lights NISSAN TERRANO 2002 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2002, Model line: TERRANO, Model: NISSAN TERRANO 2002Pages: 1767, PDF Size: 41.51 MB

Page 95 of 1767

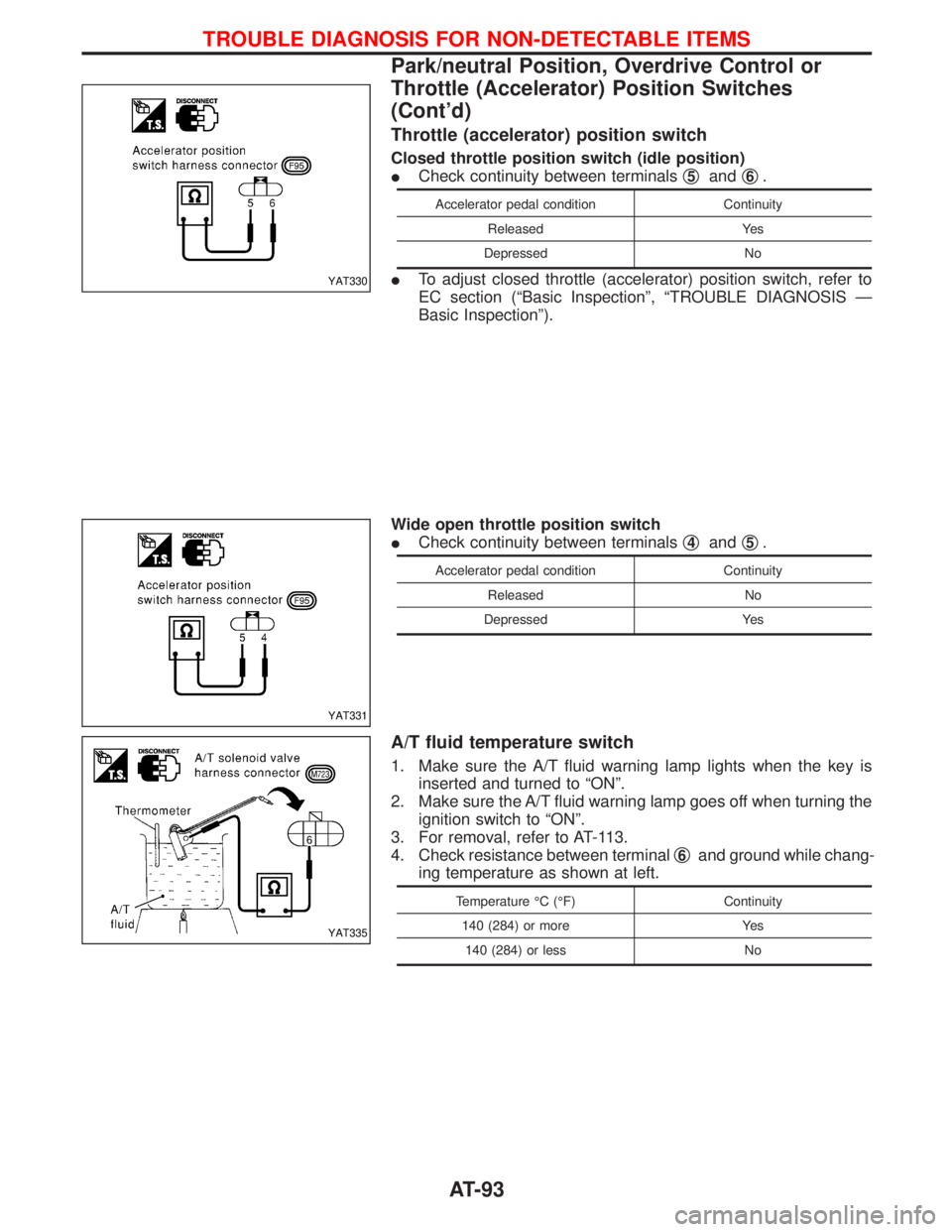

Throttle (accelerator) position switch

Closed throttle position switch (idle position)

ICheck continuity between terminalsq

5andq6.

Accelerator pedal condition Continuity

Released Yes

Depressed No

ITo adjust closed throttle (accelerator) position switch, refer to

EC section (ªBasic Inspectionº, ªTROUBLE DIAGNOSIS Ð

Basic Inspectionº).

Wide open throttle position switch

ICheck continuity between terminalsq

4andq5.

Accelerator pedal condition Continuity

Released No

Depressed Yes

A/T fluid temperature switch

1. Make sure the A/T fluid warning lamp lights when the key is

inserted and turned to ªONº.

2. Make sure the A/T fluid warning lamp goes off when turning the

ignition switch to ªONº.

3. For removal, refer to AT-113.

4. Check resistance between terminalq

6and ground while chang-

ing temperature as shown at left.

Temperature ÉC (ÉF) Continuity

140 (284) or more Yes

140 (284) or less No

YAT330

YAT331

YAT335

TROUBLE DIAGNOSIS FOR NON-DETECTABLE ITEMS

Park/neutral Position, Overdrive Control or

Throttle (Accelerator) Position Switches

(Cont'd)

AT-93

Page 396 of 1767

IIf the battery is disconnected, the emission-related diagnostic information will be lost after approx.

24 hours.

IErasing the emission-related diagnostic information using CONSULT-II is easier and quicker than

switching the diagnostic test mode using the data link connector.

NATS (Nissan Anti-Theft System)

IIf the security indicator lights up with the ignition switch in

the ªONº position or ªNATS MALFUNCTIONº is displayed

on ªSELF-DIAG RESULTSº screen, perform self-diagnostic

results mode with CONSULT-II using NATS program card.

Refer to ªNATS (Nissan Anti-Theft System)º in EL section.

IConfirm no self-diagnostic results of NATS is displayed

before touching ªERASEº in ªSELF-DIAG RESULTSº mode

with CONSULT-II.

IWhen replacing ECM, initialization of NATS system and

registration of all NATS ignition key IDs must be carried out

with CONSULT-II using NATS program card.

Therefore, be sure to receive all keys from vehicle owner.

Regarding the procedures of NATS initialization and NATS

ignition key ID registration, refer to CONSULT-II operation

manual, NATS.

Malfunction Indicator (MI)

DESCRIPTION

The MI is located on the instrument panel.

