fuel cap NISSAN TIIDA 2009 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2009, Model line: TIIDA, Model: NISSAN TIIDA 2009Pages: 4331, PDF Size: 58.04 MB

Page 1381 of 4331

EC

NP

O

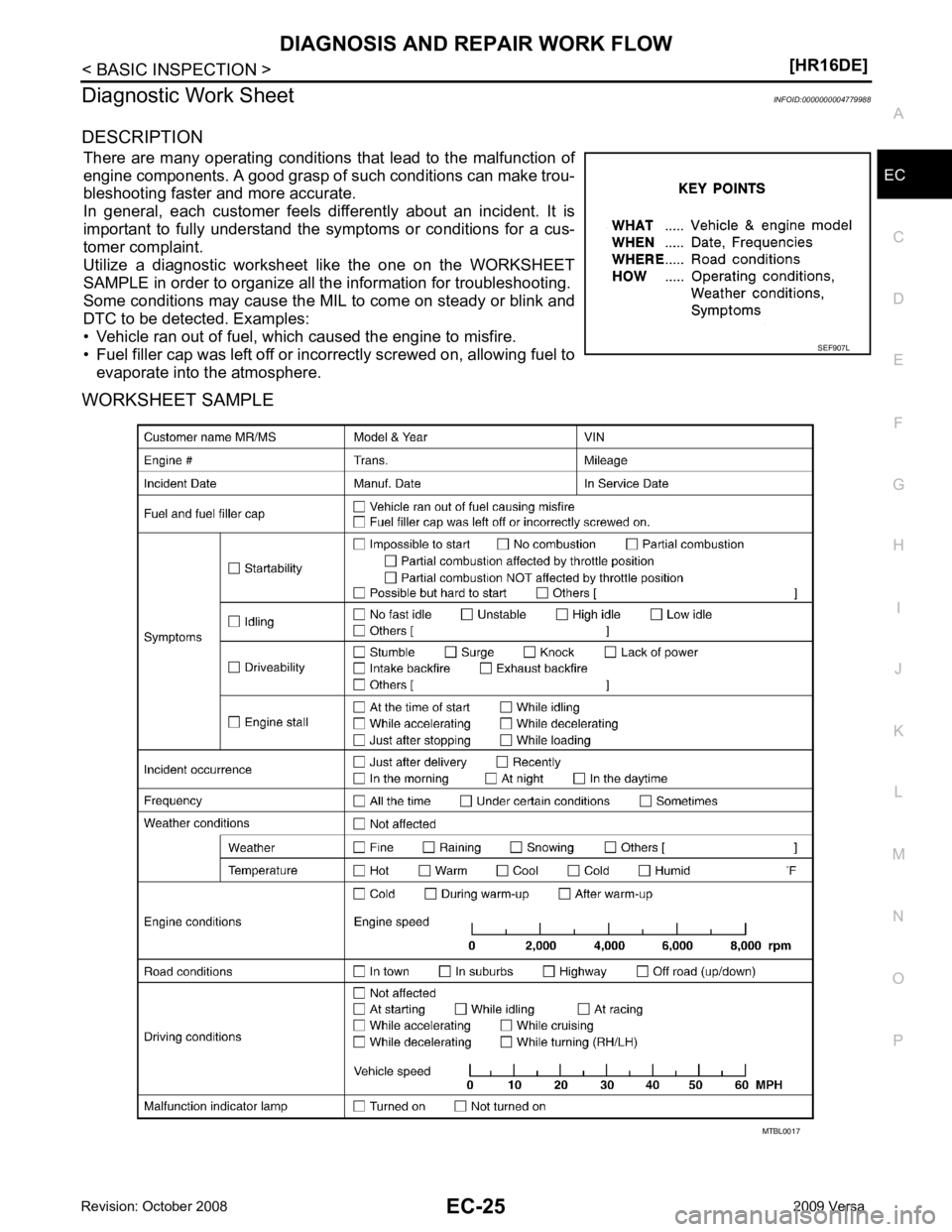

Diagnostic Work Sheet

INFOID:0000000004779988

DESCRIPTION There are many operating conditions that lead to the malfunction of

engine components. A good grasp of such conditions can make trou-

bleshooting faster and more accurate.

In general, each customer feels differently about an incident. It is

important to fully understand the symptoms or conditions for a cus-

tomer complaint.

Utilize a diagnostic worksheet like the one on the WORKSHEET

SAMPLE in order to organize all the information for troubleshooting.

Some conditions may cause the MI L to come on steady or blink and

DTC to be detected. Examples:

• Vehicle ran out of fuel, which caused the engine to misfire.

