oil NISSAN TERRANO 2004 Service Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2004, Model line: TERRANO, Model: NISSAN TERRANO 2004Pages: 1833, PDF Size: 53.42 MB

Page 96 of 1833

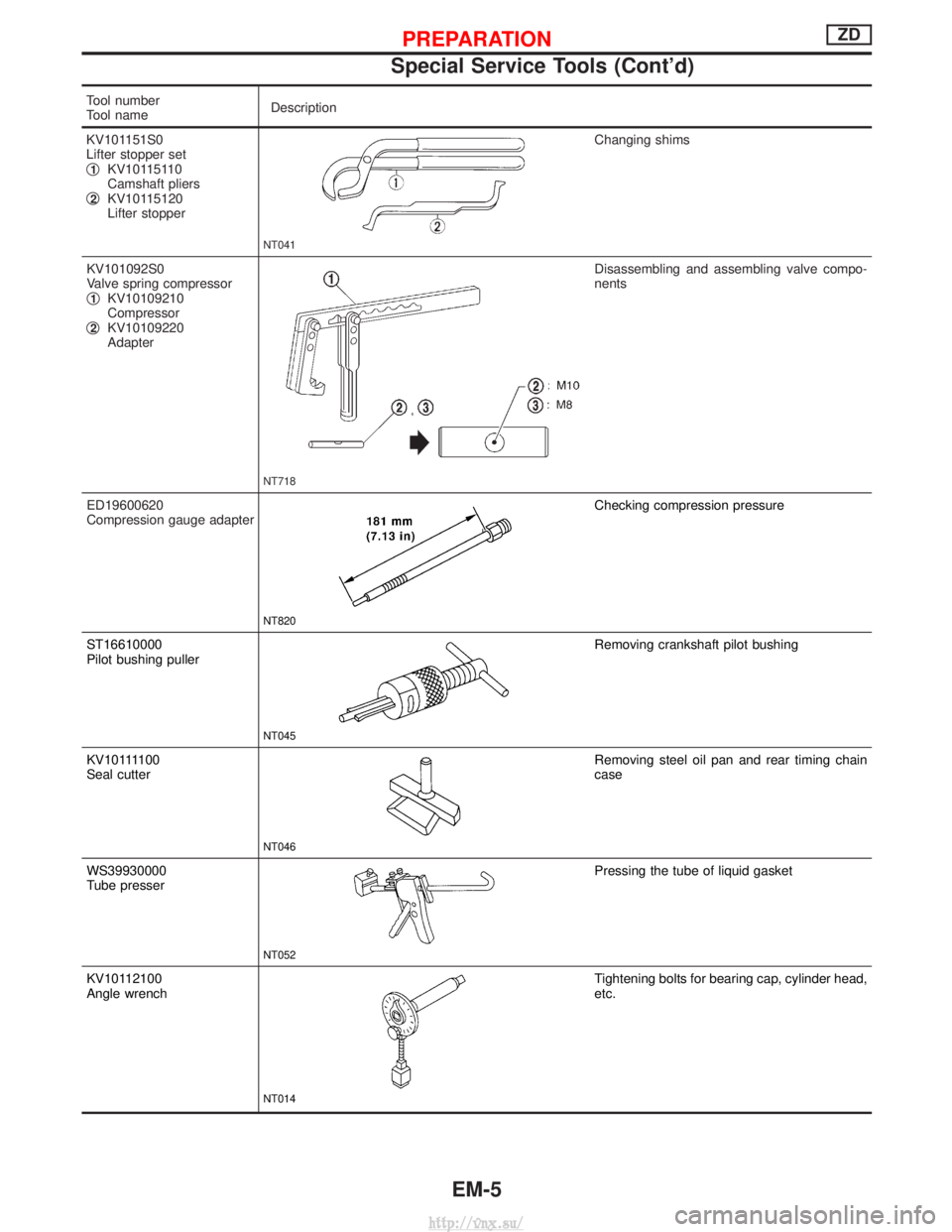

Tool number

Tool nameDescription

KV101151S0

Lifter stopper set

q

1KV10115110

Camshaft pliers

q

2KV10115120

Lifter stopper

NT041

Changing shims

KV101092S0

Valve spring compressor

q

1KV10109210

Compressor

q

2KV10109220

Adapter

NT718

Disassembling and assembling valve compo-

nents

ED19600620

Compression gauge adapter

NT820

Checking compression pressure

ST16610000

Pilot bushing puller

NT045

Removing crankshaft pilot bushing

KV101111 0 0

Seal cutter

NT046

Removing steel oil pan and rear timing chain

case

WS39930000

Tube presser

NT052

Pressing the tube of liquid gasket

KV10112100

Angle wrench

NT014

Tightening bolts for bearing cap, cylinder head,

etc.

PREPARATIONZD

Special Service Tools (Cont'd)

