Engine mechanical NISSAN TIIDA 2008 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2008, Model line: TIIDA, Model: NISSAN TIIDA 2008Pages: 2771, PDF Size: 60.61 MB

Page 1 of 2771

-1

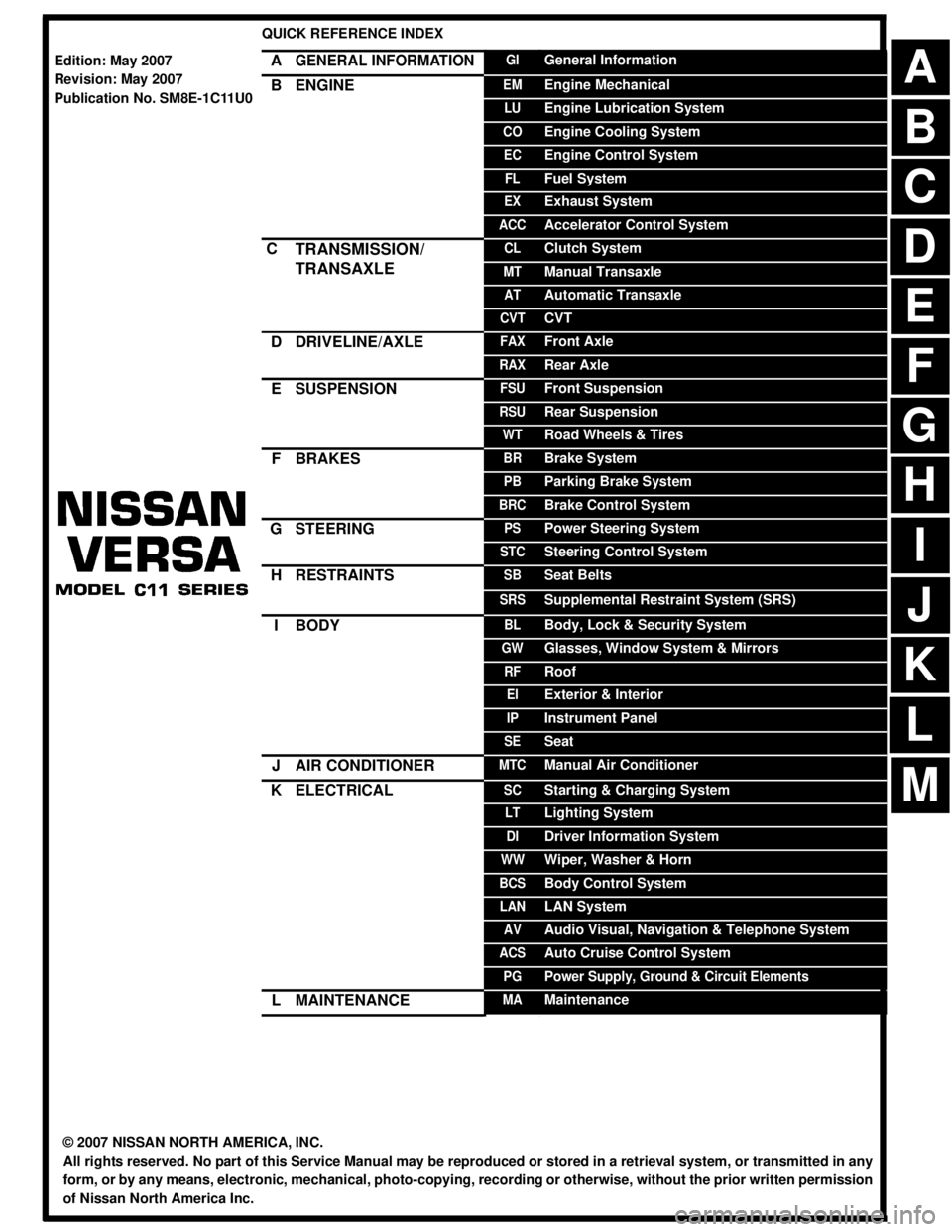

QUICK REFERENCE INDEX

AGENERAL INFORMATIONGIGeneral Information

BENGINEEMEngine Mechanical

LUEngine Lubrication System

COEngine Cooling System

ECEngine Control System

FLFuel System

EXExhaust System

ACCAccelerator Control System

CTRANSMISSION/

TRANSAXLECLClutch System

MTManual Transaxle

ATAutomatic Transaxle

CVTCVT

DDRIVELINE/AXLEFAXFront Axle

RAXRear Axle

ESUSPENSIONFSUFront Suspension

RSURear Suspension

WTRoad Wheels & Tires

FBRAKESBRBrake System

PBParking Brake System

BRCBrake Control System

GSTEERINGPSPower Steering System

STCSteering Control System

HRESTRAINTSSBSeat Belts

SRSSupplemental Restraint System (SRS)

IBODYBLBody, Lock & Security System

GWGlasses, Window System & Mirrors

RFRoof

EIExterior & Interior

IPInstrument Panel

SESeat

JAIR CONDITIONERMTCManual Air Conditioner

KELECTRICALSCStarting & Charging System

LTLighting System

DIDriver Information System

WWWiper, Washer & Horn

BCSBody Control System

LANLAN System

AVAudio Visual, Navigation & Telephone System

ACSAuto Cruise Control System

PGPower Supply, Ground & Circuit Elements

LMAINTENANCEMAMaintenance

Edition: May 2007

Revision: May 2007

Publication No. SM8E-1C11U0

B

D

© 2007 NISSAN NORTH AMERICA, INC.

All rights reserved. No part of this Service Manual may be reproduced or stored in a retrieval system, or transmitted in any

form, or by any means, electronic, mechanical, photo-copying, recording or otherwise, without the prior written permission

of Nissan North America Inc.

A

C

E

F

G

H

I

J

K

L

M

Page 19 of 2771

PRECAUTIONS

AT-7

< SERVICE INFORMATION >

D

E

F

G

H

I

J

K

L

MA

B

AT

N

O

P

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000001703151

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and whether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SRS and SB section of this Service Man-

ual.

WARNING:

• To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including incorrect removal and installation of the SRS, can lead to personal

injury caused by unintentional activation of the system. For removal of Spiral Cable and Air Bag

Module, see the SRS section.

• Do not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identified by yellow and/or orange harnesses or har-

ness connectors.

Precaution Necessary for Steering Wheel Rotation After Battery Disconnect

INFOID:0000000001703152

NOTE:

• This Procedure is applied only to models with Intelligent Key system and NVIS/IVIS (NISSAN/INFINITI

VEHICLE IMMOBILIZER SYSTEM - NATS).

• Remove and install all control units after disconnecting both battery cables with the ignition knob in the

″LOCK″ position.

• Always use CONSULT-III to perform self-diagnosis as a part of each function inspection after finishing work.

If DTC is detected, perform trouble diagnosis according to self-diagnostic results.

For models equipped with the Intelligent Key system and NVIS/IVIS, an electrically controlled steering lock

mechanism is adopted on the key cylinder.

For this reason, if the battery is disconnected or if the battery is discharged, the steering wheel will lock and

steering wheel rotation will become impossible.

If steering wheel rotation is required when battery power is interrupted, follow the procedure below before

starting the repair operation.

