boot NISSAN TIIDA 2009 Service Owner's Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2009, Model line: TIIDA, Model: NISSAN TIIDA 2009Pages: 4331, PDF Size: 58.04 MB

Page 3262 of 4331

GI

N

O P

SYMBOLS

How to Follow Trouble Diagnosis INFOID:0000000004307360

DESCRIPTION NOTICE:

Trouble diagnoses indicate work procedures required to diagnose problems effectively. Observe the following

instructions before diagnosing.

1. Before performing trouble diagno ses, read the “Preliminary Check” , the “Symptom Chart” or the

“Work Flow”.

2. After repairs, re-check that the prob lem has been completely eliminated.

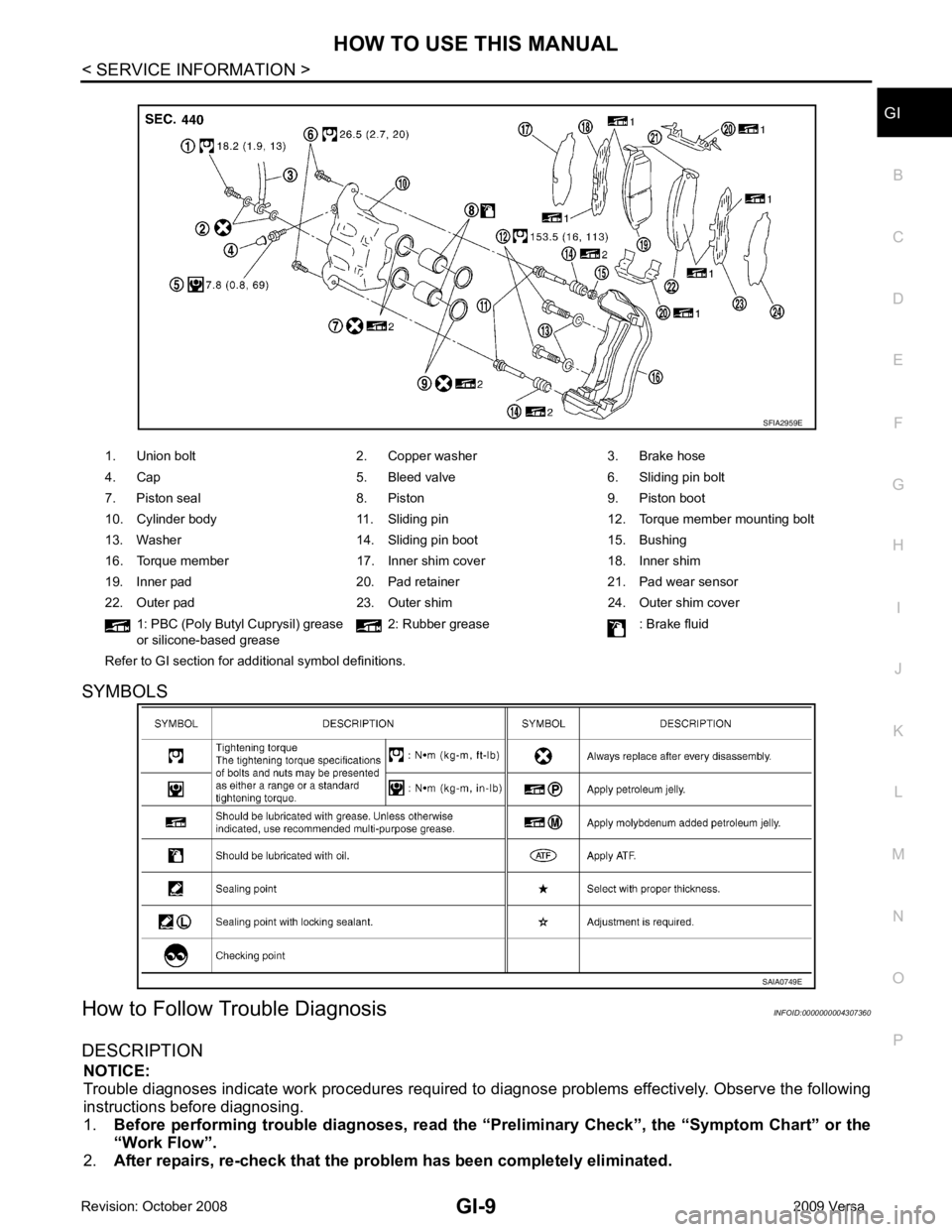

1. Union bolt 2. Copper washer 3. Brake hose

4. Cap 5. Bleed valve 6. Sliding pin bolt

7. Piston seal 8. Piston 9. Piston boot

10. Cylinder body 11. Sliding pin 12. Torque member mounting bolt

13. Washer 14. Sliding pin boot 15. Bushing

16. Torque member 17. Inner shim cover 18. Inner shim

19. Inner pad 20. Pad retainer 21. Pad wear sensor

22. Outer pad 23. Outer shim 24. Outer shim cover 1: PBC (Poly Butyl Cuprysil) grease

or silicone-based grease 2: Rubber grease : Brake fluid

Refer to GI section for additional symbol definitions.

Page 3382 of 4331

Removal and Installation " .

