fuel pump NISSAN TIIDA 2009 Service Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2009, Model line: TIIDA, Model: NISSAN TIIDA 2009Pages: 4331, PDF Size: 58.04 MB

Page 1846 of 4331

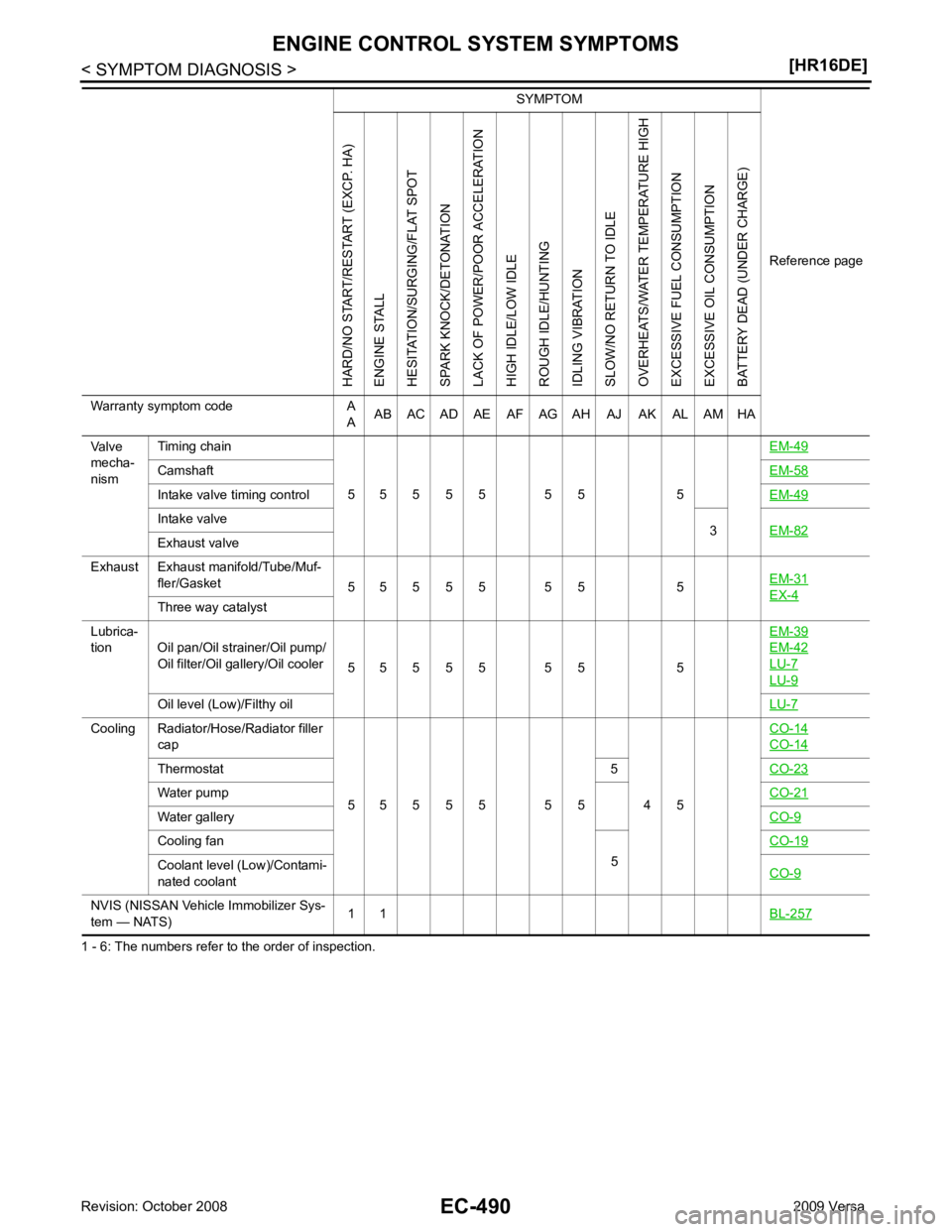

Camshaft

EM-58Intake valve timing control

EM-49Intake valve

3EM-82 Exhaust valve

Exhaust Exhaust manifold/Tube/Muf- fler/Gasket 5 5 5 5 5 5 5 5 EM-31 EX-4

Three way catalyst

Lubrica-

tion Oil pan/Oil strainer/Oil pump/ Oil filter/Oil gallery/Oil cooler 5 5 5 5 5 5 5 5 EM-39 EM-42

LU-7

LU-9

Oil level (Low)/Filthy oil

LU-7Cooling Radiator/Hose/Radiator filler

cap

5 5 5 5 5 5 5 4 5 CO-14 CO-14

Thermostat 5

CO-23Water pump

CO-21Water gallery

CO-9Cooling fan

5CO-19Coolant level (Low)/Contami-

nated coolant CO-9NVIS (NISSAN Vehicle Immobilizer Sys-

tem — NATS) 1 1

BL-257 SYMPTOM

Reference pageHARD/NO START/RESTART (EXCP. HA)

