load capacity NISSAN TERRANO 2002 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2002, Model line: TERRANO, Model: NISSAN TERRANO 2002Pages: 1767, PDF Size: 41.51 MB

Page 1422 of 1767

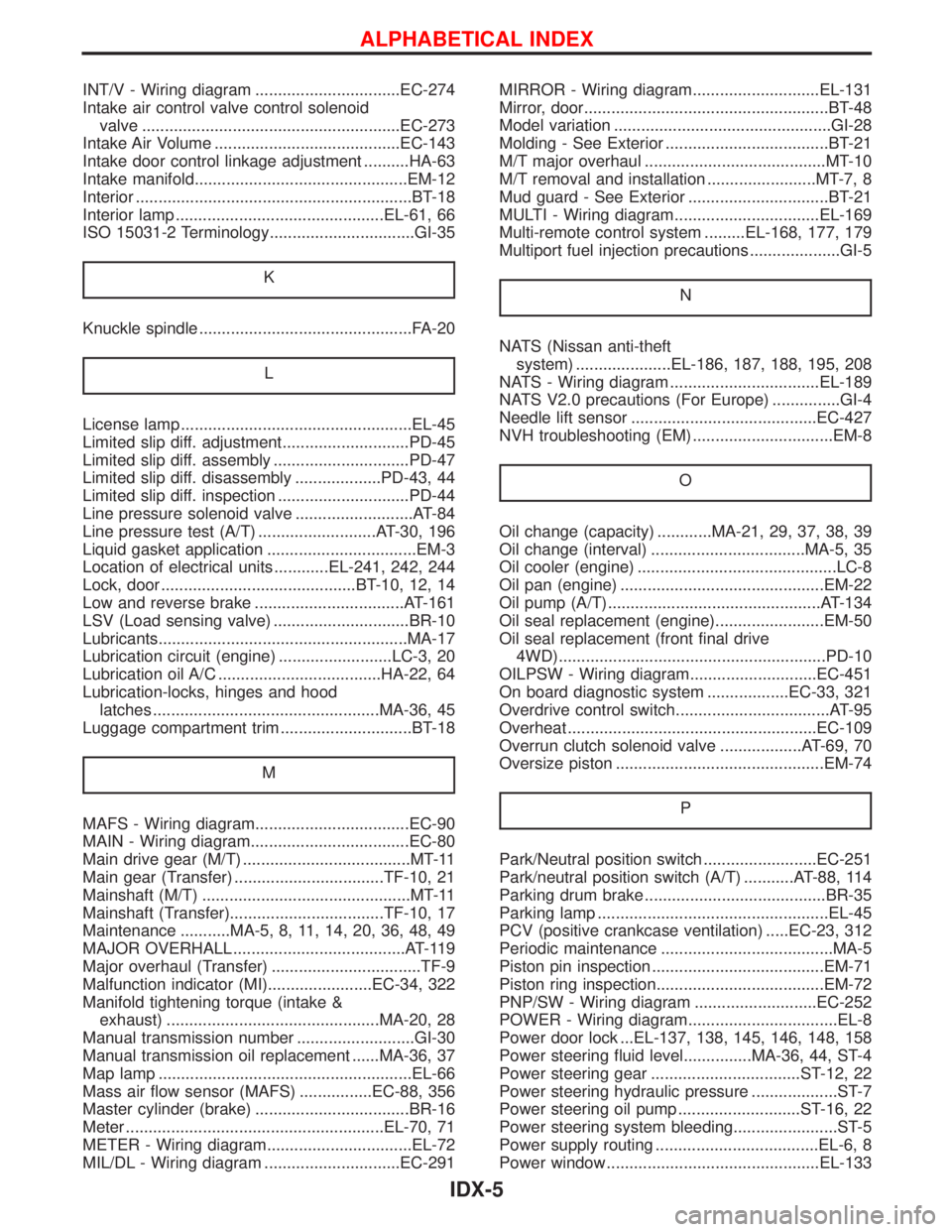

INT/V - Wiring diagram ................................EC-274

Intake air control valve control solenoid

valve .........................................................EC-273

Intake Air Volume .........................................EC-143

Intake door control linkage adjustment ..........HA-63

Intake manifold...............................................EM-12

Interior .............................................................BT-18

Interior lamp ..............................................EL-61, 66

ISO 15031-2 Terminology................................GI-35

K

Knuckle spindle ...............................................FA-20

L

License lamp ...................................................EL-45

Limited slip diff. adjustment............................PD-45

Limited slip diff. assembly ..............................PD-47

Limited slip diff. disassembly ...................PD-43, 44

Limited slip diff. inspection .............................PD-44

Line pressure solenoid valve ..........................AT-84

Line pressure test (A/T) ..........................AT-30, 196

Liquid gasket application .................................EM-3

Location of electrical units ............EL-241, 242, 244

Lock, door ...........................................BT-10, 12, 14

Low and reverse brake .................................AT-161

LSV (Load sensing valve) ..............................BR-10

Lubricants.......................................................MA-17

Lubrication circuit (engine) .........................LC-3, 20

Lubrication oil A/C ....................................HA-22, 64

Lubrication-locks, hinges and hood

latches ..................................................MA-36, 45

Luggage compartment trim .............................BT-18

M

MAFS - Wiring diagram..................................EC-90

MAIN - Wiring diagram...................................EC-80

Main drive gear (M/T) .....................................MT-11

Main gear (Transfer) .................................TF-10, 21

Mainshaft (M/T) ..............................................MT-11

Mainshaft (Transfer)..................................TF-10, 17

Maintenance ...........MA-5, 8, 11, 14, 20, 36, 48, 49

MAJOR OVERHALL ......................................AT-119

Major overhaul (Transfer) .................................TF-9

Malfunction indicator (MI).......................EC-34, 322

Manifold tightening torque (intake &

exhaust) ...............................................MA-20, 28

Manual transmission number ..........................GI-30

Manual transmission oil replacement ......MA-36, 37

Map lamp ........................................................EL-66

Mass air flow sensor (MAFS) ................EC-88, 356

Master cylinder (brake) ..................................BR-16

Meter .........................................................EL-70, 71

METER - Wiring diagram................................EL-72

MIL/DL - Wiring diagram ..............................EC-291MIRROR - Wiring diagram............................EL-131

