NISSAN TIIDA 2008 Service Repair Manual

Manufacturer: NISSAN, Model Year: 2008, Model line: TIIDA, Model: NISSAN TIIDA 2008Pages: 2771, PDF Size: 60.61 MB

Page 1471 of 2771

DTC P0605 ECM

EC-397

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

DTC P0605 ECM

Component DescriptionINFOID:0000000001702913

The ECM consists of a microcomputer and connectors for signal

input and output and for power supply. The ECM controls the engine.

On Board Diagnosis LogicINFOID:0000000001702914

This self-diagnosis has one or two trip detection logic.

FAIL-SAFE MODE

ECM enters fail-safe mode when malfunction A is detected.

DTC Confirmation ProcedureINFOID:0000000001702915

Perform PROCEDURE FOR MALFUNCTION A first. If the 1st trip DTC cannot be confirmed, perform

PROCEDURE FOR MALFUNCTION B. If there is no malfunction on PROCEDURE FOR MALFUNCTION

B, perform PROCEDURE FOR MALFUNCTION C.

NOTE:

If DTC Confirmation Procedure has been previously conducted, always turn ignition switch OFF and wait at

least 10 seconds before conducting the next test.

PROCEDURE FOR MALFUNCTION A

With CONSULT-II

1. Turn ignition switch ON.

2. Select “DATA MONITOR” mode with CONSULT-II.

3. If 1st trip DTC is detected, go to EC-398, "

Diagnosis Procedure".

With GST

PBIA9222J

DTC No. Trouble diagnosis name DTC detecting condition Possible cause

P0605

0605Engine control moduleA) ECM calculation function is malfunctioning.

•ECM B) ECM EEP-ROM system is malfunctioning.

C) ECM self shut-off function is malfunctioning.

Detected items Engine operation condition in fail-safe mode

Malfunction A• ECM stops the electric throttle control actuator control, throttle valve is maintained at a fixed opening (approx. 5

degrees) by the return spring.

• ECM deactivates ASCD operation.

SEF058Y

Page 1472 of 2771

EC-398

< SERVICE INFORMATION >

DTC P0605 ECM

Follow the procedure “With CONSULT-II” above.

PROCEDURE FOR MALFUNCTION B

With CONSULT-II

1. Turn ignition switch ON and wait at least 1 second.

2. Select “DATA MONITOR” mode with CONSULT-II.

3. Turn ignition switch OFF, wait at least 10 seconds and then turn

ON.

4. If 1st trip DTC is detected, go to EC-398, "

Diagnosis Procedure".

With GST

Follow the procedure “With CONSULT-II” above.

PROCEDURE FOR MALFUNCTION C

With CONSULT-II

1. Turn ignition switch ON and wait at least 1 second.

2. Select “DATA MONITOR” mode with CONSULT-II.

3. Turn ignition switch OFF, wait at least 10 seconds and then turn

ON.

4. Repeat step 3 for 32 times.

5. If 1st trip DTC is detected, go to EC-398, "

Diagnosis Procedure".

With GST

Follow the procedure “With CONSULT-II” above.

Diagnosis ProcedureINFOID:0000000001702916

1.INSPECTION START

With CONSULT-II

1. Turn ignition switch ON.

2. Select “SELF DIAG RESULTS” mode with CONSULT-II.

3. Touch “ERASE”.

4.Perform DTC Confirmation Procedure.

See EC-397, "

DTC Confirmation Procedure".

5. Is the 1st trip DTC P0605 displayed again?

With GST

1. Turn ignition switch ON.

2. Select Service $04 with GST.

3.Perform DTC Confirmation Procedure.

See EC-397, "

DTC Confirmation Procedure".

4. Is the 1st trip DTC P0605 displayed again?

Ye s o r N o

Ye s > > G O T O 2 .

No >>INSPECTION END

SEF058Y

SEF058Y

Page 1473 of 2771

DTC P0605 ECM

EC-399

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

2.REPLACE ECM

1. Replace ECM.

2. Perform initialization of NVIS(NATS) system and registration of all NVIS(NATS) ignition key IDs.

Refer to BL-211, "

ECM Re-communicating Function".

