oil change NISSAN TIIDA 2008 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2008, Model line: TIIDA, Model: NISSAN TIIDA 2008Pages: 2771, PDF Size: 60.61 MB

Page 7 of 2771

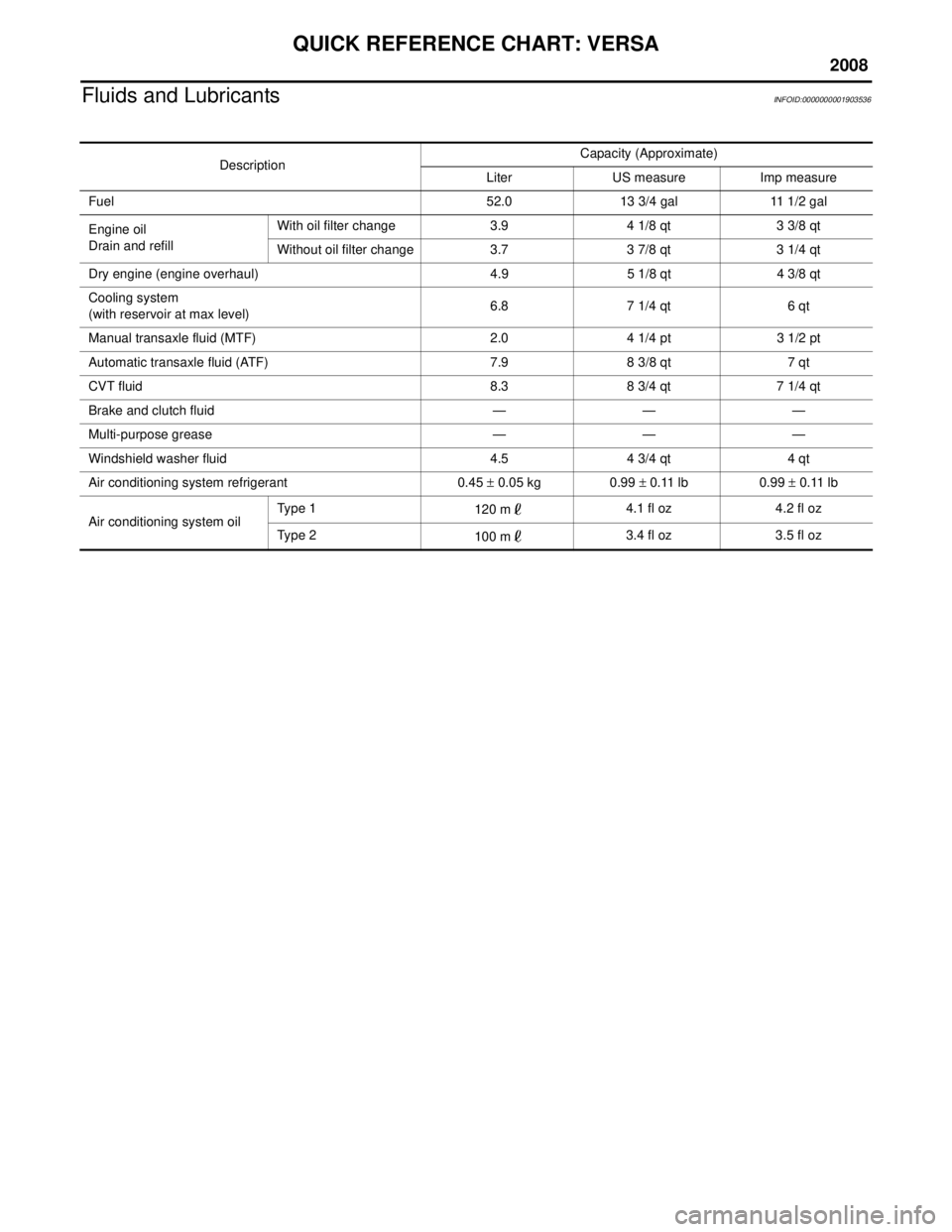

QUICK REFERENCE CHART: VERSA

2008

Fluids and LubricantsINFOID:0000000001903536

DescriptionCapacity (Approximate)