Mirror, door......................................................BT-48

Model variation ................................................GI-28

Molding - See Exterior ....................................BT-21

M/T major overhaul ........................................MT-10

M/T removal and installation ........................MT-7, 8

Mud guard - See Exterior ...............................BT-21

MULTI - Wiring diagram................................EL-169

Multi-remote control system .........EL-168, 177, 179

Multiport fuel injection precautions ....................GI-5

N

NATS (Nissan anti-theft

system) .....................EL-186, 187, 188, 195, 208

NATS - Wiring diagram .................................EL-189

NATS V2.0 precautions (For Europe) ...............GI-4

Needle lift sensor .........................................EC-427

NVH troubleshooting (EM) ...............................EM-8

O

Oil change (capacity) ............MA-21, 29, 37, 38, 39

Oil change (interval) ..................................MA-5, 35

Oil cooler (engine) ............................................LC-8

Oil pan (engine) .............................................EM-22

Oil pump (A/T)...............................................AT-134

Oil seal replacement (engine)........................EM-50

Oil seal replacement (front final drive

4WD)...........................................................PD-10

OILPSW - Wiring diagram............................EC-451

On board diagnostic system ..................EC-33, 321

Overdrive control switch..................................AT-95

Overheat .......................................................EC-109

Overrun clutch solenoid valve ..................AT-69, 70

Oversize piston ..............................................EM-74

P

Park/Neutral position switch .........................EC-251

Park/neutral position switch (A/T) ...........AT-88, 114