EM-5

http://vnx.su/

Page 100 of 1833

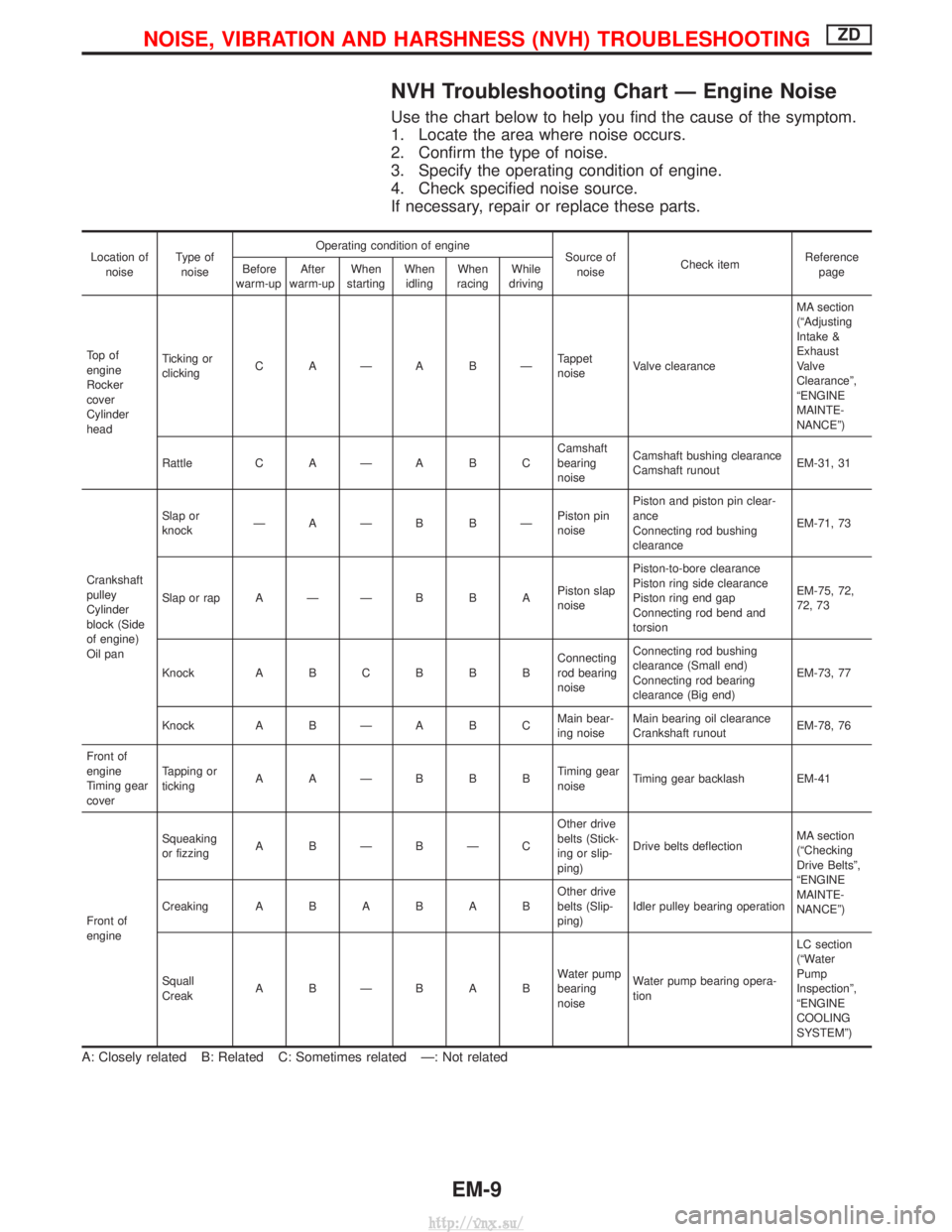

NVH Troubleshooting Chart Ð Engine Noise

Use the chart below to help you find the cause of the symptom.

1. Locate the area where noise occurs.

2. Confirm the type of noise.

3. Specify the operating condition of engine.

4. Check specified noise source.

If necessary, repair or replace these parts.

Location ofnoise Type of

noise Operating condition of engine

Source of

noise Check item Reference

page

Before

warm-up After

warm-up When

starting When

idling When

racing While

driving

To p o f

engine

Rocker

cover

Cylinder

head Ticking or

clicking

C AÐA BÐ Tappet

noiseValve clearance MA section

(ªAdjusting

Intake &

Exhaust

Valve

Clearanceº,

ªENGINE

MAINTE-

NANCEº)

Rattle C A Ð A B C Camshaft

bearing

noiseCamshaft bushing clearance

Camshaft runout

EM-31, 31

Crankshaft

pulley

Cylinder

block (Side

of engine)

Oil pan Slap or

knock

ÐAÐB BÐ Piston pin

noisePiston and piston pin clear-

ance

Connecting rod bushing

clearance

EM-71, 73

Slap or rap A Ð Ð B B A Piston slap

noisePiston-to-bore clearance

Piston ring side clearance

Piston ring end gap

Connecting rod bend and

torsion EM-75, 72,

72, 73

Knock A B C B B B Connecting

rod bearing

noiseConnecting rod bushing

clearance (Small end)

Connecting rod bearing

clearance (Big end)

EM-73, 77

Knock A B Ð A B C Main bear-

ing noiseMain bearing oil clearance

Crankshaft runout

EM-78, 76

Front of

engine

Timing gear

cover Tapping or

ticking

AAÐBBB Timing gear

noiseTiming gear backlash EM-41

Front of

engine Squeaking

or fizzing

A BÐBÐC Other drive

belts (Stick-

ing or slip-

ping)Drive belts deflection

MA section

(ªChecking

Drive Beltsº,

ªENGINE

MAINTE-

NANCEº)

Creaking

ABABAB Other drive

belts (Slip-

ping)Idler pulley bearing operation

Squall

Creak ABÐBAB Water pump

bearing

noiseWater pump bearing opera-

tion LC section

(ªWater

Pump

Inspectionº,

ªENGINE

COOLING

SYSTEMº)