Liter US measure Imp measure

Fuel 52.0 13 3/4 gal 11 1/2 gal

Engine oil

Drain and refill With oil filter change 3.9 4 1/8 qt 3 3/8 qt

Without oil filter change 3.7 3 7/8 qt 3 1/4 qt

Dry engine (engine overhaul) 4.9 5 1/8 qt 4 3/8 qt

Cooling system

(with reservoir at max level) 6.8 7 1/4 qt 6 qt

Manual transaxle fluid (MTF) 2.0 4 1/4 pt 3 1/2 pt

Automatic transaxle fluid (ATF) 7.9 8 3/8 qt 7 qt

CVT fluid 8.3 8 3/4 qt 7 1/4 qt

Brake and clutch fluid — — —

Multi-purpose grease — — —

Windshield washer fluid 4.5 4 3/4 qt 4 qt

Air conditioning system refrigerant 0.45 ± 0.05 kg 0.99 ± 0.11 lb 0.99 ± 0.11 lb

Air conditioning system oil Typ e 1

120 m4.1 fl oz 4.2 fl oz

Typ e 2 100 m3.4 fl oz 3.5 fl oz

Page 79 of 2771

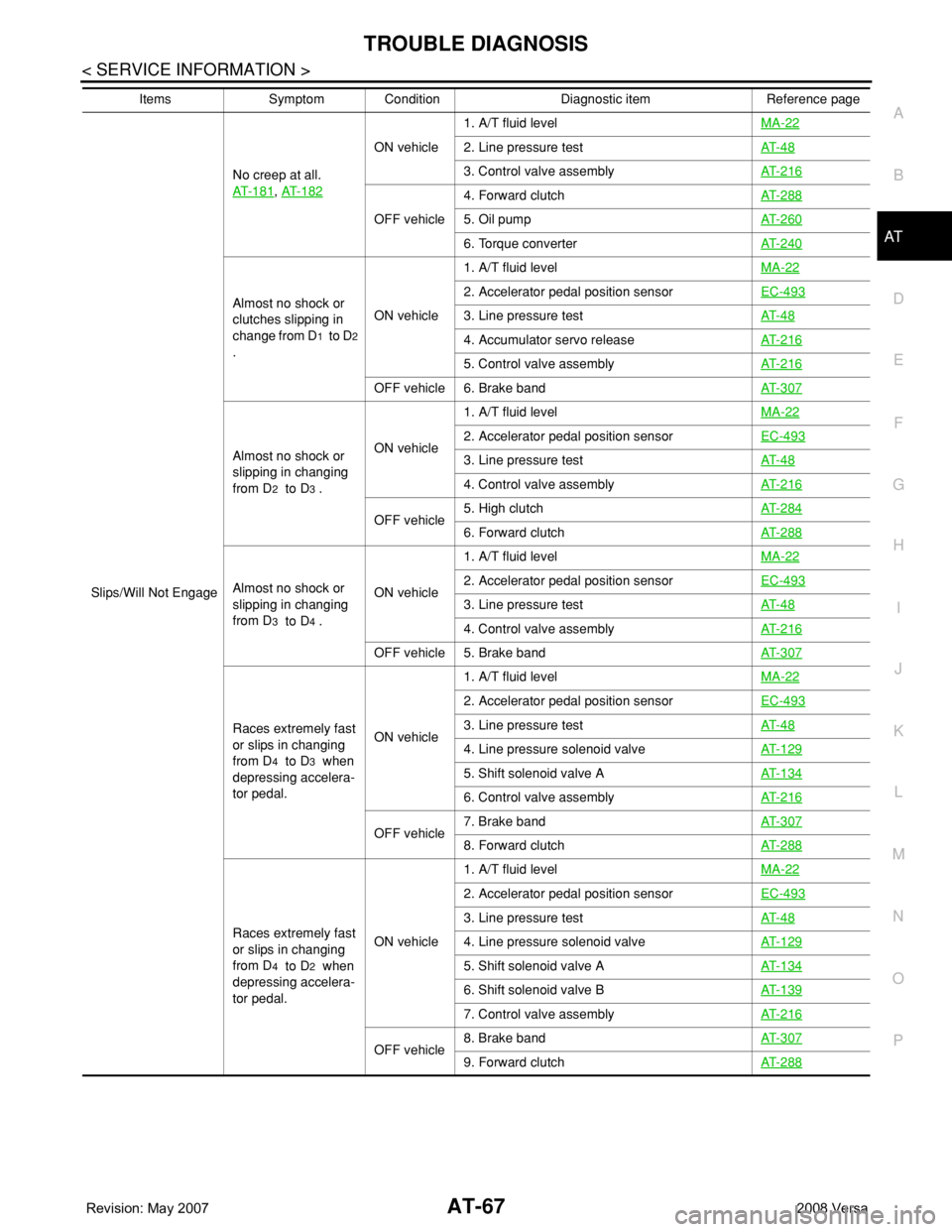

TROUBLE DIAGNOSIS

AT-67

< SERVICE INFORMATION >

D

E

F

G

H

I

J

K

L

MA

B

AT

N

O

P

Slips/Will Not EngageNo creep at all.