1. The MI will light up when the ignition switch is turned ON with-

out the engine running. This is a bulb check.

IIf the MI does not light up, refer to EL section (ªWARNING

LAMPS AND CHIMEº) or see EC-291.

2. When the engine is started, the MI should go off.

If the MI remains on, the on board diagnostic system has

detected an engine system malfunction.

If MI illuminates or blinks irregularly after starting engine,

water may have accumulated in fuel filter. Drain water from

fuel filter. Refer to MA section.

SEF252Z

SAT652J

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTIONZD30DDTi

Diagnostic Trouble Code (DTC) (Cont'd)

EC-34

Page 698 of 1767

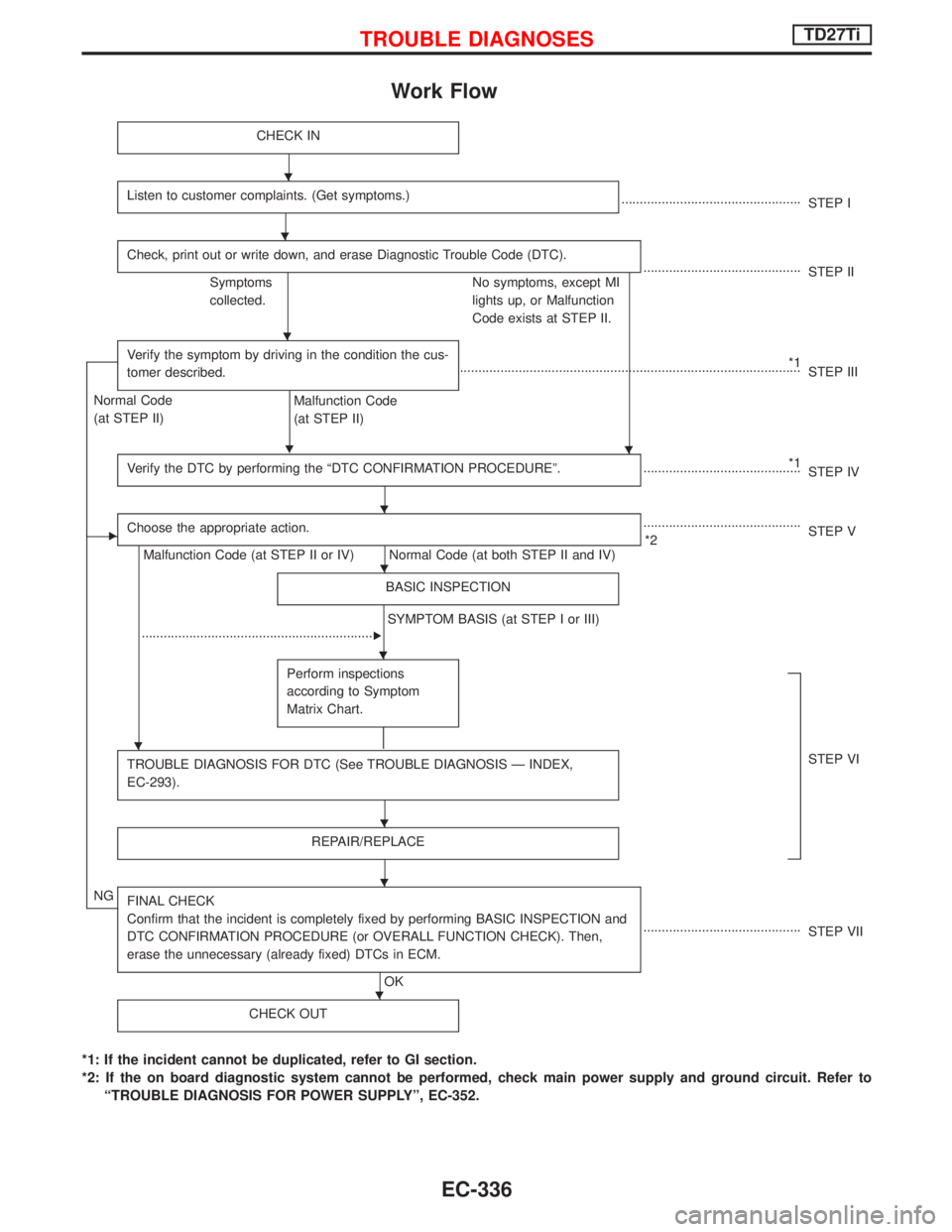

Work Flow

CHECK IN

Listen to customer complaints. (Get symptoms.).................................................

STEP I

Check, print out or write down, and erase Diagnostic Trouble Code (DTC).

...........................................

STEP II

Symptoms

collected.No symptoms, except MI

lights up, or Malfunction

Code exists at STEP II.

Verify the symptom by driving in the condition the cus-

tomer described.

H

*1

.............................................................................................

STEP III

Normal Code

(at STEP II)

Malfunction Code

(at STEP II)

Verify the DTC by performing the ªDTC CONFIRMATION PROCEDUREº.

*1

...........................................

STEP IV

EChoose the appropriate action.

Malfunction Code (at STEP II or IV) Normal Code (at both STEP II and IV)...........................................

*2STEP V

BASIC INSPECTION

SYMPTOM BASIS (at STEP I or III)

................................................................

E

Perform inspections

according to Symptom

Matrix Chart.

TROUBLE DIAGNOSIS FOR DTC (See TROUBLE DIAGNOSIS Ð INDEX,

EC-293).STEP VI

REPAIR/REPLACE

NGFINAL CHECK

Confirm that the incident is completely fixed by performing BASIC INSPECTION and

DTC CONFIRMATION PROCEDURE (or OVERALL FUNCTION CHECK). Then,

erase the unnecessary (already fixed) DTCs in ECM.

OK...........................................

STEP VII

CHECK OUT

*1: If the incident cannot be duplicated, refer to GI section.

*2: If the on board diagnostic system cannot be performed, check main power supply and ground circuit. Refer to

ªTROUBLE DIAGNOSIS FOR POWER SUPPLYº, EC-352.

