOT DIS-

PLAY ............................................................... ...

76

Description ........................................................... ...76

Diagnosis Procedure ...............................................76

THE DOOR OPEN WARNING CONTINUES

DISPLAYING, OR DOES NOT DISPLAY ...... ...

77

Description ........................................................... ...77

Diagnosis Procedure ...............................................77

THE TRUNK OPEN WARNING CONTINUES

DISPLAYING, OR DOES NOT DISPLAY ...... ...

78

Description ........................................................... ...78

Diagnosis Procedure ...............................................78

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 3258 of 4801

MWI

MWI-3

C

D E

F

G H

I

J

K L

M B

A

O P

THE STEERING SWITCHES ARE INOPERA-

TIVE ................................................................ ....

79

Description .......................................................... ....79

Diagnosis Procedure ...............................................79

THE AMBIENT TEMPERATURE DISPLAY IS

INCORRECT ................................................... ....

80

Description .......................................................... ....80

Diagnosis Procedure ...............................................80

NORMAL OPERATING CONDITION .................81

COMPASS ............................................................. ....81

COMPASS : Description ..........................................81

REMOVAL AND INSTALLA TION ...............82

COMBINATION METER ...................................82

Removal and Installation ..................................... ....82

AMBIENT SENSOR ..........................................83

Removal and Installation .........................................83

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 3259 of 4801

MWI-4

< PRECAUTION >

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000009951603

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severi ty of injury to the driver and front passenger for certain

types of collision. Information necessary to service the system safely is included in the SR and SB section of

this Service Manual.

WARNING:

• To avoid rendering the SRS inopera tive, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISS AN/INFINITI dealer.

• Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintent ional activation of the system. For re moval of Spiral Cable and Air Bag

Module, see the SR section.

• Do not use electrical test equipmen t on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harn esses can be identified by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Unit or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or electri c power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers , always switch the Ignition OFF, disconnect the

battery and wait at least three minutes before performing any service.