OPERATION PROCEDURE

1. Connect both battery cables.

NOTE:

Supply power using jumper cables if battery is discharged.

2. Use the Intelligent Key or mechanical key to turn the ignition switch to the ″ACC″ position. At this time, the

steering lock will be released.

3. Disconnect both battery cables. The steering lock will remain released and the steering wheel can be

rotated.

4. Perform the necessary repair operation.

5. When the repair work is completed, return the ignition switch to the ″LOCK″ position before connecting

the battery cables. (At this time, the steering lock mechanism will engage.)

6. Perform a self-diagnosis check of all control units using CONSULT-III.

Precaution for On Board Diagnosis (OBD) System of A/T and EngineINFOID:0000000001703153

The ECM has an on board diagnostic system. It will light up the malfunction indicator lamp (MIL) to warn the

driver of a malfunction causing emission deterioration.

CAUTION:

Page 33 of 2771

A/T CONTROL SYSTEM

AT-21

< SERVICE INFORMATION >

D

E

F

G

H

I

J

K

L

MA

B

AT

N

O

P

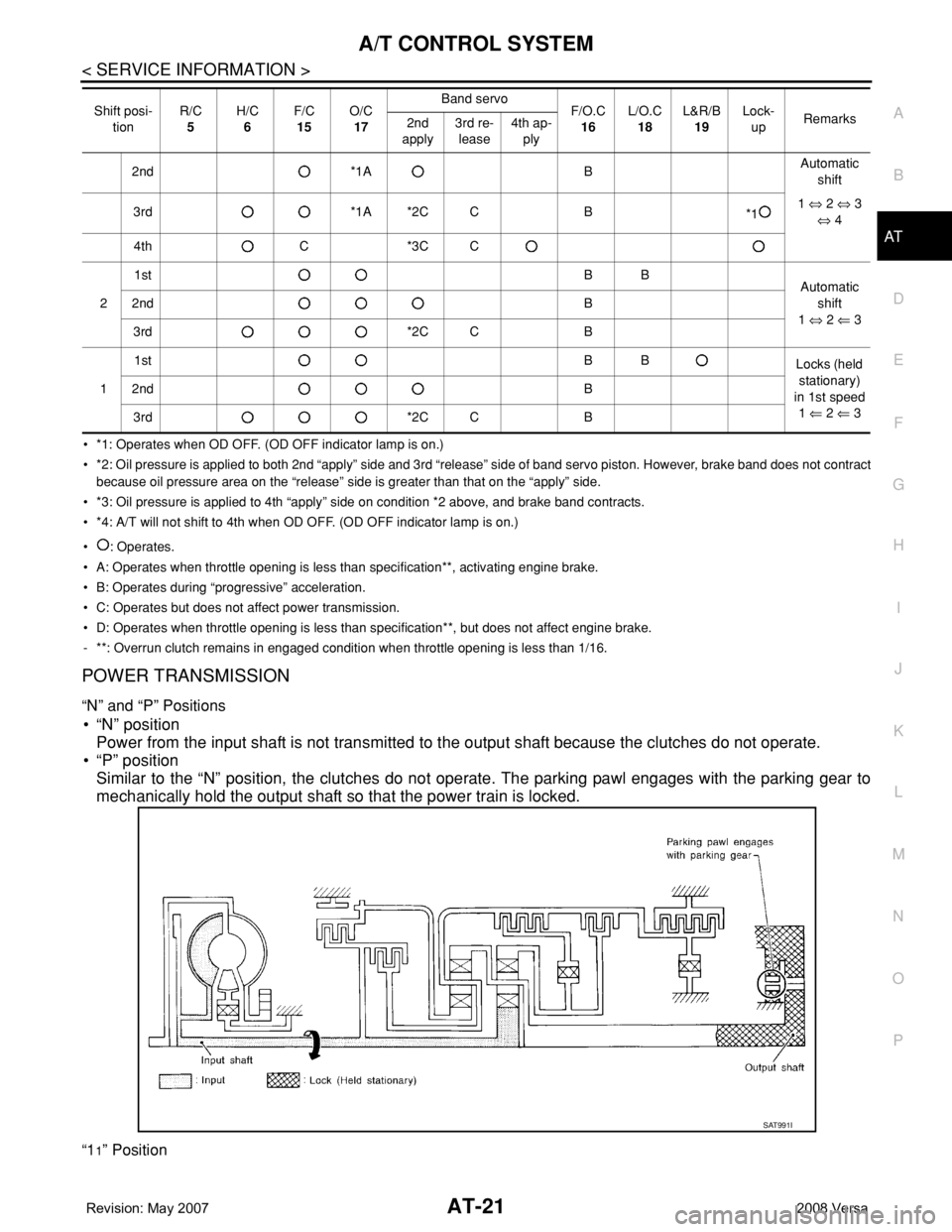

• *1: Operates when OD OFF. (OD OFF indicator lamp is on.)

• *2: Oil pressure is applied to both 2nd “apply” side and 3rd “release” side of band servo piston. However, brake band does not contract

because oil pressure area on the “release” side is greater than that on the “apply” side.

• *3: Oil pressure is applied to 4th “apply” side on condition *2 above, and brake band contracts.

• *4: A/T will not shift to 4th when OD OFF. (OD OFF indicator lamp is on.)

• : Operates.

• A: Operates when throttle opening is less than specification**, activating engine brake.

• B: Operates during “progressive” acceleration.

• C: Operates but does not affect power transmission.

• D: Operates when throttle opening is less than specification**, but does not affect engine brake.

- **: Overrun clutch remains in engaged condition when throttle opening is less than 1/16.

POWER TRANSMISSION

“N” and “P” Positions

• “N” position

Power from the input shaft is not transmitted to the output shaft because the clutches do not operate.

• “P” position

Similar to the “N” position, the clutches do not operate. The parking pawl engages with the parking gear to

mechanically hold the output shaft so that the power train is locked.

“11” Position

2nd *1A BAutomatic

shift

3rd *1A *2C C B

*11 ⇔ 2 ⇔ 3

⇔ 4

4th C *3C C

21stBB

Automatic

shift

1 ⇔ 2 ⇐ 3 2ndB

3rd *2C C B

11stBB

Locks (held

stationary)