3. Perform EC-75, "

VIN Registration".

4. Perform EC-76, "

Accelerator Pedal Released Position Learning".

5. Perform EC-76, "

Throttle Valve Closed Position Learning".

6. Perform EC-76, "

Idle Air Volume Learning".

>>INSPECTION END

Page 1474 of 2771

EC-400

< SERVICE INFORMATION >

DTC P0643 SENSOR POWER SUPPLY

DTC P0643 SENSOR POWER SUPPLY

On Board Diagnosis LogicINFOID:0000000001702917

This self-diagnosis has the one trip detection logic.

FAIL-SAFE MODE

When the malfunction is detected, ECM enters fail-safe mode and the MIL lights up.

DTC Confirmation ProcedureINFOID:0000000001702918

NOTE:

If DTC Confirmation Procedure has been previously conducted, always turn ignition switch OFF and wait at

least 10 seconds before conducting the next test.

TESTING CONDITION:

Before performing the following procedure, confirm that battery voltage is more than 8V at idle.

WITH CONSULT-II

1. Turn ignition switch ON.

2. Select “DATA MONITOR” mode with CONSULT-II.

3. Start engine and let it idle for 1 second.

4. If DTC is detected, go to EC-402, "

Diagnosis Procedure".

WITH GST

Follow the procedure “WITH CONSULT-II” above.

DTC No.Trouble diagnosis

nameDTC detecting condition Possible cause

P0643

0643Sensor power supply

circuit shortECM detects a voltage of power source for

sensor is excessively low or high.• Harness or connectors

(APP sensor 1 circuit is shorted.)

(Throttle position sensor circuit is shorted.)

[Camshaft position sensor (PHASE) circuit is

shorted.]

• Accelerator pedal position sensor

• Throttle position sensor

• Camshaft position sensor (PHASE)

Engine operation condition in fail-safe mode

ECM stops the electric throttle control actuator control, throttle valve is maintained at a fixed opening (approx. 5 degrees) by the return

spring.

