NISSAN TIIDA 2008 Service Repair Manual

Manufacturer: NISSAN, Model Year: 2008, Model line: TIIDA, Model: NISSAN TIIDA 2008Pages: 2771, PDF Size: 60.61 MB

Page 901 of 2771

CVT-62

< SERVICE INFORMATION >

DTC P0615 START SIGNAL CIRCUIT

Diagnosis Procedure

INFOID:0000000001703482

1.CHECK STARTER RELAY SIGNAL

With CONSULT-III

1. Turn ignition switch ON. (Do not start engine.)

2. Select “SELECTION FROM MENU” in “DATA MONITOR” mode for “TRANSMISSION” with CONSULT-III

and check monitor “STRTR RLY OUT”, “STRTR RLY MON”(PNP relay) ON/OFF.

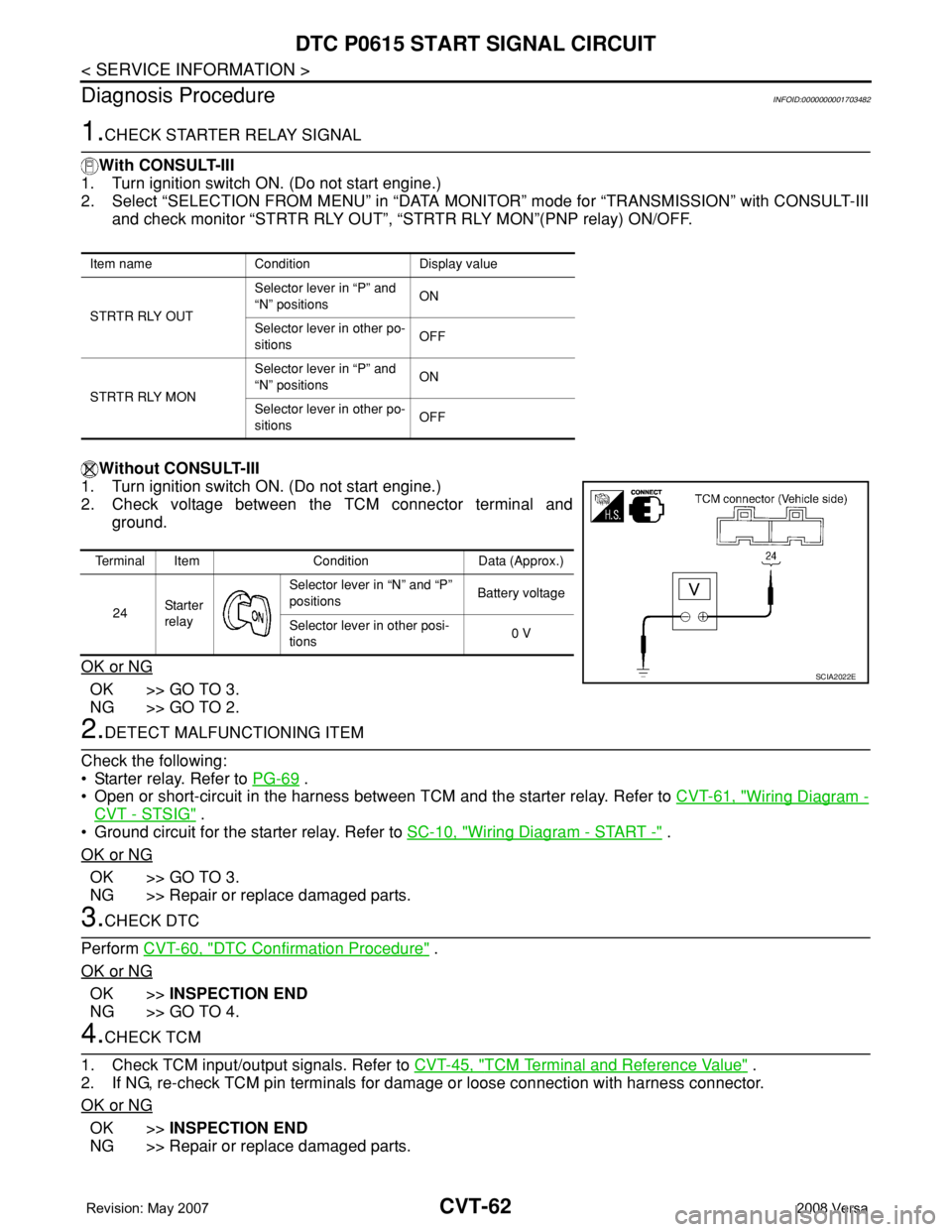

Without CONSULT-III

1. Turn ignition switch ON. (Do not start engine.)

2. Check voltage between the TCM connector terminal and

ground.

OK or NG

OK >> GO TO 3.

NG >> GO TO 2.

2.DETECT MALFUNCTIONING ITEM

Check the following:

• Starter relay. Refer to PG-69

.

• Open or short-circuit in the harness between TCM and the starter relay. Refer to CVT-61, "

Wiring Diagram -

CVT - STSIG" .

• Ground circuit for the starter relay. Refer to SC-10, "

Wiring Diagram - START -" .

OK or NG

OK >> GO TO 3.

NG >> Repair or replace damaged parts.

3.CHECK DTC

Perform CVT-60, "

DTC Confirmation Procedure" .

OK or NG

OK >>INSPECTION END

NG >> GO TO 4.

4.CHECK TCM

1. Check TCM input/output signals. Refer to CVT-45, "

TCM Terminal and Reference Value" .