4. Remove front pillar garnish. Refer to EI-39 .

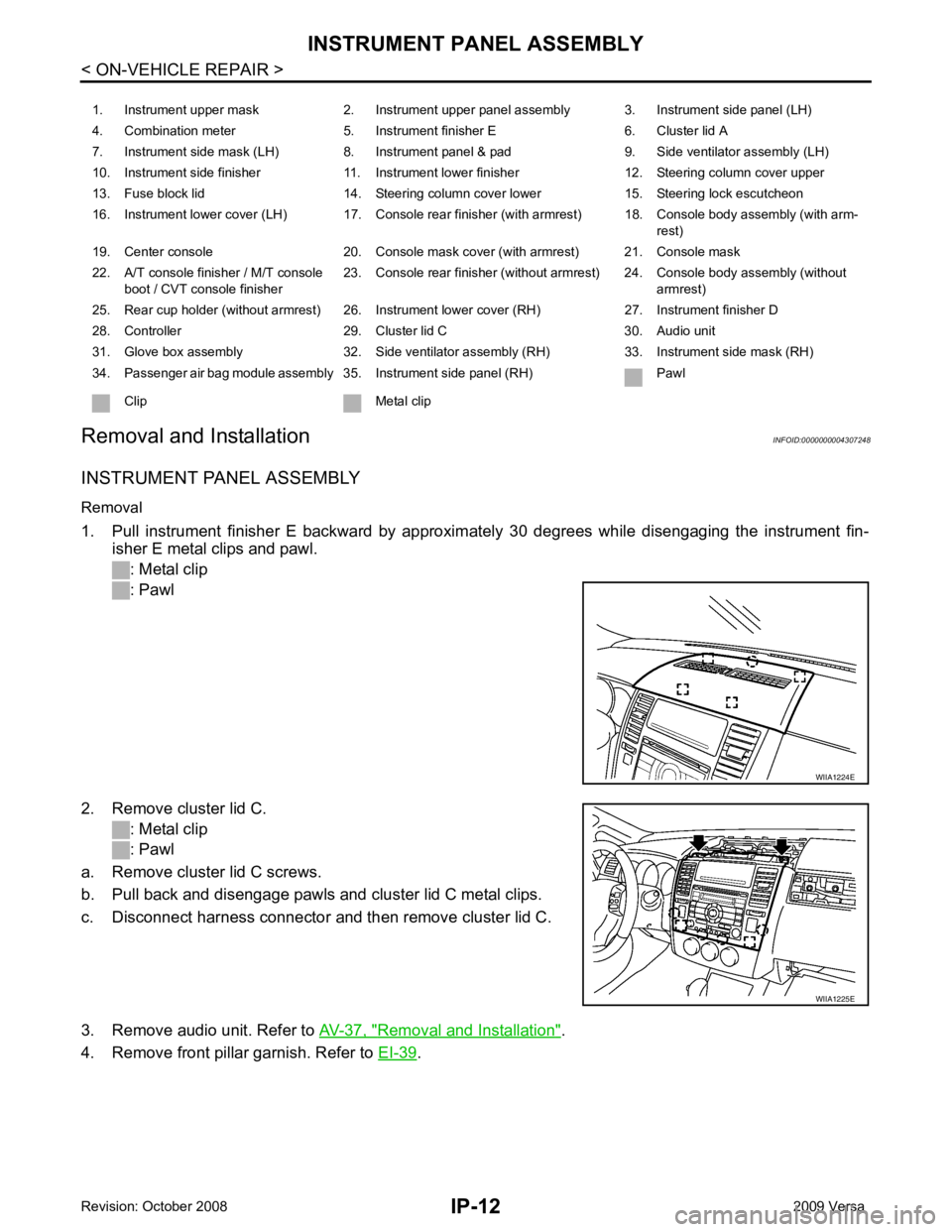

1. Instrument upper mask 2. Instrument upper panel assembly 3. Instrument side panel (LH)

4. Combination meter 5. Instrument finisher E 6. Cluster lid A

7. Instrument side mask (LH) 8. Instrument panel & pad 9. Side ventilator assembly (LH)

10. Instrument side finisher 11. Instrument lower finisher 12. Steering column cover upper

13. Fuse block lid 14. Steering column cover lower 15. Steering lock escutcheon

16. Instrument lower cover (LH) 17. Console rear finisher (with armrest) 18. Console body assembly (with arm- rest)

19. Center console 20. Console mask cover (with armrest) 21. Console mask

22. A/T console finisher / M/T console boot / CVT console finisher 23. Console rear finisher (without armrest) 24. Console body assembly (without

armrest)

25. Rear cup holder (without armrest) 26. Instrument lower cover (RH) 27. Instrument finisher D

28. Controller 29. Cluster lid C 30. Audio unit

31. Glove box assembly 32. Side ventilator assembly (RH) 33. Instrument side mask (RH)

34. Passenger air bag module assembly 35. Instrument side panel (RH) Pawl

Clip Metal clip WIIA1225E

Page 3392 of 4331

341, " Removal and Installation " (CVT),

AT-212, " Control Device

Removal and Installation " (A/T).

