wiper fluid NISSAN TERRANO 2004 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2004, Model line: TERRANO, Model: NISSAN TERRANO 2004Pages: 1833, PDF Size: 53.42 MB

Page 44 of 1833

Shown below are Pre-delivery Inspection items required for the new vehicle. It is recommended that

necessary items other than those listed here be added, paying due regard to the conditions in each

country.

Perform applicable items on each model. Consult text of this section for specifications.

UNDER HOOD Ð engine off

lRadiator coolant level and coolant hose connections for leaks

l Battery fluid level, specific gravity and conditions of battery terminals

l Drive belts tension

l Fuel filter for water or dust, and fuel lines and connections for leaks

l Engine oil level and oil leaks

l Brake and clutch reservoirs fluid level and fluid lines for leaks

l Windshield and rear window washer and headlamp cleaner reservoir fluid level

l Power steering reservoir fluid level and hose connections for leaks

ON INSIDE AND OUTSIDE

lRemove front spring/strut spacer (if applicable)

l Operation of all instruments, gauges, lights and accessories

l Operation of horn(s), wiper and washer

l Steering lock for operation

l Check air conditioner for gas leaks

l Front and rear seats, and seat belts for operation

l All moldings, trims and fittings for fit and alignment

l All windows for operation and alignment

l Hood, tailgate, door panels for fit and alignment

l Latches, keys and locks for operation

l Weatherstrips for adhesion and fit

l Headlamp aiming

l Tighten wheel nuts (Inc. inner nuts if applicable)

l Tire pressure (Inc. spare tire)

l Check front wheels for toe-in

l Install clock/voltmeter/room lamp fuse (if applicable)

l Install deodorizing filter to air conditioner (if applicable)

l Remove wiper blade protectors (if applicable)

UNDER BODY

lManual transmission/transaxle, transfer and differential gear oil level

l Brake and fuel lines and oil/fluid reservoirs for leaks

l Tighten bolts and nuts of steering linkage and gear box, suspension, propeller shafts and drive shafts

l Tighten rear body bolts and nuts (Models with wooden bed only)

ROAD TEST

lClutch operation

l Parking brake operation

l Service brake operation

l Automatic transmission/transaxle shift timing and kickdown (if applicable)

l Steering control and returnability

l Engine performance

l Squeaks and rattles

ENGINE OPERATING AND HOT

lAdjust idle speed

l Automatic transmission/transaxle fluid level (if applicable)

l Engine idling and stop knob operation

FINAL INSPECTION

lInstall necessary parts (outside mirror, wheel covers, seat belts, mat, carpet or mud flaps)

l Inspect for interior and exterior metal and paint damage

l Check for spare tire, jack, tools (wheel check) and literature

l Wash, clean interior and exterior

PRE-DELIVERY INSPECTION ITEMS

MA-3

http://vnx.su/

Page 45 of 1833

General maintenance includes those items which should be checked during normal day-to-day operation of

the vehicle. They are essential if the vehicle is to continue functioning correctly. Owners can perform the

checks and inspections themselves, or they can be carried out by a NISSAN dealer.

ItemReference pages

OUTSIDE THE VEHICLE

The maintenance items listed here should be checked periodically, unless otherwise specified.

Tires Check the pressure with a gauge weekly when at a service station, including the spare,

and adjust to the specified pressure if necessary. Check carefully for damage, cuts or excessive

wear. Ð

Windshield wiper blades Check for cracks or wear if not functioning correctly. Ð

Doors and engine hood Check that all doors, the engine hood, the trunk lid and back door

function correctly. Also ensure that all latches lock securely. Lubricate if necessary. Make sure

that the secondary latch prevents the hood from opening when the primary latch is released.

When driving in areas using road salt or other corrosive materials, check for lubrication more

often. MA-45

Tire rotation Tires should be rotated every 5,000 km (3,000 miles). MA-43

INSIDE THE VEHICLE

The maintenance items listed here should be checked on a regular basis, such as when per-

forming periodic maintenance, cleaning the vehicle etc.

