sunroof NISSAN TIIDA 2009 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2009, Model line: TIIDA, Model: NISSAN TIIDA 2009Pages: 4331, PDF Size: 58.04 MB

Page 448 of 4331

System Description " .

• Remote keyless entry system. Refer to BL-58, " System Description " .

• Power window system (with power windows). Refer to GW-19, " System Description " .

NOTE

• Sunroof system (with sunroof). Refer to RF-11, " System Description " .

NOTE

• Room lamp timer. Refer to LT-91, " System Description " .

• Rear wiper and washer system (Hatchback). Refer to WW-25, " System Description " .

NOTE:

Power supply only. No system control.

SYSTEMS CONTROLLED BY BCM AND IPDM E/R

• Panic system. Refer to BL-58, " System Description " .

• Vehicle security (theft warning) system. Refer to BL-219, " System Description " .

• NVIS(NATS) system. Refer to BL-248, " System Description " .

• Headlamp, tail lamp and battery saver control systems. Refer to LT-73, " System Description " ,

LT-4, " System

Description " or

LT-25, " System Description " .

• Front fog lamp (with front fog lamps). Refer to LT-39, " System Description " .

• Front wiper and washer system. Refer to WW-3, " System Description " .

• Rear window defogger system. Refer to GW-51, " System Description " .

SYSTEMS CONTROLLED BY BCM AND COMBINATION METER

• Warning chime. Refer to DI-42, " System Description " .

• Turn signal and hazard warning lamps. Refer to LT-48, " System Description " .

SYSTEMS CONTROLLED BY BCM AND INTELLIGENT KEY UNIT (WITH INTELLIGENT KEY)

• Intelligent Key system. Refer to BL-88, " System Description " .