2. If NG, re-check TCM pin terminals for damage or loose connection with harness connector.

OK or NG

OK >>INSPECTION END

NG >> Repair or replace damaged parts.

Item name Condition Display value

STRTR RLY OUTSelector lever in “P” and

“N” positionsON

Selector lever in other po-

sitionsOFF

STRTR RLY MONSelector lever in “P” and

“N” positionsON

Selector lever in other po-

sitionsOFF

Terminal Item Condition Data (Approx.)

24Sta r te r

relaySelector lever in “N” and “P”

positionsBattery voltage

Selector lever in other posi-

tions0 V

SCIA2022E

Page 902 of 2771

DTC P0703 STOP LAMP SWITCH CIRCUIT

CVT-63

< SERVICE INFORMATION >

D

E

F

G

H

I

J

K

L

MA

B

CVT

N

O

P

DTC P0703 STOP LAMP SWITCH CIRCUIT

DescriptionINFOID:0000000001703483

ON, OFF status of the stop lamp switch is sent via the CAN communication from the combination meter to

TCM using the signal.

CONSULT-III Reference Value in Data Monitor ModeINFOID:0000000001703484

On Board Diagnosis LogicINFOID:0000000001703485

• This is not an OBD-II self-diagnostic item.

• Diagnostic trouble code “P0703 BRAKE SW/CIRC” with CONSULT-III is detected when the stop lamp switch

does not switch to ON and OFF.

- The stop lamp switch does not switch to ON, OFF.

Possible CauseINFOID:0000000001703486

• Harness or connectors

(Stop lamp switch, and combination meter circuit are open or shorted.)

(CAN communication line is open or shorted.)

• Stop lamp switch

DTC Confirmation ProcedureINFOID:0000000001703487

CAUTION:

Always drive vehicle at a safe speed.

NOTE:

If “DTC Confirmation Procedure” has been previously performed, always turn ignition switch OFF and

wait at least 10 seconds before performing the next test.

After the repair, touch “ERASE” on “SELF-DIAG RESULTS” and then perform the following procedure to con-

firm the malfunction is eliminated.

WITH CONSULT-III

1. Turn ignition switch ON. (Do not start engine.)

2. Select “DATA MONITOR” mode for “TRANSMISSION” with CONSULT-III.

3. Start engine.

4. Start vehicle for at least 3 consecutive seconds.

5. If DTC is detected, go to CVT-63, "

Diagnosis Procedure".

Diagnosis ProcedureINFOID:0000000001703488

1.CHECK CAN COMMUNICATION LINE

Perform the self-diagnosis check. Refer to CVT-47, "

CONSULT-III Function (TRANSMISSION)".

Is any malfunction of the

“U1000 CAN COMM CIRCUIT” indicated?

YES >> Check CAN communication line. Refer to CVT-56.

NO >> GO TO 2.

2.CHECK STOP LAMP SWITCH CIRCUIT

With CONSULT-III

1. Turn ignition switch ON. (Do not start engine.)

2. Select “ECU INPUT SIGNALS” in “DATA MONITOR” mode for “TRANSMISSION” with CONSULT-III.

3. Read out ON/OFF switching action of the “BRAKE SW”.

Item name Condition Display value

BRAKE SWDepressed brake pedal ON

Released brake pedal OFF

Page 903 of 2771

CVT-64

< SERVICE INFORMATION >

DTC P0703 STOP LAMP SWITCH CIRCUIT

OK or NG

OK >>INSPECTION END

NG >> GO TO 3.