Lights Make sure that the headlights, stop lights, tail lights, turn signal lights, and other lights

are all operating correctly and installed securely. Also check headlight aim. Ð

Warning lights and buzzers/chimes Make sure that all warning lights and buzzers/chimes are

functioning correctly. Ð

Steering wheel Check that it has the specified play. Check for changes in the steering

operation, such as excessive free play, hard steering or strange noises. Free play: Less than 35 mm (1.38 in) Ð

Seat belts Check that all parts of the seat belt system (e.g. buckles, anchors, adjusters and

retractors) operate properly and smoothly, and are installed securely. Check the belt webbing for

cuts, fraying, wear of damage. MA-46

UNDER THE HOOD AND VEHICLE

The maintenance items listed here should be checked periodically e.g. each time you check the

engine oil or refuel.

Windshield washer fluid Check that there is adequate fluid in the tank.

Engine coolant level Check the coolant level when the engine is cold. MA-22

Engine oil level Check the level after parking the vehicle (on level ground) and turning off the

engine. MA-21

Brake and clutch fluid level Make sure that the brake fluid level is between the ªMAXº and

ªMINº lines on the reservoir. MA-36/MA-40

Battery Check the fluid level in each cell. It should be between the ªMAXº and ªMINº lines. Ð

GENERAL MAINTENANCE

MA-4

http://vnx.su/

Page 1515 of 1833

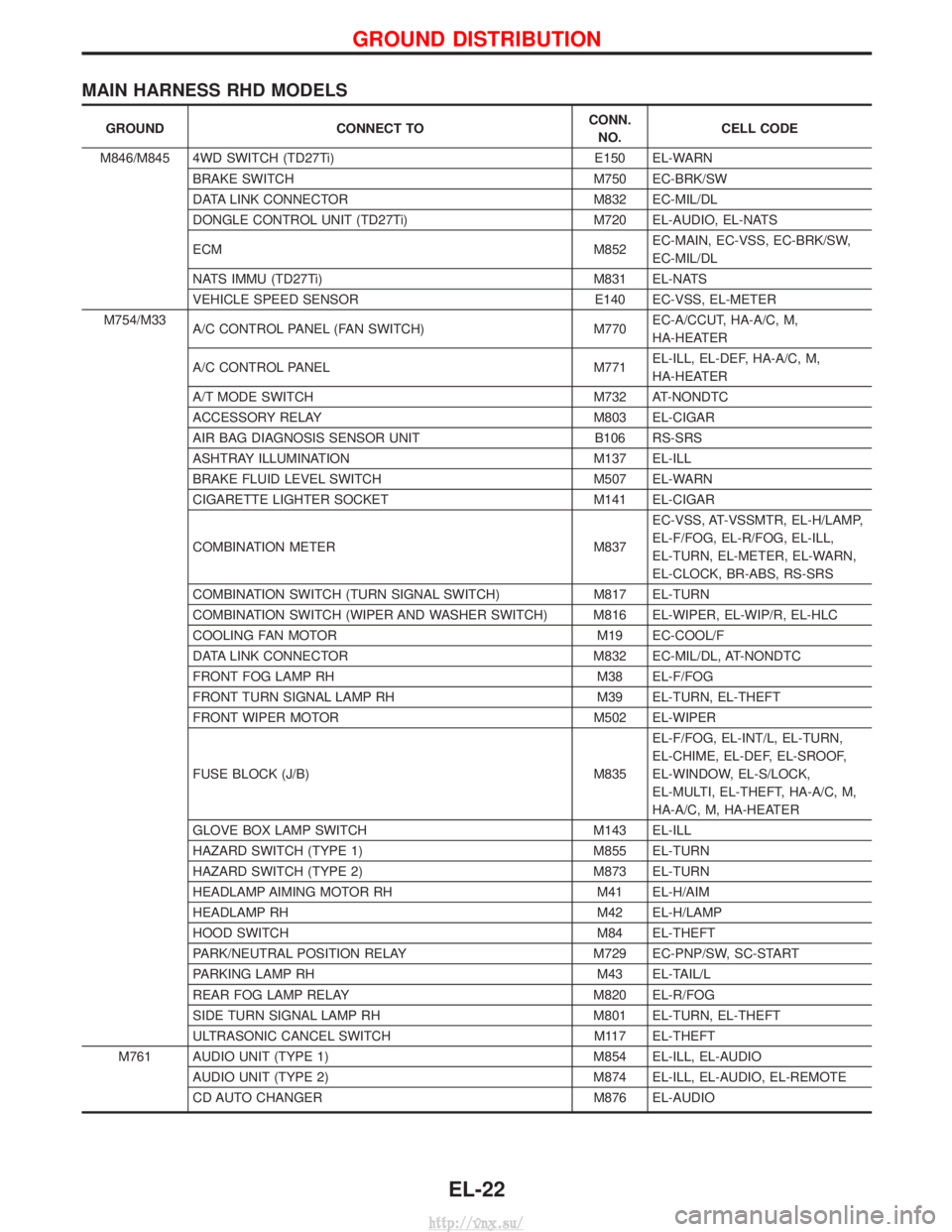

MAIN HARNESS RHD MODELS

GROUNDCONNECT TO CONN.

