fuel tank removal NISSAN TIIDA 2010 Service User Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2010, Model line: TIIDA, Model: NISSAN TIIDA 2010Pages: 3745, PDF Size: 73.67 MB

Page 2149 of 3745

![NISSAN TIIDA 2010 Service User Guide EC-884

< SERVICE INFORMATION >[MR18DE]

DTC P0461 FUEL LEVEL SENSOR

12. Check “FUEL LEVEL SE” output voltage and note it.

13. Confirm whether the voltage changes more than 0.03 V during step 7 to 1 NISSAN TIIDA 2010 Service User Guide EC-884

< SERVICE INFORMATION >[MR18DE]

DTC P0461 FUEL LEVEL SENSOR

12. Check “FUEL LEVEL SE” output voltage and note it.

13. Confirm whether the voltage changes more than 0.03 V during step 7 to 1](/img/5/57397/w960_57397-2148.png)

EC-884

< SERVICE INFORMATION >[MR18DE]

DTC P0461 FUEL LEVEL SENSOR

12. Check “FUEL LEVEL SE” output voltage and note it.

13. Confirm whether the voltage changes more than 0.03 V during step 7 to 10 and 10 to 12.

If NG, go to EC-884, "

Diagnosis Procedure".

WITH GST

NOTE:

Start from step 8, if it is possible to confirm that the fuel cannot be drained by 30 (7-7/8 US gal, 6-5/8

Imp gal) in advance.

1. Prepare a fuel container and a spare hose.

2. Release fuel pressure from fuel line, refer to EC-582, "

Fuel Pressure Check".

3. Remove the fuel feed hose on the fuel level sensor unit.

4. Connect a spare fuel hose where the fuel feed hose was removed.

5. Turn ignition switch ON.

6. Drain fuel by 30 (7-7/8 US gal, 6-5/8 Imp gal) from the fuel tank using proper equipment.

7. Confirm that the fuel gauge indication varies.

8. Fill fuel into the fuel tank for 30 (7-7/8 US gal, 6-5/8 Imp gal).

9. Confirm that the fuel gauge indication varies.

10. If NG, go to EC-884, "

Diagnosis Procedure".

Diagnosis ProcedureINFOID:0000000005532734

1.CHECK FUEL GAUGE OPERATION

Refer to DI-11, "

Self-Diagnosis Mode of Combination Meter".

OK or NG

OK >> GO TO 2.

NG >> Follow the instruction of DI-11, "

Self-Diagnosis Mode of Combination Meter".

2.CHECK FUEL LEVEL SENSOR AND CIRCUIT

Refer to DI-17, "

Fuel Level Sensor Signal Inspection".

OK or NG

OK >> GO TO 3.

NG >> Repair or replace malfunctioning parts.

3.CHECK INTERMITTENT INCIDENT

Refer to EC-632

.

>> INSPECTION END

Removal and InstallationINFOID:0000000005532735

FUEL LEVEL SENSOR

Refer to FL-6, "Removal and Installation".

Revision: January 20102010 Versa

Page 2442 of 3745

![NISSAN TIIDA 2010 Service User Guide ENGINE ASSEMBLYEM-83

< REMOVAL AND INSTALLATION > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EM

NP

O

• If items or work required are not covered by the engine section, follow the procedures in the applica-

bl NISSAN TIIDA 2010 Service User Guide ENGINE ASSEMBLYEM-83

< REMOVAL AND INSTALLATION > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EM

NP

O

• If items or work required are not covered by the engine section, follow the procedures in the applica-

bl](/img/5/57397/w960_57397-2441.png)

ENGINE ASSEMBLYEM-83

< REMOVAL AND INSTALLATION > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EM

NP

O

• If items or work required are not covered by the engine section, follow the procedures in the applica-

ble sections.

• Always use the support poin t specified for lifting.

• Use either 2-pole lift type or separate type lift as best you can. If board-on type is used for unavoid-

able reasons, support at the rear axle jacking point with a transmission jack or similar tool before

starting work, in preparation for the backward shif t of center of gravity.

• For supporting points fo r lifting and jacking point at rear axle, refer to GI-38, "

Garage Jack and

Safety Stand and 2-Pole Lift".

REMOVAL

Outline

Remove the engine and the transaxle assembly from t he vehicle downward. Separate the engine and the tran-

saxle.

Preparation

1. Remove the hood assembly. Refer to BL-14, "Removal and Installation".

2. Remove the cowl top cover and cowl top extension assembly. Refer to EI-22, "

Removal and Installation".

3. Release fuel pressure. Refer to EC-496, "

Inspection".

4. Drain engine coolant from radiator. Refer to CO-12, "

Changing Engine Coolant".

CAUTION:

• Perform this step when the engine is cold.

• Never spill engine coolant on drive belt.

