brakes NISSAN TIIDA 2008 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2008, Model line: TIIDA, Model: NISSAN TIIDA 2008Pages: 2771, PDF Size: 60.61 MB

Page 1 of 2771

-1

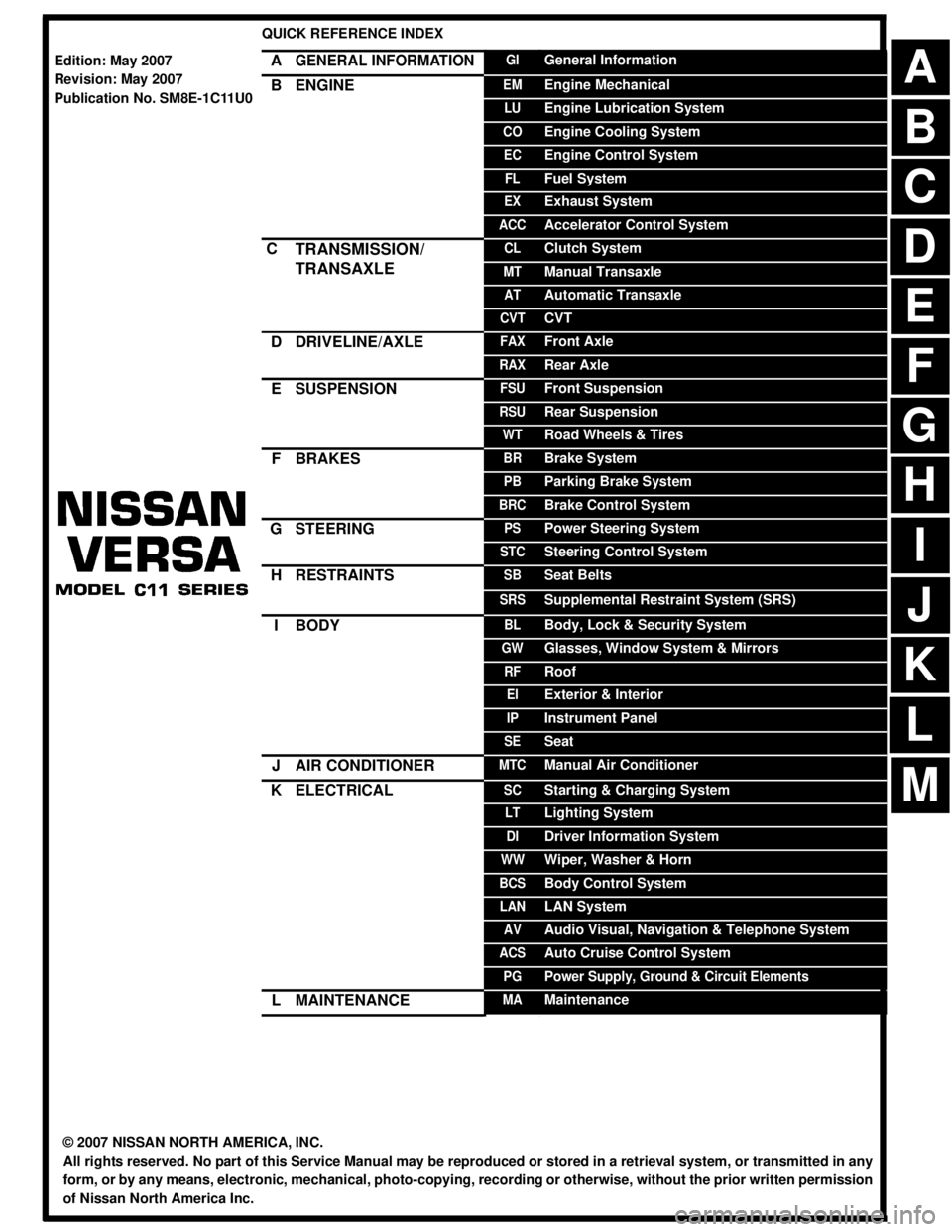

QUICK REFERENCE INDEX

AGENERAL INFORMATIONGIGeneral Information

BENGINEEMEngine Mechanical

LUEngine Lubrication System

COEngine Cooling System

ECEngine Control System

FLFuel System

EXExhaust System

ACCAccelerator Control System

CTRANSMISSION/

TRANSAXLECLClutch System

MTManual Transaxle

ATAutomatic Transaxle

CVTCVT

DDRIVELINE/AXLEFAXFront Axle

RAXRear Axle

ESUSPENSIONFSUFront Suspension

RSURear Suspension

WTRoad Wheels & Tires

FBRAKESBRBrake System

PBParking Brake System

BRCBrake Control System

GSTEERINGPSPower Steering System

STCSteering Control System

HRESTRAINTSSBSeat Belts

SRSSupplemental Restraint System (SRS)

IBODYBLBody, Lock & Security System

GWGlasses, Window System & Mirrors

RFRoof

EIExterior & Interior

IPInstrument Panel

SESeat

JAIR CONDITIONERMTCManual Air Conditioner

KELECTRICALSCStarting & Charging System

LTLighting System

DIDriver Information System

WWWiper, Washer & Horn

BCSBody Control System

LANLAN System

AVAudio Visual, Navigation & Telephone System

ACSAuto Cruise Control System

PGPower Supply, Ground & Circuit Elements

LMAINTENANCEMAMaintenance

Edition: May 2007

Revision: May 2007

Publication No. SM8E-1C11U0

B

D

© 2007 NISSAN NORTH AMERICA, INC.

All rights reserved. No part of this Service Manual may be reproduced or stored in a retrieval system, or transmitted in any

form, or by any means, electronic, mechanical, photo-copying, recording or otherwise, without the prior written permission

of Nissan North America Inc.