ENGINE STALL

HESITATION/SURGING/FLAT SPOT

SPARK KNOCK/DETONATION

LACK OF POWER/POOR ACCELERATION

HIGH IDLE/LOW IDLE

ROUGH IDLE/HUNTING

IDLING VIBRATION

SLOW/NO RETURN TO IDLE

OVERHEATS/WATER TEMPERATURE HIGH

EXCESSIVE FUEL CONSUMPTION

EXCESSIVE OIL CONSUMPTION

BATTERY DEAD (UNDER CHARGE)

Warranty symptom code A AAB AC AD AE AF AG AH AJ AK AL AM HA

Page 1851 of 4331

EC

NP

O

•

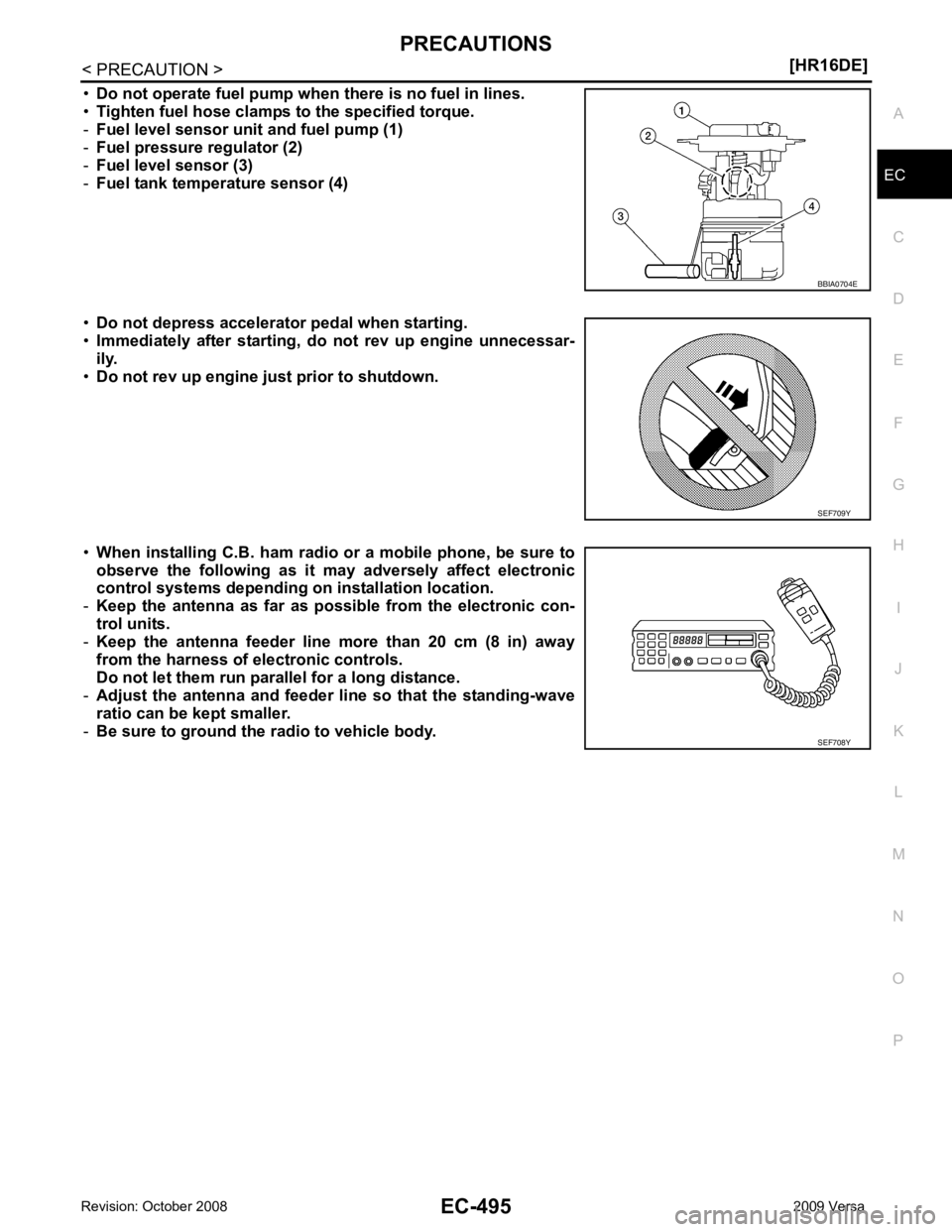

Do not operate fuel pump when there is no fuel in lines.

• Tighten fuel hose clamps to the specified torque.

- Fuel level sensor unit and fuel pump (1)

- Fuel pressure regulator (2)

- Fuel level sensor (3)

- Fuel tank temperature sensor (4)

• Do not depress accelerator pedal when starting.

• Immediately after starting, do not rev up engine unnecessar-

ily.

• Do not rev up engine ju st prior to shutdown.

• When installing C.B. ham radio or a mobile phone, be sure to

observe the following as it may adversely affect electronic

control systems depending on installation location.

- Keep the antenna as far as possible from the electronic con-

trol units.

- Keep the antenna feeder line more than 20 cm (8 in) away

from the harness of electronic controls.

Do not let them run para llel for a long distance.

- Adjust the antenna and feeder line so that the standing-wave

ratio can be kept smaller.

- Be sure to ground the radio to vehicle body.