SEF058Y

Page 1475 of 2771

DTC P0643 SENSOR POWER SUPPLY

EC-401

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

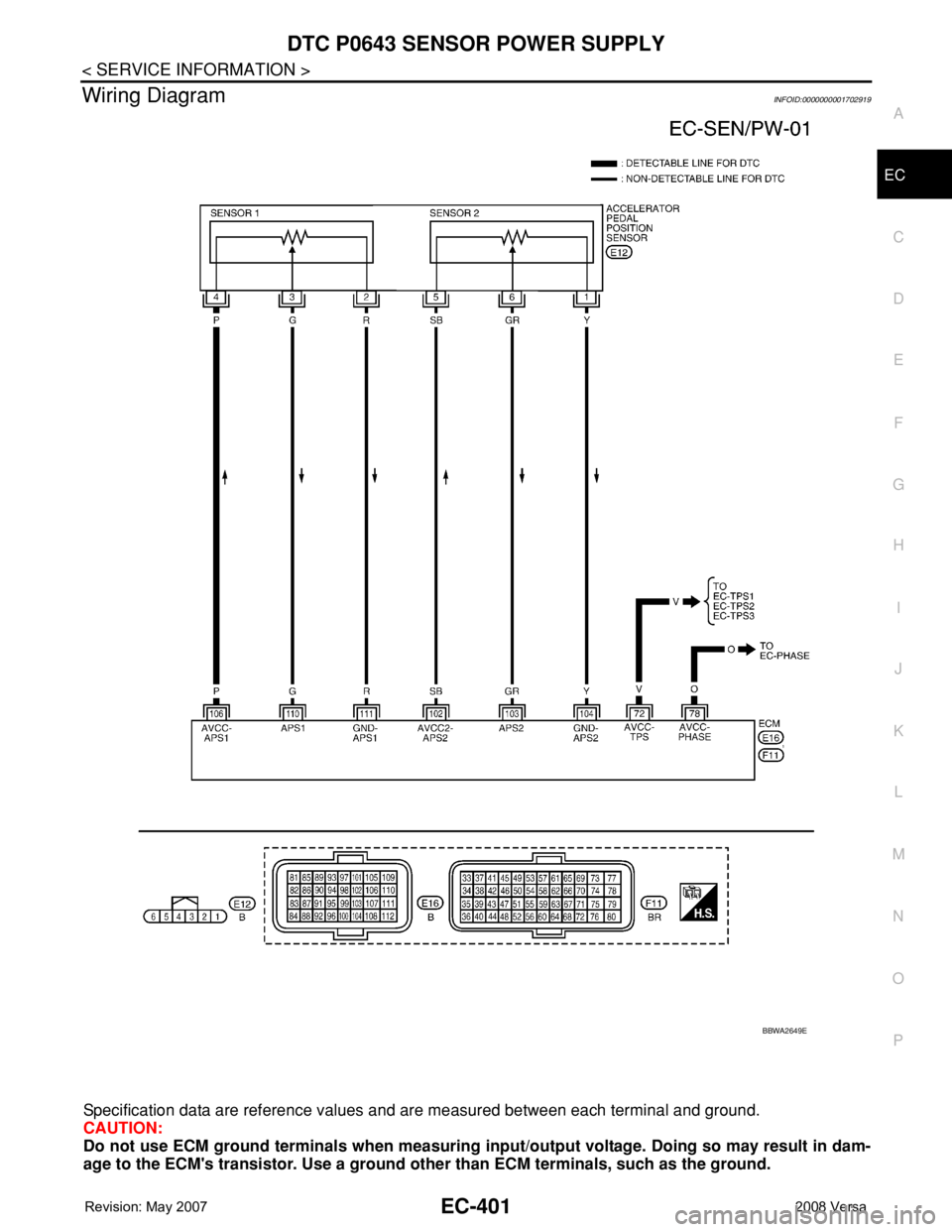

Wiring DiagramINFOID:0000000001702919

Specification data are reference values and are measured between each terminal and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may result in dam-

age to the ECM's transistor. Use a ground other than ECM terminals, such as the ground.