A

C

E

F

G

H

I

J

K

L

M

Page 16 of 2771

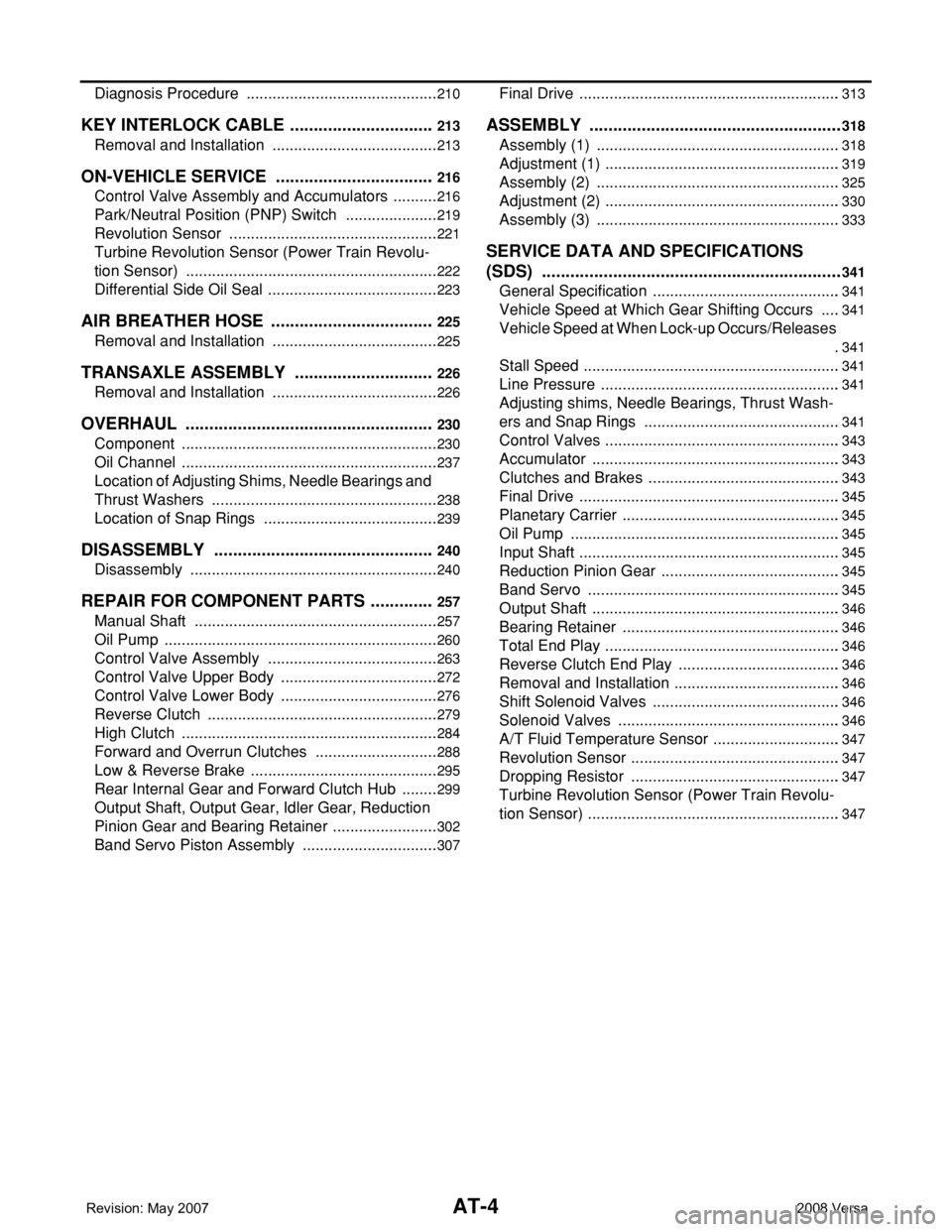

AT-4

Diagnosis Procedure .............................................210

KEY INTERLOCK CABLE ...............................213

Removal and Installation .......................................213

ON-VEHICLE SERVICE ..................................216

Control Valve Assembly and Accumulators ...........216

Park/Neutral Position (PNP) Switch ......................219

Revolution Sensor .................................................221

Turbine Revolution Sensor (Power Train Revolu-

tion Sensor) ...........................................................

222

Differential Side Oil Seal ........................................223

AIR BREATHER HOSE ...................................225

Removal and Installation .......................................225

TRANSAXLE ASSEMBLY ..............................226

Removal and Installation .......................................226

OVERHAUL .....................................................230

Component ............................................................230

Oil Channel ............................................................237

Location of Adjusting Shims, Needle Bearings and

Thrust Washers .....................................................

238

Location of Snap Rings .........................................239

DISASSEMBLY ...............................................240

Disassembly ..........................................................240

REPAIR FOR COMPONENT PARTS ..............257

Manual Shaft .........................................................257

Oil Pump ................................................................260

Control Valve Assembly ........................................263

Control Valve Upper Body .....................................272

Control Valve Lower Body .....................................276

Reverse Clutch ......................................................279

High Clutch ............................................................284

Forward and Overrun Clutches .............................288

Low & Reverse Brake ............................................295

Rear Internal Gear and Forward Clutch Hub .........299

Output Shaft, Output Gear, Idler Gear, Reduction

Pinion Gear and Bearing Retainer .........................

302

Band Servo Piston Assembly ................................307

Final Drive .............................................................313

ASSEMBLY ......................................................318

Assembly (1) .........................................................318

Adjustment (1) .......................................................319

Assembly (2) .........................................................325

Adjustment (2) .......................................................330

Assembly (3) .........................................................333

SERVICE DATA AND SPECIFICATIONS

(SDS) ................................................................

341

General Specification ............................................341

Vehicle Speed at Which Gear Shifting Occurs .....341

Vehicle Speed at When Lock-up Occurs/Releases

.

341

Stall Speed ............................................................341

Line Pressure ........................................................341

Adjusting shims, Needle Bearings, Thrust Wash-

ers and Snap Rings ..............................................

341

Control Valves .......................................................343

Accumulator ..........................................................343

Clutches and Brakes .............................................343

Final Drive .............................................................345

Planetary Carrier ...................................................345

Oil Pump ...............................................................345

Input Shaft .............................................................345

Reduction Pinion Gear ..........................................345

Band Servo ...........................................................345

Output Shaft ..........................................................346

Bearing Retainer ...................................................346

Total End Play .......................................................346

Reverse Clutch End Play ......................................346

Removal and Installation .......................................346

Shift Solenoid Valves ............................................346

Solenoid Valves ....................................................346

A/T Fluid Temperature Sensor ..............................347

Revolution Sensor .................................................347

Dropping Resistor .................................................347

Turbine Revolution Sensor (Power Train Revolu-

tion Sensor) ...........................................................