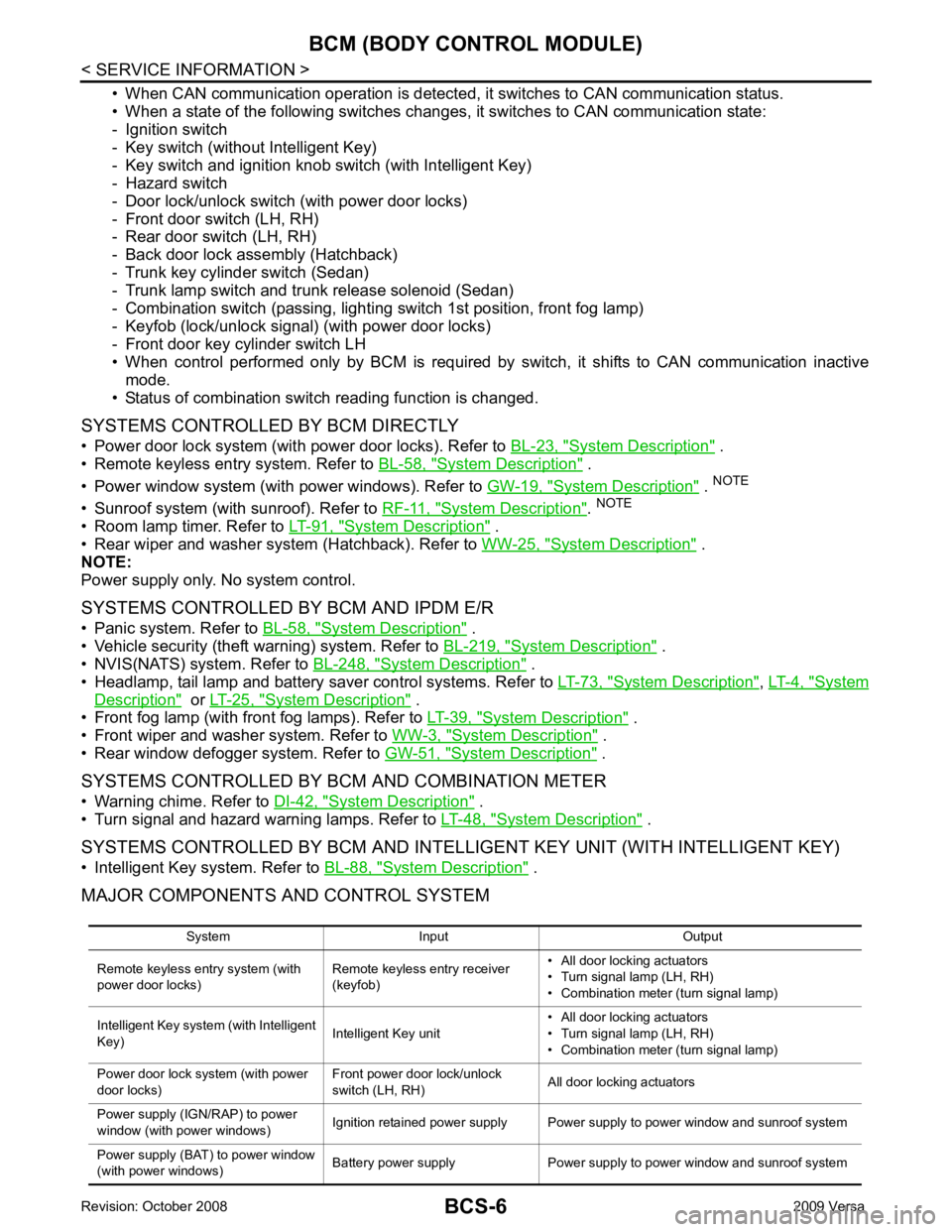

MAJOR COMPONENTS AND CONTROL SYSTEM

System Input Output

Remote keyless entry system (with

power door locks) Remote keyless entry receiver

(keyfob) • All door locking actuators

• Turn signal lamp (LH, RH)

• Combination meter (turn signal lamp)

Intelligent Key system (with Intelligent

Key) Intelligent Key unit• All door locking actuators

• Turn signal lamp (LH, RH)

• Combination meter (turn signal lamp)

Power door lock system (with power

door locks) Front power door lock/unlock

switch (LH, RH) All door locking actuators

Power supply (IGN/RAP) to power

window (with power windows) Ignition retained power supply Power supply to power window and sunroof system

Power supply (BAT) to power window

(with power windows) Battery power supply Power supply to power window and sunroof system

Page 2900 of 4331

EI

N

O P

3. The trunk lid torsion bars knocking together

4. A loose license plate or bracket

Most of these incidents can be repaired by adjusting, se curing or insulating the item(s) or component(s) caus-

ing the noise.

SUNROOF/HEADLINING Noises in the sunroof/headlining area can often be traced to one of the following:

1. Sunroof lid, rail, linkage or seals making a rattle or light knocking noise

2. Sun visor shaft shaking in the holder

3. Front or rear windshield touching headliner and squeaking

Again, pressing on the components to stop the noise while duplicating the conditions can isolate most of these

incidents. Repairs usually consist of insulating with felt cloth tape.

OVERHEAD CONSOLE (FRONT AND REAR) Overhead console noises are often caused by the cons ole panel clips not being engaged correctly. Most of

these incidents are repaired by pushing up on the c onsole at the clip locations until the clips engage.

In addition look for:

1. Loose harness or harness connectors.

2. Front console map/reading lamp lens loose.

3. Loose screws at console attachment points.

SEATS When isolating seat noise it's important to note the pos ition the seat is in and the load placed on the seat when

the noise is present. These conditions should be duplic ated when verifying and isolating the cause of the

noise.

Cause of seat noise include:

1. Headrest rods and holder

2. A squeak between the seat pad cushion and frame

3. The rear seatback lock and bracket

These noises can be isolated by moving or pressing on the suspected components while duplicating the con-

ditions under which the noise occurs. Most of thes e incidents can be repaired by repositioning the component

or applying urethane tape to the contact area.

UNDERHOOD Some interior noise may be caused by components under the hood or on the engine wall. The noise is then

transmitted into the passenger compartment.

Causes of transmitted underhood noise include:

1. Any component installed on the engine wall

2. Components that pass through the engine wall

3. Engine wall mounts and connectors

4. Loose radiator pins

5. Hood bumpers out of adjustment

6. Hood striker out of adjustment

These noises can be difficult to isolate since they cannot be reached from the interior of the vehicle. The best

method is to secure, move or insulate one component at a time and test drive the vehicle. Also, engine RPM

or load can be changed to isolate the noise. Repairs c an usually be made by moving, adjusting, securing, or

insulating the component causing the noise.

Page 2940 of 4331

EI

N

O P

Removal and Installation - Hatchback

INFOID:0000000004307236

REMOVAL 1. Disconnect the negative and positive battery term inals, then wait at least three minutes.

2. Remove front seat assembly RH/LH. Refer to SE-12, " Removal and Installation " .

3. Remove rear seat cushion and rear seatback. Refer to SE-16, " Removal and Installation " .

4. Remove front seat belt shoulder anchor RH/LH. Refer to SB-4, " Removal and Installation of Front Seat

Belt " .