BBWA2649E

Page 1476 of 2771

EC-402

< SERVICE INFORMATION >

DTC P0643 SENSOR POWER SUPPLY

Diagnosis Procedure

INFOID:0000000001702920

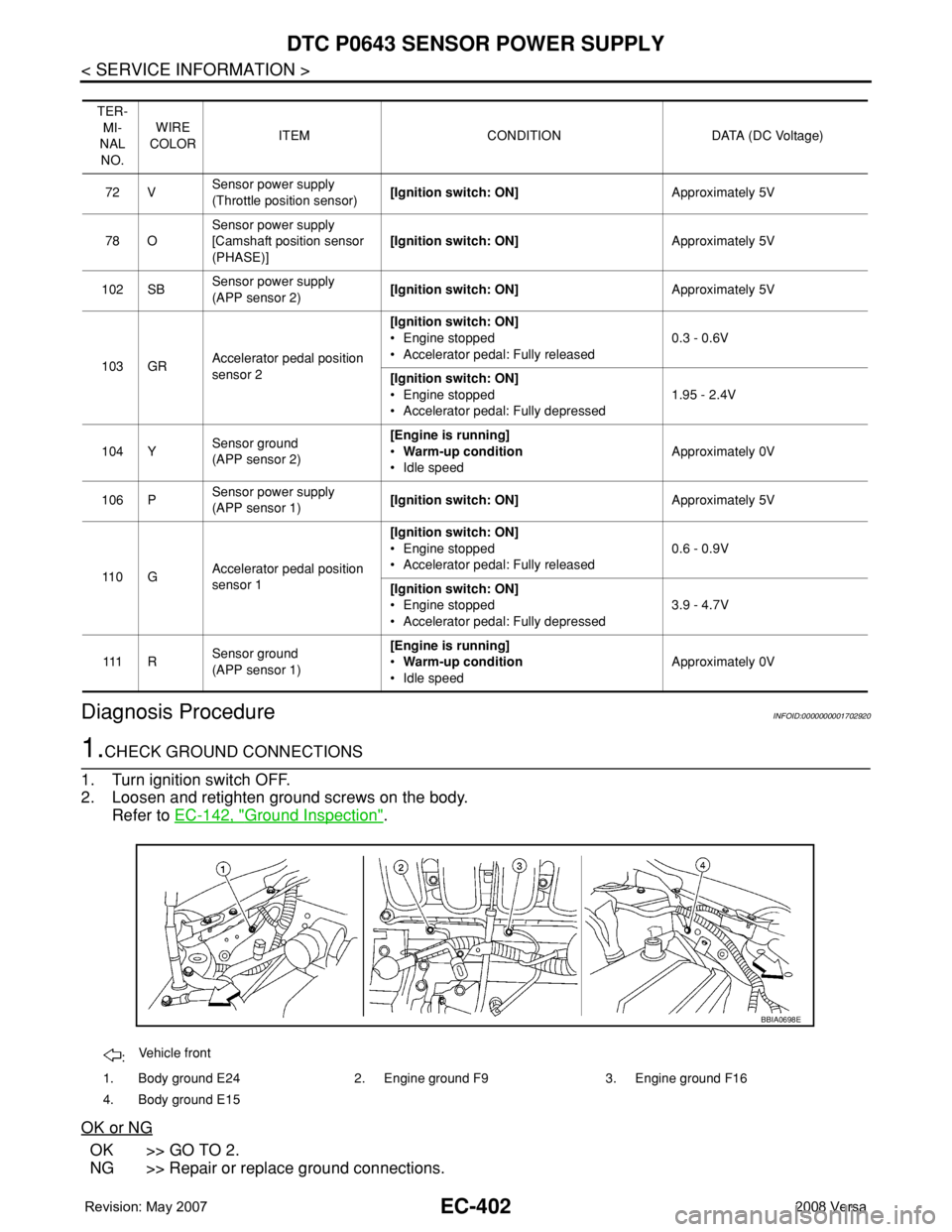

1.CHECK GROUND CONNECTIONS

1. Turn ignition switch OFF.

2. Loosen and retighten ground screws on the body.

Refer to EC-142, "

Ground Inspection".

OK or NG

OK >> GO TO 2.

NG >> Repair or replace ground connections.

TER-

MI-

NAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

72 VSensor power supply

(Throttle position sensor)[Ignition switch: ON]Approximately 5V

78 OSensor power supply

[Camshaft position sensor

(PHASE)][Ignition switch: ON]Approximately 5V

102 SBSensor power supply

(APP sensor 2)[Ignition switch: ON]Approximately 5V

103 GRAccelerator pedal position

sensor 2[Ignition switch: ON]

• Engine stopped

• Accelerator pedal: Fully released0.3 - 0.6V

[Ignition switch: ON]

• Engine stopped

• Accelerator pedal: Fully depressed1.95 - 2.4V

104 YSensor ground

(APP sensor 2)[Engine is running]

•Warm-up condition

• Idle speedApproximately 0V

106 PSensor power supply

(APP sensor 1)[Ignition switch: ON]Approximately 5V

11 0 GAccelerator pedal position

sensor 1[Ignition switch: ON]

• Engine stopped

• Accelerator pedal: Fully released0.6 - 0.9V

[Ignition switch: ON]

• Engine stopped

• Accelerator pedal: Fully depressed3.9 - 4.7V

111 RSensor ground

(APP sensor 1)[Engine is running]