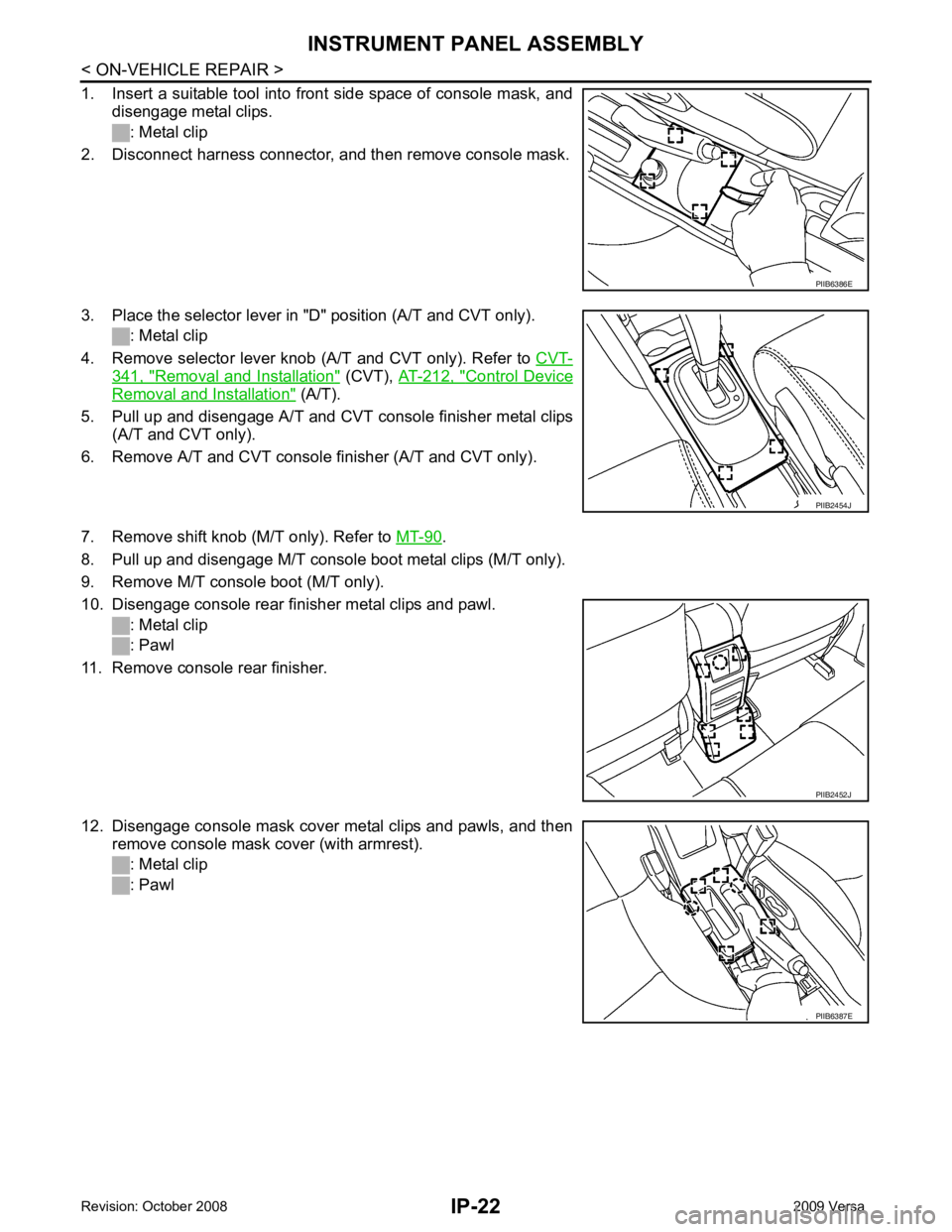

5. Pull up and disengage A/T and CVT console finisher metal clips (A/T and CVT only).

6. Remove A/T and CVT console finisher (A/T and CVT only).

7. Remove shift knob (M/T only). Refer to MT-90 .

8. Pull up and disengage M/T console boot metal clips (M/T only).

9. Remove M/T console boot (M/T only).

10. Disengage console rear finisher metal clips and pawl. : Metal clip

: Pawl

11. Remove console rear finisher.

12. Disengage console mask cover metal clips and pawls, and then remove console mask cover (with armrest).

: Metal clip

: Pawl PIIB2454J

PIIB6387E

Page 3754 of 4331

MA

N

O P

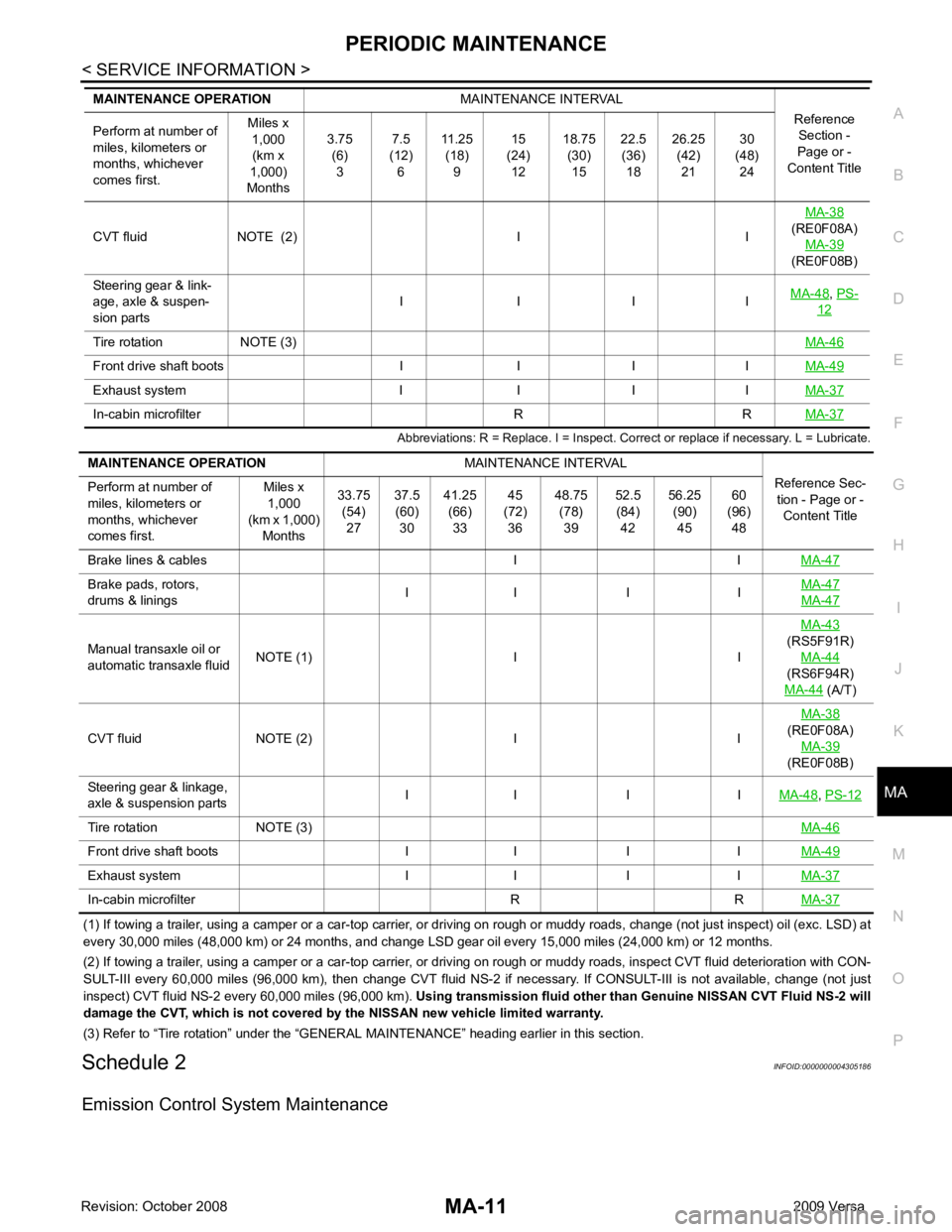

Abbreviations: R = Replace. I = Inspect. Corr

ect or replace if necessary. L = Lubricate.

(1) If towing a trailer, using a camper or a car-top carrier, or driving on rough or muddy roads, change (not just inspect) oil (exc. LSD) at

every 30,000 miles (48,000 km) or 24 months, and change LSD gear oil every 15,000 miles (24,000 km) or 12 months.

(2) If towing a trailer, using a camper or a car-top carrier, or driving on rough or muddy roads, inspect CVT fluid deteriorati on with CON-

SULT-III every 60,000 miles (96,000 km), then change CVT fluid NS-2 if necessary. If CONSULT-III is not available, change (not just

inspect) CVT fluid NS-2 every 60,000 miles (96,000 km). Using transmission fluid other than Genuine NISSAN CVT Fluid NS-2 will

