coolant temperature NISSAN TIIDA 2010 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2010, Model line: TIIDA, Model: NISSAN TIIDA 2010Pages: 3745, PDF Size: 73.67 MB

Page 3144 of 3745

PERIODIC MAINTENANCEMA-9

< SERVICE INFORMATION >

C

DE

F

G H

I

J

K

M A

B

MA

N

O P

PERIODIC MAINTENANCE

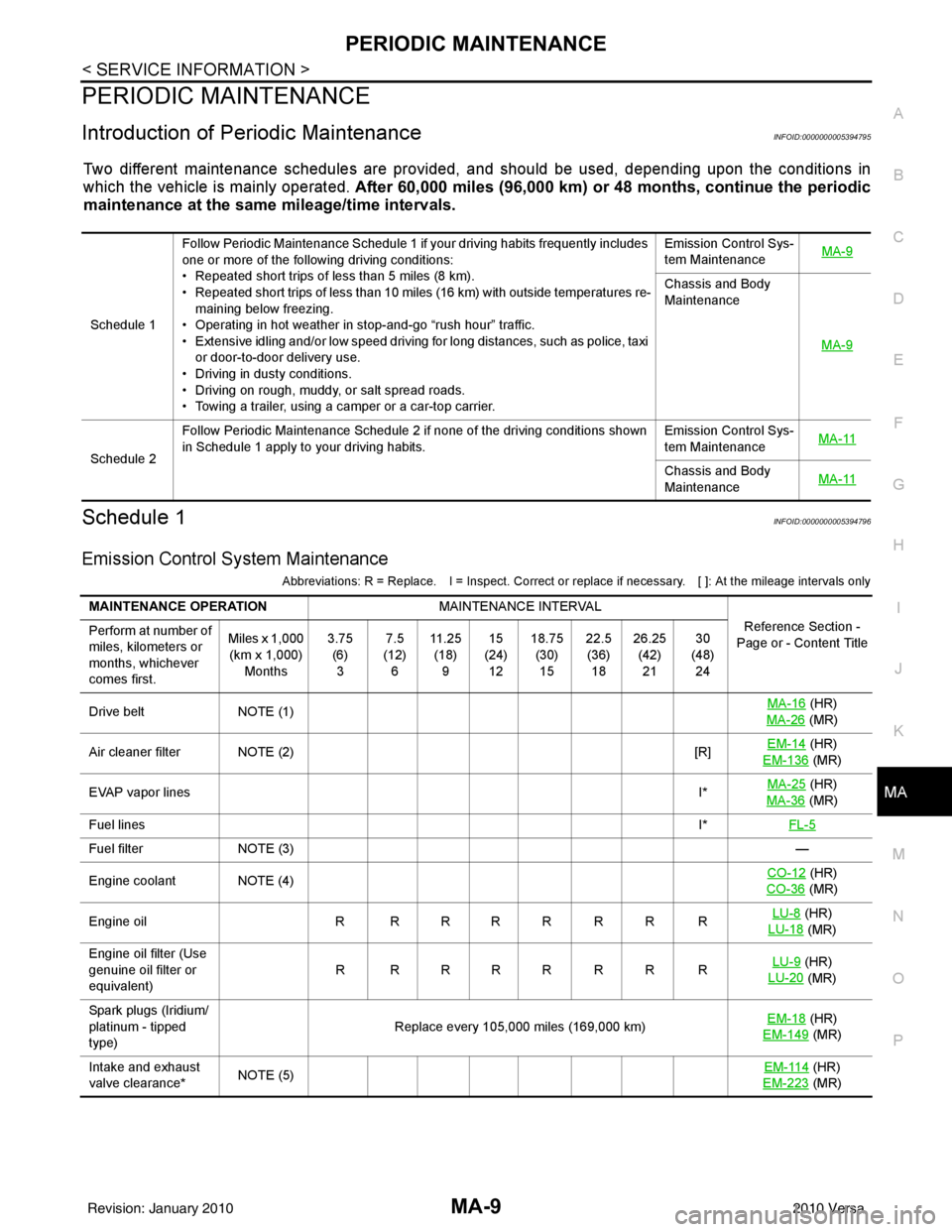

Introduction of Periodic MaintenanceINFOID:0000000005394795

Two different maintenance schedules are provi ded, and should be used, depending upon the conditions in

which the vehicle is mainly operated. After 60,000 miles (96,000 km) or 48 months, continue the periodic

maintenance at the same mileage/time intervals.

Schedule 1INFOID:0000000005394796

Emission Control System Maintenance

Abbreviations: R = Replace. I = Inspect. Correct or r eplace if necessary. [ ]: At the mileage intervals only

Schedule 1Follow Periodic Maintenance Schedule 1 if your driving habits frequently includes

one or more of the following driving conditions:

• Repeated short trips of less than 5 miles (8 km).

• Repeated short trips of less than 10 miles (16 km) with outside temperatures re-

maining below freezing.

• Operating in hot weather in stop-and-go “rush hour” traffic.

• Extensive idling and/or low speed driving for long distances, such as police, taxi

or door-to-door delivery use.

• Driving in dusty conditions.

• Driving on rough, muddy, or salt spread roads.

• Towing a trailer, using a camper or a car-top carrier. Emission Control Sys-

tem Maintenance

MA-9

Chassis and Body

Maintenance

MA-9

Schedule 2Follow Periodic Maintenance Schedule 2 if none of the driving conditions shown

in Schedule 1 apply to your driving habits.

