dimensions NISSAN TIIDA 2009 Service User Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2009, Model line: TIIDA, Model: NISSAN TIIDA 2009Pages: 4331, PDF Size: 58.04 MB

Page 3032 of 4331

EM

NP

O

• Set a try square (A) along the side of valve spring and rotate

spring. Measure the maximum clearance between the top of spring

and try square.

• If it exceeds the limit, replace valve spring.

Valve Spring Dimensions and Valve Spring Pressure Load • Check the valve spring pressure at specified spring height.

• If the installation load or load with valve open is out of the stan- dard, replace valve spring.

ASSEMBLY 1. Install the valve guide, if necessary. CAUTION:

Replace with oversize [0.2 mm (0.008 in)] valve guide.

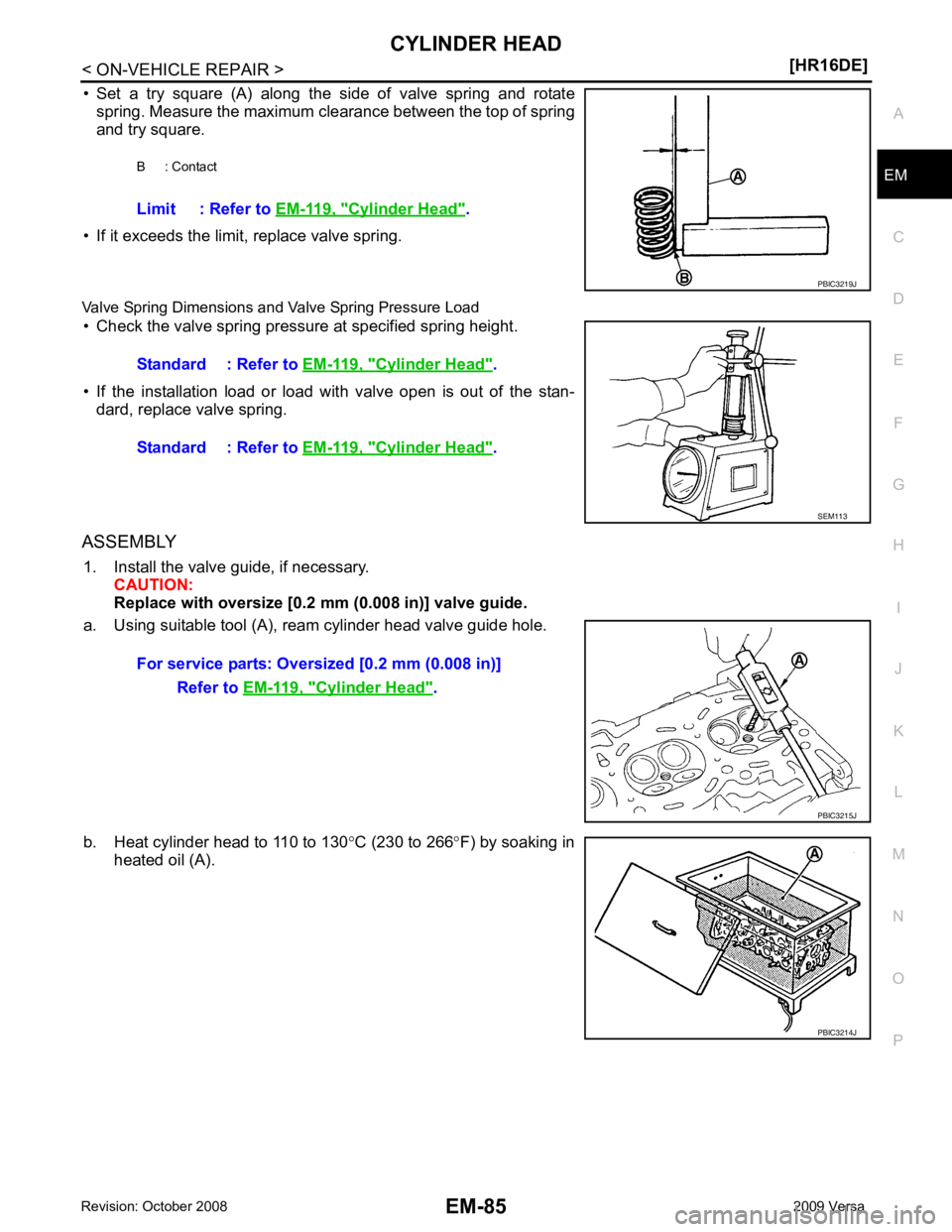

a. Using suitable tool (A), ream cylinder head valve guide hole.