5. Remove center console body assembly. Refer to IP-11 .

6. Remove front pillar garnish RH/LH. Refer to EI-40, " Removal and Installation " .

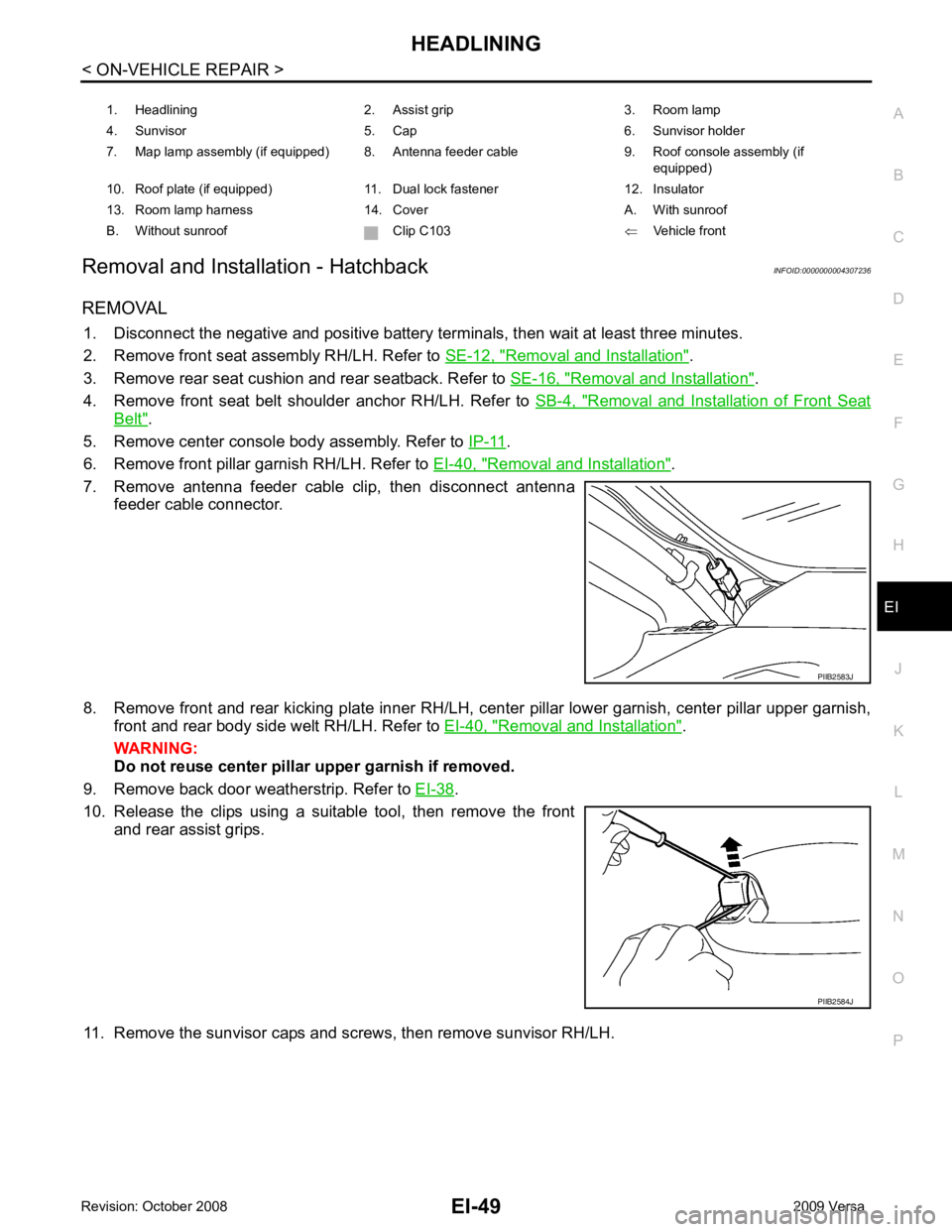

7. Remove antenna feeder cable clip, then disconnect antenna feeder cable connector.

8. Remove front and rear kicking plate inner RH/LH, cent er pillar lower garnish, center pillar upper garnish,

front and rear body side welt RH/LH. Refer to EI-40, " Removal and Installation " .

WARNING:

Do not reuse center pillar upper garnish if removed.

9. Remove back door weatherstrip. Refer to EI-38 .

10. Release the clips using a suitable tool, then remove the front and rear assist grips.

11. Remove the sunvisor caps and screws, then remove sunvisor RH/LH. 1. Headlining 2. Assist grip 3. Room lamp

4. Sunvisor 5. Cap 6. Sunvisor holder

7. Map lamp assembly (if equipped) 8. Antenna feeder cable 9. Roof console assembly (if equipped)

10. Roof plate (if equipped) 11. Dual lock fastener 12. Insulator

13. Room lamp harness 14. Cover A. With sunroof

B. Without sunroof Clip C103 ⇐Vehicle front PIIB2584J

Page 3312 of 4331

GW

N

O P

Most of these incidents can be repaired by adjusting, se

curing or insulating the item(s) or component(s) caus-

ing the noise.