damage the CVT, which is not covered by the NISSAN new vehicle limited warranty.

(3) Refer to “Tire rotation” under the “GENERAL MAINTENANCE” heading earlier in this section.

Schedule 2 INFOID:0000000004305186

Emission Control System Maintenance CVT fluid NOTE (2) I I

MA-38

(RE0F08A) MA-39

(RE0F08B)

Steering gear & link-

age, axle & suspen-

sion parts I I I I

MA-48 ,

PS- 12

Tire rotation NOTE (3)

MA-46Front drive shaft boots I I I I

MA-49Exhaust system I I I I

MA-37In-cabin microfilter R R

MA-37Brake pads, rotors,

drums & linings I I I I MA-47 MA-47

Manual transaxle oil or

automatic transaxle fluid NOTE (1) I I MA-43

(RS5F91R) MA-44

(RS6F94R)

MA-44 (A/T)

CVT fluid NOTE (2) I I MA-38

(RE0F08A)

MA-39

(RE0F08B)

Steering gear & linkage,

axle & suspension parts I I I I

MA-48 ,

PS-12 Tire rotation NOTE (3)

MA-46Front drive shaft boots I I I I

MA-49Exhaust system I I I I

MA-37In-cabin microfilter R R

MA-37

Page 3756 of 4331

MA

N

O P

(1) Using transmission fluid other than Genuine NISSAN CVT Flui

d NS-2 will damage the CVT, which is not covered by the

NISSAN new vehicle limited warranty .

(2) Refer to “Tire rotation” under the “GENERAL MAINTENANCE” heading earlier in this section.

Steering gear & linkage, axle &

suspension parts I I

MA-48 ,

PS-12 Tire rotation NOTE (2)

