engine control system NISSAN TIIDA 2009 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2009, Model line: TIIDA, Model: NISSAN TIIDA 2009Pages: 4331, PDF Size: 58.04 MB

Page 2747 of 4331

EC

NP

O

DTC P0507 ISC SYSTEM

Description INFOID:0000000004500259

NOTE:

If DTC P0507 is displayed with ot her DTC, first perform the trouble diagnosis for the other DTC.

The ECM controls the engine idle speed to a specified leve l through the fine adjustment of the air, which is let

into the intake manifold, by operating the electric thrott le control actuator. The operating of the throttle valve is

varied to allow for optimum control of the engine id ling speed. The ECM calculates the actual engine speed

from signals of camshaft position sensor (POS) and camshaft position sensor (PHASE).

The ECM controls the electric throttle control actuator so that the engine speed coincides with the target value

memorized in the ECM. The target engine speed is t he lowest speed at which the engine can operate steadily.

The optimum value stored in the ECM is determined by taking into consideration various engine conditions,

such as during warming up, deceleration, and engine load (air conditioner, power steering and cooling fan

operation, etc.).

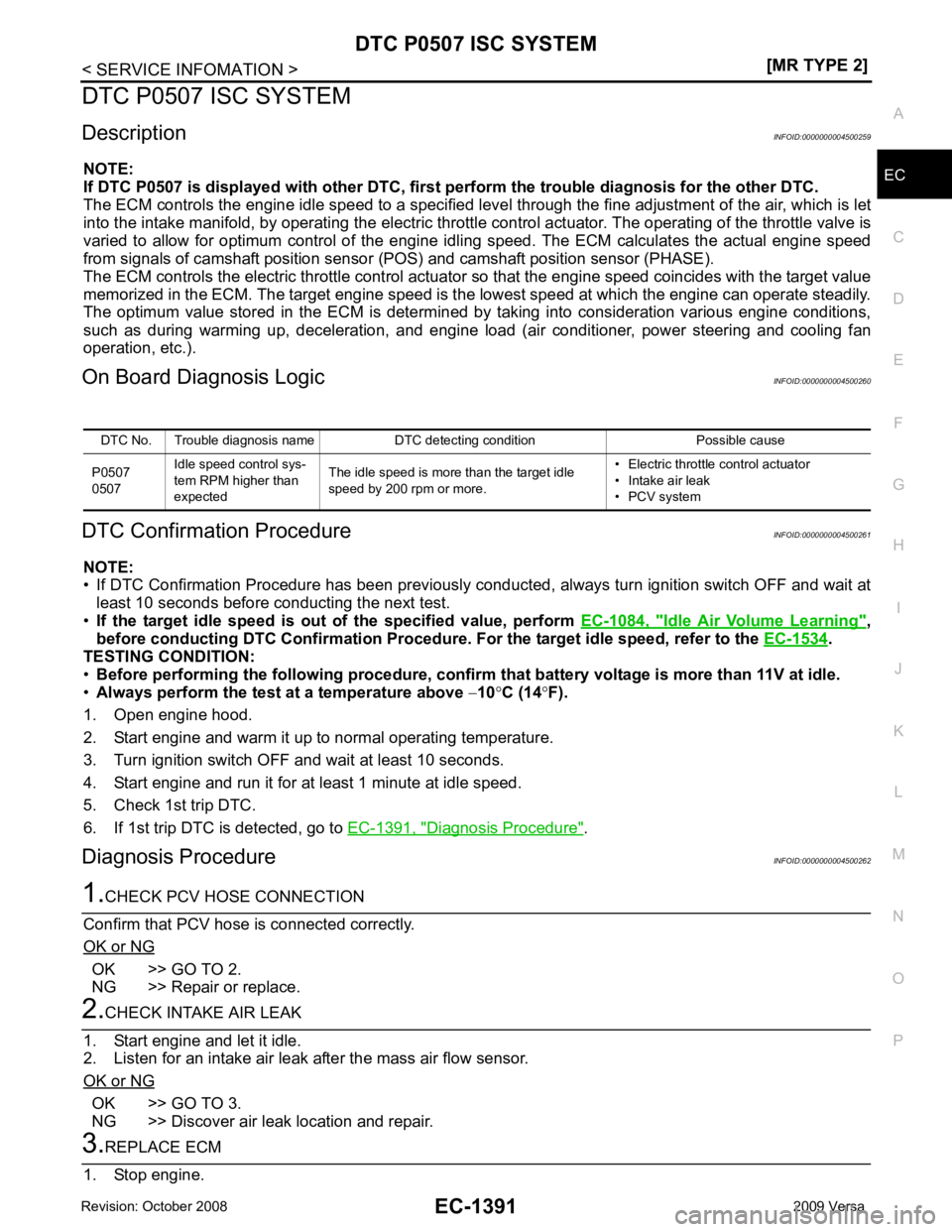

On Board Diagnosis Logic INFOID:0000000004500260

DTC Confirmation Procedure INFOID:0000000004500261

NOTE:

• If DTC Confirmation Procedure has been previously conduc ted, always turn ignition switch OFF and wait at

least 10 seconds before conducting the next test.