NO. CELL CODE

M846/M845 4WD SWITCH (TD27Ti) E150 EL-WARN

BRAKE SWITCH M750 EC-BRK/SW

DATA LINK CONNECTOR M832 EC-MIL/DL

DONGLE CONTROL UNIT (TD27Ti) M720 EL-AUDIO, EL-NATS

ECM M852EC-MAIN, EC-VSS, EC-BRK/SW,

EC-MIL/DL

NATS IMMU (TD27Ti) M831 EL-NATS

VEHICLE SPEED SENSOR E140 EC-VSS, EL-METER

M754/M33 A/C CONTROL PANEL (FAN SWITCH) M770EC-A/CCUT, HA-A/C, M,

HA-HEATER

A/C CONTROL PANEL M771EL-ILL, EL-DEF, HA-A/C, M,

HA-HEATER

A/T MODE SWITCH M732 AT-NONDTC

ACCESSORY RELAY M803 EL-CIGAR

AIR BAG DIAGNOSIS SENSOR UNIT B106 RS-SRS

ASHTRAY ILLUMINATION M137 EL-ILL

BRAKE FLUID LEVEL SWITCH M507 EL-WARN

CIGARETTE LIGHTER SOCKET M141 EL-CIGAR

COMBINATION METER M837EC-VSS, AT-VSSMTR, EL-H/LAMP,

EL-F/FOG, EL-R/FOG, EL-ILL,

EL-TURN, EL-METER, EL-WARN,

EL-CLOCK, BR-ABS, RS-SRS

COMBINATION SWITCH (TURN SIGNAL SWITCH) M817 EL-TURN

COMBINATION SWITCH (WIPER AND WASHER SWITCH) M816 EL-WIPER, EL-WIP/R, EL-HLC

COOLING FAN MOTOR M19 EC-COOL/F

DATA LINK CONNECTOR M832 EC-MIL/DL, AT-NONDTC

FRONT FOG LAMP RH M38 EL-F/FOG

FRONT TURN SIGNAL LAMP RH M39 EL-TURN, EL-THEFT

FRONT WIPER MOTOR M502 EL-WIPER

FUSE BLOCK (J/B) M835 EL-F/FOG, EL-INT/L, EL-TURN,

EL-CHIME, EL-DEF, EL-SROOF,

EL-WINDOW, EL-S/LOCK,

EL-MULTI, EL-THEFT, HA-A/C, M,

