oil NISSAN TIIDA 2008 Service Manual PDF

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2008, Model line: TIIDA, Model: NISSAN TIIDA 2008Pages: 2771, PDF Size: 60.61 MB

Page 273 of 2771

REPAIR FOR COMPONENT PARTS

AT-261

< SERVICE INFORMATION >

D

E

F

G

H

I

J

K

L

MA

B

AT

N

O

P

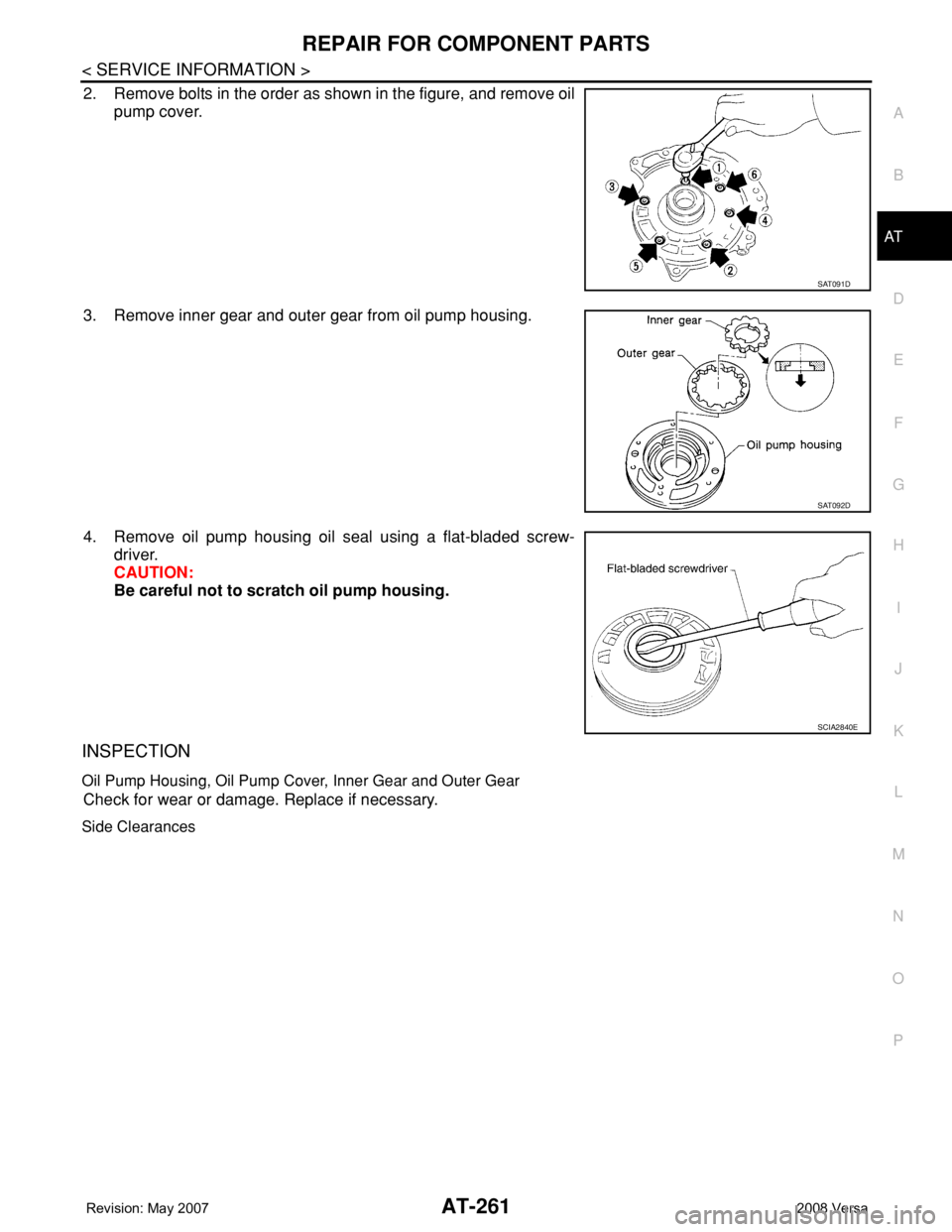

2. Remove bolts in the order as shown in the figure, and remove oil

pump cover.

3. Remove inner gear and outer gear from oil pump housing.

4. Remove oil pump housing oil seal using a flat-bladed screw-

driver.

CAUTION:

Be careful not to scratch oil pump housing.

INSPECTION

Oil Pump Housing, Oil Pump Cover, Inner Gear and Outer Gear

Check for wear or damage. Replace if necessary.