• Fuel filler cap was left off or incorrectly screwed on, allowing fuel to evaporate into the atmosphere.

WORKSHEET SAMPLE

Page 1544 of 4331

![NISSAN TIIDA 2009 Service Repair Manual EC-188< COMPONENT DIAGNOSIS >

[HR16DE]

P0131 A/F SENSOR 1

P0131 A/F SENSOR 1

Description INFOID:0000000004780111

The air fuel ratio (A/F) sensor 1 is a planar one-cell limit current sen-

sor. The se NISSAN TIIDA 2009 Service Repair Manual EC-188< COMPONENT DIAGNOSIS >

[HR16DE]

P0131 A/F SENSOR 1

P0131 A/F SENSOR 1

Description INFOID:0000000004780111

The air fuel ratio (A/F) sensor 1 is a planar one-cell limit current sen-

sor. The se](/img/5/57398/w960_57398-1543.png)

EC-188< COMPONENT DIAGNOSIS >

[HR16DE]

P0131 A/F SENSOR 1

P0131 A/F SENSOR 1

Description INFOID:0000000004780111

The air fuel ratio (A/F) sensor 1 is a planar one-cell limit current sen-

sor. The sensor element of the A/F sensor 1 is composed an elec-

trode layer, which transports ions. It has a heater in the element.

The sensor is capable of precise measurement = 1, but also in the

lean and rich range. Together with its control electronics, the sensor

outputs a clear, continuous signal throughout a wide range.

The exhaust gas components diffuse through the diffusion layer at

the sensor cell. An electrode layer is applied voltage, and this current

relative oxygen density in lean. Also this current relative hydrocar-

bon density in rich.

Therefore, the A/F sensor 1 is able to indicate air fuel ratio by this

electrode layer of current. In additi on, a heater is integrated in the

sensor to ensure the required operating temperature of about 800 °C

(1,472 °F).

DTC Logic INFOID:0000000004780112

DTC DETECTION LOGIC

To judge the malfunction, the diagnosis checks that t he A/F signal computed by ECM from the A/F sensor 1

signal is not inordinately low.

DTC CONFIRMATION PROCEDURE 1.

PRECONDITIONING

If DTC Confirmation Procedure has been previously conduc ted, always turn ignition switch OFF and wait at

least 10 seconds before conducting the next test.

TESTING CONDITION:

Before performing the following procedure, confirm that battery voltage is more than 10.5 V at idle.

>> GO TO 2. 2.

CHECK A/F SENSOR FUNCTION

With CONSULT-III

1. Start engine and warm it up to normal operating temperature.

2. Select “A/F SEN1 (B1)” in “D ATA MONITOR” mode with CONSULT-III.

3. Check “A/F SEN1 (B1)” indication.

With GST

Follow the procedure “With CONSULT-III” above.

Is the indication constantly approx. 0 V? JMBIA0112GB

PBIB3354E

DTC No. Trouble diagnosis name DTC detecting condition Possible Cause

P0131 Air fuel ratio (A/F) sensor 1

circuit low voltage • The A/F signal computed by ECM from the A/F

sensor 1 signal is constantly approx. 0 V. • Harness or connectors

(The A/F sensor 1 circuit is open or

shorted.)

• A/F sensor 1

Page 1549 of 4331

![NISSAN TIIDA 2009 Service Repair Manual P0132 A/F SENSOR 1

EC-193

< COMPONENT DIAGNOSIS >

[HR16DE] C

D E

F

G H

I

J

K L

M A EC

NP

O

P0132 A/F SENSOR 1

Description INFOID:0000000004780114

The air fuel ratio (A/F) sensor 1 is a planar one-cell NISSAN TIIDA 2009 Service Repair Manual P0132 A/F SENSOR 1

EC-193

< COMPONENT DIAGNOSIS >

[HR16DE] C

D E

F

G H

I

J

K L

M A EC

NP

O

P0132 A/F SENSOR 1

Description INFOID:0000000004780114

The air fuel ratio (A/F) sensor 1 is a planar one-cell](/img/5/57398/w960_57398-1548.png)

P0132 A/F SENSOR 1

EC-193

< COMPONENT DIAGNOSIS >

[HR16DE] C

D E

F

G H

I

J

K L

M A EC

NP

O

P0132 A/F SENSOR 1

Description INFOID:0000000004780114

The air fuel ratio (A/F) sensor 1 is a planar one-cell limit current sen-

sor. The sensor element of the A/F sensor 1 is composed an elec-

trode layer, which transports ions. It has a heater in the element.

The sensor is capable of precise m easurement = 1, but also in the

lean and rich range. Together with its control electronics, the sensor

outputs a clear, continuous signal throughout a wide range.

