Control panel NISSAN TIIDA 2008 Service User Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2008, Model line: TIIDA, Model: NISSAN TIIDA 2008Pages: 2771, PDF Size: 60.61 MB

Page 1908 of 2771

SQUEAK AND RATTLE TROUBLE DIAGNOSES

GW-7

< SERVICE INFORMATION >

C

D

E

F

G

H

J

K

L

MA

B

GW

N

O

P

SILICONE GREASE

Used instead of UHMW tape that will be visible or not fit.

Note: Will only last a few months.

SILICONE SPRAY

Use when grease cannot be applied.

DUCT TAPE

Use to eliminate movement.

CONFIRM THE REPAIR

Confirm that the cause of a noise is repaired by test driving the vehicle. Operate the vehicle under the same

conditions as when the noise originally occurred. Refer to the notes on the Diagnostic Worksheet.

Generic Squeak and Rattle TroubleshootingINFOID:0000000001704133

Refer to Table of Contents for specific component removal and installation information.

INSTRUMENT PANEL

Most incidents are caused by contact and movement between:

1. The cluster lid A and instrument panel

2. Acrylic lens and combination meter housing

3. Instrument panel to front pillar garnish

4. Instrument panel to windshield

5. Instrument panel mounting pins

6. Wiring harnesses behind the combination meter

7. A/C defroster duct and duct joint

These incidents can usually be located by tapping or moving the components to duplicate the noise or by

pressing on the components while driving to stop the noise. Most of these incidents can be repaired by apply-

ing felt cloth tape or silicone spray (in hard to reach areas). Urethane pads can be used to insulate wiring har-

ness.

CAUTION:

Do not use silicone spray to isolate a squeak or rattle. If you saturate the area with silicone, you will

not be able to recheck the repair.

CENTER CONSOLE

Components to pay attention to include:

1. Shifter assembly cover to finisher

2. A/C control unit and cluster lid C

3. Wiring harnesses behind audio and A/C control unit

The instrument panel repair and isolation procedures also apply to the center console.

DOORS

Pay attention to the:

1. Finisher and inner panel making a slapping noise

2. Inside handle escutcheon to door finisher

3. Wiring harnesses tapping

4. Door striker out of alignment causing a popping noise on starts and stops

Tapping or moving the components or pressing on them while driving to duplicate the conditions can isolate

many of these incidents. You can usually insulate the areas with felt cloth tape or insulator foam blocks from

the NISSAN Squeak and Rattle Kit (J-43980) to repair the noise.

TRUNK

Trunk noises are often caused by a loose jack or loose items put into the trunk by the owner.

In addition look for:

1. Trunk lid bumpers out of adjustment

2. Trunk lid striker out of adjustment

3. The trunk lid torsion bars knocking together

4. A loose license plate or bracket

Page 1972 of 2771

IP-6

< SYMPTOM DIAGNOSIS >

SQUEAK AND RATTLE TROUBLE DIAGNOSES

The following materials, not found in the kit, can also be used to repair squeaks and rattles.

UHMW (TEFLON) TAPE

Insulates where slight movement is present. Ideal for instrument panel applications.

SILICONE GREASE

Used in place of UHMW tape that will be visible or not fit.

Note: Will only last a few months.

SILICONE SPRAY

Use when grease cannot be applied.

DUCT TAPE

Use to eliminate movement.

CONFIRM THE REPAIR

Confirm that the cause of a noise is repaired by test driving the vehicle. Operate the vehicle under the same

conditions as when the noise originally occurred. Refer to the notes on the Diagnostic Worksheet.

Generic Squeak and Rattle TroubleshootingINFOID:0000000001704249

Refer to Table of Contents for specific component removal and installation information.

INSTRUMENT PANEL

Most incidents are caused by contact and movement between:

1. The cluster lid A and instrument panel

2. Acrylic lens and combination meter housing

3. Instrument panel to front pillar garnish

4. Instrument panel to windshield

5. Instrument panel mounting pins

6. Wiring harnesses behind the combination meter

7. A/C defroster duct and duct joint

These incidents can usually be located by tapping or moving the components to duplicate the noise or by

pressing on the components while driving to stop the noise. Most of these incidents can be repaired by apply-

ing felt cloth tape or silicone spray (in hard to reach areas). Urethane pads can be used to insulate wiring har-

ness.

CAUTION:

Do not use silicone spray to isolate a squeak or rattle. If you saturate the area with silicone, you will

not be able to recheck the repair.

CENTER CONSOLE

Components to pay attention to include:

1. Shifter assembly cover to finisher

2. A/C control unit and cluster lid C

3. Wiring harnesses behind audio and A/C control unit

The instrument panel repair and isolation procedures also apply to the center console.

DOORS

Pay attention to the:

1. Finisher and inner panel making a slapping noise

2. Inside handle escutcheon to door finisher

3. Wiring harnesses tapping

4. Door striker out of alignment causing a popping noise on starts and stops

Tapping or moving the components or pressing on them while driving to duplicate the conditions can isolate

many of these incidents. You can usually insulate the areas with felt cloth tape or insulator foam blocks from

the NISSAN Squeak and Rattle Kit (J-43980) to repair the noise.

TRUNK

Trunk noises are often caused by a loose jack or loose items put into the trunk by the owner.