in 1st speed

1 ⇐ 2 ⇐ 3 2ndB

3rd *2C C B Shift posi-

tionR/C

5H/C

6F/C

15O/C

17Band servo

F/O.C

16L/O.C

18L&R/B

19Lock-

upRemarks

2nd

apply3rd re-

lease4th ap-

ply

SAT991I

Page 85 of 2771

TROUBLE DIAGNOSIS

AT-73

< SERVICE INFORMATION >

D

E

F

G

H

I

J

K

L

MA

B

AT

N

O

P

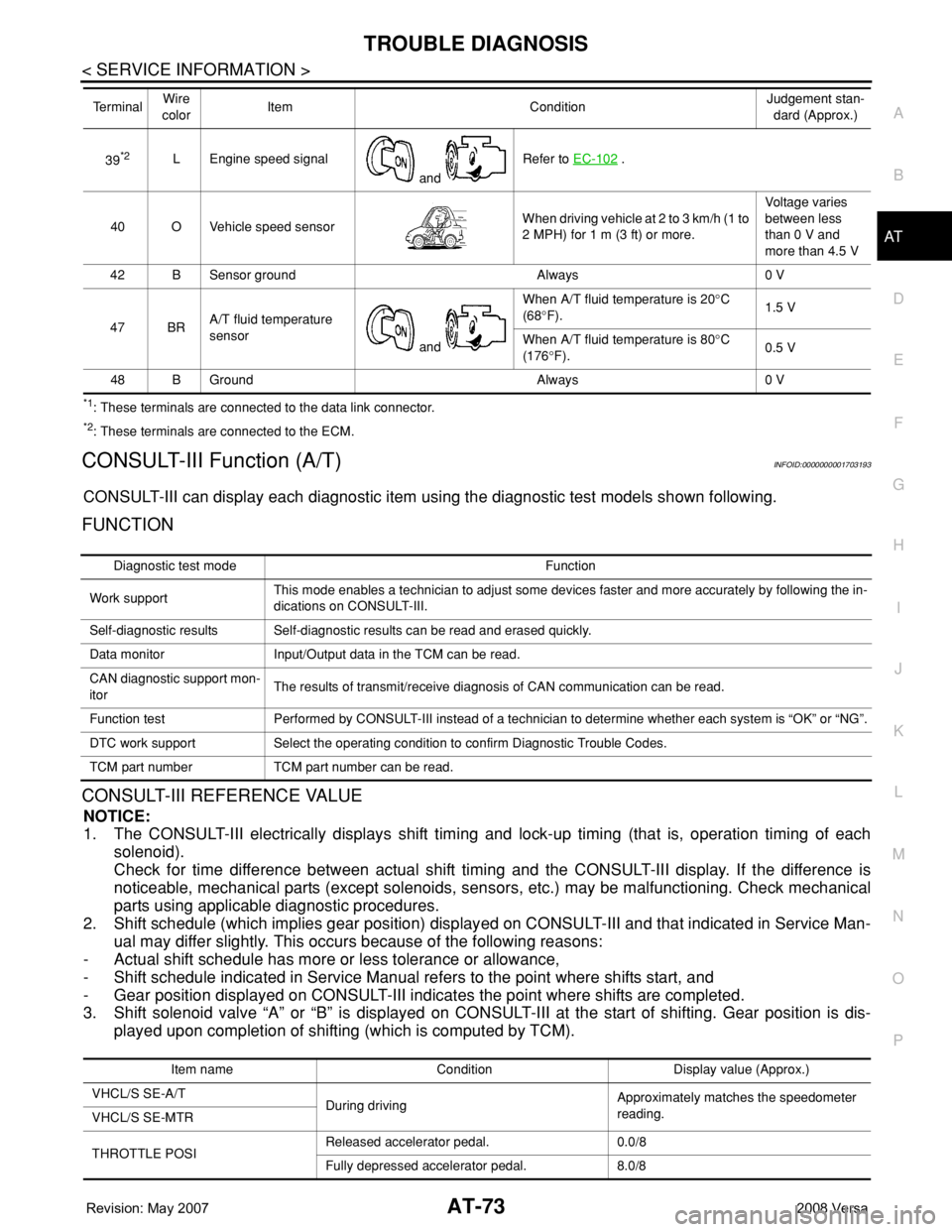

*1: These terminals are connected to the data link connector.

*2: These terminals are connected to the ECM.

CONSULT-III Function (A/T)INFOID:0000000001703193

CONSULT-III can display each diagnostic item using the diagnostic test models shown following.

FUNCTION

CONSULT-III REFERENCE VALUE

NOTICE:

1. The CONSULT-III electrically displays shift timing and lock-up timing (that is, operation timing of each

solenoid).

Check for time difference between actual shift timing and the CONSULT-III display. If the difference is

noticeable, mechanical parts (except solenoids, sensors, etc.) may be malfunctioning. Check mechanical

parts using applicable diagnostic procedures.

2. Shift schedule (which implies gear position) displayed on CONSULT-III and that indicated in Service Man-

ual may differ slightly. This occurs because of the following reasons:

- Actual shift schedule has more or less tolerance or allowance,

- Shift schedule indicated in Service Manual refers to the point where shifts start, and

- Gear position displayed on CONSULT-III indicates the point where shifts are completed.

3. Shift solenoid valve “A” or “B” is displayed on CONSULT-III at the start of shifting. Gear position is dis-

played upon completion of shifting (which is computed by TCM).

39*2L Engine speed signal

and Refer to EC-102 .

40 O Vehicle speed sensorWhen driving vehicle at 2 to 3 km/h (1 to

2 MPH) for 1 m (3 ft) or more.Voltage varies

between less

than 0 V and

more than 4.5 V

42 B Sensor ground Always 0 V

47 BRA/T fluid temperature

sensor

and When A/T fluid temperature is 20°C

(68°F).1.5 V

When A/T fluid temperature is 80°C

(176°F).0.5 V

48 B Ground Always 0 V Te r m i n a lWire

colorItem ConditionJudgement stan-

dard (Approx.)

Diagnostic test mode Function

Work supportThis mode enables a technician to adjust some devices faster and more accurately by following the in-

dications on CONSULT-III.

Self-diagnostic results Self-diagnostic results can be read and erased quickly.

Data monitor Input/Output data in the TCM can be read.

CAN diagnostic support mon-

itorThe results of transmit/receive diagnosis of CAN communication can be read.

Function test Performed by CONSULT-III instead of a technician to determine whether each system is “OK” or “NG”.

DTC work support Select the operating condition to confirm Diagnostic Trouble Codes.

TCM part number TCM part number can be read.

Item name Condition Display value (Approx.)

VHCL/S SE-A/T

During drivingApproximately matches the speedometer

reading.

VHCL/S SE-MTR

THROTTLE POSIReleased accelerator pedal. 0.0/8

Fully depressed accelerator pedal. 8.0/8

Page 117 of 2771

DTC P0731 A/T 1ST GEAR FUNCTION

AT-105

< SERVICE INFORMATION >

D

E

F

G

H

I

J

K

L

MA

B

AT

N

O

P

DTC P0731 A/T 1ST GEAR FUNCTION

DescriptionINFOID:0000000001703231

• This malfunction will not be detected while the OD OFF indicator lamp is indicating another self-diagnosis

malfunction.

• This malfunction is detected when the A/T does not shift into first gear position as instructed by the TCM.

This is not caused by electrical malfunction (circuits open or shorted) but by mechanical malfunction such as

control valve sticking, improper solenoid valve operation, etc.

On Board Diagnosis LogicINFOID:0000000001703232

• This is an OBD-II self-diagnostic item.

• Diagnostic trouble code “P0731 A/T 1ST GR FNCTN” with CONSULT-III is detected when A/T cannot be

shifted to the 1st gear position even if electrical circuit is good.

• This diagnosis monitors actual gear position by checking the torque converter slip ratio calculated by TCM

as follows:

Torque converter slip ratio = A x C/B

A: Output shaft revolution signal from revolution sensor

B: Engine speed signal from ECM

C: Gear ratio determined as gear position which TCM supposes

If the actual gear position is higher than the position (1st) supposed by TCM, the slip ratio will be more than

normal. In case the ratio exceeds the specified value, TCM judges this diagnosis malfunction.