Emission Control Sys-

tem Maintenance

MA-11Chassis and Body

Maintenance

MA-11

MAINTENANCE OPERATION

MAINTENANCE INTERVAL

Reference Section -

Page or - Content Title

Perform at number of

miles, kilometers or

months, whichever

comes first. Miles x 1,000

(km x 1,000) Months 3.75

(6)3 7.5

(12) 6 11 . 2 5

(18) 9 15

(24) 12 18.75

(30)15 22.5

(36) 18 26.25

(42)21 30

(48) 24

Drive belt NOTE (1) MA-16

(HR)

MA-26

(MR)

Air cleaner filter NOTE (2) [R]EM-14

(HR)

EM-136

(MR)

EVAP vapor lines I*MA-25

(HR)

MA-36

(MR)

Fuel lines I*FL-5

Fuel filter NOTE (3) —

Engine coolant NOTE (4) CO-12

(HR)

CO-36

(MR)

Engine oil R R R R R R R R LU-8

(HR)

LU-18

(MR)

Engine oil filter (Use

genuine oil filter or

equivalent) RRRRRRRR

LU-9

(HR)

LU-20

(MR)

Spark plugs (Iridium/

platinum - tipped

type) Replace every 105,000 miles (169,000 km)

EM-18

(HR)

EM-149

(MR)

Intake and exhaust

valve clearance* NOTE (5) EM-114

(HR)

EM-223

(MR)

Revision: January 20102010 Versa

Page 3150 of 3745

RECOMMENDED FLUIDS AND LUBRICANTSMA-15

< SERVICE INFORMATION >

C

DE

F

G H

I

J

K

M A

B

MA

N

O P

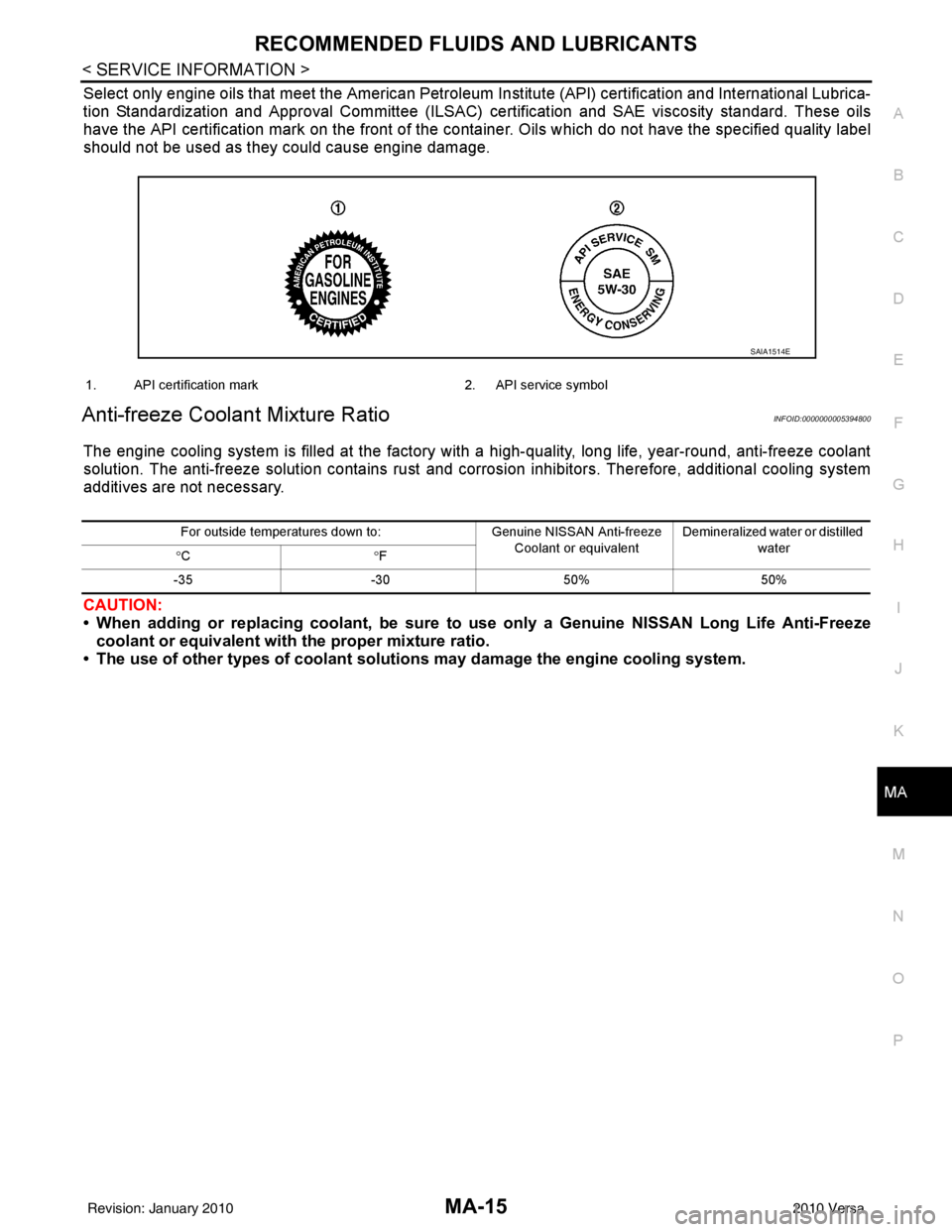

Select only engine oils that meet the American Petroleum Institute (API) certification and International Lubrica-

tion Standardization and Approval Committee (ILSAC) ce rtification and SAE viscosity standard. These oils

have the API certification mark on the front of the container. Oils which do not have the specified quality label

should not be used as they could cause engine damage.