H

H

H

H

H

H

H

H

H

H

H

TROUBLE DIAGNOSESTD27Ti

EC-336

Page 1002 of 1767

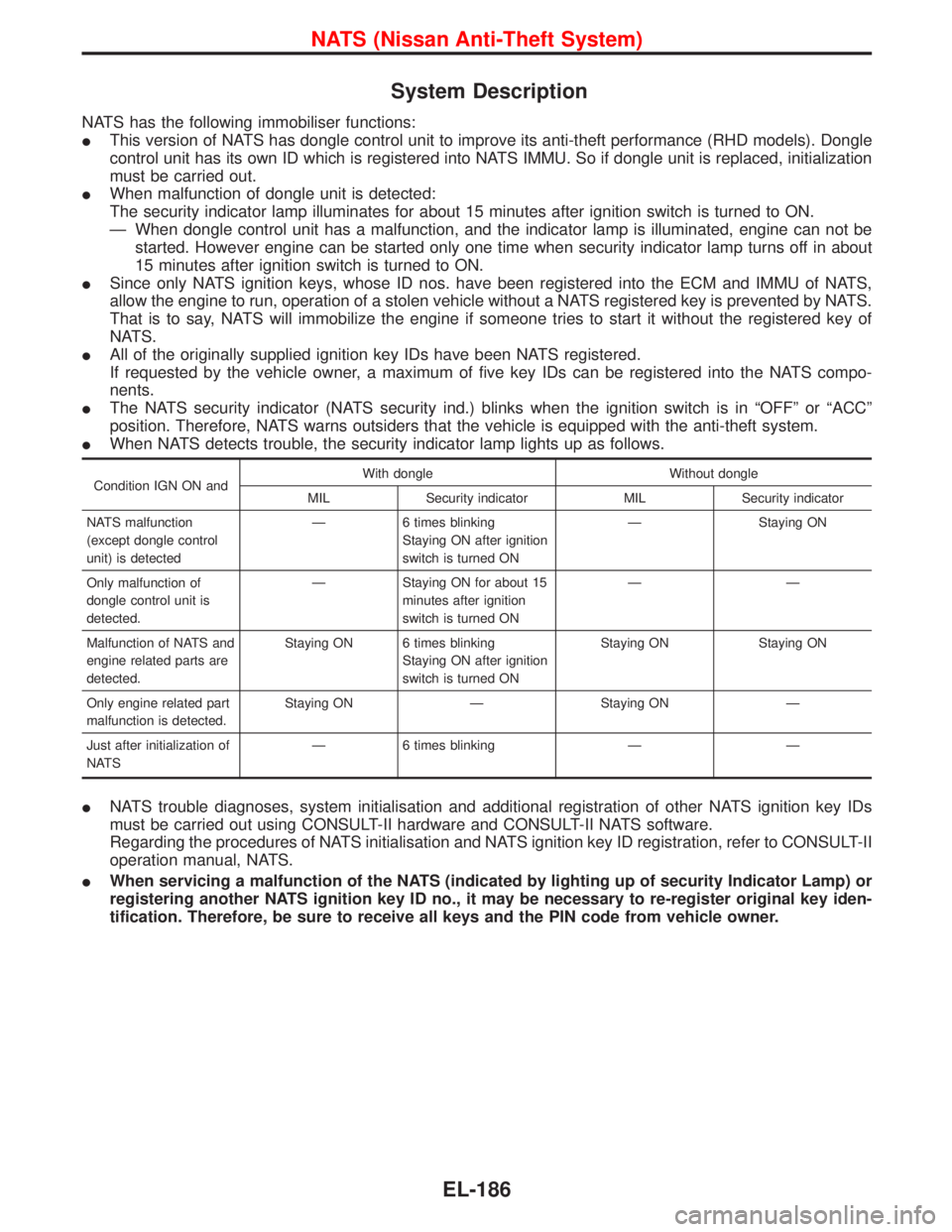

System Description

NATS has the following immobiliser functions:

IThis version of NATS has dongle control unit to improve its anti-theft performance (RHD models). Dongle

control unit has its own ID which is registered into NATS IMMU. So if dongle unit is replaced, initialization

must be carried out.

IWhen malfunction of dongle unit is detected:

The security indicator lamp illuminates for about 15 minutes after ignition switch is turned to ON.

Ð When dongle control unit has a malfunction, and the indicator lamp is illuminated, engine can not be

started. However engine can be started only one time when security indicator lamp turns off in about

15 minutes after ignition switch is turned to ON.

ISince only NATS ignition keys, whose ID nos. have been registered into the ECM and IMMU of NATS,

allow the engine to run, operation of a stolen vehicle without a NATS registered key is prevented by NATS.

That is to say, NATS will immobilize the engine if someone tries to start it without the registered key of

NATS.

IAll of the originally supplied ignition key IDs have been NATS registered.

If requested by the vehicle owner, a maximum of five key IDs can be registered into the NATS compo-

nents.

IThe NATS security indicator (NATS security ind.) blinks when the ignition switch is in ªOFFº or ªACCº

position. Therefore, NATS warns outsiders that the vehicle is equipped with the anti-theft system.

IWhen NATS detects trouble, the security indicator lamp lights up as follows.

Condition IGN ON andWith dongle Without dongle

MIL Security indicator MIL Security indicator

NATS malfunction

(except dongle control

unit) is detectedÐ 6 times blinking

Staying ON after ignition

switch is turned ONÐ Staying ON

Only malfunction of

dongle control unit is

detected.Ð Staying ON for about 15

minutes after ignition

switch is turned ONÐÐ

Malfunction of NATS and

engine related parts are

detected.Staying ON 6 times blinking

Staying ON after ignition

switch is turned ONStaying ON Staying ON

Only engine related part

malfunction is detected.Staying ON Ð Staying ON Ð

Just after initialization of

NATSÐ 6 times blinking Ð Ð

INATS trouble diagnoses, system initialisation and additional registration of other NATS ignition key IDs

must be carried out using CONSULT-II hardware and CONSULT-II NATS software.

Regarding the procedures of NATS initialisation and NATS ignition key ID registration, refer to CONSULT-II

operation manual, NATS.

IWhen servicing a malfunction of the NATS (indicated by lighting up of security Indicator Lamp) or

registering another NATS ignition key ID no., it may be necessary to re-register original key iden-

tification. Therefore, be sure to receive all keys and the PIN code from vehicle owner.