In addition look for:

1. Trunk lid bumpers out of adjustment

2. Trunk lid striker out of adjustment

Page 1977 of 2771

INSTRUMENT PANEL ASSEMBLY

IP-11

< ON-VEHICLE REPAIR >

C

D

E

F

G

H

J

K

L

MA

B

IP

N

O

P

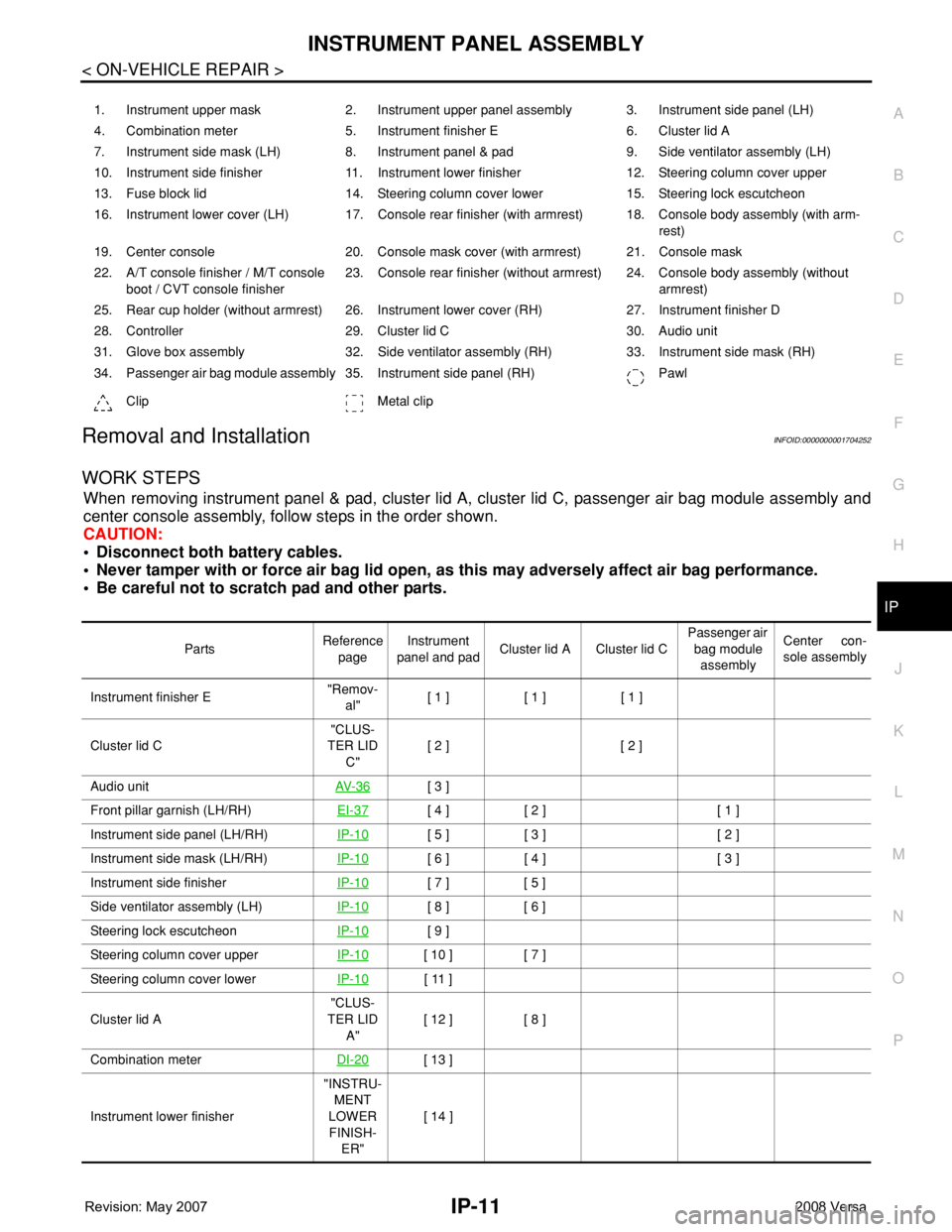

Removal and InstallationINFOID:0000000001704252

WORK STEPS

When removing instrument panel & pad, cluster lid A, cluster lid C, passenger air bag module assembly and

center console assembly, follow steps in the order shown.

CAUTION:

• Disconnect both battery cables.

• Never tamper with or force air bag lid open, as this may adversely affect air bag performance.

• Be careful not to scratch pad and other parts.

1. Instrument upper mask 2. Instrument upper panel assembly 3. Instrument side panel (LH)

4. Combination meter 5. Instrument finisher E 6. Cluster lid A

7. Instrument side mask (LH) 8. Instrument panel & pad 9. Side ventilator assembly (LH)

10. Instrument side finisher 11. Instrument lower finisher 12. Steering column cover upper

13. Fuse block lid 14. Steering column cover lower 15. Steering lock escutcheon

16. Instrument lower cover (LH) 17. Console rear finisher (with armrest) 18. Console body assembly (with arm-

rest)

19. Center console 20. Console mask cover (with armrest) 21. Console mask

22. A/T console finisher / M/T console

boot / CVT console finisher23. Console rear finisher (without armrest) 24. Console body assembly (without

armrest)

25. Rear cup holder (without armrest) 26. Instrument lower cover (RH) 27. Instrument finisher D

28. Controller 29. Cluster lid C 30. Audio unit

31. Glove box assembly 32. Side ventilator assembly (RH) 33. Instrument side mask (RH)

34. Passenger air bag module assembly 35. Instrument side panel (RH) Pawl

Clip Metal clip

PartsReference

pageInstrument

panel and padCluster lid A Cluster lid C Passenger air

bag module

assemblyCenter con-

sole assembly

Instrument finisher E"Remov-

al"[ 1 ] [ 1 ] [ 1 ]

Cluster lid C"CLUS-

TER LID

C"[ 2 ] [ 2 ]

Audio unitAV- 3 6

[ 3 ]

Front pillar garnish (LH/RH)EI-37

[ 4 ] [ 2 ] [ 1 ]

Instrument side panel (LH/RH)IP-10

[ 5 ] [ 3 ] [ 2 ]

Instrument side mask (LH/RH)IP-10

[ 6 ] [ 4 ] [ 3 ]

Instrument side finisherIP-10

[ 7 ] [ 5 ]

Side ventilator assembly (LH)IP-10

[ 8 ] [ 6 ]

Steering lock escutcheonIP-10

[ 9 ]

Steering column cover upperIP-10

[ 10 ] [ 7 ]

Steering column cover lowerIP-10

[ 11 ]

Cluster lid A"CLUS-

TER LID

A"[ 12 ] [ 8 ]

Combination meterDI-20

[ 13 ]

Instrument lower finisher"INSTRU-

MENT

LOWER

FINISH-

ER"[ 14 ]

Page 1978 of 2771

![NISSAN TIIDA 2008 Service User Guide IP-12

< ON-VEHICLE REPAIR >

INSTRUMENT PANEL ASSEMBLY

[ ]: Number indicates step in removal procedures.