AT- 1 8 1

, AT- 1 8 2

ON vehicle1. A/T fluid levelMA-222. Line pressure testAT- 4 8

3. Control valve assemblyAT- 2 1 6

OFF vehicle4. Forward clutchAT- 2 8 85. Oil pumpAT- 2 6 0

6. Torque converterAT- 2 4 0

Almost no shock or

clutches slipping in

change from D

1 to D2

.ON vehicle1. A/T fluid levelMA-22

2. Accelerator pedal position sensorEC-493

3. Line pressure testAT- 4 8

4. Accumulator servo releaseAT- 2 1 6

5. Control valve assemblyAT- 2 1 6

OFF vehicle 6. Brake bandAT- 3 0 7

Almost no shock or

slipping in changing

from D

2 to D3 .ON vehicle1. A/T fluid levelMA-22

2. Accelerator pedal position sensorEC-493

3. Line pressure testAT- 4 8

4. Control valve assemblyAT- 2 1 6

OFF vehicle5. High clutchAT- 2 8 46. Forward clutchAT- 2 8 8

Almost no shock or

slipping in changing

from D

3 to D4 .ON vehicle1. A/T fluid levelMA-22

2. Accelerator pedal position sensorEC-493

3. Line pressure testAT- 4 8

4. Control valve assemblyAT- 2 1 6

OFF vehicle 5. Brake bandAT- 3 0 7

Races extremely fast

or slips in changing

from D

4 to D3 when

depressing accelera-

tor pedal.ON vehicle1. A/T fluid levelMA-22

2. Accelerator pedal position sensorEC-493

3. Line pressure testAT- 4 8

4. Line pressure solenoid valveAT- 1 2 9

5. Shift solenoid valve AAT- 1 3 4

6. Control valve assemblyAT- 2 1 6

OFF vehicle7. Brake bandAT- 3 0 78. Forward clutchAT- 2 8 8

Races extremely fast

or slips in changing

from D

4 to D2 when

depressing accelera-

tor pedal.ON vehicle1. A/T fluid levelMA-22

2. Accelerator pedal position sensorEC-493

3. Line pressure testAT- 4 8

4. Line pressure solenoid valveAT- 1 2 9

5. Shift solenoid valve AAT- 1 3 4

6. Shift solenoid valve BAT- 1 3 9

7. Control valve assemblyAT- 2 1 6

OFF vehicle8. Brake bandAT- 3 0 79. Forward clutchAT- 2 8 8

Items Symptom Condition Diagnostic item Reference page

Page 381 of 2771

AV-22

< SERVICE INFORMATION >

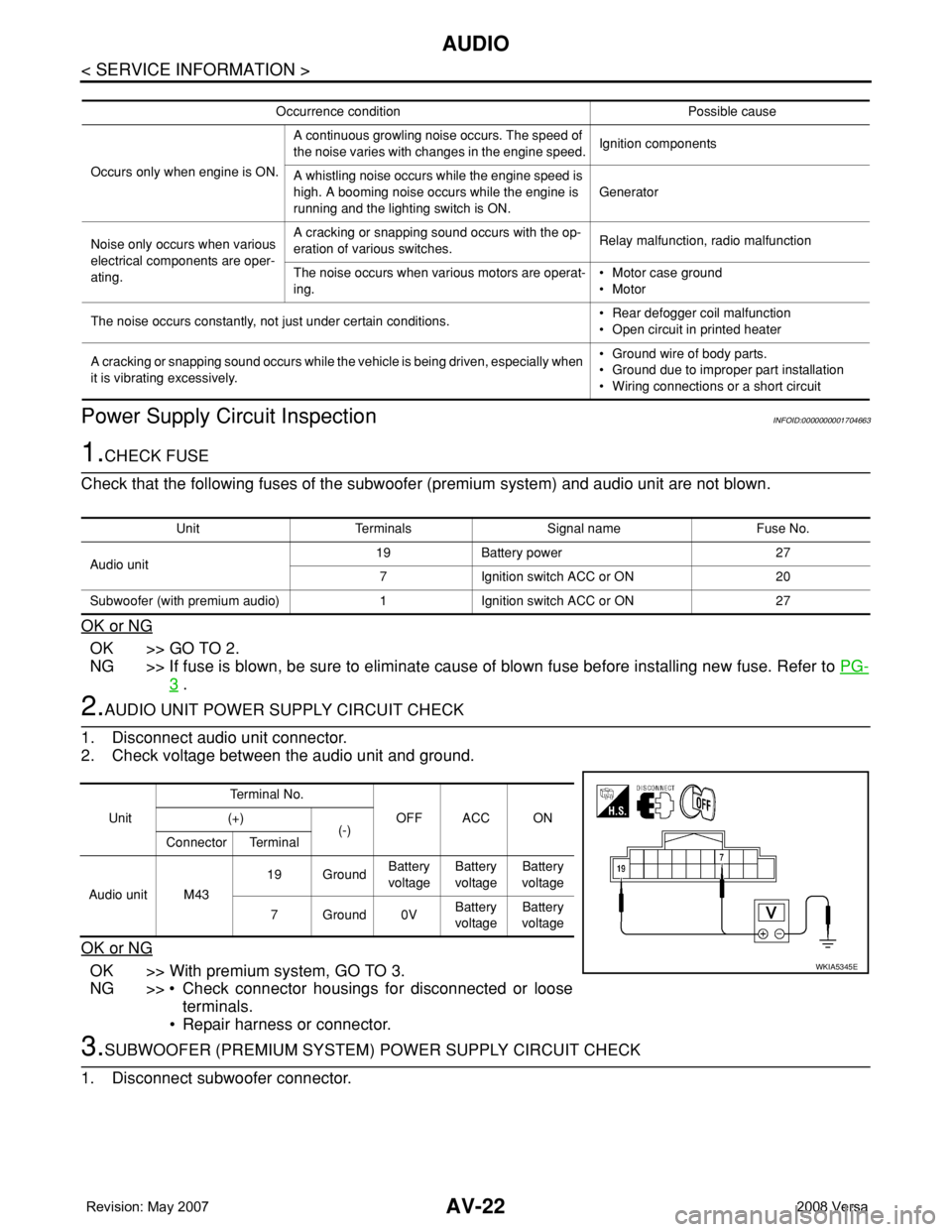

AUDIO

Power Supply Circuit Inspection

INFOID:0000000001704663

1.CHECK FUSE

Check that the following fuses of the subwoofer (premium system) and audio unit are not blown.

OK or NG

OK >> GO TO 2.

NG >> If fuse is blown, be sure to eliminate cause of blown fuse before installing new fuse. Refer to PG-

3 .

2.AUDIO UNIT POWER SUPPLY CIRCUIT CHECK

1. Disconnect audio unit connector.

2. Check voltage between the audio unit and ground.

OK or NG

OK >> With premium system, GO TO 3.

NG >> • Check connector housings for disconnected or loose

terminals.

• Repair harness or connector.

3.SUBWOOFER (PREMIUM SYSTEM) POWER SUPPLY CIRCUIT CHECK

1. Disconnect subwoofer connector.

Occurrence condition Possible cause

Occurs only when engine is ON.A continuous growling noise occurs. The speed of

the noise varies with changes in the engine speed.Ignition components

A whistling noise occurs while the engine speed is

high. A booming noise occurs while the engine is

running and the lighting switch is ON.Generator

Noise only occurs when various

electrical components are oper-

ating.A cracking or snapping sound occurs with the op-

eration of various switches.Relay malfunction, radio malfunction

The noise occurs when various motors are operat-

ing.• Motor case ground

• Motor

The noise occurs constantly, not just under certain conditions.• Rear defogger coil malfunction

• Open circuit in printed heater

A cracking or snapping sound occurs while the vehicle is being driven, especially when

it is vibrating excessively.• Ground wire of body parts.

• Ground due to improper part installation

• Wiring connections or a short circuit

Unit Terminals Signal name Fuse No.

Audio unit19 Battery power 27

7 Ignition switch ACC or ON 20

Subwoofer (with premium audio) 1 Ignition switch ACC or ON 27

UnitTe r m i n a l N o .

OFF ACC ON (+)

(-)