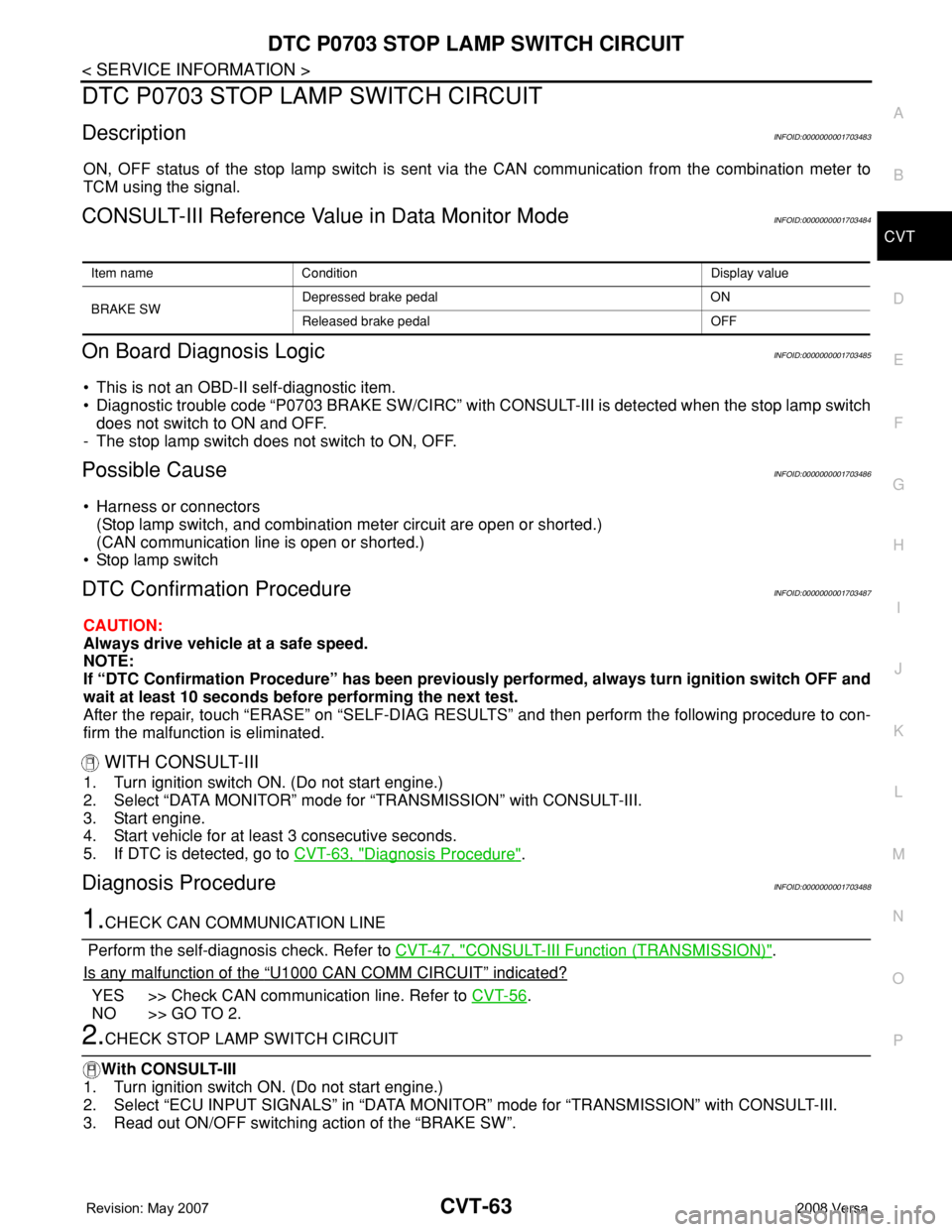

3.CHECK STOP LAMP SWITCH

Check continuity between stop lamp switch harness connector E13

terminals 1 and 2. Refer to CVT-149, "

Wiring Diagram - CVT - NON-

DTC".

Check stop lamp switch after adjusting brake pedal — refer to

BR-5

.

OK or NG

OK >> Check the following. If NG, repair or replace damaged parts.

• Harness for short or open between battery and stop lamp switch.

• Harness for short or open between stop lamp switch and combination meter.

NG >> Repair or replace the stop lamp switch.