This malfunction will be caused when either shift solenoid valve A is stuck open or shift solenoid valve B is

stuck open.

• Gear positions supposed by TCM are as follows:

In case of gear position with no malfunctions: 1, 2, 3 and 4 positions

In case of gear position with shift solenoid valve A stuck open: 2*, 2, 3 and 3 positions

In case of gear position with shift solenoid valve B stuck open: 4*, 3, 3 and 4 positions to each gear position

above

*: “P0731 A/T 1ST GR FNCTN” is detected.

Possible CauseINFOID:0000000001703233

• Shift solenoid valve A

• Shift solenoid valve B

• Each clutch

• Hydraulic control circuit

DTC Confirmation ProcedureINFOID:0000000001703234

CAUTION:

• Always drive vehicle at a safe speed.

• If performing this “DTC Confirmation Procedure” again, always turn ignition switch OFF and wait at

least 10 seconds before continuing.

After the repair, perform the following procedure to confirm the malfunction is eliminated.

WITH CONSULT-III

1. Start engine and select “DATA MONITOR” mode for “A/T” with CONSULT-III.

2. Touch “START”.

3. Make sure that output voltage of A/T fluid temperature sensor is within the range below.

FLUID TEMP SE: 0.4 - 1.5 V

If out of range, drive the vehicle to decrease the voltage (warm up the fluid) or stop engine to increase the

voltage (cool down the fluid).

4. Select “1ST GR FNCTN P0731” of “DTC WORK SUPPORT” mode for “A/T” with CONSULT-III and touch

“START”.

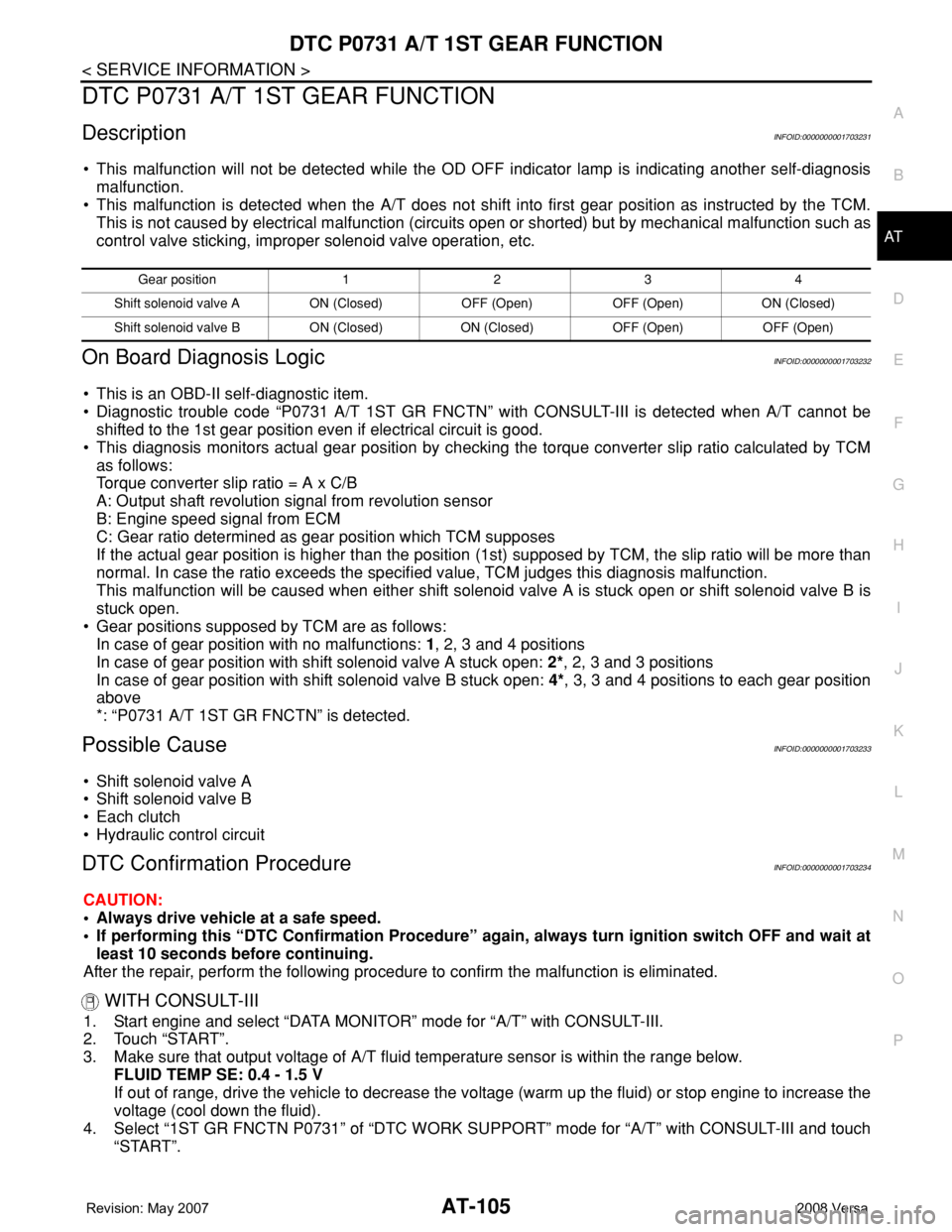

Gear position 1 2 3 4

Shift solenoid valve A ON (Closed) OFF (Open) OFF (Open) ON (Closed)

Shift solenoid valve B ON (Closed) ON (Closed) OFF (Open) OFF (Open)

Page 120 of 2771

AT-108

< SERVICE INFORMATION >

DTC P0732 A/T 2ND GEAR FUNCTION

DTC P0732 A/T 2ND GEAR FUNCTION

DescriptionINFOID:0000000001703236

• This malfunction will not be detected while the OD OFF indicator lamp is indicating another self-diagnosis

malfunction.

• This malfunction is detected when the A/T does not shift into second gear position as instructed by the TCM.

This is not caused by electrical malfunction (circuits open or shorted) but by mechanical malfunction such as

control valve sticking, improper solenoid valve operation, etc.

On Board Diagnosis LogicINFOID:0000000001703237

• This is an OBD-II self-diagnostic item.

• Diagnostic trouble code “P0732 A/T 2ND GR FNCTN” with CONSULT-III is detected when A/T cannot be

shifted to the 2nd gear position even if electrical circuit is good.

• This diagnosis monitors actual gear position by checking the torque converter slip ratio calculated by TCM

as follows:

Torque converter slip ratio = A x C/B

A: Output shaft revolution signal from revolution sensor

B: Engine speed signal from ECM

C: Gear ratio determined as gear position which TCM supposes

If the actual gear position is higher than the position (2nd) supposed by TCM, the slip ratio will be more than

normal. In case the ratio exceeds the specified value, TCM judges this diagnosis malfunction.

This malfunction will be caused when shift solenoid valve B is stuck open.