Page 1855 of 4331

EC

NP

O

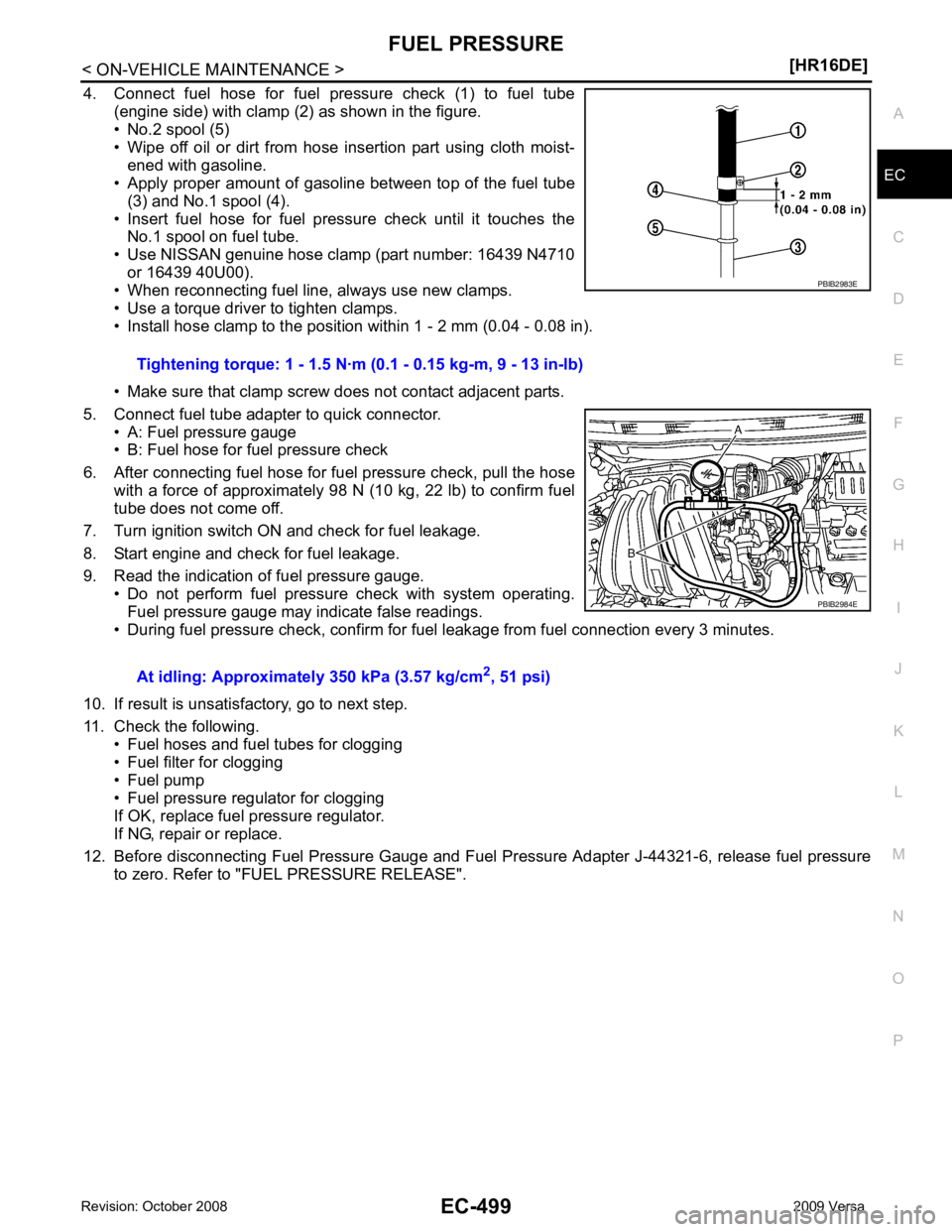

4. Connect fuel hose for fuel pressure check (1) to fuel tube

(engine side) with clamp (2) as shown in the figure.

• No.2 spool (5)

• Wipe off oil or dirt from hose insertion part using cloth moist-

ened with gasoline.

• Apply proper amount of gasoline between top of the fuel tube

(3) and No.1 spool (4).

• Insert fuel hose for fuel pressure check until it touches the No.1 spool on fuel tube.

• Use NISSAN genuine hose clamp (part number: 16439 N4710 or 16439 40U00).

• When reconnecting fuel line, always use new clamps.

• Use a torque driver to tighten clamps.

• Install hose clamp to the positi on within 1 - 2 mm (0.04 - 0.08 in).

• Make sure that clamp screw does not contact adjacent parts.

5. Connect fuel tube adapter to quick connector. • A: Fuel pressure gauge

• B: Fuel hose for fuel pressure check

6. After connecting fuel hose for fuel pressure check, pull the hose with a force of approximately 98 N (10 kg, 22 lb) to confirm fuel

tube does not come off.

7. Turn ignition switch ON and check for fuel leakage.

8. Start engine and check for fuel leakage.

9. Read the indication of fuel pressure gauge. • Do not perform fuel pressure check with system operating.

Fuel pressure gauge may indicate false readings.

• During fuel pressure check, confirm for f uel leakage from fuel connection every 3 minutes.

10. If result is unsatisfactory, go to next step.

11. Check the following. • Fuel hoses and fuel tubes for clogging

• Fuel filter for clogging

• Fuel pump

• Fuel pressure regulator for clogging

If OK, replace fuel pressure regulator.

