indicator NISSAN TIIDA 2008 Service User Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2008, Model line: TIIDA, Model: NISSAN TIIDA 2008Pages: 2771, PDF Size: 60.61 MB

Page 48 of 2771

AT-36

< SERVICE INFORMATION >

ON BOARD DIAGNOSTIC (OBD) SYSTEM

ON BOARD DIAGNOSTIC (OBD) SYSTEM

IntroductionINFOID:0000000001703172

A/T system has two self-diagnostic systems.

The first is emission-related on board diagnostic system (OBD-II) performed by the TCM in combination with

the ECM. The malfunction is indicated by the MIL (malfunction indicator lamp) and is stored as a DTC in the

ECM memory but not the TCM memory.

The second is the TCM original self-diagnosis indicated by the OD OFF indicator lamp. The malfunction is

stored in the TCM memory. The detected items are overlapped with OBD-II self-diagnostic items. For detail,

refer to AT-73, "

CONSULT-III Function (A/T)" .

OBD-II Function for A/T SystemINFOID:0000000001703173

The ECM provides emission-related on board diagnostic (OBD-II) functions for the A/T system. One function

is to receive a signal from the TCM used with OBD-related parts of the A/T system. The signal is sent to the

ECM when a malfunction occurs in the corresponding OBD-related part. The other function is to indicate a

diagnostic result by means of the MIL (malfunction indicator lamp) on the instrument panel. Sensors, switches

and solenoid valves are used as sensing elements.

The MIL automatically illuminates in One or Two Trip Detection Logic when a malfunction is sensed in relation

to A/T system parts.

One or Two Trip Detection Logic of OBD-IIINFOID:0000000001703174

ONE TRIP DETECTION LOGIC

If a malfunction is sensed during the first test drive, the MIL will illuminate and the malfunction will be stored in

the ECM memory as a DTC. The TCM is not provided with such a memory function.

TWO TRIP DETECTION LOGIC

When a malfunction is sensed during the first test drive, it is stored in the ECM memory as a 1st trip DTC

(diagnostic trouble code) or 1st trip freeze frame data. At this point, the MIL will not illuminate. — 1st trip

If the same malfunction as that experienced during the first test drive is sensed during the second test drive,

the MIL will illuminate. — 2nd trip

The “trip” in the “One or Two Trip Detection Logic” means a driving mode in which self-diagnosis is performed

during vehicle operation.

OBD-II Diagnostic Trouble Code (DTC)INFOID:0000000001703175

HOW TO READ DTC AND 1ST TRIP DTC

DTC and 1st trip DTC can be read by the following methods.

( with CONSULT-III or GST) CONSULT-III or GST (Generic Scan Tool) Examples: P0705, P0720 etc.

These DTC are prescribed by SAE J2012.

(CONSULT-III also displays the malfunctioning component or system.)

•1st trip DTC No. is the same as DTC No.

•Output of the diagnostic trouble code indicates that the indicated circuit has a malfunction. How-

ever, in case of the Mode II and GST, they do not indicate whether the malfunction is still occurring or

occurred in the past and returned to normal.

CONSULT-III can identify them as shown below, therefore, CONSULT-III (if available) is recom-

mended.

DTC or 1st trip DTC of a malfunction is displayed in SELF-DIAGNOSTIC RESULTS mode for “ENGINE” with

CONSULT-III. Time data indicates how many times the vehicle was driven after the last detection of a DTC.

If the DTC is being detected currently, the time data will be “0”.

If a 1st trip DTC is stored in the ECM, the time data will be “1t”.

Freeze Frame Data and 1st Trip Freeze Frame Data

The ECM has a memory function, which stores the driving condition such as fuel system status, calculated

load value, engine coolant temperature, short term fuel trim, long term fuel trim, engine speed and vehicle

speed at the moment the ECM detects a malfunction.

Page 49 of 2771

ON BOARD DIAGNOSTIC (OBD) SYSTEM

AT-37

< SERVICE INFORMATION >

D

E

F

G

H

I

J

K

L

MA

B

AT

N

O

P

Data which are stored in the ECM memory, along with the 1st trip DTC, are called 1st trip freeze frame data,

and the data, stored together with the DTC data, are called freeze frame data and displayed on CONSULT-III

or GST. The 1st trip freeze frame data can only be displayed on the CONSULT-III screen, not on the GST. For

detail, refer to EC-109, "

CONSULT-II Function (ENGINE)" .

Only one set of freeze frame data (either 1st trip freeze frame data of freeze frame data) can be stored in the

ECM. 1st trip freeze frame data is stored in the ECM memory along with the 1st trip DTC. There is no priority

for 1st trip freeze frame data and it is updated each time a different 1st trip DTC is detected. However, once

freeze frame data (2nd trip detection/MIL on) is stored in the ECM memory, 1st trip freeze frame data is no

longer stored. Remember, only one set of freeze frame data can be stored in the ECM. The ECM has the fol-

lowing priorities to update the data.

Both 1st trip freeze frame data and freeze frame data (along with the DTC) are cleared when the ECM mem-

ory is erased.

HOW TO ERASE DTC

The diagnostic trouble code can be erased by CONSULT-III, GST or ECM DIAGNOSTIC TEST MODE as

described following.

•If the battery cable is disconnected, the diagnostic trouble code will be cleared within 24 hours.

•When you erase the DTC, using CONSULT-III or GST is easier and quicker than switching the mode

selector on the ECM.

The following emission-related diagnostic information is cleared from the ECM memory when erasing DTC

related to OBD-II. For details, refer to EC-47, "

Emission-related Diagnostic Information" .

•Diagnostic trouble codes (DTC)

•1st trip diagnostic trouble codes (1st trip DTC)

•Freeze frame data

•1st trip freeze frame data

•System readiness test (SRT) codes

•Test values

HOW TO ERASE DTC (WITH CONSULT-III)

•If a DTC is displayed for both ECM and TCM, it is necessary to be erased for both ECM and TCM.

1. If the ignition switch stays ON after repair work, be sure to turn ignition switch OFF once. Wait at least 10

seconds and then turn it ON (engine stopped) again.

2. Turn CONSULT-III “ON” and touch “A/T”.

3. Touch “SELF-DIAG RESULTS”.

4. Touch “ERASE”. (The DTC in the TCM will be erased.) Then touch “BACK” twice.

5. Touch “ENGINE”.

6. Touch “SELF-DIAG RESULTS”.

7. Touch “ERASE”. (The DTC in the ECM will be erased.)

HOW TO ERASE DTC (WITH GST)

1. If the ignition switch stays ON after repair work, be sure to turn ignition switch OFF once. Wait at least 10

seconds and then turn it ON (engine stopped) again.

2. Perform “TCM SELF-DIAGNOSTIC PROCEDURE (No Tools)”. Refer to AT-78, "

Diagnosis Procedure

without CONSULT-III" . (The engine warm-up step can be skipped when performing the diagnosis only to

erase the DTC.)

3. Select Mode 4 with Generic Scan Tool (GST). For details, refer to EC-119, "

Generic Scan Tool (GST)

Function" .

HOW TO ERASE DTC (NO TOOLS)

The OD OFF indicator lamp is located on the combination meter.

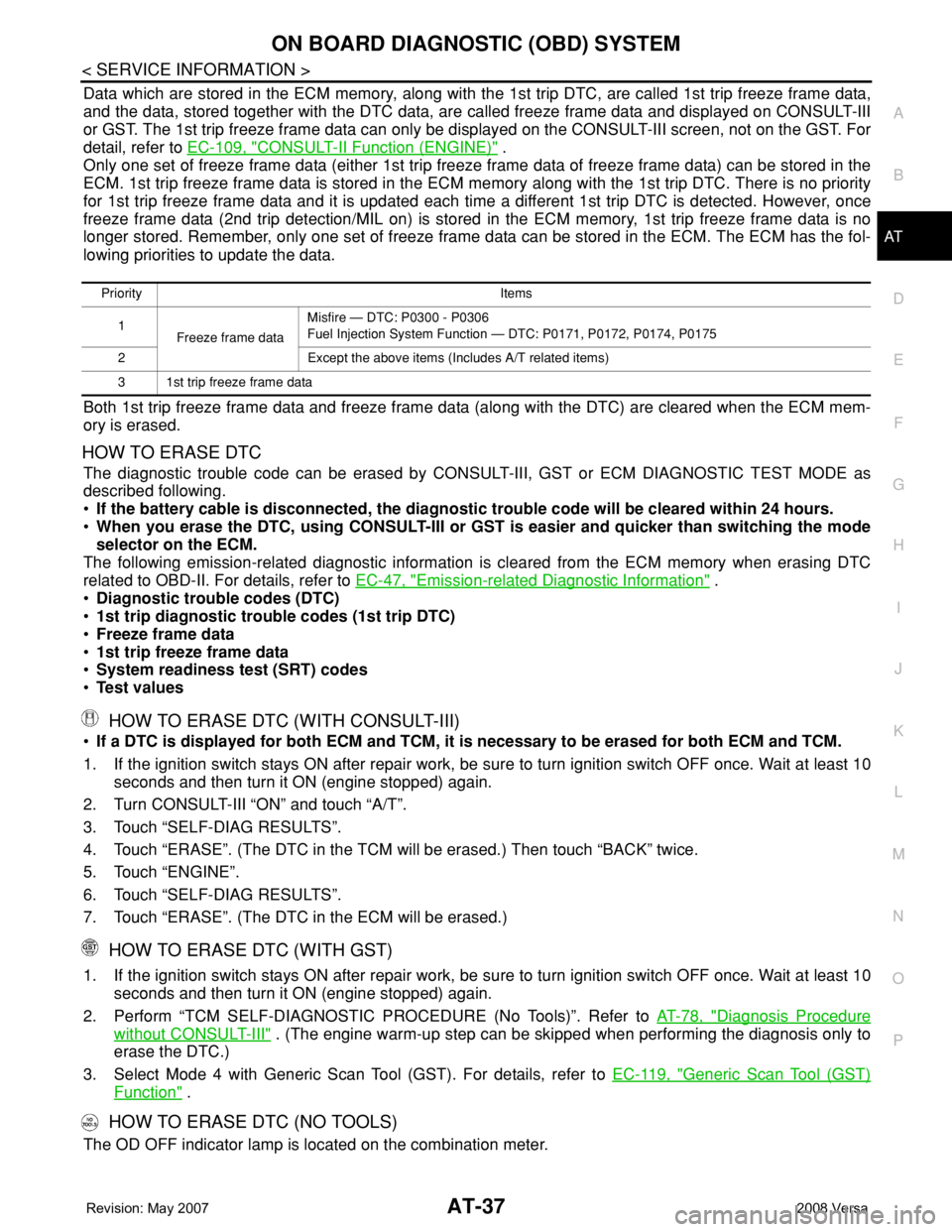

Priority Items

1

Freeze frame dataMisfire — DTC: P0300 - P0306

Fuel Injection System Function — DTC: P0171, P0172, P0174, P0175

2 Except the above items (Includes A/T related items)

3 1st trip freeze frame data

Page 50 of 2771

AT-38

< SERVICE INFORMATION >

ON BOARD DIAGNOSTIC (OBD) SYSTEM

1. If the ignition switch stays ON after repair work, be sure to turn ignition switch OFF once. Wait at least 10

seconds and then turn it ON (engine stopped) again.

2. Perform “TCM SELF-DIAGNOSTIC PROCEDURE (No Tools)”. Refer to AT-78, "

Diagnosis Procedure

without CONSULT-III" . (The engine warm-up step can be skipped when performing the diagnosis only to

erase the DTC.)

3. Perform “OBD-II SELF-DIAGNOSTIC PROCEDURE (No tools)”. Refer to EC-47, "

Emission-related Diag-

nostic Information" .

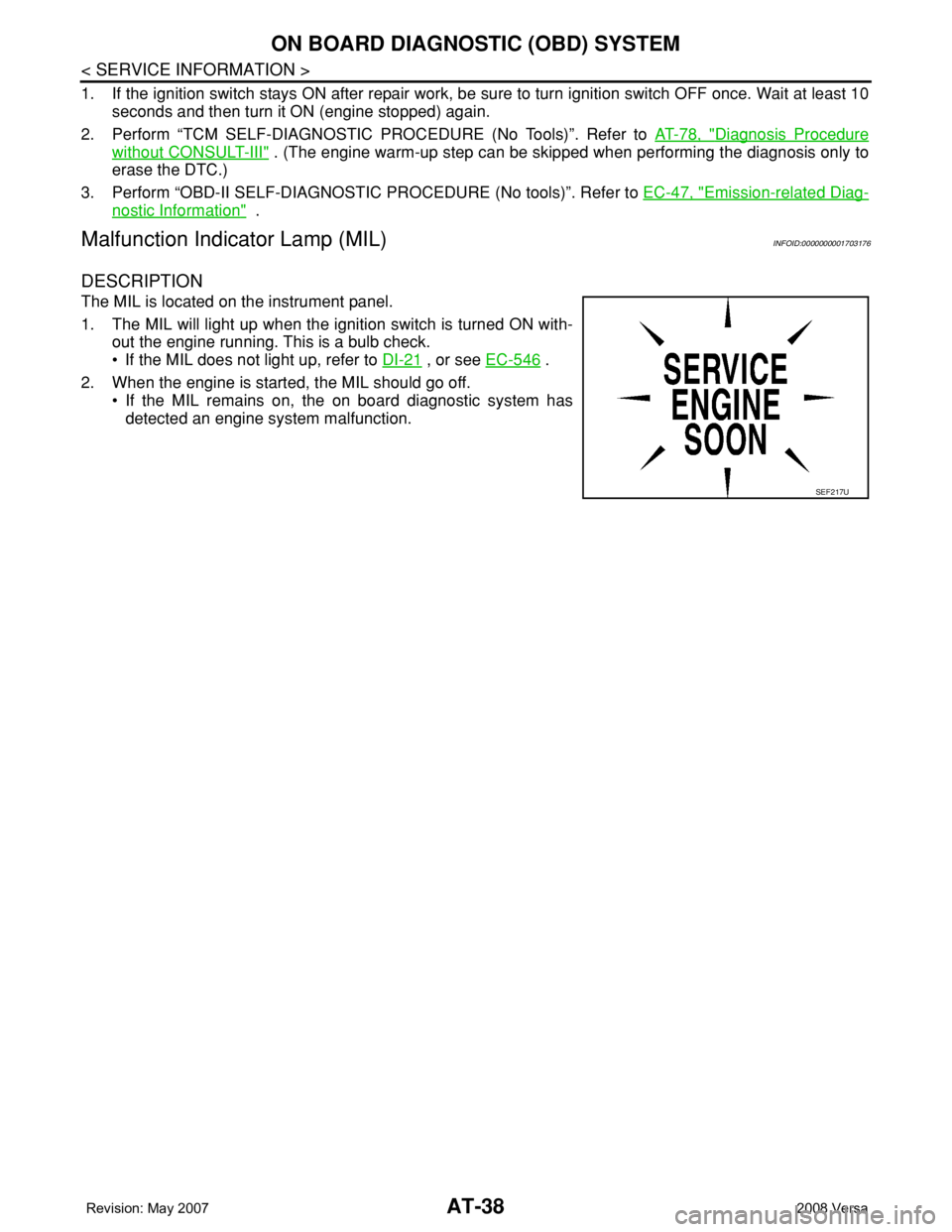

Malfunction Indicator Lamp (MIL)INFOID:0000000001703176

DESCRIPTION

The MIL is located on the instrument panel.

1. The MIL will light up when the ignition switch is turned ON with-

out the engine running. This is a bulb check.

• If the MIL does not light up, refer to DI-21

, or see EC-546 .

2. When the engine is started, the MIL should go off.

• If the MIL remains on, the on board diagnostic system has

detected an engine system malfunction.

SEF217U

Page 55 of 2771

TROUBLE DIAGNOSIS

AT-43

< SERVICE INFORMATION >

D

E

F

G

H

I

J

K

L

MA

B

AT

N

O

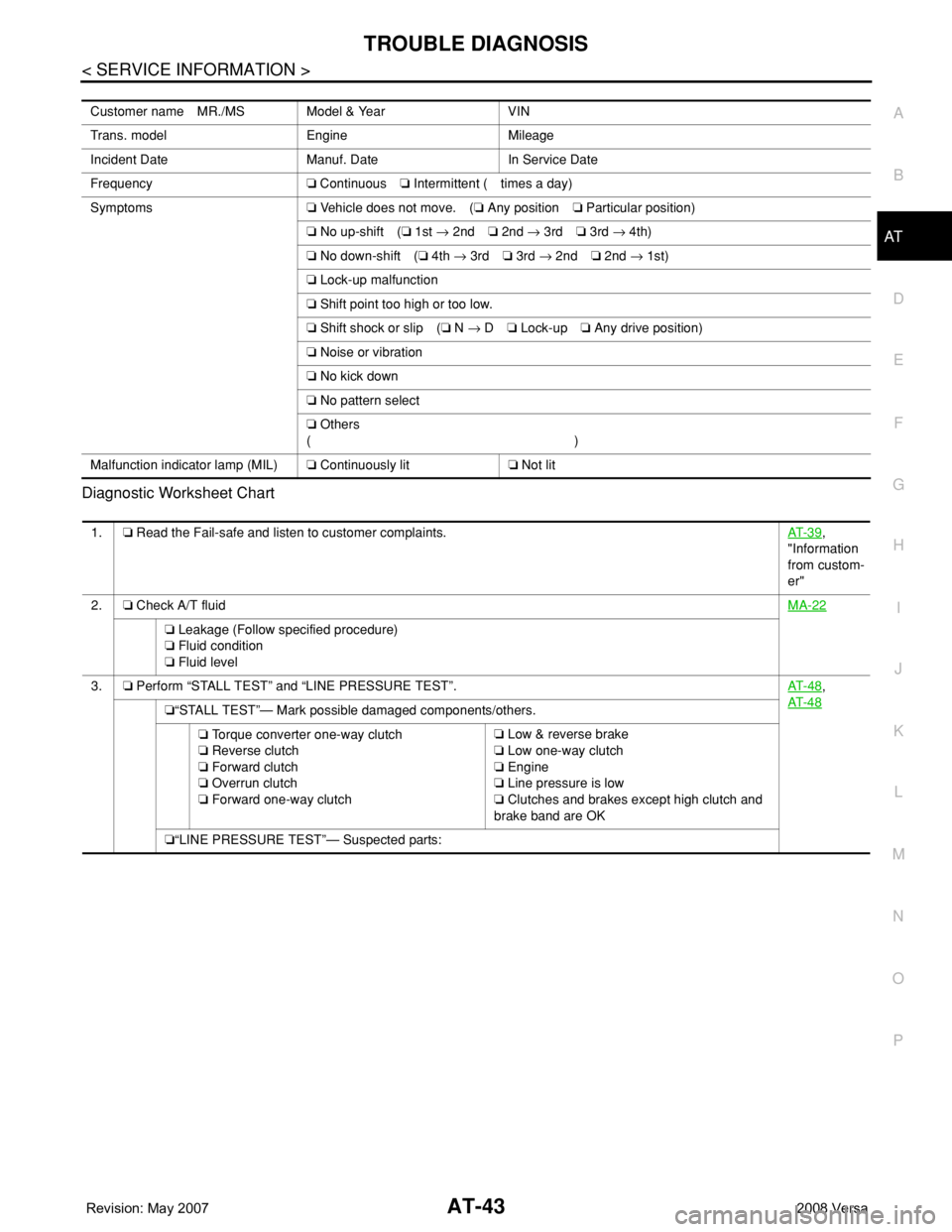

P Diagnostic Worksheet Chart

Customer name MR./MS Model & Year VIN

Trans. model Engine Mileage

Incident Date Manuf. Date In Service Date

Frequency❏ Continuous❏ Intermittent ( times a day)

Symptoms❏ Vehicle does not move. (❏ Any position❏ Particular position)

❏ No up-shift (❏ 1st → 2nd❏ 2nd → 3rd❏ 3rd → 4th)

❏ No down-shift (❏ 4th → 3rd❏ 3rd → 2nd❏ 2nd → 1st)

❏ Lock-up malfunction

❏ Shift point too high or too low.

❏ Shift shock or slip (❏ N → D❏ Lock-up❏ Any drive position)

❏ Noise or vibration

❏ No kick down

❏ No pattern select

❏ Others

()

Malfunction indicator lamp (MIL)❏ Continuously lit❏ Not lit

1.❏ Read the Fail-safe and listen to customer complaints.AT- 3 9,

"Information

from custom-

er"

2.❏ Check A/T fluidMA-22

❏ Leakage (Follow specified procedure)

❏ Fluid condition

❏ Fluid level

3.❏ Perform “STALL TEST” and “LINE PRESSURE TEST”.AT- 4 8

,

AT- 4 8

❏“STALL TEST”— Mark possible damaged components/others.

❏ Torque converter one-way clutch

❏ Reverse clutch

❏ Forward clutch

❏ Overrun clutch

❏ Forward one-way clutch❏ Low & reverse brake

❏ Low one-way clutch

❏ Engine

❏ Line pressure is low

❏ Clutches and brakes except high clutch and

brake band are OK

❏“LINE PRESSURE TEST”— Suspected parts:

Page 56 of 2771

AT-44

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS

4.❏ Perform “Road Test”.AT- 5 2

4-1. “Check Before Engine is Started”AT- 5 3

❏AT- 1 7 6 , "OD OFF Indicator Lamp Does Not Come On"

❏ Perform self-diagnosis. Enter checks for detected items. AT- 7 3 , AT- 7 8 .

❏AT- 8 3

.

❏AT- 8 6

.

❏AT- 9 1

.

❏AT- 9 6

.

❏AT- 1 0 1

.

❏AT- 1 0 5

❏AT- 1 0 8 .

❏AT- 111

.

❏AT- 11 4

.

❏AT- 11 9

.

❏AT- 1 2 4

.

❏AT- 1 2 9

.

❏AT- 1 3 4

.

❏AT- 1 3 9

.

❏AT- 1 4 4

.

❏AT- 1 4 9

.

❏AT- 1 5 2

.

❏AT- 1 5 8

.

❏AT- 1 6 3

.

❏AT- 1 6 4

.

4-2. “Check at Idle”AT- 5 3

❏AT- 1 7 8 , "Engine Cannot Be Started in "P" and "N" Position" .

❏AT- 1 7 9 , "

In "P" Position, Vehicle Moves Forward or Backward When Pushed" .

❏AT- 1 7 9 , "

In "N" Position, Vehicle Moves" .

❏AT- 1 8 0 , "

Large Shock "N" → "R" Position" .

❏AT- 1 8 1 , "

Vehicle Does Not Creep Backward in "R" Position" .

❏AT- 1 8 2 , "

Vehicle Does Not Creep Forward in "D", "2" or "1" Position" .

Page 58 of 2771

AT-46

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS

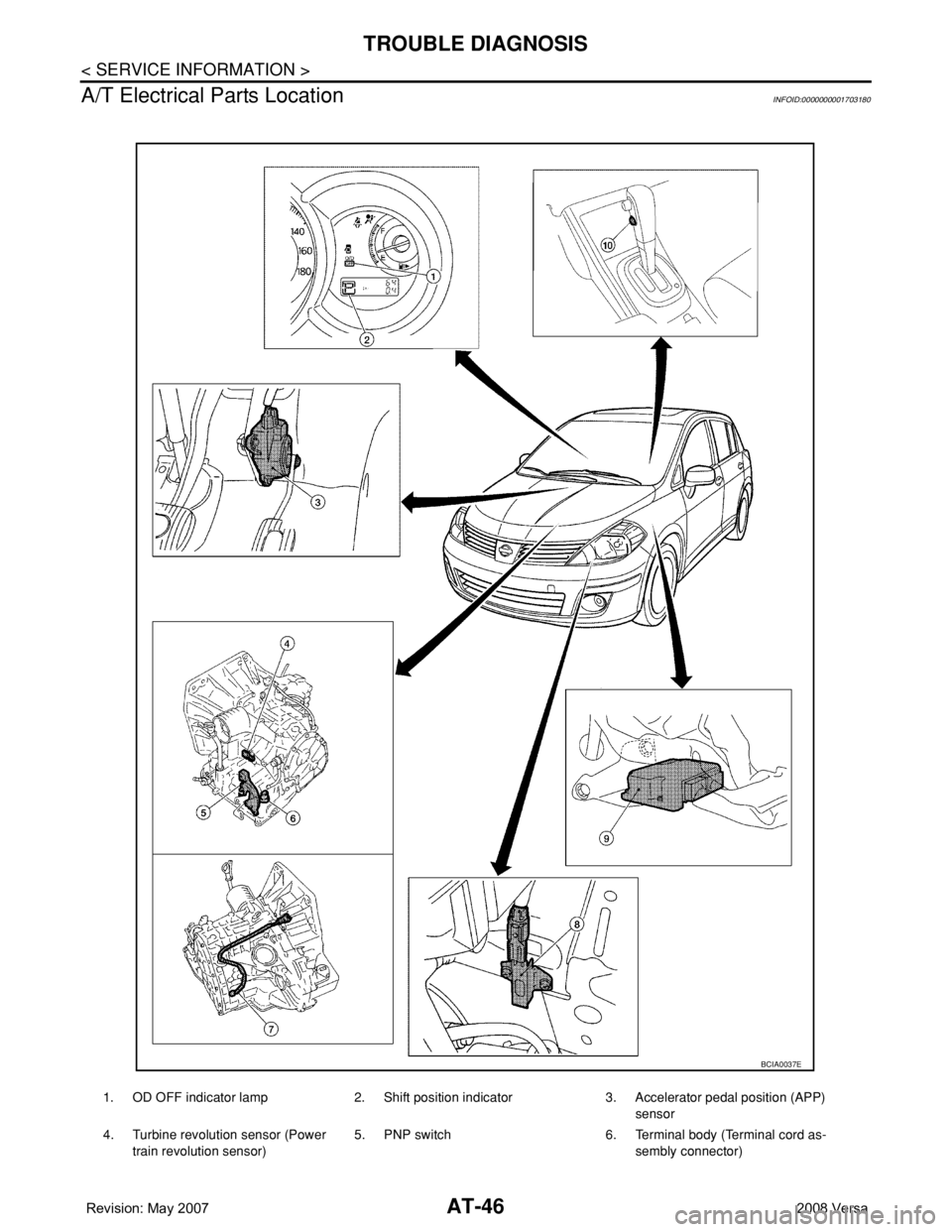

A/T Electrical Parts Location

INFOID:0000000001703180

1. OD OFF indicator lamp 2. Shift position indicator 3. Accelerator pedal position (APP)

sensor

4. Turbine revolution sensor (Power

train revolution sensor)5. PNP switch 6. Terminal body (Terminal cord as-

sembly connector)

BCIA0037E

Page 60 of 2771

AT-48

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS

Inspections Before Trouble Diagnosis

INFOID:0000000001703182

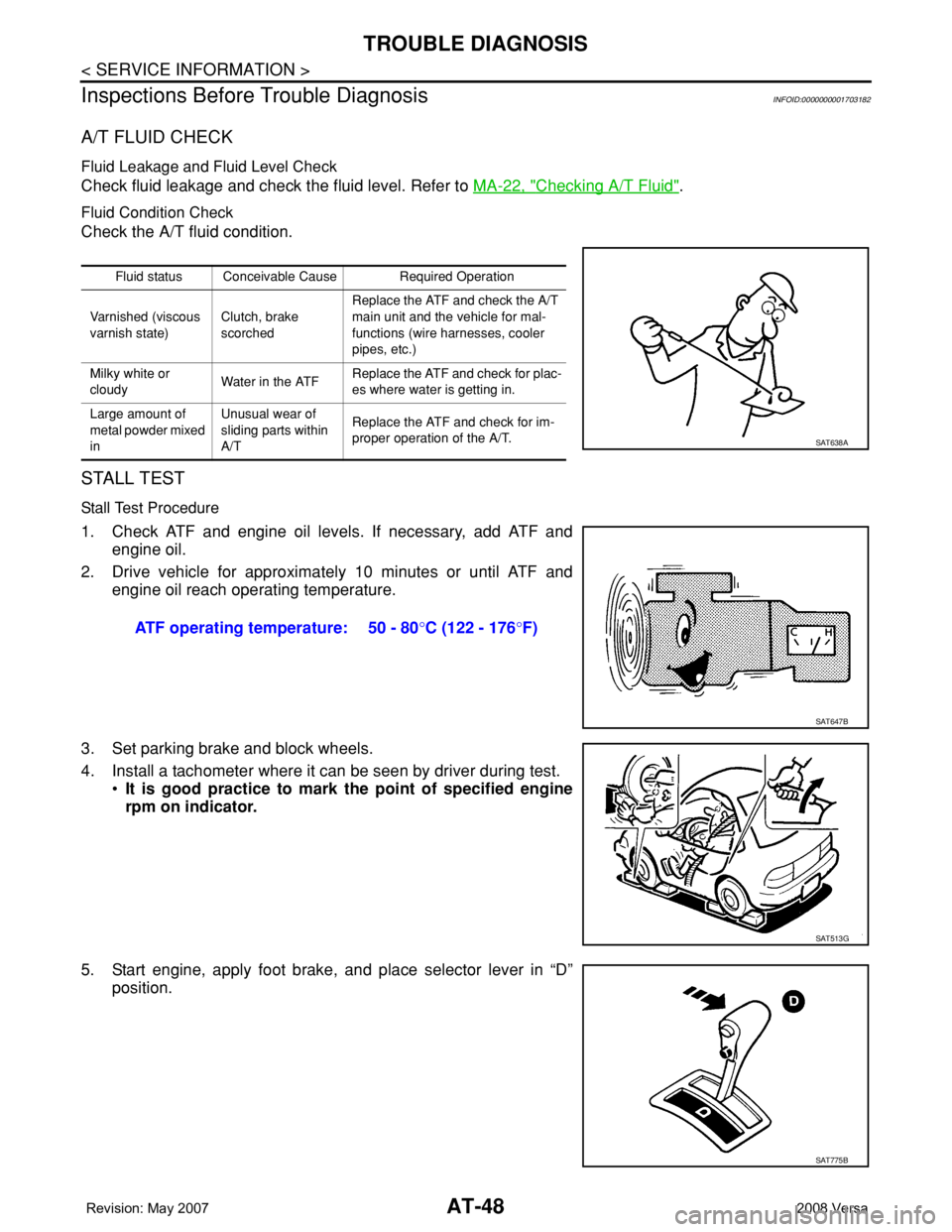

A/T FLUID CHECK

Fluid Leakage and Fluid Level Check

Check fluid leakage and check the fluid level. Refer to MA-22, "Checking A/T Fluid".

Fluid Condition Check

Check the A/T fluid condition.

STALL TEST

Stall Test Procedure

1. Check ATF and engine oil levels. If necessary, add ATF and

engine oil.

2. Drive vehicle for approximately 10 minutes or until ATF and

engine oil reach operating temperature.

3. Set parking brake and block wheels.

4. Install a tachometer where it can be seen by driver during test.

•It is good practice to mark the point of specified engine

rpm on indicator.

5. Start engine, apply foot brake, and place selector lever in “D”

position.

Fluid status Conceivable Cause Required Operation

Varnished (viscous

varnish state)Clutch, brake

scorchedReplace the ATF and check the A/T

main unit and the vehicle for mal-

functions (wire harnesses, cooler

pipes, etc.)

Milky white or

cloudyWater in the ATFReplace the ATF and check for plac-

es where water is getting in.

Large amount of

metal powder mixed

inUnusual wear of

sliding parts within

A/TReplace the ATF and check for im-

proper operation of the A/T.

SAT638A

ATF operating temperature: 50 - 80°C (122 - 176°F)

SAT647B

SAT513G

SAT775B

Page 61 of 2771

TROUBLE DIAGNOSIS

AT-49

< SERVICE INFORMATION >

D

E

F

G

H

I

J

K

L

MA

B

AT

N

O

P

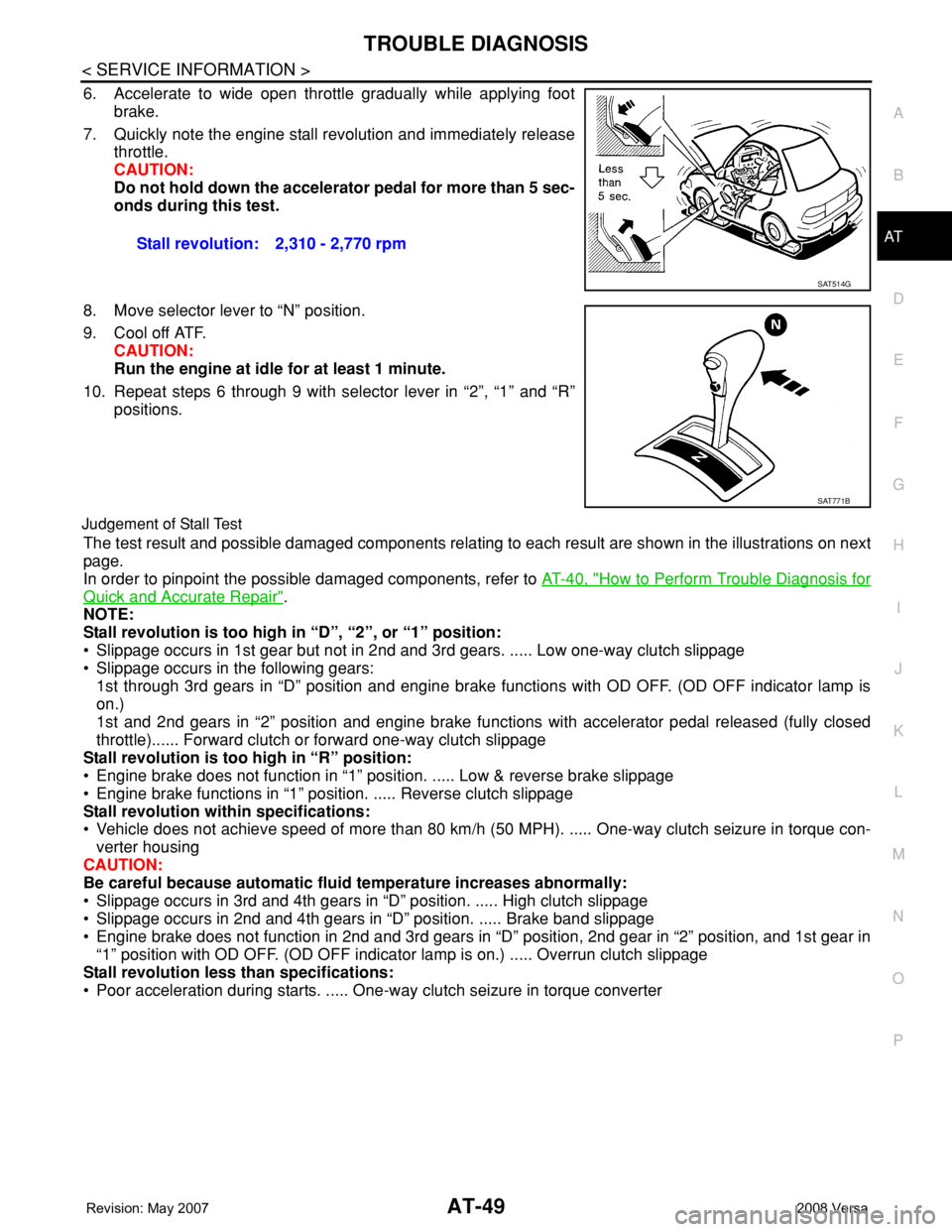

6. Accelerate to wide open throttle gradually while applying foot

brake.

7. Quickly note the engine stall revolution and immediately release

throttle.

CAUTION:

Do not hold down the accelerator pedal for more than 5 sec-

onds during this test.

8. Move selector lever to “N” position.

9. Cool off ATF.

CAUTION:

Run the engine at idle for at least 1 minute.

10. Repeat steps 6 through 9 with selector lever in “2”, “1” and “R”

positions.

Judgement of Stall Test

The test result and possible damaged components relating to each result are shown in the illustrations on next

page.

In order to pinpoint the possible damaged components, refer to AT-40, "

How to Perform Trouble Diagnosis for

Quick and Accurate Repair".

NOTE:

Stall revolution is too high in “D”, “2”, or “1” position:

• Slippage occurs in 1st gear but not in 2nd and 3rd gears. ..... Low one-way clutch slippage

• Slippage occurs in the following gears:

1st through 3rd gears in “D” position and engine brake functions with OD OFF. (OD OFF indicator lamp is

on.)

1st and 2nd gears in “2” position and engine brake functions with accelerator pedal released (fully closed

throttle)...... Forward clutch or forward one-way clutch slippage

Stall revolution is too high in “R” position:

• Engine brake does not function in “1” position. ..... Low & reverse brake slippage

• Engine brake functions in “1” position. ..... Reverse clutch slippage

Stall revolution within specifications:

• Vehicle does not achieve speed of more than 80 km/h (50 MPH). ..... One-way clutch seizure in torque con-

verter housing

CAUTION:

Be careful because automatic fluid temperature increases abnormally:

• Slippage occurs in 3rd and 4th gears in “D” position. ..... High clutch slippage

• Slippage occurs in 2nd and 4th gears in “D” position. ..... Brake band slippage

• Engine brake does not function in 2nd and 3rd gears in “D” position, 2nd gear in “2” position, and 1st gear in

“1” position with OD OFF. (OD OFF indicator lamp is on.) ..... Overrun clutch slippage

Stall revolution less than specifications:

• Poor acceleration during starts. ..... One-way clutch seizure in torque converter Stall revolution: 2,310 - 2,770 rpm

SAT514G

SAT771B

Page 65 of 2771

TROUBLE DIAGNOSIS

AT-53

< SERVICE INFORMATION >

D

E

F

G

H

I

J

K

L

MA

B

AT

N

O

P

• Before road test, familiarize yourself with all test procedures and

items to check.

• Perform tests on all items until specified symptom is found. Trou-

bleshoot the items which are checked out to be no good after road

test. Refer to AT-73, "

CONSULT-III Function (A/T)" , AT-78, "Diag-

nosis Procedure without CONSULT-III" and AT-173 .

Check Before Engine Is StartedINFOID:0000000001703184

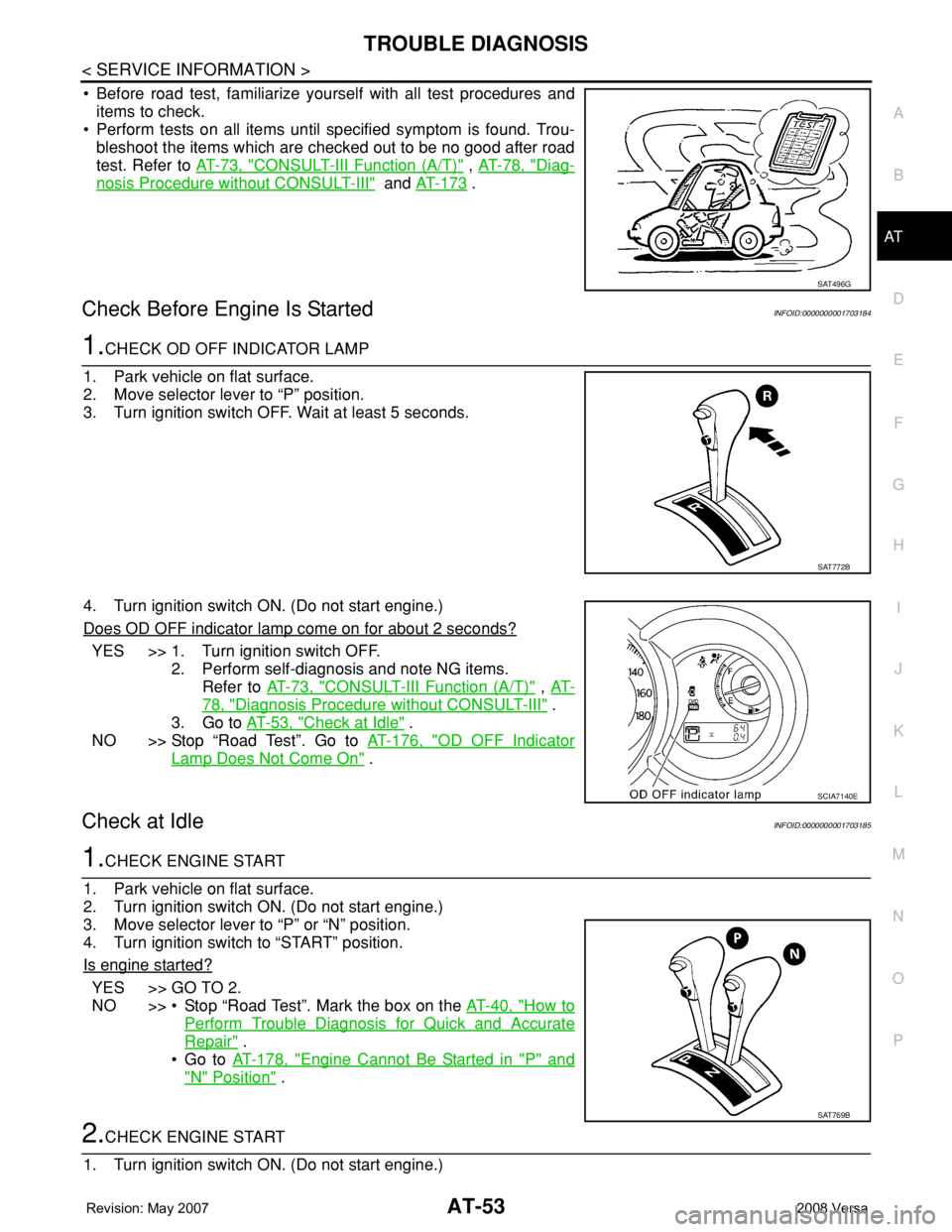

1.CHECK OD OFF INDICATOR LAMP

1. Park vehicle on flat surface.

2. Move selector lever to “P” position.

3. Turn ignition switch OFF. Wait at least 5 seconds.

4. Turn ignition switch ON. (Do not start engine.)

Does OD OFF indicator lamp come on for about 2 seconds?

YES >> 1. Turn ignition switch OFF.

2. Perform self-diagnosis and note NG items.

Refer to AT-73, "

CONSULT-III Function (A/T)" , AT-

78, "Diagnosis Procedure without CONSULT-III" .

3. Go to AT-53, "

Check at Idle" .

NO >> Stop “Road Test”. Go to AT-176, "

OD OFF Indicator

Lamp Does Not Come On" .

Check at IdleINFOID:0000000001703185

1.CHECK ENGINE START

1. Park vehicle on flat surface.

2. Turn ignition switch ON. (Do not start engine.)

3. Move selector lever to “P” or “N” position.

4. Turn ignition switch to “START” position.

Is engine started?

YES >> GO TO 2.

NO >> • Stop “Road Test”. Mark the box on the AT-40, "

How to

Perform Trouble Diagnosis for Quick and Accurate

Repair" .

•Go to AT-178, "

Engine Cannot Be Started in "P" and

"N" Position" .

2.CHECK ENGINE START

1. Turn ignition switch ON. (Do not start engine.)

SAT496G

SAT772B

SCIA7140E

SAT769B

Page 68 of 2771

AT-56

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS

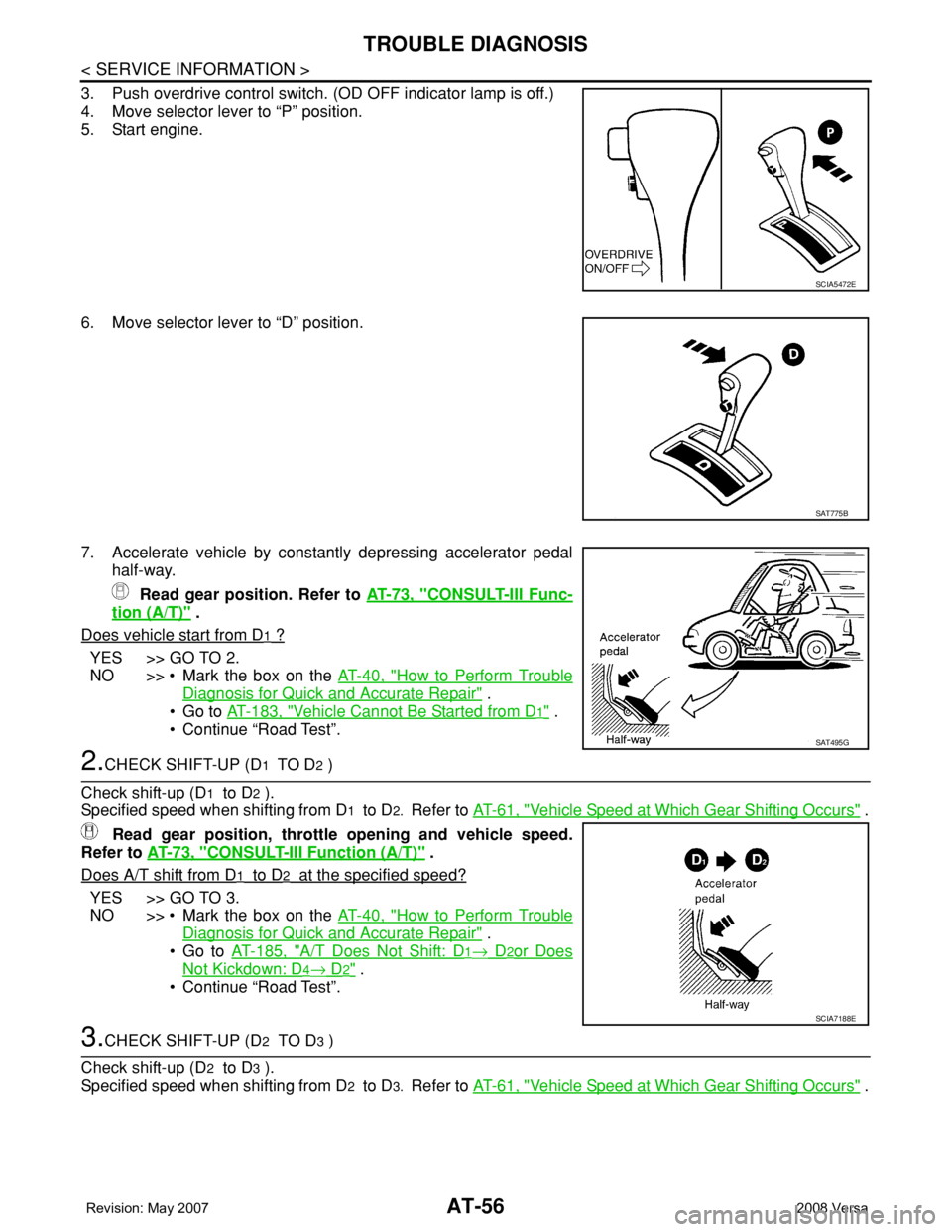

3. Push overdrive control switch. (OD OFF indicator lamp is off.)

4. Move selector lever to “P” position.

5. Start engine.

6. Move selector lever to “D” position.

7. Accelerate vehicle by constantly depressing accelerator pedal

half-way.

Read gear position. Refer to AT-73, "

CONSULT-III Func-

tion (A/T)" .

Does vehicle start from D

1 ?

YES >> GO TO 2.

NO >> • Mark the box on the AT-40, "

How to Perform Trouble

Diagnosis for Quick and Accurate Repair" .

•Go to AT-183, "

Vehicle Cannot Be Started from D1" .

• Continue “Road Test”.

2.CHECK SHIFT-UP (D1 TO D2 )

Check shift-up (D

1 to D2 ).

Specified speed when shifting from D

1 to D2. Refer to AT-61, "Vehicle Speed at Which Gear Shifting Occurs" .

Read gear position, throttle opening and vehicle speed.

Refer to AT-73, "

CONSULT-III Function (A/T)" .

Does A/T shift from D

1 to D2 at the specified speed?

YES >> GO TO 3.

NO >> • Mark the box on the AT-40, "

How to Perform Trouble

Diagnosis for Quick and Accurate Repair" .

•Go to AT-185, "

A/T Does Not Shift: D1→ D2or Does

Not Kickdown: D4→ D2" .

• Continue “Road Test”.

3.CHECK SHIFT-UP (D2 TO D3 )

Check shift-up (D

2 to D3 ).

Specified speed when shifting from D

2 to D3. Refer to AT-61, "Vehicle Speed at Which Gear Shifting Occurs" .

SCIA5472E

SAT775B

SAT495G

SCIA7188E