Anti-freeze Coolant Mixture RatioINFOID:0000000005394800

The engine cooling system is filled at the factory wit h a high-quality, long life, year-round, anti-freeze coolant

solution. The anti-freeze solution contains rust and corrosion inhibitors. Therefore, additional cooling system

additives are not necessary.

CAUTION:

• When adding or replacing coolant, be sure to use only a Genuine NISSAN Long Life Anti-Freeze

coolant or equivalent with the proper mixture ratio.

• The use of other types of coolant soluti ons may damage the engine cooling system.

SAIA1514E

1. API certification mark 2. API service symbol

For outside temperatures down to: Genuine NISSAN Anti-freeze

Coolant or equivalent Demineralized water or distilled

water

° C °F

-35 -3050% 50%

Revision: January 20102010 Versa

Page 3154 of 3745

ENGINE MAINTENANCE (HR16DE)MA-19

< SERVICE INFORMATION >

C

DE

F

G H

I

J

K

M A

B

MA

N

O P

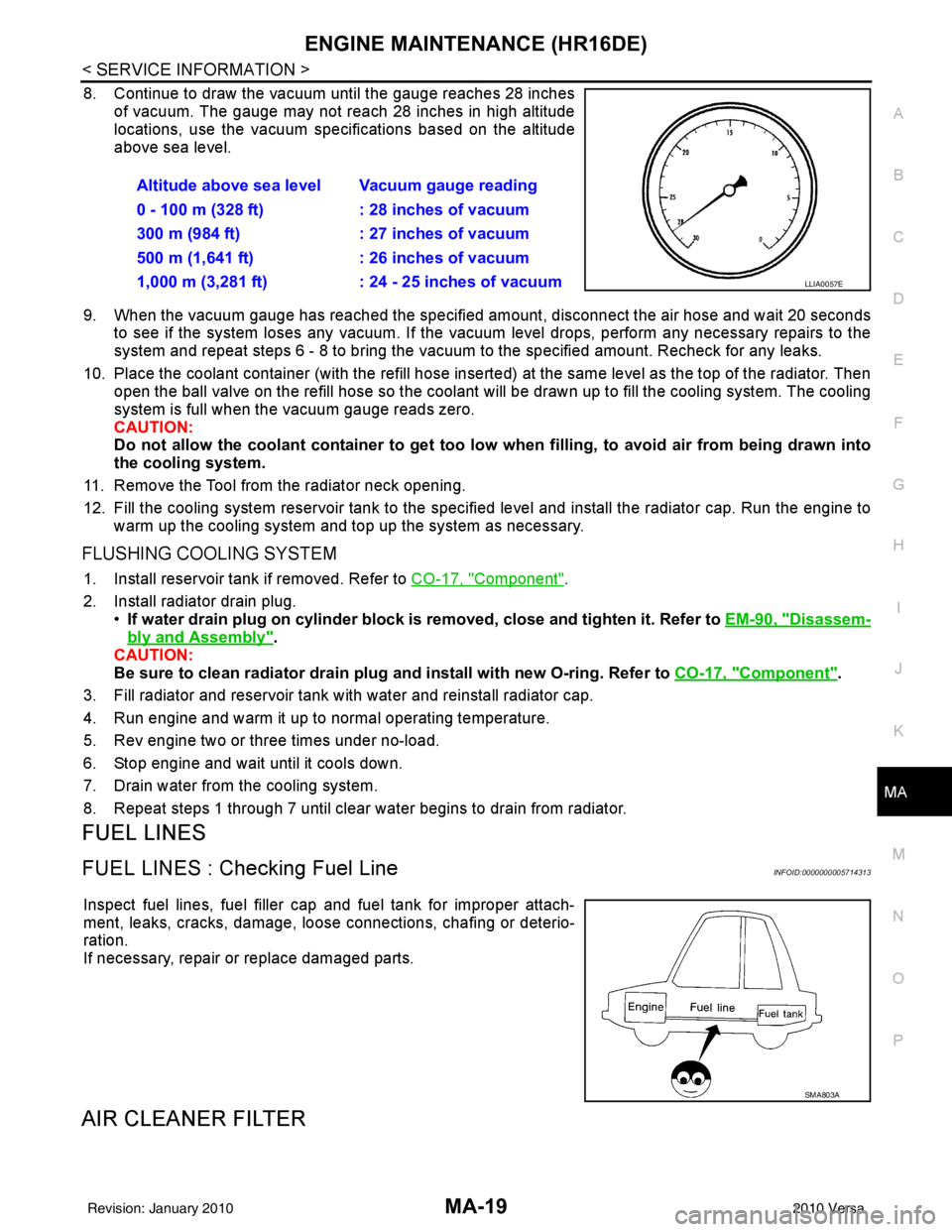

8. Continue to draw the vacuum until the gauge reaches 28 inches of vacuum. The gauge may not reach 28 inches in high altitude

locations, use the vacuum specifications based on the altitude

above sea level.

9. When the vacuum gauge has reached the specified amount, disconnect the air hose and wait 20 seconds

to see if the system loses any vacuum. If the vacuum level drops, perform any necessary repairs to the

system and repeat steps 6 - 8 to br ing the vacuum to the specified amount. Recheck for any leaks.

10. Place the coolant container (with the refill hose inserted) at the same level as the top of the radiator. Then

open the ball valve on the refill hose so the coolant will be drawn up to fill the cooling system. The cooling

system is full when the vacuum gauge reads zero.