•Warm-up condition

• Idle speedApproximately 0V

:Vehicle front

1. Body ground E24 2. Engine ground F9 3. Engine ground F16

4. Body ground E15

BBIA0698E

Page 1477 of 2771

DTC P0643 SENSOR POWER SUPPLY

EC-403

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

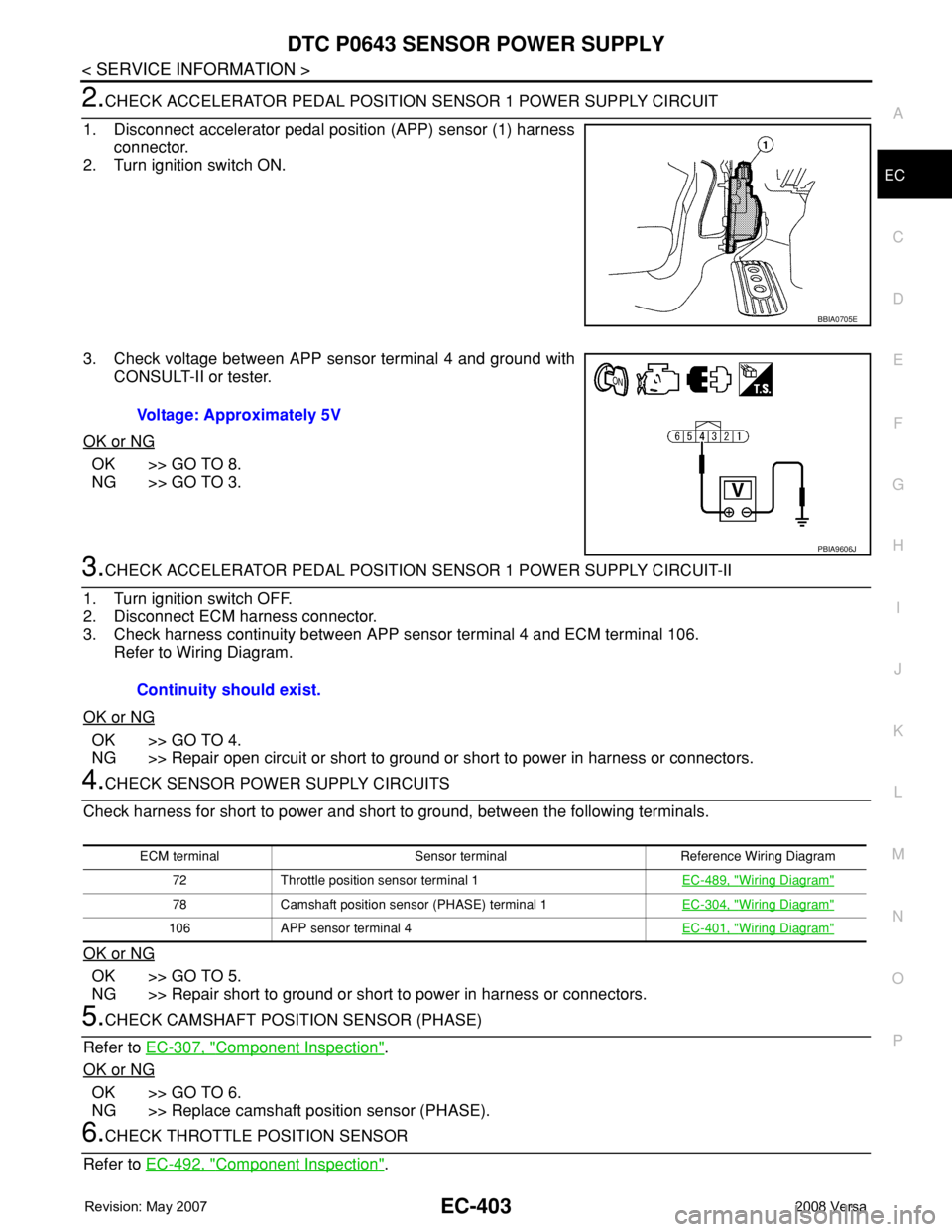

2.CHECK ACCELERATOR PEDAL POSITION SENSOR 1 POWER SUPPLY CIRCUIT

1. Disconnect accelerator pedal position (APP) sensor (1) harness

connector.

2. Turn ignition switch ON.

3. Check voltage between APP sensor terminal 4 and ground with

CONSULT-II or tester.

OK or NG

OK >> GO TO 8.

NG >> GO TO 3.

3.CHECK ACCELERATOR PEDAL POSITION SENSOR 1 POWER SUPPLY CIRCUIT-II

1. Turn ignition switch OFF.

2. Disconnect ECM harness connector.

3. Check harness continuity between APP sensor terminal 4 and ECM terminal 106.

Refer to Wiring Diagram.

OK or NG

OK >> GO TO 4.

NG >> Repair open circuit or short to ground or short to power in harness or connectors.

4.CHECK SENSOR POWER SUPPLY CIRCUITS

Check harness for short to power and short to ground, between the following terminals.

OK or NG

OK >> GO TO 5.

NG >> Repair short to ground or short to power in harness or connectors.