INSTRUMENT PANEL ASSEMBLY

Removal

1. Pull instrument finisher E backward by approximately 30

deg NISSAN TIIDA 2008 Service User Guide IP-12

< ON-VEHICLE REPAIR >

INSTRUMENT PANEL ASSEMBLY

[ ]: Number indicates step in removal procedures.

INSTRUMENT PANEL ASSEMBLY

Removal

1. Pull instrument finisher E backward by approximately 30

deg](/img/5/57399/w960_57399-1977.png)

IP-12

< ON-VEHICLE REPAIR >

INSTRUMENT PANEL ASSEMBLY

[ ]: Number indicates step in removal procedures.

INSTRUMENT PANEL ASSEMBLY

Removal

1. Pull instrument finisher E backward by approximately 30

degrees while disengaging the instrument finisher E metal clips

and pawl.

Glove box assembly"GLOVE

BOX AS-

SEMBLY"[ 15 ]

Side ventilator assembly (RH)IP-10

[ 16 ] [ 4 ]

Passenger air bag module assemblySRS-38

[ 17 ] [ 5 ]

Instrument upper maskIP-10

[ 18 ]

Instrument finisher DIP-10

[ 19 ]

Controller MTC-55

[ 20 ]

Instrument upper panel assembly IP-10

[ 21 ]

Console mask"Remov-

al"[ 22 ] [ 1 ]

CVT, A/T console finisherIP-23

[ 23 ] [ 2 ]

M/T console bootIP-23

[ 23 ] [ 2 ]

Console rear finisherIP-23

[ 24 ] [ 3 ]

Console mask cover (with arm rest)IP-23

[ 25 ] [ 4 ]

Rear cup holder (without arm rest)IP-23

[ 25 ] [ 4 ]

Console body assemblyIP-23

[ 26 ] [ 5 ]

Instrument lower cover (LH/RH)"INSTRU-

MENT

LOWER

FINISH-

ER"[ 27 ] [ 6 ]

Center console assembly"CEN-

TER

CON-

SOLE AS-

SEMBLY"[ 28 ] [ 7 ]

Fuse block lidIP-10

[ 29 ]

Lighting and turn signal switchLT- 6 0

[ 30 ]

Wiper & washer switchWW-22

[ 31 ]

Instrument panel & padIP-10

[ 32 ] PartsReference

pageInstrument

panel and padCluster lid A Cluster lid C Passenger air

bag module

assemblyCenter con-

sole assembly

WIIA1224E

Page 1982 of 2771

IP-16

< ON-VEHICLE REPAIR >

INSTRUMENT PANEL ASSEMBLY

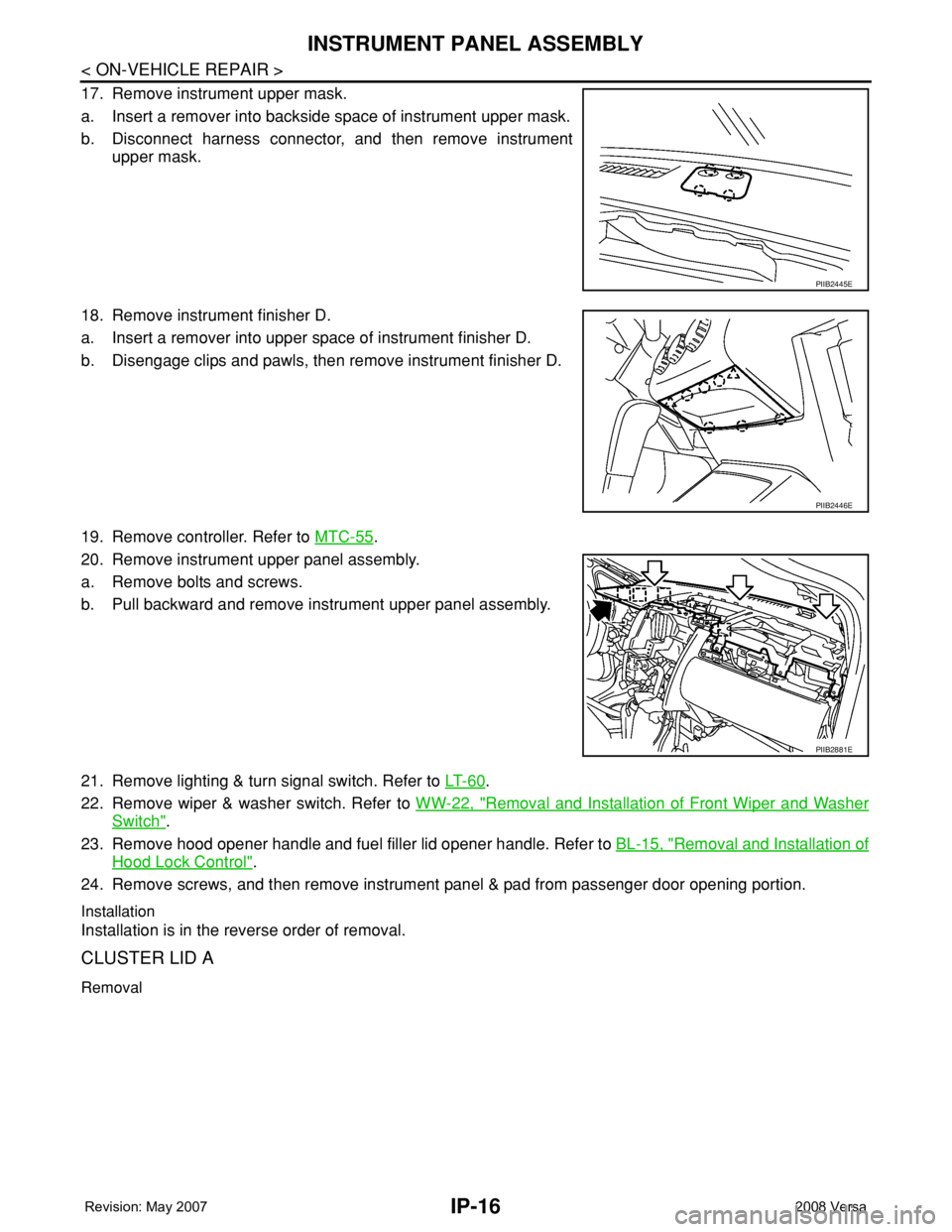

17. Remove instrument upper mask.

a. Insert a remover into backside space of instrument upper mask.

b. Disconnect harness connector, and then remove instrument

upper mask.

18. Remove instrument finisher D.

a. Insert a remover into upper space of instrument finisher D.

b. Disengage clips and pawls, then remove instrument finisher D.

19. Remove controller. Refer to MTC-55

.

20. Remove instrument upper panel assembly.

a. Remove bolts and screws.

b. Pull backward and remove instrument upper panel assembly.

21. Remove lighting & turn signal switch. Refer to LT- 6 0

.

22. Remove wiper & washer switch. Refer to WW-22, "

Removal and Installation of Front Wiper and Washer

Switch".

23. Remove hood opener handle and fuel filler lid opener handle. Refer to BL-15, "

Removal and Installation of

Hood Lock Control".

24. Remove screws, and then remove instrument panel & pad from passenger door opening portion.

Installation

Installation is in the reverse order of removal.

CLUSTER LID A

Removal

PIIB2445E

PIIB2446E

PIIB2881E

Page 1988 of 2771

IP-22

< ON-VEHICLE REPAIR >

INSTRUMENT PANEL ASSEMBLY

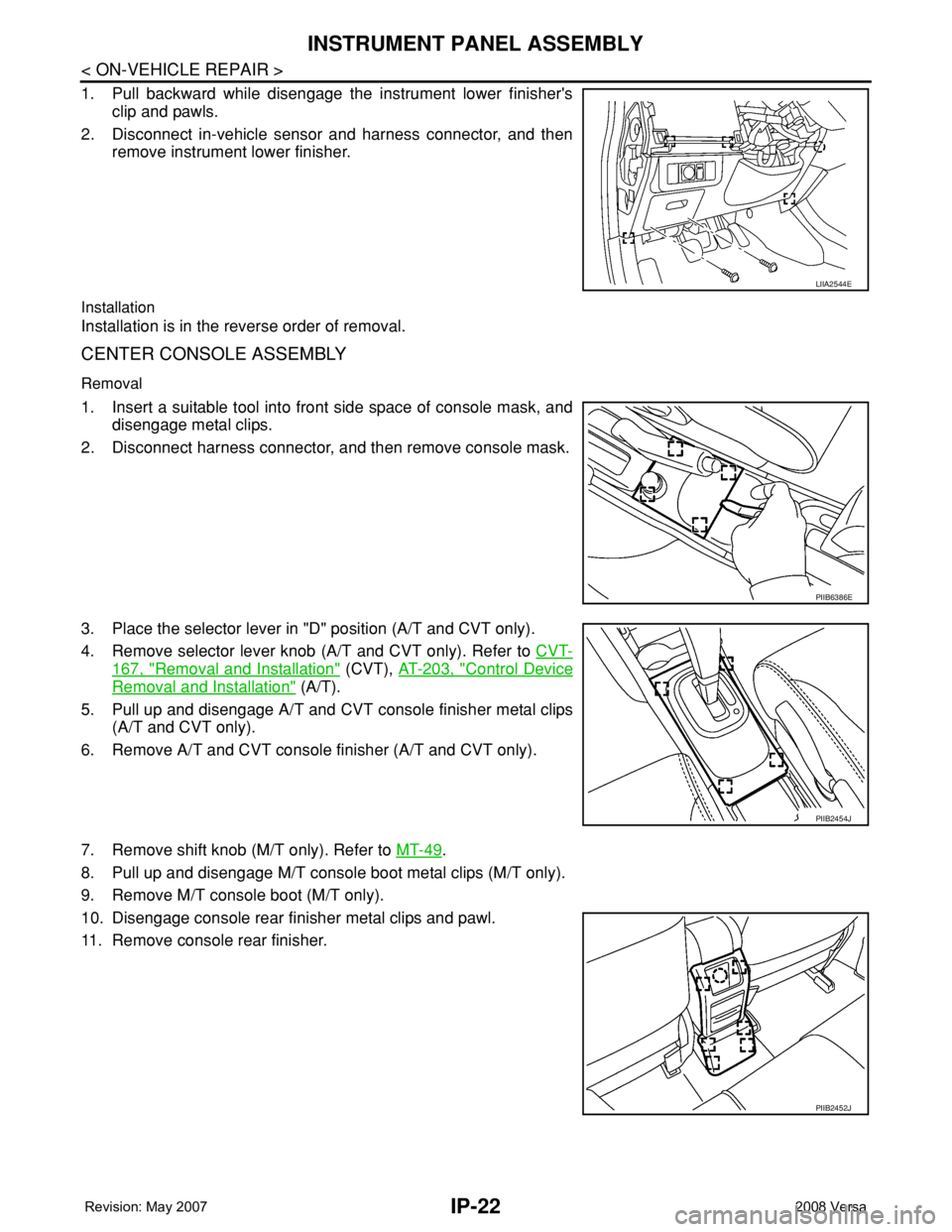

1. Pull backward while disengage the instrument lower finisher's

clip and pawls.

2. Disconnect in-vehicle sensor and harness connector, and then

remove instrument lower finisher.

Installation

Installation is in the reverse order of removal.

CENTER CONSOLE ASSEMBLY

Removal

1. Insert a suitable tool into front side space of console mask, and

disengage metal clips.

2. Disconnect harness connector, and then remove console mask.

3. Place the selector lever in "D" position (A/T and CVT only).

4. Remove selector lever knob (A/T and CVT only). Refer to CVT-

167, "Removal and Installation" (CVT), AT-203, "Control Device

Removal and Installation" (A/T).

5. Pull up and disengage A/T and CVT console finisher metal clips

(A/T and CVT only).

6. Remove A/T and CVT console finisher (A/T and CVT only).

7. Remove shift knob (M/T only). Refer to MT-49

.

8. Pull up and disengage M/T console boot metal clips (M/T only).

9. Remove M/T console boot (M/T only).

10. Disengage console rear finisher metal clips and pawl.

11. Remove console rear finisher.

LIIA2544E

PIIB6386E

PIIB2454J

PIIB2452J

Page 1991 of 2771

INSTRUMENT PANEL ASSEMBLY

IP-25

< ON-VEHICLE REPAIR >

C

D

E

F

G

H

J

K

L

MA

B

IP

N

O

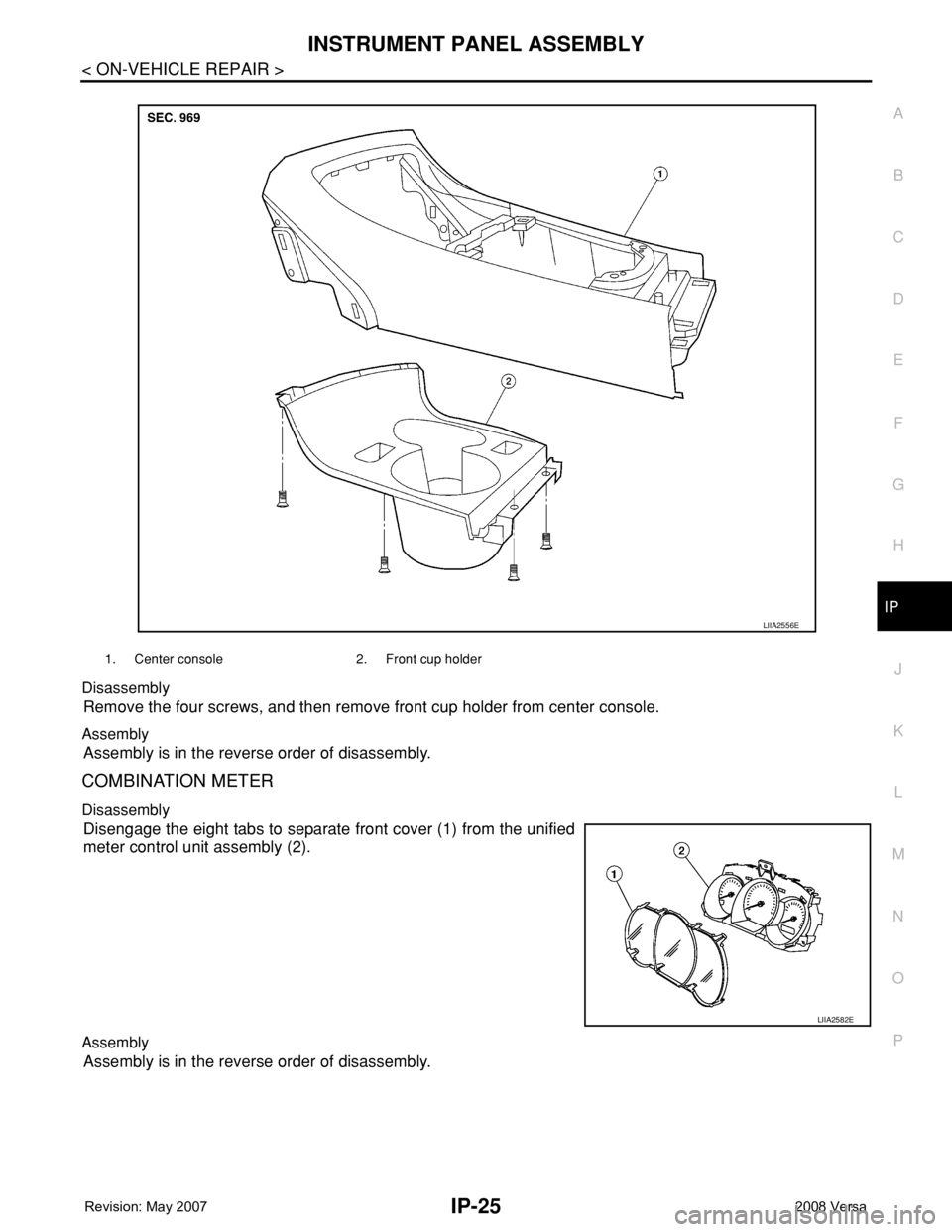

P Disassembly

Remove the four screws, and then remove front cup holder from center console.

Assembly

Assembly is in the reverse order of disassembly.

COMBINATION METER

Disassembly

Disengage the eight tabs to separate front cover (1) from the unified

meter control unit assembly (2).

Assembly

Assembly is in the reverse order of disassembly.

1. Center console 2. Front cup holder

LIIA2556E

LIIA2582E

Page 2347 of 2771

PRECAUTIONS

MTC-9

< SERVICE INFORMATION >

C

D

E

F

G

H

I

K

L

MA

B

MTC

N

O

P

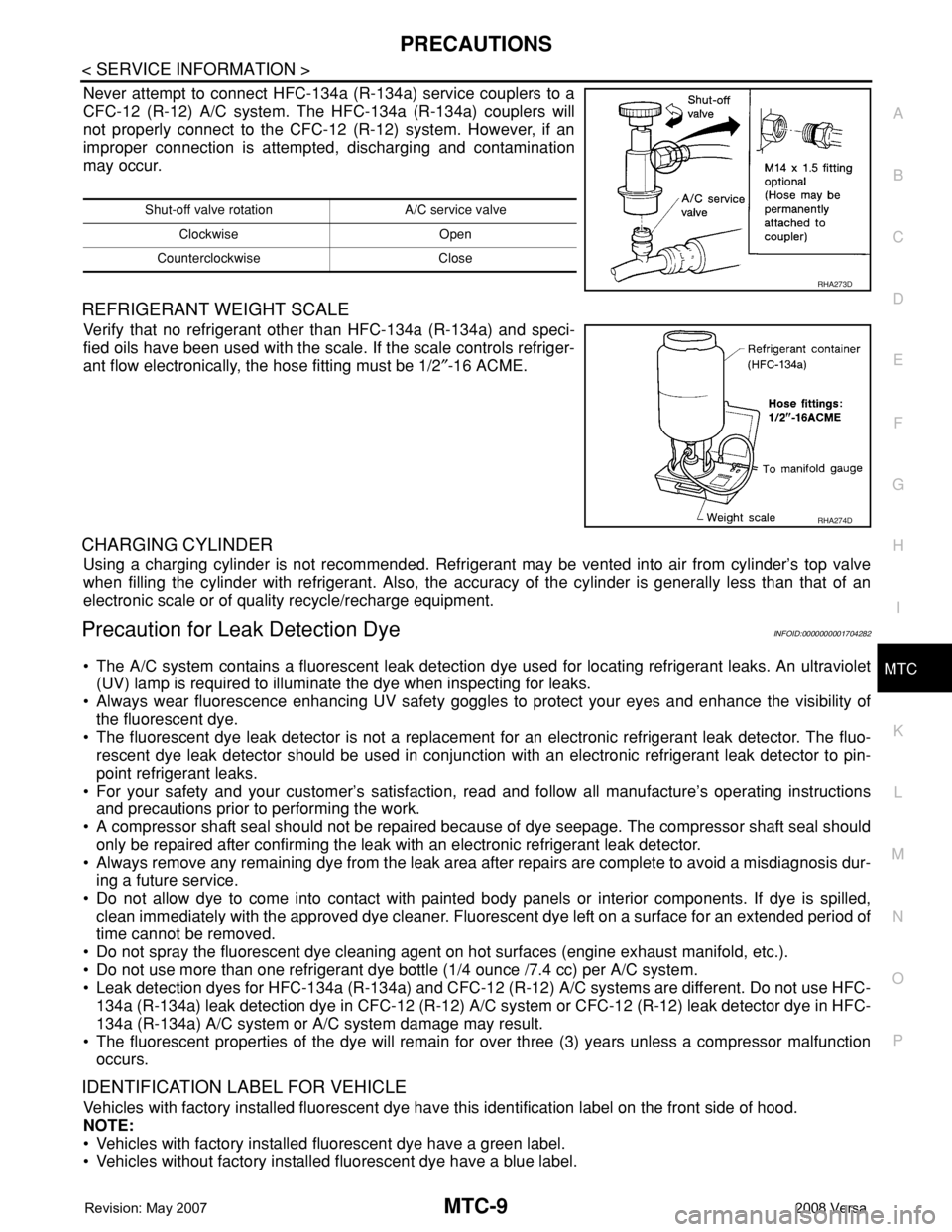

Never attempt to connect HFC-134a (R-134a) service couplers to a

CFC-12 (R-12) A/C system. The HFC-134a (R-134a) couplers will

not properly connect to the CFC-12 (R-12) system. However, if an

improper connection is attempted, discharging and contamination

may occur.

REFRIGERANT WEIGHT SCALE

Verify that no refrigerant other than HFC-134a (R-134a) and speci-

fied oils have been used with the scale. If the scale controls refriger-

ant flow electronically, the hose fitting must be 1/2″-16 ACME.

CHARGING CYLINDER

Using a charging cylinder is not recommended. Refrigerant may be vented into air from cylinder’s top valve

when filling the cylinder with refrigerant. Also, the accuracy of the cylinder is generally less than that of an

electronic scale or of quality recycle/recharge equipment.

Precaution for Leak Detection DyeINFOID:0000000001704282

• The A/C system contains a fluorescent leak detection dye used for locating refrigerant leaks. An ultraviolet

(UV) lamp is required to illuminate the dye when inspecting for leaks.

• Always wear fluorescence enhancing UV safety goggles to protect your eyes and enhance the visibility of

the fluorescent dye.

• The fluorescent dye leak detector is not a replacement for an electronic refrigerant leak detector. The fluo-

rescent dye leak detector should be used in conjunction with an electronic refrigerant leak detector to pin-

point refrigerant leaks.

• For your safety and your customer’s satisfaction, read and follow all manufacture’s operating instructions

and precautions prior to performing the work.

• A compressor shaft seal should not be repaired because of dye seepage. The compressor shaft seal should

only be repaired after confirming the leak with an electronic refrigerant leak detector.

• Always remove any remaining dye from the leak area after repairs are complete to avoid a misdiagnosis dur-

ing a future service.

• Do not allow dye to come into contact with painted body panels or interior components. If dye is spilled,

clean immediately with the approved dye cleaner. Fluorescent dye left on a surface for an extended period of

time cannot be removed.

• Do not spray the fluorescent dye cleaning agent on hot surfaces (engine exhaust manifold, etc.).

• Do not use more than one refrigerant dye bottle (1/4 ounce /7.4 cc) per A/C system.

• Leak detection dyes for HFC-134a (R-134a) and CFC-12 (R-12) A/C systems are different. Do not use HFC-

134a (R-134a) leak detection dye in CFC-12 (R-12) A/C system or CFC-12 (R-12) leak detector dye in HFC-

134a (R-134a) A/C system or A/C system damage may result.

• The fluorescent properties of the dye will remain for over three (3) years unless a compressor malfunction

occurs.

IDENTIFICATION LABEL FOR VEHICLE

Vehicles with factory installed fluorescent dye have this identification label on the front side of hood.

NOTE:

• Vehicles with factory installed fluorescent dye have a green label.

• Vehicles without factory installed fluorescent dye have a blue label.

Shut-off valve rotation A/C service valve

Clockwise Open

Counterclockwise Close

RHA273D

RHA274D

Page 2393 of 2771

CONTROLLER

MTC-55

< SERVICE INFORMATION >

C

D

E

F

G

H

I

K

L

MA

B

MTC

N

O

P

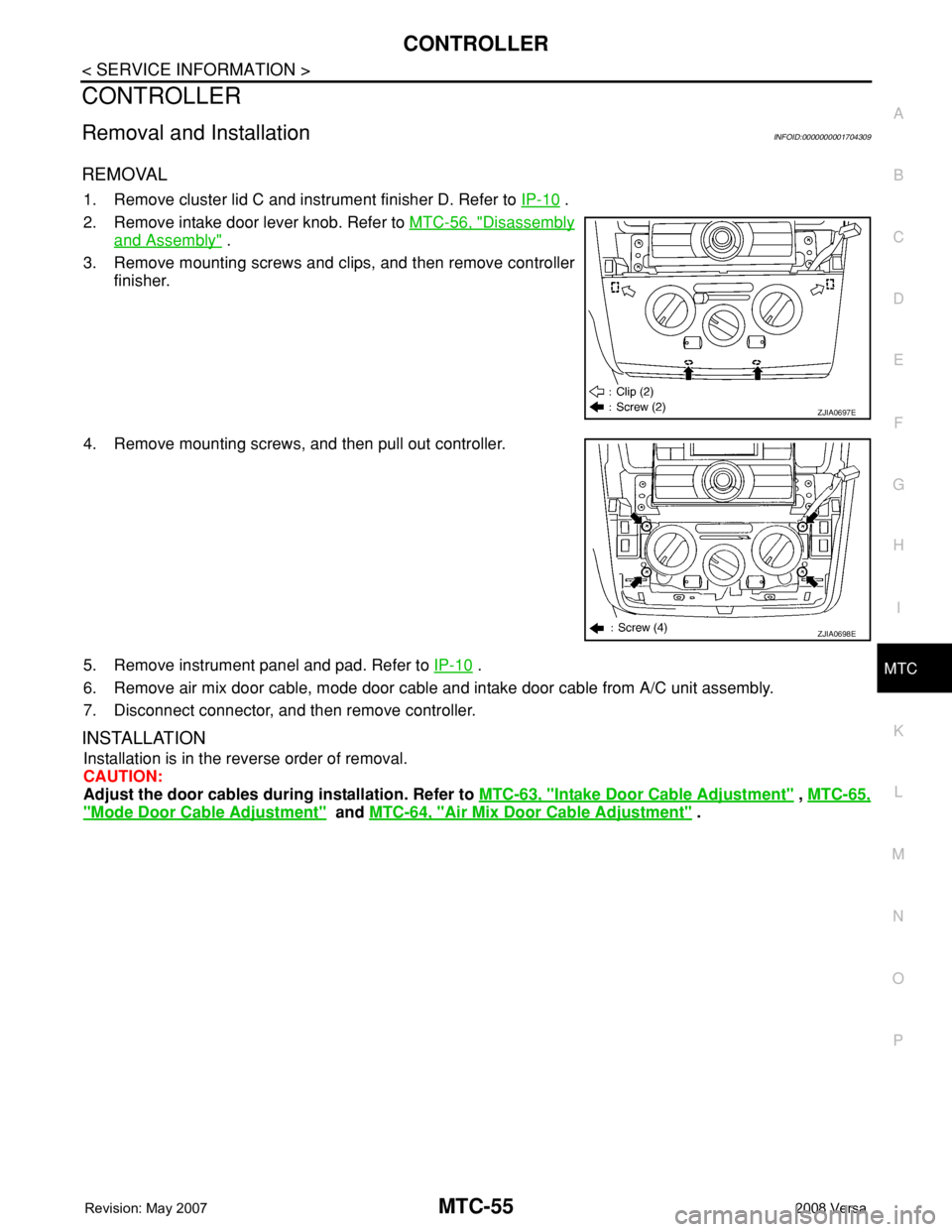

CONTROLLER

Removal and InstallationINFOID:0000000001704309

REMOVAL

1. Remove cluster lid C and instrument finisher D. Refer to IP-10 .

2. Remove intake door lever knob. Refer to MTC-56, "

Disassembly

and Assembly" .

3. Remove mounting screws and clips, and then remove controller

finisher.

4. Remove mounting screws, and then pull out controller.

5. Remove instrument panel and pad. Refer to IP-10

.