NATS (Nissan Anti-Theft System)

EL-186

Page 1012 of 1767

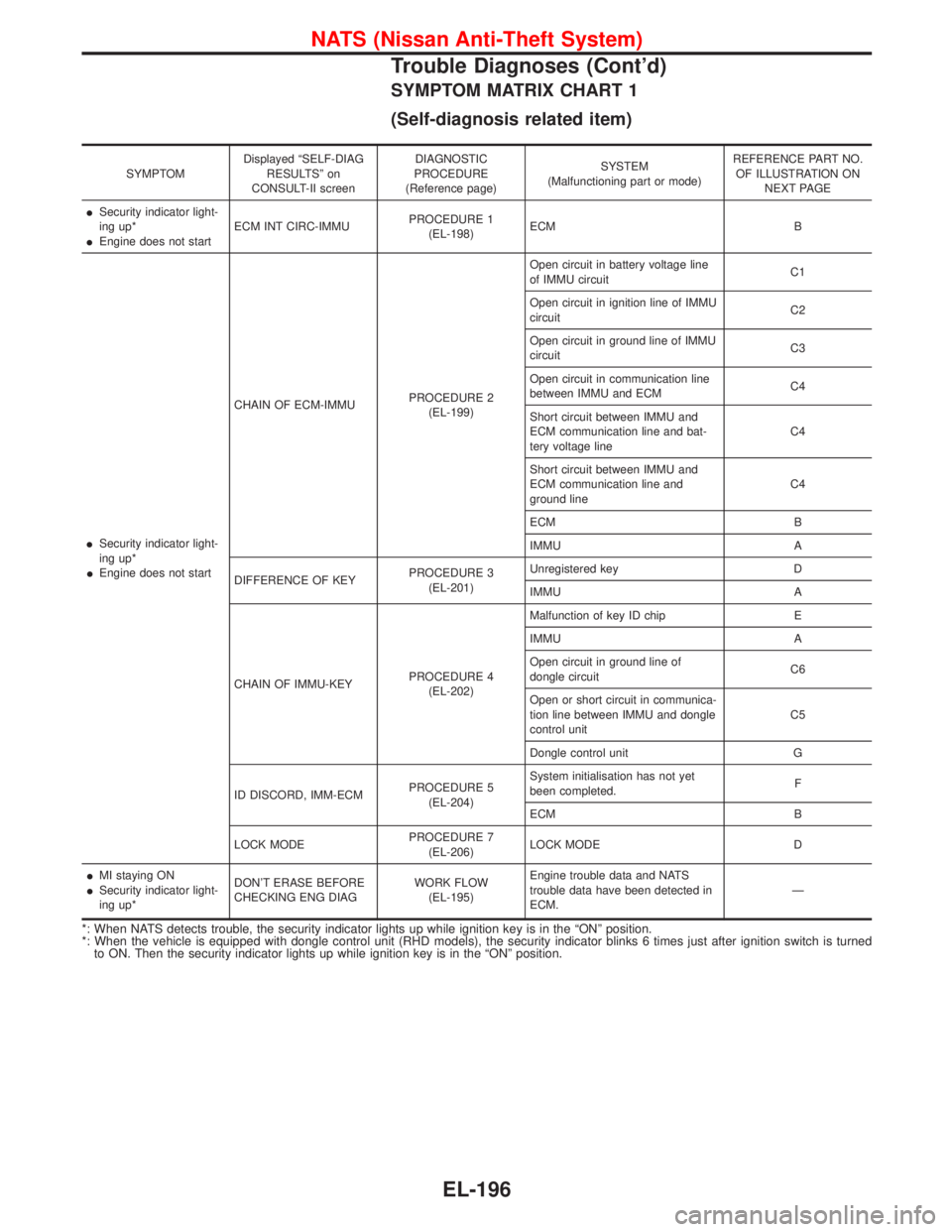

SYMPTOM MATRIX CHART 1

(Self-diagnosis related item)

SYMPTOMDisplayed ªSELF-DIAG

RESULTSº on

CONSULT-II screenDIAGNOSTIC

PROCEDURE

(Reference page)SYSTEM

(Malfunctioning part or mode)REFERENCE PART NO.

OF ILLUSTRATION ON

NEXT PAGE

ISecurity indicator light-

ing up*

IEngine does not startECM INT CIRC-IMMUPROCEDURE 1

(EL-198)ECM B

ISecurity indicator light-

ing up*

IEngine does not startCHAIN OF ECM-IMMUPROCEDURE 2

(EL-199)Open circuit in battery voltage line

of IMMU circuitC1

Open circuit in ignition line of IMMU

circuitC2

Open circuit in ground line of IMMU

circuitC3

Open circuit in communication line

between IMMU and ECMC4

Short circuit between IMMU and

ECM communication line and bat-

tery voltage lineC4

Short circuit between IMMU and

ECM communication line and

ground lineC4

ECM B

IMMU A

DIFFERENCE OF KEYPROCEDURE 3

(EL-201)Unregistered key D

IMMU A

CHAIN OF IMMU-KEYPROCEDURE 4

(EL-202)Malfunction of key ID chip E

IMMU A

Open circuit in ground line of

dongle circuitC6

Open or short circuit in communica-

tion line between IMMU and dongle

control unitC5

Dongle control unit G

ID DISCORD, IMM-ECMPROCEDURE 5

(EL-204)System initialisation has not yet

been completed.F

ECM B

LOCK MODEPROCEDURE 7

(EL-206)LOCK MODE D

IMI staying ON

ISecurity indicator light-

ing up*DON'T ERASE BEFORE

CHECKING ENG DIAGWORK FLOW

(EL-195)Engine trouble data and NATS

trouble data have been detected in

ECM.Ð

*: When NATS detects trouble, the security indicator lights up while ignition key is in the ªONº position.

*: When the vehicle is equipped with dongle control unit (RHD models), the security indicator blinks 6 times just after ignition switch is turned

to ON. Then the security indicator lights up while ignition key is in the ªONº position.