b. Heat cylinder head to 110 to 130 °C (230 to 266 °F) by soaking in

heated oil (A). B : Contact

Limit : Refer to EM-119, " Cylinder Head " .

Cylinder Head " .

Standard : Refer to EM-119, " Cylinder Head " .

Cylinder Head " .

PBIC3214J

Page 3033 of 4331

![NISSAN TIIDA 2009 Service User Guide EM-86< ON-VEHICLE REPAIR >

[HR16DE]

CYLINDER HEAD

c. Using suitable tool, press valve guide (1) from camshaft side to the dimensions as shown.

WARNING:

Cylinder head (2) contains h eat. Wear protectiv NISSAN TIIDA 2009 Service User Guide EM-86< ON-VEHICLE REPAIR >

[HR16DE]

CYLINDER HEAD

c. Using suitable tool, press valve guide (1) from camshaft side to the dimensions as shown.

WARNING:

Cylinder head (2) contains h eat. Wear protectiv](/img/5/57398/w960_57398-3032.png)

EM-86< ON-VEHICLE REPAIR >

[HR16DE]

CYLINDER HEAD

c. Using suitable tool, press valve guide (1) from camshaft side to the dimensions as shown.

WARNING:

Cylinder head (2) contains h eat. Wear protective equipment

to avoid getting burned.

d. Using suitable tool (A), apply reamer finish to valve guide.

2. Install the valve seat, if necessary. CAUTION:

Replace with oversize [0.5 mm (0.020 in)] valve seat.

a. Ream cylinder head recess diameter (a) for service valve seat.

• Be sure to ream in circles concentric to valve guide center.This will enable valve to fit correctly.

b. Heat cylinder head to 110 to 130 °C (230 to 266 °F) by soaking in

heated oil (A).

c. Provide valve seats cooled well with dry ice. Force fit valve seat into cylinder head. WARNING:

• Cylinder head contains heat. Wear prot ective equipment to avoid getting burned.

• Avoid directly touching cold valve seats. Projection “H”: Refer to

EM-119, " Cylinder Head " .

PBIC3217J

Standard: Refer to

EM-119, " Cylinder Head " .

PBIC3215J

For service parts: Oversize [0.5 mm (0.020 in)]

Refer to EM-119, " Cylinder Head " .

JPBIA0188ZZ

PBIC3214J

Page 3034 of 4331

![NISSAN TIIDA 2009 Service User Guide CYLINDER HEAD

EM-87

< ON-VEHICLE REPAIR >

[HR16DE] C

D E

F

G H

I

J

K L

M A EM

NP

O

d. Using suitable tool or valve seat grinder, finish seat to the speci-

fied dimensions. Refer to EM-119, " Cylinder NISSAN TIIDA 2009 Service User Guide CYLINDER HEAD

EM-87

< ON-VEHICLE REPAIR >

[HR16DE] C

D E

F

G H

I

J

K L

M A EM

NP

O

d. Using suitable tool or valve seat grinder, finish seat to the speci-

fied dimensions. Refer to EM-119, " Cylinder](/img/5/57398/w960_57398-3033.png)

CYLINDER HEAD

EM-87

< ON-VEHICLE REPAIR >

[HR16DE] C

D E

F

G H

I

J

K L

M A EM

NP

O

d. Using suitable tool or valve seat grinder, finish seat to the speci-

fied dimensions. Refer to EM-119, " Cylinder Head " .