A: Closely related B: Related C: Sometimes related Ð: Not related

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTINGZD

EM-9

http://vnx.su/

Page 101 of 1833

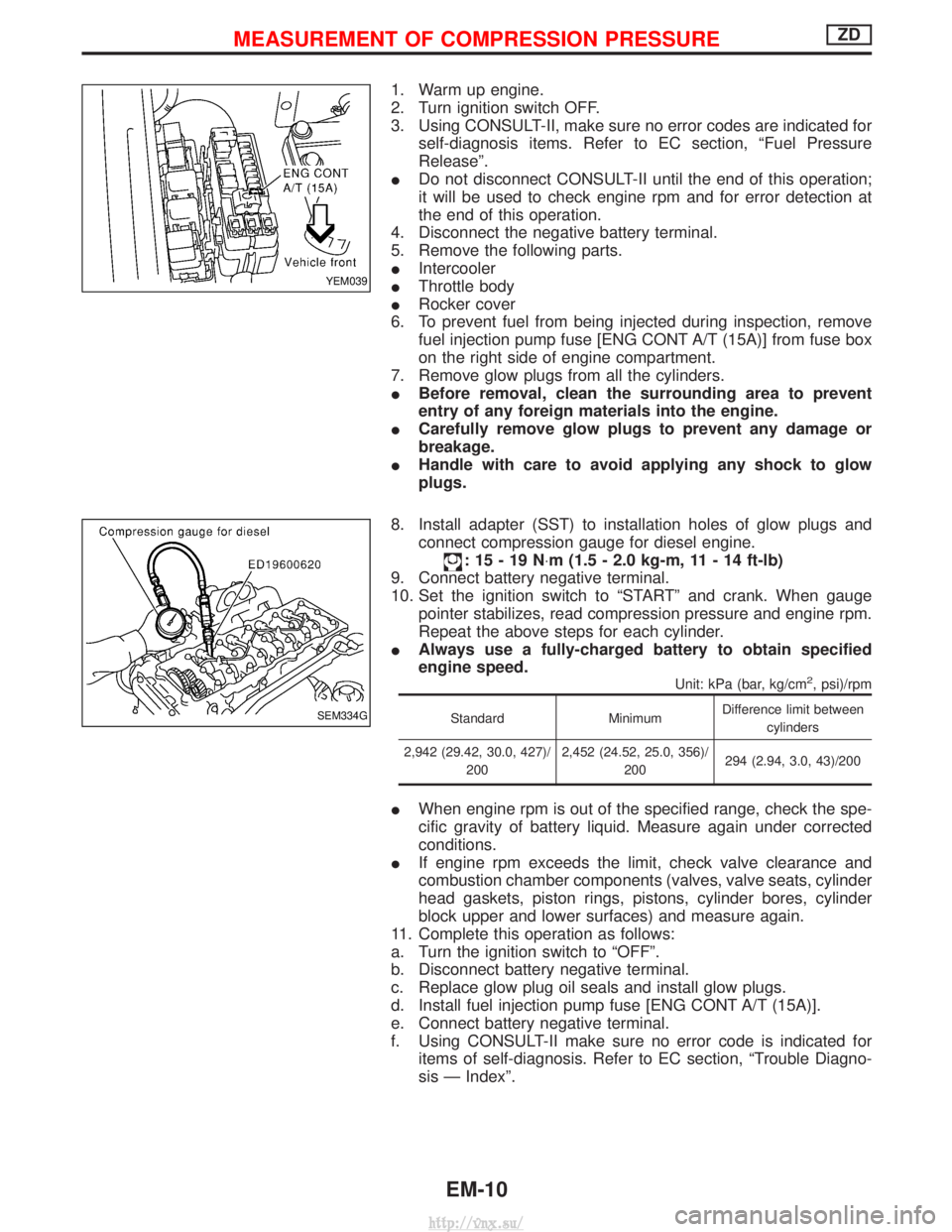

1. Warm up engine.

2. Turn ignition switch OFF.

3. Using CONSULT-II, make sure no error codes are indicated forself-diagnosis items. Refer to EC section, ªFuel Pressure

Releaseº.

I Do not disconnect CONSULT-II until the end of this operation;

it will be used to check engine rpm and for error detection at

the end of this operation.

4. Disconnect the negative battery terminal.

5. Remove the following parts.

I Intercooler

I Throttle body

I Rocker cover

6. To prevent fuel from being injected during inspection, remove fuel injection pump fuse [ENG CONT A/T (15A)] from fuse box

on the right side of engine compartment.

7. Remove glow plugs from all the cylinders.

I Before removal, clean the surrounding area to prevent

entry of any foreign materials into the engine.

I Carefully remove glow plugs to prevent any damage or

breakage.

I Handle with care to avoid applying any shock to glow

plugs.

8. Install adapter (SST) to installation holes of glow plugs and connect compression gauge for diesel engine.

:15-19N ×m (1.5 - 2.0 kg-m, 11 - 14 ft-lb)

9. Connect battery negative terminal.

10. Set the ignition switch to ªSTARTº and crank. When gauge pointer stabilizes, read compression pressure and engine rpm.

Repeat the above steps for each cylinder.

I Always use a fully-charged battery to obtain specified

engine speed.

Unit: kPa (bar, kg/cm2, psi)/rpm

Standard MinimumDifference limit between

cylinders

2,942 (29.42, 30.0, 427)/ 200 2,452 (24.52, 25.0, 356)/

200 294 (2.94, 3.0, 43)/200

I

When engine rpm is out of the specified range, check the spe-

cific gravity of battery liquid. Measure again under corrected

conditions.

I If engine rpm exceeds the limit, check valve clearance and

combustion chamber components (valves, valve seats, cylinder

head gaskets, piston rings, pistons, cylinder bores, cylinder

block upper and lower surfaces) and measure again.

11. Complete this operation as follows:

a. Turn the ignition switch to ªOFFº.

b. Disconnect battery negative terminal.

c. Replace glow plug oil seals and install glow plugs.

d. Install fuel injection pump fuse [ENG CONT A/T (15A)].

e. Connect battery negative terminal.

f. Using CONSULT-II make sure no error code is indicated for items of self-diagnosis. Refer to EC section, ªTrouble Diagno-

sis Ð Indexº.