MA-46Front drive shaft boots I I I I

MA-49Exhaust system I I

MA-37In-cabin microfilter R R R R

MA-37

Page 3792 of 4331

MA

N

O P

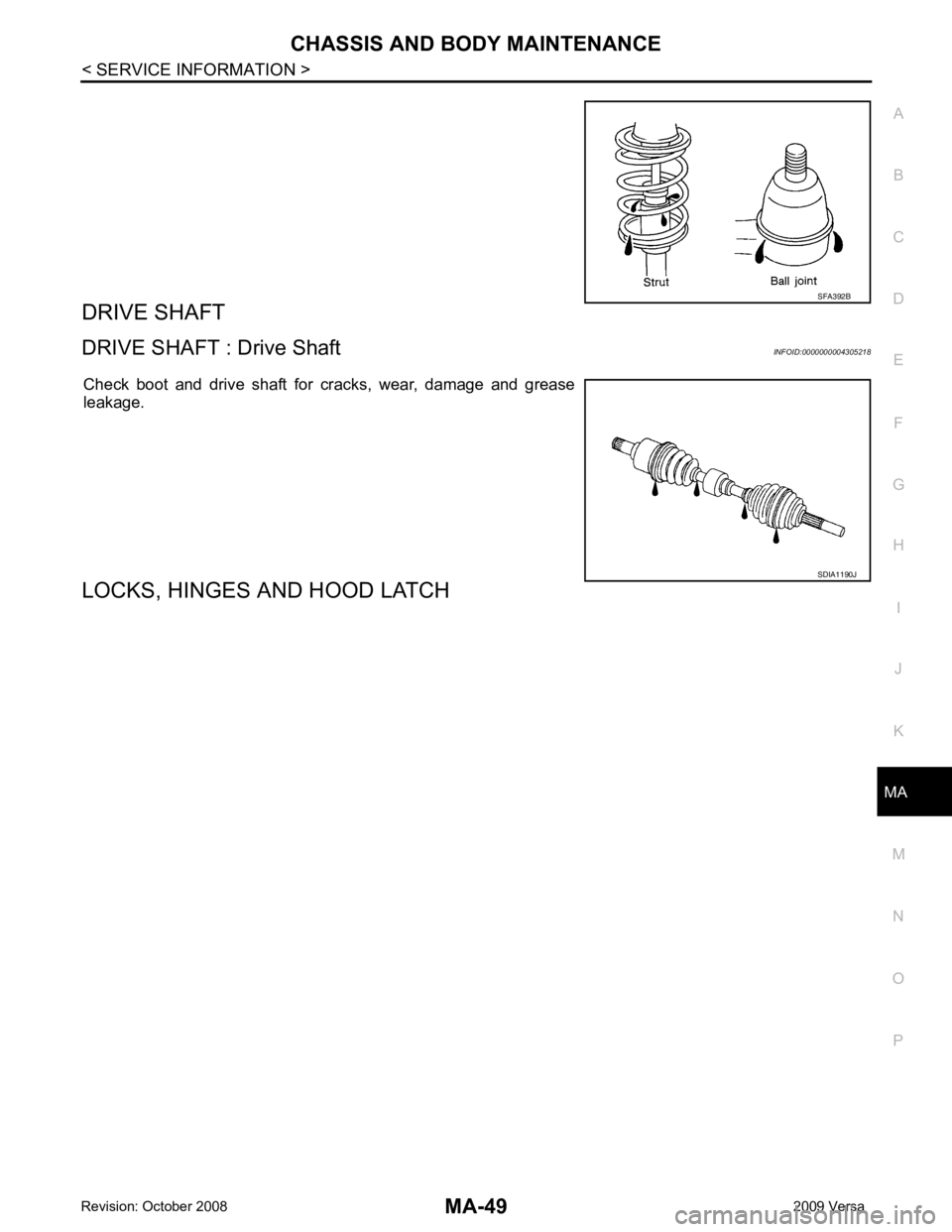

DRIVE SHAFT

DRIVE SHAFT : Drive Shaft INFOID:0000000004305218

Check boot and drive shaft for cracks, wear, damage and grease

leakage.

LOCKS, HINGES AND HOOD LATCH SDIA1190J

Page 3850 of 4331

Removal and

Installation " .