Item name Condition Display value

BRAKE SWDepressed brake pedal ON

Released brake pedal OFF

Condition Continuity

When brake pedal is depressed Yes

When brake pedal is released No

SCIA7982E

Page 904 of 2771

DTC P0705 PARK/NEUTRAL POSITION SWITCH

CVT-65

< SERVICE INFORMATION >

D

E

F

G

H

I

J

K

L

MA

B

CVT

N

O

P

DTC P0705 PARK/NEUTRAL POSITION SWITCH

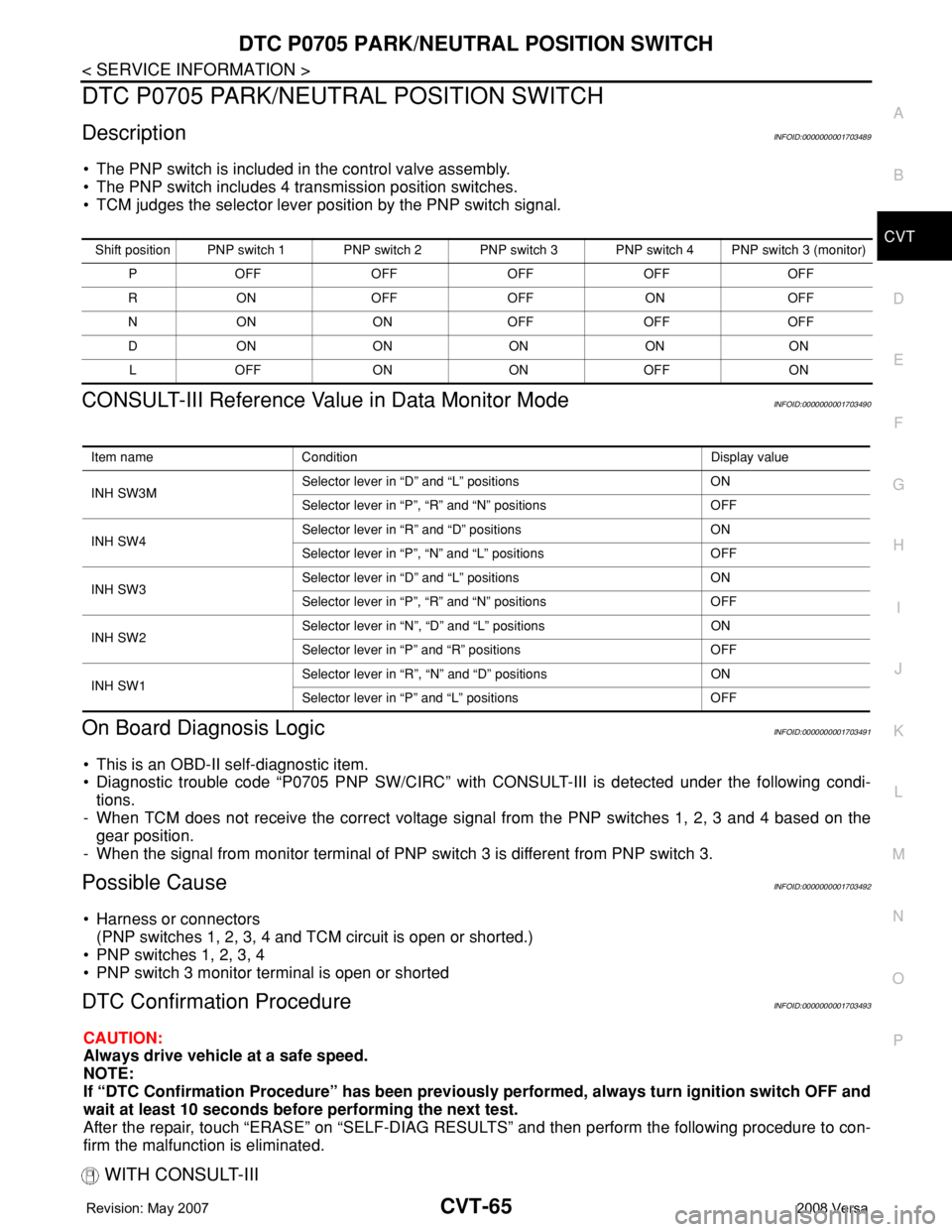

DescriptionINFOID:0000000001703489

• The PNP switch is included in the control valve assembly.

• The PNP switch includes 4 transmission position switches.

• TCM judges the selector lever position by the PNP switch signal.

CONSULT-III Reference Value in Data Monitor ModeINFOID:0000000001703490

On Board Diagnosis LogicINFOID:0000000001703491

• This is an OBD-II self-diagnostic item.

• Diagnostic trouble code “P0705 PNP SW/CIRC” with CONSULT-III is detected under the following condi-

tions.

- When TCM does not receive the correct voltage signal from the PNP switches 1, 2, 3 and 4 based on the

gear position.

- When the signal from monitor terminal of PNP switch 3 is different from PNP switch 3.

Possible CauseINFOID:0000000001703492

• Harness or connectors

(PNP switches 1, 2, 3, 4 and TCM circuit is open or shorted.)

• PNP switches 1, 2, 3, 4

• PNP switch 3 monitor terminal is open or shorted

DTC Confirmation ProcedureINFOID:0000000001703493

CAUTION:

Always drive vehicle at a safe speed.

NOTE:

If “DTC Confirmation Procedure” has been previously performed, always turn ignition switch OFF and

wait at least 10 seconds before performing the next test.

After the repair, touch “ERASE” on “SELF-DIAG RESULTS” and then perform the following procedure to con-

firm the malfunction is eliminated.

WITH CONSULT-III

Shift position PNP switch 1 PNP switch 2 PNP switch 3 PNP switch 4 PNP switch 3 (monitor)

P OFF OFF OFF OFF OFF

R ON OFF OFF ON OFF

N ON ON OFF OFF OFF

DONONONON ON

L OFF ON ON OFF ON

Item name Condition Display value

INH SW3MSelector lever in “D” and “L” positions ON

Selector lever in “P”, “R” and “N” positions OFF

INH SW4Selector lever in “R” and “D” positions ON

Selector lever in “P”, “N” and “L” positions OFF

INH SW3Selector lever in “D” and “L” positions ON

Selector lever in “P”, “R” and “N” positions OFF

INH SW2Selector lever in “N”, “D” and “L” positions ON

Selector lever in “P” and “R” positions OFF

INH SW1Selector lever in “R”, “N” and “D” positions ON

Selector lever in “P” and “L” positions OFF

Page 905 of 2771

CVT-66

< SERVICE INFORMATION >

DTC P0705 PARK/NEUTRAL POSITION SWITCH

1. Turn ignition switch ON. (Do not start engine.)

2. Select “DATA MONITOR” mode for “TRANSMISSION” with CONSULT-III.

3. Start engine.

4. Drive vehicle and maintain the following conditions for at least 2 consecutive seconds.

VEHICLE SPEED: More than 10 km/h (6 MPH)

ENG SPEED: More than 450 rpm

ACC PEDAL OPEN: More than 1.0/8

5. If DTC is detected, go to CVT-68, "

Diagnosis Procedure" .

WITH GST

Follow the procedure “WITH CONSULT-III”.