YEM039

SEM334G

MEASUREMENT OF COMPRESSION PRESSUREZD

EM-10

http://vnx.su/

Page 106 of 1833

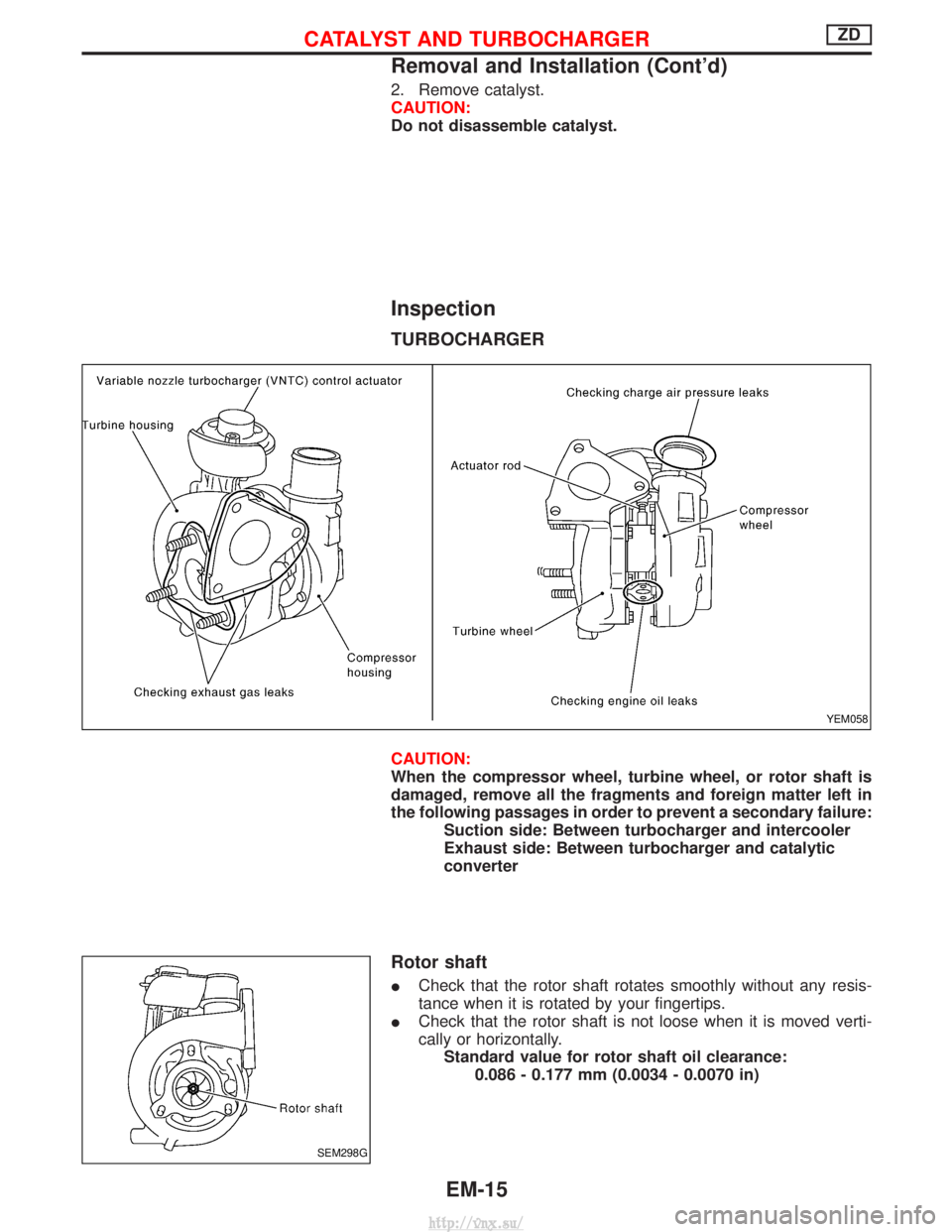

2. Remove catalyst.

CAUTION:

Do not disassemble catalyst.

Inspection

TURBOCHARGER

CAUTION:

When the compressor wheel, turbine wheel, or rotor shaft is

damaged, remove all the fragments and foreign matter left in

the following passages in order to prevent a secondary failure:Suction side: Between turbocharger and intercooler

Exhaust side: Between turbocharger and catalytic

converter

Rotor shaft

ICheck that the rotor shaft rotates smoothly without any resis-

tance when it is rotated by your fingertips.

I Check that the rotor shaft is not loose when it is moved verti-

cally or horizontally.

Standard value for rotor shaft oil clearance: 0.086 - 0.177 mm (0.0034 - 0.0070 in)

YEM058

SEM298G

CATALYST AND TURBOCHARGERZD

Removal and Installation (Cont'd)

EM-15

http://vnx.su/

Page 107 of 1833

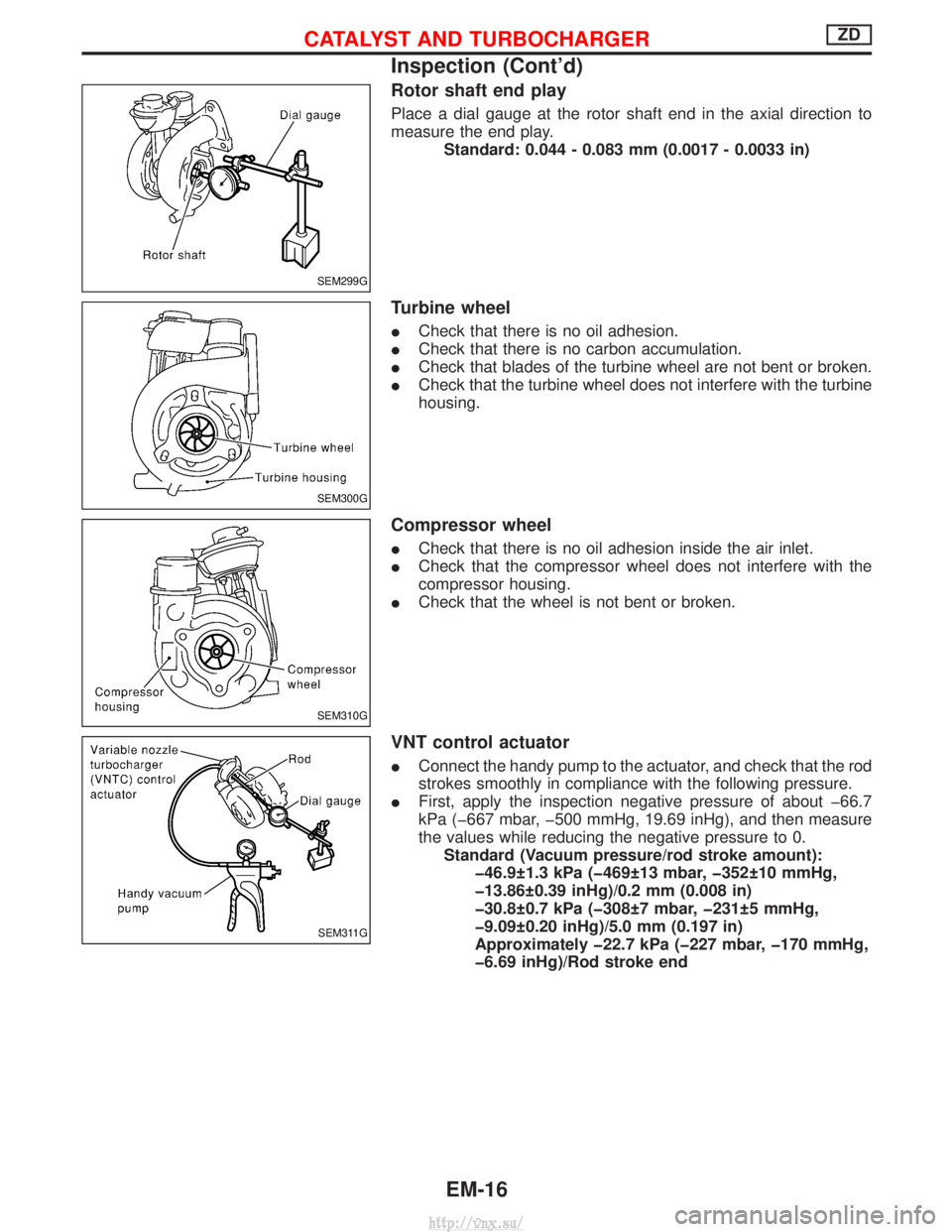

Rotor shaft end play

Place a dial gauge at the rotor shaft end in the axial direction to

measure the end play.Standard: 0.044 - 0.083 mm (0.0017 - 0.0033 in)

Turbine wheel

ICheck that there is no oil adhesion.