CAUTION:

Do not allow the coolant container to get too low when filling, to avoid air from being drawn into

the cooling system.

11. Remove the Tool from the radiator neck opening.

12. Fill the cooling system reservoir tank to the specif ied level and install the radiator cap. Run the engine to

warm up the cooling system and top up the system as necessary.

FLUSHING COOLING SYSTEM

1. Install reservoir tank if removed. Refer to CO-17, "Component".

2. Install radiator drain plug. •If water drain plug on cylinder block is removed, close and tighten it. Refer to EM-90, "

Disassem-

bly and Assembly".

CAUTION:

Be sure to clean radiator drain plug and install with new O-ring. Refer to CO-17, "

Component".

3. Fill radiator and reservoir tank with water and reinstall radiator cap.

4. Run engine and warm it up to normal operating temperature.

5. Rev engine two or three times under no-load.

6. Stop engine and wait until it cools down.

7. Drain water from the cooling system.

8. Repeat steps 1 through 7 until clear water begins to drain from radiator.

FUEL LINES

FUEL LINES : Checking Fuel LineINFOID:0000000005714313

Inspect fuel lines, fuel filler cap and fuel tank for improper attach-

ment, leaks, cracks, damage, loos e connections, chafing or deterio-

ration.

If necessary, repair or replace damaged parts.

AIR CLEANER FILTER

Altitude above sea level Vacuum gauge reading

0 - 100 m (328 ft) : 28 inches of vacuum

300 m (984 ft) : 27 inches of vacuum

500 m (1,641 ft) : 26 inches of vacuum

1,000 m (3,281 ft) : 24 - 25 inches of vacuum

LLIA0057E

SMA803A

Revision: January 20102010 Versa

Page 3332 of 3745

TROUBLE DIAGNOSISMTC-53

< SERVICE INFORMATION >

C

DE

F

G H

I

K L

M A

B

MTC

N

O P

Insufficient HeatingINFOID:0000000005396504

SYMPTOM: Insufficient heating

INSPECTION FLOW

1.CONFIRM SYMPTOM BY PERFORMING OPERAT IONAL CHECK - TEMPERATURE INCREASE

1. Turn temperature control dial clockwise to maximum heat position.

2. Check for hot air at discharge air outlets.

Can the symptom be duplicated?

YES >> GO TO 3.

NO >> GO TO 2.

2.CHECK FOR ANY SYMPTOMS

Perform a complete operational check for any symptoms. Refer to MTC-31, "

Operational Check" .

Does another symptom exist?

YES >> Refer to MTC-23, "How to Perform Trouble Diagnosis for Quick and Accurate Repair" .

NO >> System OK.

3.CHECK FOR SERVICE BULLETINS

Check for any service bulletins.

>> GO TO 4.

4.CHECK COOLANT SYSTEM

1. Check engine coolant level. Refer to CO-12, "

Inspection" (HR16DE) or CO-36, "Inspection" (MR18DE).

2. Check hoses for leaks or kinks.

3. Check Radiator cap. Refer to CO-15, "

Checking Radiator Cap" HR16DE or CO-39, "Checking Radiator

Cap" (MR18DE).

OK or NG

OK >> GO TO 5.

NG >> Repair/replace as necessary.

5.CHECK AIR MIX DOOR CABLE

Check air mix door cable operation. Refer to MTC-65, "

Air Mix Door Cable Adjustment" .