Side Clearances

SAT091D

SAT092D

SCIA2840E

Page 274 of 2771

AT-262

< SERVICE INFORMATION >

REPAIR FOR COMPONENT PARTS

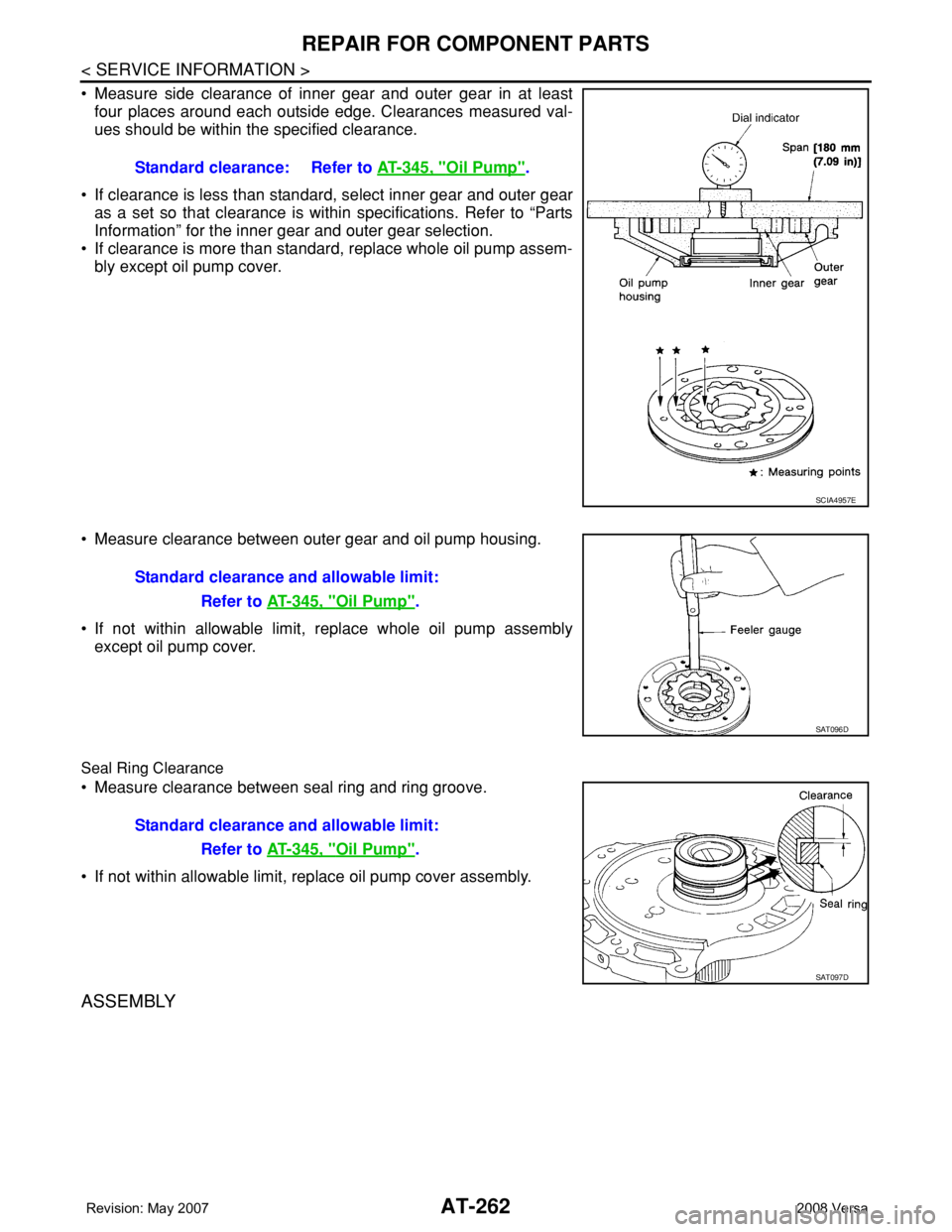

• Measure side clearance of inner gear and outer gear in at least

four places around each outside edge. Clearances measured val-

ues should be within the specified clearance.

• If clearance is less than standard, select inner gear and outer gear

as a set so that clearance is within specifications. Refer to “Parts

Information” for the inner gear and outer gear selection.

• If clearance is more than standard, replace whole oil pump assem-

bly except oil pump cover.

• Measure clearance between outer gear and oil pump housing.

• If not within allowable limit, replace whole oil pump assembly

except oil pump cover.

Seal Ring Clearance

• Measure clearance between seal ring and ring groove.

• If not within allowable limit, replace oil pump cover assembly.

ASSEMBLY

Standard clearance: Refer to AT-345, "Oil Pump".

SCIA4957E

Standard clearance and allowable limit:

Refer to AT-345, "

Oil Pump".

SAT096D

Standard clearance and allowable limit:

Refer to AT-345, "

Oil Pump".