Parking drum brake ........................................BR-35

Parking lamp ...................................................EL-45

PCV (positive crankcase ventilation) .....EC-23, 312

Periodic maintenance ......................................MA-5

Piston pin inspection ......................................EM-71

Piston ring inspection.....................................EM-72

PNP/SW - Wiring diagram ...........................EC-252

POWER - Wiring diagram.................................EL-8

Power door lock ...EL-137, 138, 145, 146, 148, 158

Power steering fluid level...............MA-36, 44, ST-4

Power steering gear .................................ST-12, 22

Power steering hydraulic pressure ...................ST-7

Power steering oil pump ...........................ST-16, 22

Power steering system bleeding.......................ST-5

Power supply routing ....................................EL-6, 8

Power window ...............................................EL-133

ALPHABETICAL INDEX

IDX-5

Page 1603 of 1767

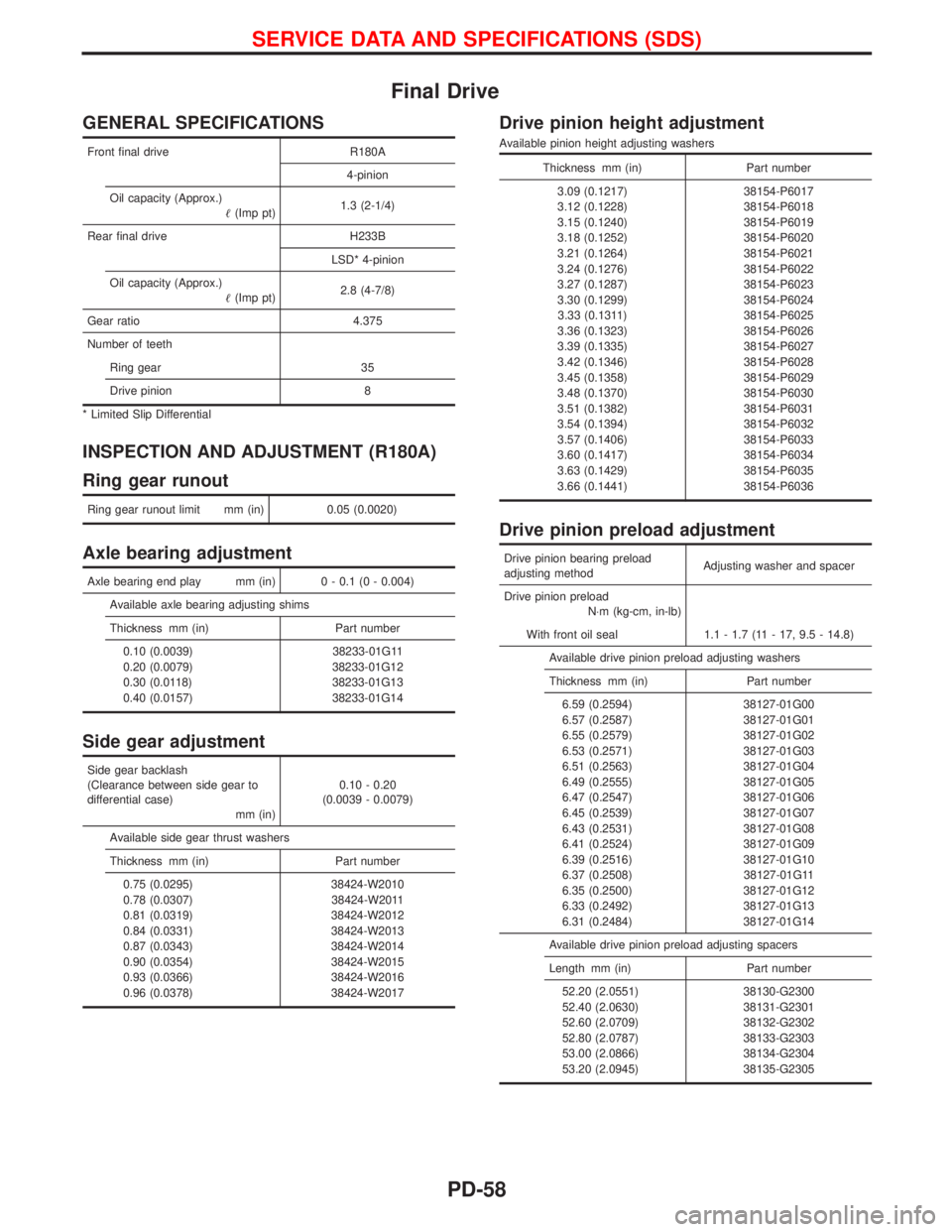

Final Drive

GENERAL SPECIFICATIONS

Front final drive R180A

4-pinion

Oil capacity (Approx.)

(Imp pt)1.3 (2-1/4)

Rear final drive H233B

LSD* 4-pinion

Oil capacity (Approx.)

(Imp pt)2.8 (4-7/8)

Gear ratio 4.375

Number of teeth

Ring gear 35

Drive pinion 8

* Limited Slip Differential

INSPECTION AND ADJUSTMENT (R180A)

Ring gear runout

Ring gear runout limit mm (in) 0.05 (0.0020)

Axle bearing adjustment

Axle bearing end play mm (in) 0 - 0.1 (0 - 0.004)

Available axle bearing adjusting shims

Thickness mm (in) Part number

0.10 (0.0039) 38233-01G11

0.20 (0.0079) 38233-01G12

0.30 (0.0118) 38233-01G13

0.40 (0.0157) 38233-01G14

Side gear adjustment

Side gear backlash

(Clearance between side gear to

differential case)

mm (in)0.10 - 0.20

(0.0039 - 0.0079)