Page 906 of 2771

DTC P0705 PARK/NEUTRAL POSITION SWITCH

CVT-67

< SERVICE INFORMATION >

D

E

F

G

H

I

J

K

L

MA

B

CVT

N

O

P

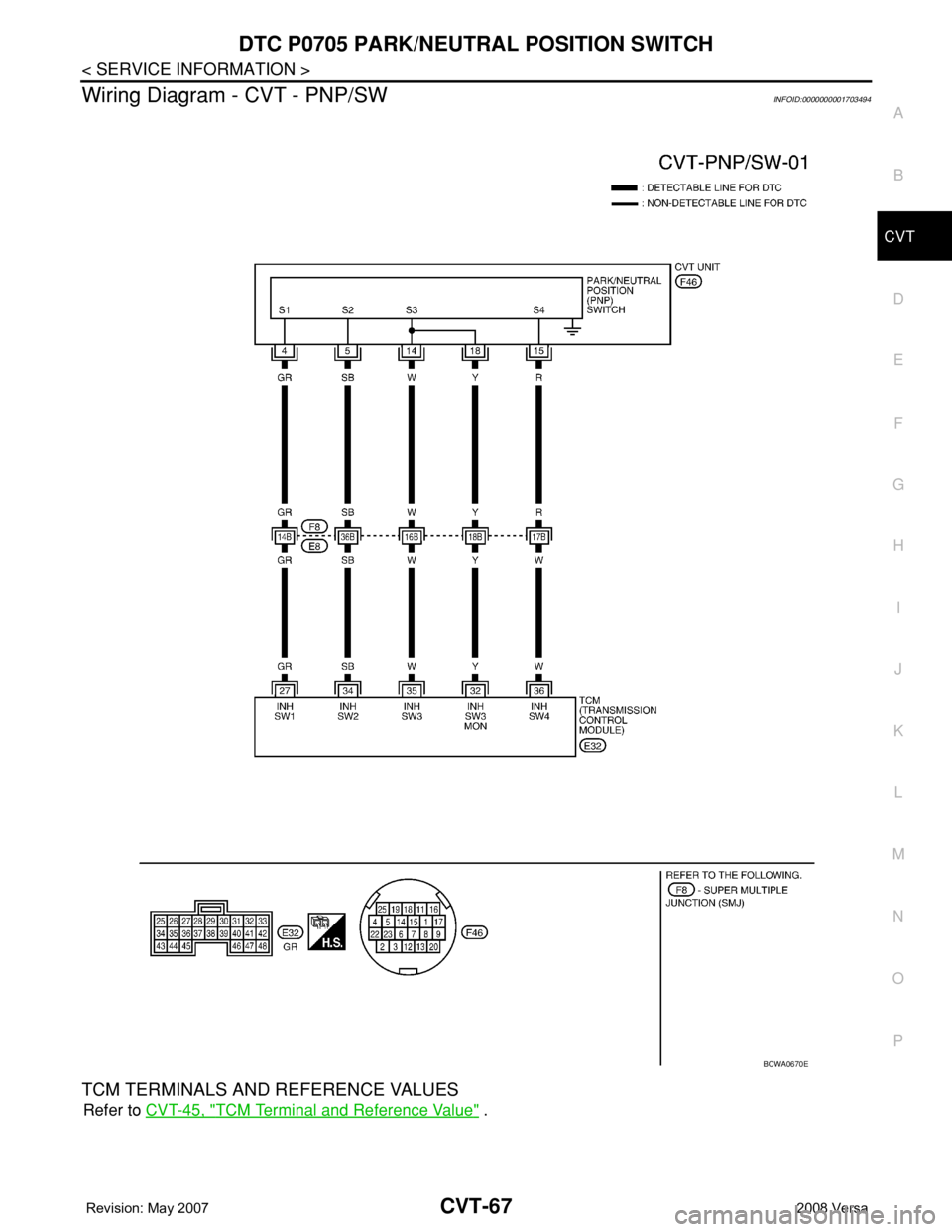

Wiring Diagram - CVT - PNP/SWINFOID:0000000001703494

TCM TERMINALS AND REFERENCE VALUES

Refer to CVT-45, "TCM Terminal and Reference Value" .