HA-A/C, M, HA-HEATER

GLOVE BOX LAMP SWITCH M143 EL-ILL

HAZARD SWITCH (TYPE 1) M855 EL-TURN

HAZARD SWITCH (TYPE 2) M873 EL-TURN

HEADLAMP AIMING MOTOR RH M41 EL-H/AIM

HEADLAMP RH M42 EL-H/LAMP

HOOD SWITCH M84 EL-THEFT

PARK/NEUTRAL POSITION RELAY M729 EC-PNP/SW, SC-START

PARKING LAMP RH M43 EL-TAIL/L

REAR FOG LAMP RELAY M820 EL-R/FOG

SIDE TURN SIGNAL LAMP RH M801 EL-TURN, EL-THEFT

ULTRASONIC CANCEL SWITCH M117 EL-THEFT

M761 AUDIO UNIT (TYPE 1) M854 EL-ILL, EL-AUDIO AUDIO UNIT (TYPE 2) M874 EL-ILL, EL-AUDIO, EL-REMOTE

CD AUTO CHANGER M876 EL-AUDIO

GROUND DISTRIBUTION

EL-22

http://vnx.su/

Page 1609 of 1833

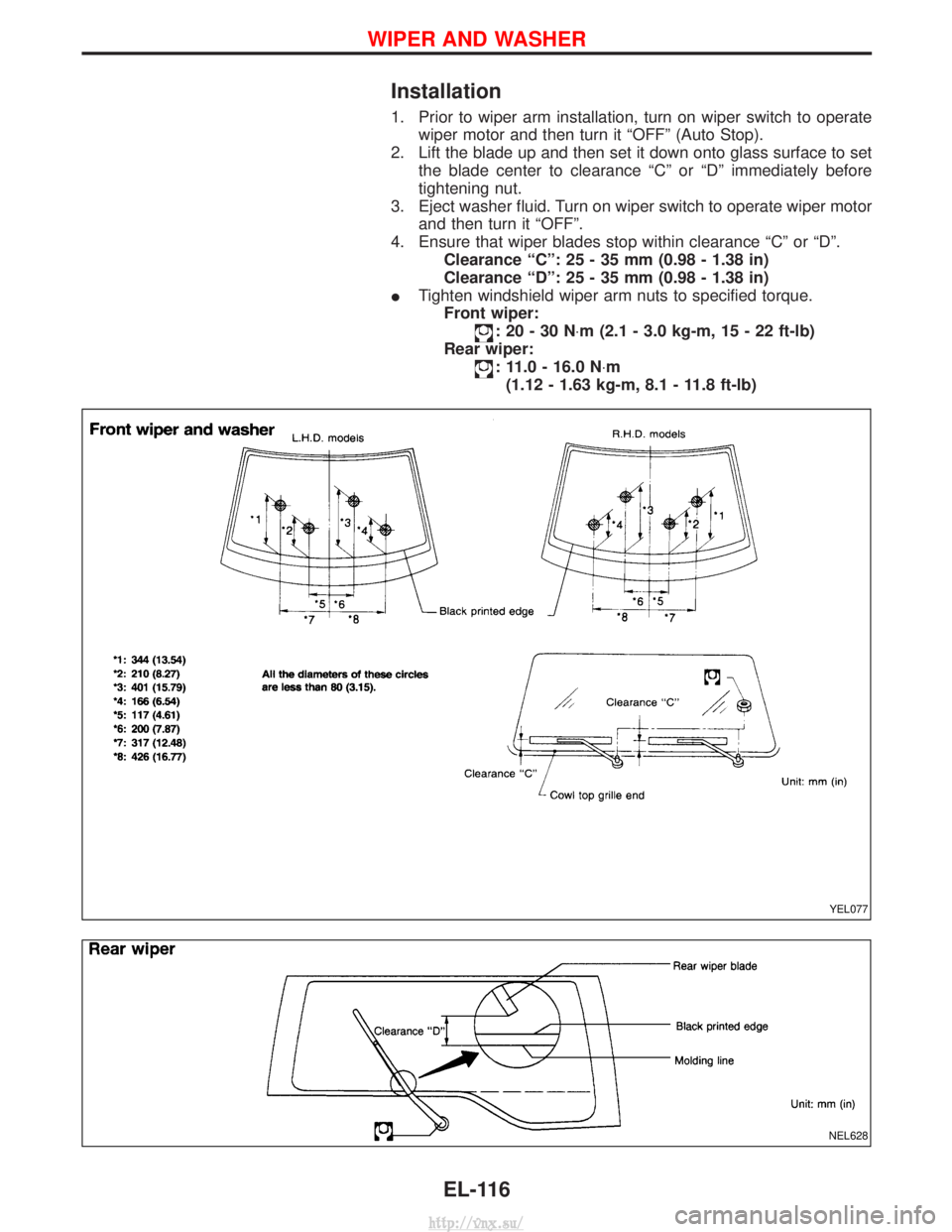

Installation

1. Prior to wiper arm installation, turn on wiper switch to operatewiper motor and then turn it ªOFFº (Auto Stop).

2. Lift the blade up and then set it down onto glass surface to set the blade center to clearance ªCº or ªDº immediately before

tightening nut.

3. Eject washer fluid. Turn on wiper switch to operate wiper motor and then turn it ªOFFº.

4. Ensure that wiper blades stop within clearance ªCº or ªDº. Clearance ªCº: 25 - 35 mm (0.98 - 1.38 in)

Clearance ªDº: 25 - 35 mm (0.98 - 1.38 in)

I Tighten windshield wiper arm nuts to specified torque.