I Check that there is no carbon accumulation.

I Check that blades of the turbine wheel are not bent or broken.

I Check that the turbine wheel does not interfere with the turbine

housing.

Compressor wheel

ICheck that there is no oil adhesion inside the air inlet.

I Check that the compressor wheel does not interfere with the

compressor housing.

I Check that the wheel is not bent or broken.

VNT control actuator

IConnect the handy pump to the actuator, and check that the rod

strokes smoothly in compliance with the following pressure.

I First, apply the inspection negative pressure of about þ66.7

kPa (þ667 mbar, þ500 mmHg, 19.69 inHg), and then measure

the values while reducing the negative pressure to 0.

Standard (Vacuum pressure/rod stroke amount): þ46.9 1.3 kPa (þ469 13 mbar, þ352 10 mmHg,

þ13.86 0.39 inHg)/0.2 mm (0.008 in)

þ30.8 0.7 kPa (þ308 7 mbar, þ231 5 mmHg,

þ9.09 0.20 inHg)/5.0 mm (0.197 in)

Approximately þ22.7 kPa (þ227 mbar, þ170 mmHg,

þ6.69 inHg)/Rod stroke end

SEM299G

SEM300G

SEM310G

SEM311G

CATALYST AND TURBOCHARGERZD

Inspection (Cont'd)

EM-16

http://vnx.su/

Page 108 of 1833

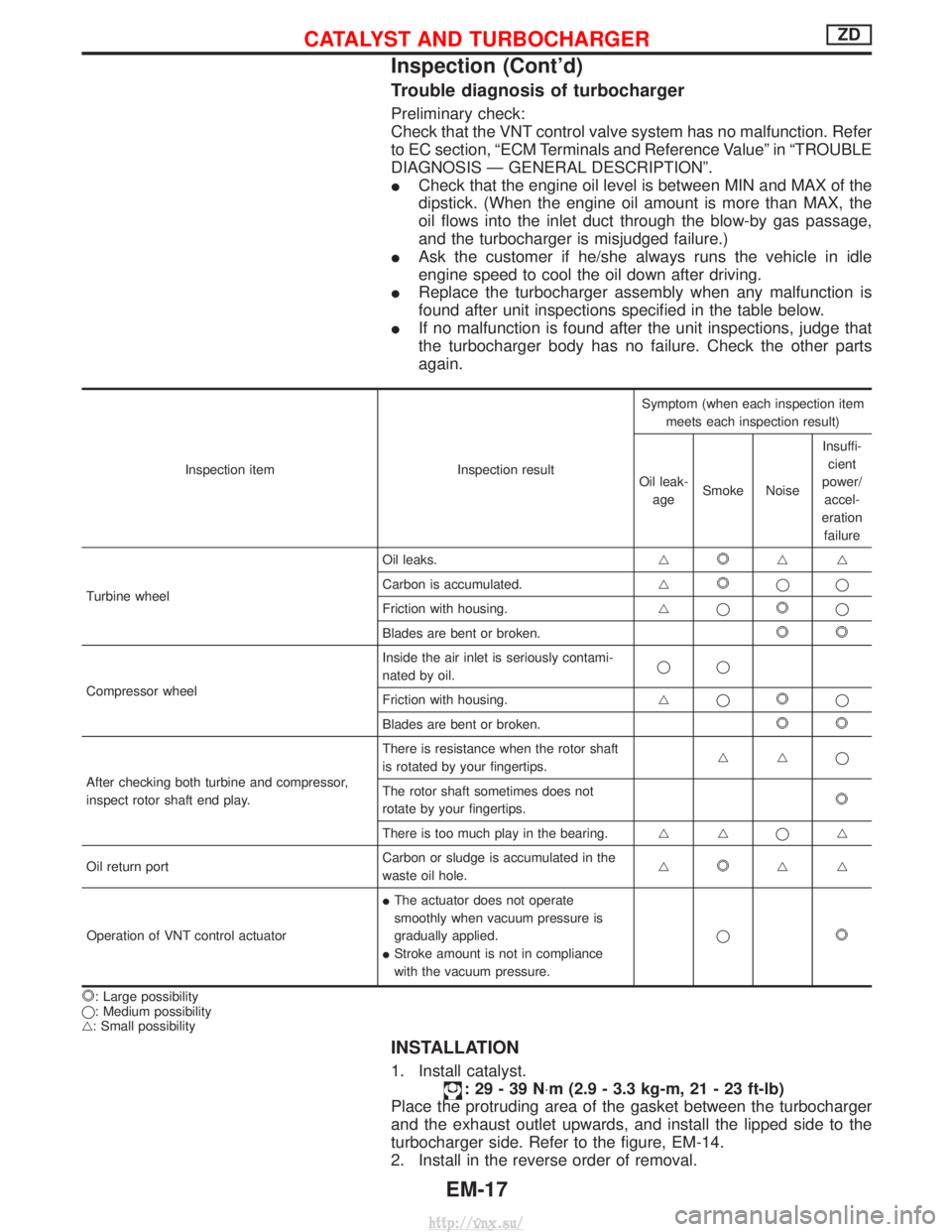

Trouble diagnosis of turbocharger

Preliminary check:

Check that the VNT control valve system has no malfunction. Refer

to EC section, ªECM Terminals and Reference Valueº in ªTROUBLE

DIAGNOSIS Ð GENERAL DESCRIPTIONº.

ICheck that the engine oil level is between MIN and MAX of the

dipstick. (When the engine oil amount is more than MAX, the

oil flows into the inlet duct through the blow-by gas passage,

and the turbocharger is misjudged failure.)

I Ask the customer if he/she always runs the vehicle in idle

engine speed to cool the oil down after driving.

I Replace the turbocharger assembly when any malfunction is

found after unit inspections specified in the table below.

I If no malfunction is found after the unit inspections, judge that

the turbocharger body has no failure. Check the other parts

again.