SUNROOF/HEADLINING Noises in the sunroof/headlining area can often be traced to one of the following:

1. Sunroof lid, rail, linkage or seals making a rattle or light knocking noise

2. Sun visor shaft shaking in the holder

3. Front or rear windshield touching headliner and squeaking

Again, pressing on the components to stop the noise while duplicating the conditions can isolate most of these

incidents. Repairs usually consist of insulating with felt cloth tape.

OVERHEAD CONSOLE (FRONT AND REAR) Overhead console noises are often caused by the cons ole panel clips not being engaged correctly. Most of

these incidents are repaired by pushing up on the c onsole at the clip locations until the clips engage.

In addition look for:

1. Loose harness or harness connectors.

2. Front console map/reading lamp lense loose.

3. Loose screws at console attachment points.

SEATS When isolating seat noise it's important to note the pos ition the seat is in and the load placed on the seat when

the noise is present. These conditions should be duplic ated when verifying and isolating the cause of the

noise.

Cause of seat noise include:

1. Headrest rods and holder

2. A squeak between the seat pad cushion and frame

3. The rear seatback lock and bracket

These noises can be isolated by moving or pressing on the suspected components while duplicating the con-

ditions under which the noise occurs. Most of thes e incidents can be repaired by repositioning the component

or applying urethane tape to the contact area.

UNDERHOOD Some interior noise may be caused by components under the hood or on the engine wall. The noise is then

transmitted into the passenger compartment.

Causes of transmitted underhood noise include:

1. Any component mounted to the engine wall

2. Components that pass through the engine wall

3. Engine wall mounts and connectors

4. Loose radiator mounting pins

5. Hood bumpers out of adjustment

6. Hood striker out of adjustment

These noises can be difficult to isolate since they cannot be reached from the interior of the vehicle. The best

method is to secure, move or insulate one component at a time and test drive the vehicle. Also, engine RPM

or load can be changed to isolate the noise. Repairs c an usually be made by moving, adjusting, securing, or

insulating the component causing the noise.

Page 3333 of 4331

Terminal and Reference Value for BCM " .

Work Flow INFOID:0000000004306861

1. Check the symptom and customer's requests.

2. Understand the outline of system. Refer to GW-19, " System Description " .

3. According to the trouble diagnosis chart, repa ir or replace the cause of the malfunction.

Refer to GW-31, " Trouble Diagnosis Symptom Chart " .

4. Does power window system operate normally? If Yes, GO TO 5, If No, GO TO 3.

5. Inspection End.

CONSULT-III Function (BCM) INFOID:0000000004306862

CONSULT-III can display each diagnostic item us ing the diagnostic test modes shown following.