BCWA0670E

Page 907 of 2771

CVT-68

< SERVICE INFORMATION >

DTC P0705 PARK/NEUTRAL POSITION SWITCH

Diagnosis Procedure

INFOID:0000000001703495

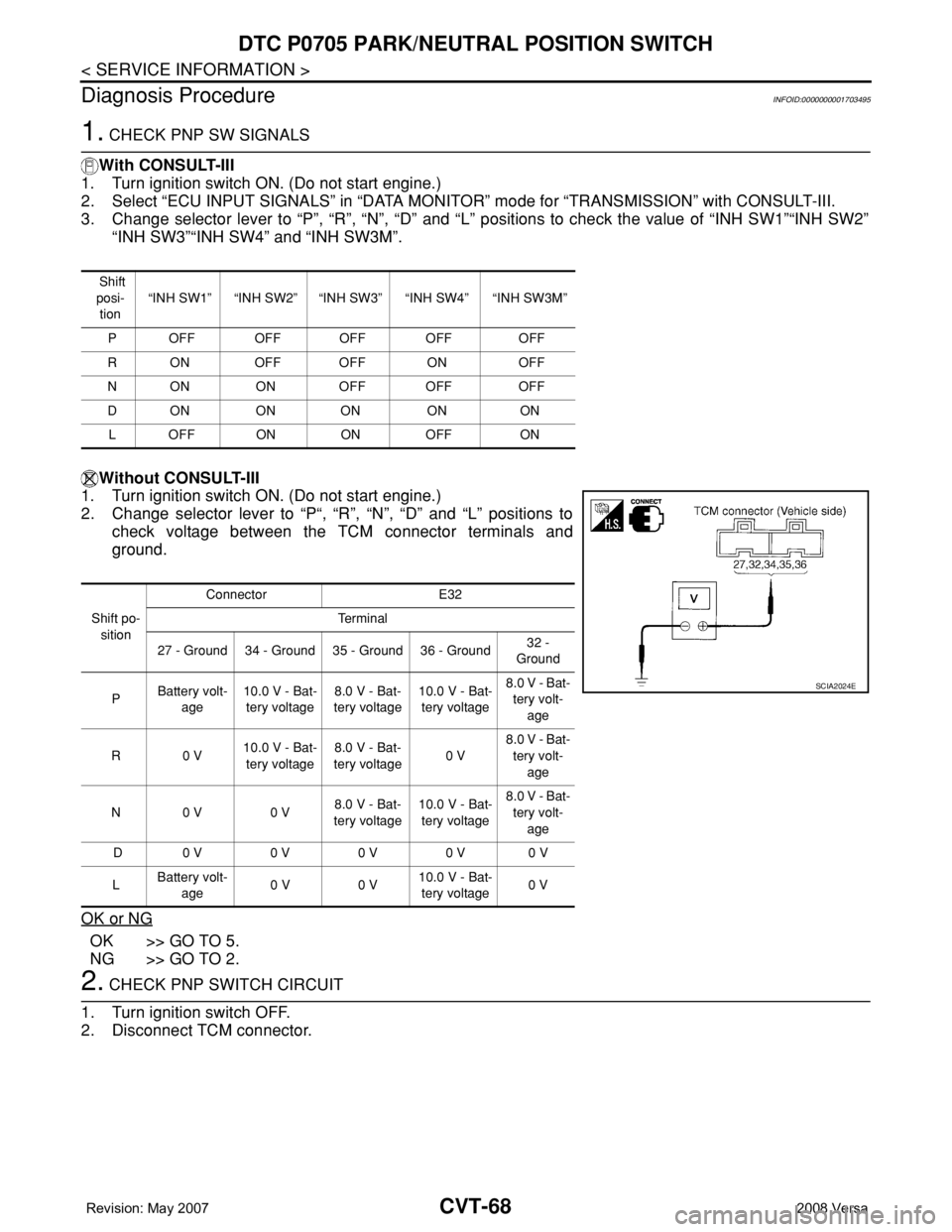

1. CHECK PNP SW SIGNALS

With CONSULT-III

1. Turn ignition switch ON. (Do not start engine.)

2. Select “ECU INPUT SIGNALS” in “DATA MONITOR” mode for “TRANSMISSION” with CONSULT-III.

3. Change selector lever to “P”, “R”, “N”, “D” and “L” positions to check the value of “INH SW1”“INH SW2”

“INH SW3”“INH SW4” and “INH SW3M”.

Without CONSULT-III

1. Turn ignition switch ON. (Do not start engine.)

2. Change selector lever to “P“, “R”, “N”, “D” and “L” positions to

check voltage between the TCM connector terminals and

ground.

OK or NG

OK >> GO TO 5.

NG >> GO TO 2.

2. CHECK PNP SWITCH CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect TCM connector.

Shift

posi-

tion“INH SW1” “INH SW2” “INH SW3” “INH SW4” “INH SW3M”