Connector Terminal

Audio unit M4319 GroundBattery

voltageBattery

voltageBattery

voltage

7Ground0VBattery

voltageBattery

voltage

WKIA5345E

Page 843 of 2771

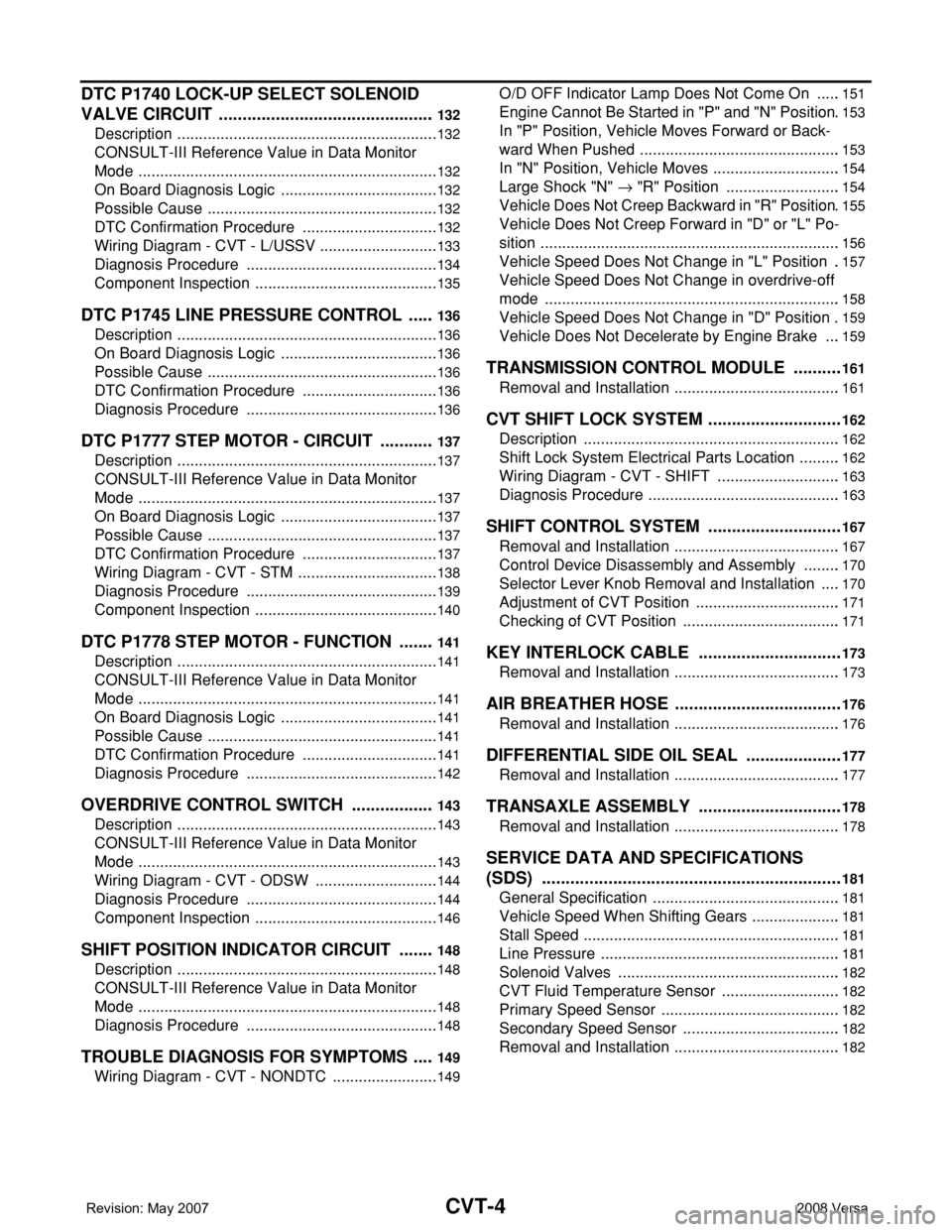

CVT-4

DTC P1740 LOCK-UP SELECT SOLENOID

VALVE CIRCUIT ..............................................

132

Description .............................................................132

CONSULT-III Reference Value in Data Monitor

Mode ......................................................................

132

On Board Diagnosis Logic .....................................132

Possible Cause ......................................................132

DTC Confirmation Procedure ................................132

Wiring Diagram - CVT - L/USSV ............................133

Diagnosis Procedure .............................................134

Component Inspection ...........................................135

DTC P1745 LINE PRESSURE CONTROL ......136

Description .............................................................136

On Board Diagnosis Logic .....................................136

Possible Cause ......................................................136

DTC Confirmation Procedure ................................136

Diagnosis Procedure .............................................136

DTC P1777 STEP MOTOR - CIRCUIT ............137

Description .............................................................137

CONSULT-III Reference Value in Data Monitor

Mode ......................................................................

137

On Board Diagnosis Logic .....................................137

Possible Cause ......................................................137

DTC Confirmation Procedure ................................137

Wiring Diagram - CVT - STM .................................138

Diagnosis Procedure .............................................139

Component Inspection ...........................................140

DTC P1778 STEP MOTOR - FUNCTION ........141

Description .............................................................141

CONSULT-III Reference Value in Data Monitor

Mode ......................................................................

141

On Board Diagnosis Logic .....................................141

Possible Cause ......................................................141

DTC Confirmation Procedure ................................141

Diagnosis Procedure .............................................142

OVERDRIVE CONTROL SWITCH ..................143

Description .............................................................143

CONSULT-III Reference Value in Data Monitor

Mode ......................................................................

143

Wiring Diagram - CVT - ODSW .............................144

Diagnosis Procedure .............................................144

Component Inspection ...........................................146

SHIFT POSITION INDICATOR CIRCUIT ........148

Description .............................................................148

CONSULT-III Reference Value in Data Monitor

Mode ......................................................................

148

Diagnosis Procedure .............................................148

TROUBLE DIAGNOSIS FOR SYMPTOMS .....149

Wiring Diagram - CVT - NONDTC .........................149

O/D OFF Indicator Lamp Does Not Come On ......151

Engine Cannot Be Started in "P" and "N" Position .153

In "P" Position, Vehicle Moves Forward or Back-

ward When Pushed ...............................................

153

In "N" Position, Vehicle Moves ..............................154

Large Shock "N" → "R" Position ...........................154

Vehicle Does Not Creep Backward in "R" Position .155

Vehicle Does Not Creep Forward in "D" or "L" Po-

sition ......................................................................

156

Vehicle Speed Does Not Change in "L" Position ..157

Vehicle Speed Does Not Change in overdrive-off

mode .....................................................................

158

Vehicle Speed Does Not Change in "D" Position .159

Vehicle Does Not Decelerate by Engine Brake ....159

TRANSMISSION CONTROL MODULE ...........161

Removal and Installation .......................................161

CVT SHIFT LOCK SYSTEM .............................162

Description ............................................................162

Shift Lock System Electrical Parts Location ..........162

Wiring Diagram - CVT - SHIFT .............................163

Diagnosis Procedure .............................................163

SHIFT CONTROL SYSTEM .............................167

Removal and Installation .......................................167

Control Device Disassembly and Assembly .........170

Selector Lever Knob Removal and Installation .....170

Adjustment of CVT Position ..................................171

Checking of CVT Position .....................................171

KEY INTERLOCK CABLE ...............................173

Removal and Installation .......................................173

AIR BREATHER HOSE ....................................176

Removal and Installation .......................................176

DIFFERENTIAL SIDE OIL SEAL .....................177

Removal and Installation .......................................177

TRANSAXLE ASSEMBLY ...............................178

Removal and Installation .......................................178

SERVICE DATA AND SPECIFICATIONS

(SDS) ................................................................

181

General Specification ............................................181

Vehicle Speed When Shifting Gears .....................181

Stall Speed ............................................................181

Line Pressure ........................................................181

Solenoid Valves ....................................................182

CVT Fluid Temperature Sensor ............................182

Primary Speed Sensor ..........................................182

Secondary Speed Sensor .....................................182

Removal and Installation .......................................182

Page 868 of 2771

TROUBLE DIAGNOSIS

CVT-29

< SERVICE INFORMATION >

D

E

F

G

H

I

J

K

L

MA

B

CVT

N

O

P

TROUBLE DIAGNOSIS

DTC Inspection Priority ChartINFOID:0000000001703451

If some DTCs are displayed at the same time, perform inspections one by one based on the following priority

chart.