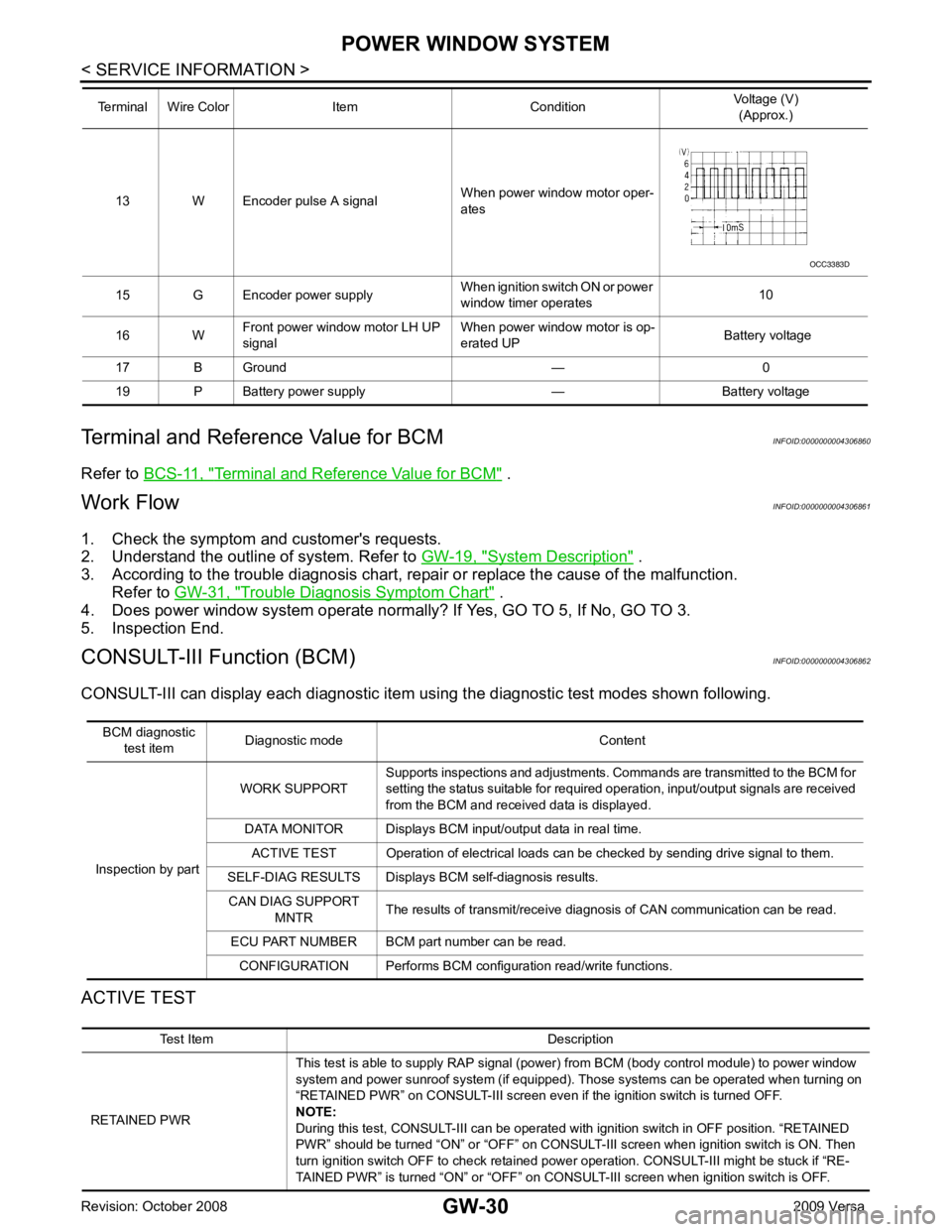

ACTIVE TEST 13 W Encoder pulse A signal

When power window motor oper-

ates

15 G Encoder power supply When ignition switch ON or power

window timer operates 10

16 W Front power window motor LH UP

signal When power window motor is op-

erated UP Battery voltage

17 B Ground — 0

19 P Battery power supply — Battery voltage

Terminal Wire Color Item Condition

Voltage (V)

(Approx.) Test Item Description

RETAINED PWR This test is able to supply RAP signal (powe

r) from BCM (body control module) to power window

system and power sunroof system (if equipped). Those systems can be operated when turning on

“RETAINED PWR” on CONSULT-III screen even if the ignition switch is turned OFF.

NOTE:

During this test, CONSULT-III can be operated with ignition switch in OFF position. “RETAINED

PWR” should be turned “ON” or “OFF” on CONSULT-III screen when ignition switch is ON. Then

turn ignition switch OFF to check retained power operation. CONSULT-III might be stuck if “RE-

TAINED PWR” is turned “ON” or “OFF” on CO NSULT-III screen when ignition switch is OFF.