Available side gear thrust washers

Thickness mm (in) Part number

0.75 (0.0295) 38424-W2010

0.78 (0.0307) 38424-W2011

0.81 (0.0319) 38424-W2012

0.84 (0.0331) 38424-W2013

0.87 (0.0343) 38424-W2014

0.90 (0.0354) 38424-W2015

0.93 (0.0366) 38424-W2016

0.96 (0.0378) 38424-W2017

Drive pinion height adjustment

Available pinion height adjusting washers

Thickness mm (in) Part number

3.09 (0.1217) 38154-P6017

3.12 (0.1228) 38154-P6018

3.15 (0.1240) 38154-P6019

3.18 (0.1252) 38154-P6020

3.21 (0.1264) 38154-P6021

3.24 (0.1276) 38154-P6022

3.27 (0.1287) 38154-P6023

3.30 (0.1299) 38154-P6024

3.33 (0.1311) 38154-P6025

3.36 (0.1323) 38154-P6026

3.39 (0.1335) 38154-P6027

3.42 (0.1346) 38154-P6028

3.45 (0.1358) 38154-P6029

3.48 (0.1370) 38154-P6030

3.51 (0.1382) 38154-P6031

3.54 (0.1394) 38154-P6032

3.57 (0.1406) 38154-P6033

3.60 (0.1417) 38154-P6034

3.63 (0.1429) 38154-P6035

3.66 (0.1441) 38154-P6036

Drive pinion preload adjustment

Drive pinion bearing preload

adjusting methodAdjusting washer and spacer

Drive pinion preload

N×m (kg-cm, in-lb)

With front oil seal 1.1 - 1.7 (11 - 17, 9.5 - 14.8)

Available drive pinion preload adjusting washers

Thickness mm (in) Part number

6.59 (0.2594) 38127-01G00

6.57 (0.2587) 38127-01G01

6.55 (0.2579) 38127-01G02

6.53 (0.2571) 38127-01G03

6.51 (0.2563) 38127-01G04

6.49 (0.2555) 38127-01G05

6.47 (0.2547) 38127-01G06

6.45 (0.2539) 38127-01G07

6.43 (0.2531) 38127-01G08

6.41 (0.2524) 38127-01G09

6.39 (0.2516) 38127-01G10

6.37 (0.2508) 38127-01G11

6.35 (0.2500) 38127-01G12

6.33 (0.2492) 38127-01G13

6.31 (0.2484) 38127-01G14

Available drive pinion preload adjusting spacers

Length mm (in) Part number

52.20 (2.0551) 38130-G2300

52.40 (2.0630) 38131-G2301

52.60 (2.0709) 38132-G2302

52.80 (2.0787) 38133-G2303

53.00 (2.0866) 38134-G2304

53.20 (2.0945) 38135-G2305

SERVICE DATA AND SPECIFICATIONS (SDS)