347

Page 55 of 2771

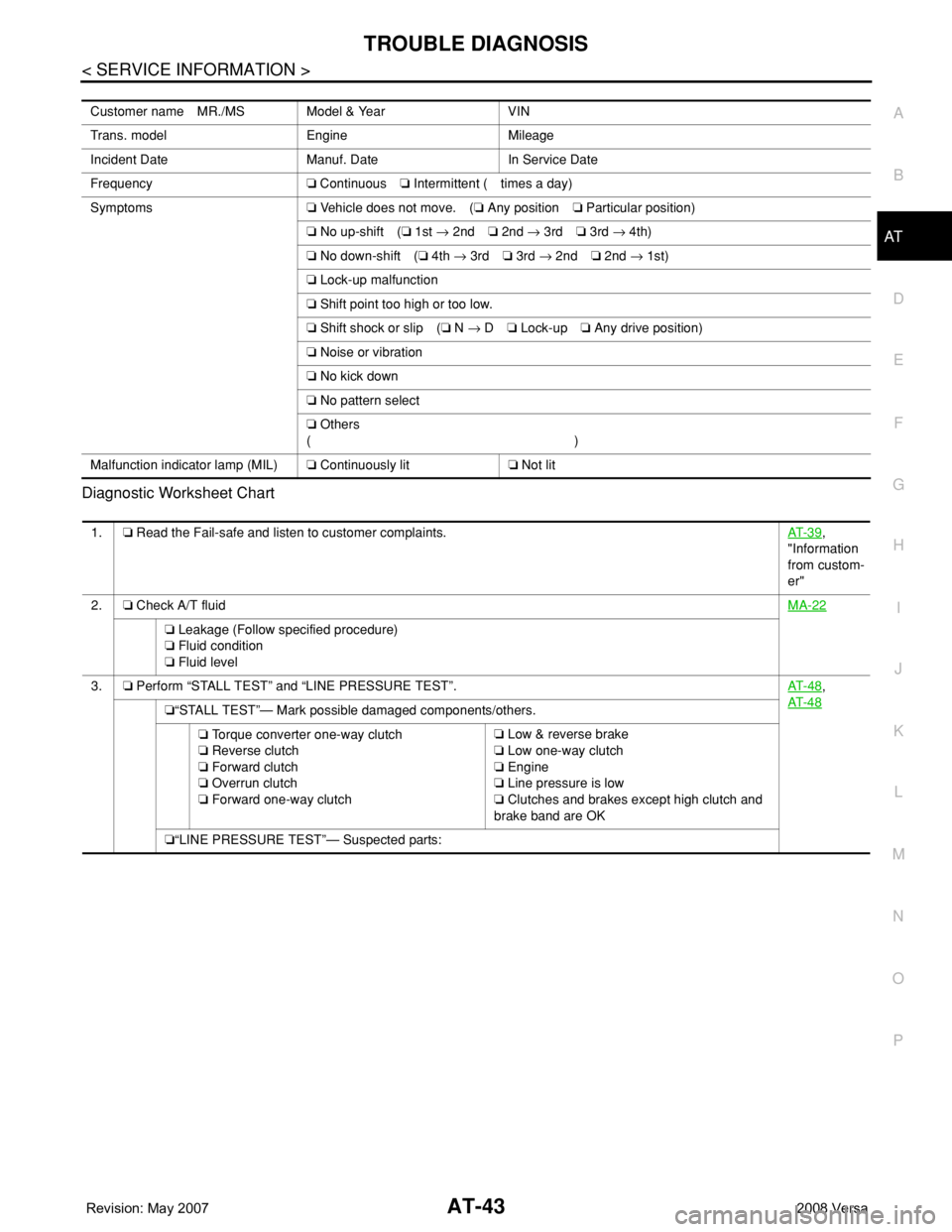

TROUBLE DIAGNOSIS

AT-43

< SERVICE INFORMATION >

D

E

F

G

H

I

J

K

L

MA

B

AT

N

O

P Diagnostic Worksheet Chart

Customer name MR./MS Model & Year VIN

Trans. model Engine Mileage

Incident Date Manuf. Date In Service Date

Frequency❏ Continuous❏ Intermittent ( times a day)

Symptoms❏ Vehicle does not move. (❏ Any position❏ Particular position)

❏ No up-shift (❏ 1st → 2nd❏ 2nd → 3rd❏ 3rd → 4th)

❏ No down-shift (❏ 4th → 3rd❏ 3rd → 2nd❏ 2nd → 1st)

❏ Lock-up malfunction

❏ Shift point too high or too low.

❏ Shift shock or slip (❏ N → D❏ Lock-up❏ Any drive position)

❏ Noise or vibration

❏ No kick down

❏ No pattern select

❏ Others

()

Malfunction indicator lamp (MIL)❏ Continuously lit❏ Not lit

1.❏ Read the Fail-safe and listen to customer complaints.AT- 3 9,

"Information

from custom-

er"

2.❏ Check A/T fluidMA-22

❏ Leakage (Follow specified procedure)

❏ Fluid condition

❏ Fluid level

3.❏ Perform “STALL TEST” and “LINE PRESSURE TEST”.AT- 4 8

,

AT- 4 8

❏“STALL TEST”— Mark possible damaged components/others.

❏ Torque converter one-way clutch

❏ Reverse clutch

❏ Forward clutch

❏ Overrun clutch

❏ Forward one-way clutch❏ Low & reverse brake

❏ Low one-way clutch

❏ Engine

❏ Line pressure is low

❏ Clutches and brakes except high clutch and

brake band are OK

❏“LINE PRESSURE TEST”— Suspected parts:

Page 78 of 2771

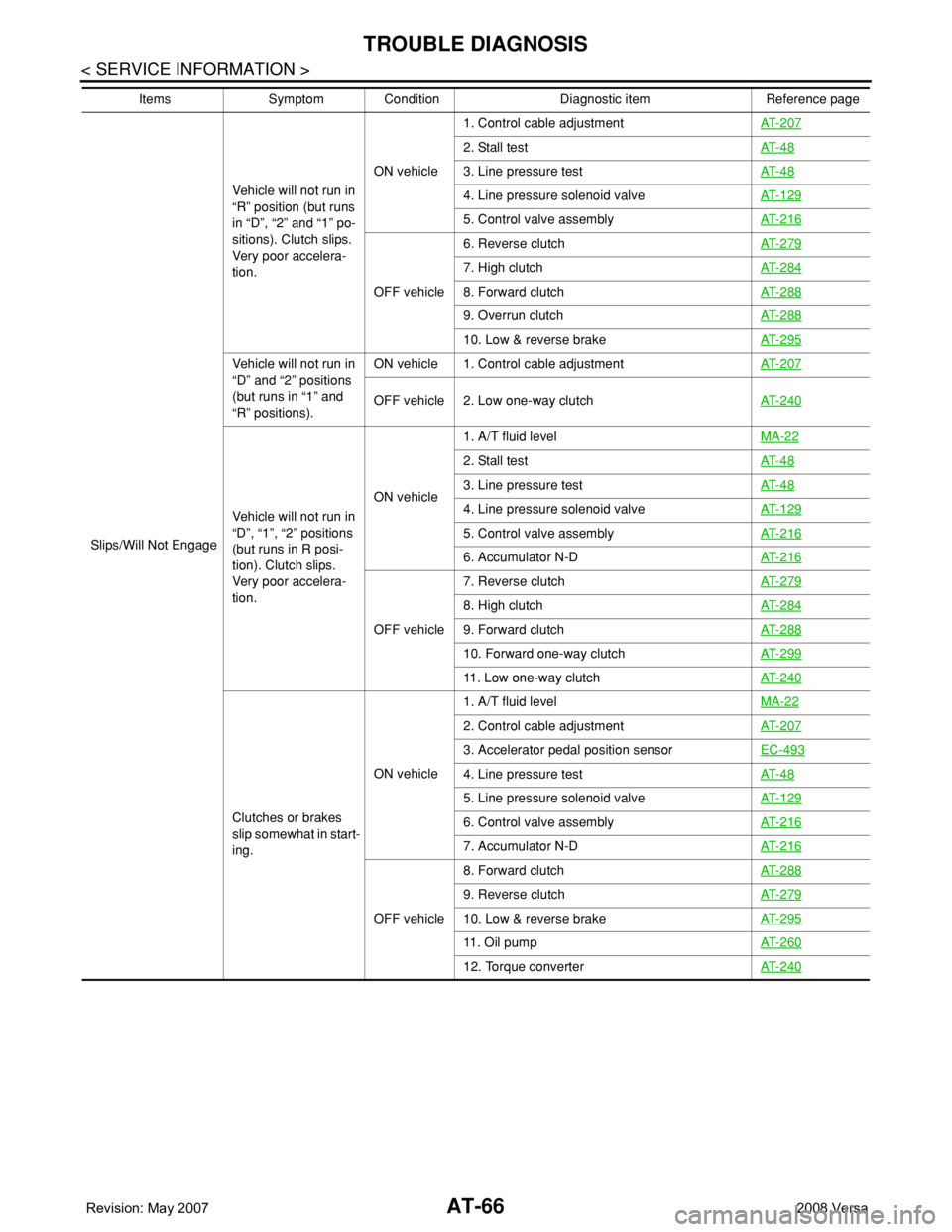

AT-66

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS

Slips/Will Not EngageVehicle will not run in

“R” position (but runs

in “D”, “2” and “1” po-

sitions). Clutch slips.

Very poor accelera-

tion.ON vehicle1. Control cable adjustmentAT- 2 0 7

2. Stall testAT- 4 8

3. Line pressure testAT- 4 8

4. Line pressure solenoid valveAT- 1 2 9

5. Control valve assemblyAT- 2 1 6

OFF vehicle6. Reverse clutchAT- 2 7 9

7. High clutchAT- 2 8 4

8. Forward clutchAT- 2 8 8

9. Overrun clutchAT- 2 8 8

10. Low & reverse brakeAT- 2 9 5

Vehicle will not run in

“D” and “2” positions

(but runs in “1” and

“R” positions).ON vehicle 1. Control cable adjustmentAT- 2 0 7

OFF vehicle 2. Low one-way clutchAT- 2 4 0

Vehicle will not run in

“D”, “1”, “2” positions

(but runs in R posi-

tion). Clutch slips.