If NG, repair or replace.

12. Before disconnecting Fuel Pressure Gauge and Fuel Pressure Adapter J-44321-6, release fuel pressure

to zero. Refer to "FUEL PRESSURE RELEASE". Tightening torque: 1 - 1.5 N·m

(0.1 - 0.15 kg-m, 9 - 13 in-lb)

At idling: Approximately 350 kPa (3.57 kg/cm 2

, 51 psi) PBIB2984E

Page 1871 of 4331

![NISSAN TIIDA 2009 Service Service Manual PRECAUTIONS

EC-515

< SERVICE INFOMATION >

[MR TYPE 1] C

D E

F

G H

I

J

K L

M A EC

NP

O

•

Do not operate fuel pump when there is no fuel in lines.

• Tighten fuel hose clamps to the specified torqu NISSAN TIIDA 2009 Service Service Manual PRECAUTIONS

EC-515

< SERVICE INFOMATION >

[MR TYPE 1] C

D E

F

G H

I

J

K L

M A EC

NP

O

•

Do not operate fuel pump when there is no fuel in lines.

• Tighten fuel hose clamps to the specified torqu](/img/5/57398/w960_57398-1870.png)

PRECAUTIONS

EC-515

< SERVICE INFOMATION >

[MR TYPE 1] C

D E

F

G H

I

J

K L

M A EC

NP

O

•

Do not operate fuel pump when there is no fuel in lines.

• Tighten fuel hose clamps to the specified torque.

- Fuel level sensor unit and fuel pump (1)

- Fuel pressure regulator (2)

- Fuel level sensor (3)

- Fuel tank temperature sensor (4)

• Do not depress accelerator pedal when starting.

• Immediately after starting, do not rev up engine unnecessar-

ily.

• Do not rev up engine ju st prior to shutdown.

• When installing C.B. ham radio or a mobile phone, be sure to

observe the following as it may adversely affect electronic

control systems depending on installation location.

- Keep the antenna as far as possible from the electronic con-

trol units.

- Keep the antenna feeder line more than 20 cm (8 in) away

from the harness of electronic controls.

Do not let them run para llel for a long distance.

- Adjust the antenna and feeder line so that the standing-wave

radio can be kept smaller.

- Be sure to ground the radio to vehicle body. BBIA0704E

SEF709Y

SEF708Y

Page 1887 of 4331

![NISSAN TIIDA 2009 Service Service Manual EVAPORATIVE EMISSION SYSTEM

EC-531

< SERVICE INFOMATION >

[MR TYPE 1] C

D E

F

G H

I

J

K L

M A EC

NP

O

Positive pressure is delivered to the EVAP system through the EVAP

service port. If fuel vapor lea NISSAN TIIDA 2009 Service Service Manual EVAPORATIVE EMISSION SYSTEM

EC-531

< SERVICE INFOMATION >

[MR TYPE 1] C

D E

F

G H

I

J

K L

M A EC

NP

O

Positive pressure is delivered to the EVAP system through the EVAP

service port. If fuel vapor lea](/img/5/57398/w960_57398-1886.png)

EVAPORATIVE EMISSION SYSTEM

EC-531

< SERVICE INFOMATION >

[MR TYPE 1] C

D E

F

G H

I

J

K L

M A EC

NP

O

Positive pressure is delivered to the EVAP system through the EVAP

service port. If fuel vapor leakage in the EVAP system occurs, use a

leak detector to locate the leak.

Removal and Installation INFOID:0000000004537030

EVAP CANISTER Tighten EVAP canister as shown in the figure.

EVAP CANISTER VENT CONTROL VALVE 1. Turn EVAP canister vent control valve counterclockwise.

• Lock (A)

• Unlock (B)

2. Remove the EVAP canister vent control valve.

Always replace O-ring with a new one.

How to Detect Fuel Vapor Leakage INFOID:0000000004537031

CAUTION:

• Never use compressed air or a high pressure pump.

• Do not exceed 4.12 kPa (0.042 kg/cm 2

, 0.6 psi) of pressure in EVAP system.

NOTE:

• Do not start engine.

• Improper installation of EVAP service port adapter to the EVAP service port may cause a leak.