OK or NG

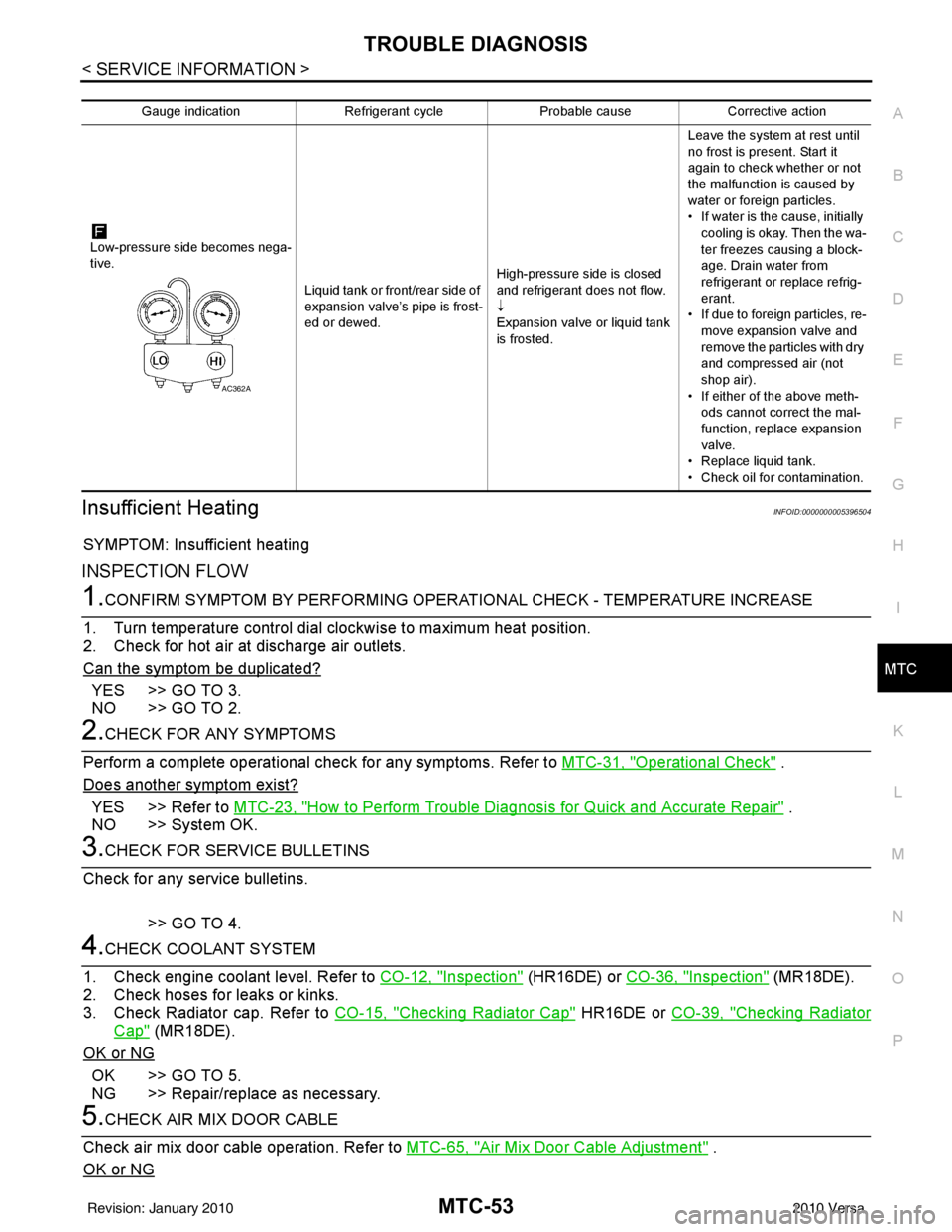

Gauge indication Refrigerant cycleProbable causeCorrective action

Low-pressure side becomes nega-

tive. Liquid tank or front/rear side of

expansion valve’s pipe is frost-

ed or dewed.High-pressure side is closed

and refrigerant does not flow.

↓

Expansion valve or liquid tank

is frosted.Leave the system at rest until

no frost is present. Start it

again to check whether or not

the malfunction is caused by

water or foreign particles.

• If water is the cause, initially

cooling is okay. Then the wa-

ter freezes causing a block-

age. Drain water from

refrigerant or replace refrig-

erant.

• If due to foreign particles, re-

move expansion valve and

remove the particles with dry

and compressed air (not

shop air).

• If either of the above meth- ods cannot correct the mal-

function, replace expansion

valve.

• Replace liquid tank.

• Check oil for contamination.

AC362A

Revision: January 20102010 Versa

Page 3333 of 3745

MTC-54

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS

YES >> GO TO 6.

NO >> Adjust or replace air mix door cable. Refer to MTC-65, "

Air Mix Door Cable Adjustment" .

6.CHECK AIR DUCTS

Check ducts for air leaks.

OK or NG

OK >> GO TO 7.

NG >> Repair air leaks.

7.CHECK HEATER HOSE TEMPERATURES

1. Start engine and warm it up to normal operating temperature.

2. Touch both the inlet and outlet heater hoses. The inlet hose should be hot and the outlet hose should be

warm.

Is the inlet hose hot and the outlet hose warm?

YES >> GO TO 8.

NO >> Both hoses warm: GO TO 9.

8.CHECK ENGINE COOLANT TEMPERATURE SENSOR

Check engine control temperature sensor. Refer to EC-690, "

Component Inspection" (MR18DE) or EC-163,

"Component Inspection" (HR16DE).

OK or NG

OK >> System OK.

NG >> Repair or replace as necessary. Retest.

9.CHECK HEATER HOSES

Check heater hoses for proper installation.

OK or NG

OK >> GO TO 10.

NG >> Repair /replace as necessary. Retest GO TO 7.

10.BACK FLUSH HEATER CORE

1. Back flush heater core.

2. Drain the water from the system.

3. Refill system with new engine coolant. Refer to CO-12, "

Changing Engine Coolant" (HR16DE) or CO-36,

"Changing Engine Coolant" (MR18DE) .

4. Start engine and warm it up to normal operating temperature.

5. Touch both the inlet and outlet heater hoses. The inlet hose should be hot and the outlet hose should be

warm.

Is the inlet hose hot and the outlet hose warm?

YES >> System OK.

NO >> Replace heater core and refill engine coolant. Refer to MTC-68, "

Removal and Installation" .