Very poor accelera-

tion.ON vehicle1. A/T fluid levelMA-22

2. Stall testAT- 4 8

3. Line pressure testAT- 4 8

4. Line pressure solenoid valveAT- 1 2 9

5. Control valve assemblyAT- 2 1 6

6. Accumulator N-DAT- 2 1 6

OFF vehicle7. Reverse clutchAT- 2 7 9

8. High clutchAT- 2 8 4

9. Forward clutchAT- 2 8 8

10. Forward one-way clutchAT- 2 9 9

11. Low one-way clutchAT- 2 4 0

Clutches or brakes

slip somewhat in start-

ing.ON vehicle1. A/T fluid levelMA-22

2. Control cable adjustmentAT- 2 0 7

3. Accelerator pedal position sensorEC-493

4. Line pressure testAT- 4 8

5. Line pressure solenoid valveAT- 1 2 9

6. Control valve assemblyAT- 2 1 6

7. Accumulator N-DAT- 2 1 6

OFF vehicle8. Forward clutchAT- 2 8 8

9. Reverse clutchAT- 2 7 9

10. Low & reverse brakeAT- 2 9 5

11 . O i l p u m pAT- 2 6 0

12. Torque converterAT- 2 4 0

Items Symptom Condition Diagnostic item Reference page

Page 293 of 2771

REPAIR FOR COMPONENT PARTS

AT-281

< SERVICE INFORMATION >

D

E

F

G

H

I

J

K

L

MA

B

AT

N

O

P

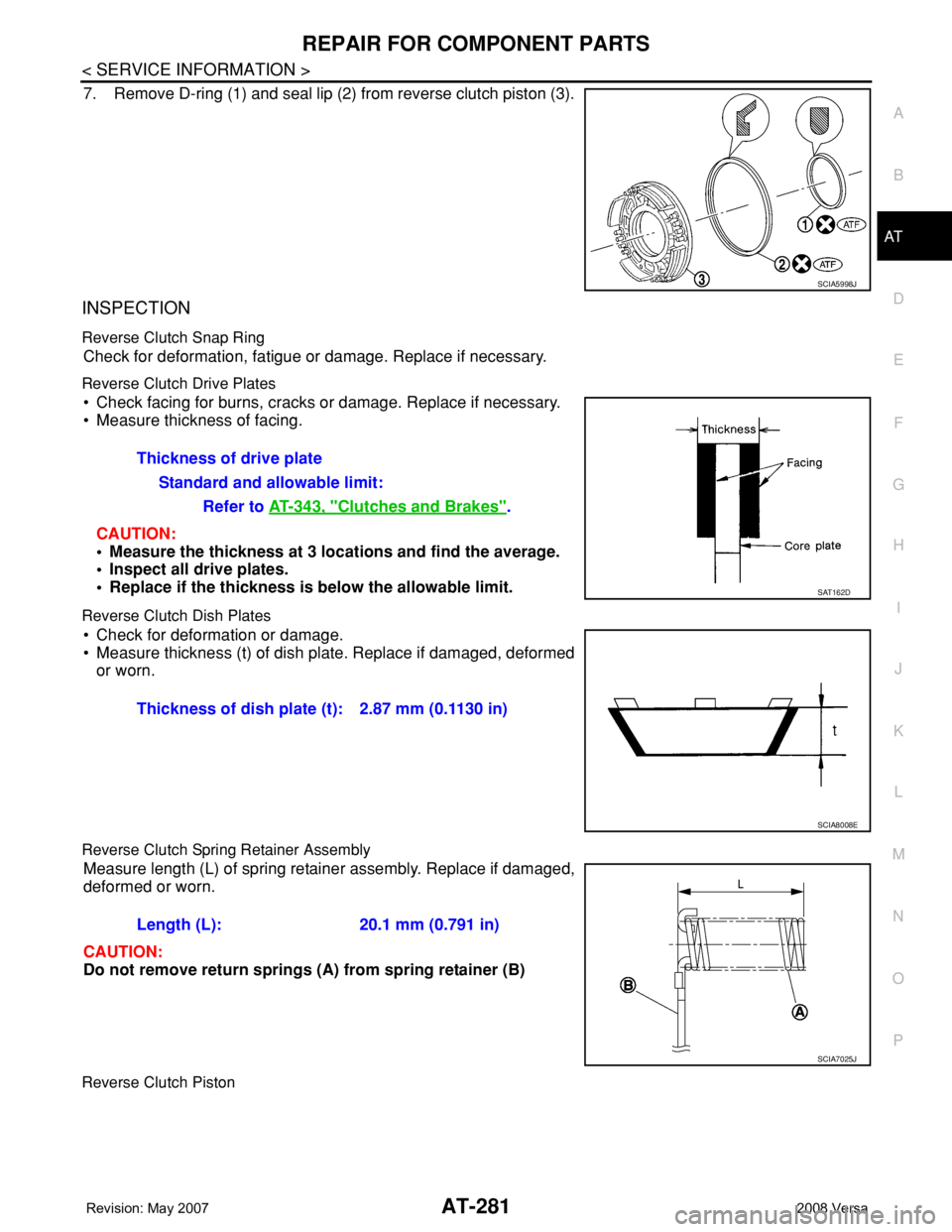

7. Remove D-ring (1) and seal lip (2) from reverse clutch piston (3).

INSPECTION

Reverse Clutch Snap Ring

Check for deformation, fatigue or damage. Replace if necessary.

Reverse Clutch Drive Plates

• Check facing for burns, cracks or damage. Replace if necessary.

• Measure thickness of facing.

CAUTION:

• Measure the thickness at 3 locations and find the average.

• Inspect all drive plates.

• Replace if the thickness is below the allowable limit.

Reverse Clutch Dish Plates

• Check for deformation or damage.

• Measure thickness (t) of dish plate. Replace if damaged, deformed

or worn.

Reverse Clutch Spring Retainer Assembly

Measure length (L) of spring retainer assembly. Replace if damaged,

deformed or worn.

CAUTION:

Do not remove return springs (A) from spring retainer (B)

Reverse Clutch Piston

SCIA5998J

Thickness of drive plate

Standard and allowable limit:

Refer to AT-343, "

Clutches and Brakes".

SAT162D

Thickness of dish plate (t): 2.87 mm (0.1130 in)

SCIA8008E

Length (L): 20.1 mm (0.791 in)

SCIA7025J

Page 296 of 2771

AT-284

< SERVICE INFORMATION >

REPAIR FOR COMPONENT PARTS

7. Measure clearance between retaining plate and snap ring using

feeler gauge. If not within allowable limit, select proper retaining

plate. Refer to “Parts Information” for retaining plate selection.

8. Check operation of reverse clutch. Refer to "DISASSEMBLY".

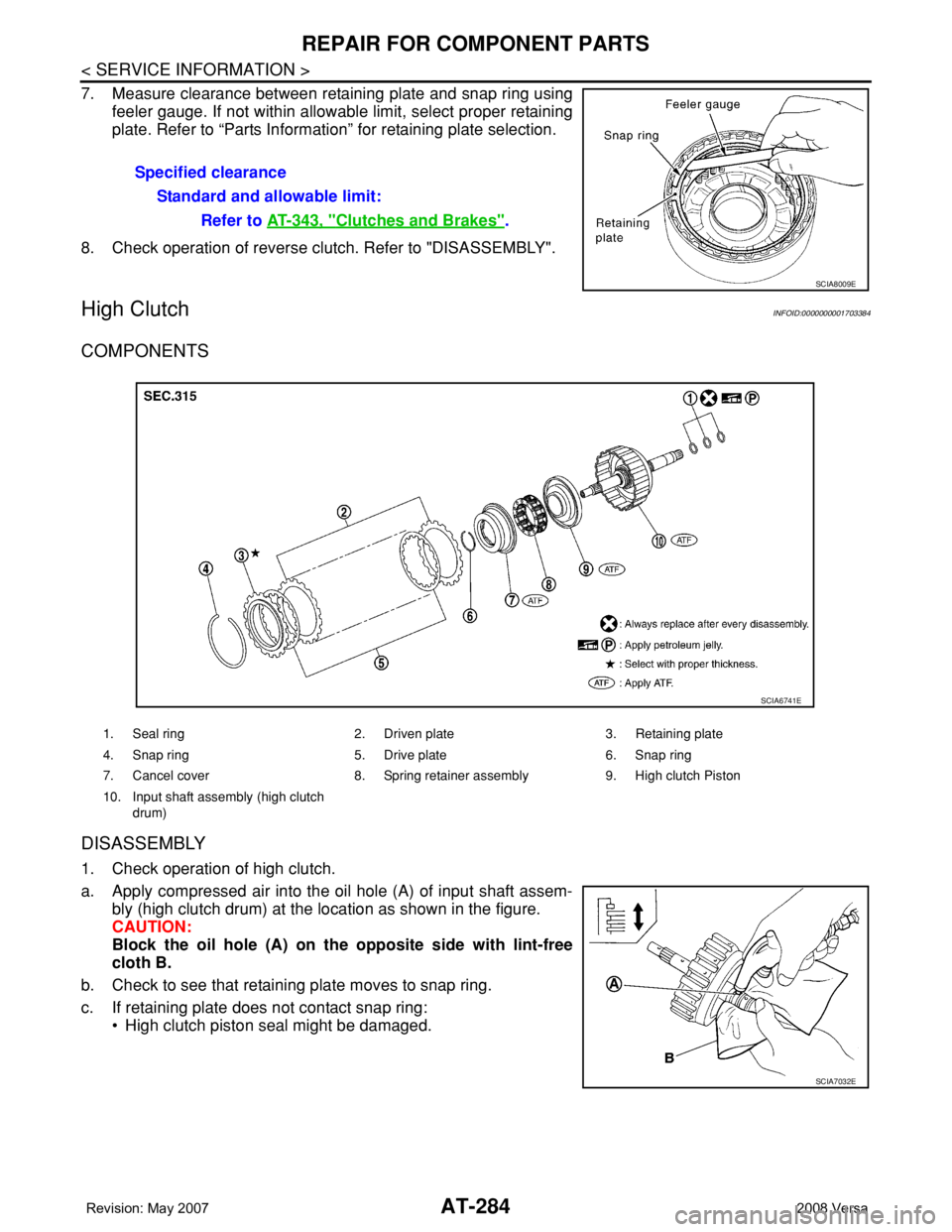

High ClutchINFOID:0000000001703384

COMPONENTS

DISASSEMBLY

1. Check operation of high clutch.

a. Apply compressed air into the oil hole (A) of input shaft assem-

bly (high clutch drum) at the location as shown in the figure.

CAUTION:

Block the oil hole (A) on the opposite side with lint-free

cloth B.

b. Check to see that retaining plate moves to snap ring.

c. If retaining plate does not contact snap ring:

• High clutch piston seal might be damaged.Specified clearance

Standard and allowable limit:

Refer to AT-343, "

Clutches and Brakes".