SAT097D

Page 275 of 2771

REPAIR FOR COMPONENT PARTS

AT-263

< SERVICE INFORMATION >

D

E

F

G

H

I

J

K

L

MA

B

AT

N

O

P

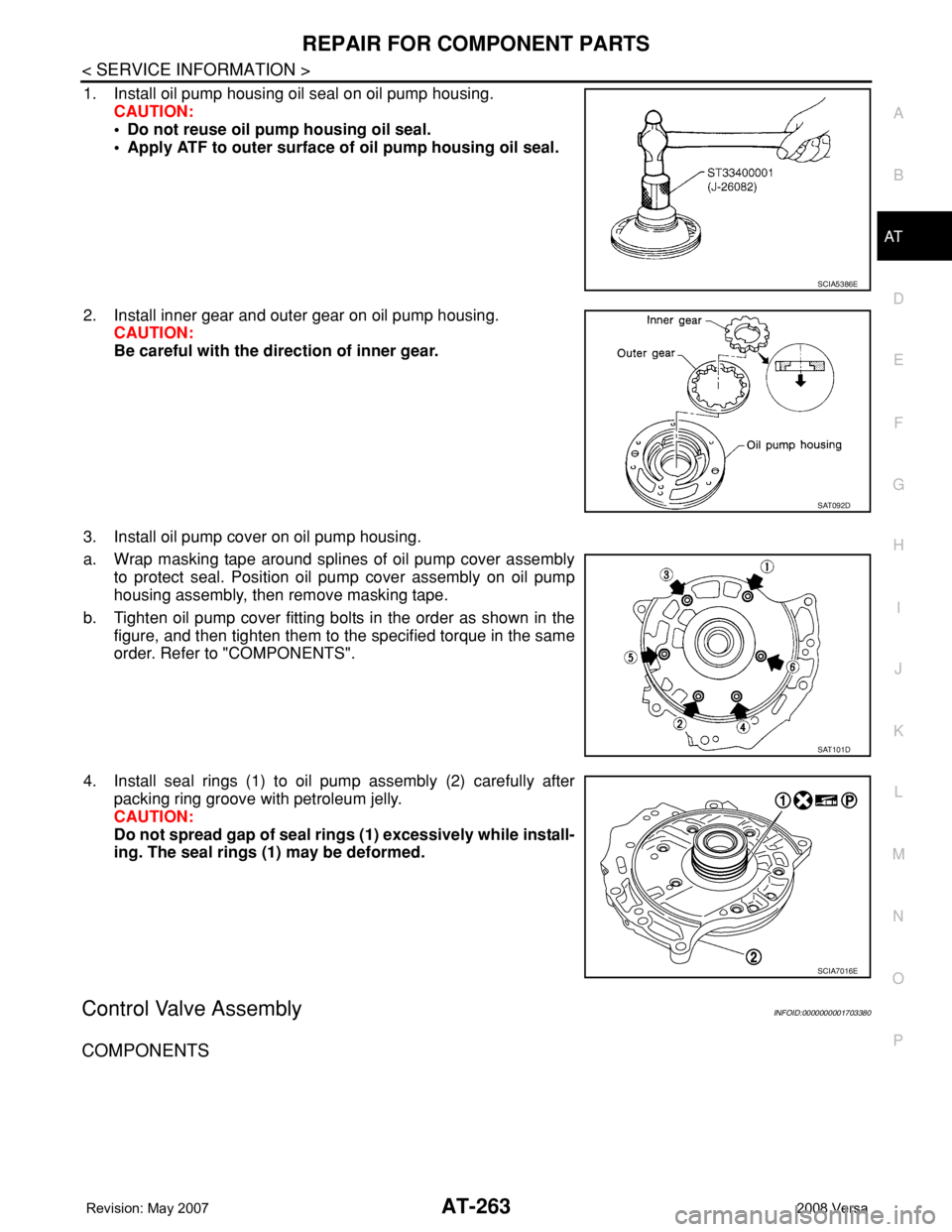

1. Install oil pump housing oil seal on oil pump housing.

CAUTION:

• Do not reuse oil pump housing oil seal.

• Apply ATF to outer surface of oil pump housing oil seal.

2. Install inner gear and outer gear on oil pump housing.

CAUTION:

Be careful with the direction of inner gear.

3. Install oil pump cover on oil pump housing.

a. Wrap masking tape around splines of oil pump cover assembly

to protect seal. Position oil pump cover assembly on oil pump

housing assembly, then remove masking tape.

b. Tighten oil pump cover fitting bolts in the order as shown in the

figure, and then tighten them to the specified torque in the same

order. Refer to "COMPONENTS".

4. Install seal rings (1) to oil pump assembly (2) carefully after

packing ring groove with petroleum jelly.

CAUTION:

Do not spread gap of seal rings (1) excessively while install-

ing. The seal rings (1) may be deformed.