NOTE:

If DTC “U1000 CAN COMM CIRCUIT” is displayed with other DTCs, first perform the trouble diagnosis

for “DTC U1000 CAN COMMUNICATION LINE”. Refer to CVT-56

.

Fail-SafeINFOID:0000000001703452

The TCM has an electrical fail-safe mode. This mode makes it possible to operate even if there is an error in a

main electronic control input/output signal circuit.

FAIL-SAFE FUNCTION

If any malfunction occurs in a sensor or solenoid, this function controls the CVT to make driving possible.

Output Speed Sensor (Secondary Speed Sensor)

The shift pattern is changed in accordance with throttle position when an unexpected signal is sent from the

output speed sensor (secondary speed sensor) to the TCM. The overdrive-off mode is inhibited, and the tran-

saxle is put in “D”.

Input Speed Sensor (Primary Speed Sensor)

The shift pattern is changed in accordance with throttle position and secondary speed (vehicle speed) when

an unexpected signal is sent from the input speed sensor (primary speed sensor) to the TCM. The sport mode

is inhibited, and the transaxle is put in “D”.

PNP Switch

If an unexpected signal is sent from the PNP switch to the TCM, the transaxle is put in “D”.

CVT Fluid Temperature Sensor

If an unexpected signal is sent from the CVT fluid temperature sensor to the TCM, the gear ratio in use before

receiving the unexpected signal is maintained or the gear ratio is controlled to keep engine speed under 3500

rpm.

Transmission Fluid Pressure Sensor A (Secondary Pressure Sensor)

• If an unexpected signal is sent from the transmission fluid pressure sensor A (secondary pressure sensor) to

the TCM, the secondary pressure feedback control is stopped and the offset value obtained before the non-

standard condition occurs is used to control line pressure.

• If transmission fluid pressure sensor A (secondary pressure sensor) error signal is input to TCM, secondary

pressure feedback control stops, but line pressure is controlled normally.

Pressure Control Solenoid A (Line Pressure Solenoid)

If an unexpected signal is sent from the solenoid to the TCM, the pressure control solenoid A (line pressure

solenoid) is turned OFF to achieve the maximum fluid pressure.

Pressure Control Solenoid B (Secondary Pressure Solenoid)

If an unexpected signal is sent from the solenoid to the TCM, the pressure control solenoid B (secondary pres-

sure solenoid) is turned OFF to achieve the maximum fluid pressure.

Torque Converter Clutch Solenoid

If an unexpected signal is sent from the solenoid to the TCM, the torque converter clutch solenoid is turned

OFF to cancel the lock-up.

Ste p M oto r

If an unexpected signal is sent from the step motor to the TCM, the step motor coil phases “A” through “D” are

all turned OFF to hold the gear ratio used right before the non-standard condition occurred.

CVT Lock-up Select Solenoid

Priority Detected items (DTC)

1 U1000 CAN communication line

2 Except above

Page 882 of 2771

TROUBLE DIAGNOSIS

CVT-43

< SERVICE INFORMATION >

D

E

F

G

H

I

J

K

L

MA

B

CVT

N

O

P

Cruise TestINFOID:0000000001703460

1.CHECK VEHICLE SPEED WHEN SHIFTING GEARS — PART 1

1. Drive vehicle for approximately 10 minutes to warm engine oil and CVT fluid up to operating temperature.

2. Park vehicle on flat surface.

3. Move selector lever to “P” position.

4. Start engine.

5. Move selector lever to “L” position.

6. Accelerate vehicle to 2/8-way throttle depressing accelerator

pedal constantly.

Read vehicle speed and engine speed. Refer to CVT-45,

"Vehicle Speed When Shifting Gears" .

OK or NG

OK >> GO TO 2.

NG >> Mark the box of CVT-157, "

Vehicle Speed Does Not

Change in "L" Position" on the CVT-30, "How to Per-

form Trouble Diagnosis for Quick and Accurate Repair" .

Continue “Road Test”.

2.CHECK VEHICLE SPEED WHEN SHIFTING GEARS — PART 2

1. Park vehicle on flat surface.

2. Move selector lever to “D” position.

3. Push overdrive control switch. (O/D OFF indicator lamp is on.)

4. Accelerate vehicle to 2/8-way throttle depressing accelerator

pedal constantly.

Read vehicle speed and engine speed. Refer to CVT-45,

"Vehicle Speed When Shifting Gears" .

OK or NG

OK >> GO TO 3.

NG >> Mark the box of CVT-158, "

Vehicle Speed Does Not

Change in overdrive-off mode" on the CVT-30, "How to

Perform Trouble Diagnosis for Quick and Accurate

Repair" . Continue “Road Test”.

3.CHECK VEHICLE SPEED WHEN SHIFTING GEARS — PART 3

1. Park vehicle on flat surface.

2. Move selector lever to “D” position.

3. Push overdrive control switch. (O/D OFF indicator lamp is off.)

4. Accelerate vehicle to 2/8-way throttle depressing accelerator

pedal constantly.

Read vehicle speed and engine speed. Refer to CVT-45,

"Vehicle Speed When Shifting Gears" .

OK or NG

OK >> GO TO 4.

NG >> Mark the box of CVT-159, "

Vehicle Speed Does Not

Change in "D" Position" on the CVT-30, "How to Per-

form Trouble Diagnosis for Quick and Accurate Repair" .

Continue “Road Test”.

4.CHECK VEHICLE SPEED WHEN SHIFTING GEARS — PART 4

1. Park vehicle on flat surface.

2. Move selector lever to “L” position. CVT fluid operating temperature: 50 - 80°C (122 - 176°F)

SCIA6644E

SCIA6644E

SCIA6644E

Page 888 of 2771

TROUBLE DIAGNOSIS

CVT-49

< SERVICE INFORMATION >

D

E

F

G

H

I

J

K

L

MA

B

CVT

N

O

P

*: Models without ABS does not indicate.