• Gear positions supposed by TCM are as follows:

In case of gear position with no malfunctions: 1, 2, 3 and 4 positions

In case of gear position with shift solenoid valve B stuck open: 4, 3*, 3 and 4 positions to each gear position

above

*: “P0732 A/T 2ND GR FNCTN” is detected.

Possible CauseINFOID:0000000001703238

• Shift solenoid valve B

• Each clutch

• Hydraulic control circuit

DTC Confirmation ProcedureINFOID:0000000001703239

CAUTION:

• Always drive vehicle at a safe speed.

• If performing this “DTC Confirmation Procedure” again, always turn ignition switch OFF and wait at

least 10 seconds before continuing.

After the repair, perform the following procedure to confirm the malfunction is eliminated.

WITH CONSULT-III

1. Start engine and select “DATA MONITOR” mode for “A/T” with CONSULT-III.

2. Touch “START”.

3. Make sure that output voltage of A/T fluid temperature sensor is within the range below.

FLUID TEMP SE: 0.4 - 1.5 V

If out of range, drive the vehicle to decrease the voltage (warm up the fluid) or stop engine to increase the

voltage (cool down the fluid).

4. Select “2ND GR FNCTN P0732” of “DTC WORK SUPPORT” mode for “A/T” with CONSULT-III and touch

“START”.

5. Accelerate vehicle to 45 to 50 km/h (28 to 31 MPH) under the following conditions and release the accel-

erator pedal completely.

THROTTLE POSI: Less than 1.0/8

SLCT LVR POSI: “D” position

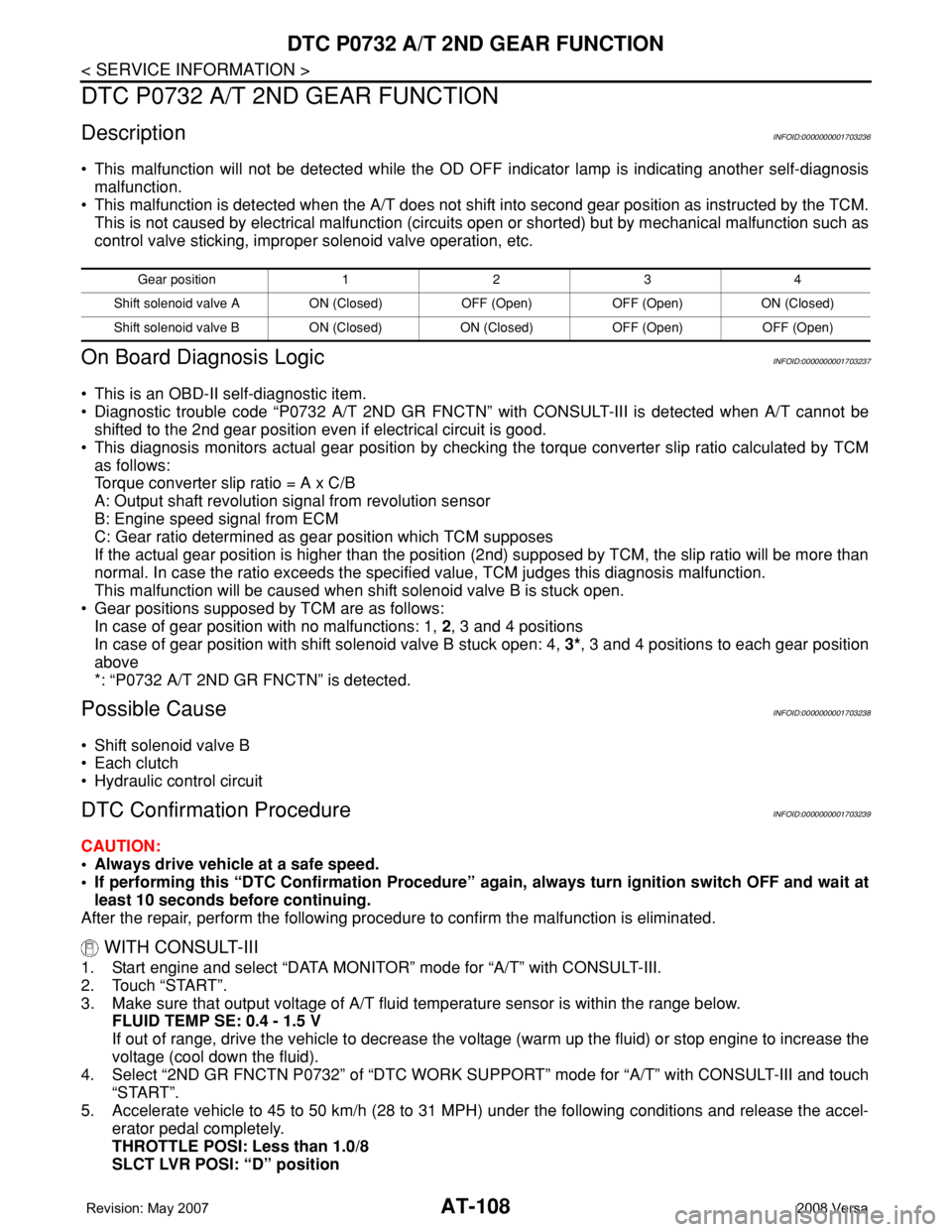

Gear position 1 2 3 4

Shift solenoid valve A ON (Closed) OFF (Open) OFF (Open) ON (Closed)

Shift solenoid valve B ON (Closed)ON (Closed) OFF (Open) OFF (Open)

Page 123 of 2771

DTC P0733 A/T 3RD GEAR FUNCTION

AT-111

< SERVICE INFORMATION >

D

E

F

G

H

I

J

K

L

MA

B

AT

N

O

P

DTC P0733 A/T 3RD GEAR FUNCTION

DescriptionINFOID:0000000001703241

• This malfunction will not be detected while the OD OFF indicator lamp is indicating another self-diagnosis

malfunction.

• This malfunction is detected when the A/T does not shift into third gear position as instructed by the TCM.

This is not caused by electrical malfunction (circuits open or shorted) but by mechanical malfunction such as

control valve sticking, improper solenoid valve operation, malfunctioning servo piston or brake band, etc.

On Board Diagnosis LogicINFOID:0000000001703242

• This is an OBD-II self-diagnostic item.

• Diagnostic trouble code “P0733 A/T 3RD GR FNCTN” with CONSULT-III is detected when A/T cannot be

shifted to the 3rd gear position even if electrical circuit is good.

• This diagnosis monitors actual gear position by checking the torque converter slip ratio calculated by TCM

as follows:

Torque converter slip ratio = A x C/B

A: Output shaft revolution signal from revolution sensor

B: Engine speed signal from ECM

C: Gear ratio determined as gear position which TCM supposes

If the actual gear position is higher than the position (3rd) supposed by TCM, the slip ratio will be more than

normal. In case the ratio exceeds the specified value, TCM judges this diagnosis malfunction.

This malfunction will be caused when shift solenoid valve A is stuck closed.

• Gear positions supposed by TCM are as follows.

In case of gear position with no malfunctions: 1, 2, 3 and 4 positions

In case of gear position with shift solenoid valve A stuck closed: 1, 1, 4* and 4 positions to each gear position

above

*: “P0733 A/T 3RD GR FNCTN” is detected.