The exhaust gas components diffuse through the diffusion layer at

the sensor cell. An electrode layer is applied voltage, and this current

relative oxygen density in lean. Also this current relative hydrocar-

bon density in rich.

Therefore, the A/F sensor 1 is able to indicate air fuel ratio by this

electrode layer of current. In addition, a heater is integrated in the

sensor to ensure the required operating temperature of about 800 °C

(1,472 °F).

DTC Logic INFOID:0000000004780115

DTC DETECTION LOGIC To judge the malfunction, the diagnosis checks that the A/F signal computed by ECM from the A/F sensor 1

signal is not inordinately high.

DTC CONFIRMATION PROCEDURE 1.

PRECONDITIONING

If DTC Confirmation Procedure has been previously conduc ted, always turn ignition switch OFF and wait at

least 10 seconds before conducting the next test.

TESTING CONDITION:

Before performing the following procedure, confirm that battery voltage is more than 10.5 V at idle.

>> GO TO 2. 2.

CHECK A/F SENSOR FUNCTION

With CONSULT-III

1. Start engine and warm it up to normal operating temperature.

2. Select “A/F SEN1 (B1)” in “DAT A MONITOR” mode with CONSULT-III.

3. Check “A/F SEN1 (B1)” indication.

With GST

Follow the procedure “With CONSULT-IIII” above.

Is the indication constantly approx. 5 V? JMBIA0112GB

PBIB3354E

DTC No. Trouble diagnosis name DTC detecting condition Possible Cause

P0132 Air fuel ratio (A/F) sensor 1

circuit high voltage • The A/F signal computed by ECM from the A/F

sensor 1 signal is constantly approx. 5 V. • Harness or connectors

(The A/F sensor 1 circuit is open or

shorted.)

• A/F sensor 1

Page 1554 of 4331

![NISSAN TIIDA 2009 Service Repair Manual EC-198< COMPONENT DIAGNOSIS >

[HR16DE]

P0133 A/F SENSOR 1

P0133 A/F SENSOR 1

Description INFOID:0000000004780117

The air fuel ratio (A/F) sensor 1 is a planar one-cell limit current sen-

sor. The se NISSAN TIIDA 2009 Service Repair Manual EC-198< COMPONENT DIAGNOSIS >

[HR16DE]

P0133 A/F SENSOR 1

P0133 A/F SENSOR 1

Description INFOID:0000000004780117

The air fuel ratio (A/F) sensor 1 is a planar one-cell limit current sen-

sor. The se](/img/5/57398/w960_57398-1553.png)

EC-198< COMPONENT DIAGNOSIS >

[HR16DE]

P0133 A/F SENSOR 1

P0133 A/F SENSOR 1

Description INFOID:0000000004780117

The air fuel ratio (A/F) sensor 1 is a planar one-cell limit current sen-

sor. The sensor element of the A/F sensor 1 is composed an elec-

trode layer, which transports ions. It has a heater in the element.

The sensor is capable of precise measurement = 1, but also in the

lean and rich range. Together with its control electronics, the sensor

outputs a clear, continuous signal throughout a wide range.

The exhaust gas components diffuse through the diffusion layer at

the sensor cell. An electrode layer is applied voltage, and this current

relative oxygen density in lean. Also this current relative hydrocar-

bon density in rich.

Therefore, the A/F sensor 1 is able to indicate air fuel ratio by this

electrode layer of current. In additi on, a heater is integrated in the

sensor to ensure the required operating temperature of about 800 °C

(1,472 °F).

DTC Logic INFOID:0000000004780118

DTC DETECTION LOGIC

To judge the malfunction of A/F sensor 1, this diagnosis measures response time of the A/F signal computed

by ECM from the A/F sensor 1 signal. The time is compensated by engine operating (speed and load), fuel

feedback control constant, and the A/F sensor 1 temper ature index. Judgment is based on whether the com-

pensated time (the A/F signal cycling time index) is inordinately long or not.

DTC CONFIRMATION PROCEDURE 1.

PRECONDITIONING

If DTC Confirmation Procedure has been previously conduc ted, always turn ignition switch OFF and wait at

least 10 seconds before conducting the next test.

TESTING CONDITION:

Before performing the following procedure, confirm that battery voltage is more than 11 V at idle.

Do you have CONSULT-III? YES >> GO TO 2.

NO >> GO TO 5. 2.

PERFORM DTC CONFIRMATION PROCEDURE-I JMBIA0112GB

PBIB3354E

DTC No. Trouble diagnosis name DTC detecting condition Possible Cause

P0133 Air fuel ratio (A/F) sensor

1 circuit slow response • The response of the A/F signal computed

by ECM from A/F sensor 1 signal takes

more than the specified time. • Harness or connectors

(The A/F sensor 1 circuit is open or shorted.)