CAUTION:

When using the valve seat cutt er, firmly grip cutter handle

with both hands. Then, press on the contacting surface all

around the circumference to cu t in a single drive. Improper

pressure on with cutter or cu tting many different times may

result in stage valve seat.

e. Using compound, grind to adjust valve fitting.

f. Check again for normal contact. Refer to EM-82, " Disassembly and Assembly " .

3. Install valve oil seal. • Install with Tool (A) to match dimension as shown.

4. Install valve spring seat.

5. Install valve. • Install larger diameter to intake side.

6. Install valve spring. NOTE:

It can be installed in either direction.

7. Install valve spring retainer.

8. Install valve collet. • Compress valve spring with Tool (A). Install valve collet with amagnet hand (B).

CAUTION:

Be careful not to damage valve lifter holes.

• Tap valve stem edge lightly with a plastic hammer after instal-

lation to check its installed condition.

9. Install valve lifter.

10. Install spark plug with a suitable tool. SEM934C

Height “H” : 13.2 - 13.8 mm (0.520 - 0.543 in)

Tool number : KV10115600 (J-38958) PBIC3211J

Tool number : KV10116200 (J-26336-B)

: KV10115900 (J-26336-20)

: KV10109220 ( — ) PBIC3727E

Page 3057 of 4331

![NISSAN TIIDA 2009 Service User Guide EM-110< DISASSEMBLY AND ASSEMBLY >

[HR16DE]

CYLINDER BLOCK

CONNECTING ROD BEARING CRUSH HEIGHT

• When connecting rod bearing cap is removed after being tightened to the specified torque with co NISSAN TIIDA 2009 Service User Guide EM-110< DISASSEMBLY AND ASSEMBLY >

[HR16DE]

CYLINDER BLOCK

CONNECTING ROD BEARING CRUSH HEIGHT

• When connecting rod bearing cap is removed after being tightened to the specified torque with co](/img/5/57398/w960_57398-3056.png)

EM-110< DISASSEMBLY AND ASSEMBLY >

[HR16DE]

CYLINDER BLOCK

CONNECTING ROD BEARING CRUSH HEIGHT

• When connecting rod bearing cap is removed after being tightened to the specified torque with connecting rod bearings installed, the

tip end of bearing must protrude. Refer to EM-96, " Disassembly

and Assembly " .

• If the standard is not met, replace connecting rod bearings.

MAIN BEARING CAP BOLT OUTER DIAMETER

• Measure the outer diameters (“d 1”, “d 2”) at two positions as shown.

• If reduction appears in a position other than “d 2 ”, regard it as “d 2”.

• If it exceeds the limit (a large difference in dimensions), replace main bearing cap bolt with a new one.

CONNECTING ROD CAP BOLT OUTER DIAMETER

• Measure the outer diameter “d” at position as shown.

• If reduction appears in a position other than “d”, regard it as “d”.

• When “d” falls below the limit (when it becomes thinner), replace connecting rod cap bolt with a new one.

FLYWHEEL DEFLECTION

• Measure the deflection of flywheel contact surface to clutch with a

dial indicator.

• If measured value is out of the standard, replace flywheel. Standard: There must be crush height. PBIC1646E

Limit (“d

1”–“d 2”): 0.2 mm (0.008 in) PBIC3768E

Limit: 7.75 mm (0.3051 in)

PBIC3769E

Standard : 0.25 mm (0.0098 in) or less.

PBIC2646E

Page 3058 of 4331

EM

NP

O

HOW TO SELECT PISTON AND BEARING

Description INFOID:0000000004784319

• The identification grade stamped on each part is the grade for the dimension measured in new condition.

This grade cannot apply to reused parts.

• For reused or repaired parts, measure the dimens ion accurately. Determine the grade by comparing the

measurement with the values of each selection table.

• For details of the measurement method of each part , the reuse standards and the selection method of the

selective fitting parts, follow the procedures.