Possible CauseINFOID:0000000001703243

• Shift solenoid valve A

• Each clutch

• Hydraulic control circuit

DTC Confirmation ProcedureINFOID:0000000001703244

CAUTION:

• Always drive vehicle at a safe speed.

• If performing this “DTC Confirmation Procedure” again, always turn ignition switch OFF and wait at

least 10 seconds before continuing.

After the repair, perform the following procedure to confirm the malfunction is eliminated.

WITH CONSULT-III

1. Start engine and select “DATA MONITOR” mode for “A/T” with CONSULT-III.

2. Touch “START”.

3. Make sure that output voltage of A/T fluid temperature sensor is within the range below.

FLUID TEMP SE: 0.4 - 1.5 V

If out of range, drive the vehicle to decrease the voltage (warm up the fluid) or stop engine to increase the

voltage (cool down the fluid).

4. Select “3RD GR FNCTN P0733” of “DTC WORK SUPPORT” mode for “A/T” with CONSULT-III and touch

“START”.

5. Accelerate vehicle to 60 to 75 km/h (37 to 47 MPH) under the following conditions and release the accel-

erator pedal completely.

THROTTLE POSI: Less than 1.0/8 (at all times during step 4)

SLCT LVR POSI: “D” position

Gear position 1 2 3 4

Shift solenoid valve A ON (Closed) OFF (Open) OFF (Open) ON (Closed)

Shift solenoid valve B ON (Closed) ON (Closed) OFF (Open) OFF (Open)

Page 126 of 2771

AT-114

< SERVICE INFORMATION >

DTC P0734 A/T 4TH GEAR FUNCTION

DTC P0734 A/T 4TH GEAR FUNCTION

DescriptionINFOID:0000000001703246

• This malfunction will not be detected while the OD OFF indicator lamp is indicating another self-diagnosis

malfunction.

• This malfunction is detected when the A/T does not shift into fourth gear position or the torque converter

clutch does not lock up as instructed by the TCM. This is not caused by electrical malfunction (circuits open

or shorted) but by mechanical malfunction such as control valve sticking, improper solenoid valve operation,

malfunctioning oil pump or torque converter clutch, etc.

CONSULT-III Reference Value in Data Monitor ModeINFOID:0000000001703247

Remarks: Specification data are reference values.

On Board Diagnosis LogicINFOID:0000000001703248

• This is an OBD-II self-diagnostic item.

• Diagnostic trouble code “P0734 A/T 4TH GR FNCTN” with CONSULT-III is detected when A/T cannot be

shifted to the 4th gear position even if electrical circuit is good.

• This diagnosis monitors actual gear position by checking the torque converter slip ratio calculated by TCM

as follows:

Torque converter slip ratio = A x C/B

A: Output shaft revolution signal from revolution sensor

B: Engine speed signal from ECM

C: Gear ratio determined as gear position which TCM supposes

If the actual gear position is much lower than the position (4th) supposed by TCM, the slip ratio will be much

less than normal. In case the ratio does not reach the specified value, TCM judges this diagnosis malfunc-

tion.

This malfunction will be caused when shift solenoid valve A is stuck open or shift solenoid valve B is stuck

closed.

• Gear positions supposed by TCM are as follows.

In case of gear position with no malfunctions: 1, 2, 3 and 4 positions

In case of gear position with shift solenoid valve A stuck open: 2, 2, 3 and 3* positions

In case of gear position with shift solenoid valve B stuck closed: 1, 2, 2 and 1* positions to each gear position

above

*: “P0734 A/T 4TH GR FNCTN” is detected.

Possible CauseINFOID:0000000001703249

• Shift solenoid valve A

• Shift solenoid valve B

• Line pressure solenoid valve

• Each clutch

• Hydraulic control circuit

DTC Confirmation ProcedureINFOID:0000000001703250

CAUTION:

• Always drive vehicle at a safe speed.

• If performing this “DTC Confirmation Procedure” again, always turn ignition switch OFF and wait at

least 10 seconds before continuing.

After the repair, perform the following procedure to confirm the malfunction is eliminated.

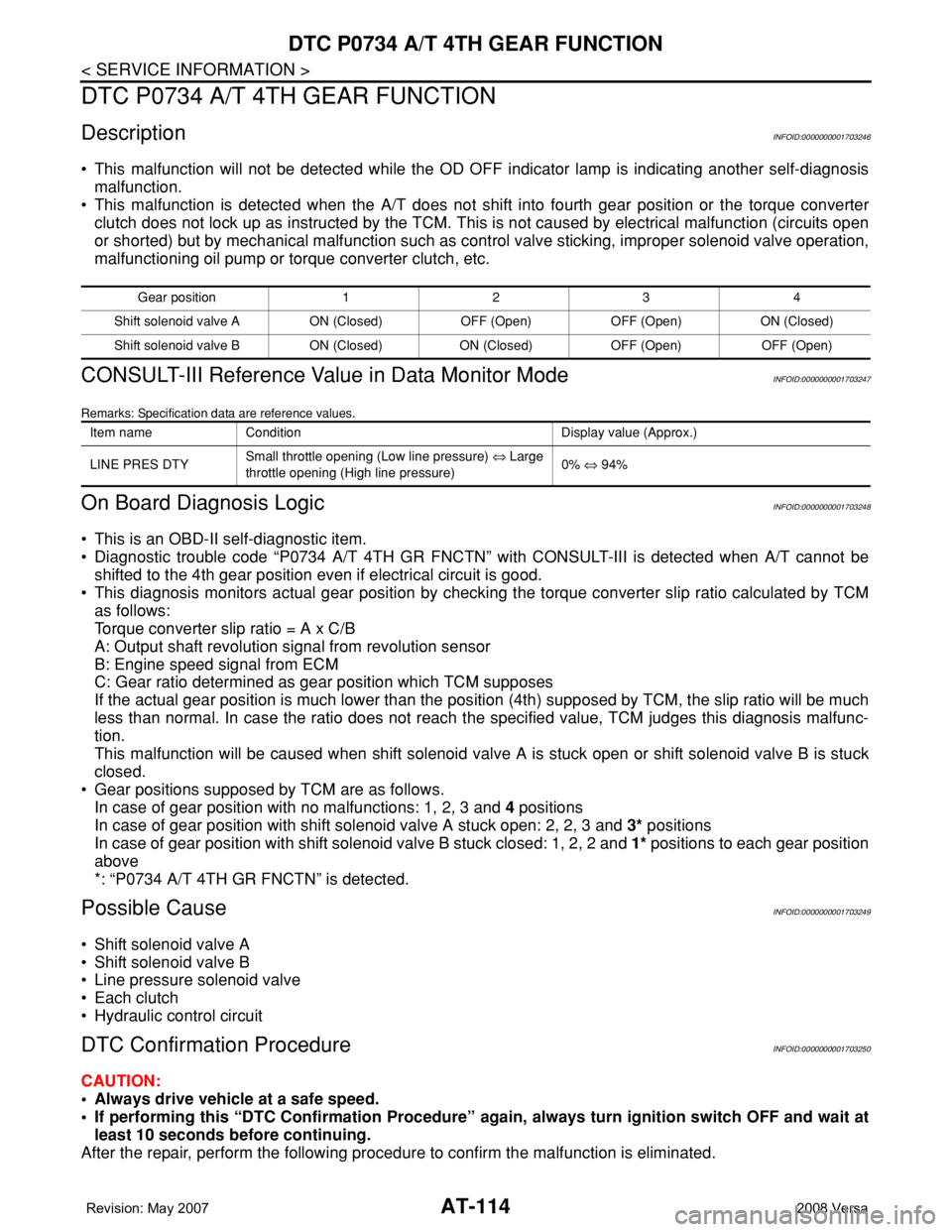

Gear position 1 2 3 4

Shift solenoid valve A ON (Closed) OFF (Open) OFF (Open) ON (Closed)

Shift solenoid valve B ON (Closed) ON (Closed) OFF (Open) OFF (Open)

Item name Condition Display value (Approx.)