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 3262 of 4801

MWI

COMPONENT PARTSMWI-7

< SYSTEM DESCRIPTION >

C

D E

F

G H

I

J

K L

M B

A

O P

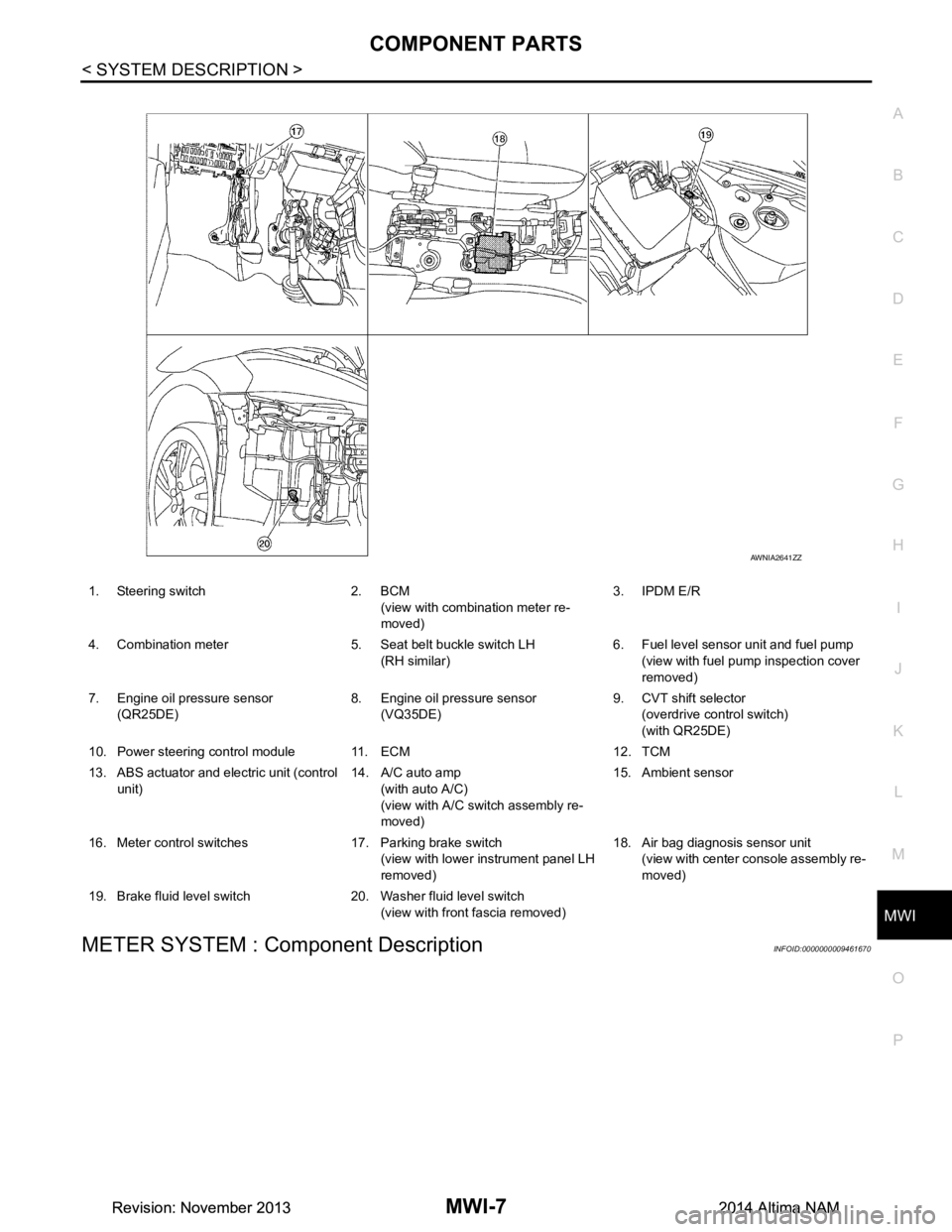

METER SYSTEM : Component DescriptionINFOID:0000000009461670

1. Steering switch 2. BCM (view with combination meter re-

moved) 3. IPDM E/R

4. Combination meter 5. Seat belt buckle switch LH (RH similar) 6. Fuel level sensor unit and fuel pump

(view with fuel pump inspection cover

removed)

7. Engine oil pressure sensor (QR25DE) 8. Engine oil pressure sensor

(VQ35DE) 9. CVT shift selector

(overdrive control switch)

(with QR25DE)

10. Power steering control module 11. ECM 12. TCM

13. ABS actuator and electric unit (control unit) 14. A/C auto amp

(with auto A/C)

(view with A/C swit ch assembly re-

moved) 15. Ambient sensor

16. Meter control switches 17. Parking brake switch (view with lower instrument panel LH

removed) 18. Air bag diagnosis sensor unit

(view with center console assembly re-

moved)