NoiseINFOID:0000000005396505

SYMPTOM: Noise

INSPECTION FLOW

Revision: January 20102010 Versa

Page 3429 of 3745

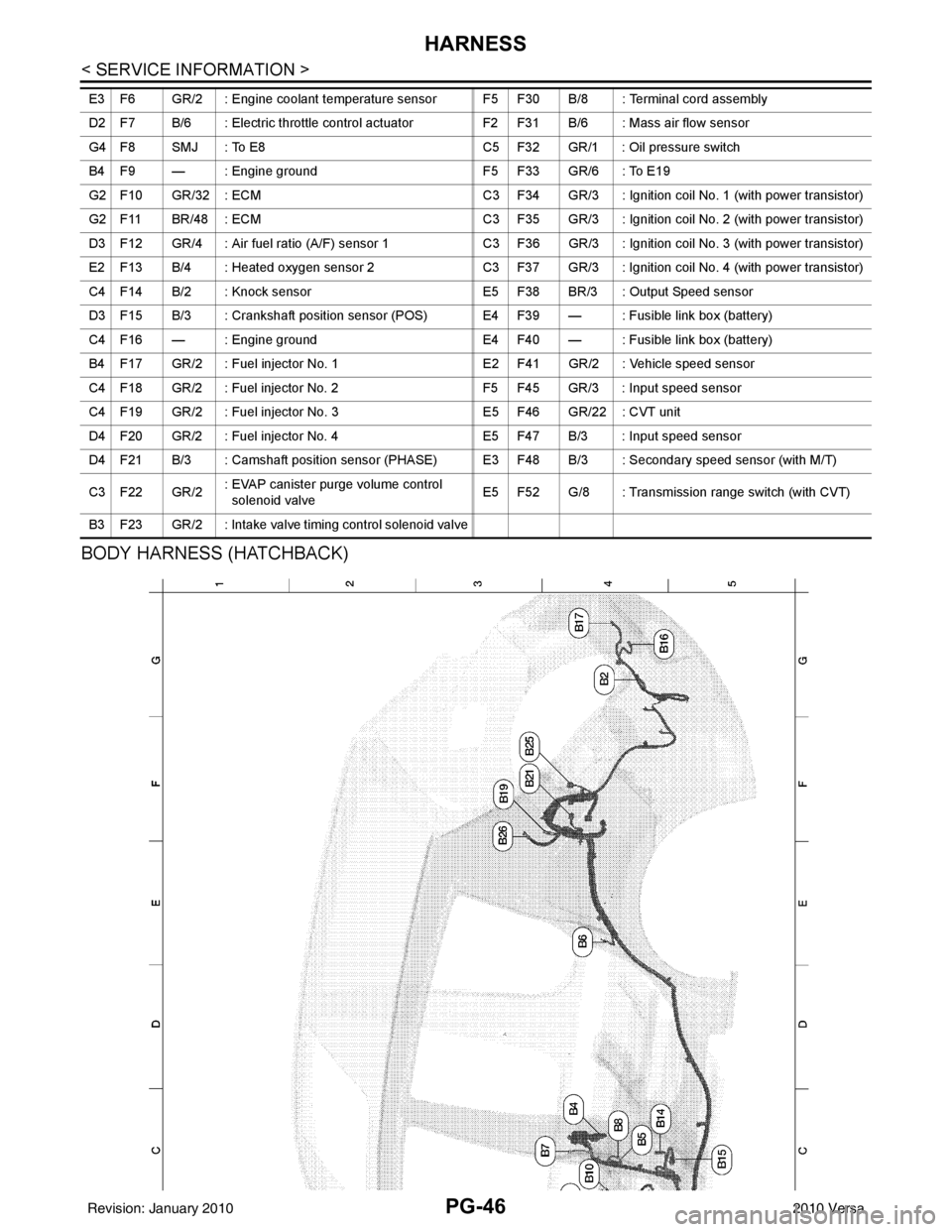

PG-46

< SERVICE INFORMATION >

HARNESS

BODY HARNESS (HATCHBACK)

E3 F6 GR/2 : Engine coolant temperature sensor F5 F30 B/8 : Terminal cord assembly

D2 F7 B/6 : Electric throttle control actuatorF2 F31 B/6 : Mass air flow sensor

G4 F8 SMJ : To E8 C5 F32 GR/1 : Oil pressure switch

B4 F9 — : Engine ground F5 F33 GR/6 : To E19

G2 F10 GR/32 : ECM C3 F34 GR/3 : Ignition coil No. 1 (with power transistor)

G2 F11 BR/48 : ECM C3 F35 GR/3 : Ignition coil No. 2 (with power transistor)

D3 F12 GR/4 : Air fuel ratio (A/F) sensor 1 C3 F36 GR/3 : Ignition coil No. 3 (with power transistor)

E2 F13 B/4 : Heated oxygen sensor 2 C3 F37 GR/3 : Ignition coil No. 4 (with power transistor)

C4 F14 B/2 : Knock sensor E5 F38 BR/3 : Output Speed sensor

D3 F15 B/3 : Crankshaft position sensor (POS) E4 F39 — : Fusible link box (battery)

C4 F16 — : Engine ground E4 F40 — : Fusible link box (battery)

B4 F17 GR/2 : Fuel injector No. 1 E2 F41 GR/2 : Vehicle speed sensor

C4 F18 GR/2 : Fuel injector No. 2 F5 F45 GR/3 : Input speed sensor

C4 F19 GR/2 : Fuel injector No. 3E5 F46 GR/22 : CVT unit

D4 F20 GR/2 : Fuel injector No. 4 E5 F47 B/3 : Input speed sensor

D4 F21 B/3 : Camshaft position sensor (PHASE) E3 F48 B/3 : Secondary speed sensor (with M/T)

C3 F22 GR/2 : EVAP canister purge volume control

solenoid valve E5 F52 G/8 : Transmission range switch (with CVT)