NATS (Nissan Anti-Theft System)

Trouble Diagnoses (Cont'd)

EL-196

Page 1462 of 1767

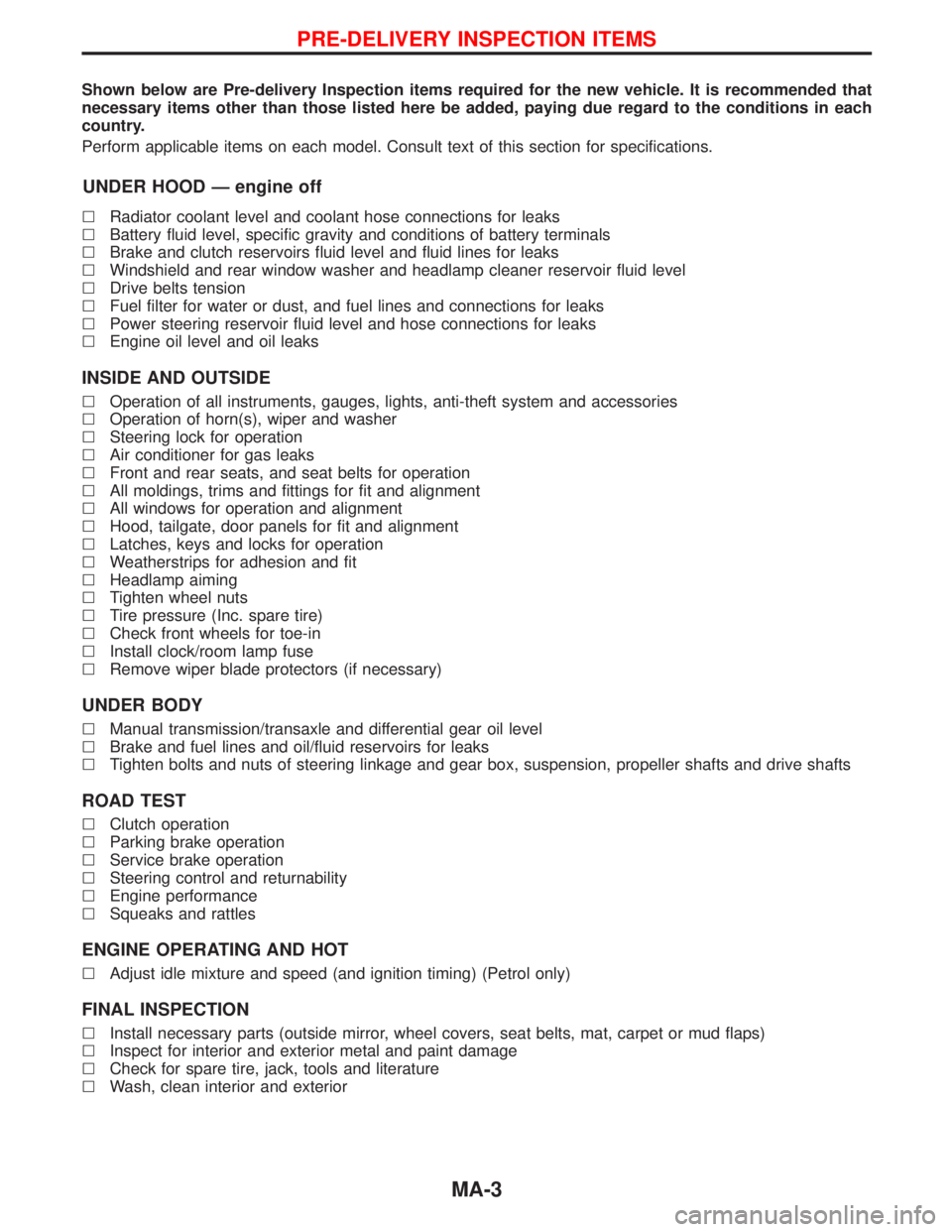

Shown below are Pre-delivery Inspection items required for the new vehicle. It is recommended that

necessary items other than those listed here be added, paying due regard to the conditions in each

country.

Perform applicable items on each model. Consult text of this section for specifications.

UNDER HOOD Ð engine off

lRadiator coolant level and coolant hose connections for leaks

lBattery fluid level, specific gravity and conditions of battery terminals

lBrake and clutch reservoirs fluid level and fluid lines for leaks

lWindshield and rear window washer and headlamp cleaner reservoir fluid level

lDrive belts tension

lFuel filter for water or dust, and fuel lines and connections for leaks

lPower steering reservoir fluid level and hose connections for leaks

lEngine oil level and oil leaks

INSIDE AND OUTSIDE

lOperation of all instruments, gauges, lights, anti-theft system and accessories

lOperation of horn(s), wiper and washer

lSteering lock for operation

lAir conditioner for gas leaks

lFront and rear seats, and seat belts for operation

lAll moldings, trims and fittings for fit and alignment

lAll windows for operation and alignment

lHood, tailgate, door panels for fit and alignment

lLatches, keys and locks for operation

lWeatherstrips for adhesion and fit

lHeadlamp aiming

lTighten wheel nuts

lTire pressure (Inc. spare tire)

lCheck front wheels for toe-in

lInstall clock/room lamp fuse

lRemove wiper blade protectors (if necessary)

UNDER BODY

lManual transmission/transaxle and differential gear oil level

lBrake and fuel lines and oil/fluid reservoirs for leaks

lTighten bolts and nuts of steering linkage and gear box, suspension, propeller shafts and drive shafts

ROAD TEST

lClutch operation

lParking brake operation

lService brake operation

lSteering control and returnability

lEngine performance

lSqueaks and rattles

ENGINE OPERATING AND HOT

lAdjust idle mixture and speed (and ignition timing) (Petrol only)

FINAL INSPECTION

lInstall necessary parts (outside mirror, wheel covers, seat belts, mat, carpet or mud flaps)