LINE PRES DTYSmall throttle opening (Low line pressure) ⇔ Large

throttle opening (High line pressure)0% ⇔ 94%

Page 136 of 2771

AT-124

< SERVICE INFORMATION >

DTC P0744 A/T TCC S/V FUNCTION (LOCK-UP)

DTC P0744 A/T TCC S/V FUNCTION (LOCK-UP)

DescriptionINFOID:0000000001703260

• This malfunction will not be detected while the OD OFF indicator lamp is indicating another self-diagnosis

malfunction.

• This malfunction is detected when the A/T does not shift into fourth gear position or the torque converter

clutch does not lock-up as instructed by the TCM. This is not caused by electrical malfunction (circuits open

or shorted) but by mechanical malfunction such as control valve sticking, improper solenoid valve operation,

malfunctioning oil pump or torque converter clutch, etc.

CONSULT-III Reference Value in Data Monitor ModeINFOID:0000000001703261

Remarks: Specification data are reference values.

On Board Diagnosis LogicINFOID:0000000001703262

• This is an OBD-II self-diagnostic item.

• Diagnostic trouble code “P0744 A/T TCC S/V FNCTN” with CONSULT-III is detected when A/T cannot per-

form lock-up even if electrical circuit is good.

• This diagnosis monitors actual gear position by checking the torque converter slip ratio calculated by TCM

as follows:

Torque converter slip ratio = A x C/B

A: Output shaft revolution signal from revolution sensor

B: Engine speed signal from ECM

C: Gear ratio determined as gear position which TCM supposes

If the actual gear position is much lower than the position (4th) supposed by TCM, the slip ratio will be much

less than normal. In case the ratio does not reach the specified value, TCM judges this diagnosis malfunc-

tion.

This malfunction will be caused when shift solenoid valve B is stuck closed.

• Gear positions supposed by TCM are as follows.

In case of gear position with no malfunctions: 1, 2, 3 and 4 positions

In case of gear position with shift solenoid valve B stuck closed: 1, 2, 2 and 1* positions to each gear position

above

*: “P0744 A/T TCC S/V FNCTN” is detected.

Possible CauseINFOID:0000000001703263

• Line pressure solenoid valve

• Torque converter clutch solenoid valve

• Each clutch

• Hydraulic control circuit

DTC Confirmation ProcedureINFOID:0000000001703264

CAUTION:

• Always drive vehicle at a safe speed.

• If performing this “DTC Confirmation Procedure” again, always turn ignition switch OFF and wait at

least 10 seconds before continuing.

After the repair, perform the following procedure to confirm the malfunction is eliminated.

WITH CONSULT-III

1. Start engine and select “DATA MONITOR” mode for “A/T” with CONSULT-III.

2. Touch “START”.

3. Make sure that output voltage of A/T fluid temperature sensor is within the range below.

FLUID TEMP SE: 0.4 - 1.5 V

If out of range, drive vehicle to decrease voltage (warm up the fluid) or stop engine to increase voltage

(cool down the fluid).

4. Select “TCC S/V FNCTN P0744” of “DTC WORK SUPPORT” mode for “A/T” with CONSULT-III and touch

“START”.

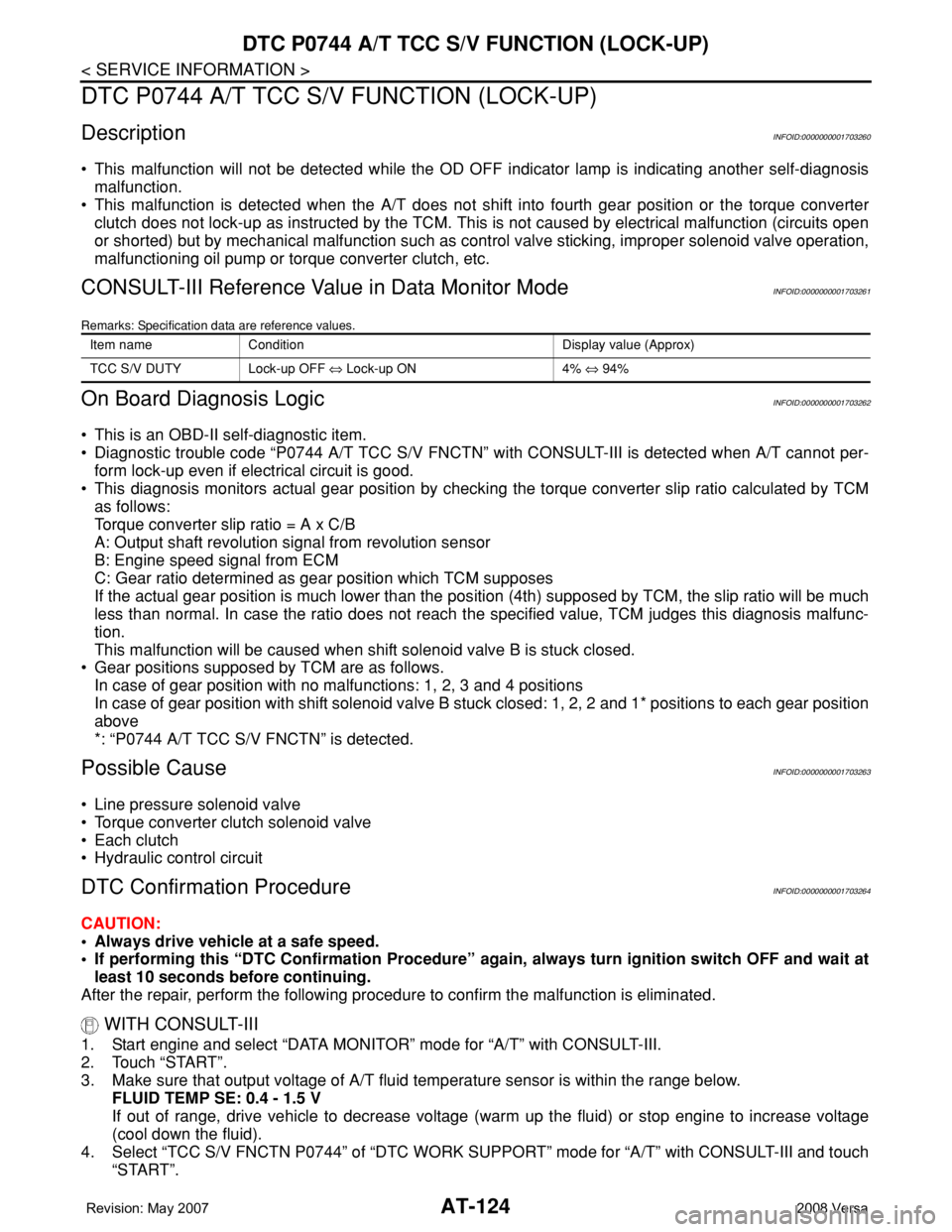

Item name Condition Display value (Approx)

TCC S/V DUTY Lock-up OFF ⇔ Lock-up ON 4% ⇔ 94%

Page 510 of 2771

BL-76

< SERVICE INFORMATION >

INTELLIGENT KEY SYSTEM

System Description

INFOID:0000000001703999

• The Intelligent Key system is a system that makes it possible to lock and unlock the door locks (door lock/

unlock function), and start the engine (engine start function) by carrying around the Intelligent Key (without

some key operation), which operates based on the results of electronic ID verification using two-way com-

munications between the Intelligent Key and the vehicle (Intelligent Key unit).

• Vehicles equipped with a manual transmission include a key interlock solenoid located in the steering col-

umn to prevent accidental shut-off of the ignition switch and locking of the steering wheel during driving con-

dition when the vehicle is moving.

CAUTION:

The driver should always carry the Intelligent Key

• Operation of the remote controller buttons on the Intelligent Key also provides the same functions as the

remote control entry system. (Remote keyless entry functions)

• If an action that does not meet the operating conditions of the Intelligent Key system is taken, the buzzer

goes off to inform the driver. (Warning chime functions)

• When a door lock is locked or unlocked with request switch or remote controller button operation, the hazard

lamps flash and the buzzer (outside vehicle) sounds (Hazard and buzzer reminder function).

• Even if the Intelligent Key battery is completely discharged, the door locks can be locked and unlocked and

the engine started with the mechanical key built into the Intelligent Key.

• The settings for each function can be changed with the CONSULT-III.

• If an Intelligent Key is lost, a new Intelligent Key can be registered. A maximum of 4 Intelligent Keys can be

registered.

• It has been made possible to diagnose the system and register an Intelligent Key with the CONSULT-III.

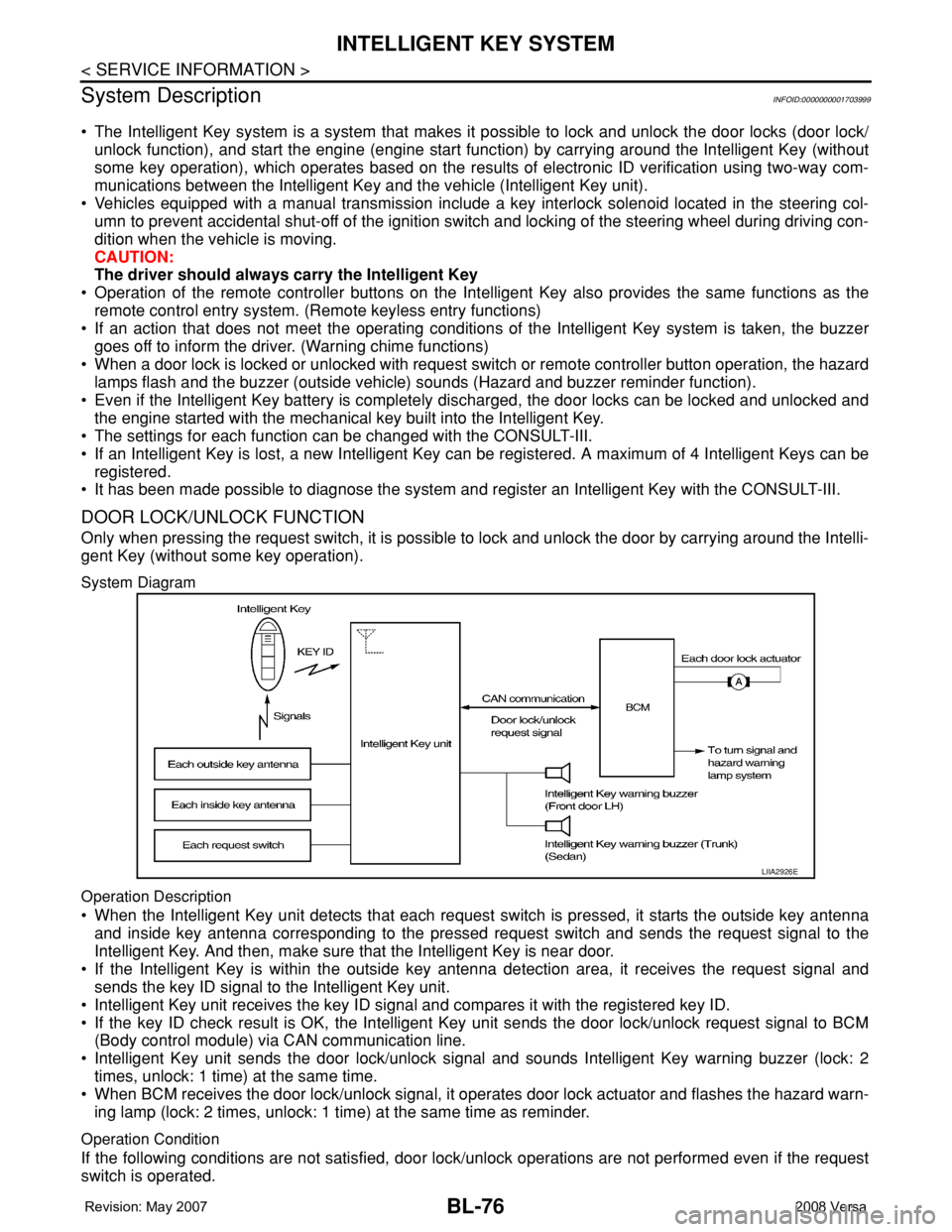

DOOR LOCK/UNLOCK FUNCTION

Only when pressing the request switch, it is possible to lock and unlock the door by carrying around the Intelli-

gent Key (without some key operation).

System Diagram

Operation Description

• When the Intelligent Key unit detects that each request switch is pressed, it starts the outside key antenna

and inside key antenna corresponding to the pressed request switch and sends the request signal to the

Intelligent Key. And then, make sure that the Intelligent Key is near door.

• If the Intelligent Key is within the outside key antenna detection area, it receives the request signal and

sends the key ID signal to the Intelligent Key unit.

• Intelligent Key unit receives the key ID signal and compares it with the registered key ID.

• If the key ID check result is OK, the Intelligent Key unit sends the door lock/unlock request signal to BCM

(Body control module) via CAN communication line.

• Intelligent Key unit sends the door lock/unlock signal and sounds Intelligent Key warning buzzer (lock: 2

times, unlock: 1 time) at the same time.

• When BCM receives the door lock/unlock signal, it operates door lock actuator and flashes the hazard warn-

ing lamp (lock: 2 times, unlock: 1 time) at the same time as reminder.

Operation Condition

If the following conditions are not satisfied, door lock/unlock operations are not performed even if the request

switch is operated.

LIIA2926E