Page 3998 of 4331

PG

N

O P

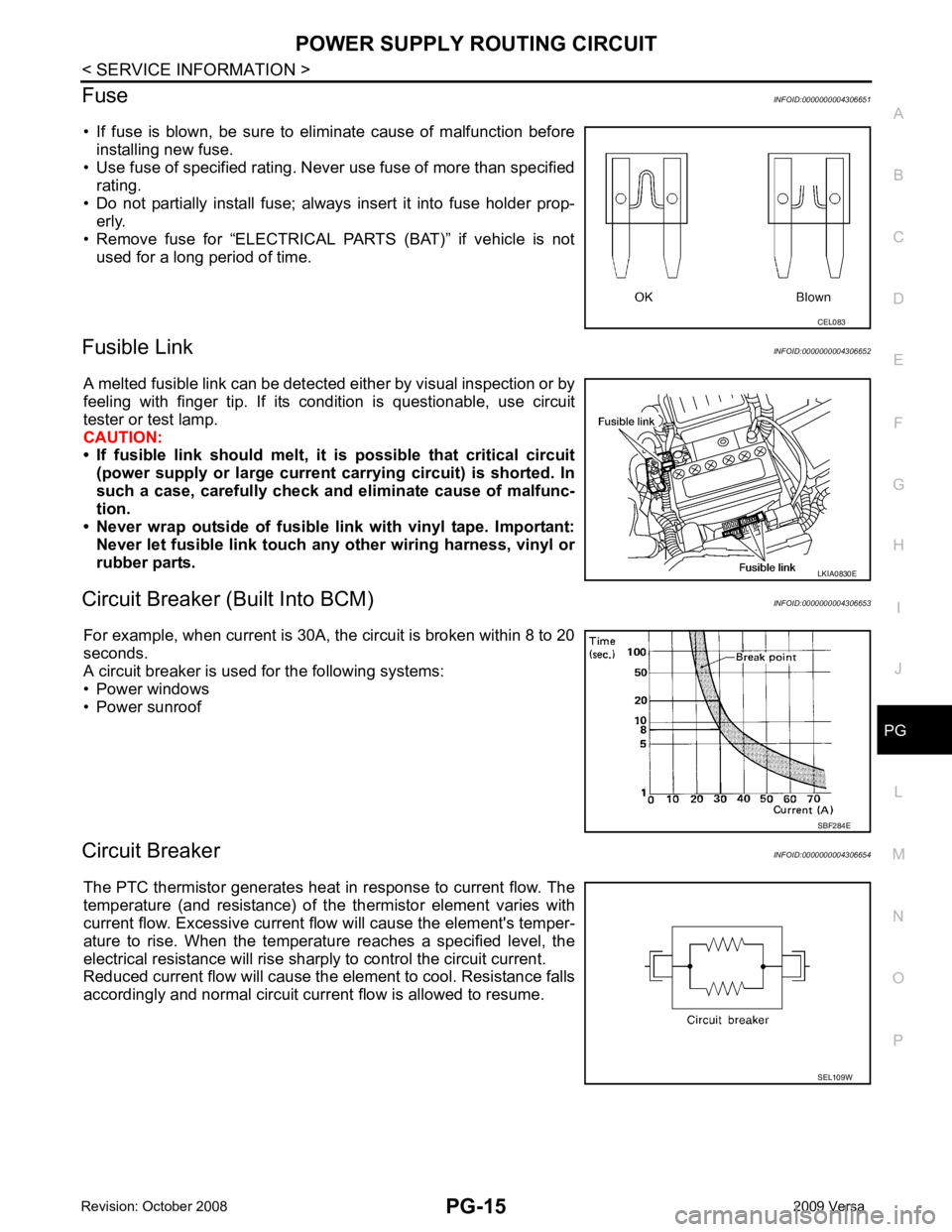

Fuse

INFOID:0000000004306651

• If fuse is blown, be sure to eliminate cause of malfunction before installing new fuse.

• Use fuse of specified rating. Never use fuse of more than specified

rating.

• Do not partially install fuse; always insert it into fuse holder prop- erly.

• Remove fuse for “ELECTRICAL PARTS (BAT)” if vehicle is not

used for a long period of time.

Fusible Link INFOID:0000000004306652

A melted fusible link can be detected either by visual inspection or by

feeling with finger tip. If its condition is questionable, use circuit

tester or test lamp.

CAUTION:

• If fusible link should melt, it is possible that critical circuit

(power supply or large current carrying circuit) is shorted. In

such a case, carefully check and eliminate cause of malfunc-

tion.

• Never wrap outside of fusible li nk with vinyl tape. Important:

Never let fusible link touch any other wiring harness, vinyl or

rubber parts.

Circuit Breaker (B uilt Into BCM) INFOID:0000000004306653

For example, when current is 30A, the circuit is broken within 8 to 20

seconds.

A circuit breaker is used for the following systems:

• Power windows

• Power sunroof

Circuit Breaker INFOID:0000000004306654

The PTC thermistor generates heat in response to current flow. The

temperature (and resistance) of t he thermistor element varies with

current flow. Excessive current flow will cause the element's temper-

ature to rise. When the temperature reaches a specified level, the

electrical resistance will rise shar ply to control the circuit current.

Reduced current flow will cause the element to cool. Resistance falls

accordingly and normal circuit current flow is allowed to resume. LKIA0830E

SEL109W

Page 4082 of 4331

RF

N

O P

CONTENTS

ROOF

PRECAUTION ....... ........................................2

PRECAUTIONS .............................................. .....2

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

2

Precaution Necessary fo r Steering Wheel Rota-

tion After Battery Disconnect ............................... ......

2

Precaution ........................................................... ......2

PREPARATION .... ........................................4

PREPARATION .............................................. .....4

Commercial Service Tool .................................... ......4

SYMPTOM DIAGNOSIS ..... ..........................5

SQUEAK AND RATTLE TROUBLE DIAG-

NOSES ........................ ........................................5

Work Flow ........................................................... ......5

Generic Squeak and Rattle Troubleshooting ...... ......7

Diagnostic Worksheet ......................................... ......9

FUNCTION DIAGNOSIS .. ............................11

TROUBLE DIAGNOSIS ................................. ....11 Component Parts and Harness Connector Loca-

tion ....................................................................... ....