Connecting Rod Bearing INFOID:0000000004784320

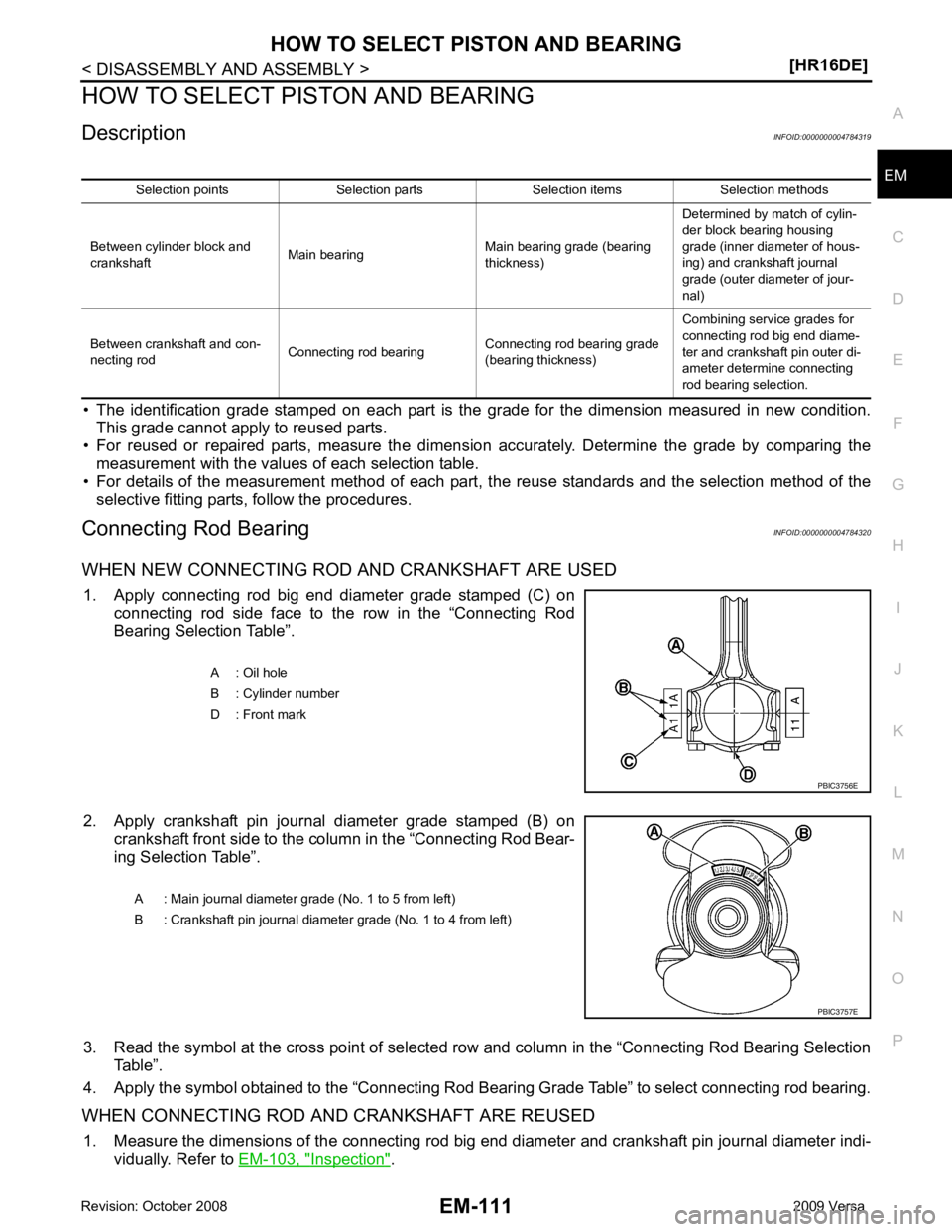

WHEN NEW CONNECTING ROD AND CRANKSHAFT ARE USED 1. Apply connecting rod big end diameter grade stamped (C) on connecting rod side face to the row in the “Connecting Rod

Bearing Selection Table”.

2. Apply crankshaft pin journal diameter grade stamped (B) on crankshaft front side to the column in the “Connecting Rod Bear-

ing Selection Table”.

3. Read the symbol at the cross point of selected ro w and column in the “Connecting Rod Bearing Selection

Table”.