• If the target idle speed is out of the specified value, perform EC-1084, " Idle Air Volume Learning " ,

before conducting DTC Confirmation Procedure. For the target idle speed, refer to the EC-1534 .

TESTING CONDITION:

• Before performing the following procedure, confirm that battery voltage is more than 11V at idle.

• Always perform the test at a temperature above −10 °C (14 °F).

1. Open engine hood.

2. Start engine and warm it up to normal operating temperature.

3. Turn ignition switch OFF and wait at least 10 seconds.

4. Start engine and run it for at least 1 minute at idle speed.

5. Check 1st trip DTC.

6. If 1st trip DTC is detected, go to EC-1391, " Diagnosis Procedure " .

Diagnosis Procedure INFOID:0000000004500262OK >> GO TO 2.

NG >> Repair or replace. OK >> GO TO 3.

NG >> Discover air leak location and repair.

Page 2749 of 4331

![NISSAN TIIDA 2009 Service Repair Manual DTC P0605 ECM

EC-1393

< SERVICE INFOMATION >

[MR TYPE 2] C

D E

F

G H

I

J

K L

M A EC

NP

O

DTC P0605 ECM

Component Description INFOID:0000000004500263

The ECM consists of a microcomputer and conn NISSAN TIIDA 2009 Service Repair Manual DTC P0605 ECM

EC-1393

< SERVICE INFOMATION >

[MR TYPE 2] C

D E

F

G H

I

J

K L

M A EC

NP

O

DTC P0605 ECM

Component Description INFOID:0000000004500263

The ECM consists of a microcomputer and conn](/img/5/57398/w960_57398-2748.png)

DTC P0605 ECM

EC-1393

< SERVICE INFOMATION >

[MR TYPE 2] C

D E

F

G H

I

J

K L

M A EC

NP

O

DTC P0605 ECM

Component Description INFOID:0000000004500263

The ECM consists of a microcomputer and connectors for signal

input and output and for power supply. The ECM controls the engine.

On Board Diagnosis Logic INFOID:0000000004500264

This self-diagnosis has one or two trip detection logic.

FAIL-SAFE MODE ECM enters fail-safe mode when malfunction A is detected.

DTC Confirmation Procedure INFOID:0000000004500265

Perform PROCEDURE FOR MALFUNCTION A first. If th e 1st trip DTC cannot be confirmed, perform

PROCEDURE FOR MALFUNCTION B. If there is no malfunction on PROCEDURE FOR MALFUNCTION

B, perform PROCEDURE FOR MALFUNCTION C.

NOTE:

If DTC Confirmation Procedure has been previously conduc ted, always turn ignition switch OFF and wait at

least 10 seconds before conducting the next test.

PROCEDURE FOR MALFUNCTION A 1. Turn ignition switch ON.

2. Check 1st trip DTC.

3. If 1st trip DTC is detected, go to EC-1394, " Diagnosis Procedure " .

PROCEDURE FOR MALFUNCTION B 1. Turn ignition switch ON and wait at least 1 second.

2. Turn ignition switch OFF, wait at least 10 seconds and then turn ON.

3. Check 1st trip DTC.

4. If 1st trip DTC is detected, go to EC-1394, " Diagnosis Procedure " .

PROCEDURE FOR MALFUNCTION C 1. Turn ignition switch ON and wait at least 1 second.

2. Turn ignition switch OFF, wait at least 10 seconds and then turn ON.

3. Repeat step 2 for 32 times. PBIA9222J

DTC No. Trouble diagnosis name DTC detecting condition Possible cause

P0605

0605 Engine control module A) ECM calculation function is malfunctioning.

• ECM

B) ECM EEP-ROM system is malfunctioning.

C) ECM self shut-off function is malfunctioning. Detected items Engine operation condition in fail-safe mode

Malfunction A • ECM stops the electric throttle control actuator control, throttle valve is maintained at a fixed opening (approx. 5

degrees) by the return spring.

• ECM deactivates ASCD operation.

Page 2764 of 4331

![NISSAN TIIDA 2009 Service Repair Manual EC-1408< SERVICE INFOMATION >

[MR TYPE 2]

DTC P1217 ENGINE

OVER TEMPERATURE

DTC P1217 ENGINE OVER TEMPERATURE

System Description INFOID:0000000004500279

SYSTEM DESCRIPTION

NOTE:

• If DTC P1217 is d NISSAN TIIDA 2009 Service Repair Manual EC-1408< SERVICE INFOMATION >

[MR TYPE 2]

DTC P1217 ENGINE

OVER TEMPERATURE

DTC P1217 ENGINE OVER TEMPERATURE

System Description INFOID:0000000004500279

SYSTEM DESCRIPTION

NOTE:

• If DTC P1217 is d](/img/5/57398/w960_57398-2763.png)

EC-1408< SERVICE INFOMATION >

[MR TYPE 2]

DTC P1217 ENGINE

OVER TEMPERATURE

DTC P1217 ENGINE OVER TEMPERATURE

System Description INFOID:0000000004500279

SYSTEM DESCRIPTION

NOTE:

• If DTC P1217 is displayed with DTC UXXXX, first perform the tr ouble diagnosis for DTC UXXXX.