SCIA8009E

1. Seal ring 2. Driven plate 3. Retaining plate

4. Snap ring 5. Drive plate 6. Snap ring

7. Cancel cover 8. Spring retainer assembly 9. High clutch Piston

10. Input shaft assembly (high clutch

drum)

SCIA6741E

SCIA7032E

Page 298 of 2771

AT-286

< SERVICE INFORMATION >

REPAIR FOR COMPONENT PARTS

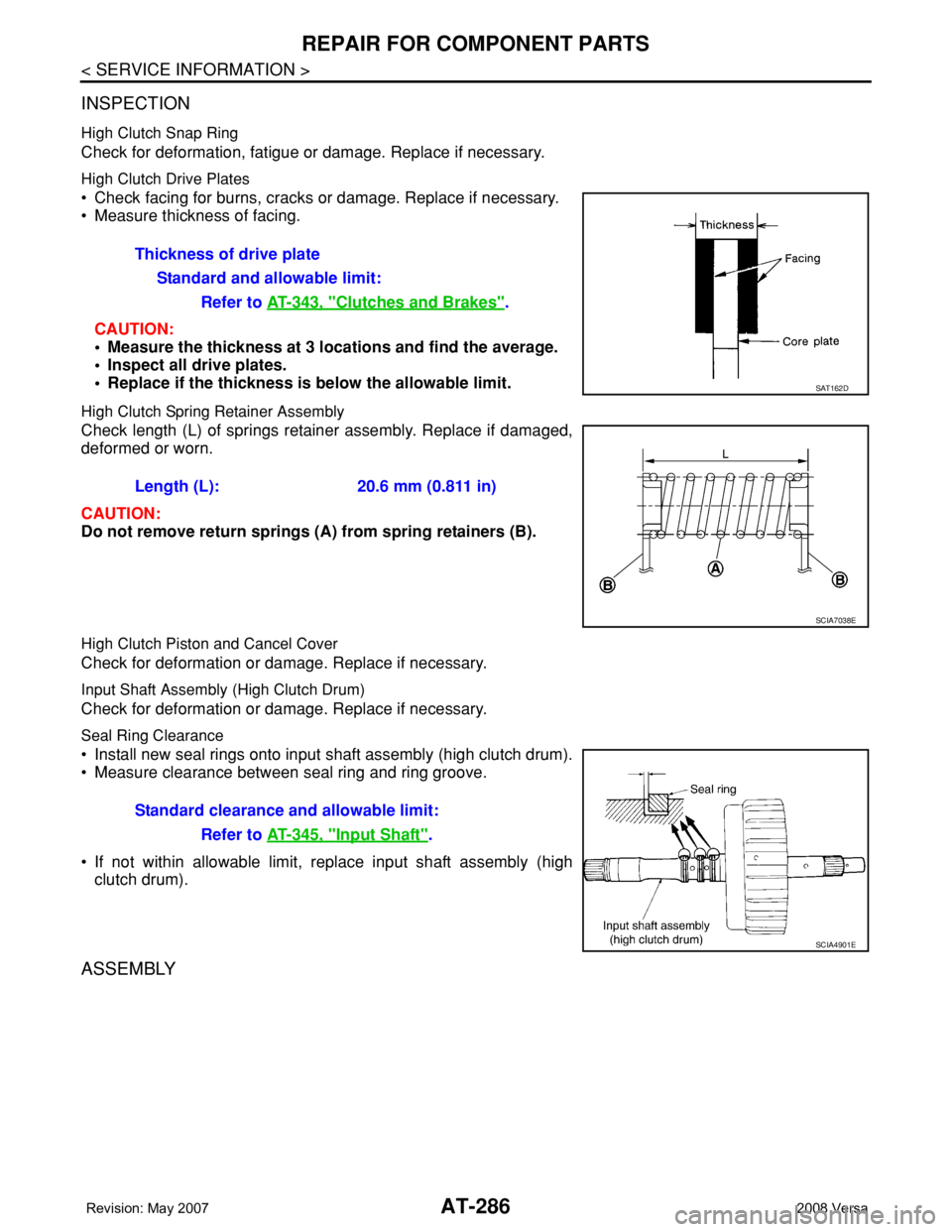

INSPECTION

High Clutch Snap Ring

Check for deformation, fatigue or damage. Replace if necessary.

High Clutch Drive Plates

• Check facing for burns, cracks or damage. Replace if necessary.

• Measure thickness of facing.

CAUTION:

• Measure the thickness at 3 locations and find the average.

• Inspect all drive plates.

• Replace if the thickness is below the allowable limit.

High Clutch Spring Retainer Assembly

Check length (L) of springs retainer assembly. Replace if damaged,

deformed or worn.

CAUTION:

Do not remove return springs (A) from spring retainers (B).

High Clutch Piston and Cancel Cover

Check for deformation or damage. Replace if necessary.

Input Shaft Assembly (High Clutch Drum)

Check for deformation or damage. Replace if necessary.

Seal Ring Clearance

• Install new seal rings onto input shaft assembly (high clutch drum).

• Measure clearance between seal ring and ring groove.

• If not within allowable limit, replace input shaft assembly (high

clutch drum).

ASSEMBLY

Thickness of drive plate

Standard and allowable limit:

Refer to AT-343, "

Clutches and Brakes".

SAT162D

Length (L): 20.6 mm (0.811 in)

SCIA7038E

Standard clearance and allowable limit:

Refer to AT-345, "

Input Shaft".