• A/F sensor 1

• A/F sensor 1 heater

• Fuel pressure

• Fuel injector

• Intake air leaks

• Exhaust gas leaks

• PCV

• Mass air flow sensor

Page 1568 of 4331

![NISSAN TIIDA 2009 Service Repair Manual EC-212< COMPONENT DIAGNOSIS >

[HR16DE]

P0138 HO2S2

P0138 HO2S2

Description INFOID:0000000004780125

The heated oxygen sensor 2, after three way catalyst (manifold),

monitors the oxygen level i NISSAN TIIDA 2009 Service Repair Manual EC-212< COMPONENT DIAGNOSIS >

[HR16DE]

P0138 HO2S2

P0138 HO2S2

Description INFOID:0000000004780125

The heated oxygen sensor 2, after three way catalyst (manifold),

monitors the oxygen level i](/img/5/57398/w960_57398-1567.png)

EC-212< COMPONENT DIAGNOSIS >

[HR16DE]

P0138 HO2S2

P0138 HO2S2

Description INFOID:0000000004780125

The heated oxygen sensor 2, after three way catalyst (manifold),

monitors the oxygen level in the exhaust gas on each bank.

Even if switching characteristics of the air fuel ratio (A/F) sensor 1

are shifted, the air-fuel ratio is cont rolled to stoichiometric, by the sig-

nal from the heated oxygen sensor 2.

This sensor is made of ceramic zirconia. The zirconia generates volt-

age from approximately 1 V in richer conditions to 0 V in leaner con-

ditions.

Under normal conditions the heated ox ygen sensor 2 is not used for

engine control operation.

DTC Logic INFOID:0000000004780126

DTC DETECTION LOGIC

The heated oxygen sensor 2 has a much longer switching time between rich and lean than the air fuel ratio (A/

F) sensor 1. The oxygen storage capa city of the three way catalyst (manifold) causes the longer switching

time.

MALFUNCTION A

To judge the malfunctions of heated oxygen sensor 2, ECM monitors

whether the voltage is unusually high during the various driving con-

dition such as fuel-cut.

MALFUNCTION B

To judge the malfunctions of heated oxygen sensor 2, ECM monitors

whether the minimum voltage of sensor is sufficiently low during the

various driving condition such as fuel-cut. SEF327R

PBIB1848E

PBIB2376E

DTC No. Trouble diagnosis name DTC detecting condition Possible cause

P0138 Heated oxygen sensor 2

circuit high voltage A)

An excessively high voltage from the

sensor is sent to ECM. • Harness or connectors

(The sensor circuit is open or shorted)

• Heated oxygen sensor 2

B) The minimum voltage from the sensor is

not reached to the specified voltage. • Harness or connectors

(The sensor circuit is open or shorted)

• Heated oxygen sensor 2

• Fuel pressure

• Fuel injector

Page 1577 of 4331

![NISSAN TIIDA 2009 Service Repair Manual P0139 HO2S2

EC-221

< COMPONENT DIAGNOSIS >

[HR16DE] C

D E

F

G H

I

J

K L

M A EC

NP

O

P0139 HO2S2

Description INFOID:0000000004780130

The heated oxygen sensor 2, after three way catalyst (manif NISSAN TIIDA 2009 Service Repair Manual P0139 HO2S2

EC-221

< COMPONENT DIAGNOSIS >

[HR16DE] C

D E

F

G H

I

J

K L

M A EC

NP

O

P0139 HO2S2

Description INFOID:0000000004780130

The heated oxygen sensor 2, after three way catalyst (manif](/img/5/57398/w960_57398-1576.png)

P0139 HO2S2

EC-221

< COMPONENT DIAGNOSIS >

[HR16DE] C

D E

F

G H

I

J

K L

M A EC

NP

O

P0139 HO2S2

Description INFOID:0000000004780130

The heated oxygen sensor 2, after three way catalyst (manifold),

monitors the oxygen level in the exhaust gas on each bank.

Even if switching characteristics of the air fuel ratio (A/F) sensor 1

are shifted, the air-fuel ratio is controlled to stoichiometric, by the sig-

nal from the heated oxygen sensor 2.

This sensor is made of ceramic zirconia. The zirconia generates volt-

age from approximately 1 V in richer conditions to 0 V in leaner con-

ditions.

Under normal conditions the heated oxygen sensor 2 is not used for

engine control operation.