• If DTC P1217 is displayed with DTC P0607, first pe rform the trouble diagnosis for DTC P0607. Refer

to EC-1395 .

Cooling Fan Control

*1: The ECM determines the start signal status by the signals of engine speed and battery voltage.

*2: This signal is sent to ECM through CAN communication line.

The ECM controls the cooling fan corresponding to the vehicle speed, engine coolant temperature, refrigerant

pressure, and air conditioner ON signal. The contro l system has 3-step control [HIGH/LOW/OFF].

Cooling Fan Operation

Models with A/C

Models without A/C Sensor Input Signal to ECM ECM function Actuator

Crankshaft position sensor (POS)

Camshaft position sensor (PHASE) Engine speed*

1

Cooling fan

control IPDM E/R

(Cooling fan relays)

Battery

Battery voltage*1

ABS actuator and electric unit (control unit)

Vehicle speed*2

Combination meter

Engine coolant temperature sensor Engine coolant temperature

Air conditioner switch Air conditioner ON signal*2

Refrigerant pressure sensor Refrigerant pressure PBIB2483E

PBIB3335E

Page 2765 of 4331

EC

NP

O

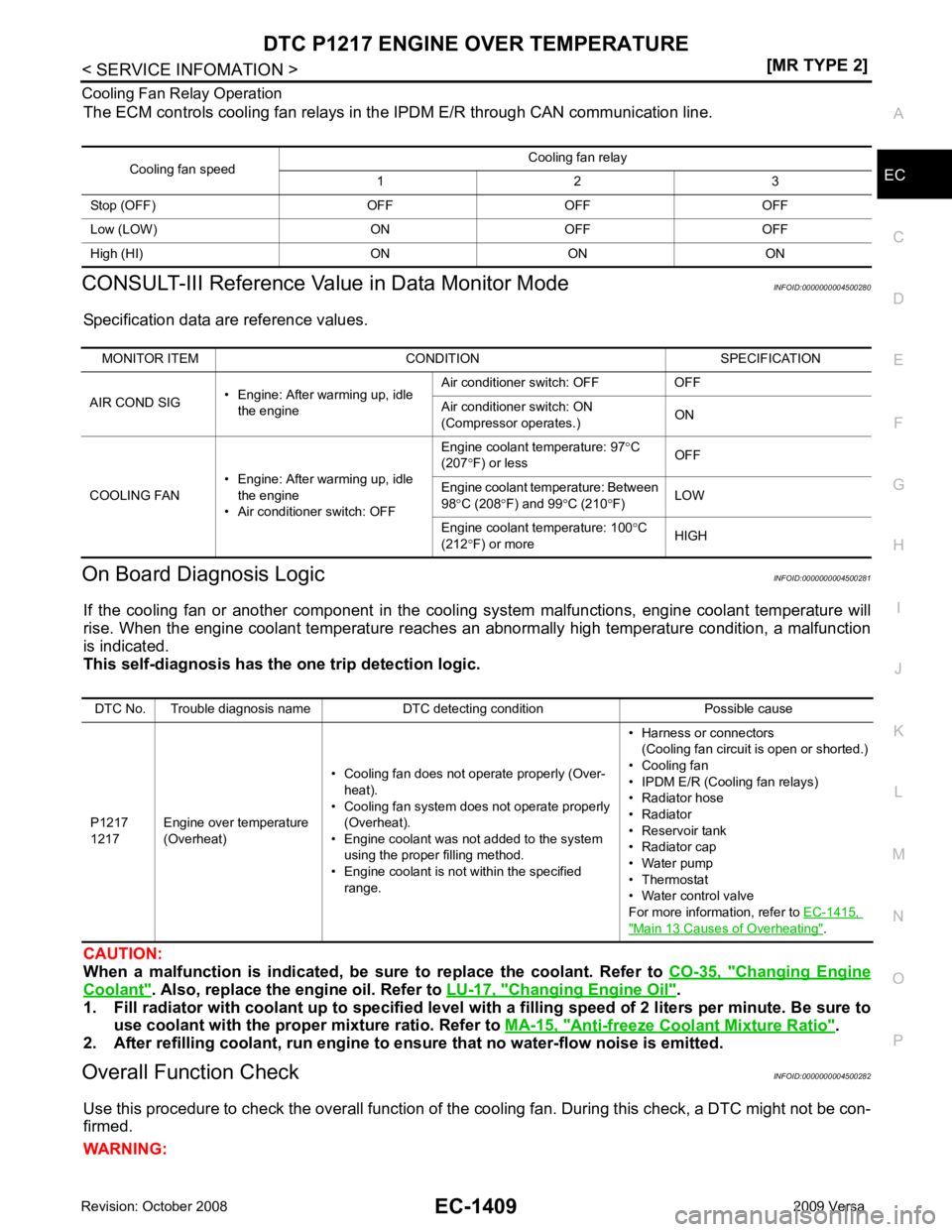

Cooling Fan Relay Operation

The ECM controls cooling fan relays in the IPDM E/R through CAN communication line.