WITH CONSULT-III

1. Attach the EVAP service port adapter securely to the EVAP service port.

2. Also attach the pressure pump and hose to the EVAP service port adapter. SEF462UC

PBIB1214E

PBIB3091E

Page 1889 of 4331

EC

NP

O

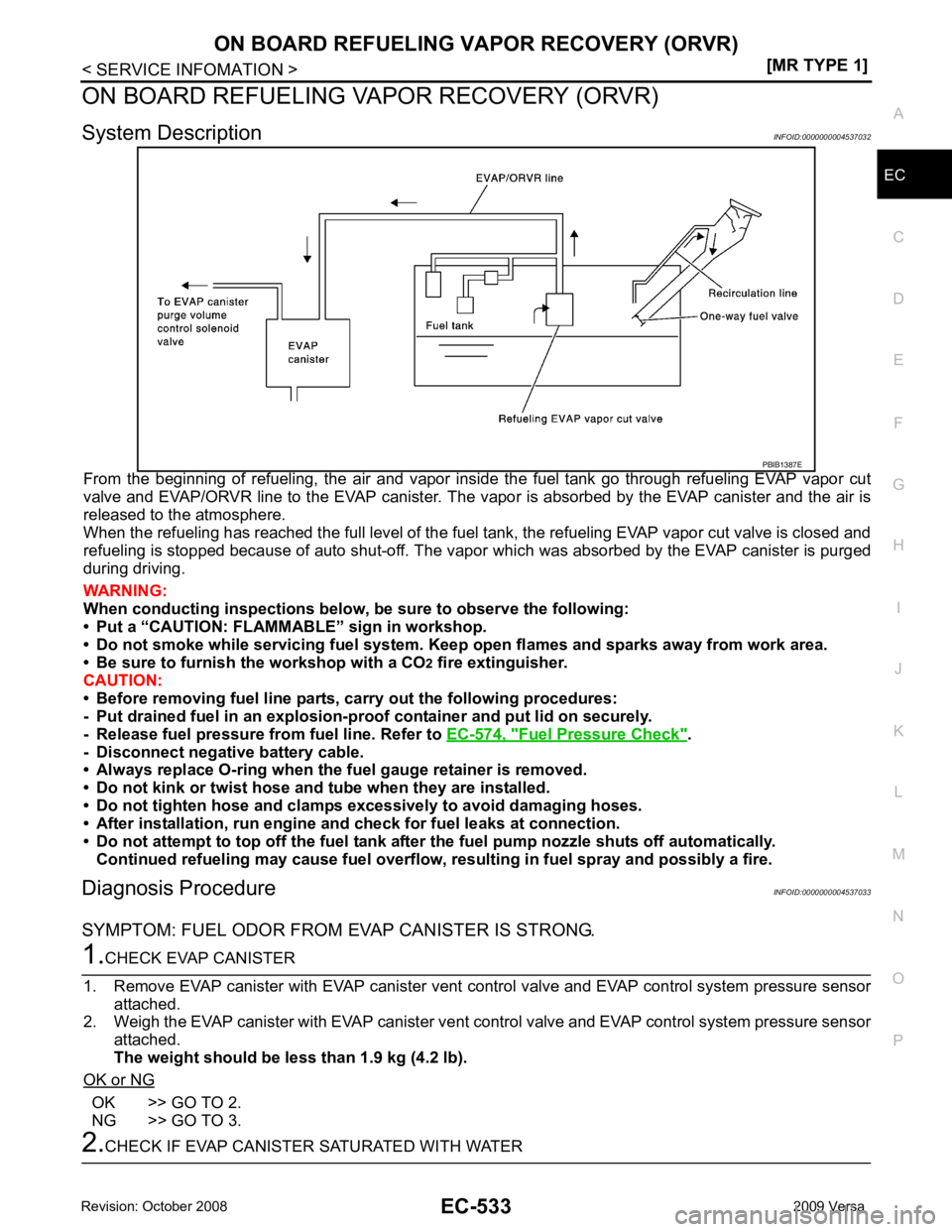

ON BOARD REFUELING VAPOR RECOVERY (ORVR)

System Description INFOID:0000000004537032

From the beginning of refueling, the air and vapor insi de the fuel tank go through refueling EVAP vapor cut

valve and EVAP/ORVR line to the EVAP canister. The v apor is absorbed by the EVAP canister and the air is

released to the atmosphere.

When the refueling has reached the full level of the fuel tank, the refueling EVAP vapor cut valve is closed and

refueling is stopped because of auto shut-off. The vapor which was absorbed by the EVAP canister is purged

during driving.

WARNING:

When conducting inspectio ns below, be sure to observe the following:

• Put a “CAUTION: FLAMMABL E” sign in workshop.

• Do not smoke while servicing fuel system. Keep open flames and sparks away from work area.

• Be sure to furnish the workshop with a CO 2

fire extinguisher.

CAUTION:

• Before removing fuel line parts, carry out the following procedures:

- Put drained fuel in an explosion-proof containe r and put lid on securely.

- Release fuel pressure from fuel line. Refer to EC-574, " Fuel Pressure Check " .

- Disconnect negative battery cable.

• Always replace O-ring when the fu el gauge retainer is removed.

• Do not kink or twist hose and tube when they are installed.

• Do not tighten hose and clamps excessively to avoid damaging hoses.

• After installation, run engine a nd check for fuel leaks at connection.

• Do not attempt to top off the fuel tank after the fuel pump nozzle shuts off automatically.

Continued refueling may cause fuel overflow, r esulting in fuel spray and possibly a fire.

Diagnosis Procedure INFOID:0000000004537033

SYMPTOM: FUEL ODOR FROM EVAP CANISTER IS STRONG. OK >> GO TO 2.

NG >> GO TO 3.