5.CHECK CAMSHAFT POSITION SENSOR (PHASE)

Refer to EC-307, "

Component Inspection".

OK or NG

OK >> GO TO 6.

NG >> Replace camshaft position sensor (PHASE).

6.CHECK THROTTLE POSITION SENSOR

Refer to EC-492, "

Component Inspection".

BBIA0705E

Voltage: Approximately 5V

PBIA9606J

Continuity should exist.

ECM terminal Sensor terminal Reference Wiring Diagram

72 Throttle position sensor terminal 1EC-489, "

Wiring Diagram"

78 Camshaft position sensor (PHASE) terminal 1EC-304, "Wiring Diagram"

106 APP sensor terminal 4EC-401, "Wiring Diagram"

Page 1478 of 2771

EC-404

< SERVICE INFORMATION >

DTC P0643 SENSOR POWER SUPPLY

OK or NG

OK >> GO TO 8.

NG >> GO TO 7.

7.REPLACE ELECTRIC THROTTLE CONTROL ACTUATOR

1. Replace the electric throttle control actuator.

2. Perform EC-76, "

Throttle Valve Closed Position Learning".

3. Perform EC-76, "

Idle Air Volume Learning".

>>INSPECTION END

8.CHECK APP SENSOR

Refer to EC-499, "

Component Inspection".

OK or NG

OK >> GO TO 9.

NG >> GO TO 8.

9.REPLACE ACCELERATOR PEDAL ASSEMBLY

1. Replace accelerator pedal assembly.

2. Perform EC-76, "

Accelerator Pedal Released Position Learning".

3. Perform EC-76, "

Throttle Valve Closed Position Learning".

4. Perform EC-76, "

Idle Air Volume Learning".

>>INSPECTION END

10.CHECK INTERMITTENT INCIDENT

Refer to EC-136

.

>>INSPECTION END

Page 1479 of 2771

DTC P0850 PNP SWITCH

EC-405

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

DTC P0850 PNP SWITCH

Component DescriptionINFOID:0000000001702921

When the shift lever position is P or N (A/T, CVT), Neutral (M/T), park/neutral position (PNP) switch is ON.

ECM detects the position because the continuity of the line (the ON signal) exists.

CONSULT-II Reference Value in Data Monitor ModeINFOID:0000000001702922

Specification data are reference values.

On Board Diagnosis LogicINFOID:0000000001702923

DTC Confirmation ProcedureINFOID:0000000001702924

CAUTION:

Always drive vehicle at a safe speed.

NOTE:

If DTC Confirmation Procedure has been previously conducted, always turn ignition switch OFF and wait at

least 10 seconds before conducting the next test.