DTC Logic INFOID:0000000004780131

DTC DETECTION LOGIC The heated oxygen sensor 2 has a much longer switching time

between rich and lean than the air fuel ratio (A/F) sensor 1. The oxy-

gen storage capacity of the three way catalyst (manifold) causes the

longer switching time. To judge the malfunctions of heated oxygen

sensor 2, ECM monitors whether the switching response of the sen-

sor's voltage is faster than specified during the various driving condi-

tion such as fuel-cut.

DTC CONFIRMATION PROCEDURE 1.

INSPECTION START

Do you have CONSULT-III?

Do you have CONSULT-III? YES >> GO TO 2.

NO >> GO TO 5. 2.

PRECONDITIONING

If DTC Confirmation Procedure has been previously conduc ted, always turn ignition switch OFF and wait at

least 10 seconds before conducting the next test.

>> GO TO 3. 3.

PERFORM DTC CONFIRMATION PROCEDURE

With CONSULT-III

1. Turn ignition switch ON and select “DATA MONITOR” mode with CONSULT-III.

2. Start engine and warm it up to normal operating temperature. SEF327R

SEF302U

DTC No. Trouble diagnosis name DTC detecting condition Possible cause

P0139 Heated oxygen sensor 2

circuit slow response It takes more time for the sensor to respond

between rich and lean than the specified

time. • Harness or connectors

(The sensor circuit is open or shorted)