19. Brake fluid level switch 20. Washer fluid level switch (view with front fascia removed)

AWNIA2641ZZ

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 3263 of 4801

MWI-8

< SYSTEM DESCRIPTION >

COMPONENT PARTS

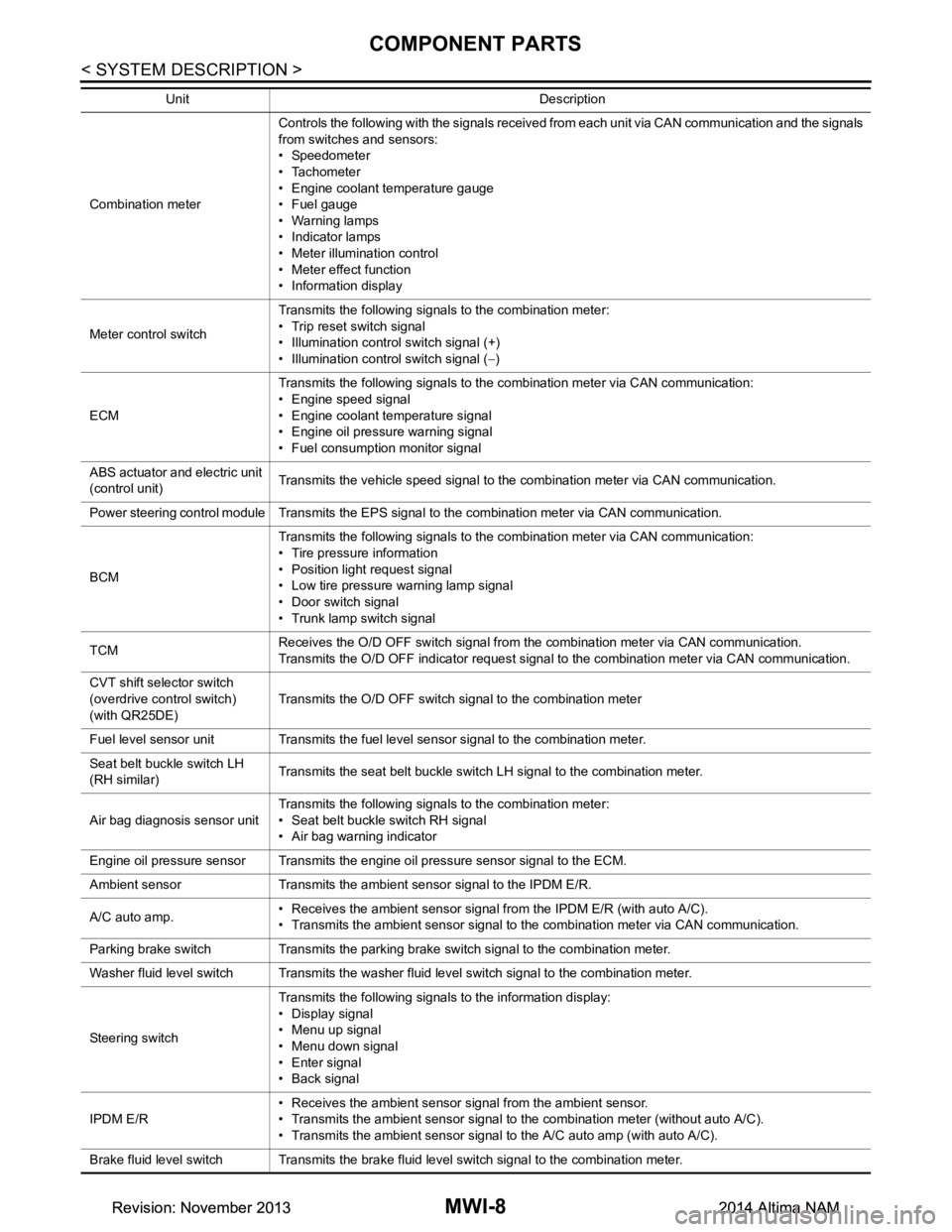

Unit Description

Combination meter Controls the following with the signals received from each unit via CAN communication and the signals

from switches and sensors:

• Speedometer

• Tachometer

• Engine coolant temperature gauge

• Fuel gauge

• Warning lamps

• Indicator lamps

• Meter illumination control

• Meter effect function

• Information display

Meter control switch Transmits the following signals to the combination meter:

• Trip reset switch signal

• Illumination control switch signal (+)

• Illumination control switch signal ( −)

ECM Transmits the following signals to the combination meter via CAN communication:

• Engine speed signal

• Engine coolant temperature signal

• Engine oil pressure warning signal

• Fuel consumption monitor signal

ABS actuator and electric unit

(control unit) Transmits the vehicle speed signal to the combination meter via CAN communication.

Power steering control module Transmits the EPS signal to the combination meter via CAN communication.

BCM Transmits the following signals to the combination meter via CAN communication:

• Tire pressure information

• Position light request signal

• Low tire pressure warning lamp signal

• Door switch signal

• Trunk lamp switch signal

TCM Receives the O/D OFF switch signal from the combination meter via CAN communication.

Transmits the O/D OFF indicator request signal to the combination meter via CAN communication.

CVT shift selector switch

(overdrive co ntrol switch)

(with QR25DE) Transmits the O/D OFF switch signal to the combination meter

Fuel level sensor unit Transmits the fuel level sensor signal to the combination meter.

Seat belt buckle switch LH

(RH similar) Transmits the seat belt buckle switch LH signal to the combination meter.

Air bag diagnosis sensor unit Transmits the following signals to the combination meter:

• Seat belt buckle switch RH signal

• Air bag warning indicator

Engine oil pressure sensor Transmits the engine oil pressure sensor signal to the ECM.

Ambient sensor Transmits the ambient sensor signal to the IPDM E/R.

A/C auto amp. • Receives the ambient sensor signal from the IPDM E/R (with auto A/C).

• Transmits the ambient sensor signal to the combination meter via CAN communication.

Parking brake switch Transmits the parking brake switch signal to the combination meter.

Washer fluid level switch Transmits the washer fluid level switch signal to the combination meter.