CONSULT-III Reference Val ue in Data Monitor Mode INFOID:0000000004500280

Specification data are reference values.

On Board Diagnosis Logic INFOID:0000000004500281

If the cooling fan or another component in the cooli ng system malfunctions, engine coolant temperature will

rise. When the engine coolant temperature reaches an abnormally high temperature condition, a malfunction

is indicated.

This self-diagnosis has the on e trip detection logic.

CAUTION:

When a malfunction is in dicated, be sure to replace the coolant. Refer to CO-35, " Changing Engine

Coolant " . Also, replace the engine oil. Refer to

LU-17, " Changing Engine Oil " .

1. Fill radiator with coolant up to specified level with a filling speed of 2 liters per minute. Be sure to

use coolant with the proper mixture ratio. Refer to MA-15, " Anti-freeze Coolant Mixture Ratio " .

2. After refilling coolant, run engine to ensure that no water-flow noise is emitted.

Overall Function Check INFOID:0000000004500282

Use this procedure to check the overall function of the cooling fan. During this check, a DTC might not be con-

firmed.

WARNING: Cooling fan speed

Cooling fan relay

1 2 3

Stop (OFF) OFF OFF OFF

Low (LOW) ON OFF OFF

High (HI) ON ON ON MONITOR ITEM CONDITION SPECIFICATION

AIR COND SIG • Engine: After warming up, idle

the engine Air conditioner switch: OFF OFF

Air conditioner switch: ON

(Compressor operates.) ON

COOLING FAN • Engine: After warming up, idle

the engine

• Air conditioner switch: OFF Engine coolant temperature: 97

°C

(207 °F) or less OFF

Engine coolant temperature: Between

98 °C (208 °F) and 99 °C (210 °F) LOW

Engine coolant temperature: 100 °C

(212 °F) or more HIGHDTC No. Trouble diagnosis name DTC detecting condition Possible cause

P1217

1217 Engine over temperature

(Overheat) • Cooling fan does not operate properly (Over-

heat).

• Cooling fan system does not operate properly (Overheat).

• Engine coolant was not added to the system using the proper filling method.

• Engine coolant is not within the specified

range. • Harness or connectors

(Cooling fan circuit is open or shorted.)

• Cooling fan

• IPDM E/R (Cooling fan relays)

• Radiator hose

• Radiator

• Reservoir tank

• Radiator cap

• Water pump

• Thermostat

• Water control valve

For more information, refer to EC-1415, " Main 13 Causes of Overheating " .