P OFF OFF OFF OFF OFF

R ON OFF OFF ON OFF

N ON ON OFF OFF OFF

DON ON ON ON ON

L OFF ON ON OFF ON

Shift po-

sitionConnector E32

Te r m i n a l

27 - Ground 34 - Ground 35 - Ground 36 - Ground32 -

Ground

PBattery volt-

age10.0 V - Bat-

tery voltage8.0 V - Bat-

tery voltage10.0 V - Bat-

tery voltage8.0 V - Bat-

tery volt-

age

R0 V10.0 V - Bat-

tery voltage8.0 V - Bat-

tery voltage0 V8.0 V - Bat-

tery volt-

age

N0 V 0 V8.0 V - Bat-

tery voltage10.0 V - Bat-

tery voltage8.0 V - Bat-

tery volt-

age

D 0 V 0 V 0 V 0 V 0 V

LBattery volt-

age0 V 0 V10.0 V - Bat-

tery voltage0 V

SCIA2024E

Page 908 of 2771

DTC P0705 PARK/NEUTRAL POSITION SWITCH

CVT-69

< SERVICE INFORMATION >

D

E

F

G

H

I

J

K

L

MA

B

CVT

N

O

P

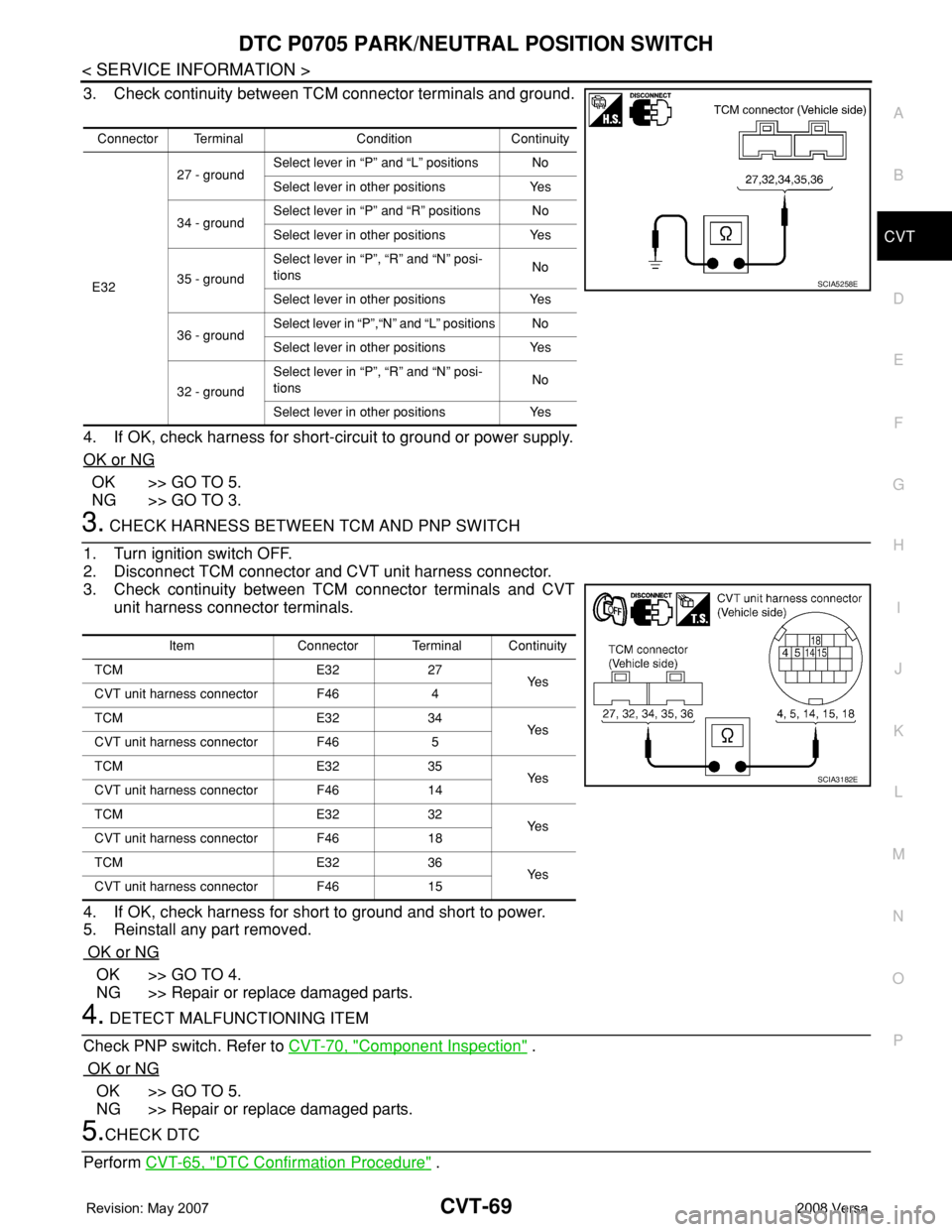

3. Check continuity between TCM connector terminals and ground.

4. If OK, check harness for short-circuit to ground or power supply.

OK or NG

OK >> GO TO 5.

NG >> GO TO 3.

3. CHECK HARNESS BETWEEN TCM AND PNP SWITCH

1. Turn ignition switch OFF.

2. Disconnect TCM connector and CVT unit harness connector.

3. Check continuity between TCM connector terminals and CVT

unit harness connector terminals.

4. If OK, check harness for short to ground and short to power.

5. Reinstall any part removed.

OK or NG

OK >> GO TO 4.

NG >> Repair or replace damaged parts.

4. DETECT MALFUNCTIONING ITEM

Check PNP switch. Refer to CVT-70, "

Component Inspection" .

OK or NG

OK >> GO TO 5.

NG >> Repair or replace damaged parts.

5.CHECK DTC

Perform CVT-65, "

DTC Confirmation Procedure" .

Connector Terminal Condition Continuity

E3227 - groundSelect lever in “P” and “L” positions No

Select lever in other positions Yes

34 - groundSelect lever in “P” and “R” positions No

Select lever in other positions Yes

35 - groundSelect lever in “P”, “R” and “N” posi-

tionsNo

Select lever in other positions Yes

36 - groundSelect lever in “P”,“N” and “L” positions No

Select lever in other positions Yes

32 - groundSelect lever in “P”, “R” and “N” posi-

tionsNo

Select lever in other positions Yes

SCIA5258E

Item Connector Terminal Continuity

TCM E32 27

Ye s

CVT unit harness connector F46 4

TCM E32 34

Ye s

CVT unit harness connector F46 5

TCM E32 35

Ye s

CVT unit harness connector F46 14

TCM E32 32

Ye s

CVT unit harness connector F46 18

TCM E32 36

Ye s

CVT unit harness connector F46 15

SCIA3182E

Page 909 of 2771

CVT-70

< SERVICE INFORMATION >

DTC P0705 PARK/NEUTRAL POSITION SWITCH

OK or NG

OK >>INSPECTION END

NG >> GO TO 6.

6.CHECK TCM

1. Check TCM input/output signals. Refer to CVT-45, "

TCM Terminal and Reference Value" .

2. If NG, re-check TCM pin terminals for damage or loose connection with harness connector.

OK or NG

OK >>INSPECTION END

NG >> 1. Repair or replace damaged parts.

2. Replace the transaxle assembly. Refer to CVT-178, "

Removal and Installation" .