4. Apply the symbol obtained to the “Connecting Rod Bear ing Grade Table” to select connecting rod bearing.

WHEN CONNECTING ROD AND CRANKSHAFT ARE REUSED 1. Measure the dimensions of the connecting rod big end diameter and crankshaft pin journal diameter indi-

vidually. Refer to EM-103, " Inspection " .

Selection points Selection parts Selection items Selection methods

Between cylinder block and

crankshaft Main bearing Main bearing grade (bearing

thickness) Determined by match of cylin-

der block bearing housing

grade (inner diameter of hous-

ing) and crankshaft journal

grade (outer diameter of jour-

nal)

Between crankshaft and con-

necting rod Connecting rod bearing Connecting rod bearing grade

(bearing thickness) Combining service grades for

connecting rod big end diame-

ter and crankshaft pin outer di-

ameter determine connecting

rod bearing selection. A : Oil hole

B : Cylinder number

D : Front mark

Page 3060 of 4331

![NISSAN TIIDA 2009 Service User Guide HOW TO SELECT PISTON AND BEARING

EM-113

< DISASSEMBLY AND ASSEMBLY >

[HR16DE] C

D E

F

G H

I

J

K L

M A EM

NP

O

In grinding crankshaft pin to

use undersize bearings, keep the

fillet R (A) [0.8 NISSAN TIIDA 2009 Service User Guide HOW TO SELECT PISTON AND BEARING

EM-113

< DISASSEMBLY AND ASSEMBLY >

[HR16DE] C

D E

F

G H

I

J

K L

M A EM

NP

O

In grinding crankshaft pin to

use undersize bearings, keep the

fillet R (A) [0.8](/img/5/57398/w960_57398-3059.png)

HOW TO SELECT PISTON AND BEARING

EM-113

< DISASSEMBLY AND ASSEMBLY >

[HR16DE] C

D E

F

G H

I

J

K L

M A EM

NP

O

In grinding crankshaft pin to

use undersize bearings, keep the

fillet R (A) [0.8 - 1.2 mm (0.031 - 0.047 in)].

Main Bearing INFOID:0000000004784321

HOW TO SELECT MAIN BEARING

When New Cylinder Block and Crankshaft Are Used

1. “Main Bearing Selection Table” rows correspond to main bearing housing grade on left side of cylinder block.

• If there is a corrected stamp mark (B) on cylinder block, use it as a correct reference.

2. Apply main journal diameter grade stamped on crankshaft front side to column in the “Main Bearing Selection Table”.

3. Read the symbol at the cross point of selected row and column in the “Main Bearing Selection Table”.

4. Apply the symbol obtained to the “Main B earing Grade Table” to select main bearing.

NOTE:

Service part is available as a set of both upper and lower.

When Cylinder Block and Crankshaft Are Reused 1. Measure the dimensions of the cylinder block ma in bearing housing inner diameter and crankshaft main

journal diameter individually. Refer to EM-103, " Inspection " .

2. Apply the measured dimension to t he “Main Bearing Selection Table”.

3. Read the symbol at the cross point of selected row and column in the “Main Bearing Selection Table”.

4. Apply the symbol obtained to the “Main B earing Grade Table” to select main bearing.

Bearing undersize table:

Refer to EM-124, " Connecting Rod Bearing " .

PBIC3263J

A : Basic stamp mark

: Engine front PBIC3760E

A : Main journal diameter grade (No. 1 to 5 from left)