Page 2777 of 4331

EC

NP

O

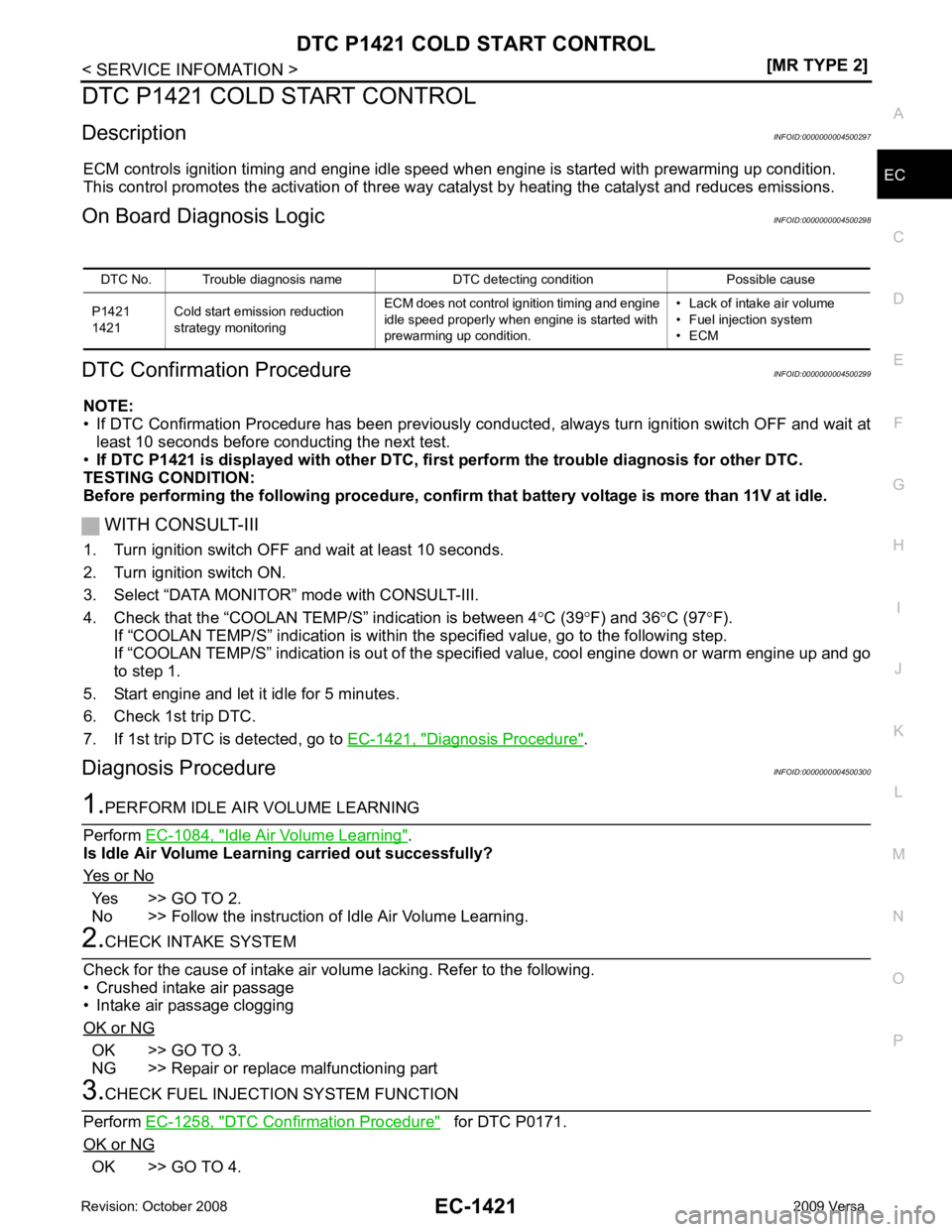

DTC P1421 COLD START CONTROL

Description INFOID:0000000004500297

ECM controls ignition timing and engine idle speed when engine is started with prewarming up condition.

This control promotes the activation of three way ca talyst by heating the catalyst and reduces emissions.

On Board Diagnosis Logic INFOID:0000000004500298

DTC Confirmation Procedure INFOID:0000000004500299

NOTE:

• If DTC Confirmation Procedure has been previously conduc ted, always turn ignition switch OFF and wait at

least 10 seconds before conducting the next test.

• If DTC P1421 is displayed with other DTC, firs t perform the trouble diagnosis for other DTC.

TESTING CONDITION:

Before performing the following procedure, confirm that battery voltage is more than 11V at idle.

WITH CONSULT-III

1. Turn ignition switch OFF and wait at least 10 seconds.

2. Turn ignition switch ON.

3. Select “DATA MONITOR” mode with CONSULT-III.

4. Check that the “COOLAN TE MP/S” indication is between 4°C (39 °F) and 36 °C (97 °F).

If “COOLAN TEMP/S” indication is within the specified value, go to the following step.

If “COOLAN TEMP/S” indication is out of the s pecified value, cool engine down or warm engine up and go

to step 1.

5. Start engine and let it idle for 5 minutes.

6. Check 1st trip DTC.

7. If 1st trip DTC is detected, go to EC-1421, " Diagnosis Procedure " .

Diagnosis Procedure INFOID:0000000004500300Idle Air Volume Learning " .

Is Idle Air Volume Learning carried out successfully?

Yes or No Yes >> GO TO 2.

No >> Follow the instruction of Idle Air Volume Learning. OK >> GO TO 3.

NG >> Repair or replace malfunctioning part DTC Confirmation Procedure " for DTC P0171.

OK or NG OK >> GO TO 4.DTC No. Trouble diagnosis name DTC detecting condition Possible cause

P1421

1421 Cold start emission reduction

strategy monitoring ECM does not control ignition timing and engine

idle speed properly when engine is started with

prewarming up condition. • Lack of intake air volume

• Fuel injection system

• ECM

Page 2825 of 4331

![NISSAN TIIDA 2009 Service Repair Manual DTC P2127, P2128 APP SENSOR

EC-1469

< SERVICE INFOMATION >

[MR TYPE 2] C

D E

F

G H

I

J

K L

M A EC

NP

O

DTC P2127, P2128 APP SENSOR

Component Description INFOID:0000000004501216

The accelerator pedal NISSAN TIIDA 2009 Service Repair Manual DTC P2127, P2128 APP SENSOR

EC-1469

< SERVICE INFOMATION >

[MR TYPE 2] C

D E

F

G H

I

J

K L

M A EC

NP

O

DTC P2127, P2128 APP SENSOR

Component Description INFOID:0000000004501216

The accelerator pedal](/img/5/57398/w960_57398-2824.png)

DTC P2127, P2128 APP SENSOR

EC-1469

< SERVICE INFOMATION >

[MR TYPE 2] C

D E

F

G H

I

J

K L

M A EC

NP

O

DTC P2127, P2128 APP SENSOR

Component Description INFOID:0000000004501216

The accelerator pedal position sensor is installed on the upper end

of the accelerator pedal assembly. The sensor detects the accelera-

tor position and sends a signal to the ECM.