Control Valve AssemblyINFOID:0000000001703380

COMPONENTS

SCIA5386E

SAT092D

SAT101D

SCIA7016E

Page 276 of 2771

AT-264

< SERVICE INFORMATION >

REPAIR FOR COMPONENT PARTS

DISASSEMBLY

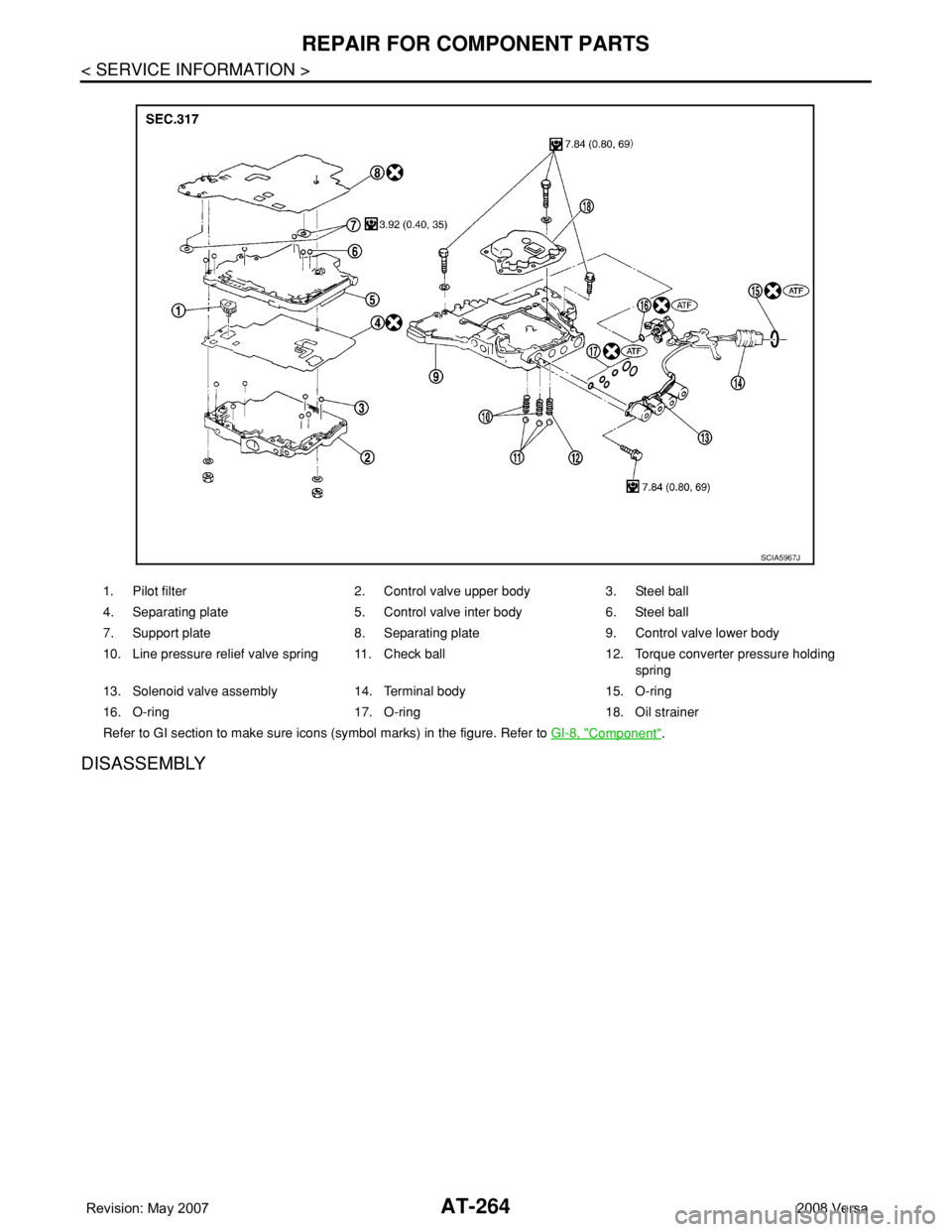

1. Pilot filter 2. Control valve upper body 3. Steel ball

4. Separating plate 5. Control valve inter body 6. Steel ball

7. Support plate 8. Separating plate 9. Control valve lower body

10. Line pressure relief valve spring 11. Check ball 12. Torque converter pressure holding

spring

13. Solenoid valve assembly 14. Terminal body 15. O-ring

16. O-ring 17. O-ring 18. Oil strainer

Refer to GI section to make sure icons (symbol marks) in the figure. Refer to GI-8, "

Component".

SCIA5967J

Page 277 of 2771

REPAIR FOR COMPONENT PARTS

AT-265

< SERVICE INFORMATION >

D

E

F

G

H

I

J

K

L

MA

B

AT

N

O

P

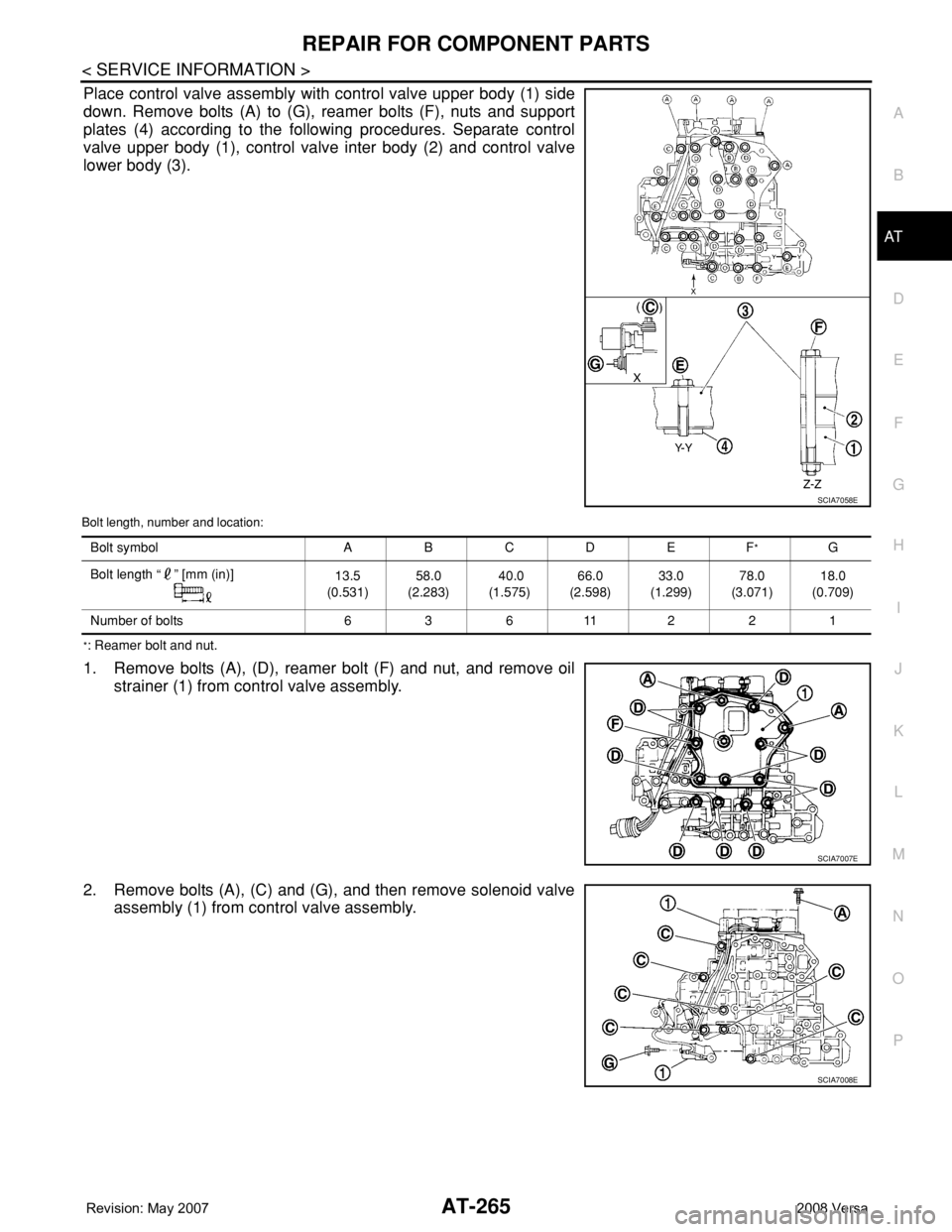

Place control valve assembly with control valve upper body (1) side

down. Remove bolts (A) to (G), reamer bolts (F), nuts and support

plates (4) according to the following procedures. Separate control

valve upper body (1), control valve inter body (2) and control valve

lower body (3).

Bolt length, number and location:

*: Reamer bolt and nut.

1. Remove bolts (A), (D), reamer bolt (F) and nut, and remove oil

strainer (1) from control valve assembly.

2. Remove bolts (A), (C) and (G), and then remove solenoid valve

assembly (1) from control valve assembly.