B : Crankshaft pin journal diameter grade (No. 1 to 4 from left) PBIC3757E

Page 3066 of 4331

EM

NP

O

Cylinder Head

INFOID:0000000004784327

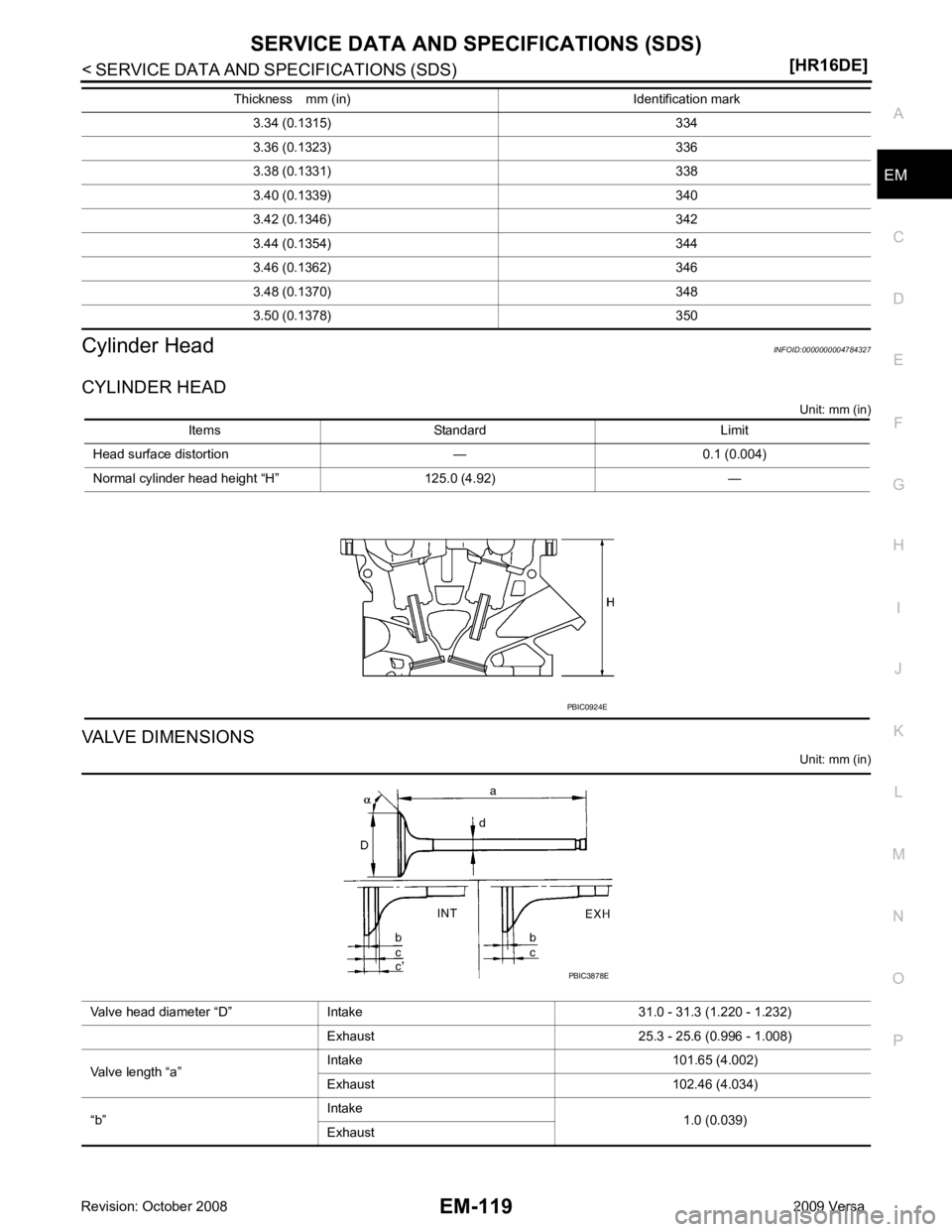

CYLINDER HEAD Unit: mm (in)

VALVE DIMENSIONS Unit: mm (in)

3.34 (0.1315) 334

3.36 (0.1323) 336

3.38 (0.1331) 338

3.40 (0.1339) 340

3.42 (0.1346) 342

3.44 (0.1354) 344

3.46 (0.1362) 346

3.48 (0.1370) 348

3.50 (0.1378) 350

Thickness mm (in) Identification mark Items Standard Limit

Head surface distortion — 0.1 (0.004)

Normal cylinder head height “H” 125.0 (4.92) —

Page 3079 of 4331

![NISSAN TIIDA 2009 Service User Guide EM-132< SERVICE INFORMATION >

[MR18DE]