Accelerator pedal position sensor has two sensors. These sensors

are a kind of potentiometers which transform the accelerator pedal

position into output voltage, and emit the voltage signal to the ECM.

In addition, these sensors detect the opening and closing speed of

the accelerator pedal and feed the voltage signals to the ECM. The

ECM judges the current opening angle of the accelerator pedal from

these signals and controls the throttle control motor based on these

signals.

Idle position of the accelerato r pedal is determined by the ECM

receiving the signal from the accelerator pedal positi on sensor. The ECM uses this signal for the engine oper-

ation such as fuel cut.

CONSULT-III Reference Val ue in Data Monitor Mode INFOID:0000000004501217

Specification data are reference values.

*: Accelerator pedal position sensor 2 signal is converted by ECM internally. Thus, it differs from ECM terminal voltage.

On Board Diagnosis Logic INFOID:0000000004500369

These self-diagnoses have the on e trip detection logic.

FAIL-SAFE MODE When the malfunction is detected, ECM ent ers fail-safe mode and the MIL lights up. PBIB1741E

MONITOR ITEM CONDITION SPECIFICATION

ACCEL SEN 1 • Ignition switch: ON

(Engine stopped) Accelerator pedal: Fully released 0.6 - 0.9V

Accelerator pedal: Fully depressed 4.0 - 4.8V

ACCEL SEN 2* • Ignition switch: ON

(Engine stopped) Accelerator pedal: Fully released 0.6 - 0.9V

Accelerator pedal: Fully depressed 3.9 - 4.8V

CLSD THL POS • Ignition switch: ON

(Engine stopped) Accelerator pedal: Fully released ON

Accelerator pedal: Slightly depressed OFF DTC No. Trouble diagnosis name DTC detecting condition Possible cause

P2127

2127 Accelerator pedal position

sensor 2 circuit low input An excessively low

voltage from the APP

sensor 2 is sent to ECM. • Harness or connectors

(APP sensor 2 circuit is open or shorted.)

[Crankshaft position sensor (POS) circuit

is shorted.]

(EVAP control system pressure sensor

circuit is shorted.)

(Refrigerant pressure sensor circuit is

shorted.)

• EVAP control system pressure sensor

• Accelerator pedal position sensor (APP sensor 2)

• Crankshaft position sensor (POS)

• Refrigerant pressure sensor

P2128

2128 Accelerator pedal position

sensor 2 circuit high input An excessively high

voltage from the APP

sensor 2 is sent to ECM. Engine operating condition in fail-safe mode

The ECM controls the electric throttle control actuator in regulating the throttle opening in order for the idle position to be within +10

degrees.

The ECM regulates the opening speed of the throttle valve to be slower than the normal condition.

So, the acceleration will be poor.

Page 2828 of 4331

![NISSAN TIIDA 2009 Service Repair Manual EC-1472< SERVICE INFOMATION >

[MR TYPE 2]

DTC P2127, P2128 APP SENSOR

Diagnosis Procedure INFOID:00000000045003721.

CHECK GROUND CONNECTIONS

1. Turn ignition switch OFF.

2. Loosen and retighten ground NISSAN TIIDA 2009 Service Repair Manual EC-1472< SERVICE INFOMATION >

[MR TYPE 2]

DTC P2127, P2128 APP SENSOR

Diagnosis Procedure INFOID:00000000045003721.

CHECK GROUND CONNECTIONS

1. Turn ignition switch OFF.

2. Loosen and retighten ground](/img/5/57398/w960_57398-2827.png)

EC-1472< SERVICE INFOMATION >

[MR TYPE 2]

DTC P2127, P2128 APP SENSOR

Diagnosis Procedure INFOID:00000000045003721.

CHECK GROUND CONNECTIONS

1. Turn ignition switch OFF.

2. Loosen and retighten ground screws on the body. Refer to EC-1144, " Ground Inspection " .

TER-

MI-

NAL

NO. WIRE

COLOR ITEM CONDITION DATA (DC Voltage)

74 W Sensor power supply

(Refrigerant pressure sen-

sor) [Ignition switch: ON]

Approximately 5V

75 BR Sensor power supply

[Crankshaft position sensor

(POS)] [Ignition switch: ON]

Approximately 5V

76 W EVAP control system pres-

sure sensor power supply [Ignition switch: ON]

Approximately 5V

102 SB Sensor power supply

(APP sensor 2) [Ignition switch: ON]

Approximately 5V

103 GR Accelerator pedal position

sensor 2 [Ignition switch: ON]

• Engine stopped

• Accelerator pedal: Fully released 0.3 - 0.6V

[Ignition switch: ON]

• Engine stopped

• Accelerator pedal: Fully depressed 1.95 - 2.4V

104 Y Sensor ground

(APP sensor 2) [Engine is running]