Inspection item Inspection resultSymptom (when each inspection item

meets each inspection result)

Oil leak- age Smoke Noise Insuffi-

cient

power/ accel-

eration failure

Turbine wheel Oil leaks.

g

gg

Carbon is accumulated. g

qq

Friction with housing. gq

q

Blades are bent or broken.

Compressor wheel Inside the air inlet is seriously contami-

nated by oil.

qq

Friction with housing. gqq

Blades are bent or broken.

After checking both turbine and compressor,

inspect rotor shaft end play. There is resistance when the rotor shaft

is rotated by your fingertips.

ggq

The rotor shaft sometimes does not

rotate by your fingertips.

There is too much play in the bearing. g gqg

Oil return port Carbon or sludge is accumulated in the

waste oil hole.g

gg

Operation of VNT control actuator I

The actuator does not operate

smoothly when vacuum pressure is

gradually applied.

I Stroke amount is not in compliance

with the vacuum pressure. q

: Large possibility

q: Medium possibility

g: Small possibility

INSTALLATION

1. Install catalyst.

:29-39N ×m (2.9 - 3.3 kg-m, 21 - 23 ft-lb)

Place the protruding area of the gasket between the turbocharger

and the exhaust outlet upwards, and install the lipped side to the

turbocharger side. Refer to the figure, EM-14.

2. Install in the reverse order of removal.

CATALYST AND TURBOCHARGERZD

Inspection (Cont'd)