SCIA7058E

Bolt symbol A B C D E F*G

Bolt length “ ” [mm (in)]

13.5

(0.531)58.0

(2.283) 40.0

(1.575)66.0

(2.598)33.0

(1.299)78.0

(3.071)18.0

(0.709)

Number of bolts 6 3 6 11 2 2 1

SCIA7007E

SCIA7008E

Page 280 of 2771

AT-268

< SERVICE INFORMATION >

REPAIR FOR COMPONENT PARTS

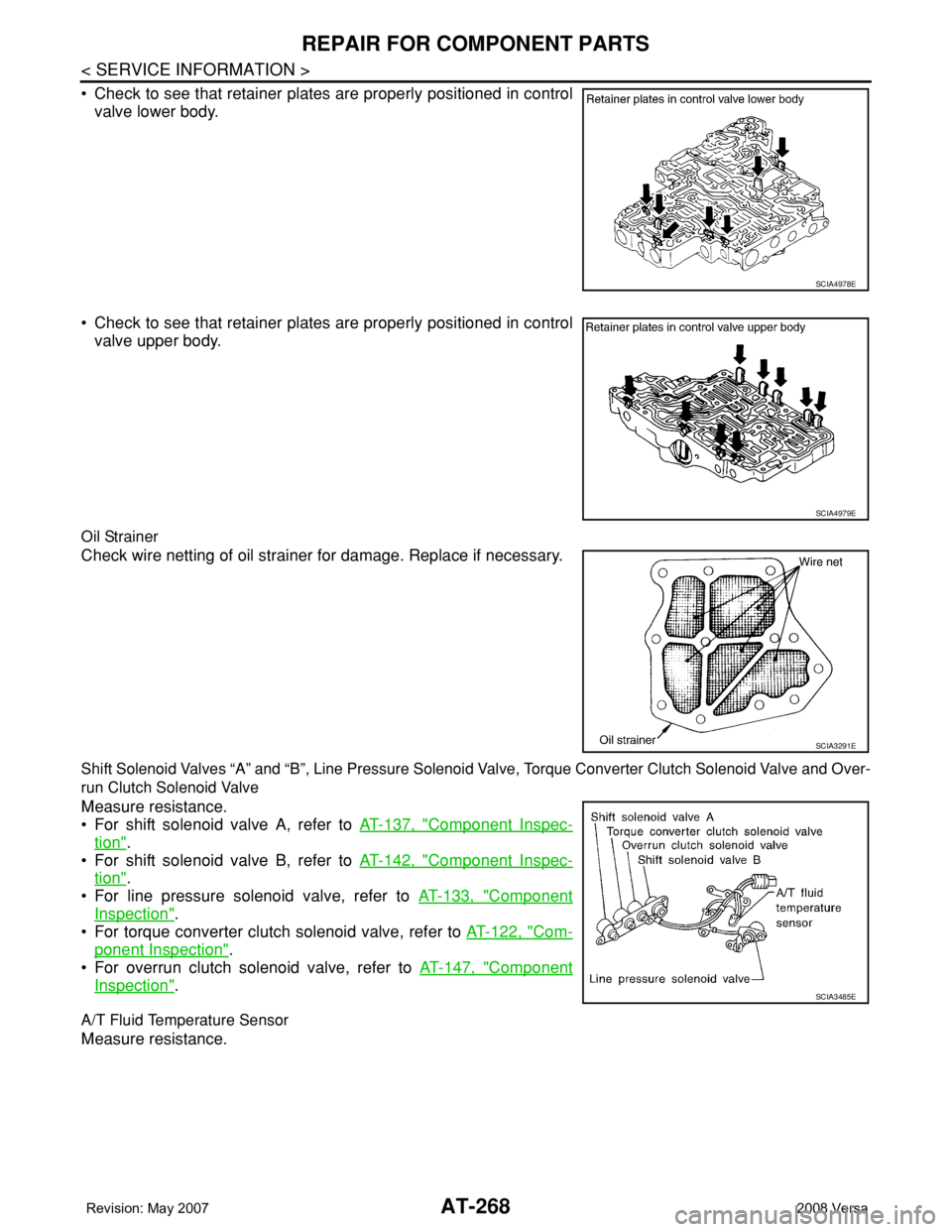

• Check to see that retainer plates are properly positioned in control

valve lower body.

• Check to see that retainer plates are properly positioned in control

valve upper body.

Oil Strainer

Check wire netting of oil strainer for damage. Replace if necessary.

Shift Solenoid Valves “A” and “B”, Line Pressure Solenoid Valve, Torque Converter Clutch Solenoid Valve and Over-

run Clutch Solenoid Valve

Measure resistance.

• For shift solenoid valve A, refer to AT-137, "

Component Inspec-

tion".

• For shift solenoid valve B, refer to AT-142, "

Component Inspec-

tion".

• For line pressure solenoid valve, refer to AT-133, "

Component

Inspection".

• For torque converter clutch solenoid valve, refer to AT-122, "

Com-

ponent Inspection".

• For overrun clutch solenoid valve, refer to AT-147, "

Component

Inspection".

A/T Fluid Temperature Sensor

Measure resistance.