5. Drain the transmission fluid. Refer to MT-11, "

Draining" (M/T).

6. Remove the following parts. • Engine under cover. Refer to EI-15, "

Removal and Installation".

• Front road wheels and tires. Refer to WT-7, "

Adjustment".

• Front fender protector (RH and LH). Refer to EI-24, "

Removal and Installation".

• Battery and battery tray. Refer to SC-7, "

Removal and Installation".

• Drive belt. Refer to EM-15, "

Removal and Installation".

• Air duct and air cleaner case assembly. Refer to EM-26, "

Exploded View".

• Radiator hose (upper and lower). Refer to CO-17, "

Component".

• Disconnect cooling fan controller wiring harness.

• Remove coolant reservoir tank.

• Remove fan shroud and cooling fan assembly. Refer to CO-19, "

Component (Models with A/C)" or CO-

19, "Component (Models without A/C)".

Engine Room LH

1. Disconnect all connections of engine harness around the engine mounting insulator (LH), and then tem-

porarily secure the engine harness into the engine side.

CAUTION:

Protect connectors using a resin bag against foreign materials.

2. Remove ground cable at transaxle side.

3. Disconnect fuel feed hose at engine side. Refer to EM-34, "

Exploded View".

4. Disconnect EVAP purge hose and brake booster vacuum hose.

5. Disconnect heater hoses, and install plugs them to prevent engine coolant from draining. Refer to CO-17,

"Component".

6. Disconnect control linkage from transaxle. Refer to AT-213, "

A/T Shift Selector Removal and Installation"

(A/T), MT-14, "Exploded View" (M/T).

7. Disconnect the clutch tube at tr ansmission side (if equipped). Refer to CL-15, "

Removal and Installation".

Engine Room RH

1. Remove ground cable between front cover and vehicle.

2. Remove generator and generator br acket (A/C models). Refer to SC-25, "

Removal and Installation".

3. Remove A/C compressor with piping connected from t he engine. Temporarily secure it on the vehicle side

with a rope to avoid putting load on it (if equipped). Refer to MTC-79, "

Removal and Installation of Com-

pressor - HR16DE".

Vehicle Underbody

Revision: January 20102010 Versa

Page 2631 of 3745

FL-1

ENGINE

C

DE

F

G H

I

J

K L

M

SECTION FL

A

FL

N

O P

CONTENTS

FUEL SYSTEM

SERVICE INFORMATION .. ..........................2

PRECAUTIONS .............................................. .....2

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

2

Precaution Necessary for Steering Wheel Rota-

tion After Battery Disconnect ............................... ......

2

PREPARATION ...................................................4

Special Service Tool ........................................... ......4

Commercial Service Tool ..........................................4

FUEL SYSTEM ....................................................5

Checking Fuel Line ............................................. ......5

General Precaution .............................................. .....5

FUEL LEVEL SENSOR UNIT, FUEL FILTER

AND FUEL PUMP ASSEMBLY .........................

6

Component ...............................................................6

Removal and Installation ..........................................6

FUEL TANK ......................................................12

Component .......................................................... ....12

Removal and Installation .........................................12

SERVICE DATA AND SPECIFICATIONS

(SDS) .................................................................