• Heated oxygen sensor 2

• Fuel pressure

• Fuel injector

• Intake air leaks

Page 1629 of 4331

EC

NP

O

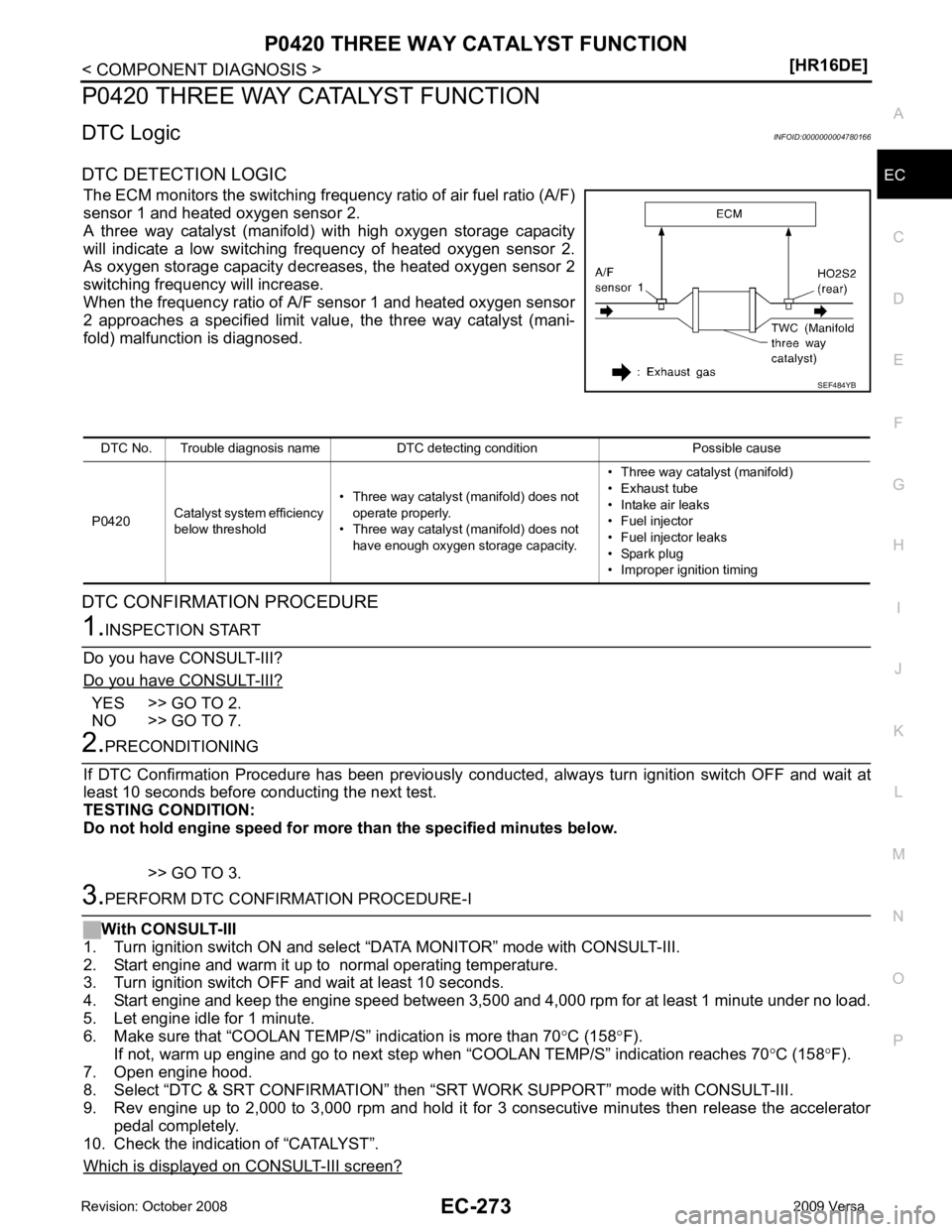

P0420 THREE WAY CATALYST FUNCTION

DTC Logic INFOID:0000000004780166

DTC DETECTION LOGIC The ECM monitors the switching frequency ratio of air fuel ratio (A/F)

sensor 1 and heated oxygen sensor 2.

A three way catalyst (manifold) with high oxygen storage capacity

will indicate a low switching frequency of heated oxygen sensor 2.

As oxygen storage capacity decr eases, the heated oxygen sensor 2

switching frequency will increase.

When the frequency ratio of A/F sensor 1 and heated oxygen sensor

2 approaches a specified limit value, the three way catalyst (mani-

fold) malfunction is diagnosed.

DTC CONFIRMATION PROCEDURE YES >> GO TO 2.

NO >> GO TO 7.

Page 1640 of 4331

![NISSAN TIIDA 2009 Service Repair Manual EC-284< COMPONENT DIAGNOSIS >

[HR16DE]

P0442 EVAP CONTROL SYSTEM

P0442 EVAP CONTROL SYSTEM

DTC Logic INFOID:0000000004780172

DTC DETECTION LOGIC

NOTE:

If DTC P0442 is displayed with DTC P0456, first p NISSAN TIIDA 2009 Service Repair Manual EC-284< COMPONENT DIAGNOSIS >

[HR16DE]

P0442 EVAP CONTROL SYSTEM

P0442 EVAP CONTROL SYSTEM

DTC Logic INFOID:0000000004780172

DTC DETECTION LOGIC

NOTE:

If DTC P0442 is displayed with DTC P0456, first p](/img/5/57398/w960_57398-1639.png)