SCIA4978E

SCIA4979E

SCIA3291E

SCIA3485E

Page 281 of 2771

REPAIR FOR COMPONENT PARTS

AT-269

< SERVICE INFORMATION >

D

E

F

G

H

I

J

K

L

MA

B

AT

N

O

P

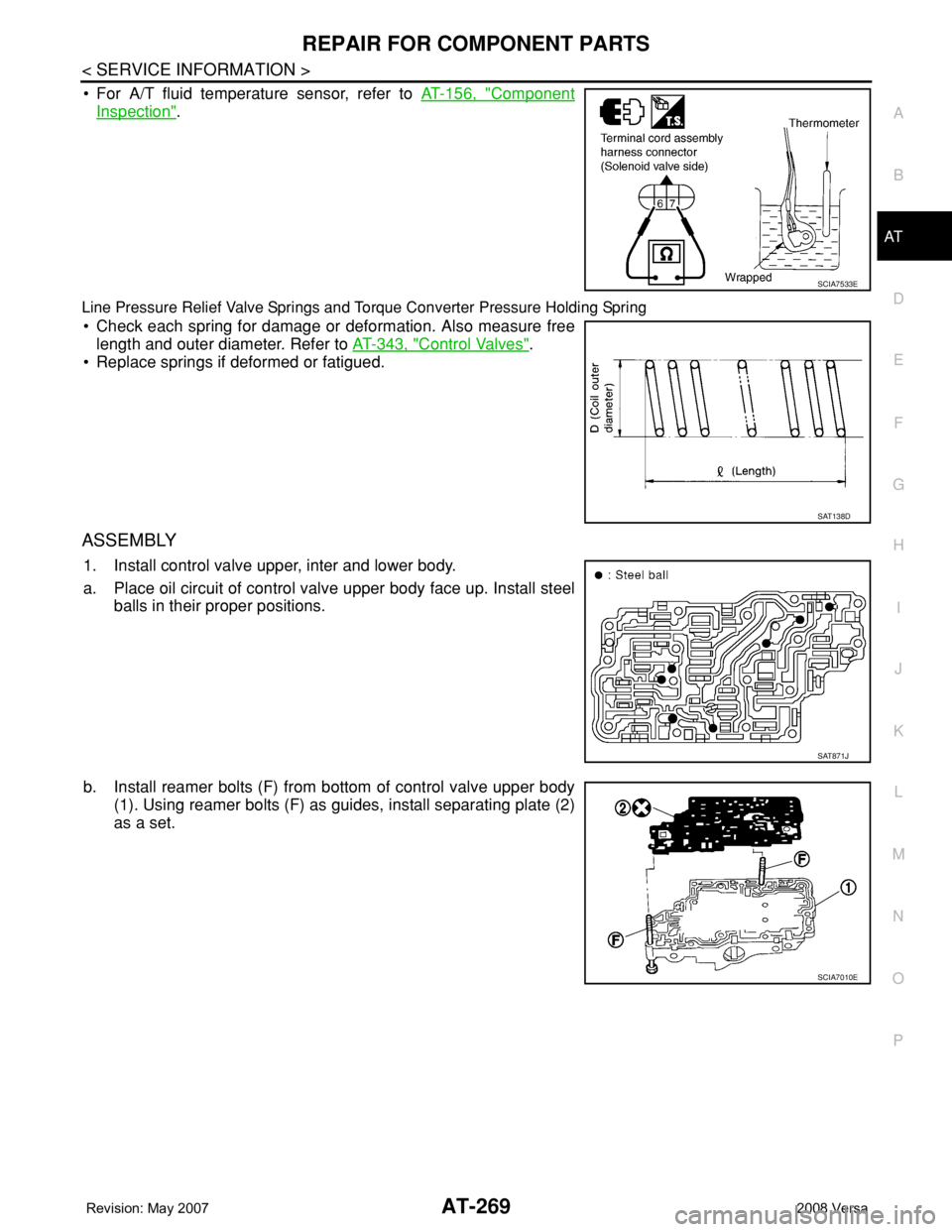

• For A/T fluid temperature sensor, refer to AT-156, "Component

Inspection".

Line Pressure Relief Valve Springs and Torque Converter Pressure Holding Spring

• Check each spring for damage or deformation. Also measure free

length and outer diameter. Refer to AT-343, "

Control Valves".

• Replace springs if deformed or fatigued.

ASSEMBLY

1. Install control valve upper, inter and lower body.

a. Place oil circuit of control valve upper body face up. Install steel

balls in their proper positions.

b. Install reamer bolts (F) from bottom of control valve upper body

(1). Using reamer bolts (F) as guides, install separating plate (2)

as a set.

SCIA7533E

SAT138D

SAT871J

SCIA7010E

Page 284 of 2771

AT-272

< SERVICE INFORMATION >

REPAIR FOR COMPONENT PARTS

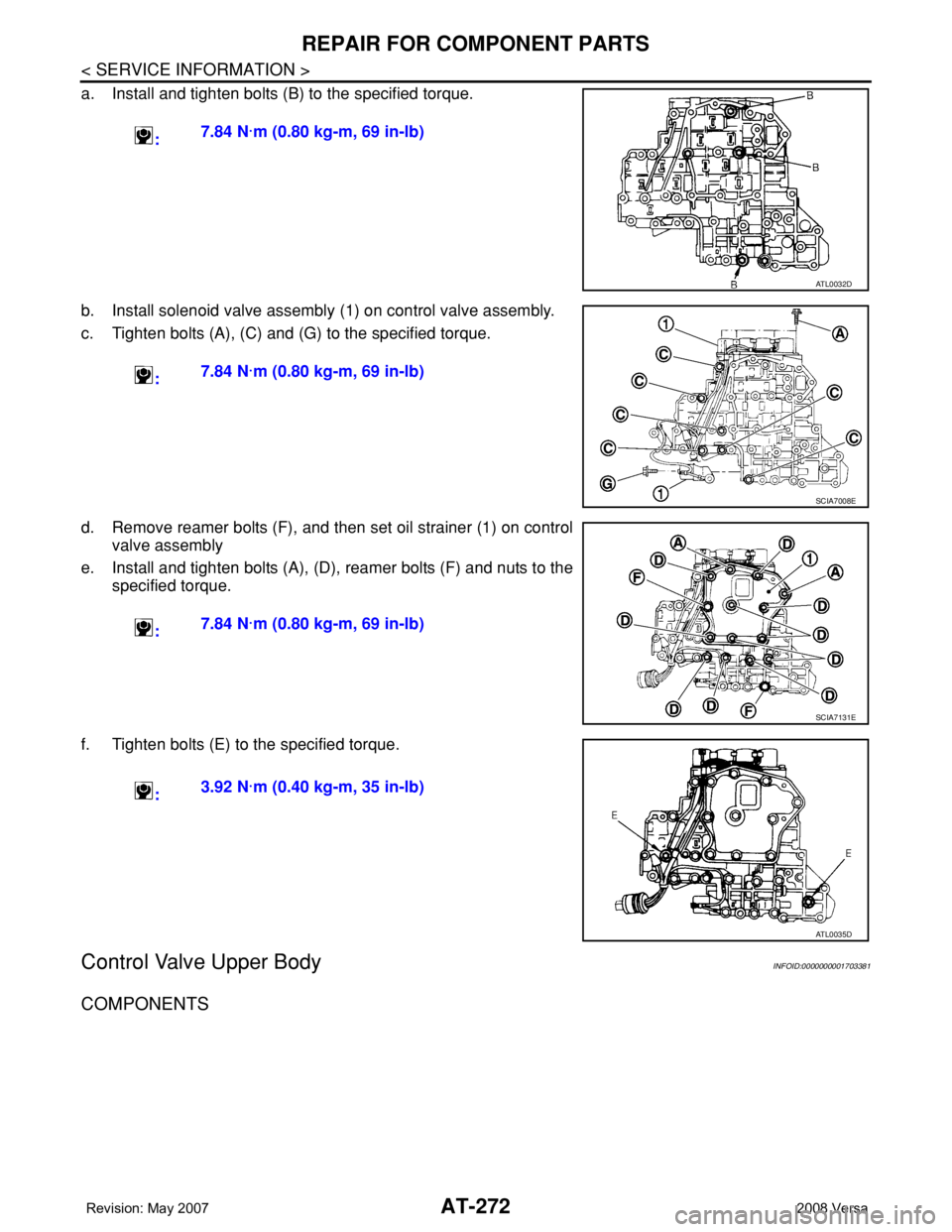

a. Install and tighten bolts (B) to the specified torque.

b. Install solenoid valve assembly (1) on control valve assembly.

c. Tighten bolts (A), (C) and (G) to the specified torque.

d. Remove reamer bolts (F), and then set oil strainer (1) on control

valve assembly

e. Install and tighten bolts (A), (D), reamer bolts (F) and nuts to the

specified torque.

f. Tighten bolts (E) to the specified torque.

Control Valve Upper BodyINFOID:0000000001703381

COMPONENTS

:7.84 N·m (0.80 kg-m, 69 in-lb)

ATL0032D

:7.84 N·m (0.80 kg-m, 69 in-lb)

SCIA7008E

:7.84 N·m (0.80 kg-m, 69 in-lb)

SCIA7131E

:3.92 N·m (0.40 kg-m, 35 in-lb)

ATL0035D

Page 292 of 2771

AT-280

< SERVICE INFORMATION >

REPAIR FOR COMPONENT PARTS

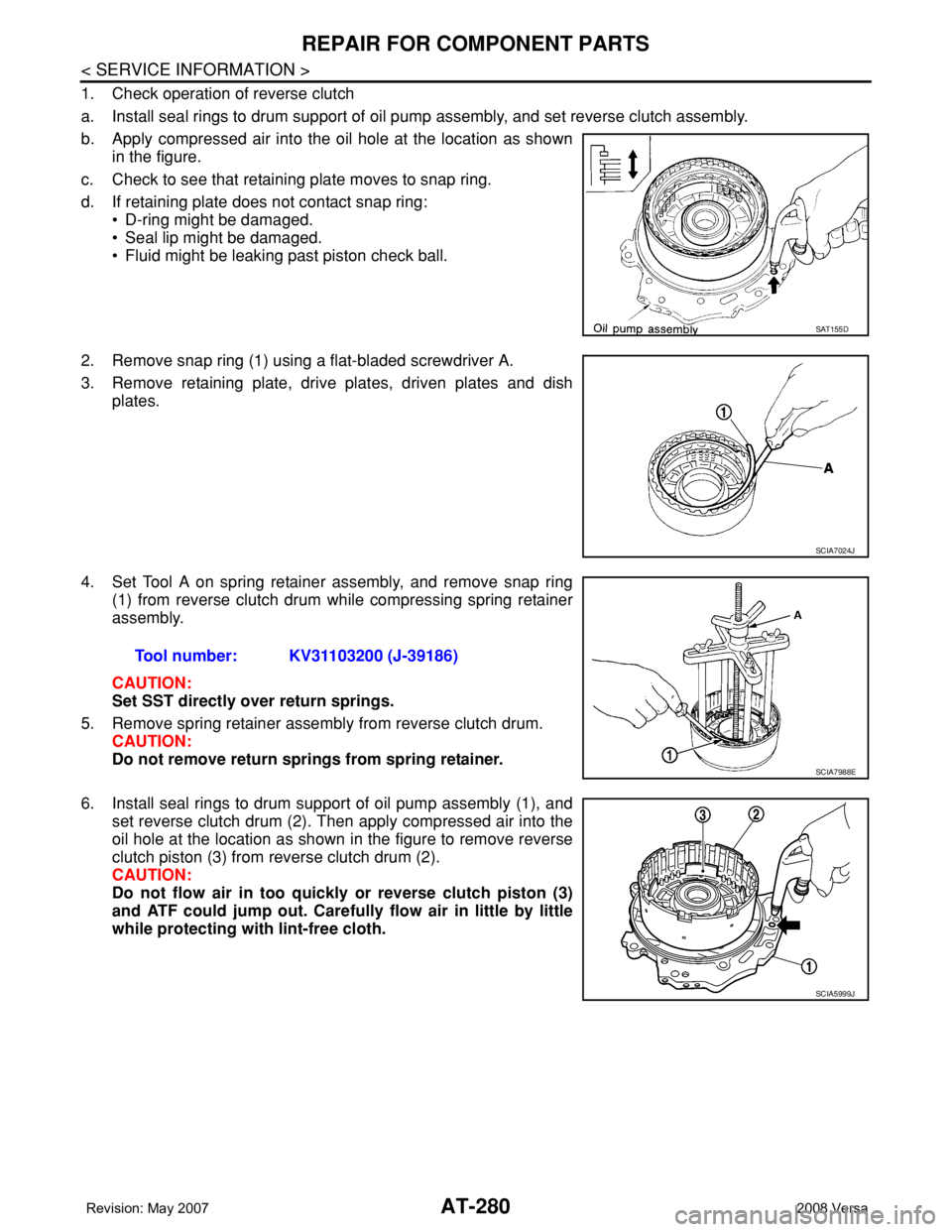

1. Check operation of reverse clutch

a. Install seal rings to drum support of oil pump assembly, and set reverse clutch assembly.

b. Apply compressed air into the oil hole at the location as shown

in the figure.

c. Check to see that retaining plate moves to snap ring.

d. If retaining plate does not contact snap ring:

• D-ring might be damaged.

• Seal lip might be damaged.

• Fluid might be leaking past piston check ball.

2. Remove snap ring (1) using a flat-bladed screwdriver A.

3. Remove retaining plate, drive plates, driven plates and dish

plates.

4. Set Tool A on spring retainer assembly, and remove snap ring

(1) from reverse clutch drum while compressing spring retainer

assembly.

CAUTION:

Set SST directly over return springs.

5. Remove spring retainer assembly from reverse clutch drum.

CAUTION:

Do not remove return springs from spring retainer.

6. Install seal rings to drum support of oil pump assembly (1), and

set reverse clutch drum (2). Then apply compressed air into the

oil hole at the location as shown in the figure to remove reverse

clutch piston (3) from reverse clutch drum (2).

CAUTION:

Do not flow air in too quickly or reverse clutch piston (3)

and ATF could jump out. Carefully flow air in little by little

while protecting with lint-free cloth.

SAT155D

SCIA7024J

Tool number: KV31103200 (J-39186)

SCIA7988E

SCIA5999J

Page 294 of 2771

AT-282

< SERVICE INFORMATION >

REPAIR FOR COMPONENT PARTS

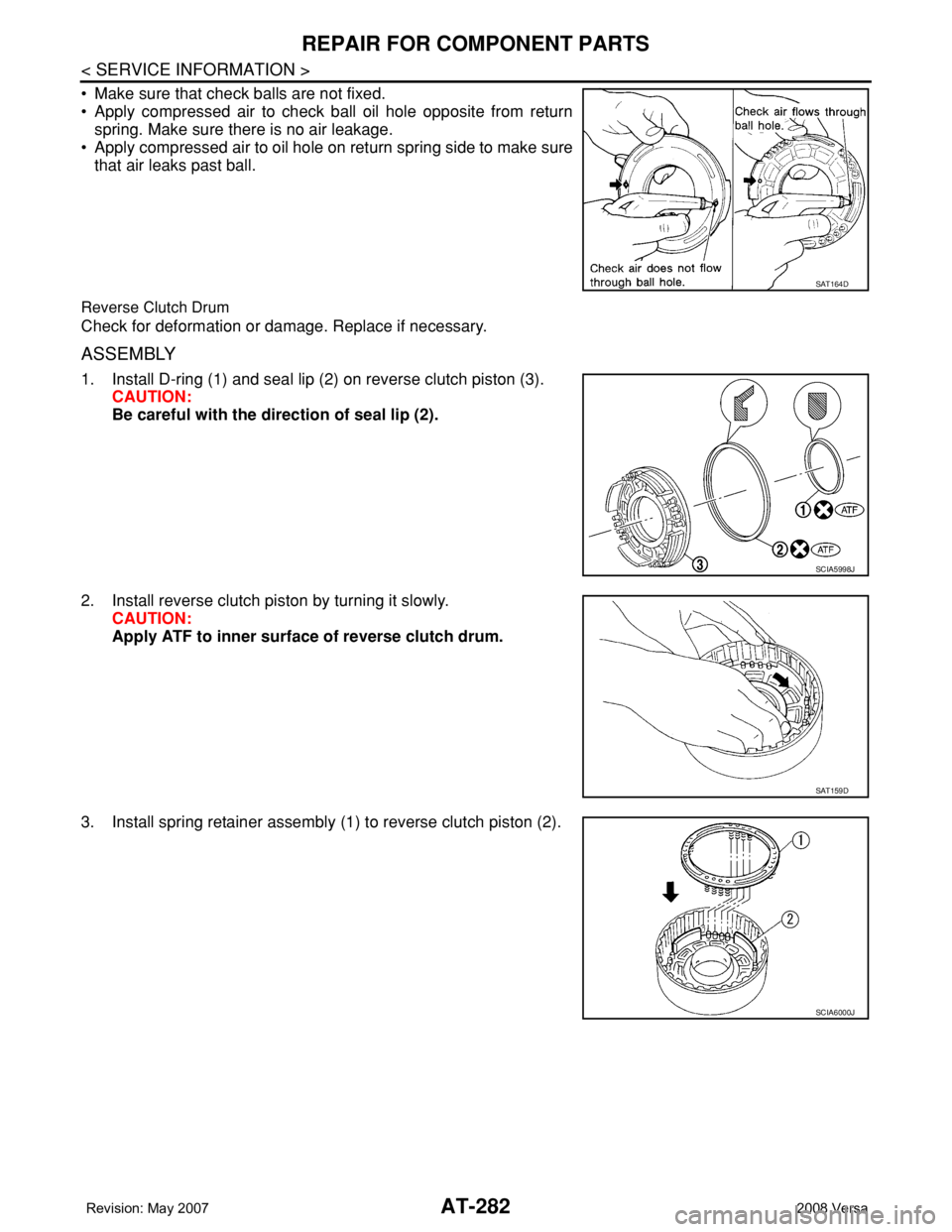

• Make sure that check balls are not fixed.

• Apply compressed air to check ball oil hole opposite from return

spring. Make sure there is no air leakage.

• Apply compressed air to oil hole on return spring side to make sure

that air leaks past ball.

Reverse Clutch Drum

Check for deformation or damage. Replace if necessary.

ASSEMBLY

1. Install D-ring (1) and seal lip (2) on reverse clutch piston (3).

CAUTION:

Be careful with the direction of seal lip (2).

2. Install reverse clutch piston by turning it slowly.

CAUTION:

Apply ATF to inner surface of reverse clutch drum.

3. Install spring retainer assembly (1) to reverse clutch piston (2).

SAT164D

SCIA5998J

SAT159D

SCIA6000J