PD-58

Page 1711 of 1767

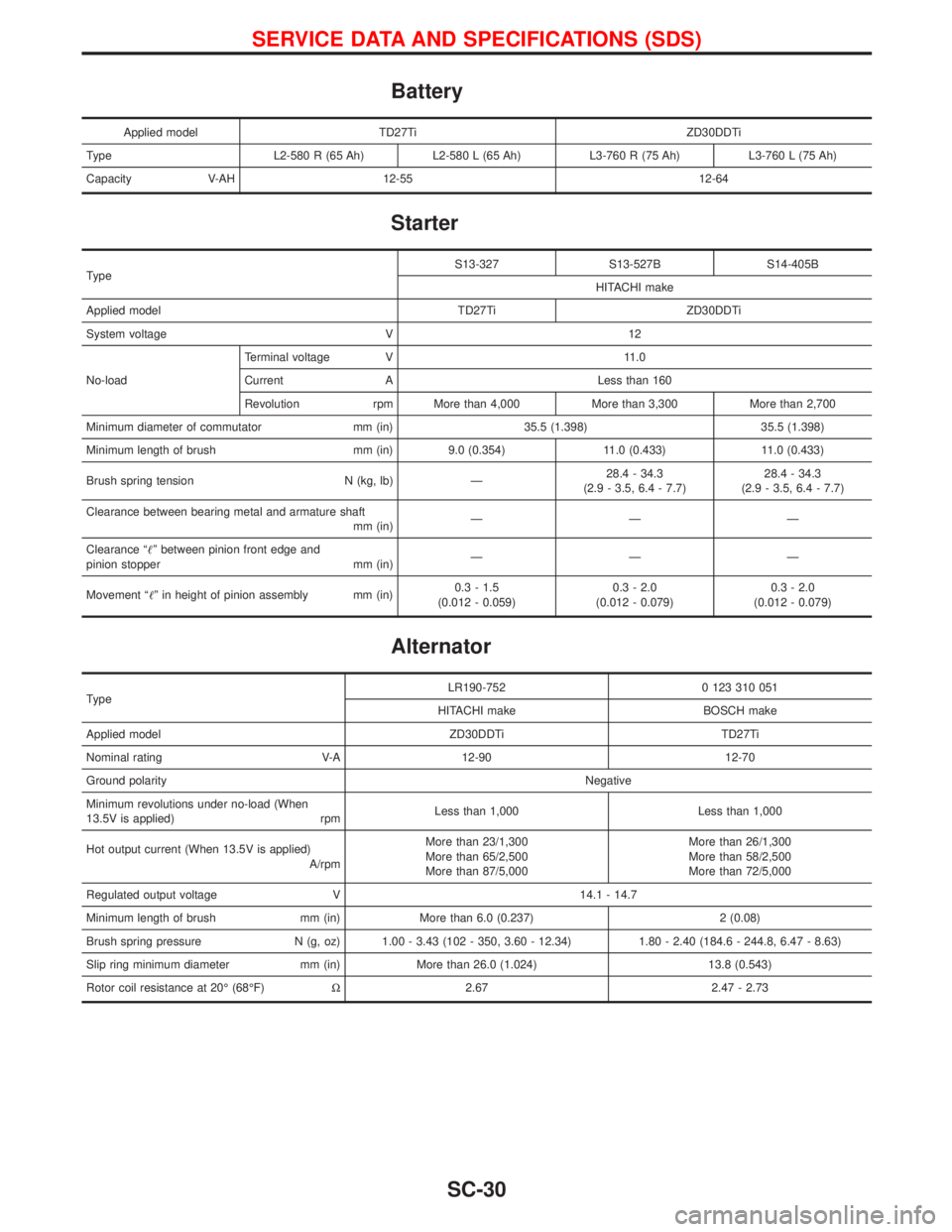

Battery

Applied model TD27Ti ZD30DDTi

Type L2-580 R (65 Ah) L2-580 L (65 Ah) L3-760 R (75 Ah) L3-760 L (75 Ah)

Capacity V-AH 12-55 12-64

Starter

TypeS13-327 S13-527B S14-405B

HITACHI make

Applied model TD27Ti ZD30DDTi

System voltage V 12

No-loadTerminal voltage V 11.0

Current A Less than 160

Revolution rpm More than 4,000 More than 3,300 More than 2,700

Minimum diameter of commutator mm (in) 35.5 (1.398) 35.5 (1.398)

Minimum length of brush mm (in) 9.0 (0.354) 11.0 (0.433) 11.0 (0.433)

Brush spring tension N (kg, lb) Ð28.4 - 34.3

(2.9 - 3.5, 6.4 - 7.7)28.4 - 34.3

(2.9 - 3.5, 6.4 - 7.7)

Clearance between bearing metal and armature shaft

mm (in)ÐÐÐ

Clearance ªº between pinion front edge and

pinion stopper mm (in)ÐÐÐ

Movement ªº in height of pinion assembly mm (in)0.3 - 1.5

(0.012 - 0.059)0.3 - 2.0

(0.012 - 0.079)0.3 - 2.0

(0.012 - 0.079)

Alternator

TypeLR190-752 0 123 310 051

HITACHI make BOSCH make

Applied model ZD30DDTi TD27Ti

Nominal rating V-A 12-90 12-70

Ground polarityNegative

Minimum revolutions under no-load (When

13.5V is applied) rpmLess than 1,000 Less than 1,000

Hot output current (When 13.5V is applied)

A/rpmMore than 23/1,300

More than 65/2,500

More than 87/5,000More than 26/1,300

More than 58/2,500

More than 72/5,000

Regulated output voltage V 14.1 - 14.7

Minimum length of brush mm (in) More than 6.0 (0.237) 2 (0.08)

Brush spring pressure N (g, oz) 1.00 - 3.43 (102 - 350, 3.60 - 12.34) 1.80 - 2.40 (184.6 - 244.8, 6.47 - 8.63)

Slip ring minimum diameter mm (in) More than 26.0 (1.024) 13.8 (0.543)

Rotor coil resistance at 20É (68ÉF)W2.67 2.47 - 2.73

SERVICE DATA AND SPECIFICATIONS (SDS)

SC-30