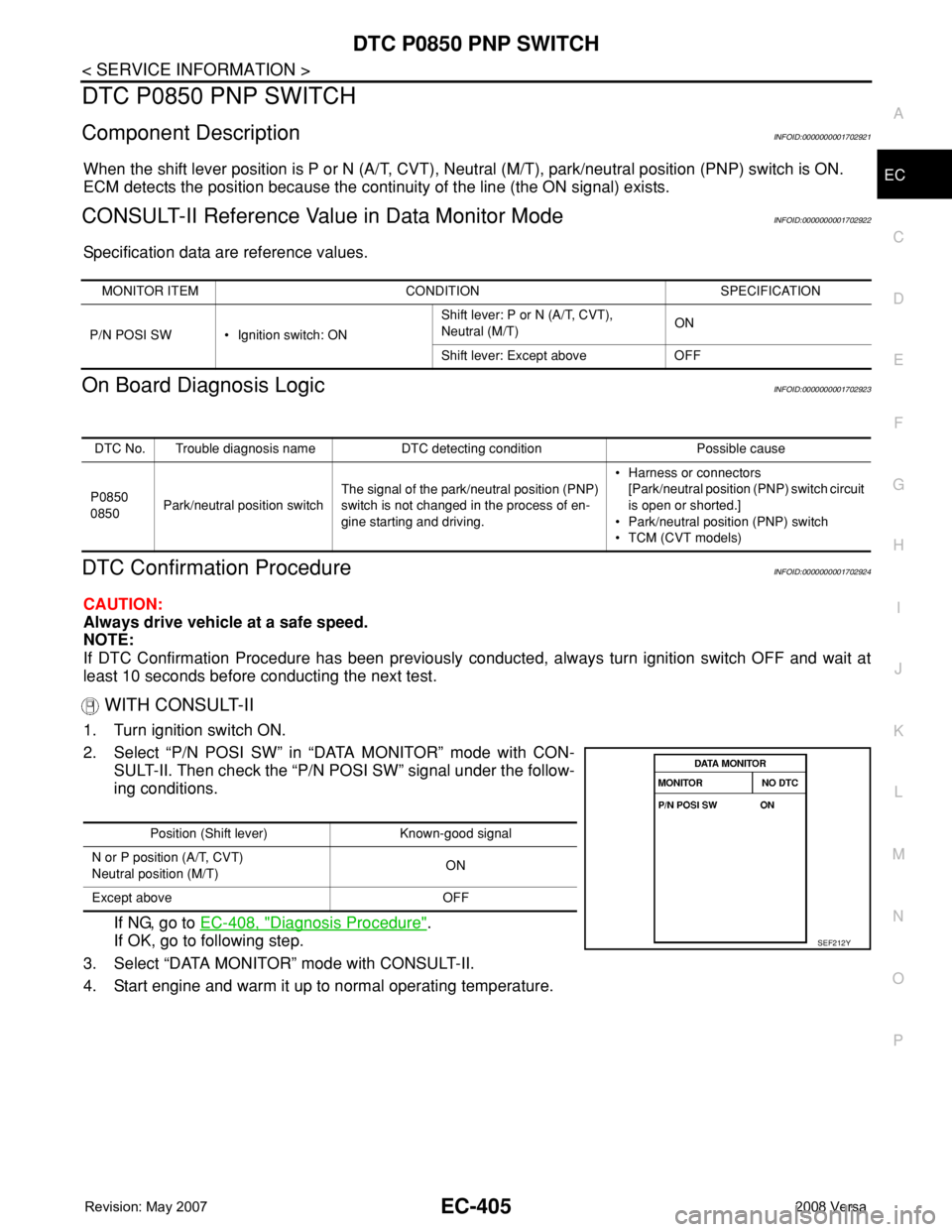

WITH CONSULT-II

1. Turn ignition switch ON.

2. Select “P/N POSI SW” in “DATA MONITOR” mode with CON-

SULT-II. Then check the “P/N POSI SW” signal under the follow-

ing conditions.

If NG, go to EC-408, "

Diagnosis Procedure".

If OK, go to following step.

3. Select “DATA MONITOR” mode with CONSULT-II.

4. Start engine and warm it up to normal operating temperature.

MONITOR ITEM CONDITION SPECIFICATION

P/N POSI SW • Ignition switch: ONShift lever: P or N (A/T, CVT),

Neutral (M/T)ON

Shift lever: Except above OFF

DTC No. Trouble diagnosis name DTC detecting condition Possible cause

P0850

0850Park/neutral position switchThe signal of the park/neutral position (PNP)

switch is not changed in the process of en-

gine starting and driving.• Harness or connectors

[Park/neutral position (PNP) switch circuit

is open or shorted.]

• Park/neutral position (PNP) switch

• TCM (CVT models)

Position (Shift lever) Known-good signal

N or P position (A/T, CVT)

Neutral position (M/T)ON

Except above OFF

SEF212Y

Page 1480 of 2771

EC-406

< SERVICE INFORMATION >

DTC P0850 PNP SWITCH

5. Maintain the following conditions for at least 60 consecutive sec-

onds.

6. If 1st trip DTC is detected, go to EC-408, "

Diagnosis Procedure".