17

Standard and Limit ..................................................17

Revision: January 20102010 Versa

Page 2636 of 3745

FL-6

< SERVICE INFORMATION >

FUEL LEVEL SENSOR UNIT, FUEL FILTER AND FUEL PUMP ASSEMBLY

FUEL LEVEL SENSOR UNIT, FUEL FILTER AND FUEL PUMP ASSEMBLY

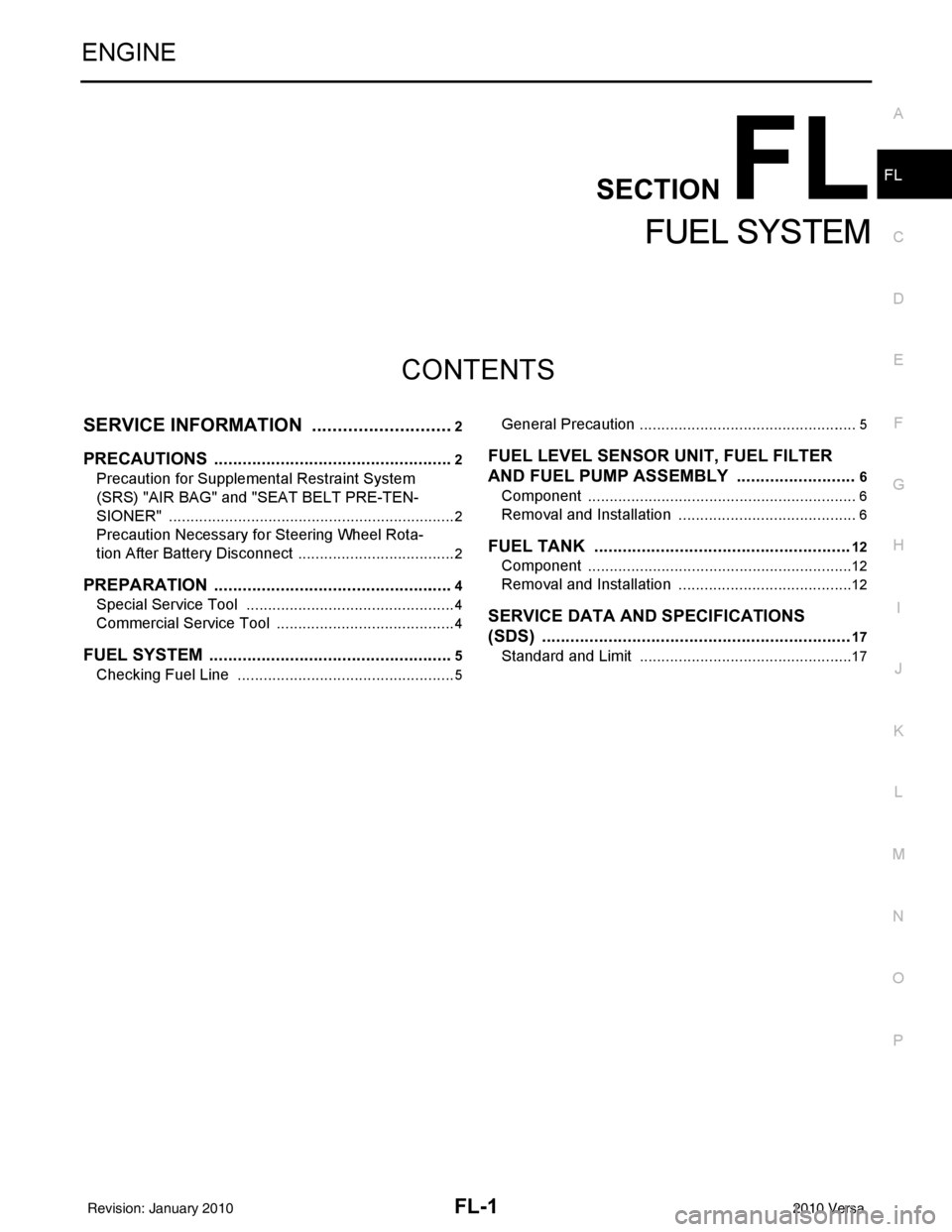

ComponentINFOID:0000000006055185

Removal and InstallationINFOID:0000000006055186

REMOVAL

WARNING:

Be sure to read “General Precautions” be fore working on the fuel system. Refer to FL-5, "

General Pre-

caution".