SCIA4901E

Page 300 of 2771

AT-288

< SERVICE INFORMATION >

REPAIR FOR COMPONENT PARTS

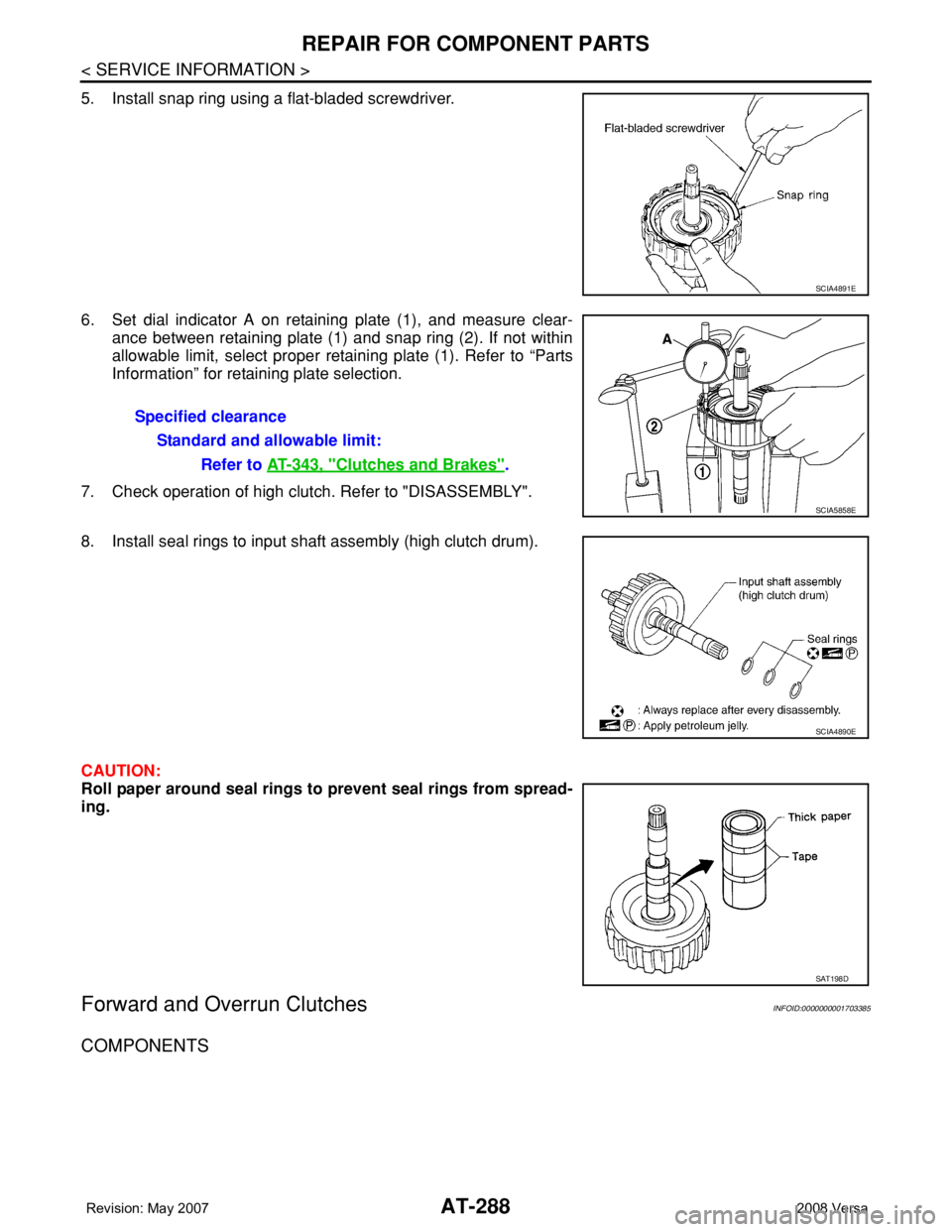

5. Install snap ring using a flat-bladed screwdriver.

6. Set dial indicator A on retaining plate (1), and measure clear-

ance between retaining plate (1) and snap ring (2). If not within

allowable limit, select proper retaining plate (1). Refer to “Parts

Information” for retaining plate selection.

7. Check operation of high clutch. Refer to "DISASSEMBLY".

8. Install seal rings to input shaft assembly (high clutch drum).

CAUTION:

Roll paper around seal rings to prevent seal rings from spread-

ing.

Forward and Overrun ClutchesINFOID:0000000001703385

COMPONENTS

SCIA4891E

Specified clearance

Standard and allowable limit:

Refer to AT-343, "

Clutches and Brakes".

SCIA5858E

SCIA4890E

SAT198D

Page 303 of 2771

REPAIR FOR COMPONENT PARTS

AT-291

< SERVICE INFORMATION >

D

E

F

G

H

I

J

K

L

MA

B

AT

N

O

P

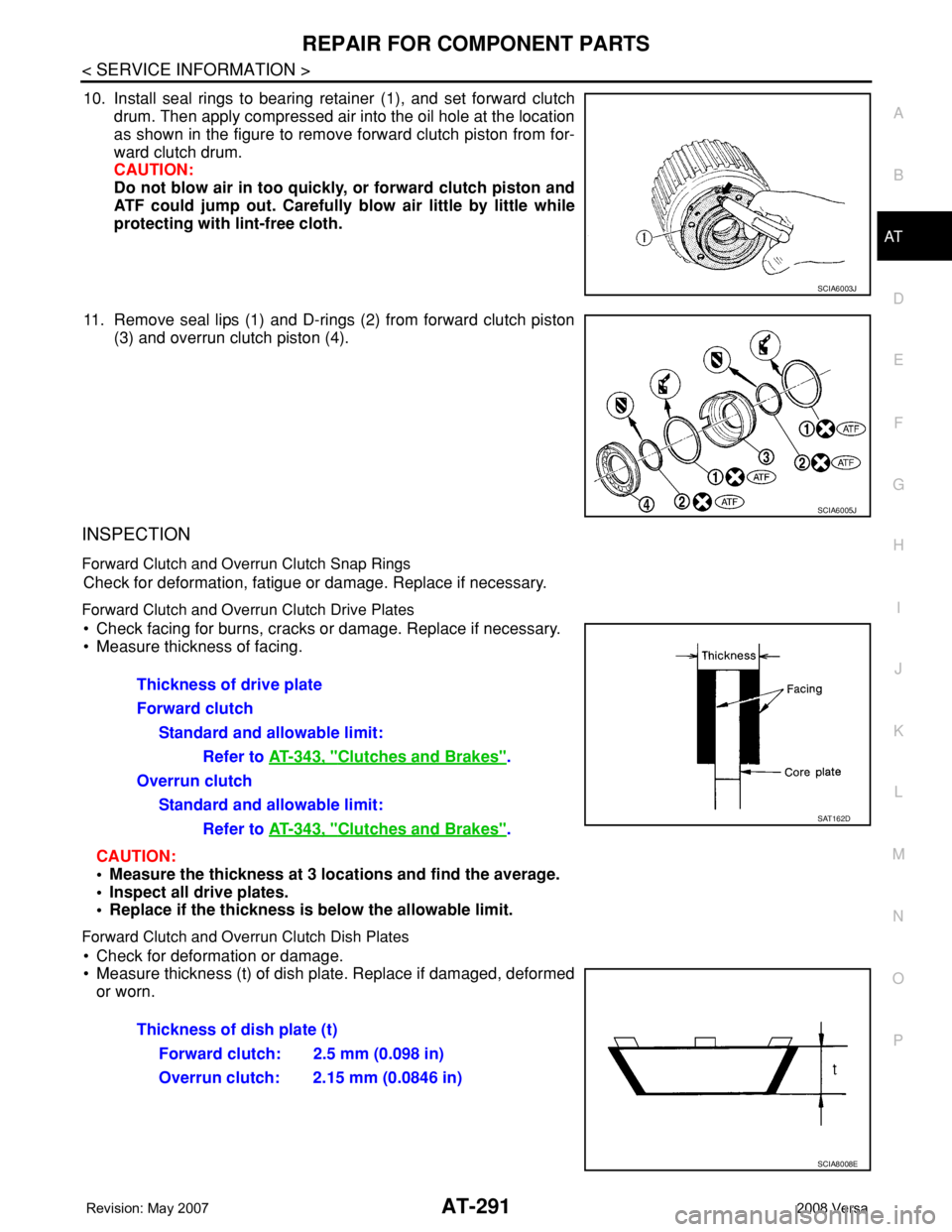

10. Install seal rings to bearing retainer (1), and set forward clutch

drum. Then apply compressed air into the oil hole at the location

as shown in the figure to remove forward clutch piston from for-

ward clutch drum.