• Warm-up condition

• Idle speed Approximately 0V

106 P Sensor power supply

(APP sensor 1) [Ignition switch: ON]

Approximately 5V

110 G Accelerator pedal position

sensor 1 [Ignition switch: ON]

• Engine stopped

• Accelerator pedal: Fully released 0.6 - 0.9V

[Ignition switch: ON]

• Engine stopped

• Accelerator pedal: Fully depressed 3.9 - 4.7V

111 R Sensor ground

(APP sensor 1) [Engine is running]

• Warm-up condition

• Idle speed Approximately 0V:

Vehicle front

1. Body ground E24 2. Engine ground F9 3. Engine ground F16

4. Body ground E15 BBIA0698E

Page 2837 of 4331

![NISSAN TIIDA 2009 Service Repair Manual DTC P2138 APP SENSOR

EC-1481

< SERVICE INFOMATION >

[MR TYPE 2] C

D E

F

G H

I

J

K L

M A EC

NP

O

DTC P2138 APP SENSOR

Component Description INFOID:0000000004501218

The accelerator pedal position se NISSAN TIIDA 2009 Service Repair Manual DTC P2138 APP SENSOR

EC-1481

< SERVICE INFOMATION >

[MR TYPE 2] C

D E

F

G H

I

J

K L

M A EC

NP

O

DTC P2138 APP SENSOR

Component Description INFOID:0000000004501218

The accelerator pedal position se](/img/5/57398/w960_57398-2836.png)

DTC P2138 APP SENSOR

EC-1481

< SERVICE INFOMATION >

[MR TYPE 2] C

D E

F

G H

I

J

K L

M A EC

NP

O

DTC P2138 APP SENSOR

Component Description INFOID:0000000004501218

The accelerator pedal position sensor is installed on the upper end

of the accelerator pedal assembly. The sensor detects the accelera-

tor position and sends a signal to the ECM.

Accelerator pedal position sensor has two sensors. These sensors

are a kind of potentiometers which transform the accelerator pedal

position into output voltage, and emit the voltage signal to the ECM.

In addition, these sensors detect the opening and closing speed of

the accelerator pedal and feed the voltage signals to the ECM. The

ECM judges the current opening angle of the accelerator pedal from

these signals and controls the throttle control motor based on these

signals.

Idle position of the accelerato r pedal is determined by the ECM

receiving the signal from the accelerator pedal positi on sensor. The ECM uses this signal for the engine oper-

ation such as fuel cut.

CONSULT-III Reference Val ue in Data Monitor Mode INFOID:0000000004501219

Specification data are reference values.

*: Accelerator pedal position sensor 2 signal is converted by ECM internally. Thus, it differs from ECM terminal voltage.

On Board Diagnosis Logic INFOID:0000000004500385

This self-diagnosis has the on e trip detection logic.

NOTE:

If DTC P2138 is displayed with DTC P0643, first perform the trouble diagnosis for DTC P0643.

Refer to EC-1396 .

FAIL-SAFE MODE When the malfunction is detected, ECM ent ers fail-safe mode and the MIL lights up. PBIB1741E

MONITOR ITEM CONDITION SPECIFICATION

ACCEL SEN 1 • Ignition switch: ON

(Engine stopped) Accelerator pedal: Fully released 0.6 - 0.9V

Accelerator pedal: Fully depressed 4.0 - 4.8V

ACCEL SEN 2* • Ignition switch: ON

(Engine stopped) Accelerator pedal: Fully released 0.6 - 0.9V

Accelerator pedal: Fully depressed 3.9 - 4.8V

CLSD THL POS • Ignition switch: ON

(Engine stopped) Accelerator pedal: Fully released ON

Accelerator pedal: Slightly depressed OFF DTC No. Trouble diagnosis name DTC detecting condition Possible cause

P2138

2138 Accelerator

pedal posi-

tion sensor circuit range/

performance Rationally incorrect voltage is sent to ECM

compared with the signals from APP sensor 1

and APP sensor 2. • Harness or connector

(APP sensor 1 and 2 circuit is open or

shorted.)

[Crankshaft position sensor (POS) circuit

is shorted.]

(EVAP control system pressure sensor

circuit is shorted.)

(Refrigerant pressure sensor circuit is

shorted.)

• Accelerator pedal position sensor (APP sensor 1 and 2)

• Crankshaft position sensor (POS)

• EVAP control system pressure sensor

• Refrigerant pressure sensor

Page 2840 of 4331

![NISSAN TIIDA 2009 Service Repair Manual EC-1484< SERVICE INFOMATION >

[MR TYPE 2]

DTC P2138 APP SENSOR

Diagnosis Procedure INFOID:00000000045003881.

CHECK GROUND CONNECTIONS

1. Turn ignition switch OFF.

2. Loosen and retighten ground screws NISSAN TIIDA 2009 Service Repair Manual EC-1484< SERVICE INFOMATION >

[MR TYPE 2]

DTC P2138 APP SENSOR

Diagnosis Procedure INFOID:00000000045003881.