EM-17

http://vnx.su/

Page 111 of 1833

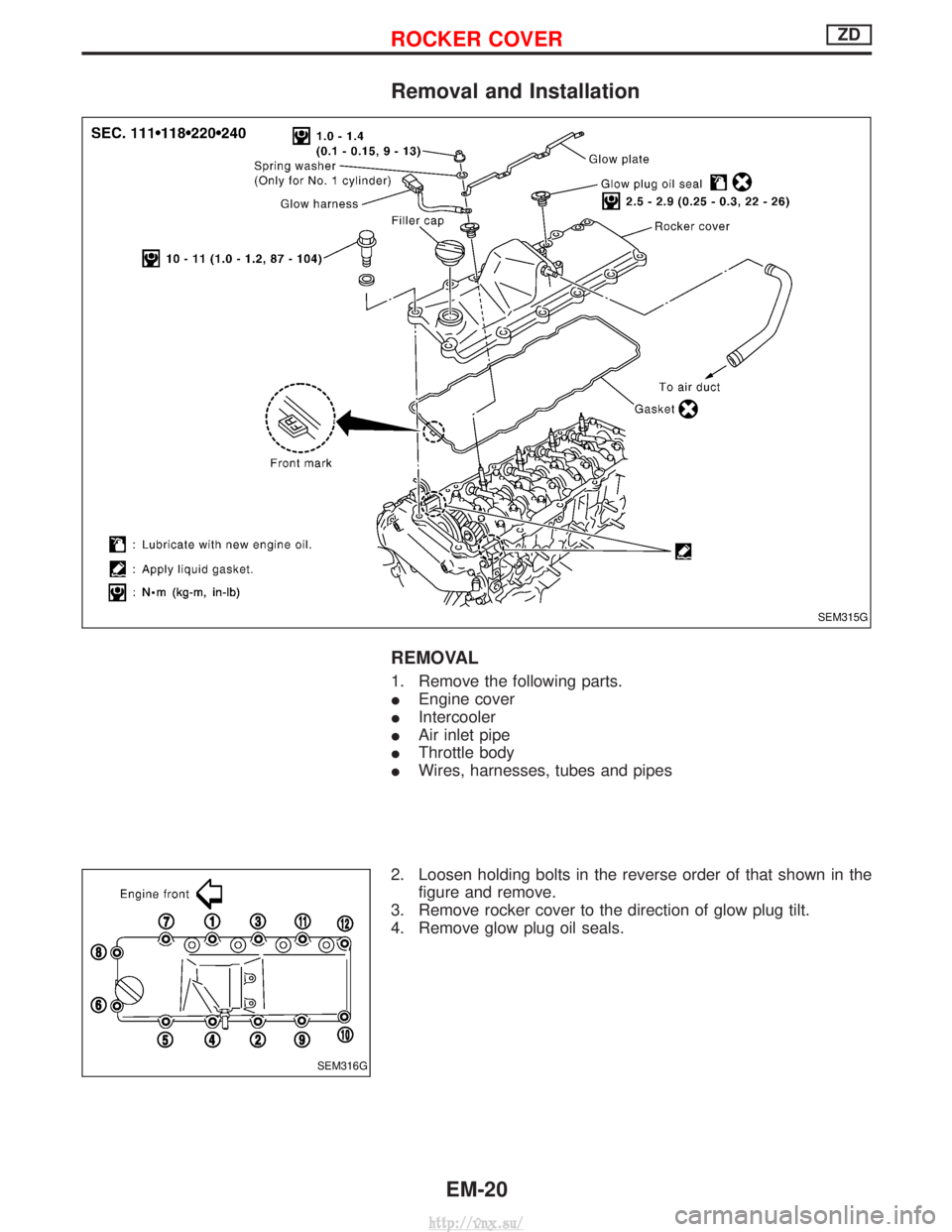

Removal and Installation

REMOVAL

1. Remove the following parts.

IEngine cover

I Intercooler

I Air inlet pipe

I Throttle body

I Wires, harnesses, tubes and pipes

2. Loosen holding bolts in the reverse order of that shown in the figure and remove.

3. Remove rocker cover to the direction of glow plug tilt.

4. Remove glow plug oil seals.

SEM315G

SEM316G

ROCKER COVERZD

EM-20

http://vnx.su/

Page 112 of 1833

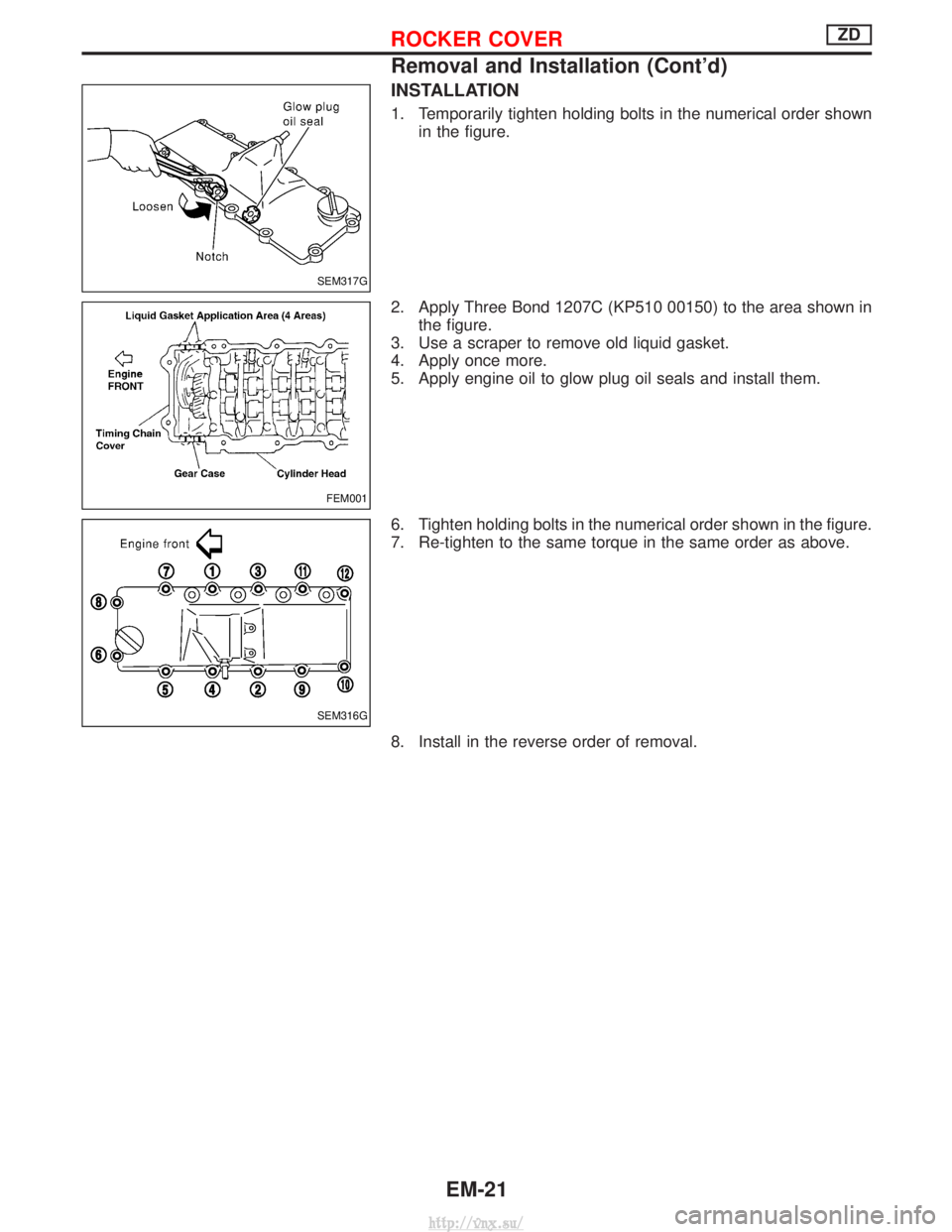

INSTALLATION

1. Temporarily tighten holding bolts in the numerical order shownin the figure.

2. Apply Three Bond 1207C (KP510 00150) to the area shown in the figure.

3. Use a scraper to remove old liquid gasket.

4. Apply once more.

5. Apply engine oil to glow plug oil seals and install them.

6. Tighten holding bolts in the numerical order shown in the figure.

7. Re-tighten to the same torque in the same order as above.

8. Install in the reverse order of removal.

SEM317G

FEM001

SEM316G

ROCKER COVERZD

Removal and Installation (Cont'd)