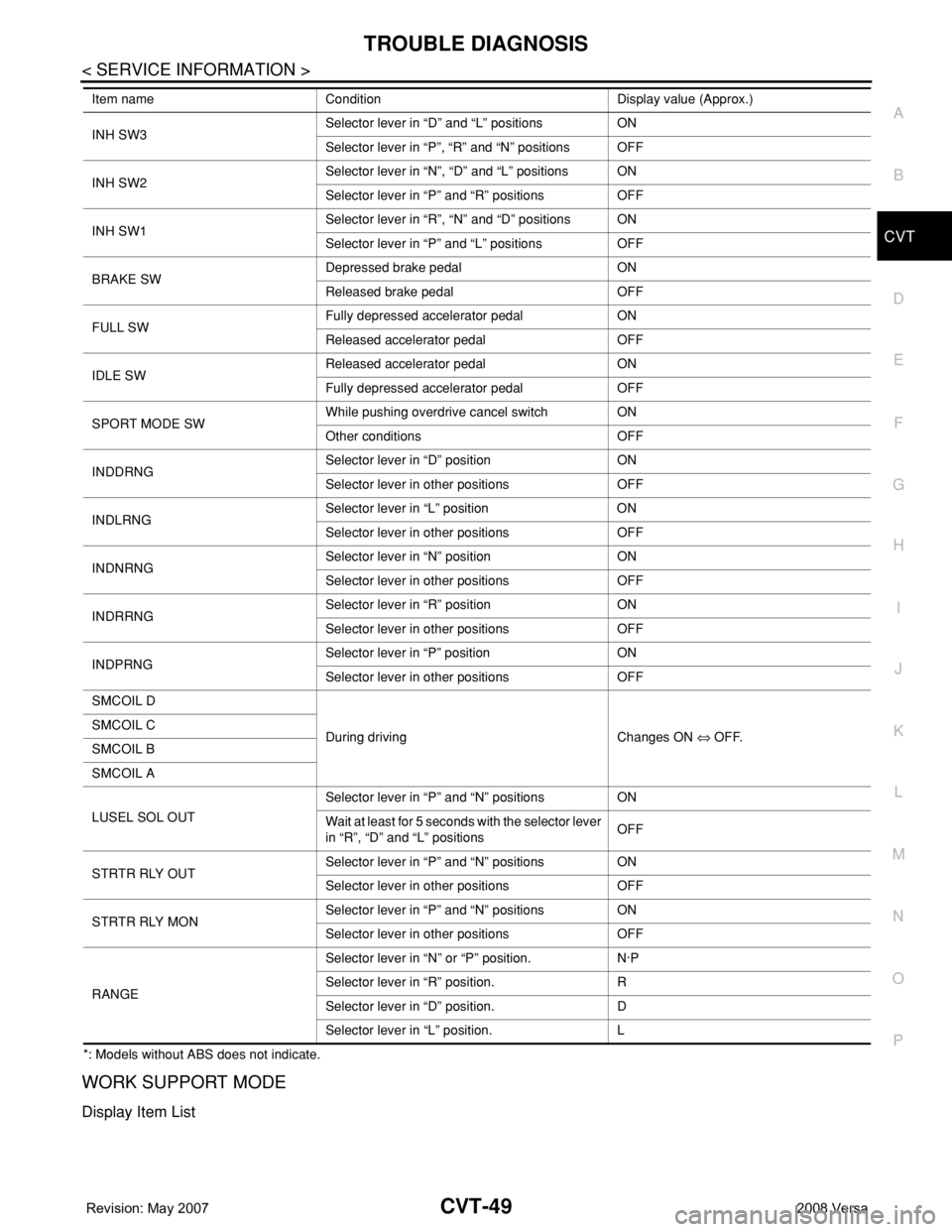

WORK SUPPORT MODE

Display Item List

INH SW3Selector lever in “D” and “L” positions ON

Selector lever in “P”, “R” and “N” positions OFF

INH SW2Selector lever in “N”, “D” and “L” positions ON

Selector lever in “P” and “R” positions OFF

INH SW1Selector lever in “R”, “N” and “D” positions ON

Selector lever in “P” and “L” positions OFF

BRAKE SWDepressed brake pedal ON

Released brake pedal OFF

FULL SWFully depressed accelerator pedal ON

Released accelerator pedal OFF

IDLE SWReleased accelerator pedal ON

Fully depressed accelerator pedal OFF

SPORT MODE SWWhile pushing overdrive cancel switch ON

Other conditions OFF

INDDRNGSelector lever in “D” position ON

Selector lever in other positions OFF

INDLRNGSelector lever in “L” position ON

Selector lever in other positions OFF

INDNRNGSelector lever in “N” position ON

Selector lever in other positions OFF

INDRRNGSelector lever in “R” position ON

Selector lever in other positions OFF

INDPRNGSelector lever in “P” position ON

Selector lever in other positions OFF

SMCOIL D

During driving Changes ON ⇔ OFF. SMCOIL C

SMCOIL B

SMCOIL A

LUSEL SOL OUTSelector lever in “P” and “N” positions ON

Wait at least for 5 seconds with the selector lever

in “R”, “D” and “L” positionsOFF

STRTR RLY OUTSelector lever in “P” and “N” positions ON

Selector lever in other positions OFF

STRTR RLY MONSelector lever in “P” and “N” positions ON

Selector lever in other positions OFF

RANGESelector lever in “N” or “P” position. N·P

Selector lever in “R” position. R

Selector lever in “D” position. D

Selector lever in “L” position. L Item name Condition Display value (Approx.)

Page 891 of 2771

CVT-52

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS

*1: Refer to CVT-27, "Malfunction Indicator Lamp (MIL)" .

*2: Models without ABS does not indicate.