Steering switch Transmits the following signals to the information display:

• Display signal

• Menu up signal

• Menu down signal

• Enter signal

• Back signal

IPDM E/R • Receives the ambient sensor signal from the ambient sensor.

• Transmits the ambient sensor signal to the combination meter (without auto A/C).

• Transmits the ambient sensor signal to the A/C auto amp (with auto A/C).

Brake fluid level switch Transmits the brake fluid level switch signal to the combination meter.

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 3264 of 4801

MWI

SYSTEMMWI-9

< SYSTEM DESCRIPTION >

C

D E

F

G H

I

J

K L

M B

A

O P

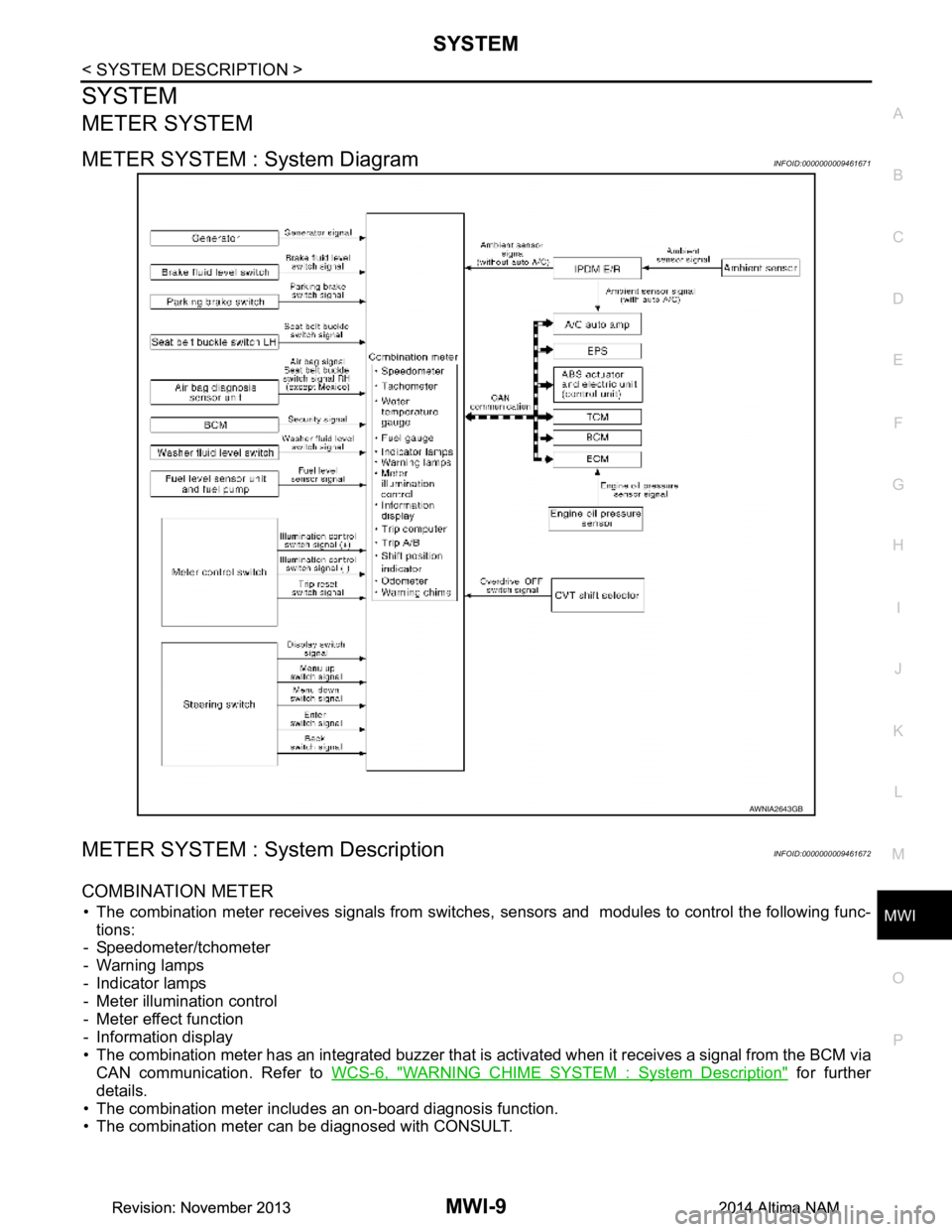

SYSTEM

METER SYSTEM

METER SYSTEM : System DiagramINFOID:0000000009461671

METER SYSTEM : System DescriptionINFOID:0000000009461672

COMBINATION METER

• The combination meter receives signals from switches, sensors and modules to control the following func-

tions:

- Speedometer/tchometer

- Warning lamps

- Indicator lamps

- Meter illumination control

- Meter effect function

- Information display

• The combination meter has an integrated buzzer that is activated when it receives a signal from the BCM via

CAN communication. Refer to WCS-6, "WARNING CHIME SYST EM : System Description"

for further

details.

• The combination meter includes an on-board diagnosis function.

• The combination meter can be diagnosed with CONSULT.

AWNIA2643GB

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 3267 of 4801

MWI-12

< SYSTEM DESCRIPTION >

SYSTEM

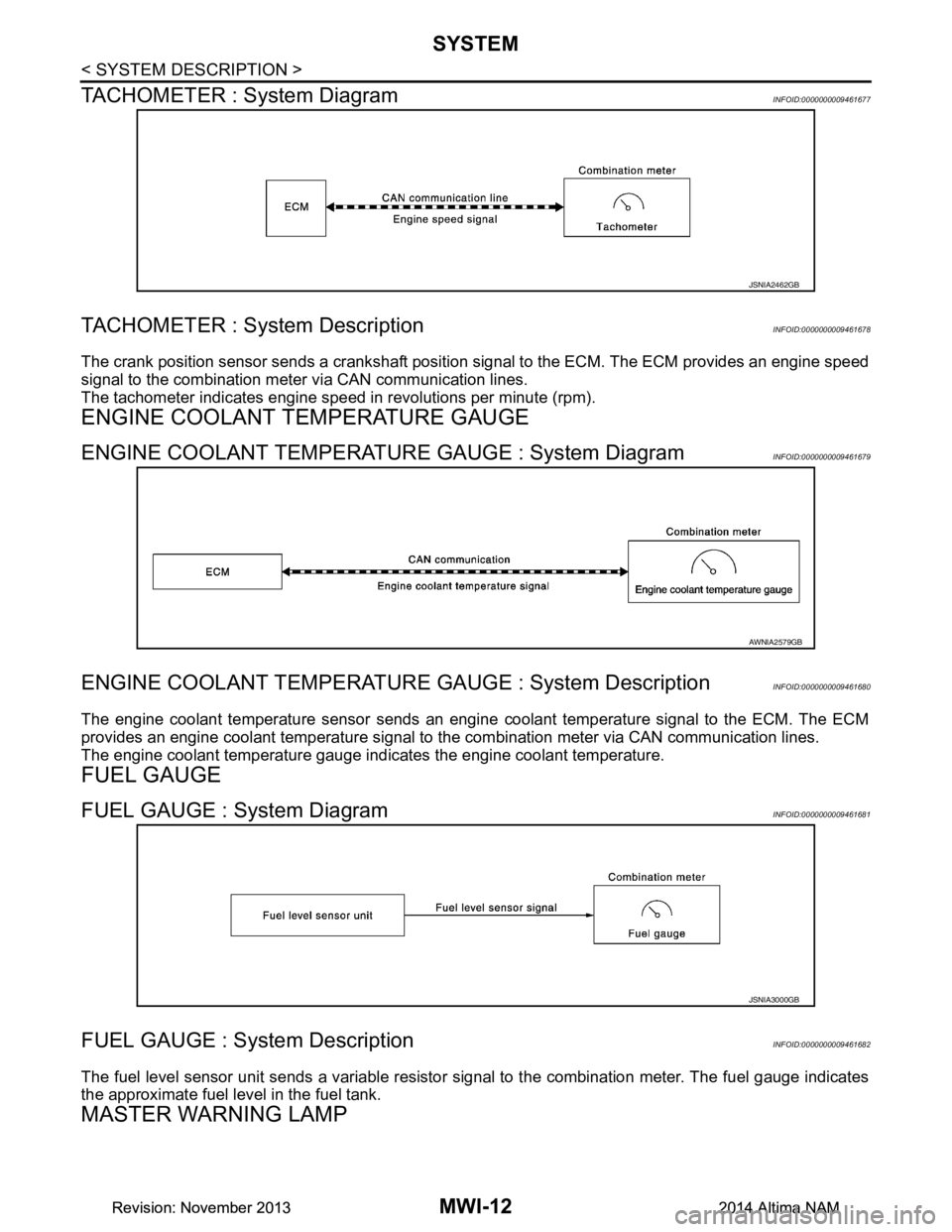

TACHOMETER : System Diagram

INFOID:0000000009461677

TACHOMETER : System DescriptionINFOID:0000000009461678

The crank position sensor sends a crankshaft positi on signal to the ECM. The ECM provides an engine speed