EM-21

http://vnx.su/

Page 113 of 1833

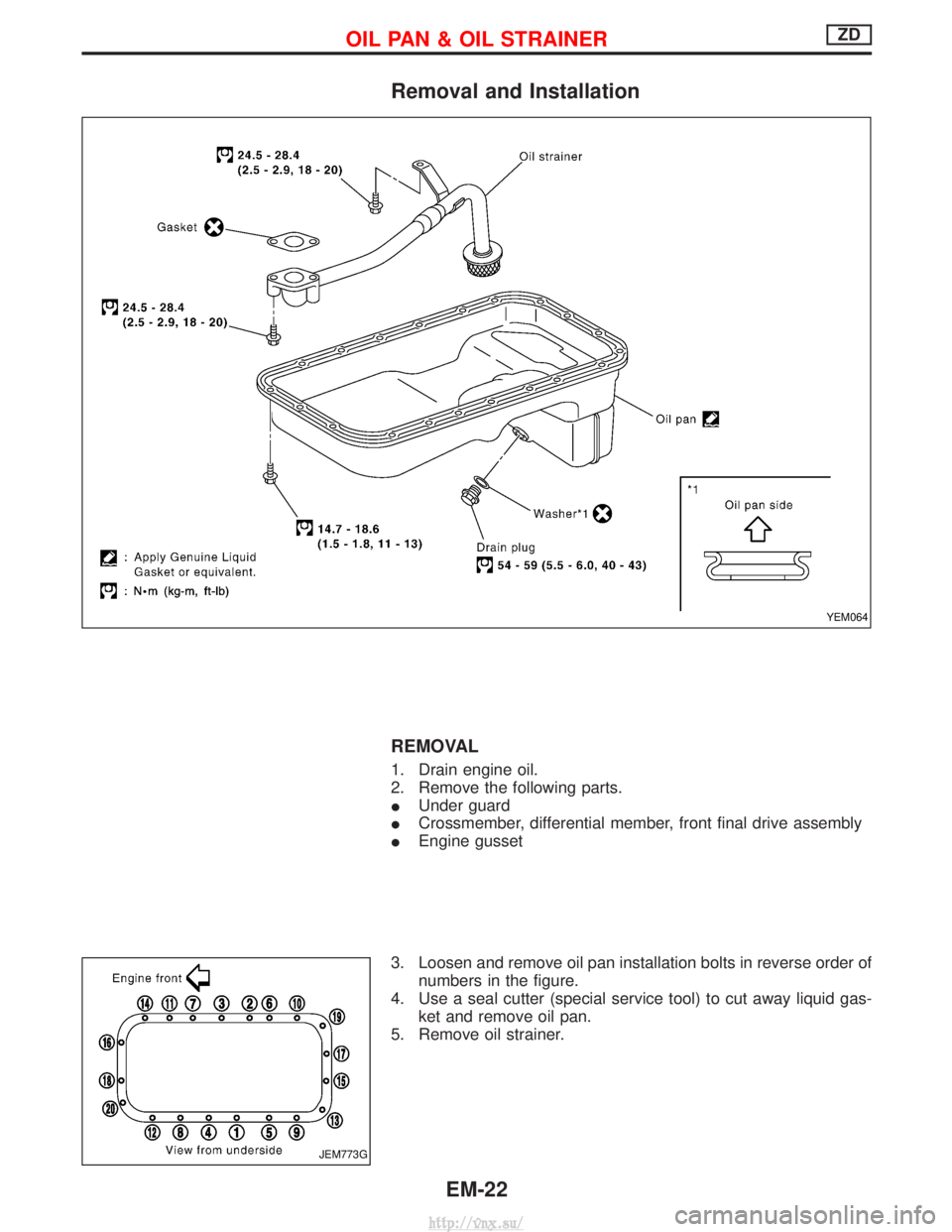

Removal and Installation

REMOVAL

1. Drain engine oil.

2. Remove the following parts.

IUnder guard

I Crossmember, differential member, front final drive assembly

I Engine gusset

3. Loosen and remove oil pan installation bolts in reverse order of numbers in the figure.

4. Use a seal cutter (special service tool) to cut away liquid gas- ket and remove oil pan.

5. Remove oil strainer.

YEM064

JEM773G

OIL PAN & OIL STRAINERZD

EM-22

http://vnx.su/

Page 114 of 1833

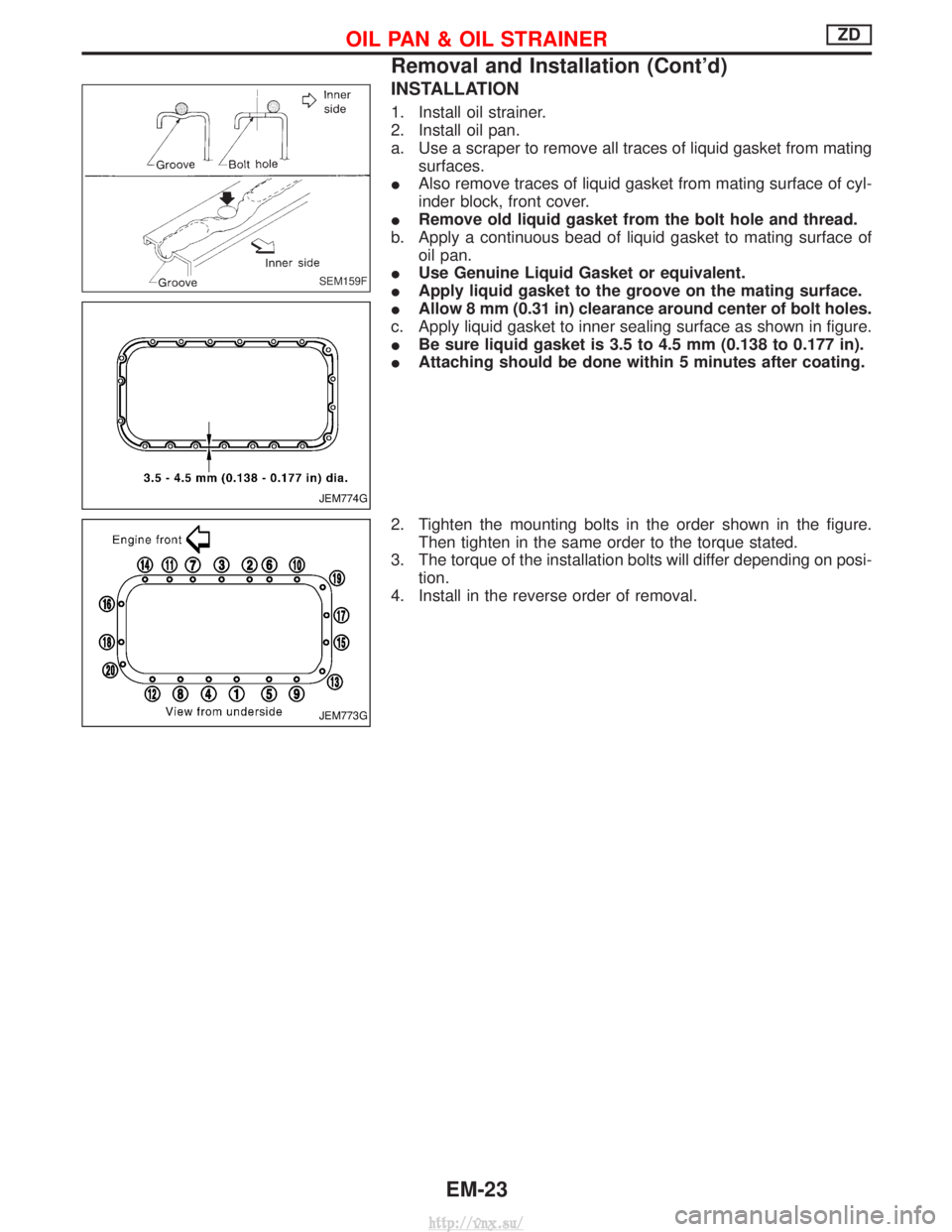

INSTALLATION

1. Install oil strainer.

2. Install oil pan.

a. Use a scraper to remove all traces of liquid gasket from matingsurfaces.

I Also remove traces of liquid gasket from mating surface of cyl-

inder block, front cover.

I Remove old liquid gasket from the bolt hole and thread.

b. Apply a continuous bead of liquid gasket to mating surface of oil pan.

I Use Genuine Liquid Gasket or equivalent.

I Apply liquid gasket to the groove on the mating surface.

I Allow 8 mm (0.31 in) clearance around center of bolt holes.

c. Apply liquid gasket to inner sealing surface as shown in figure.

I Be sure liquid gasket is 3.5 to 4.5 mm (0.138 to 0.177 in).

I Attaching should be done within 5 minutes after coating.

2. Tighten the mounting bolts in the order shown in the figure. Then tighten in the same order to the torque stated.

3. The torque of the installation bolts will differ depending on posi- tion.

4. Install in the reverse order of removal.

SEM159F

JEM774G

JEM773G

OIL PAN & OIL STRAINERZD

Removal and Installation (Cont'd)

EM-23

http://vnx.su/