PREPARATION

Commercial Service Tool INFOID:0000000004307120

KV10109300

( — )

Pulley holder Removing and installing crankshaft pulley

KV10111800

( — )

Val NISSAN TIIDA 2009 Service User Guide EM-132< SERVICE INFORMATION >

[MR18DE]

PREPARATION

Commercial Service Tool INFOID:0000000004307120

KV10109300

( — )

Pulley holder Removing and installing crankshaft pulley

KV10111800

( — )

Val](/img/5/57398/w960_57398-3078.png)

EM-132< SERVICE INFORMATION >

[MR18DE]

PREPARATION

Commercial Service Tool INFOID:0000000004307120

KV10109300

( — )

Pulley holder Removing and installing crankshaft pulley

KV10111800

( — )

Valve guide drift Removing and installing valve guide

Tool number

(Kent-Moore No.)

Tool name DescriptionNT628

PBIC4012E

(Kent-Moore No.)

Tool name Description

Power tool Loosening bolts and nuts

Spark plug wrench Removing and installing spark plug

Valve seat cutter set Finishing valve seat dimensions

Piston ring expander Removing and installing piston ring PBIC0190E

PBIC2982E

NT048

NT030

Page 3098 of 4331

EM

NP

O

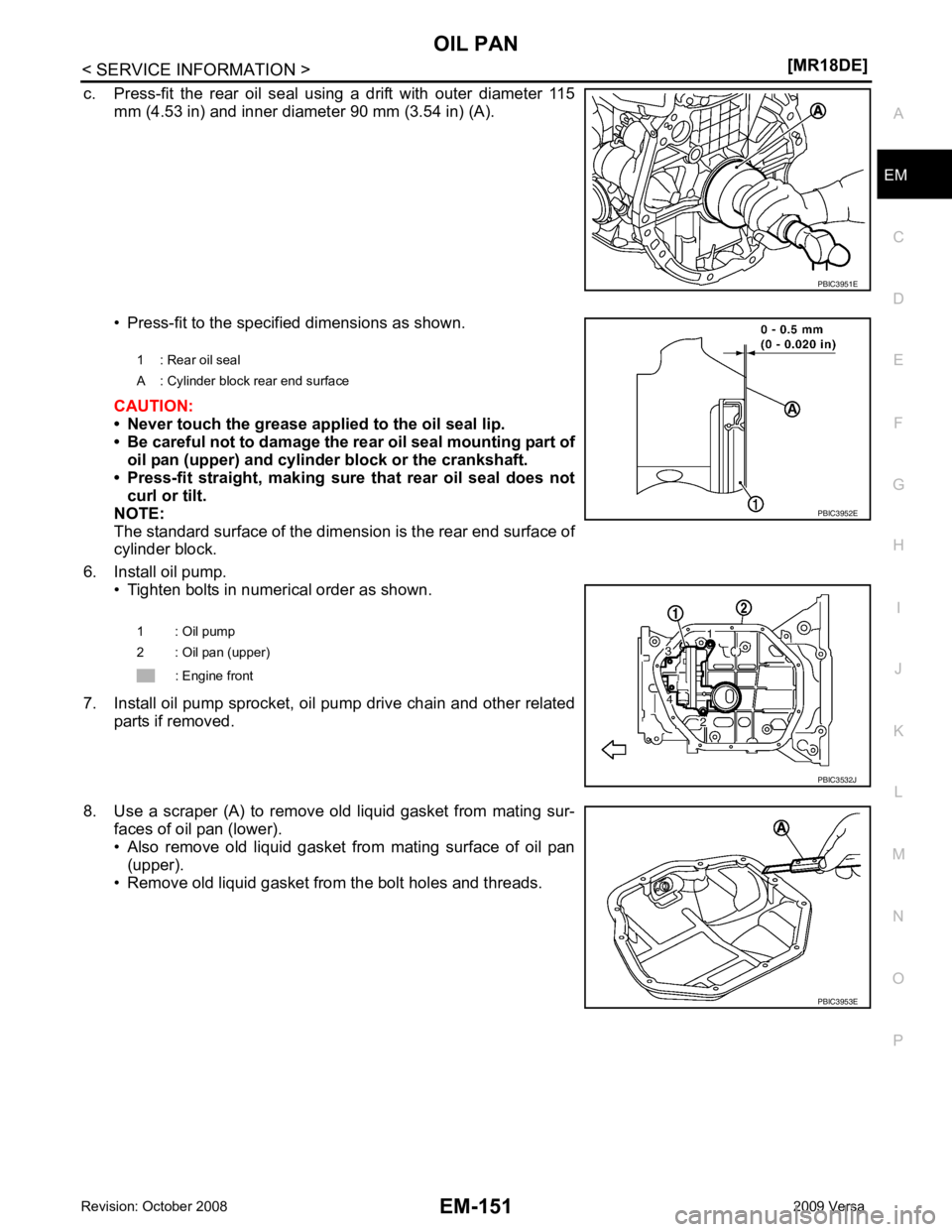

c. Press-fit the rear oil seal usi

ng a drift with outer diameter 115

mm (4.53 in) and inner diameter 90 mm (3.54 in) (A).

• Press-fit to the specified dimensions as shown.

CAUTION:

• Never touch the grease applied to the oil seal lip.

• Be careful not to damage the rear oil seal mounting part of

oil pan (upper) and cylinder block or the crankshaft.

• Press-fit straight, making sure that rear oil seal does not curl or tilt.

NOTE:

The standard surface of the dimens ion is the rear end surface of

cylinder block.

6. Install oil pump. • Tighten bolts in numerical order as shown.

7. Install oil pump sprocket, oil pump drive chain and other related parts if removed.

8. Use a scraper (A) to remove old liquid gasket from mating sur- faces of oil pan (lower).

• Also remove old liquid gasket from mating surface of oil pan (upper).