signal to the combination meter via CAN communication lines.

The tachometer indicates engine speed in revolutions per minute (rpm).

ENGINE COOLANT TEMPERATURE GAUGE

ENGINE COOLANT TEMPERATURE GAUGE : System DiagramINFOID:0000000009461679

ENGINE COOLANT TEMPERATURE GAUGE : System DescriptionINFOID:0000000009461680

The engine coolant temperature sensor sends an engine coolant temperature signal to the ECM. The ECM

provides an engine coolant temperature signal to t he combination meter via CAN communication lines.

The engine coolant temperature gauge indicates the engine coolant temperature.

FUEL GAUGE

FUEL GAUGE : System DiagramINFOID:0000000009461681

FUEL GAUGE : System DescriptionINFOID:0000000009461682

The fuel level sensor unit sends a variable resistor signal to the combination meter. The fuel gauge indicates

the approximate fuel level in the fuel tank.

MASTER WARNING LAMP

JSNIA2462GB

AWNIA2579GB

JSNIA3000GB

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 3271 of 4801

MWI-16

< SYSTEM DESCRIPTION >

SYSTEM

The LOOSE FUEL CAP message will display in the information display when the fuel-filler cap is not tightened

correctly. The message will turn off as soon as the EC M detects the fuel-filler cap is properly tightened. The

ECM provides a loose fuel cap signal to the combination meter via CAN communication.

LOW TIRE PRESSURE WARNING

This warning appears when the BCM detects low inflati on pressure or a system malfunction. The BCM sends

a signal to the combination meter via CAN communication to illuminate the low tire pressure warning lamp. In

addition, a warning message will be displayed in the vehicle information display.

DOOR OPEN WARNING

This warning appears when the ignition switch is ON and the door is open. The BCM receives a door switch

signal from the door open door switch. The BCM sends t he door switch signal to the combination meter via

CAN communication lines.

TRUNK OPEN WARNING

This warning appears when the ignition switch is ON and the trunk is opened. The BCM receives a trunk lamp

switch signal from the trunk lamp switch. The BCM s ends the trunk lamp switch signal to the combination

meter via CAN communication.

LOW FUEL WARNING

This warning appears when the fuel level in the fuel tank is less than approximately 4 US gal (15 L, 3.3 Imp

gal). A variable resistor signal is supplied to the combi nation meter from the fuel level sensor unit to determine

the amount of fuel in the fuel tank.

LOW WINDSHIELD WASHER FLUID WARNING

When the windshield washer fluid level is low, the was her fluid level switch provides a ground signal to the

combination meter and the warning is displayed. Once fluid is added, the switch opens and the warning is no

longer displayed.

RELEASE PARKING BRAKE WARNING

When the parking brake is applied, the parking brake switch provides a ground signal to the combination

meter. When the vehicle speed is greater than 4 MPH (7 km/h), the message is displayed and the warning

chime sounds.

SHIFT POSITION INDICATOR

Displays the position of the shift selector based on signals received from TCM via CAN communication.

LOW OIL PRESSURE WARNING

The low oil pressure warning appears in the information display when the combination meter receives a low

engine oil pressure signal from the ECM via CAN communication.

WARNING CHECK INDICATION

The combination meter can cause an interrupt on the information display to indicate a warning, based on sig-

nals received from each unit and switch.

Refer to Owner’s Manual for additional information display items.

COMPASS

COMPASS : DescriptionINFOID:0000000009461691

DESCRIPTION

With the ignition switch in the ON position, and the mode (N) switch

ON, the compass display will indicate the direction the vehicle is

heading.

Vehicle direction is displayed as follows:

• N: north

• E: east

• S: south

•W: west

LKIA0447E

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM