Seat NISSAN TIIDA 2008 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2008, Model line: TIIDA, Model: NISSAN TIIDA 2008Pages: 2771, PDF Size: 60.61 MB

Page 1 of 2771

-1

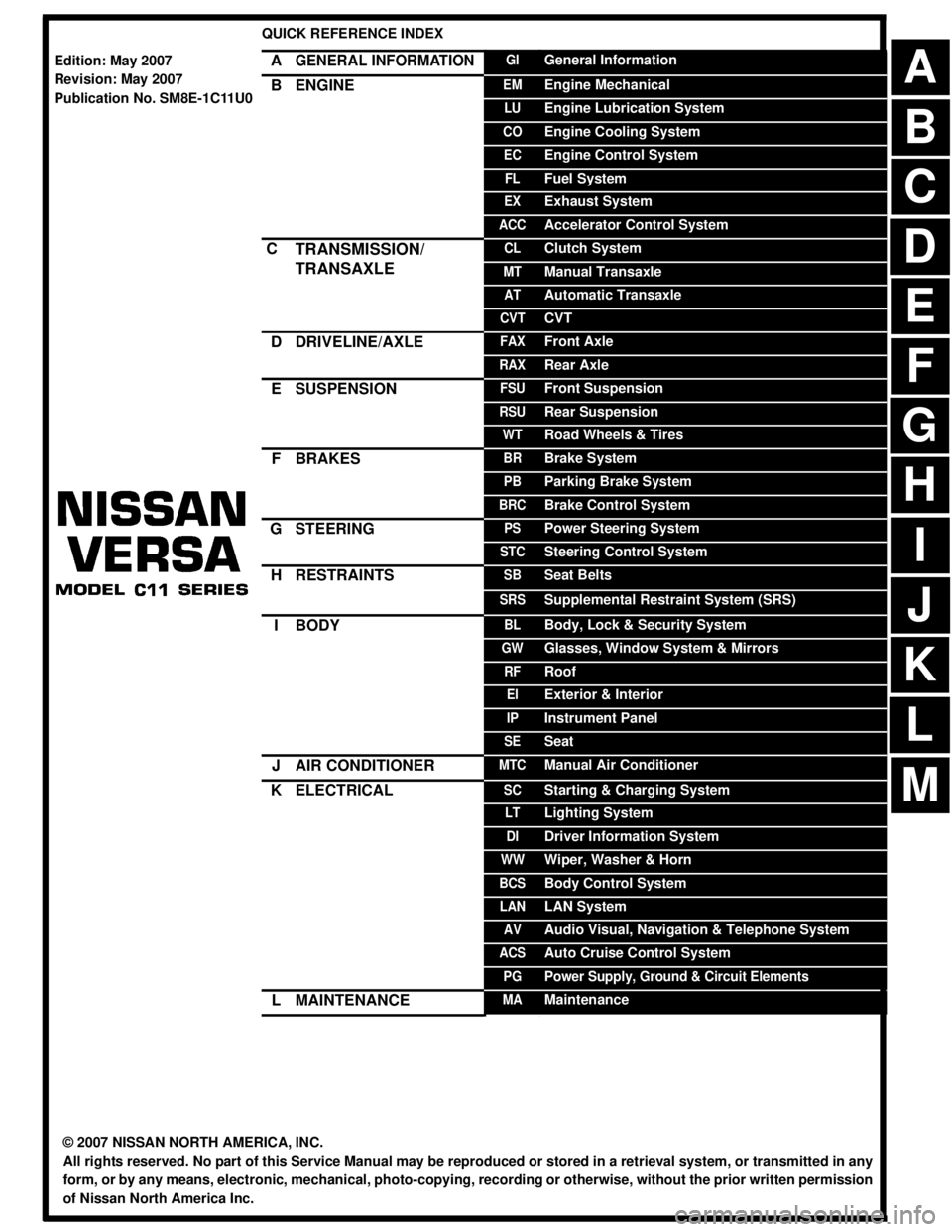

QUICK REFERENCE INDEX

AGENERAL INFORMATIONGIGeneral Information

BENGINEEMEngine Mechanical

LUEngine Lubrication System

COEngine Cooling System

ECEngine Control System

FLFuel System

EXExhaust System

ACCAccelerator Control System

CTRANSMISSION/

TRANSAXLECLClutch System

MTManual Transaxle

ATAutomatic Transaxle

CVTCVT

DDRIVELINE/AXLEFAXFront Axle

RAXRear Axle

ESUSPENSIONFSUFront Suspension

RSURear Suspension

WTRoad Wheels & Tires

FBRAKESBRBrake System

PBParking Brake System

BRCBrake Control System

GSTEERINGPSPower Steering System

STCSteering Control System

HRESTRAINTSSBSeat Belts

SRSSupplemental Restraint System (SRS)

IBODYBLBody, Lock & Security System

GWGlasses, Window System & Mirrors

RFRoof

EIExterior & Interior

IPInstrument Panel

SESeat

JAIR CONDITIONERMTCManual Air Conditioner

KELECTRICALSCStarting & Charging System

LTLighting System

DIDriver Information System

WWWiper, Washer & Horn

BCSBody Control System

LANLAN System

AVAudio Visual, Navigation & Telephone System

ACSAuto Cruise Control System

PGPower Supply, Ground & Circuit Elements

LMAINTENANCEMAMaintenance

Edition: May 2007

Revision: May 2007

Publication No. SM8E-1C11U0

B

D

© 2007 NISSAN NORTH AMERICA, INC.

All rights reserved. No part of this Service Manual may be reproduced or stored in a retrieval system, or transmitted in any

form, or by any means, electronic, mechanical, photo-copying, recording or otherwise, without the prior written permission

of Nissan North America Inc.

A

C

E

F

G

H

I

J

K

L

M

Page 8 of 2771

ACC-1

ENGINE

C

D

E

F

G

H

I

J

K

L

M

SECTION ACC

A

ACC

N

O

P

CONTENTS

ACCELERATOR CONTROL SYSTEM

SERVICE INFORMATION ............................2

PRECAUTIONS ...................................................2

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ...................................................................

2

ACCELERATOR CONTROL SYSTEM ..............3

Component ...............................................................3

Removal and Installation ..........................................3

Page 9 of 2771

ACC-2

< SERVICE INFORMATION >

PRECAUTIONS

SERVICE INFORMATION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000001703109

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and whether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SR and SB section of this Service Man-

ual.

WARNING:

• To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including incorrect removal and installation of the SRS, can lead to personal

injury caused by unintentional activation of the system. For removal of Spiral Cable and Air Bag

Module, see the SR section.

• Do not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identified by yellow and/or orange harnesses or har-

ness connectors.

Page 13 of 2771

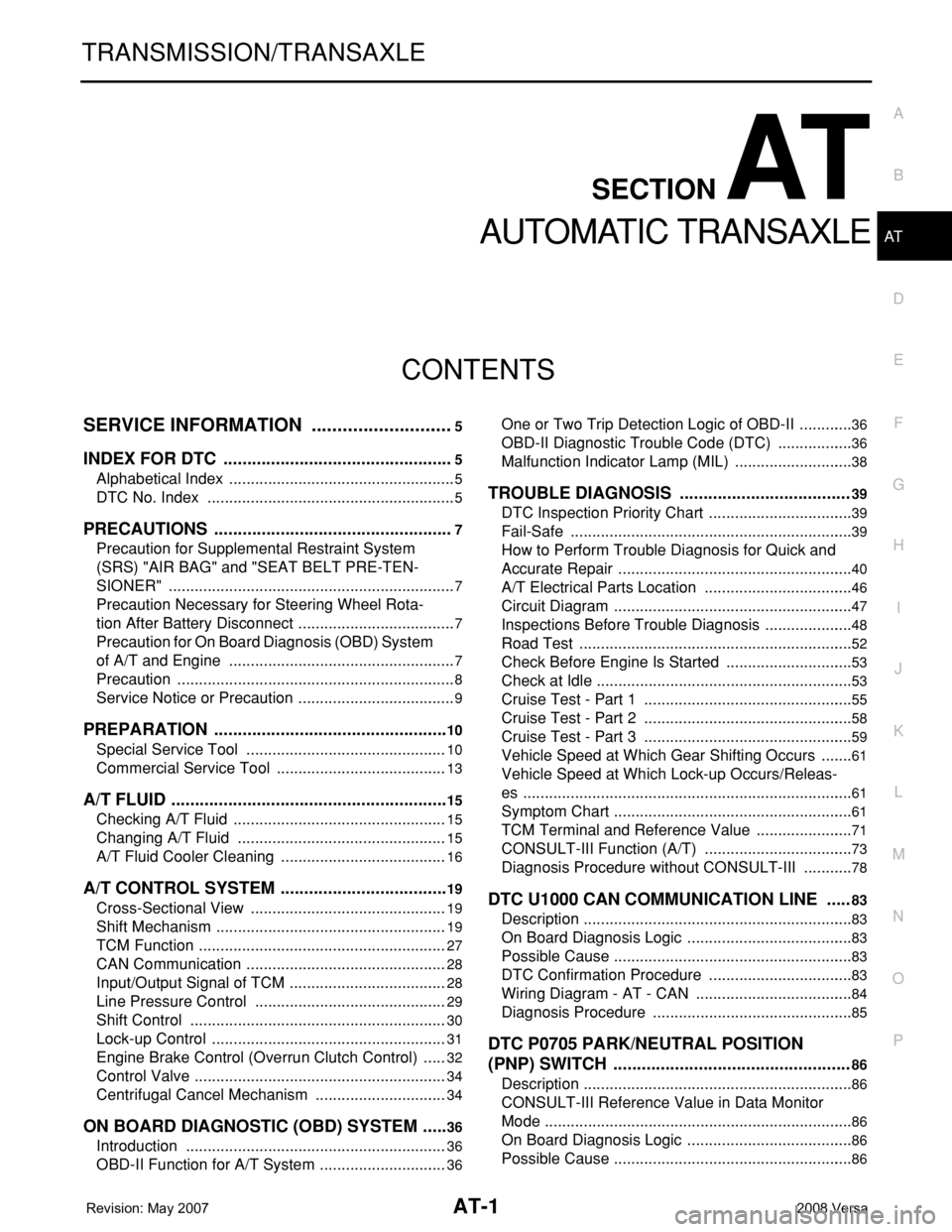

AT-1

TRANSMISSION/TRANSAXLE

D

E

F

G

H

I

J

K

L

M

SECTION AT

A

B

AT

N

O

P

CONTENTS

AUTOMATIC TRANSAXLE

SERVICE INFORMATION ............................5

INDEX FOR DTC .................................................5

Alphabetical Index .....................................................5

DTC No. Index ..........................................................5

PRECAUTIONS ...................................................7

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ...................................................................

7

Precaution Necessary for Steering Wheel Rota-

tion After Battery Disconnect .....................................

7

Precaution for On Board Diagnosis (OBD) System

of A/T and Engine .....................................................

7

Precaution .................................................................8

Service Notice or Precaution .....................................9

PREPARATION ..................................................10

Special Service Tool ...............................................10

Commercial Service Tool ........................................13

A/T FLUID ...........................................................15

Checking A/T Fluid ..................................................15

Changing A/T Fluid .................................................15

A/T Fluid Cooler Cleaning .......................................16

A/T CONTROL SYSTEM ....................................19

Cross-Sectional View ..............................................19

Shift Mechanism ......................................................19

TCM Function ..........................................................27

CAN Communication ...............................................28

Input/Output Signal of TCM .....................................28

Line Pressure Control .............................................29

Shift Control ............................................................30

Lock-up Control .......................................................31

Engine Brake Control (Overrun Clutch Control) ......32

Control Valve ...........................................................34

Centrifugal Cancel Mechanism ...............................34

ON BOARD DIAGNOSTIC (OBD) SYSTEM ......36

Introduction .............................................................36

OBD-II Function for A/T System ..............................36

One or Two Trip Detection Logic of OBD-II .............36

OBD-II Diagnostic Trouble Code (DTC) ..................36

Malfunction Indicator Lamp (MIL) ............................38

TROUBLE DIAGNOSIS ....................................39

DTC Inspection Priority Chart ..................................39

Fail-Safe ..................................................................39

How to Perform Trouble Diagnosis for Quick and

Accurate Repair .......................................................

40

A/T Electrical Parts Location ...................................46

Circuit Diagram ........................................................47

Inspections Before Trouble Diagnosis .....................48

Road Test ................................................................52

Check Before Engine Is Started ..............................53

Check at Idle ............................................................53

Cruise Test - Part 1 .................................................55

Cruise Test - Part 2 .................................................58

Cruise Test - Part 3 .................................................59

Vehicle Speed at Which Gear Shifting Occurs ........61

Vehicle Speed at Which Lock-up Occurs/Releas-

es .............................................................................

61

Symptom Chart ........................................................61

TCM Terminal and Reference Value .......................71

CONSULT-III Function (A/T) ...................................73

Diagnosis Procedure without CONSULT-III ............78

DTC U1000 CAN COMMUNICATION LINE .....83

Description ...............................................................83

On Board Diagnosis Logic .......................................83

Possible Cause ........................................................83

DTC Confirmation Procedure ..................................83

Wiring Diagram - AT - CAN .....................................84

Diagnosis Procedure ...............................................85

DTC P0705 PARK/NEUTRAL POSITION

(PNP) SWITCH ..................................................

86

Description ...............................................................86

CONSULT-III Reference Value in Data Monitor

Mode ........................................................................

86

On Board Diagnosis Logic .......................................86

Possible Cause ........................................................86

Page 19 of 2771

PRECAUTIONS

AT-7

< SERVICE INFORMATION >

D

E

F

G

H

I

J

K

L

MA

B

AT

N

O

P

PRECAUTIONS

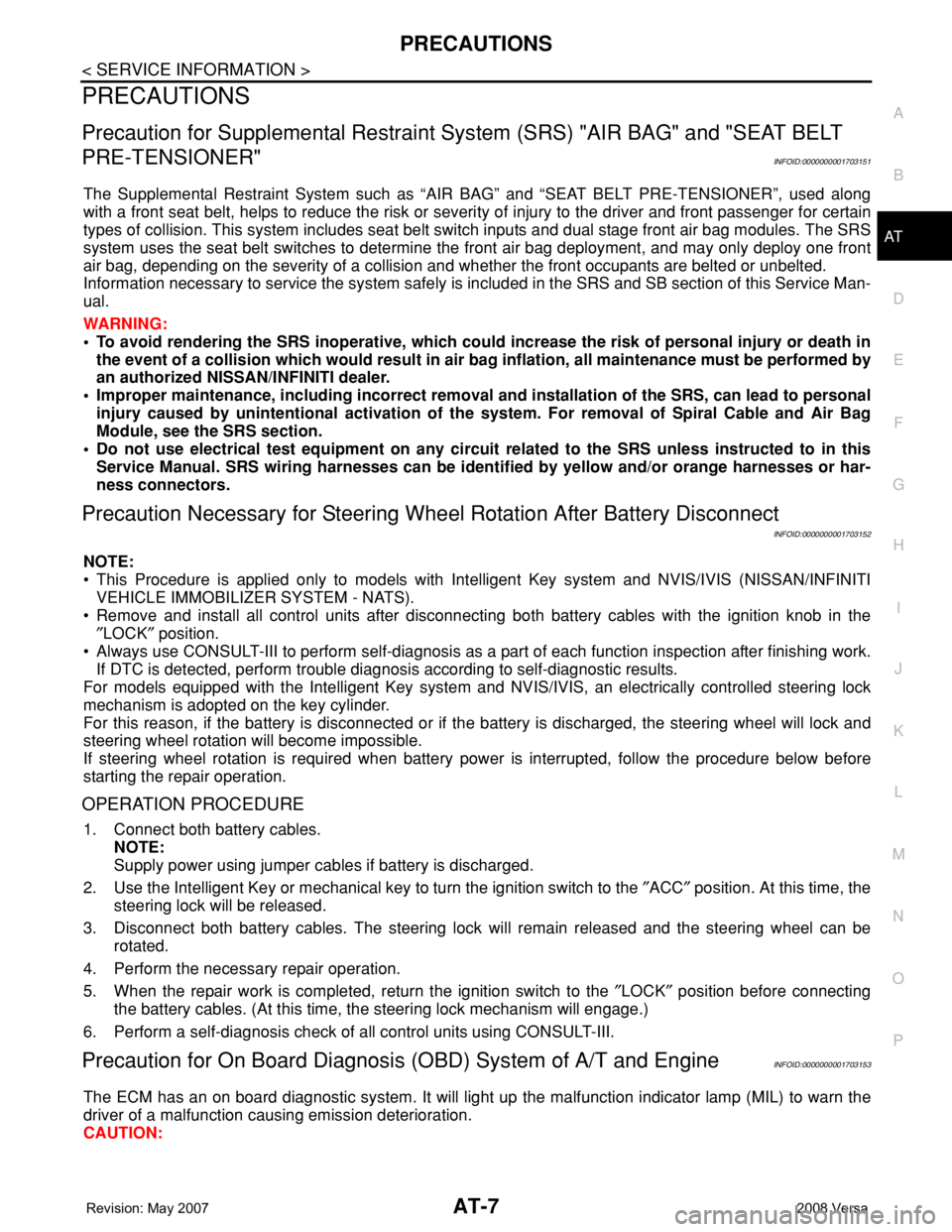

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000001703151

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and whether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SRS and SB section of this Service Man-

ual.

WARNING:

• To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including incorrect removal and installation of the SRS, can lead to personal

injury caused by unintentional activation of the system. For removal of Spiral Cable and Air Bag

Module, see the SRS section.

• Do not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identified by yellow and/or orange harnesses or har-

ness connectors.

Precaution Necessary for Steering Wheel Rotation After Battery Disconnect

INFOID:0000000001703152

NOTE:

• This Procedure is applied only to models with Intelligent Key system and NVIS/IVIS (NISSAN/INFINITI

VEHICLE IMMOBILIZER SYSTEM - NATS).

• Remove and install all control units after disconnecting both battery cables with the ignition knob in the

″LOCK″ position.

• Always use CONSULT-III to perform self-diagnosis as a part of each function inspection after finishing work.

If DTC is detected, perform trouble diagnosis according to self-diagnostic results.

For models equipped with the Intelligent Key system and NVIS/IVIS, an electrically controlled steering lock

mechanism is adopted on the key cylinder.

For this reason, if the battery is disconnected or if the battery is discharged, the steering wheel will lock and

steering wheel rotation will become impossible.

If steering wheel rotation is required when battery power is interrupted, follow the procedure below before

starting the repair operation.

OPERATION PROCEDURE

1. Connect both battery cables.

NOTE:

Supply power using jumper cables if battery is discharged.

2. Use the Intelligent Key or mechanical key to turn the ignition switch to the ″ACC″ position. At this time, the

steering lock will be released.

3. Disconnect both battery cables. The steering lock will remain released and the steering wheel can be

rotated.

4. Perform the necessary repair operation.

5. When the repair work is completed, return the ignition switch to the ″LOCK″ position before connecting

the battery cables. (At this time, the steering lock mechanism will engage.)

6. Perform a self-diagnosis check of all control units using CONSULT-III.

Precaution for On Board Diagnosis (OBD) System of A/T and EngineINFOID:0000000001703153

The ECM has an on board diagnostic system. It will light up the malfunction indicator lamp (MIL) to warn the

driver of a malfunction causing emission deterioration.

CAUTION:

Page 74 of 2771

AT-62

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS

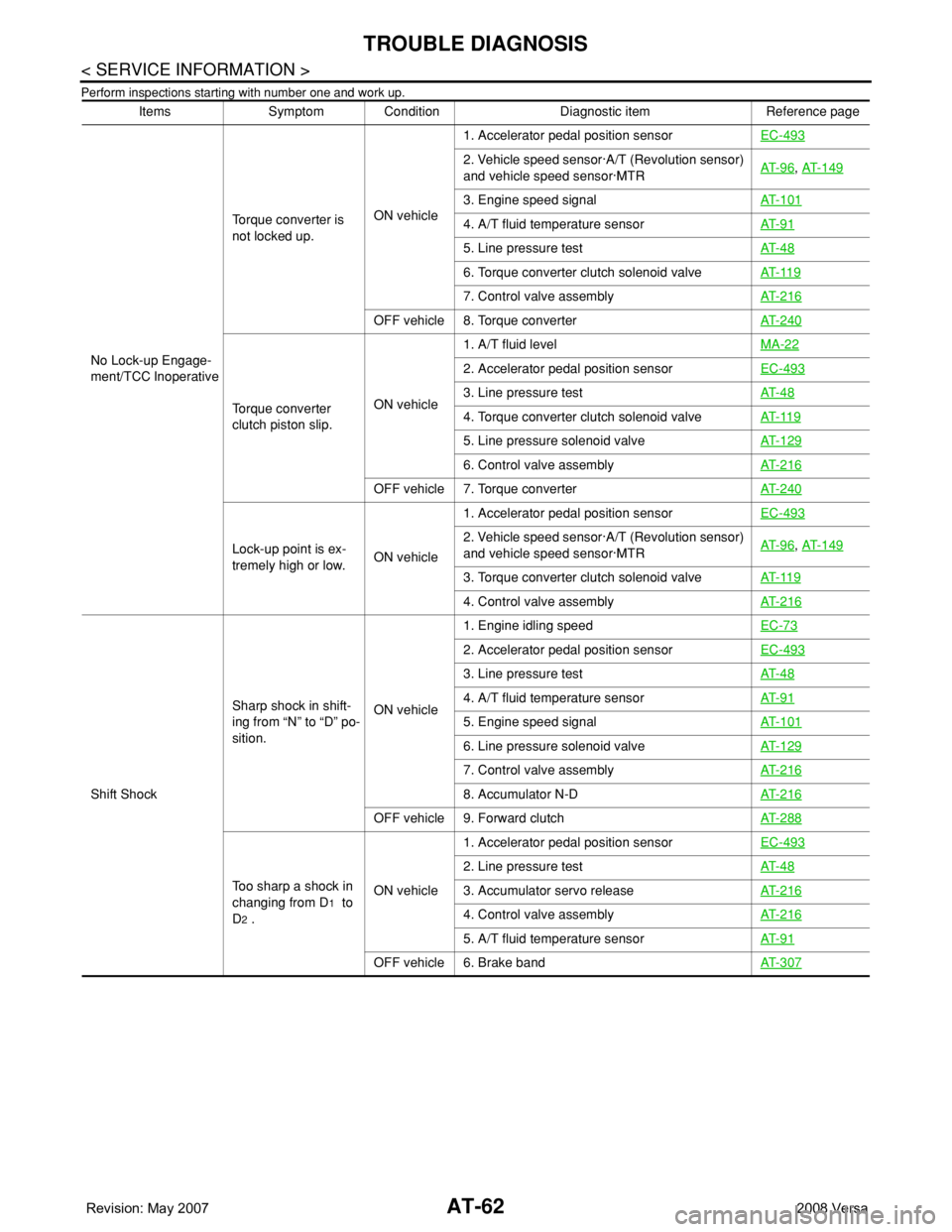

Perform inspections starting with number one and work up.

Items Symptom Condition Diagnostic item Reference page

No Lock-up Engage-

ment/TCC InoperativeTorque converter is

not locked up.ON vehicle1. Accelerator pedal position sensorEC-493

2. Vehicle speed sensor·A/T (Revolution sensor)

and vehicle speed sensor·MTRAT- 9 6, AT- 1 4 9

3. Engine speed signalAT- 1 0 1

4. A/T fluid temperature sensorAT- 9 1

5. Line pressure testAT- 4 8

6. Torque converter clutch solenoid valveAT- 11 9

7. Control valve assemblyAT- 2 1 6

OFF vehicle 8. Torque converterAT- 2 4 0

Torque converter

clutch piston slip.ON vehicle1. A/T fluid levelMA-22

2. Accelerator pedal position sensorEC-493

3. Line pressure testAT- 4 8

4. Torque converter clutch solenoid valveAT- 11 9

5. Line pressure solenoid valveAT- 1 2 9

6. Control valve assemblyAT- 2 1 6

OFF vehicle 7. Torque converterAT- 2 4 0

Lock-up point is ex-

tremely high or low.ON vehicle1. Accelerator pedal position sensorEC-4932. Vehicle speed sensor·A/T (Revolution sensor)

and vehicle speed sensor·MTRAT- 9 6, AT- 1 4 9

3. Torque converter clutch solenoid valveAT- 11 9

4. Control valve assemblyAT- 2 1 6

Shift ShockSharp shock in shift-

ing from “N” to “D” po-

sition.ON vehicle1. Engine idling speedEC-73

2. Accelerator pedal position sensorEC-493

3. Line pressure testAT- 4 8

4. A/T fluid temperature sensorAT- 9 1

5. Engine speed signalAT- 1 0 1

6. Line pressure solenoid valveAT- 1 2 9

7. Control valve assemblyAT- 2 1 6

8. Accumulator N-DAT- 2 1 6

OFF vehicle 9. Forward clutchAT- 2 8 8

Too sharp a shock in

changing from D

1 to

D

2 .ON vehicle1. Accelerator pedal position sensorEC-493

2. Line pressure testAT- 4 8

3. Accumulator servo releaseAT- 2 1 6

4. Control valve assemblyAT- 2 1 6

5. A/T fluid temperature sensorAT- 9 1

OFF vehicle 6. Brake bandAT- 3 0 7

Page 75 of 2771

TROUBLE DIAGNOSIS

AT-63

< SERVICE INFORMATION >

D

E

F

G

H

I

J

K

L

MA

B

AT

N

O

P

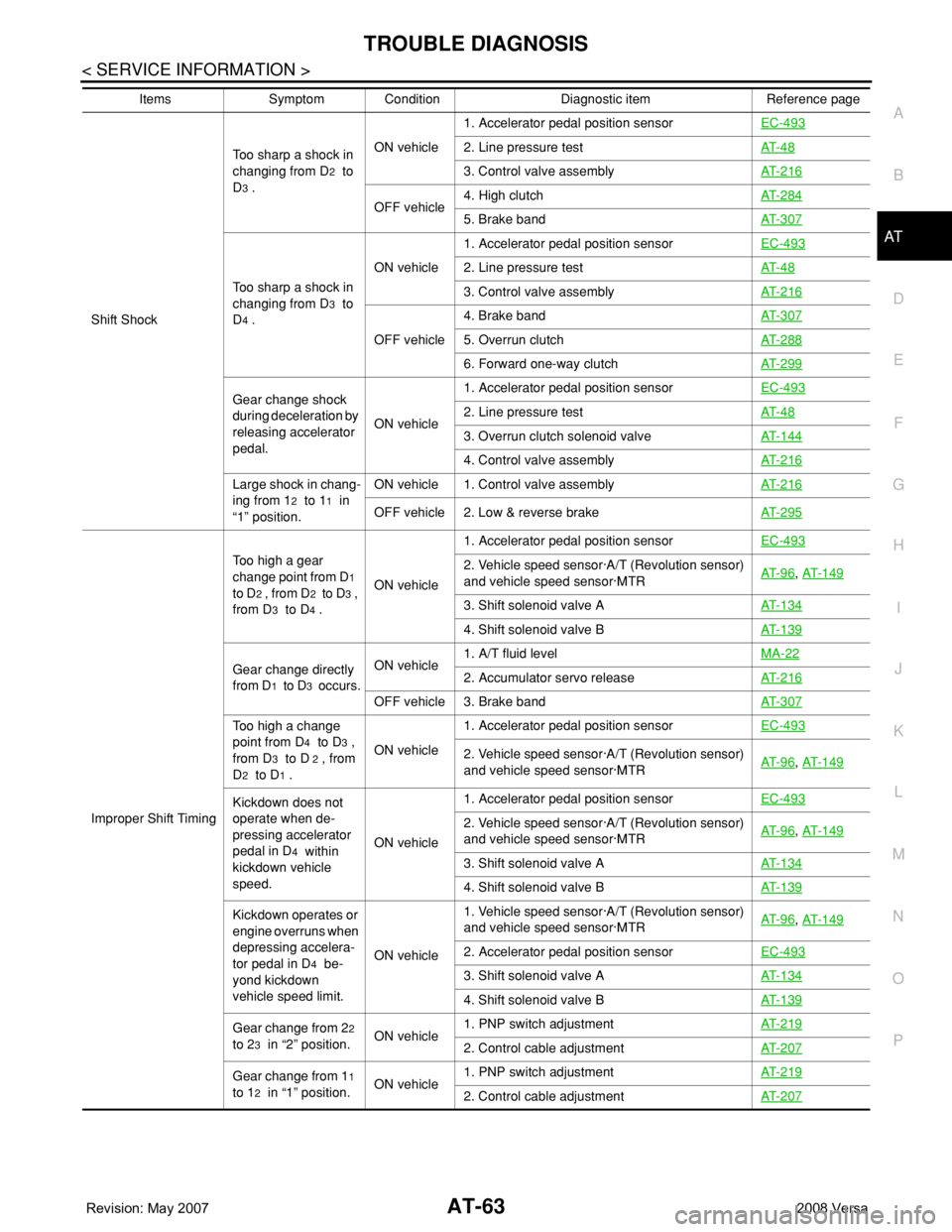

Shift ShockToo sharp a shock in

changing from D

2 to

D

3 .ON vehicle1. Accelerator pedal position sensorEC-493

2. Line pressure testAT- 4 8

3. Control valve assemblyAT- 2 1 6

OFF vehicle4. High clutchAT- 2 8 45. Brake bandAT- 3 0 7

Too sharp a shock in

changing from D

3 to

D

4 .ON vehicle1. Accelerator pedal position sensorEC-493

2. Line pressure testAT- 4 8

3. Control valve assemblyAT- 2 1 6

OFF vehicle4. Brake bandAT- 3 0 75. Overrun clutchAT- 2 8 8

6. Forward one-way clutchAT- 2 9 9

Gear change shock

during deceleration by

releasing accelerator

pedal.ON vehicle1. Accelerator pedal position sensorEC-4932. Line pressure testAT- 4 8

3. Overrun clutch solenoid valveAT- 1 4 4

4. Control valve assemblyAT- 2 1 6

Large shock in chang-

ing from 1

2 to 11 in

“1” position.ON vehicle 1. Control valve assemblyAT- 2 1 6OFF vehicle 2. Low & reverse brakeAT- 2 9 5

Improper Shift TimingToo high a gear

change point from D

1

to D

2 , from D2 to D3 ,

from D

3 to D4 .ON vehicle1. Accelerator pedal position sensorEC-493

2. Vehicle speed sensor·A/T (Revolution sensor)

and vehicle speed sensor·MTRAT- 9 6, AT- 1 4 9

3. Shift solenoid valve AAT- 1 3 4

4. Shift solenoid valve BAT- 1 3 9

Gear change directly

from D

1 to D3 occurs.ON vehicle1. A/T fluid levelMA-222. Accumulator servo releaseAT- 2 1 6

OFF vehicle 3. Brake bandAT- 3 0 7

Too high a change

point from D

4 to D3 ,

from D

3 to D 2 , from

D

2 to D1 .ON vehicle1. Accelerator pedal position sensorEC-493

2. Vehicle speed sensor·A/T (Revolution sensor)

and vehicle speed sensor·MTRAT- 9 6, AT- 1 4 9

Kickdown does not

operate when de-

pressing accelerator

pedal in D

4 within

kickdown vehicle

speed.ON vehicle1. Accelerator pedal position sensorEC-493

2. Vehicle speed sensor·A/T (Revolution sensor)

and vehicle speed sensor·MTRAT- 9 6, AT- 1 4 9

3. Shift solenoid valve AAT- 1 3 4

4. Shift solenoid valve BAT- 1 3 9

Kickdown operates or

engine overruns when

depressing accelera-

tor pedal in D

4 be-

yond kickdown

vehicle speed limit.ON vehicle1. Vehicle speed sensor·A/T (Revolution sensor)

and vehicle speed sensor·MTRAT- 9 6

, AT- 1 4 9

2. Accelerator pedal position sensorEC-493

3. Shift solenoid valve AAT- 1 3 4

4. Shift solenoid valve BAT- 1 3 9

Gear change from 22

to 2

3 in “2” position.ON vehicle1. PNP switch adjustmentAT- 2 1 92. Control cable adjustmentAT- 2 0 7

Gear change from 11

to 1

2 in “1” position.ON vehicle1. PNP switch adjustmentAT- 2 1 92. Control cable adjustmentAT- 2 0 7

Items Symptom Condition Diagnostic item Reference page

Page 79 of 2771

TROUBLE DIAGNOSIS

AT-67

< SERVICE INFORMATION >

D

E

F

G

H

I

J

K

L

MA

B

AT

N

O

P

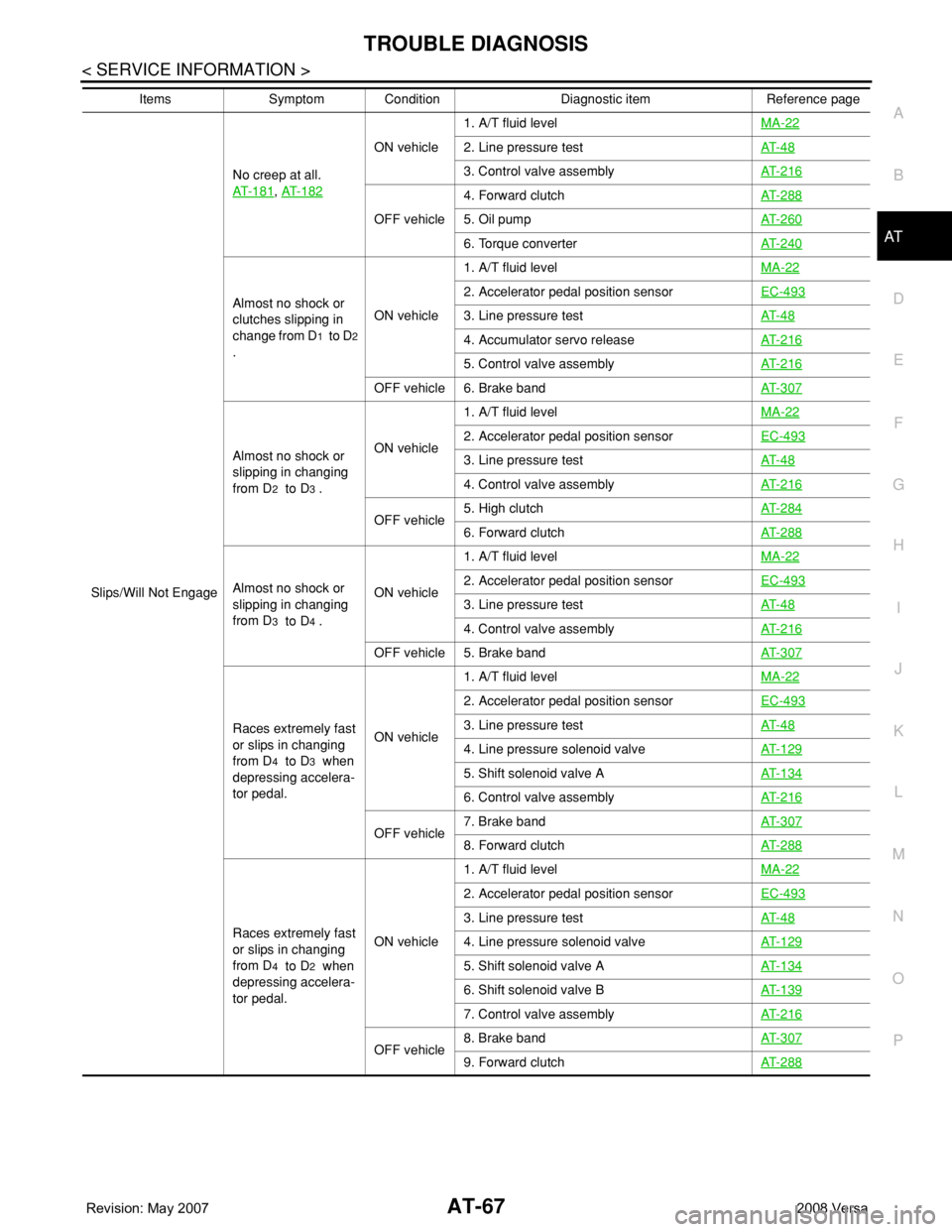

Slips/Will Not EngageNo creep at all.