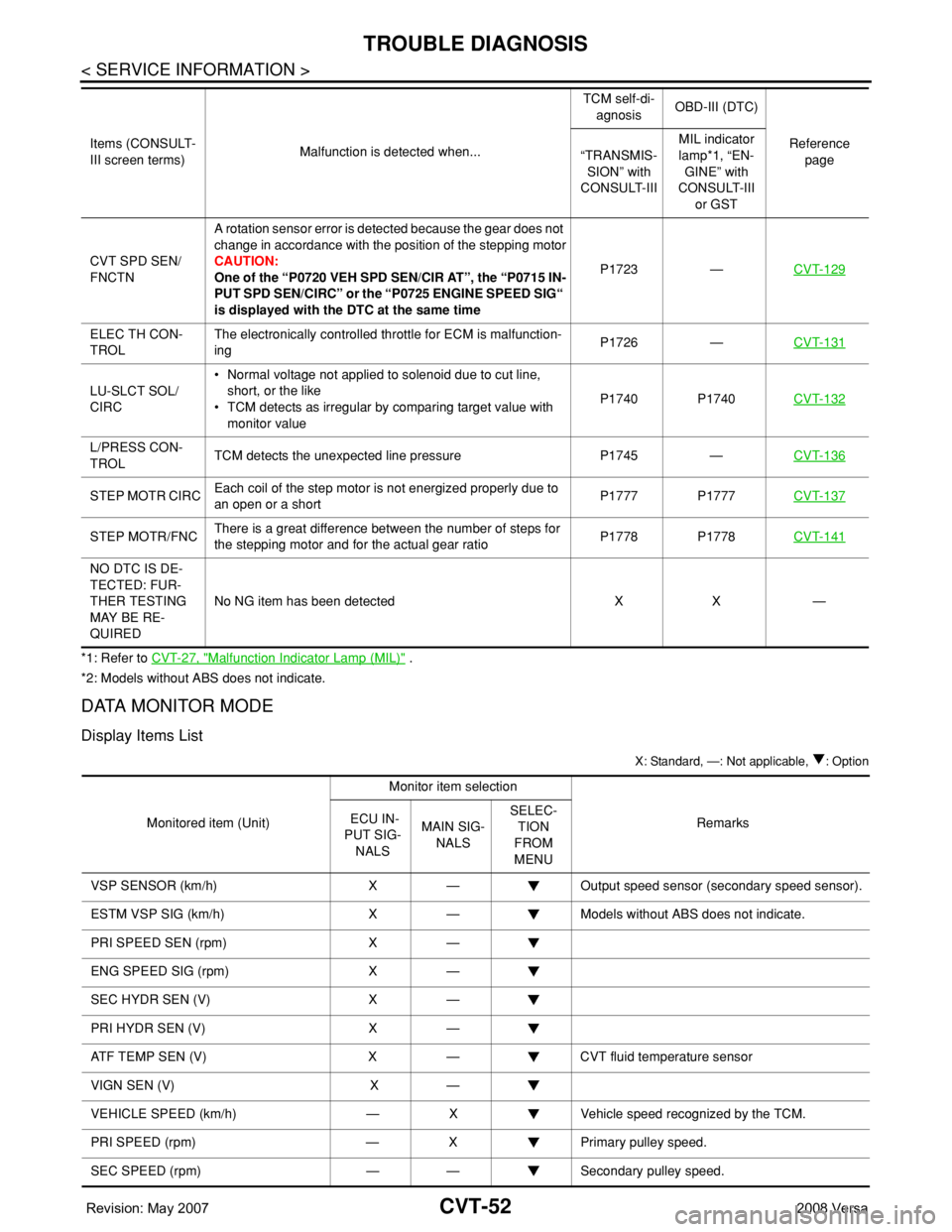

DATA MONITOR MODE

Display Items List

X: Standard, —: Not applicable, : Option

CVT SPD SEN/

FNCTNA rotation sensor error is detected because the gear does not

change in accordance with the position of the stepping motor

CAUTION:

One of the “P0720 VEH SPD SEN/CIR AT”, the “P0715 IN-

PUT SPD SEN/CIRC” or the “P0725 ENGINE SPEED SIG“

is displayed with the DTC at the same timeP1723 —CVT-129

ELEC TH CON-

TROLThe electronically controlled throttle for ECM is malfunction-

ingP1726 —CVT-131

LU-SLCT SOL/

CIRC• Normal voltage not applied to solenoid due to cut line,

short, or the like

• TCM detects as irregular by comparing target value with

monitor valueP1740 P1740CVT-132

L/PRESS CON-

TROLTCM detects the unexpected line pressure P1745 —CVT-136

STEP MOTR CIRCEach coil of the step motor is not energized properly due to

an open or a shortP1777 P1777CVT-137

STEP MOTR/FNCThere is a great difference between the number of steps for

the stepping motor and for the actual gear ratioP1778 P1778CVT-141

NO DTC IS DE-

TECTED: FUR-

THER TESTING

MAY BE RE-

QUIREDNo NG item has been detected X X — Items (CONSULT-

III screen terms)Malfunction is detected when...TCM self-di-

agnosisOBD-III (DTC)

Reference

page “TRANSMIS-

SION” with

CONSULT-IIIMIL indicator

lamp*1, “EN-

GINE” with

CONSULT-III

or GST

Monitored item (Unit)Monitor item selection

Remarks ECU IN-

PUT SIG-

NALSMAIN SIG-

NALSSELEC-

TION

FROM

MENU

VSP SENSOR (km/h) X — Output speed sensor (secondary speed sensor).

ESTM VSP SIG (km/h) X — Models without ABS does not indicate.

PRI SPEED SEN (rpm) X —

ENG SPEED SIG (rpm) X —

SEC HYDR SEN (V) X —

PRI HYDR SEN (V) X —

ATF TEMP SEN (V) X — CVT fluid temperature sensor

VIGN SEN (V) X —

VEHICLE SPEED (km/h) — X Vehicle speed recognized by the TCM.

PRI SPEED (rpm) — X Primary pulley speed.

SEC SPEED (rpm) — — Secondary pulley speed.

Page 976 of 2771

DTC P1777 STEP MOTOR - CIRCUIT

CVT-137

< SERVICE INFORMATION >

D

E

F

G

H

I

J

K

L

MA

B

CVT

N

O

P

DTC P1777 STEP MOTOR - CIRCUIT

DescriptionINFOID:0000000001703640

• The step motor is included in the control valve assembly.

• The step motor changes the step with turning 4 coils ON/OFF according to the signal from TCM. As a result,

the flow of line pressure to primary pulley is changed and pulley ratio is controlled

CONSULT-III Reference Value in Data Monitor ModeINFOID:0000000001703641

Remarks: Specification data are reference values.

On Board Diagnosis LogicINFOID:0000000001703642

• This is an OBD-II self-diagnostic item.

• Diagnostic trouble code “P1777 STEP MOTR CIRC” with CONSULT-III is detected under the following con-

ditions.

- When operating step motor ON and OFF, there is no proper change in the voltage of TCM terminal which

corresponds to it.

Possible CauseINFOID:0000000001703643

• Step motor

• Harness or connectors

(Step motor circuit is open or shorted.)

DTC Confirmation ProcedureINFOID:0000000001703644

CAUTION:

Always drive vehicle at a safe speed.

NOTE:

If “DTC Confirmation Procedure” has been previously performed, always turn ignition switch OFF and

wait at least 10 seconds before performing the next test.

After the repair, touch “ERASE” on “SELF-DIAG RESULTS” and then perform the following procedure to con-

firm the malfunction is eliminated.