11

System Description .............................................. ....11

CAN Communication System Description ........... ....13

Wiring Diagram - SROOF - .................................. ....14

Terminal and Reference Value for BCM ..................15

Terminal and Reference Value for Sunroof Motor

Assembly ............................................................. ....

16

Work Flow ............................................................ ....16

CONSULT-III Function (B CM) .................................16

Work Support ....................................................... ....17

Active Test ........................................................... ....17

Data Monitor ........................................................ ....17

Trouble Diagnosis Chart by Symptom ................. ....17

BCM Power Supply and Ground Circuit Inspection ....17

Sunroof Switch System Inspection ...................... ....17

Sunroof Motor Assembly Power Supply and

Ground Circuit Inspection .................................... ....

19

Door Switch Check .............................................. ....20

ON-VEHICLE REPAIR ..... ............................22

SUNROOF ......................................................... 22

Removal and Installation ..................................... ....22

Fitting Adjustment ................................................ ....27

Inspection ............................................................ ....28

Page 4092 of 4331

RF

N

O P

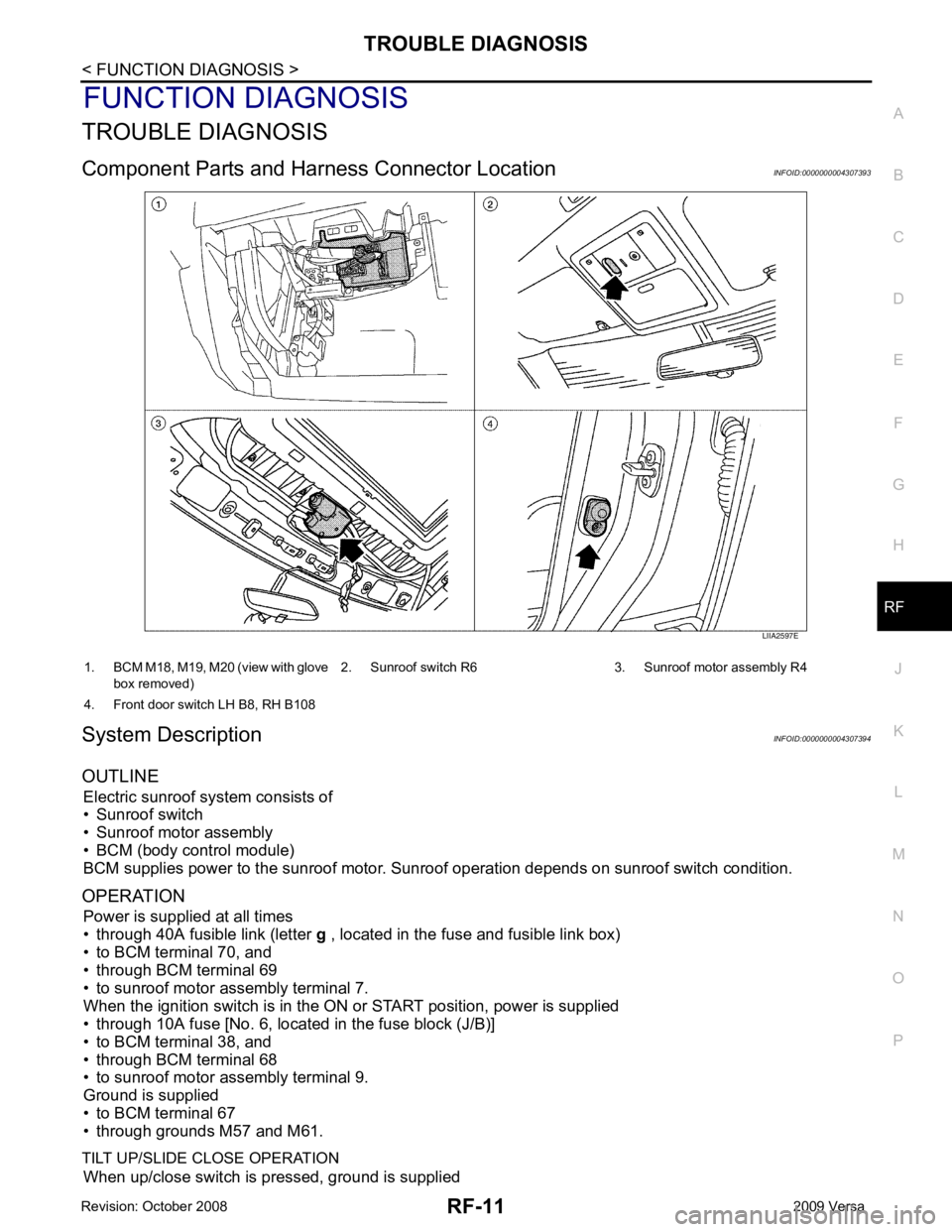

FUNCTION DIAGNOSIS

TROUBLE DIAGNOSIS

Component Parts and Har ness Connector Location INFOID:0000000004307393

System Description INFOID:0000000004307394

OUTLINE Electric sunroof system consists of

• Sunroof switch

• Sunroof motor assembly

• BCM (body control module)

BCM supplies power to the sunroof motor. S unroof operation depends on sunroof switch condition.