AT- 1 8 1

, AT- 1 8 2

ON vehicle1. A/T fluid levelMA-222. Line pressure testAT- 4 8

3. Control valve assemblyAT- 2 1 6

OFF vehicle4. Forward clutchAT- 2 8 85. Oil pumpAT- 2 6 0

6. Torque converterAT- 2 4 0

Almost no shock or

clutches slipping in

change from D

1 to D2

.ON vehicle1. A/T fluid levelMA-22

2. Accelerator pedal position sensorEC-493

3. Line pressure testAT- 4 8

4. Accumulator servo releaseAT- 2 1 6

5. Control valve assemblyAT- 2 1 6

OFF vehicle 6. Brake bandAT- 3 0 7

Almost no shock or

slipping in changing

from D

2 to D3 .ON vehicle1. A/T fluid levelMA-22

2. Accelerator pedal position sensorEC-493

3. Line pressure testAT- 4 8

4. Control valve assemblyAT- 2 1 6

OFF vehicle5. High clutchAT- 2 8 46. Forward clutchAT- 2 8 8

Almost no shock or

slipping in changing

from D

3 to D4 .ON vehicle1. A/T fluid levelMA-22

2. Accelerator pedal position sensorEC-493

3. Line pressure testAT- 4 8

4. Control valve assemblyAT- 2 1 6

OFF vehicle 5. Brake bandAT- 3 0 7

Races extremely fast

or slips in changing

from D

4 to D3 when

depressing accelera-

tor pedal.ON vehicle1. A/T fluid levelMA-22

2. Accelerator pedal position sensorEC-493

3. Line pressure testAT- 4 8

4. Line pressure solenoid valveAT- 1 2 9

5. Shift solenoid valve AAT- 1 3 4

6. Control valve assemblyAT- 2 1 6

OFF vehicle7. Brake bandAT- 3 0 78. Forward clutchAT- 2 8 8

Races extremely fast

or slips in changing

from D

4 to D2 when

depressing accelera-

tor pedal.ON vehicle1. A/T fluid levelMA-22

2. Accelerator pedal position sensorEC-493

3. Line pressure testAT- 4 8

4. Line pressure solenoid valveAT- 1 2 9

5. Shift solenoid valve AAT- 1 3 4

6. Shift solenoid valve BAT- 1 3 9

7. Control valve assemblyAT- 2 1 6

OFF vehicle8. Brake bandAT- 3 0 79. Forward clutchAT- 2 8 8

Items Symptom Condition Diagnostic item Reference page

Page 289 of 2771

REPAIR FOR COMPONENT PARTS

AT-277

< SERVICE INFORMATION >

D

E

F

G

H

I

J

K

L

MA

B

AT

N

O

P

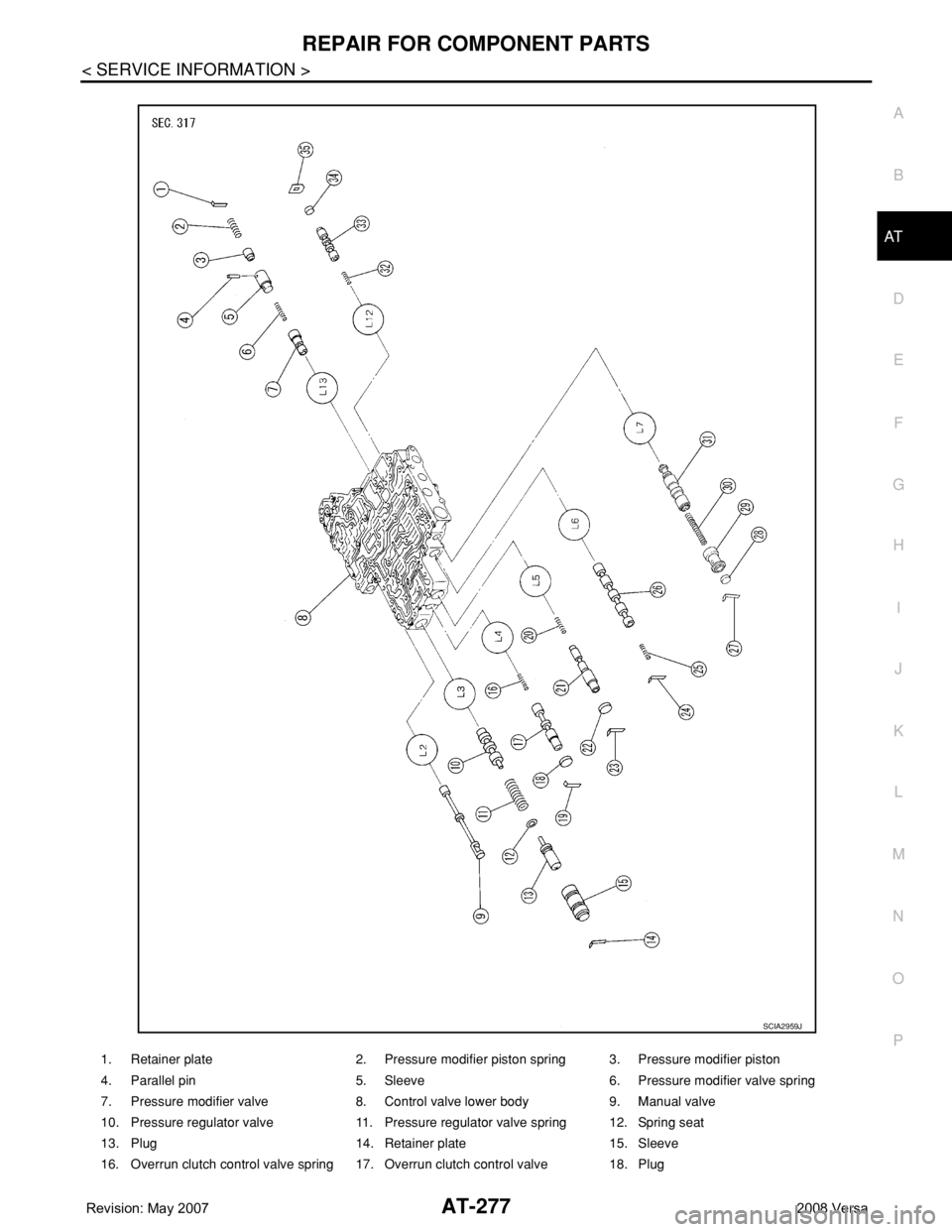

1. Retainer plate 2. Pressure modifier piston spring 3. Pressure modifier piston