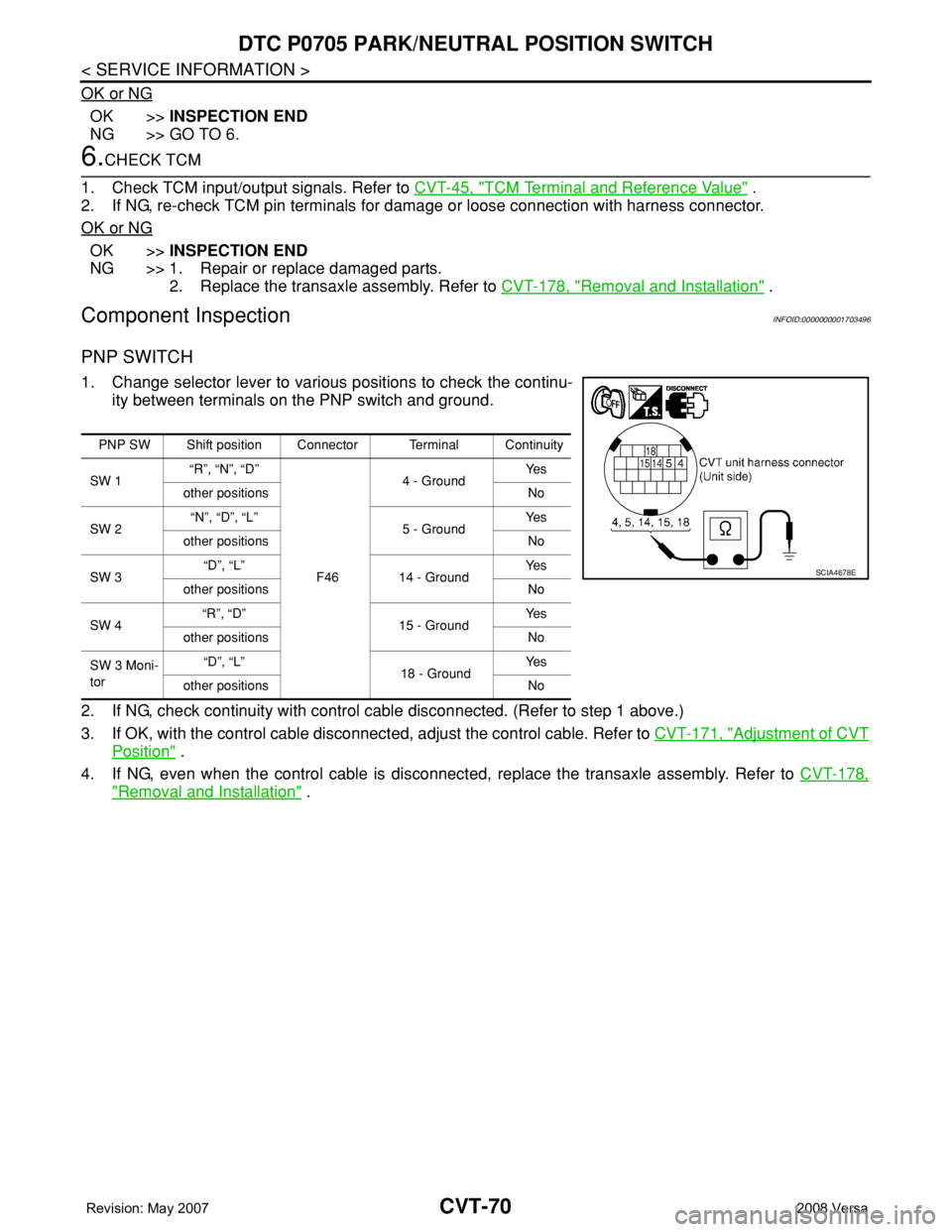

Component InspectionINFOID:0000000001703496

PNP SWITCH

1. Change selector lever to various positions to check the continu-

ity between terminals on the PNP switch and ground.

2. If NG, check continuity with control cable disconnected. (Refer to step 1 above.)

3. If OK, with the control cable disconnected, adjust the control cable. Refer to CVT-171, "

Adjustment of CVT

Position" .

4. If NG, even when the control cable is disconnected, replace the transaxle assembly. Refer to CVT-178,

"Removal and Installation" .

PNP SW Shift position Connector Terminal Continuity

SW 1“R”, “N”, “D”

F464 - Ground Ye s

other positions No

SW 2“N”, “D”, “L”

5 - Ground Ye s

other positions No

SW 3“D”, “L”

14 - Ground Ye s

other positions No

SW 4“R”, “D”

15 - Ground Ye s

other positions No

SW 3 Moni-

tor“D”, “L”

18 - Ground Ye s

other positions No

SCIA4678E

Page 910 of 2771

DTC P0710 CVT FLUID TEMPERATURE SENSOR CIRCUIT

CVT-71

< SERVICE INFORMATION >

D

E

F

G

H

I

J

K

L

MA

B

CVT

N

O

P

DTC P0710 CVT FLUID TEMPERATURE SENSOR CIRCUIT

DescriptionINFOID:0000000001703497

• The CVT fluid temperature sensor is included in the control valve assembly.

• The CVT fluid temperature sensor detects the CVT fluid temperature and sends a signal to the TCM.

CONSULT-III Reference Value in Data Monitor ModeINFOID:0000000001703498

Remarks: Specification data are reference values.

On Board Diagnosis LogicINFOID:0000000001703499

• This is an OBD-II self-diagnostic item.

• Diagnostic trouble code “P0710 ATF TEMP SEN/CIRC” with CONSULT-III is detected when TCM receives

an excessively low or high voltage from the sensor.

Possible CauseINFOID:0000000001703500

• Harness or connectors

(Sensor circuit is open or shorted.)

• CVT fluid temperature sensor

DTC Confirmation ProcedureINFOID:0000000001703501

CAUTION:

Always drive vehicle at a safe speed.

NOTE:

If “DTC Confirmation Procedure” has been previously performed, always turn ignition switch OFF and

wait at least 10 seconds before performing the next test.

After the repair, touch “ERASE” on “SELF-DIAG RESULTS” and then perform the following procedure to con-

firm the malfunction is eliminated.

WITH CONSULT-III

1. Turn ignition switch ON. (Do not start engine.)

2. Select “DATA MONITOR” mode for “TRANSMISSION” with CONSULT-III.

3. Start engine and maintain the following conditions for at least 10 minutes (Total).

VEHICLE SPEED: 10 km/h (6 MPH) or more

ENG SPEED: 450 rpm more than

ACC PEDAL OPEN: More than 1.0/8

RANGE: “D” position

4. If DTC is detected, go to CVT-73, "

Diagnosis Procedure".

WITH GST

Follow the procedure “WITH CONSULT-III”.

Item name Condition Display value (Approx.)

ATF TEMP SEN When CVT fluid temperature is 20°C (68°F). 2.0 V

When CVT fluid temperature is 80°C (176°F). 1.0 V