Front wiper:

:20-30N ×m (2.1 - 3.0 kg-m, 15 - 22 ft-lb)

Rear wiper:

: 11.0 - 16.0 N ×m

(1.12 - 1.63 kg-m, 8.1 - 11.8 ft-lb)

YEL077

NEL628

WIPER AND WASHER

EL-116

http://vnx.su/

Page 1610 of 1833

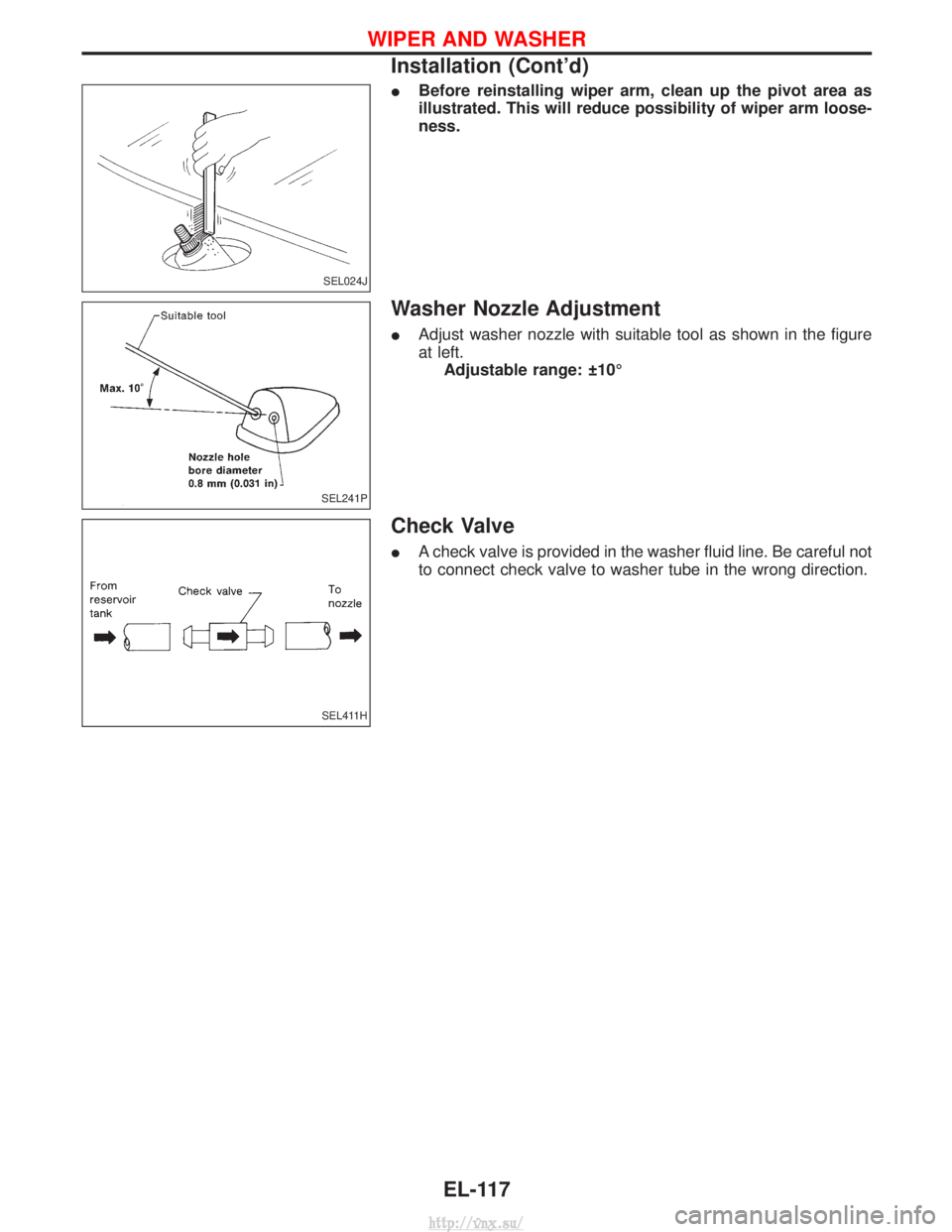

IBefore reinstalling wiper arm, clean up the pivot area as

illustrated. This will reduce possibility of wiper arm loose-

ness.

Washer Nozzle Adjustment

IAdjust washer nozzle with suitable tool as shown in the figure

at left.

Adjustable range: 10É

Check Valve

I A check valve is provided in the washer fluid line. Be careful not

to connect check valve to washer tube in the wrong direction.