CHECK GROUND CONNECTIONS

1. Turn ignition switch OFF.

2. Loosen and retighten ground screws](/img/5/57398/w960_57398-2839.png)

EC-1484< SERVICE INFOMATION >

[MR TYPE 2]

DTC P2138 APP SENSOR

Diagnosis Procedure INFOID:00000000045003881.

CHECK GROUND CONNECTIONS

1. Turn ignition switch OFF.

2. Loosen and retighten ground screws on the body. Refer to EC-1144, " Ground Inspection " .

TER-

MI-

NAL

NO. WIRE

COLOR ITEM CONDITION DATA (DC Voltage)

74 W Sensor power supply

(Refrigerant pressure sen-

sor) [Ignition switch: ON]

Approximately 5V

75 BR Sensor power supply

[Crankshaft position sensor

(POS)] [Ignition switch: ON]

Approximately 5V

76 W EVAP control system pres-

sure sensor power supply [Ignition switch: ON]

Approximately 5V

102 SB Sensor power supply

(APP sensor 2) [Ignition switch: ON]

Approximately 5V

103 GR Accelerator pedal position

sensor 2 [Ignition switch: ON]

• Engine stopped

• Accelerator pedal: Fully released 0.3 - 0.6V

[Ignition switch: ON]

• Engine stopped

• Accelerator pedal: Fully depressed 1.95 - 2.4V

104 Y Sensor ground

(APP sensor 2) [Engine is running]

• Warm-up condition

• Idle speed Approximately 0V

106 P Sensor power supply

(APP sensor 1) [Ignition switch: ON]

Approximately 5V

110 G Accelerator pedal position

sensor 1 [Ignition switch: ON]

• Engine stopped

• Accelerator pedal: Fully released 0.6 - 0.9V

[Ignition switch: ON]

• Engine stopped

• Accelerator pedal: Fully depressed 3.9 - 4.7V

111 R Sensor ground

(APP sensor 1) [Engine is running]

• Warm-up condition

• Idle speed Approximately 0V:

Vehicle front

1. Body ground E24 2. Engine ground F9 3. Engine ground F16

4. Body ground E15 BBIA0698E

Page 2869 of 4331

![NISSAN TIIDA 2009 Service Repair Manual FUEL PUMP

EC-1513

< SERVICE INFOMATION >

[MR TYPE 2] C

D E

F

G H

I

J

K L

M A EC

NP

O

FUEL PUMP

Description INFOID:0000000004500415

SYSTEM DESCRIPTION

*: ECM determines the start signal status by the s NISSAN TIIDA 2009 Service Repair Manual FUEL PUMP

EC-1513

< SERVICE INFOMATION >

[MR TYPE 2] C

D E

F

G H

I

J

K L

M A EC

NP

O

FUEL PUMP

Description INFOID:0000000004500415

SYSTEM DESCRIPTION

*: ECM determines the start signal status by the s](/img/5/57398/w960_57398-2868.png)

FUEL PUMP

EC-1513

< SERVICE INFOMATION >

[MR TYPE 2] C

D E

F

G H

I

J

K L

M A EC

NP

O

FUEL PUMP

Description INFOID:0000000004500415

SYSTEM DESCRIPTION

*: ECM determines the start signal status by the signals of engine speed and battery voltage.

The ECM activates the fuel pump for several seconds after the ignition switch is turned ON to improve engine

start ability. If the ECM receives a engine speed signal from the crankshaft position sensor (POS) and cam-

shaft position sensor (PHASE), it knows that the engi ne is rotating, and causes the pump to operate. If the

engine speed signal is not received when the ignition s witch is ON, the engine stalls. The ECM stops pump

operation and prevents battery discharging, thereby improving safety. The ECM does not directly drive the fuel

pump. It controls the ON/OFF fuel pump rela y, which in turn controls the fuel pump.

COMPONENT DESCRIPTION A turbine type design fuel pump is used in the fuel tank.

• Fuel level sensor unit and fuel pump (1)

• Fuel pressure regulator (2)

• Fuel level sensor (3)

• Fuel tank temperature sensor (4)

CONSULT-III Reference Val ue in Data Monitor Mode INFOID:0000000004500416

Specification data are reference values. Sensor Input Signal to ECM ECM Function Actuator

Crankshaft position sensor (POS)

Camshaft position sensor (PHASE) Engine speed*

Fuel pump control Fuel pump relay

Battery Battery voltage* Condition Fuel pump operation

Ignition switch is turned to ON Operates for 1 second

Engine running and cranking Operates

Engine: Stopped Stops in 1.5 seconds

Except as shown above Stops BBIA0704E

MONITOR ITEM CONDITION SPECIFICATION

FUEL PUMP RLY • For 1 second after turning ignition switch ON

• Engine running or cranking ON

• Except above conditions OFF