B3 F23 GR/2 : Intake valve timing control solenoid valve

Revision: January 20102010 Versa

Page 3442 of 3745

HARNESSPG-59

< SERVICE INFORMATION >

C

DE

F

G H

I

J

L

M A

B

PG

N

O P

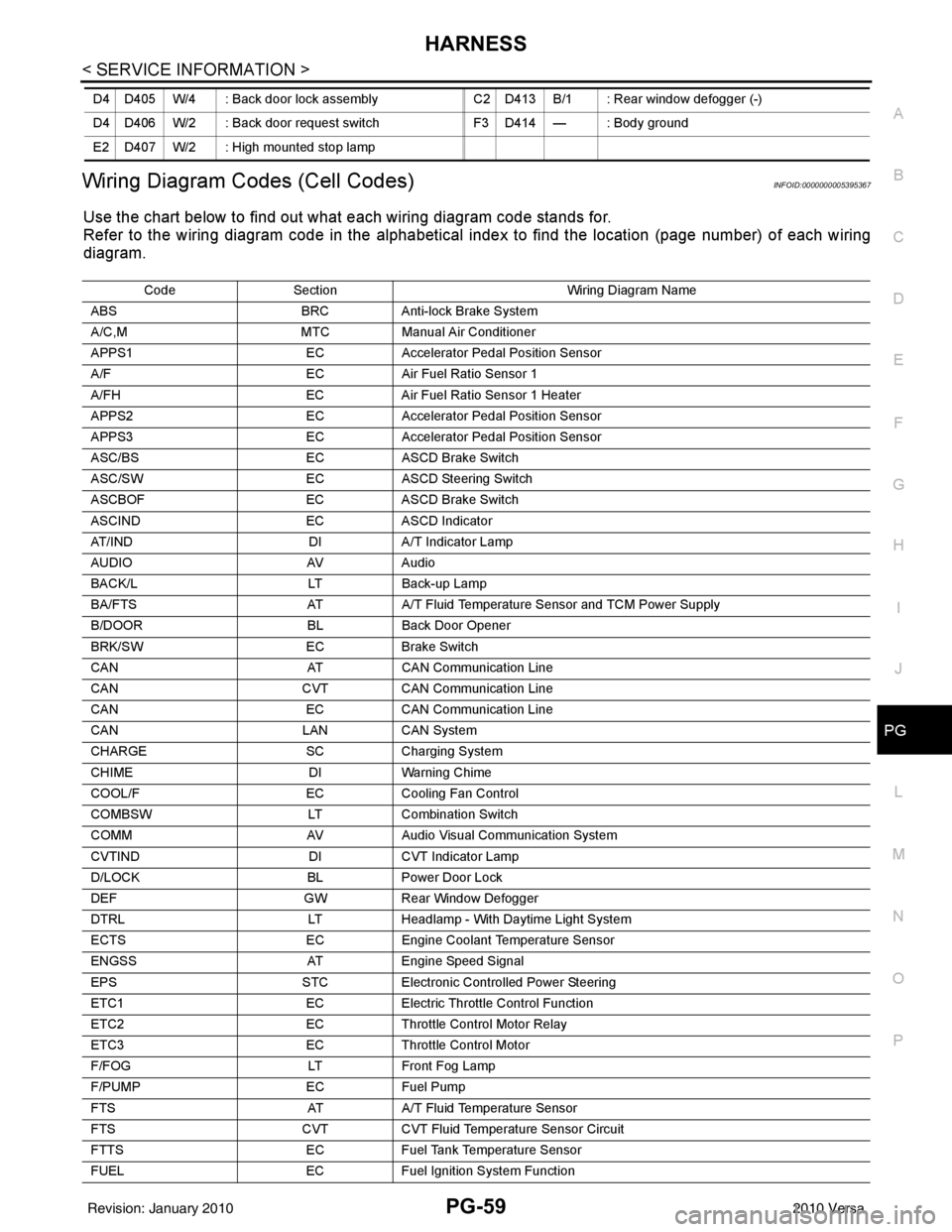

Wiring Diagram Codes (Cell Codes)INFOID:0000000005395367

Use the chart below to find out what each wiring diagram code stands for.

Refer to the wiring diagram code in the alphabetical index to find the location (page number) of each wiring

diagram.

D4 D405 W/4 : Back door lock assembly C2 D413 B/1 : Rear window defogger (-)