OPERATION Power is supplied at all times

• through 40A fusible link (letter g , located in the fuse and fusible link box)

• to BCM terminal 70, and

• through BCM terminal 69

• to sunroof motor assembly terminal 7.

When the ignition switch is in the ON or START position, power is supplied

• through 10A fuse [No. 6, located in the fuse block (J/B)]

• to BCM terminal 38, and

• through BCM terminal 68

• to sunroof motor assembly terminal 9.

Ground is supplied

• to BCM terminal 67

• through grounds M57 and M61.

TILT UP/SLIDE CLOSE OPERATION When up/close switch is pressed, ground is supplied

Page 4093 of 4331

Work Support " .

ANTI-PINCH FUNCTION

The CPU (central processing unit) of sunroof motor as sembly monitors the sunroof motor operation and the

sunroof position (fully-closed or other ) by the signals from sunroof motor.

When sunroof motor detects an interruption during the following slide close and tilt down operation, sunroof

switch controls the motor for open and the sunroof will oper ate until it reaches full up position (during tilt down

operation) or 125 mm (4.92 in) or more in an open direction (during slide close operation).

• close operation and tilt down when igniti on switch is in the ON position.

• close operation and tilt down during retained power operation.

INITIALIZATION FAILURE CONDITIONS

Initialization and teaching of system should be conducted if the following conditions exist:

• sunroof will only move in the UP/CLOSE direction, having a step by step motion

• sunroof does not have any auto operation.

INITIALIZATION PROCEDURE

If the sunroof does not close or open automatically, use the following procedure to return sunroof operation to

normal.

1. Press the switch to the UP/CLOSE position to tilt t he sunroof up fully. When the sunroof reaches the full tilt

up position it will back up a few millimeters and stop.

2. Release the UP/CLOSE switch.

3. Within 5 seconds of releasing the UP/CLOSE sw itch, press and hold the UP/CLOSE switch again. The

sunroof will move to the full open position and back to the closed position.

NOTE:

If the UP/CLOSE switch is released anytime during th is teaching process, all learned profile data will be dis-

carded and the procedure will have to be started over.

4. Release the UP/CLOSE switch. Do not disconnect power for at least two seconds. The sunroof is now ini-

tialized and taught.

Initializing procedure is complete. Confirm proper operation of the sunroof (slide open, slide closed, tilt up, tilt

down).

RE-TEACHING CONDITIONS

Re-teaching of system should be conducted if any of the following conditions exist:

• the sunroof is manually operated using the sunroof wrench with the battery discharged or disconnected.

• the sunroof is manually operated using the sunroof wrench with the key switch in the OFF position and

retained power timed out (after approximat ely 45 seconds or with a front door open).

• the sunroof motor assembly is replaced with a new one.

• the sunroof motor is removed from the sunroof assembly and operated before it is reinstalled.

Page 4094 of 4331

RF

N

O P

• the sunroof motor is removed from the sunroof

assembly and the glass panel position is changed.

RE-TEACHING PROCEDURE 1. Using the UP/CLOSE switch, move the sunroo f toward the tilt position until it stops.

2. Release the UP/CLOSE switch.

3. Press the UP/CLOSE switch again and continuously hold. The sunroof will begin to move in about 10 sec- onds.

4. Continue to hold the UP/CLOSE switch while the sunroof moves in a jogging motion to the full tilt position.

When the sunroof reaches the full tilt positi on, it will back up a few millimeters and stop.

5. Release the UP/CLOSE switch.

6. Within 5 seconds of releasing the UP/CLOSE s witch, press and hold the UP/CLOSE switch again. The

sunroof will move to the full open pos ition and back to the closed position.

NOTE:

If the UP/CLOSE switch is released anytime during th is teaching process, all learned profile data will be dis-

carded and the procedure will have to be started over.

7. Release the UP/CLOSE switch. Do not disconnect power for at least two seconds. The sunroof is now re-

taught.

CAN Communication System Description INFOID:0000000004307395

Refer to LAN-8 .