• Remove old liquid gasket from the bolt holes and threads. PBIC3953E

Page 3137 of 4331

![NISSAN TIIDA 2009 Service User Guide EM-190< SERVICE INFORMATION >

[MR18DE]

CYLINDER HEAD

3. Install valve oil seal. • Install with a valve oil seal using Tool (A) to match dimensionas shown.

NOTE:

Dimension (H) is height NISSAN TIIDA 2009 Service User Guide EM-190< SERVICE INFORMATION >

[MR18DE]

CYLINDER HEAD

3. Install valve oil seal. • Install with a valve oil seal using Tool (A) to match dimensionas shown.

NOTE:

Dimension (H) is height](/img/5/57398/w960_57398-3136.png)

EM-190< SERVICE INFORMATION >

[MR18DE]

CYLINDER HEAD

3. Install valve oil seal. • Install with a valve oil seal using Tool (A) to match dimensionas shown.

NOTE:

Dimension (H) is height that measured before installing valve

spring (with valve spring seat).

4. Install valve. • Install larger diameter to intake side.

5. Install valve spring (with valve spring seat). • Install smaller pitch (valve spring seat side) to cylinder head

side (B).

• Confirm identification color (A) of valve spring.

6. Install valve spring retainer.

7. Install valve collet. • Compress valve spring using Tool (A). Install valve collet with a magnet hand.

CAUTION:

When working, be careful not to damage valve lifter holes.

• Tap valve stem edge lightly with a plastic hammer after instal- lation to check its installed condition.

8. Install valve lifter. • Install it in the original position.

9. Install spark plug using suitable tool.

Inspection After Disassembly INFOID:0000000004307155

VALVE DIMENSIONS

• Check dimensions of each valve. For dimensions, refer to EM-227, " Standard and Limit " .

• If dimensions are out of the standard, replace valve.

VALVE GUIDE CLEARANCE

Valve Stem Diameter Tool number : KV10115600 (J-38958)

Height (H) : 15.1 - 15.7 mm (0.594 - 0.618 in) PBIC3211J

1 : Valve spring seat (Do not remove from valve spring.)

Intake : White

Exhaust : Orange PBIC3462J

Tool number : KV101092S0 (J-26336 B)

PBIC3209J