lInspect for interior and exterior metal and paint damage

lCheck for spare tire, jack, tools and literature

lWash, clean interior and exterior

PRE-DELIVERY INSPECTION ITEMS

MA-3

Page 1463 of 1767

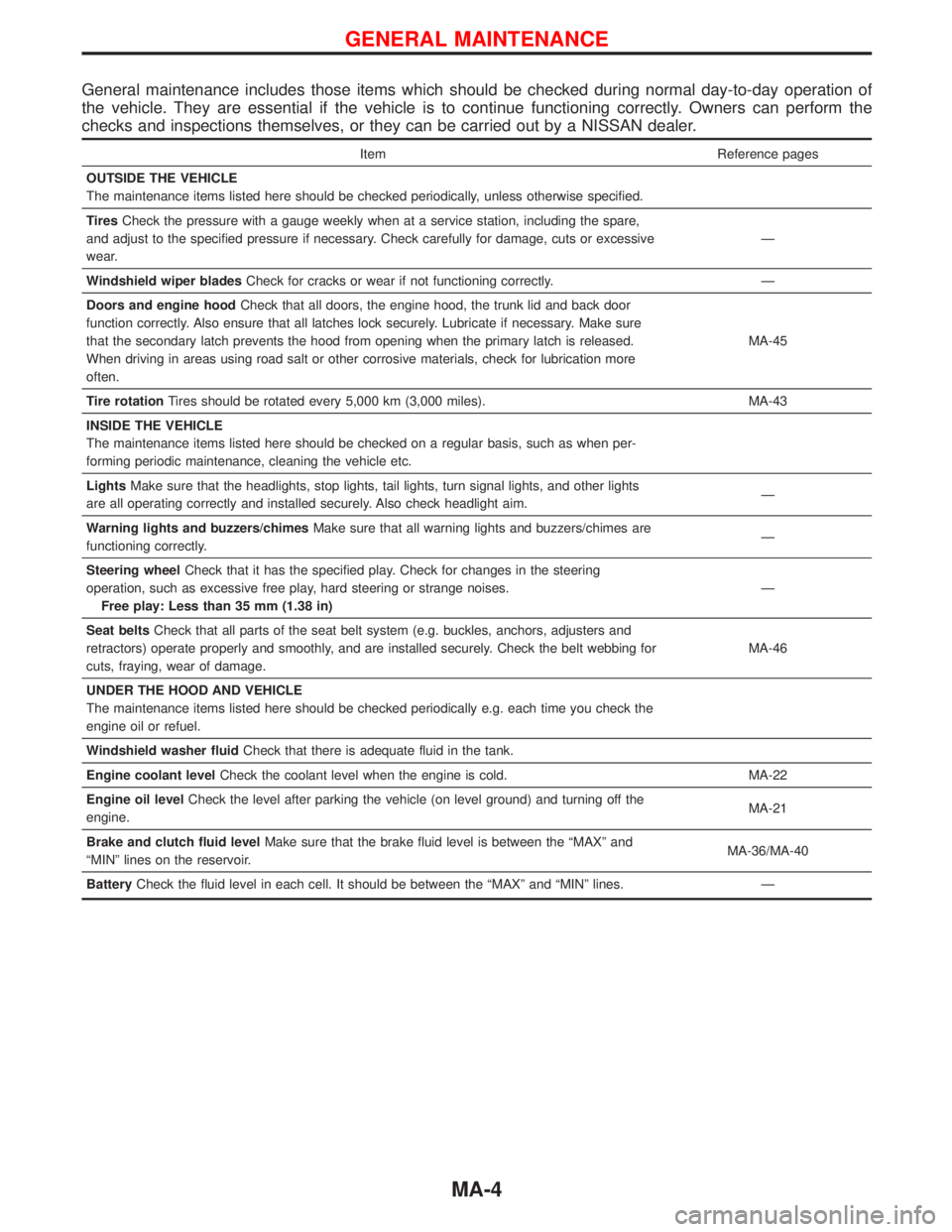

General maintenance includes those items which should be checked during normal day-to-day operation of

the vehicle. They are essential if the vehicle is to continue functioning correctly. Owners can perform the

checks and inspections themselves, or they can be carried out by a NISSAN dealer.

Item Reference pages

OUTSIDE THE VEHICLE

The maintenance items listed here should be checked periodically, unless otherwise specified.

TiresCheck the pressure with a gauge weekly when at a service station, including the spare,

and adjust to the specified pressure if necessary. Check carefully for damage, cuts or excessive

wear.Ð

Windshield wiper bladesCheck for cracks or wear if not functioning correctly. Ð

Doors and engine hoodCheck that all doors, the engine hood, the trunk lid and back door

function correctly. Also ensure that all latches lock securely. Lubricate if necessary. Make sure

that the secondary latch prevents the hood from opening when the primary latch is released.

When driving in areas using road salt or other corrosive materials, check for lubrication more

often.MA-45

Tire rotationTires should be rotated every 5,000 km (3,000 miles). MA-43

INSIDE THE VEHICLE

The maintenance items listed here should be checked on a regular basis, such as when per-

forming periodic maintenance, cleaning the vehicle etc.

LightsMake sure that the headlights, stop lights, tail lights, turn signal lights, and other lights

are all operating correctly and installed securely. Also check headlight aim.Ð

Warning lights and buzzers/chimesMake sure that all warning lights and buzzers/chimes are

functioning correctly.Ð

Steering wheelCheck that it has the specified play. Check for changes in the steering

operation, such as excessive free play, hard steering or strange noises.

Free play: Less than 35 mm (1.38 in)Ð

Seat beltsCheck that all parts of the seat belt system (e.g. buckles, anchors, adjusters and

retractors) operate properly and smoothly, and are installed securely. Check the belt webbing for

cuts, fraying, wear of damage.MA-46

UNDER THE HOOD AND VEHICLE

The maintenance items listed here should be checked periodically e.g. each time you check the

engine oil or refuel.

Windshield washer fluidCheck that there is adequate fluid in the tank.

Engine coolant levelCheck the coolant level when the engine is cold. MA-22

Engine oil levelCheck the level after parking the vehicle (on level ground) and turning off the

engine.MA-21

Brake and clutch fluid levelMake sure that the brake fluid level is between the ªMAXº and

ªMINº lines on the reservoir.MA-36/MA-40

BatteryCheck the fluid level in each cell. It should be between the ªMAXº and ªMINº lines. Ð