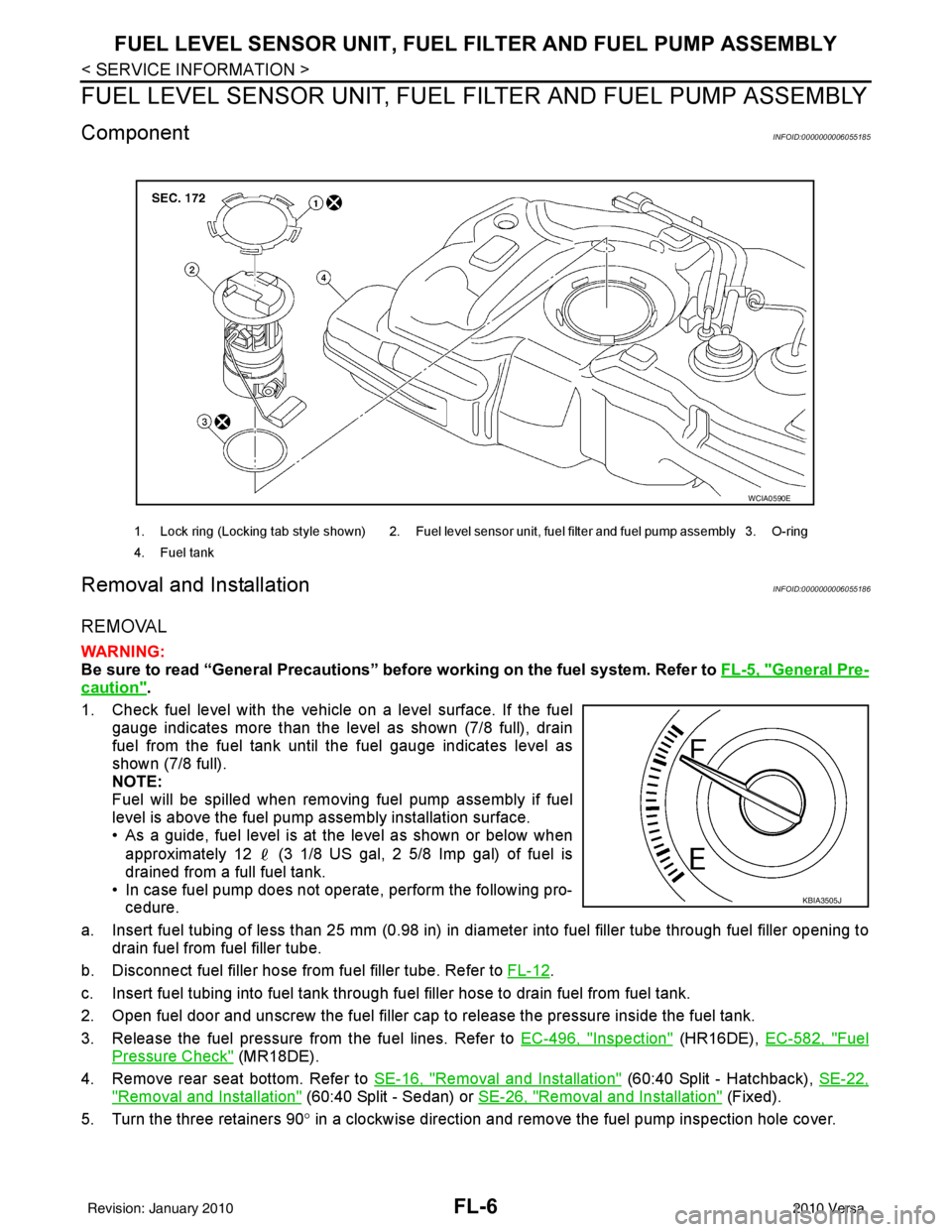

1. Check fuel level with the vehicle on a level surface. If the fuel gauge indicates more than the level as shown (7/8 full), drain

fuel from the fuel tank until the fuel gauge indicates level as

shown (7/8 full).

NOTE:

Fuel will be spilled when removing fuel pump assembly if fuel

level is above the fuel pump assembly installation surface.

• As a guide, fuel level is at the level as shown or below when

approximately 12 (3 1/8 US gal, 2 5/8 Imp gal) of fuel is

drained from a full fuel tank.

• In case fuel pump does not operate, perform the following pro- cedure.

a. Insert fuel tubing of less than 25 mm (0.98 in) in di ameter into fuel filler tube through fuel filler opening to

drain fuel from fuel filler tube.

b. Disconnect fuel filler hose from fuel filler tube. Refer to FL-12

.

c. Insert fuel tubing into fuel tank through f uel filler hose to drain fuel from fuel tank.

2. Open fuel door and unscrew the fuel filler cap to release the pressure inside the fuel tank.

3. Release the fuel pressure from the fuel lines. Refer to EC-496, "

Inspection" (HR16DE), EC-582, "Fuel

Pressure Check" (MR18DE).

4. Remove rear seat bottom. Refer to SE-16, "

Removal and Installation" (60:40 Split - Hatchback), SE-22,

"Removal and Installation" (60:40 Split - Sedan) or SE-26, "Removal and Installation" (Fixed).