CAUTION:

Do not blow air in too quickly, or forward clutch piston and

ATF could jump out. Carefully blow air little by little while

protecting with lint-free cloth.

11. Remove seal lips (1) and D-rings (2) from forward clutch piston

(3) and overrun clutch piston (4).

INSPECTION

Forward Clutch and Overrun Clutch Snap Rings

Check for deformation, fatigue or damage. Replace if necessary.

Forward Clutch and Overrun Clutch Drive Plates

• Check facing for burns, cracks or damage. Replace if necessary.

• Measure thickness of facing.

CAUTION:

• Measure the thickness at 3 locations and find the average.

• Inspect all drive plates.

• Replace if the thickness is below the allowable limit.

Forward Clutch and Overrun Clutch Dish Plates

• Check for deformation or damage.

• Measure thickness (t) of dish plate. Replace if damaged, deformed

or worn.

SCIA6003J

SCIA6005J

Thickness of drive plate

Forward clutch

Standard and allowable limit:

Refer to AT-343, "

Clutches and Brakes".

Overrun clutch

Standard and allowable limit:

Refer to AT-343, "

Clutches and Brakes".SAT162D

Thickness of dish plate (t)

Forward clutch: 2.5 mm (0.098 in)

Overrun clutch: 2.15 mm (0.0846 in)

SCIA8008E

Page 306 of 2771

AT-294

< SERVICE INFORMATION >

REPAIR FOR COMPONENT PARTS

• Do not align snap ring gap with spring retainer assembly

stopper.

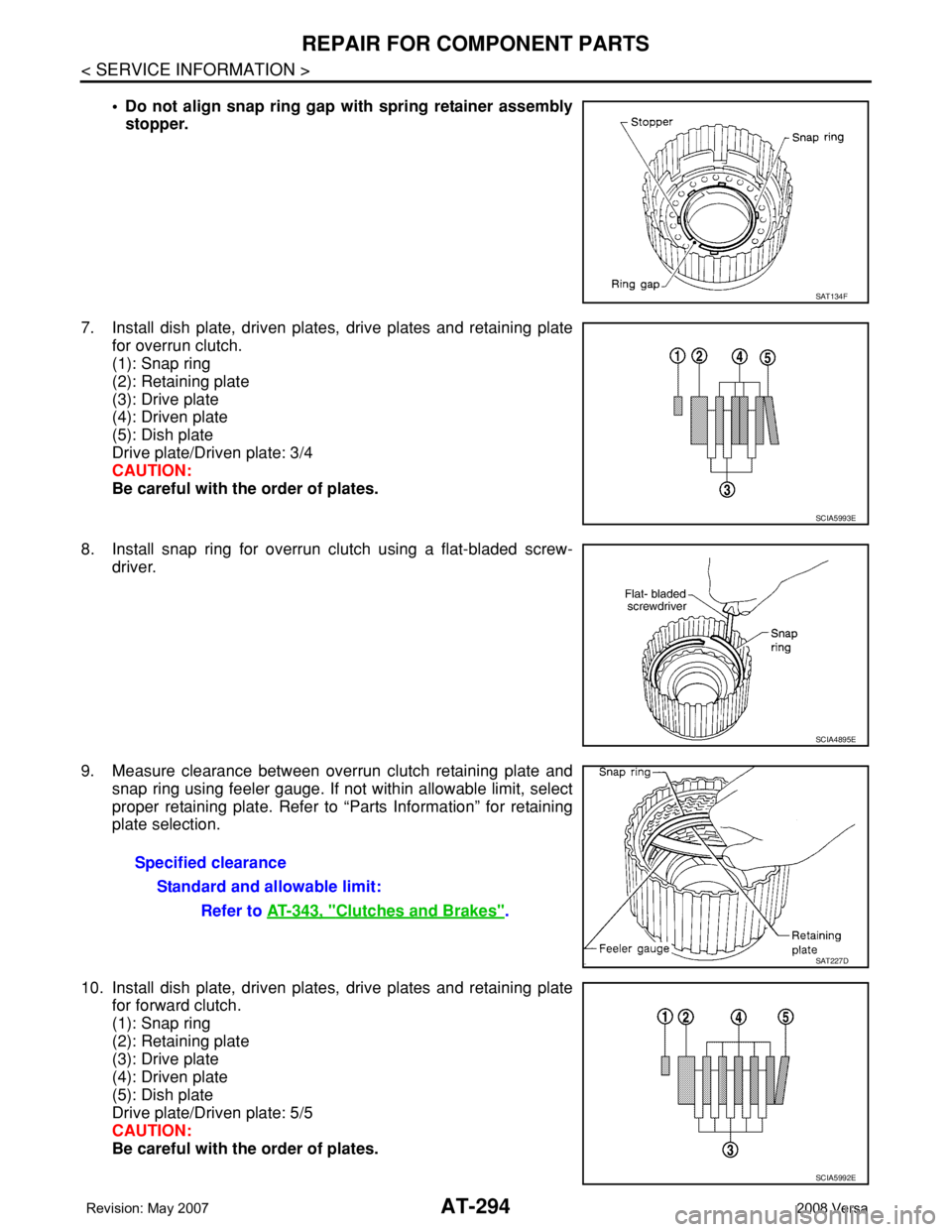

7. Install dish plate, driven plates, drive plates and retaining plate

for overrun clutch.

(1): Snap ring

(2): Retaining plate

(3): Drive plate

(4): Driven plate

(5): Dish plate

Drive plate/Driven plate: 3/4

CAUTION:

Be careful with the order of plates.

8. Install snap ring for overrun clutch using a flat-bladed screw-

driver.

9. Measure clearance between overrun clutch retaining plate and

snap ring using feeler gauge. If not within allowable limit, select

proper retaining plate. Refer to “Parts Information” for retaining

plate selection.

10. Install dish plate, driven plates, drive plates and retaining plate

for forward clutch.

(1): Snap ring

(2): Retaining plate

(3): Drive plate

(4): Driven plate

(5): Dish plate

Drive plate/Driven plate: 5/5

CAUTION:

Be careful with the order of plates.

SAT134F

SCIA5993E

SCIA4895E

Specified clearance

Standard and allowable limit:

Refer to AT-343, "

Clutches and Brakes".

SAT227D

SCIA5992E