D4 D406 W/2 : Back door request switch F3 D414 — : Body ground

E2 D407 W/2 : High mounted stop lamp

Code Section Wiring Diagram Name

ABS BRC Anti-lock Brake System

A/C,M MTC Manual Air Conditioner

APPS1 EC Accelerator Pedal Position Sensor

A/F EC Air Fuel Ratio Sensor 1

A/FH EC Air Fuel Ratio Sensor 1 Heater

APPS2 EC Accelerator Pedal Position Sensor

APPS3 EC Accelerator Pedal Position Sensor

ASC/BS EC ASCD Brake Switch

ASC/SW EC ASCD Steering Switch

ASCBOF EC ASCD Brake Switch

ASCIND EC ASCD Indicator

AT/IND DI A/T Indicator Lamp

AUDIO AV Audio

BACK/L LT Back-up Lamp

BA/FTS AT A/T Fluid Temperature Sensor and TCM Power Supply

B/DOOR BL Back Door Opener

BRK/SW EC Brake Switch

CAN AT CAN Communication Line

CAN CVT CAN Communication Line

CAN EC CAN Communication Line

CAN LAN CAN System

CHARGE SC Charging System

CHIME DI Warning Chime

COOL/F EC Cooling Fan Control

COMBSW LT Combination Switch

COMM AV Audio Visual Communication System

CVTIND DI CVT Indicator Lamp

D/LOCK BL Power Door Lock

DEF GW Rear Window Defogger

DTRL LT Headlamp - Wi th Daytime Light System

ECTS EC Engine Coolant Temperature Sensor

ENGSS AT Engine Speed Signal

EPS STC Electronic Controlled Power Steering

ETC1 EC Electric Throttle Control Function

ETC2 EC Throttle Control Motor Relay

ETC3 EC Throttle Control Motor

F/FOG LT Front Fog Lamp

F/PUMP EC Fuel Pump

FTS AT A/T Fluid Temperature Sensor

FTS CVT CVT Fluid Temperature Sensor Circuit

FTTS EC Fuel Tank Temperature Sensor

FUEL EC Fuel Ignition System Function

Revision: January 20102010 Versa

Page 3558 of 3745

STARTING SYSTEMSC-19

< SERVICE INFORMATION >

C

DE

F

G H

I

J

L

M A

B

SC

N

O P

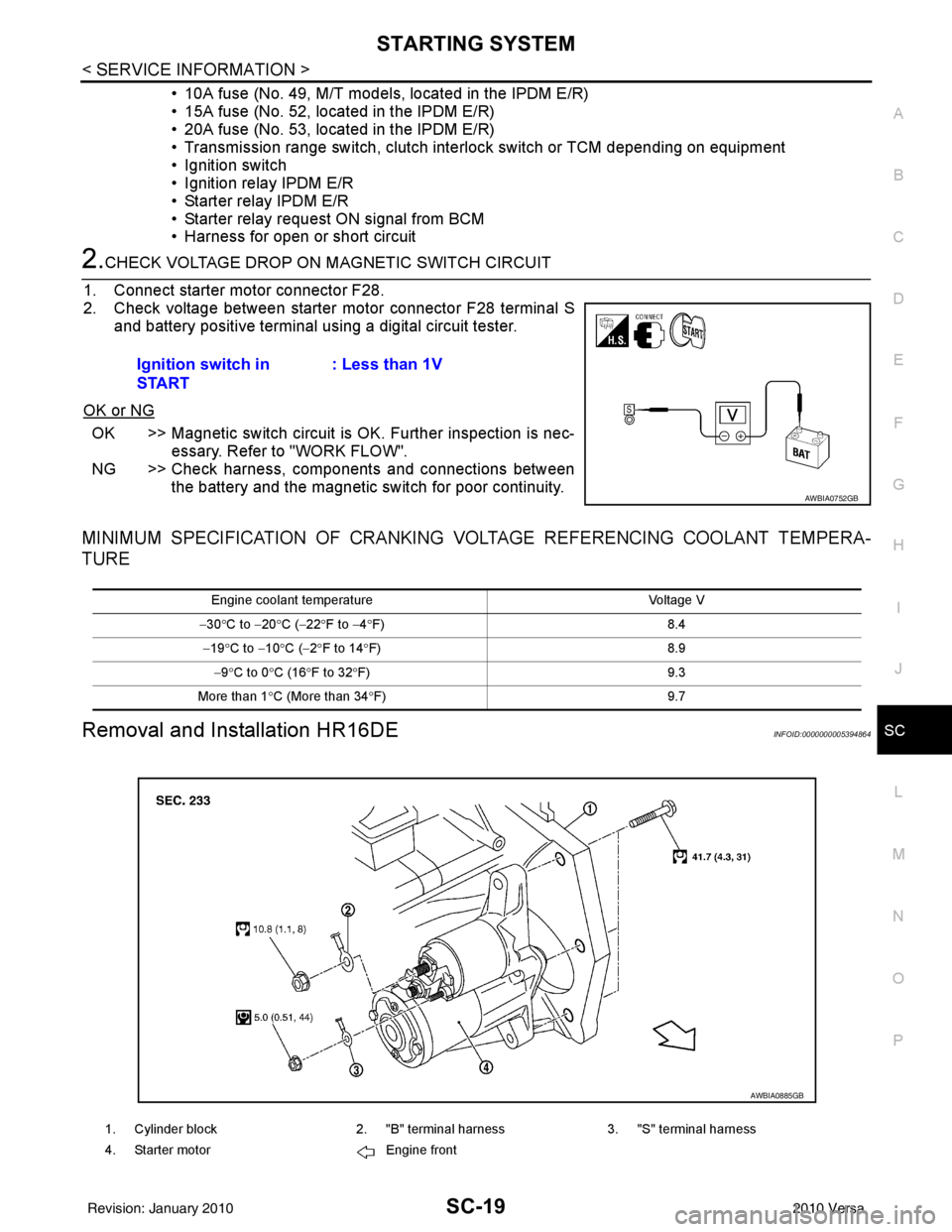

• 10A fuse (No. 49, M/T model s, located in the IPDM E/R)

• 15A fuse (No. 52, located in the IPDM E/R)

• 20A fuse (No. 53, located in the IPDM E/R)

• Transmission range switch, clutch interlock switch or TCM depending on equipment

• Ignition switch

• Ignition relay IPDM E/R

• Starter relay IPDM E/R

• Starter relay request ON signal from BCM

• Harness for open or short circuit

2.CHECK VOLTAGE DROP ON MAGNETIC SWITCH CIRCUIT

1. Connect starter motor connector F28.

2. Check voltage between starter motor connector F28 terminal S and battery positive terminal using a digital circuit tester.

OK or NG

OK >> Magnetic switch circuit is OK. Further inspection is nec-

essary. Refer to "WORK FLOW".

NG >> Check harness, components and connections between the battery and the magnetic switch for poor continuity.

MINIMUM SPECIFICATION OF CRANKING VO LTAGE REFERENCING COOLANT TEMPERA-

TURE

Removal and Installation HR16DEINFOID:0000000005394864

Ignition switch in

START : Less than 1V

AWBIA0752GB

Engine coolant temperature

Voltage V

− 30 °C to − 20°C ( −22 °F to −4 °F) 8.4

− 19 °C to − 10°C ( −2°F to 14 °F) 8.9

− 9 °C to 0 °C (16 °F to 32 °F) 9.3

More than 1 °C (More than 34 °F) 9.7

1. Cylinder block2. "B" terminal harness3. "S" terminal harness

4. Starter motor Engine front

AWBIA0885GB

Revision: January 20102010 Versa