5. Turn the three retainers 90 ° in a clockwise direction and remove the fuel pump inspection hole cover.

1. Lock ring (Locking tab style shown) 2. Fuel level sensor unit, fuel filter and fuel pump assembly 3. O-ring

4. Fuel tank

WCIA0590E

KBIA3505J

Revision: January 20102010 Versa

Page 2638 of 3745

FL-8

< SERVICE INFORMATION >

FUEL LEVEL SENSOR UNIT, FUEL FILTER AND FUEL PUMP ASSEMBLY

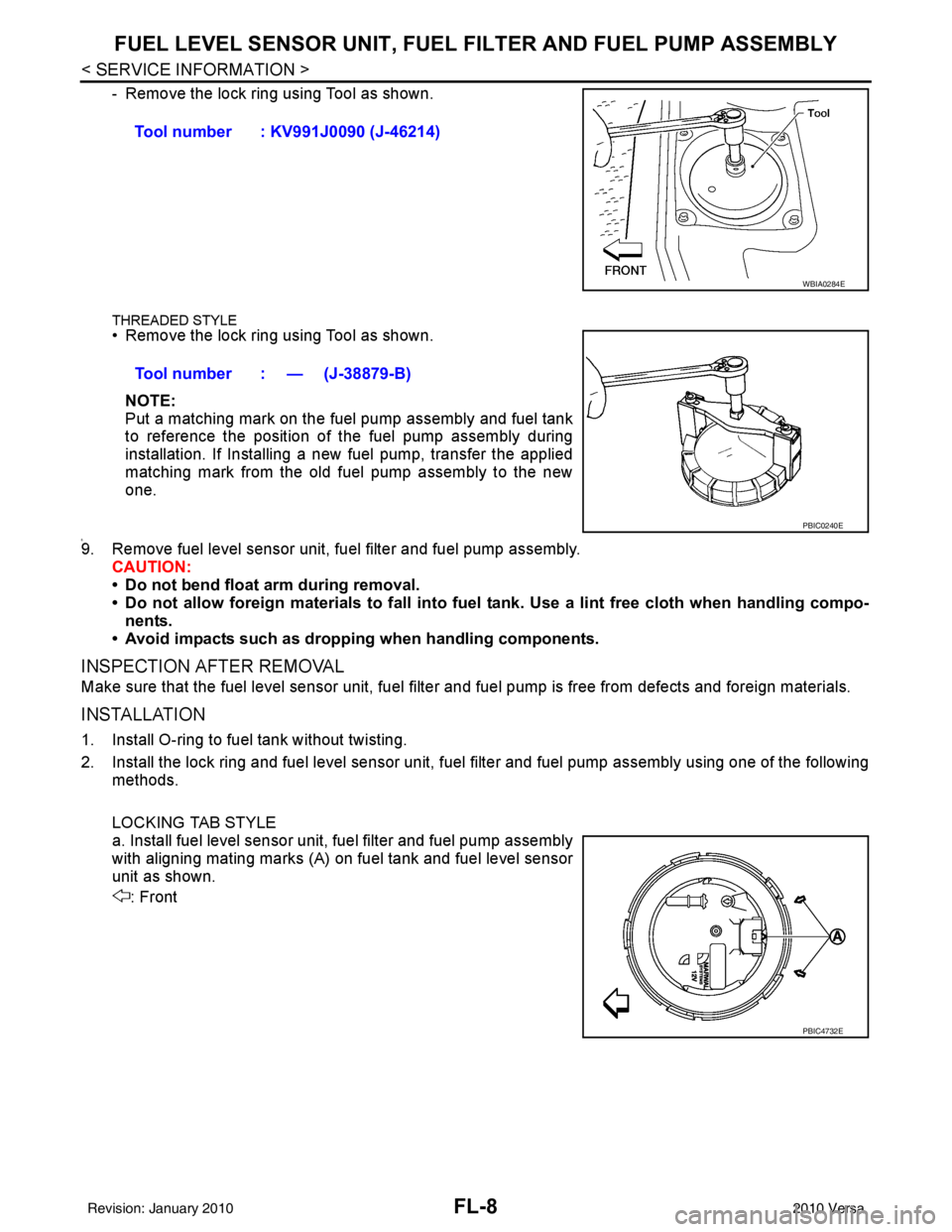

- Remove the lock ring using Tool as shown.

THREADED STYLE• Remove the lock ring using Tool as shown.

NOTE:

Put a matching mark on the fuel pump assembly and fuel tank

to reference the position of the fuel pump assembly during

installation. If Installing a new fuel pump, transfer the applied

matching mark from the old fuel pump assembly to the new

one.

8.9. Remove fuel level sensor unit, fuel filter and fuel pump assembly. CAUTION:

• Do not bend float arm during removal.

• Do not allow foreign materials to fall into fuel tank. Use a lint free cloth when handling compo-

nents.

• Avoid impacts such as dropping when handling components.

INSPECTION AFTER REMOVAL

Make sure that the fuel level sensor unit, fuel filter and fuel pump is free from defects and foreign materials.

INSTALLATION

1. Install O-ring to fuel tank without twisting.

2. Install the lock ring and fuel level sensor unit, fuel filter and fuel pump assembly using one of the following

methods.

LOCKING TAB STYLE

a. Install fuel level sensor unit, fuel filter and fuel pump assembly

with aligning mating marks (A) on fuel tank and fuel level sensor

unit as shown.

: FrontTool number : KV991J0090 (J-46214)

WBIA0284E

Tool number : — (J-38879-B)