Page 1892 of 4331

![NISSAN TIIDA 2009 Service Service Manual EC-536< SERVICE INFOMATION >

[MR TYPE 1]

ON BOARD REFUELING VAPOR RECOVERY (ORVR)

1. Remove fuel tank. Refer to FL-9 .

2. Drain fuel from the tank as follows:

a. Remove fuel feed hose located on the NISSAN TIIDA 2009 Service Service Manual EC-536< SERVICE INFOMATION >

[MR TYPE 1]

ON BOARD REFUELING VAPOR RECOVERY (ORVR)

1. Remove fuel tank. Refer to FL-9 .

2. Drain fuel from the tank as follows:

a. Remove fuel feed hose located on the](/img/5/57398/w960_57398-1891.png)

EC-536< SERVICE INFOMATION >

[MR TYPE 1]

ON BOARD REFUELING VAPOR RECOVERY (ORVR)

1. Remove fuel tank. Refer to FL-9 .

2. Drain fuel from the tank as follows:

a. Remove fuel feed hose located on the fuel gauge retainer.

b. Connect a spare fuel hose, one side to fuel gauge retainer where the hose was removed and the other

side to a fuel container.

c. Drain fuel using “FUEL PUMP RELAY” in “ACTIVE TEST” mode with CONSULT-III.

3. Check refueling EVAP vapor cut valve for being stuck to close as follows. Blow air into the refueling EVAP vapor cut valv e (from the end of EVAP/ORVR line hose), and check that

the air flows freely into the tank.

4. Check refueling EVAP vapor cut valve for being stuck to open as follows.

a. Connect vacuum pump to hose end.

b. Remove fuel gauge retainer with fuel gauge unit. Always replace O-ring with new one.

c. Put fuel tank upside down.

d. Apply vacuum pressure to hose end [ −13.3 kPa ( −100 mmHg, −3.94 inHg)] with fuel gauge retainer

remaining open and check that the pressure is applicable.

Without CONSULT-III

1. Remove fuel tank. Refer to FL-9 .

2. Drain fuel from the tank as follows:

a. Remove fuel gauge retainer.

b. Drain fuel from the tank using a handy pump into a fuel container.

3. Check refueling EVAP vapor cut valve for being stuck to close as follows. Blow air into the refueling EVAP vapor cut valv e (from the end of EVAP/ORVR line hose), and check that

the air flows freely into the tank.

4. Check refueling EVAP vapor cut valve for being stuck to open as follows.

a. Connect vacuum pump to hose end. 1. Filler tube 2. Recirculation line 3. EVAP/ORVR line

4. Vacuum/pressure handy pump 5. Fuel tank BBIA0694E

Page 1893 of 4331

![NISSAN TIIDA 2009 Service Service Manual ON BOARD REFUELING VAPOR RECOVERY (ORVR)

EC-537

< SERVICE INFOMATION >

[MR TYPE 1] C

D E

F

G H

I

J

K L

M A EC

NP

O

b. Remove fuel gauge retainer with fuel gauge unit.

Always replace O-ring with new on NISSAN TIIDA 2009 Service Service Manual ON BOARD REFUELING VAPOR RECOVERY (ORVR)

EC-537

< SERVICE INFOMATION >

[MR TYPE 1] C

D E

F

G H

I

J

K L

M A EC

NP

O

b. Remove fuel gauge retainer with fuel gauge unit.

Always replace O-ring with new on](/img/5/57398/w960_57398-1892.png)

ON BOARD REFUELING VAPOR RECOVERY (ORVR)

EC-537

< SERVICE INFOMATION >

[MR TYPE 1] C

D E

F

G H

I

J

K L

M A EC

NP

O

b. Remove fuel gauge retainer with fuel gauge unit.

Always replace O-ring with new one.

c. Put fuel tank upside down.

d. Apply vacuum pressure to hose end [ −13.3 kPa ( −100 mmHg, −3.94 inHg)] with fuel gauge retainer

remaining open and check that the pressure is applicable.