SEL024J

SEL241P

SEL411H

WIPER AND WASHER

Installation (Cont'd)

EL-117

http://vnx.su/

Page 1832 of 1833

T

Tachometer .....................................................EL-86

Tail lamp ..........................................................EL-49

TAIL/L - Wiring diagram ..................................EL-49

TCM circuit diagram ..........................................AT-7

TCM inspection table ......................................AT-46

TDC Pulse Signal .........................................EC-173

Temperature control cable and linkageadjustment ..................................................HA-63

THEFT - Wiring diagram...............................EL-248

Theft warning system ...........EL-243, 244, 247, 264

Thermo control amp. ......................................HA-61

Thermostat................................................LC-12, 31

Third (3rd) seat ...............................................BT-39

THLCNT - Wiring diagram ...........................EC-458

Three way catalyst precautions.........................GI-5

Throttle control solenoid valve .....................EC-458

Throttle position switch ...................................AT-62

Tie-rod .......................................................ST-19, 21

Tie-rod ball joints.............................................ST-20

Tightening torque of standard bolts.................GI-37

Time control system .....................EL-216, 218, 220

Timing chain ...................................................EM-26

Timing gear ....................................................EM-38

Tire rotation ....................................................MA-43

Tooth contact diff. .....................................PD-27, 52

Torque converter clutch solenoid valve ..AT-74, 146

Torsion bar spring .......................................FA-4, 30

Tow truck towing ..............................................GI-32

Towing point.....................................................GI-33

Transaxle fluid replacement.....................MA-36, 37

Transfer case ..............................................TF-9, 12

Transfer fluid replacement (Part time 4WD model) .........................................MA-36, 37

Transfer oil replacement ..........................MA-36, 38

Transmission case (M/T)..........................MT-10, 14

TRANSMT - Wiring diagram ...........................EL-98

Tread-FR&RR (Dimensions)............................GI-25

Trim...............................................BT-18, 19, 20, 21

Trunk room trim...............................................BT-47

Turbocharger ..................................................EM-14

Turbocharger charge air cooler......................EM-11

Turbocharger precautions..................................GI-5

TURN - Wiring diagram ..................................EL-62

Turn signal lamp .......................................EL-61, 62

U

Under body .....................................................BT-53

Upper link (front susp.) ...................................FA-33 V

Vacuum hose (brake system) ........................BR-20

Vacuum hose drawing (Engine

control)................................................EC-18, 327

Vacuum pump .............................EM-24, BR-24, 26

Valve clearance..............................................EM-35

Valve clearance adjustment.....................MA-20, 28

Valve guide ....................................................EM-59

Valve lifter ......................................................EM-32

Valve seat ......................................................EM-60

Valve spring ...................................................EM-61

Variable nozzle turbocharger control solenoid valve ...........................................EC-289

Vehicle identification number...........................GI-28

Vehicle speed sensor (VSS) ..................EC-99, 420

Ventilator door control rod adjustment ...........HA-61

Viscosity number (SAE)...........................MA-17, 18

VNT - Wiring diagram ..................................EC-291

VSS - Wiring diagram ..................................EC-101

W

WARN - Wiring diagram........................EL-100, 111

Warning chime ........................................EL-99, 111

Warning lamps ........................................EL-99, 100

Washer, front .................................................EL-112

Washer, rear ..................................................EL-114

Water cock control rod adjustment ................HA-63

Water pump ..............................................LC-11, 29

Water temperature gauge ...............................EL-86

Weatherstrip - See Exterior ............................BT-21

Wheel alignment (front) ....................................FA-8

Wheel balance ...............................................MA-43

Wheel bearing (front axle) ................................FA-6

Wheel bearing (rear) ..................................RA-5, 16

Wheel hub (front) ........................................FA-4, 18

Wheel sensors (ABS)...............................BR-39, 43

Wheel size .......................................................GI-30

WINDOW - Wiring diagram ..........................EL-159

Window, back door .........................................BT-47

Window, door ..................................................BT-42

Window, rear side .....................................BT-42, 43

Window, side - See Rear side window ...........BT-43

Windshield.......................................................BT-42

WIP/R - Wiring diagram ................................EL-114

WIPER - Wiring diagram .......................EL-112, 118

Wiper and washer .................................EL-112, 116

Wiper, front ....................................................EL-112

Wiper, rear.....................................................EL-114

Wiring Diagram (Cell code) list .....................EL-326

ALPHABETICAL INDEX

IDX-7

http://vnx.su/