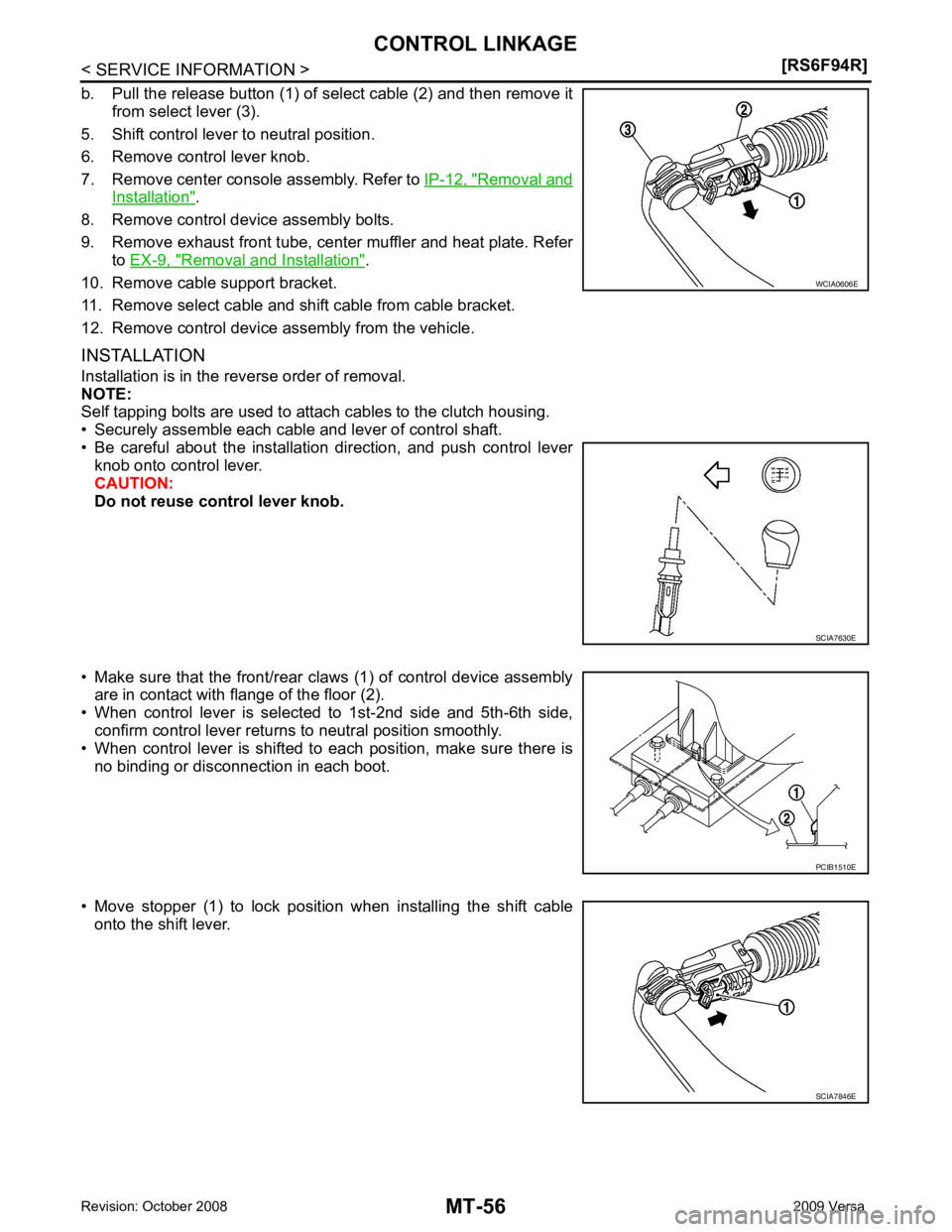

8. Remove control device assembly bolts.

9. Remove exhaust front tube, center muffler and heat plate. Refer to EX-9, " Removal and Installation " .

10. Remove cable support bracket.

11. Remove select cable and shift cable from cable bracket.

12. Remove control device assembly from the vehicle.

INSTALLATION

Installation is in the reverse order of removal.

NOTE:

Self tapping bolts are used to attach cables to the clutch housing.

• Securely assemble each cable and lever of control shaft.

• Be careful about the installation direction, and push control lever knob onto control lever.

CAUTION:

Do not reuse control lever knob.

• Make sure that the front/rear claws (1) of control device assembly are in contact with flange of the floor (2).

• When control lever is selected to 1st-2nd side and 5th-6th side,

confirm control lever returns to neutral position smoothly.

• When control lever is shifted to each position, make sure there is

no binding or disconnection in each boot.

• Move stopper (1) to lock position when installing the shift cable onto the shift lever. SCIA7630E

SCIA7846E

Page 4060 of 4331

PS-4< SERVICE INFORMATION >

PREPARATION

PREPARATION

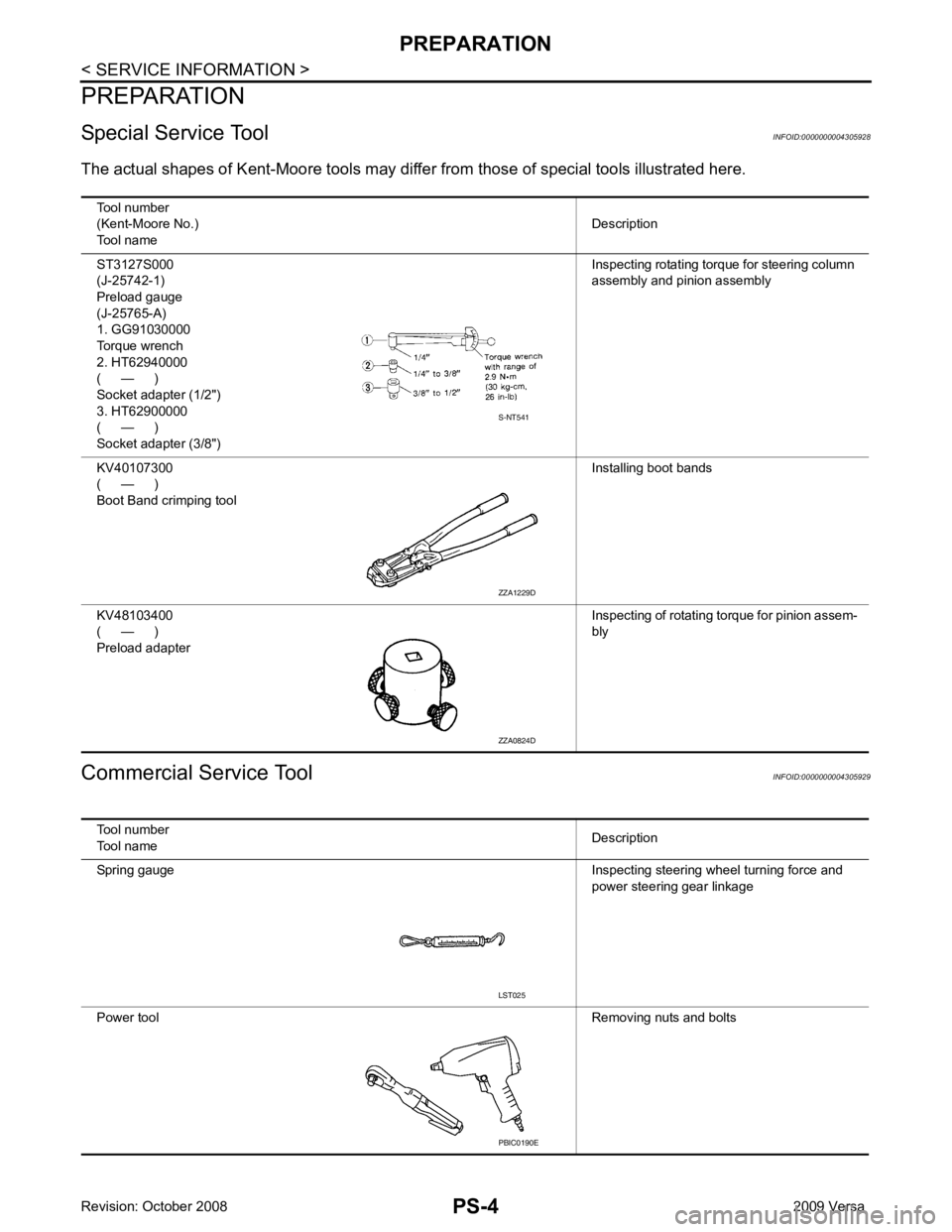

Special Service Tool INFOID:0000000004305928

The actual shapes of K ent-Moore tools may differ from thos e of special tools illustrated here.