1. Filler tube 2. Recirculation line 3. EVAP/ORVR line

4. Vacuum/pressure handy pump 5. Fuel tank BBIA0694E

Page 1931 of 4331

EC

NP

O

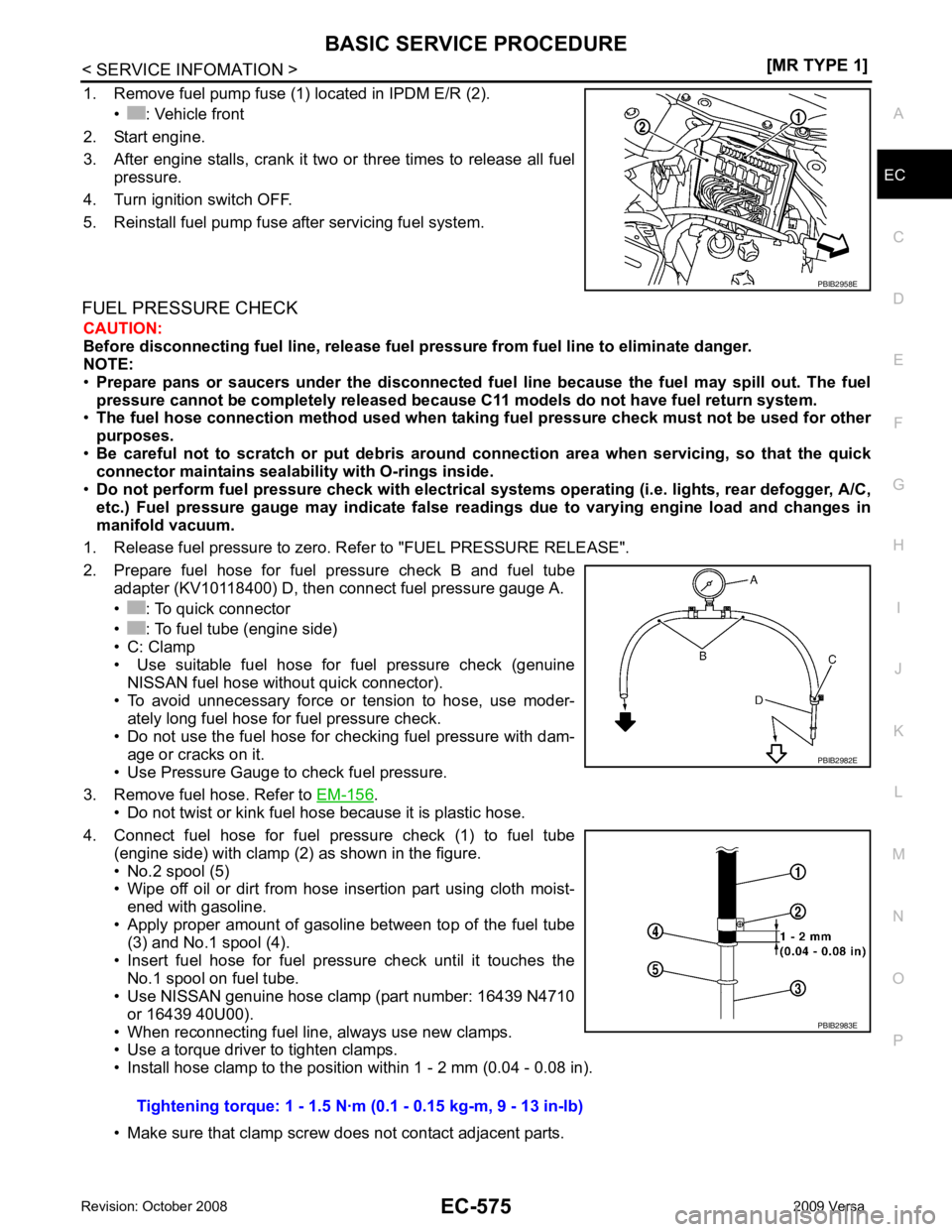

1. Remove fuel pump fuse (1) located in IPDM E/R (2).

• : Vehicle front

2. Start engine.

3. After engine stalls, crank it two or three times to release all fuel pressure.

4. Turn ignition switch OFF.

5. Reinstall fuel pump fuse after servicing fuel system.

FUEL PRESSURE CHECK CAUTION:

Before disconnecting fuel line, release fuel pressure from fuel line to eliminate danger.

NOTE:

• Prepare pans or saucers under the disconnected fuel line because the fuel may spill out. The fuel

pressure cannot be completely released because C11 models do not have fuel return system.

• The fuel hose connection method u sed when taking fuel pressure check must not be used for other

purposes.

• Be careful not to scratch or put debris around connection area when servicing, so that the quick

connector maintains sealability with O-rings inside.

• Do not perform fuel pressure check with electrical syst ems operating (i.e. lights, rear defogger, A/C,

etc.) Fuel pressure gauge may indicate false readin gs due to varying engine load and changes in

manifold vacuum.

1. Release fuel pressure to zero. Refer to "FUEL PRESSURE RELEASE".

2. Prepare fuel hose for fuel pressure check B and fuel tube adapter (KV10118400) D, then connect fuel pressure gauge A.

• : To quick connector

• : To fuel tube (engine side)

• C: Clamp

• Use suitable fuel hose for fuel pressure check (genuine

NISSAN fuel hose without quick connector).

• To avoid unnecessary force or tension to hose, use moder- ately long fuel hose for fuel pressure check.

• Do not use the fuel hose for checking fuel pressure with dam- age or cracks on it.

• Use Pressure Gauge to check fuel pressure.

3. Remove fuel hose. Refer to EM-156 .

• Do not twist or kink fuel hose because it is plastic hose.

4. Connect fuel hose for fuel pressure check (1) to fuel tube (engine side) with clamp (2) as shown in the figure.

• No.2 spool (5)

• Wipe off oil or dirt from hose insertion part using cloth moist-

ened with gasoline.

• Apply proper amount of gasoline between top of the fuel tube (3) and No.1 spool (4).

• Insert fuel hose for fuel pressure check until it touches the No.1 spool on fuel tube.

• Use NISSAN genuine hose clamp (part number: 16439 N4710

or 16439 40U00).

• When reconnecting fuel line, always use new clamps.

• Use a torque driver to tighten clamps.

• Install hose clamp to the positi on within 1 - 2 mm (0.04 - 0.08 in).

• Make sure that clamp screw does not contact adjacent parts.