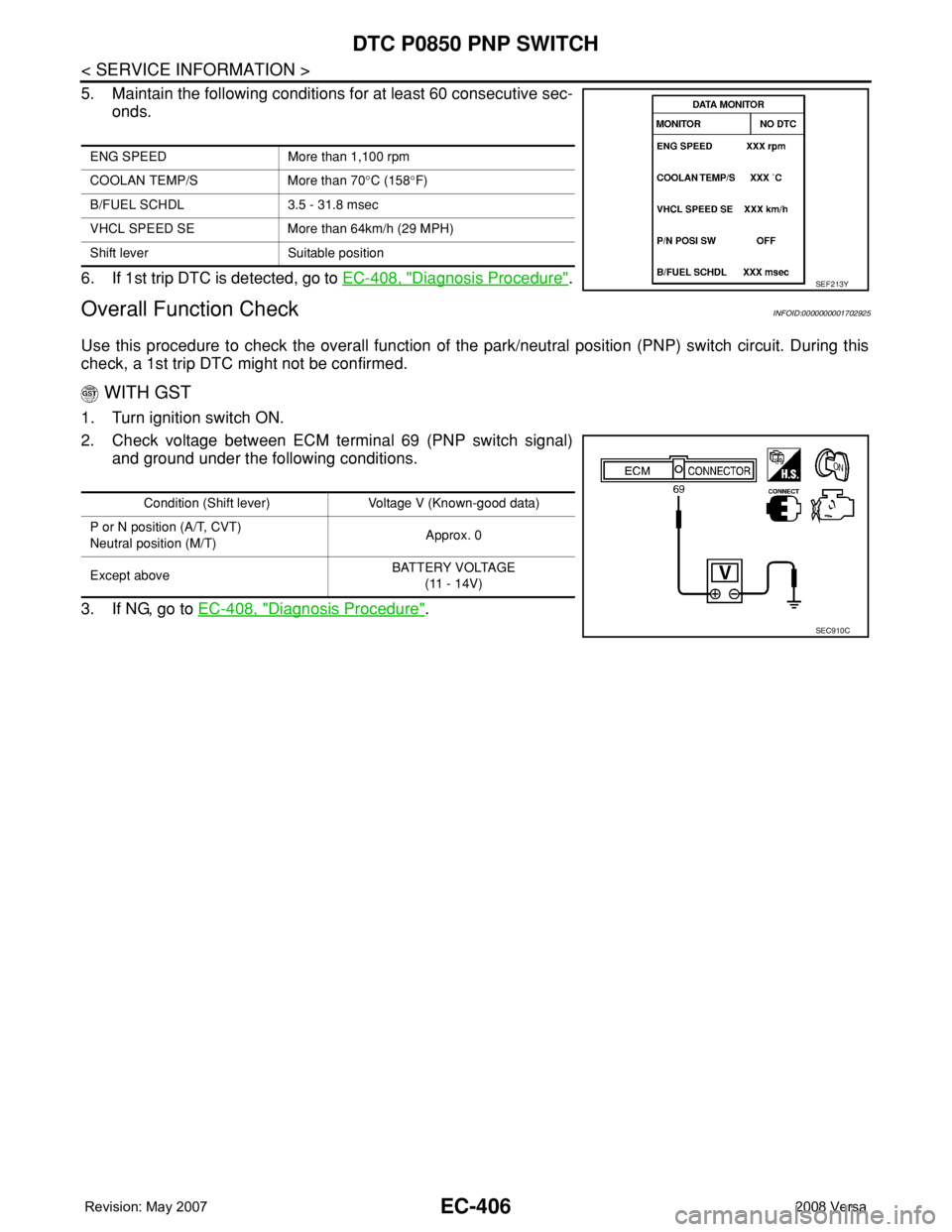

Overall Function CheckINFOID:0000000001702925

Use this procedure to check the overall function of the park/neutral position (PNP) switch circuit. During this

check, a 1st trip DTC might not be confirmed.

WITH GST

1. Turn ignition switch ON.

2. Check voltage between ECM terminal 69 (PNP switch signal)

and ground under the following conditions.

3. If NG, go to EC-408, "

Diagnosis Procedure".

ENG SPEED More than 1,100 rpm

COOLAN TEMP/S More than 70°C (158°F)

B/FUEL SCHDL 3.5 - 31.8 msec

VHCL SPEED SE More than 64km/h (29 MPH)

Shift lever Suitable position

SEF213Y

Condition (Shift lever) Voltage V (Known-good data)

P or N position (A/T, CVT)

Neutral position (M/T)Approx. 0

Except aboveBATTERY VOLTAGE

(11 - 14V)

SEC910C