6. Remove air mix door cable, mode door cable and intake door cable from A/C unit assembly.

7. Disconnect connector, and then remove controller.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

Adjust the door cables during installation. Refer to MTC-63, "

Intake Door Cable Adjustment" , MTC-65,

"Mode Door Cable Adjustment" and MTC-64, "Air Mix Door Cable Adjustment" .

ZJIA0697E

ZJIA0698E

Page 2397 of 2771

A/C UNIT ASSEMBLY

MTC-59

< SERVICE INFORMATION >

C

D

E

F

G

H

I

K

L

MA

B

MTC

N

O

P

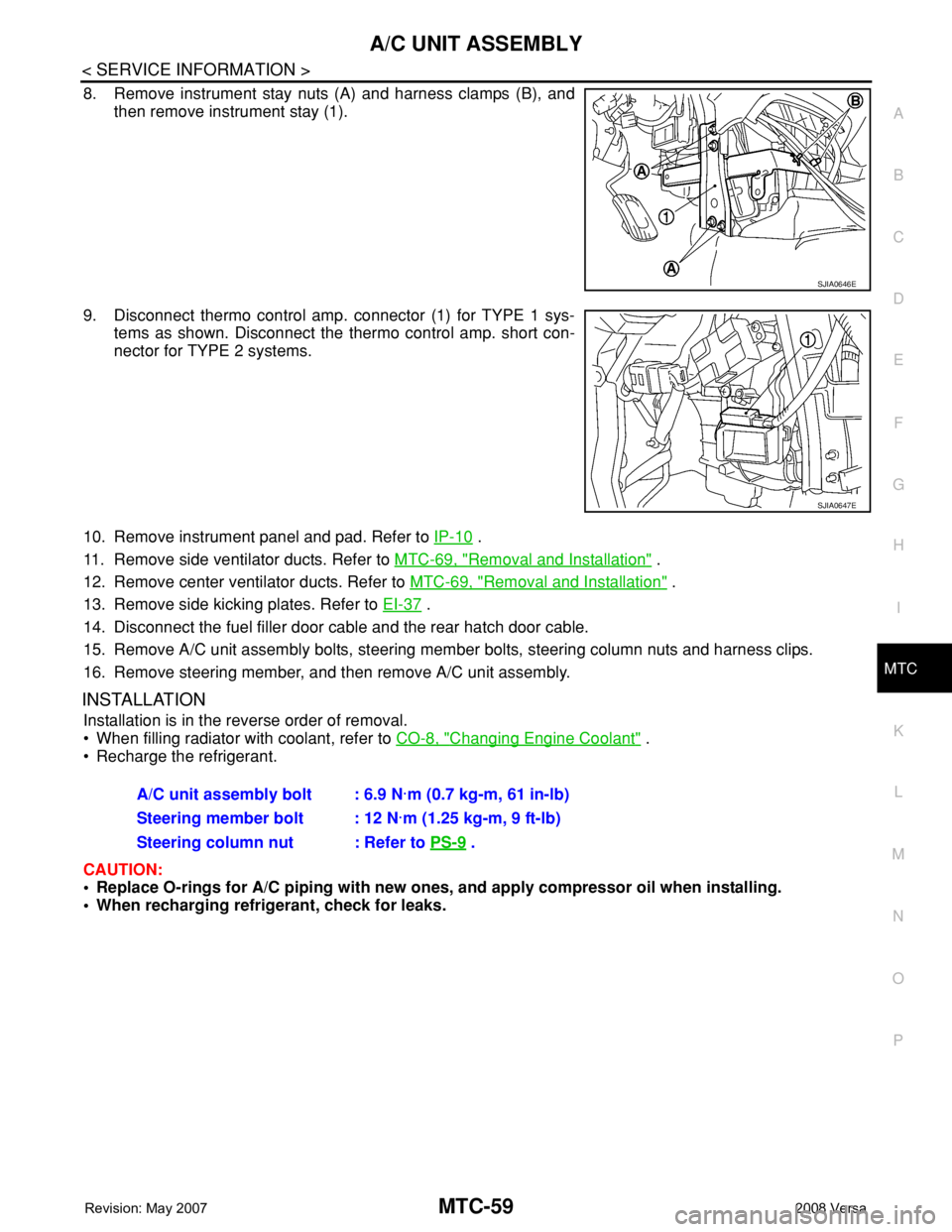

8. Remove instrument stay nuts (A) and harness clamps (B), and

then remove instrument stay (1).

9. Disconnect thermo control amp. connector (1) for TYPE 1 sys-

tems as shown. Disconnect the thermo control amp. short con-

nector for TYPE 2 systems.

10. Remove instrument panel and pad. Refer to IP-10

.

11. Remove side ventilator ducts. Refer to MTC-69, "

Removal and Installation" .

12. Remove center ventilator ducts. Refer to MTC-69, "

Removal and Installation" .

13. Remove side kicking plates. Refer to EI-37

.

14. Disconnect the fuel filler door cable and the rear hatch door cable.

15. Remove A/C unit assembly bolts, steering member bolts, steering column nuts and harness clips.

16. Remove steering member, and then remove A/C unit assembly.

INSTALLATION

Installation is in the reverse order of removal.

• When filling radiator with coolant, refer to CO-8, "

Changing Engine Coolant" .

• Recharge the refrigerant.

CAUTION:

• Replace O-rings for A/C piping with new ones, and apply compressor oil when installing.

• When recharging refrigerant, check for leaks.

SJIA0646E

SJIA0647E

A/C unit assembly bolt : 6.9 N·m (0.7 kg-m, 61 in-lb)

Steering member bolt : 12 N·m (1.25 kg-m, 9 ft-lb)

Steering column nut : Refer to PS-9

.