PBIC0240E

PBIC4732E

Revision: January 20102010 Versa

Page 2639 of 3745

FUEL LEVEL SENSOR UNIT, FUEL FILTER AND FUEL PUMP ASSEMBLYFL-9

< SERVICE INFORMATION >

C

DE

F

G H

I

J

K L

M A

FL

NP

O

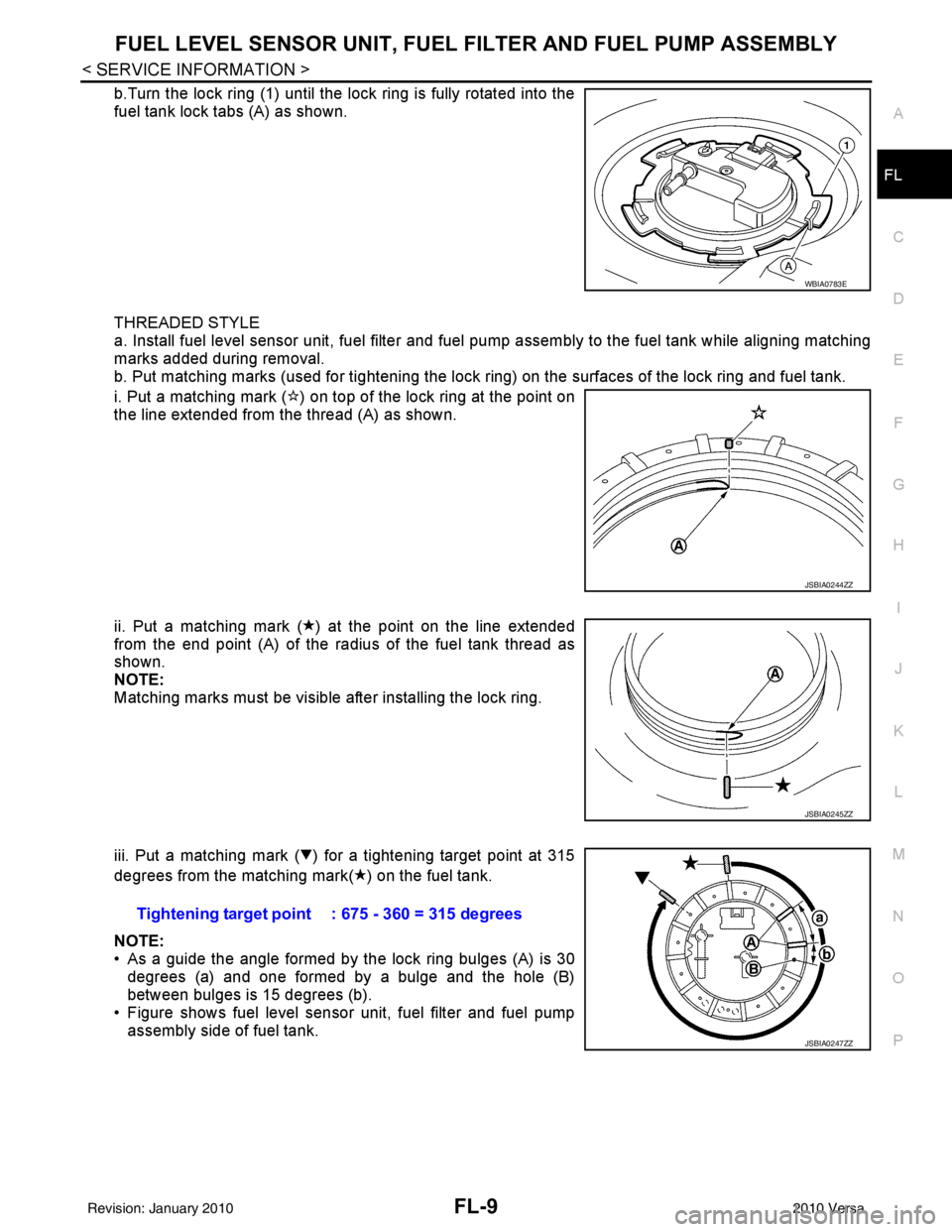

b.Turn the lock ring (1) until the lock ring is fully rotated into the

fuel tank lock tabs (A) as shown.

THREADED STYLE

a. Install fuel level sensor unit, fuel filter and fuel pump assembly to the fuel tank while aligning matching

marks added during removal.

b. Put matching marks (used for ti

ghtening the lock ring) on the surfaces of the lock ring and fuel tank.

i. Put a matching mark ( ) on top of the lock ring at the point on

the line extended from the thread (A) as shown.

ii. Put a matching mark ( ) at the point on the line extended

from the end point (A) of the radius of the fuel tank thread as

shown.

NOTE:

Matching marks must be visible after installing the lock ring.

iii. Put a matching mark ( ) for a tightening target point at 315

degrees from the matching mark( ) on the fuel tank.

NOTE:

• As a guide the angle formed by the lock ring bulges (A) is 30 degrees (a) and one formed by a bulge and the hole (B)

between bulges is 15 degrees (b).

• Figure shows fuel level sensor unit, fuel filter and fuel pump assembly side of fuel tank.