Commercial Service Tool INFOID:0000000004305929

Tool number

(Kent-Moore No.)

Tool name Description

ST3127S000

(J-25742-1)

Preload gauge

(J-25765-A)

1. GG91030000

Torque wrench

2. HT62940000

( — )

Socket adapter (1/2")

3. HT62900000

( — )

Socket adapter (3/8") Inspecting rotating torque for steering column

assembly and pinion assembly

KV40107300

( — )

Boot Band crimping tool Installing boot bands

KV48103400

( — )

Preload adapter Inspecting of rotating torque for pinion assem-

bly S-NT541

ZZA1229D

ZZA0824D

Tool number

Tool name Description

Spring gauge Inspecting steering wheel turning force and

power steering gear linkage

Power tool Removing nuts and bolts LST025

PBIC0190E

Page 4068 of 4331

Rotation " .

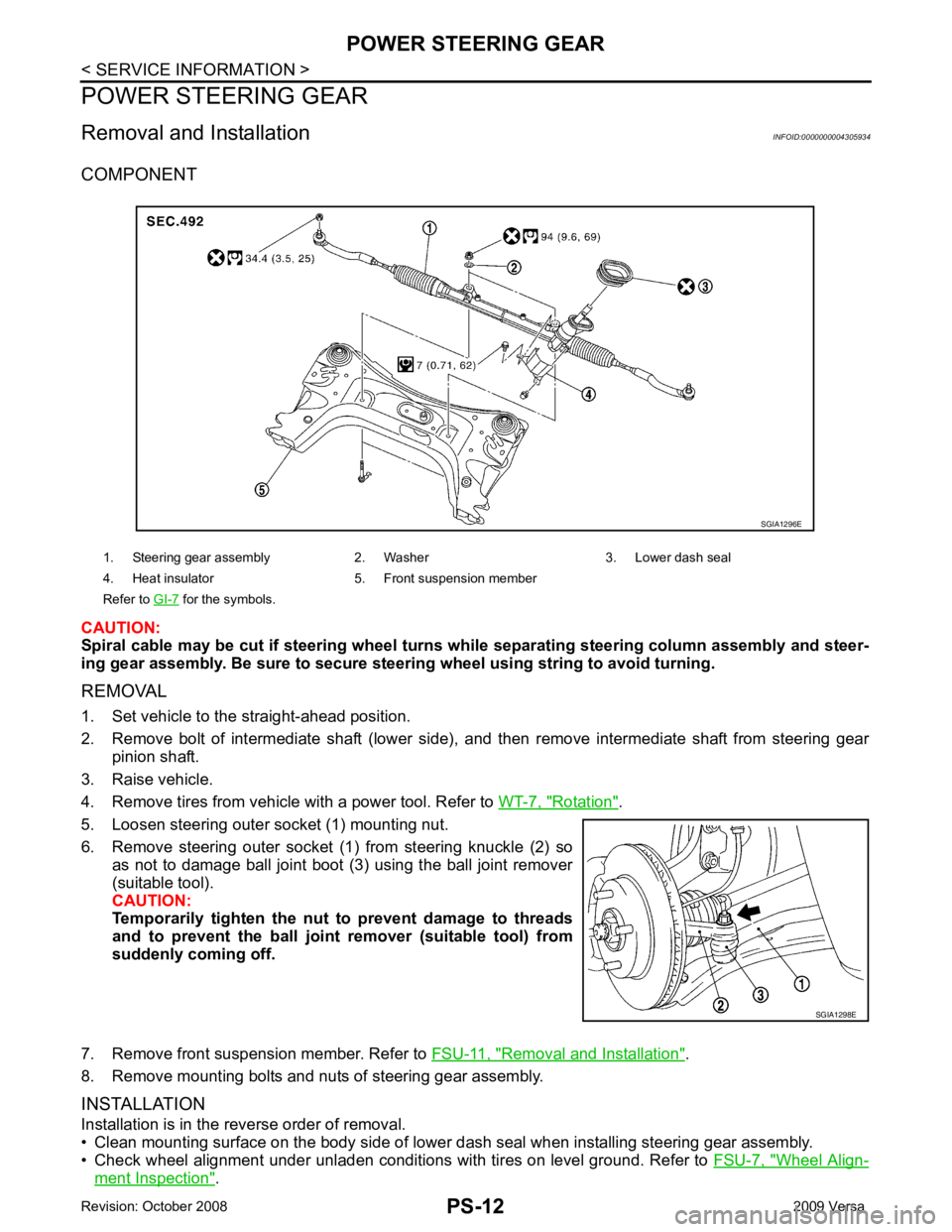

5. Loosen steering outer socket (1) mounting nut.

6. Remove steering outer socket (1) from steering knuckle (2) so as not to damage ball joint boot (3) using the ball joint remover

(suitable tool).

CAUTION:

Temporarily tighten the nut to prevent damage to threads

and to prevent the ball joint remover (suitable tool) from

suddenly coming off.

7. Remove front suspension member. Refer to FSU-11, " Removal and Installation " .

8. Remove mounting bolts and nuts of steering gear assembly.

INSTALLATION

Installation is in the reverse order of removal.

• Clean mounting surface on the body side of lower dash seal when installing steering gear assembly.

• Check wheel alignment under unladen conditions with tires on level ground. Refer to FSU-7, " Wheel Align-

ment Inspection " .