4. Parallel pin 5. Sleeve 6. Pressure modifier valve spring

7. Pressure modifier valve 8. Control valve lower body 9. Manual valve

10. Pressure regulator valve 11. Pressure regulator valve spring 12. Spring seat

13. Plug 14. Retainer plate 15. Sleeve

16. Overrun clutch control valve spring 17. Overrun clutch control valve 18. Plug

SCIA2959J

Page 332 of 2771

AT-320

< SERVICE INFORMATION >

ASSEMBLY

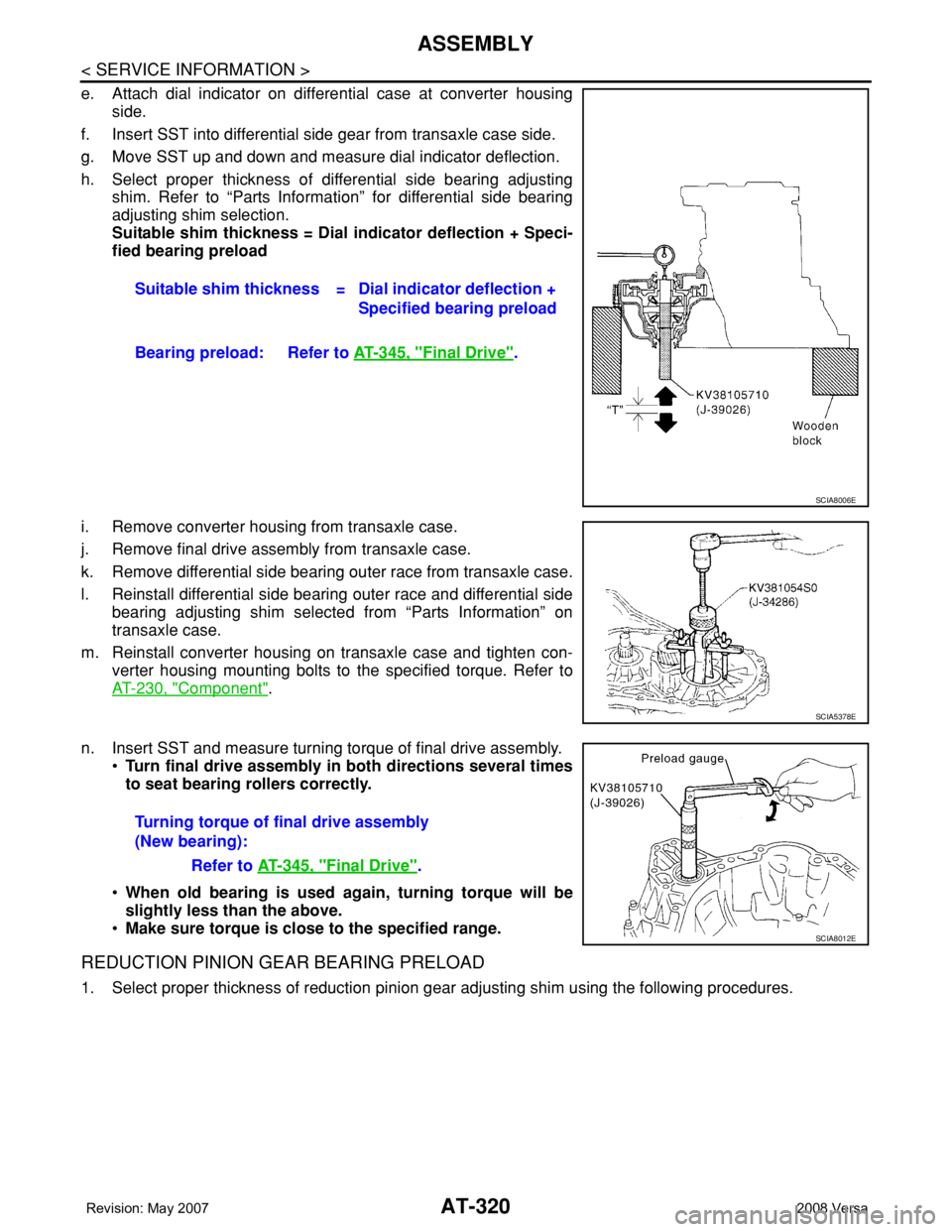

e. Attach dial indicator on differential case at converter housing

side.

f. Insert SST into differential side gear from transaxle case side.

g. Move SST up and down and measure dial indicator deflection.

h. Select proper thickness of differential side bearing adjusting

shim. Refer to “Parts Information” for differential side bearing

adjusting shim selection.

Suitable shim thickness = Dial indicator deflection + Speci-

fied bearing preload

i. Remove converter housing from transaxle case.

j. Remove final drive assembly from transaxle case.

k. Remove differential side bearing outer race from transaxle case.

l. Reinstall differential side bearing outer race and differential side

bearing adjusting shim selected from “Parts Information” on

transaxle case.

m. Reinstall converter housing on transaxle case and tighten con-

verter housing mounting bolts to the specified torque. Refer to

AT-230, "

Component".

n. Insert SST and measure turning torque of final drive assembly.

•Turn final drive assembly in both directions several times

to seat bearing rollers correctly.

•When old bearing is used again, turning torque will be

slightly less than the above.

•Make sure torque is close to the specified range.

REDUCTION PINION GEAR BEARING PRELOAD

1. Select proper thickness of reduction pinion gear adjusting shim using the following procedures.Suitable shim thickness = Dial indicator deflection +

Specified bearing preload

Bearing preload: Refer to AT-345, "

Final Drive".

SCIA8006E

SCIA5378E

Turning torque of final drive assembly

(New bearing):

Refer to AT-345, "

Final Drive".

SCIA8012E