WBIA0783E

JSBIA0244ZZ

JSBIA0245ZZ

Tightening target point : 675 - 360 = 315 degrees

JSBIA0247ZZ

Revision: January 20102010 Versa

Page 2640 of 3745

FL-10

< SERVICE INFORMATION >

FUEL LEVEL SENSOR UNIT, FUEL FILTER AND FUEL PUMP ASSEMBLY

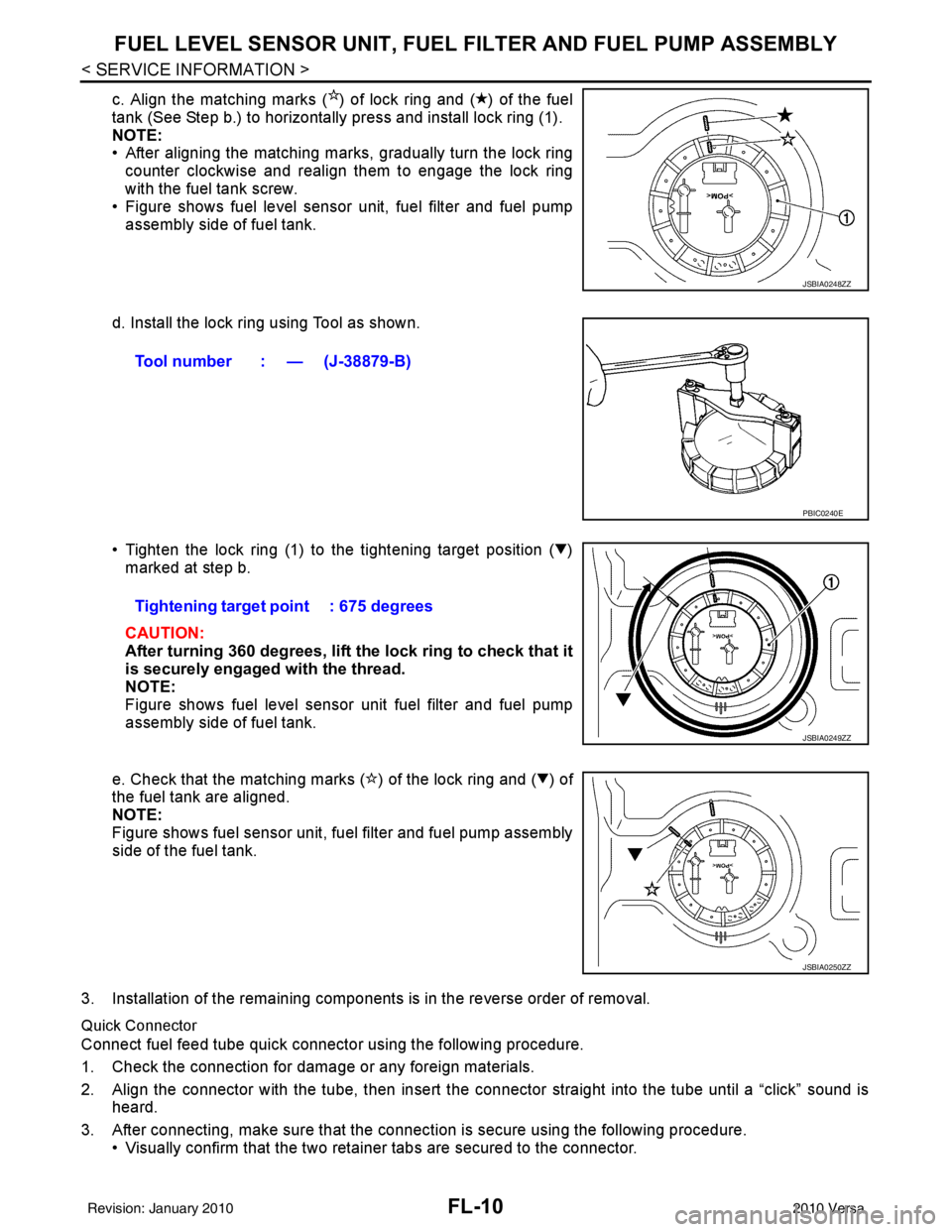

c. Align the matching marks ( ) of lock ring and ( ) of the fuel

tank (See Step b.) to horizontally press and install lock ring (1).

NOTE:

• After aligning the matching marks, gradually turn the lock ring

counter clockwise and realign them to engage the lock ring

with the fuel tank screw.

• Figure shows fuel level sensor unit, fuel filter and fuel pump

assembly side of fuel tank.

d. Install the lock ring using Tool as shown.

• Tighten the lock ring (1) to the tightening target position ( ) marked at step b.

CAUTION:

After turning 360 degrees, lift the lock ring to check that it

is securely engaged with the thread.

NOTE:

Figure shows fuel level sensor unit fuel filter and fuel pump

assembly side of fuel tank.

e. Check that the matching marks ( ) of the lock ring and ( ) of

the fuel tank are aligned.

NOTE:

Figure shows fuel sensor unit, fuel filter and fuel pump assembly

side of the fuel tank.

3. Installation of the remaining components is in the reverse order of removal.

Quick Connector

Connect fuel feed tube quick connector using the following procedure.