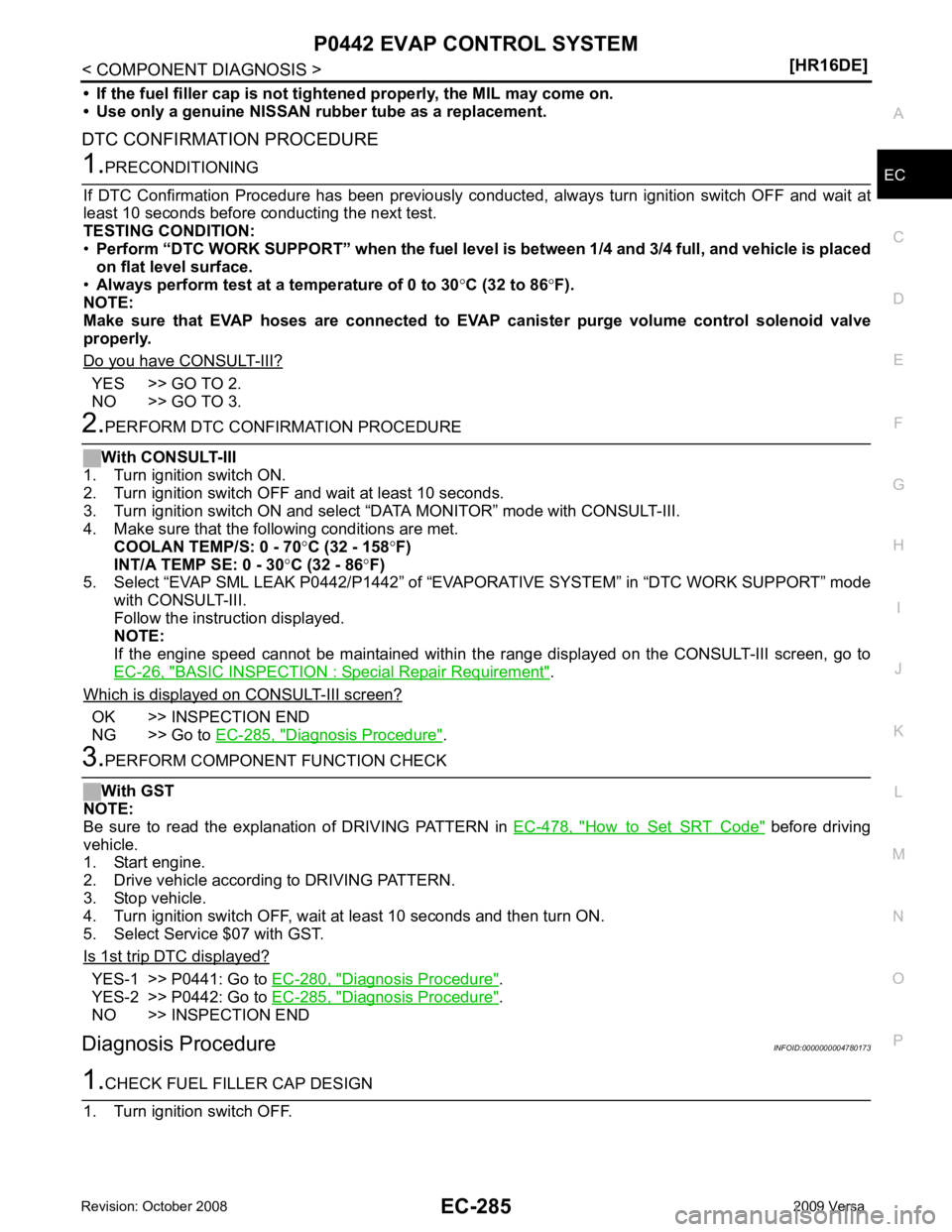

EC-284< COMPONENT DIAGNOSIS >

[HR16DE]

P0442 EVAP CONTROL SYSTEM

P0442 EVAP CONTROL SYSTEM

DTC Logic INFOID:0000000004780172

DTC DETECTION LOGIC

NOTE:

If DTC P0442 is displayed with DTC P0456, first pe rform the trouble diagnosis for DTC P0456. Refer to

EC-335, " DTC Logic " .

This diagnosis detects leaks in the EVAP purge line using engine intake manifold vacuum.

If pressure does not increase, the ECM will check for l eaks in the line between the fuel tank and EVAP canister

purge volume control solenoid valve, under the following “Vacuum test” conditions.

The EVAP canister vent control valve is closed to s hut the EVAP purge line off. The EVAP canister purge vol-

ume control solenoid valve will then be opened to depressurize the EVAP purge line using intake manifold

vacuum. After this occurs, the EVAP canister purge volume control solenoid valve will be closed.

CAUTION:

• Use only a genuine NISSAN fuel filler cap as a replacemen t. If an incorrect fuel filler cap is used, the

MIL may come on. DTC No. Trouble diagnosis name DTC detecting condition Possible cause

P0442 EVAP control system

small leak detected

(negative pressure) EVAP control system has a leak, EVAP

control system does not operate prop-

erly. • Incorrect fuel tank vacuum relief valve

• Incorrect fuel filler cap used

• Fuel filler cap remains open or fails to close.

• Foreign matter caught in fuel filler cap.

• Leak is in line between intake manifold and EVAP

canister purge volume control solenoid valve.

• Foreign matter caught in EVAP canister vent con- trol valve.