WITH CONSULT-III

1. Turn ignition switch ON and select “DATA MONITOR” mode for “TRANSMISSION” with CONSULT-III.

2. Drive vehicle for at least 5 consecutive seconds.

3. If DTC is detected, go to CVT-139, "

Diagnosis Procedure" .

WITH GST

Follow the procedure “WITH CONSULT-III”.

Item name Condition Display value (Approx.)

STM STEP

During driving−20 step - 180 step

SMCOIL A

Changes ON⇔OFF. SMCOIL B

SMCOIL C

SMCOIL D

Page 978 of 2771

DTC P1777 STEP MOTOR - CIRCUIT

CVT-139

< SERVICE INFORMATION >

D

E

F

G

H

I

J

K

L

MA

B

CVT

N

O

P

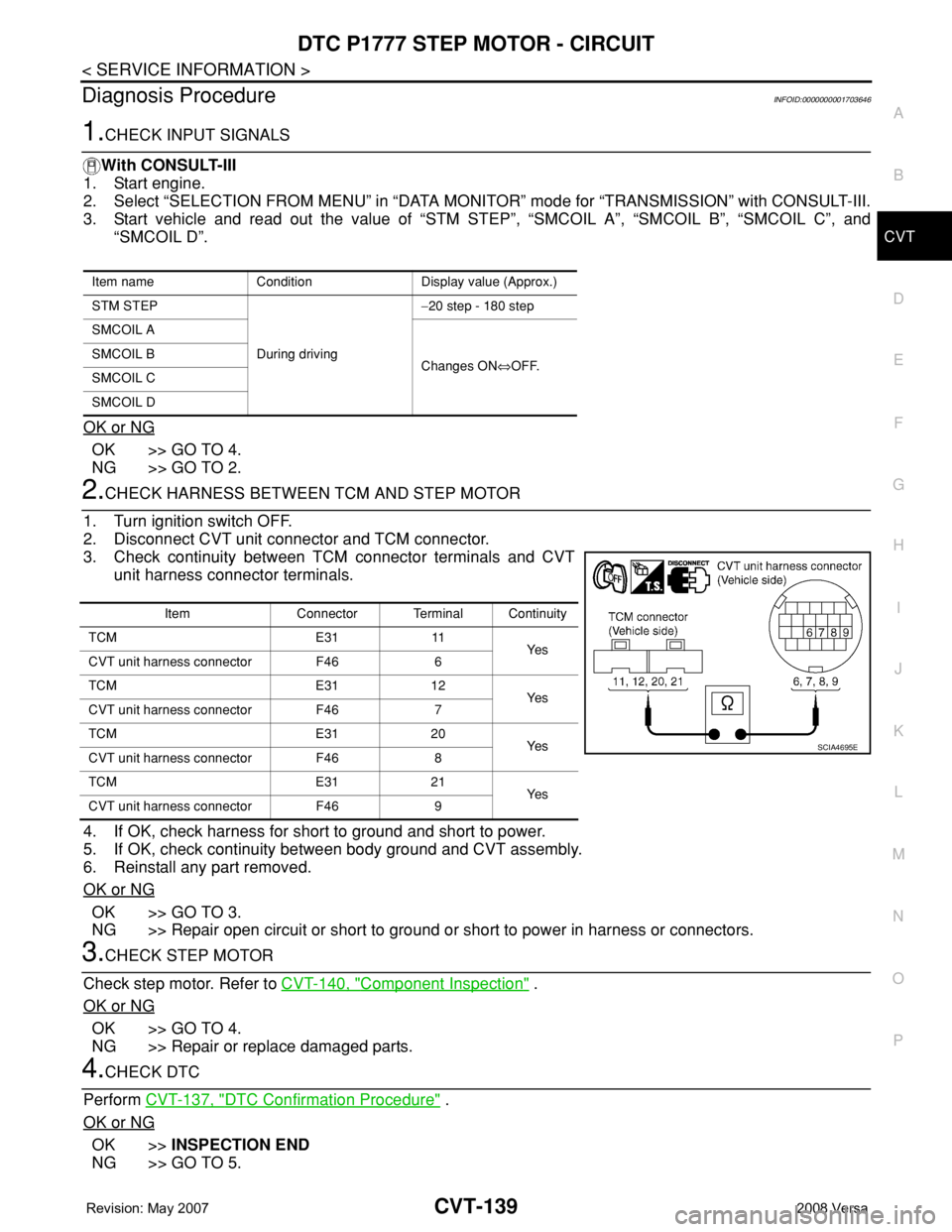

Diagnosis ProcedureINFOID:0000000001703646

1.CHECK INPUT SIGNALS

With CONSULT-III

1. Start engine.

2. Select “SELECTION FROM MENU” in “DATA MONITOR” mode for “TRANSMISSION” with CONSULT-III.

3. Start vehicle and read out the value of “STM STEP”, “SMCOIL A”, “SMCOIL B”, “SMCOIL C”, and

“SMCOIL D”.

OK or NG

OK >> GO TO 4.

NG >> GO TO 2.

2.CHECK HARNESS BETWEEN TCM AND STEP MOTOR

1. Turn ignition switch OFF.

2. Disconnect CVT unit connector and TCM connector.

3. Check continuity between TCM connector terminals and CVT

unit harness connector terminals.

4. If OK, check harness for short to ground and short to power.

5. If OK, check continuity between body ground and CVT assembly.

6. Reinstall any part removed.

OK or NG

OK >> GO TO 3.

NG >> Repair open circuit or short to ground or short to power in harness or connectors.

3.CHECK STEP MOTOR

Check step motor. Refer to CVT-140, "

Component Inspection" .

OK or NG

OK >> GO TO 4.

NG >> Repair or replace damaged parts.

4.CHECK DTC

Perform CVT-137, "

DTC Confirmation Procedure" .

OK or NG

OK >>INSPECTION END

NG >> GO TO 5.

Item name Condition Display value (Approx.)

STM STEP

During driving−20 step - 180 step

SMCOIL A

Changes ON⇔OFF. SMCOIL B

SMCOIL C

SMCOIL D

Item Connector Terminal Continuity

TCM E31 11

Ye s

CVT unit harness connector F46 6

TCM E31 12

Ye s

CVT unit harness connector F46 7

TCM E31 20

Ye s

CVT unit harness connector F46 8

TCM E31 21

Ye s

CVT unit harness connector F46 9

SCIA4695E