GENERAL MAINTENANCE

MA-4

Page 1485 of 1767

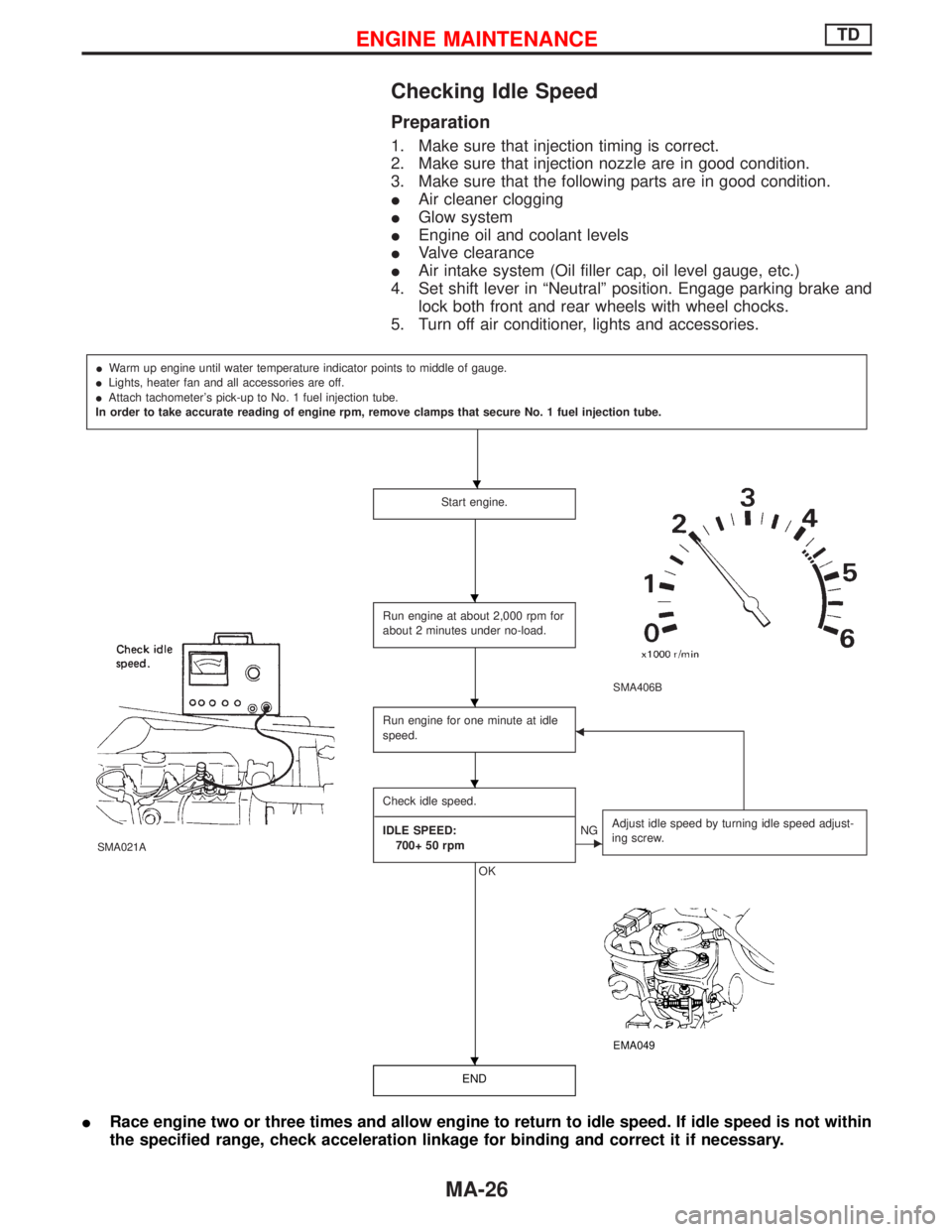

Checking Idle Speed

Preparation

1. Make sure that injection timing is correct.

2. Make sure that injection nozzle are in good condition.

3. Make sure that the following parts are in good condition.

IAir cleaner clogging

IGlow system

IEngine oil and coolant levels

IValve clearance

IAir intake system (Oil filler cap, oil level gauge, etc.)

4. Set shift lever in ªNeutralº position. Engage parking brake and

lock both front and rear wheels with wheel chocks.

5. Turn off air conditioner, lights and accessories.

IWarm up engine until water temperature indicator points to middle of gauge.

ILights, heater fan and all accessories are off.

IAttach tachometer's pick-up to No. 1 fuel injection tube.

In order to take accurate reading of engine rpm, remove clamps that secure No. 1 fuel injection tube.

Start engine.

SMA406B

SMA021A

Run engine at about 2,000 rpm for

about 2 minutes under no-load.

Run engine for one minute at idle

speed.F

Check idle speed.

----------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

IDLE SPEED:

700+ 50 rpm

OK

ENGAdjust idle speed by turning idle speed adjust-

ing screw.

EMA049

END

IRace engine two or three times and allow engine to return to idle speed. If idle speed is not within

the specified range, check acceleration linkage for binding and correct it if necessary.