Page 1942 of 4331

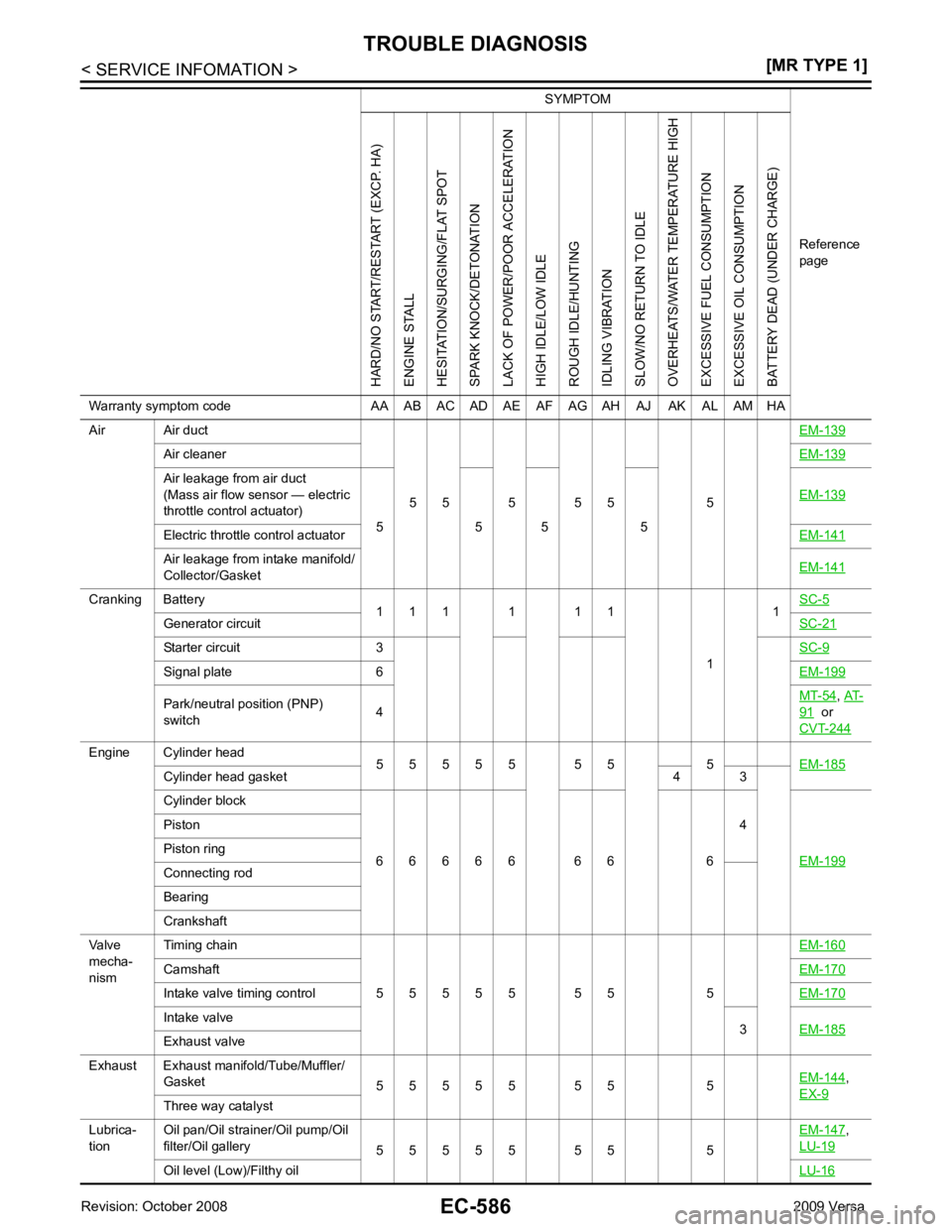

Air cleaner

EM-139Air leakage from air duct

(Mass air flow sensor — electric

throttle control actuator) 5 5 5 5 EM-139Electric throttle control actuator

EM-141Air leakage from intake manifold/

Collector/Gasket EM-141Cranking Battery

1 1 1 1 1 1

11

SC-5 Generator circuit

SC-21Starter circuit 3

SC-9Signal plate 6

EM-199Park/neutral position (PNP)

switch 4 MT-54 ,

AT- 91 or

CVT-244 Engine Cylinder head

5 5 5 5 5 5 5 5 EM-185Cylinder head gasket 4 3

Cylinder block

6 6 6 6 6 6 6 6 4

EM-199 Piston

Piston ring

Connecting rod

Bearing

Crankshaft

Valve

mecha-

nism Timing chain

5 5 5 5 5 5 5 5 EM-160Camshaft

EM-170Intake valve timing control

EM-170Intake valve

3EM-185 Exhaust valve

Exhaust Exhaust manifold/Tube/Muffler/ Gasket 5 5 5 5 5 5 5 5 EM-144 ,

EX-9 Three way catalyst

Lubrica-

tion Oil pan/Oil strainer/Oil pump/Oil

filter/Oil gallery 5 5 5 5 5 5 5 5 EM-147 ,

LU-19 Oil level (Low)/Filthy oil

LU-16SYMPTOM

Reference

pageHARD/NO START/RESTART (EXCP. HA)

ENGINE STALL

HESITATION/SURGING/FLAT SPOT

SPARK KNOCK/DETONATION

LACK OF POWER/POOR ACCELERATION

HIGH IDLE/LOW IDLE

ROUGH IDLE/HUNTING

IDLING VIBRATION

SLOW/NO RETURN TO IDLE

OVERHEATS/WATER TEMPERATURE HIGH

EXCESSIVE FUEL CONSUMPTION

EXCESSIVE OIL CONSUMPTION

BATTERY DEAD (UNDER CHARGE)

Warranty symptom code AA AB AC AD AE AF AG AH AJ AK AL AM HA