• EVAP canister or fuel tank leaks

• EVAP purge line (pipe and rubber tube) leaks

• EVAP purge line rubber tube bent

• Loose or disconnected rubber tube

• EVAP canister vent control valve and the circuit

• EVAP canister purge volume control solenoid

valve and the circuit

• Fuel tank temperature sensor

• O-ring of EVAP canister vent control valve is

missing or damaged

• EVAP canister is saturated with water

• EVAP control system pressure sensor

• Fuel level sensor and the circuit

• Refueling EVAP vapor cut valve

• ORVR system leaks

• Drain filter PBIB1026E

Page 1641 of 4331

EC

NP

O

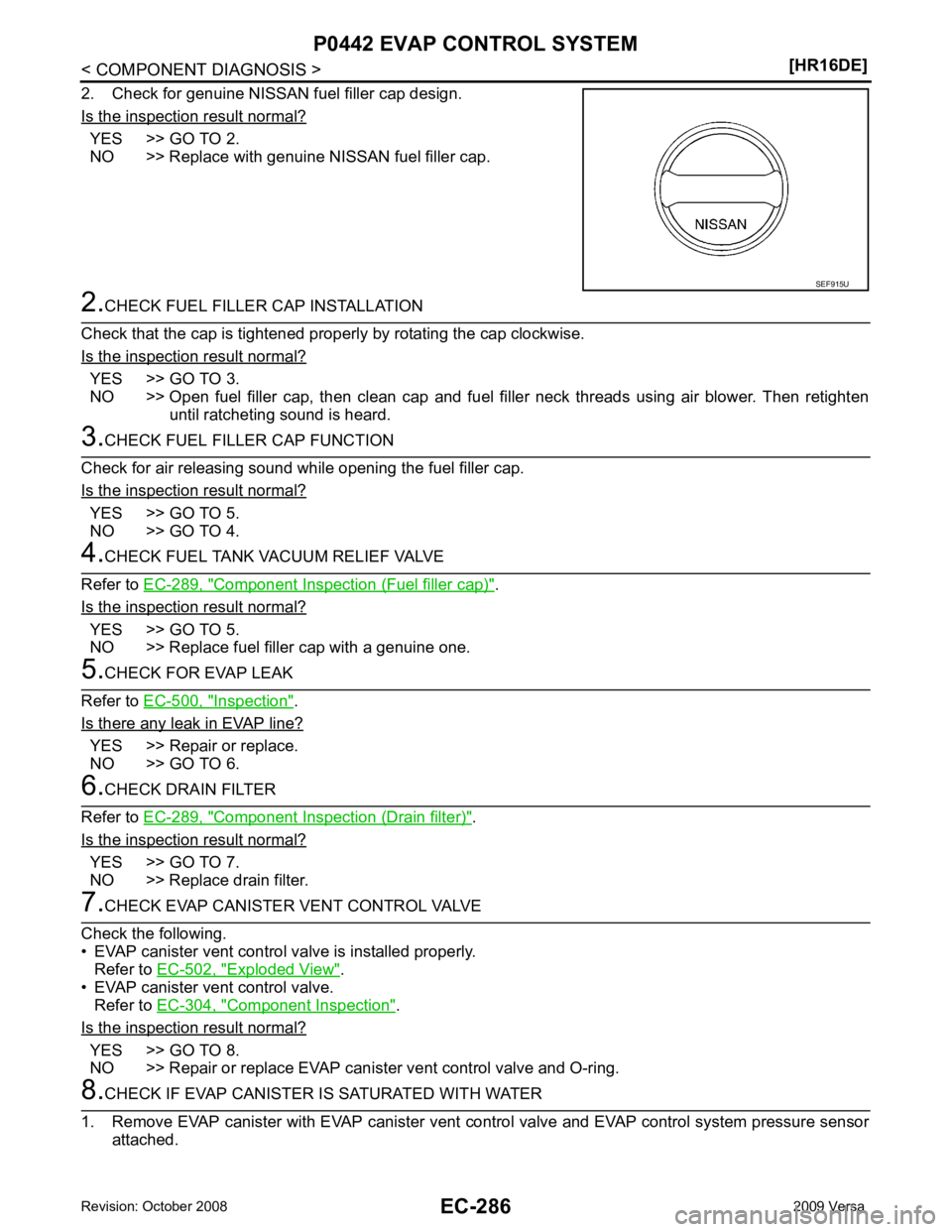

• If the fuel filler cap is not tigh

tened properly, the MIL may come on.

• Use only a genuine NISSAN rubber tube as a replacement.

DTC CONFIRMATION PROCEDURE YES >> GO TO 2.

NO >> GO TO 3. BASIC INSPECTION : Special Repair Requirement " .

Which is displayed on CONSULT-III screen? OK >> INSPECTION END

NG >> Go to EC-285, " Diagnosis Procedure " .

How to Set SRT Code " before driving

vehicle.

1. Start engine.

2. Drive vehicle according to DRIVING PATTERN.

3. Stop vehicle.

4. Turn ignition switch OFF, wait at least 10 seconds and then turn ON.

5. Select Service $07 with GST.

Is 1st trip DTC displayed? YES-1 >> P0441: Go to

EC-280, " Diagnosis Procedure " .

YES-2 >> P0442: Go to EC-285, " Diagnosis Procedure " .

NO >> INSPECTION END

Diagnosis Procedure INFOID:0000000004780173

Page 1642 of 4331

YES >> GO TO 2.

NO >> Replace with genuine NISSAN fuel filler cap. YES >> GO TO 3.

NO >> Open fuel filler cap, then clean cap and fuel filler neck threads using air blower. Then retighten until ratcheting sound is heard. YES >> GO TO 5.

NO >> GO TO 4. Component Inspection (Fuel filler cap) " .

Is the inspection result normal? YES >> GO TO 5.

NO >> Replace fuel filler cap with a genuine one. Inspection " .

Is there any leak in EVAP line? YES >> Repair or replace.

NO >> GO TO 6. Component Inspection (Drain filter) " .

Is the inspection result normal? YES >> GO TO 7.

NO >> Replace drain filter. Exploded View " .

• EVAP canister vent control valve. Refer to EC-304, " Component Inspection " .

Is the inspection result normal? YES >> GO TO 8.

NO >> Repair or replace EVAP cani ster vent control valve and O-ring.