H

H

H

H

H

ENGINE MAINTENANCETD

MA-26

Page 1648 of 1767

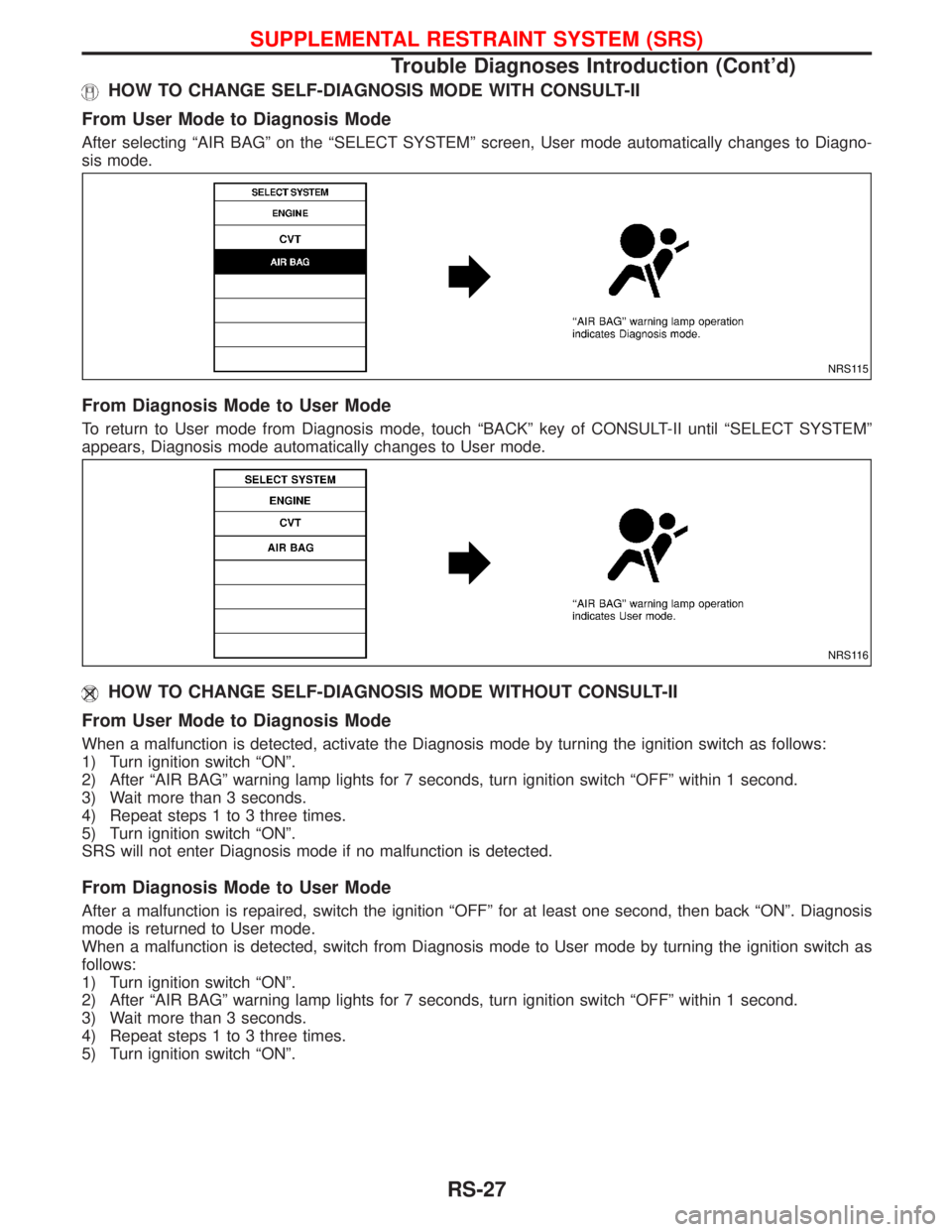

HOW TO CHANGE SELF-DIAGNOSIS MODE WITH CONSULT-II

From User Mode to Diagnosis Mode

After selecting ªAIR BAGº on the ªSELECT SYSTEMº screen, User mode automatically changes to Diagno-

sis mode.

From Diagnosis Mode to User Mode

To return to User mode from Diagnosis mode, touch ªBACKº key of CONSULT-II until ªSELECT SYSTEMº

appears, Diagnosis mode automatically changes to User mode.

HOW TO CHANGE SELF-DIAGNOSIS MODE WITHOUT CONSULT-II

From User Mode to Diagnosis Mode

When a malfunction is detected, activate the Diagnosis mode by turning the ignition switch as follows:

1) Turn ignition switch ªONº.

2) After ªAIR BAGº warning lamp lights for 7 seconds, turn ignition switch ªOFFº within 1 second.

3) Wait more than 3 seconds.

4) Repeat steps 1 to 3 three times.

5) Turn ignition switch ªONº.

SRS will not enter Diagnosis mode if no malfunction is detected.

From Diagnosis Mode to User Mode

After a malfunction is repaired, switch the ignition ªOFFº for at least one second, then back ªONº. Diagnosis

mode is returned to User mode.

When a malfunction is detected, switch from Diagnosis mode to User mode by turning the ignition switch as

follows:

1) Turn ignition switch ªONº.

2) After ªAIR BAGº warning lamp lights for 7 seconds, turn ignition switch ªOFFº within 1 second.

3) Wait more than 3 seconds.

4) Repeat steps 1 to 3 three times.

5) Turn ignition switch ªONº.

NRS115

NRS116

SUPPLEMENTAL RESTRAINT SYSTEM (SRS)

Trouble Diagnoses Introduction (Cont'd)

RS-27

Page 1667 of 1767

![NISSAN TERRANO 2002 Service Repair Manual Diagnostic item Explanation Repair order

PRE-TEN FRONT RH

[OPEN/VB-SHORT]IThe circuit for front RH seat belt pre-

tensioner is open or shorted to a power

supply circuit.1. Visually check the wiring ha NISSAN TERRANO 2002 Service Repair Manual Diagnostic item Explanation Repair order

PRE-TEN FRONT RH

[OPEN/VB-SHORT]IThe circuit for front RH seat belt pre-

tensioner is open or shorted to a power

supply circuit.1. Visually check the wiring ha](/img/5/57393/w960_57393-1666.png)

Diagnostic item Explanation Repair order

PRE-TEN FRONT RH

[OPEN/VB-SHORT]IThe circuit for front RH seat belt pre-

tensioner is open or shorted to a power

supply circuit.1. Visually check the wiring harness con-

nections.

2. Replace the harness if it has visible

damage.

3. If the harness check is OK, replace the

diagnosis sensor unit and front RH seat

belt. (Before disposing of the front RH

seat belt pre-tensioner, if must be

deployed.) PRE-TEN FRONT RH

[GND-SHORT]IThe circuit for front RH seat belt pre-

tensioner is shorted to ground.

CONTROL UNITIDiagnosis sensor unit is malfunctioning. 1. Visually check the wiring harness con-

nection.

2. Replace the harness if it has visible

damage.

3. If the harness check is OK, replace the

diagnosis sensor unit.

* Follow the procedures in numerical order when repairing malfunctioning parts, then make the final system check.

Trouble Diagnoses without CONSULT-II

DIAGNOSTIC PROCEDURE 6

Inspecting SRS malfunctioning parts by using ªAIR BAGº

warning lamp Ð Diagnosis mode

NOTE:

SRS will not enter Diagnosis mode if no malfunction is

detected in User mode.

1. Turn ignition switch ªONº.

2. After ªAIR BAGº warning lamp lights for 7 seconds, turn ignition

switch ªOFFº within 1 second.

3. Wait more than 3 seconds.

4. Repeat steps 1 to 3 three times.

5. Turn ignition switch ªONº.

SRS is now in Diagnosis mode.

6. ªAIR BAGº warning lamp operates in Diagnosis mode as fol-

lows:

NOTE:

If SRS does not enter Diagnosis mode even though malfunc-

tion is detected in User mode, check the battery voltage.

If the battery voltage is less than 9V, charge the battery. Then

go to DIAGNOSTIC PROCEDURE 7, page RS-51.

If the battery voltage is OK, replace the diagnosis sensor unit.

SRS800

SUPPLEMENTAL RESTRAINT SYSTEM (SRS)

Trouble Diagnoses with CONSULT-II (Cont'd)

RS-46