1. Steering gear assembly 2. Washer 3. Lower dash seal

4. Heat insulator 5. Front suspension member

Refer to GI-7 for the symbols.

SGIA1298E

Page 4069 of 4331

PS

N

O P

INSPECTION AFTER INSTALLATION

Rotate steering wheel to check for decentered conditi on, binding, noise or excessive steering effort.

Disassembly and Assembly INFOID:0000000004305935

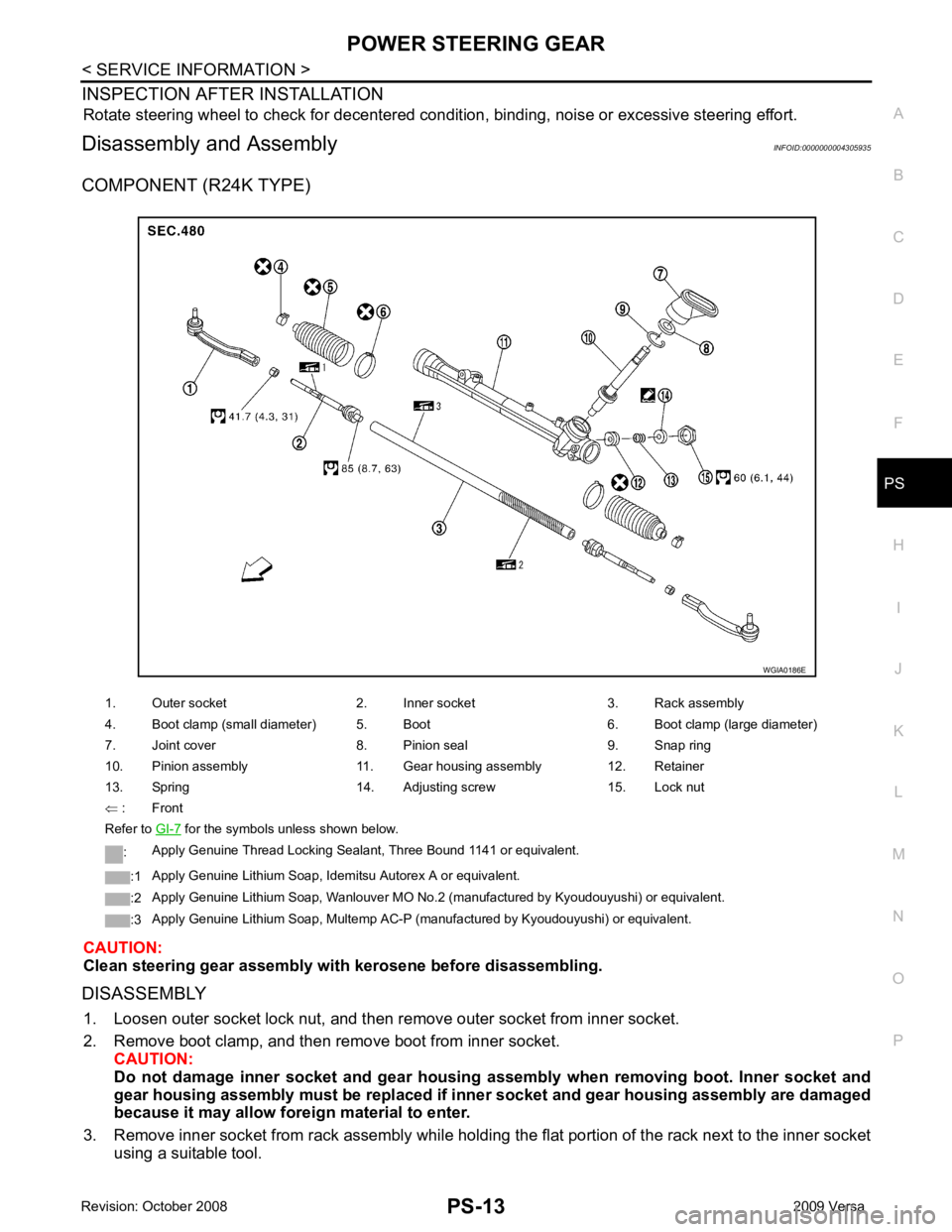

COMPONENT (R24K TYPE)

CAUTION:

Clean steering gear assembly with kerosene before disassembling.

DISASSEMBLY 1. Loosen outer socket lock nut, and then re move outer socket from inner socket.

2. Remove boot clamp, and then re move boot from inner socket.

CAUTION:

Do not damage inner socket an d gear housing assembly when re moving boot. Inner socket and

gear housing assembly must be replaced if inne r socket and gear housing assembly are damaged

because it may allow fore ign material to enter.

3. Remove inner socket from rack assembly while holdi ng the flat portion of the rack next to the inner socket

using a suitable tool.

1. Outer socket 2. Inner socket 3. Rack assembly

4. Boot clamp (small diameter) 5. Boot 6. Boot clamp (large diameter)

7. Joint cover 8. Pinion seal 9. Snap ring

10. Pinion assembly 11. Gear housing assembly 12. Retainer

13. Spring 14. Adjusting screw 15. Lock nut

⇐ : Front

Refer to GI-7 for the symbols unless shown below.

: Apply Genuine Thread Locking Sealant, Three Bound 1141 or equivalent.

:1 Apply Genuine Lithium Soap, Idemitsu Autorex A or equivalent.

:2 Apply Genuine Lithium Soap, Wanlouver MO No.2 (manufactured by Kyoudouyushi) or equivalent.

:3 Apply Genuine Lithium Soap, Multemp AC-P (manufactured by Kyoudouyushi) or equivalent.