1. Check the connection for damage or any foreign materials.

2. Align the connector with the tube, then insert the connector straight into the tube until a “click” sound is heard.

3. After connecting, make sure that the connec tion is secure using the following procedure.

• Visually confirm that the two retainer tabs are secured to the connector.

JSBIA0248ZZ

Tool number : — (J-38879-B)

PBIC0240E

Tightening target point : 675 degrees

JSBIA0249ZZ

JSBIA0250ZZ

Revision: January 20102010 Versa

Page 2642 of 3745

FL-12

< SERVICE INFORMATION >

FUEL TANK

FUEL TANK

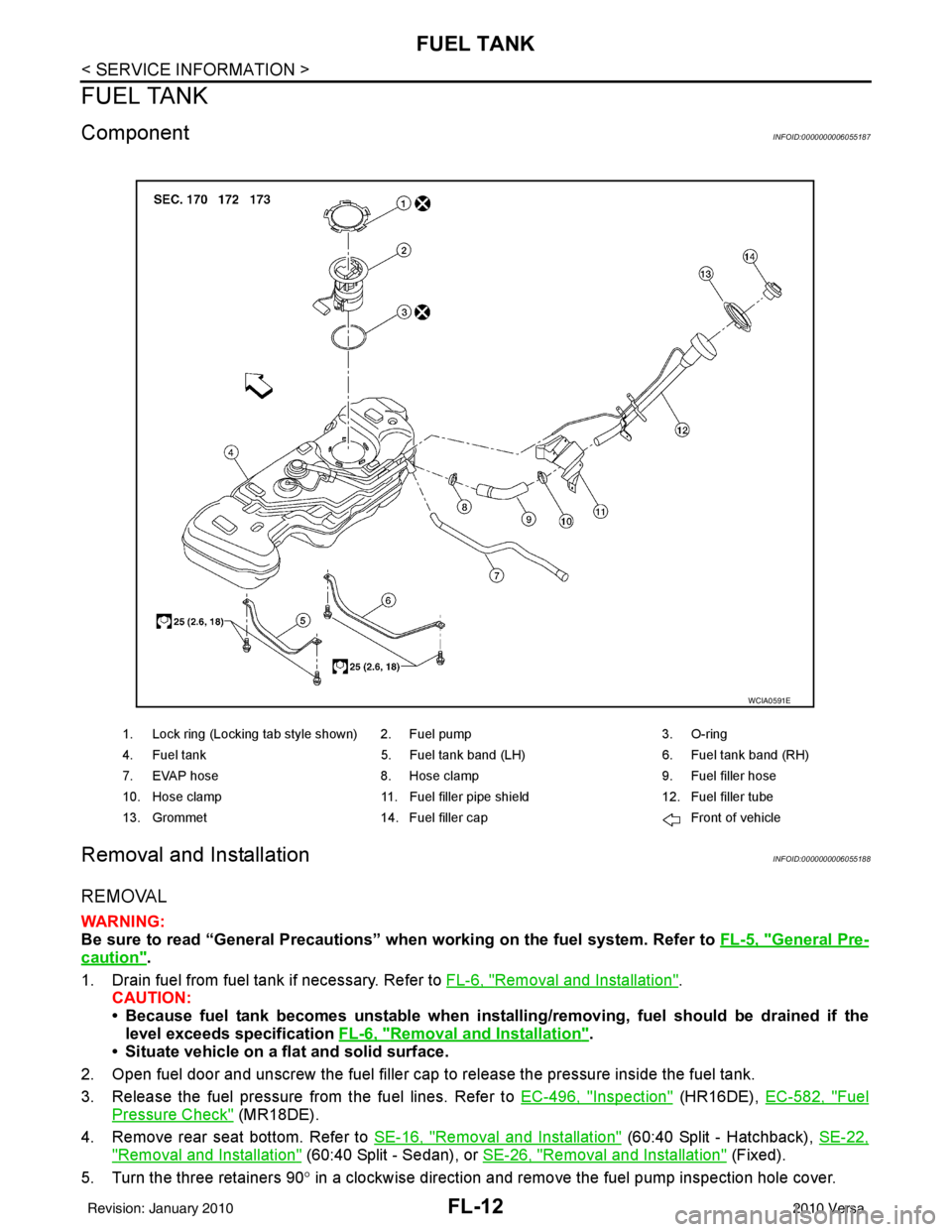

ComponentINFOID:0000000006055187

Removal and InstallationINFOID:0000000006055188

REMOVAL

WARNING:

Be sure to read “General Precautions” when working on the fuel system. Refer to FL-5, "

General Pre-

caution".

1. Drain fuel from fuel tank if necessary. Refer to FL-6, "

Removal and Installation".

CAUTION:

• Because fuel tank becomes unstable when installing/removing, fuel should be drained if the

level exceeds specification FL-6, "

Removal and Installation".

• Situate vehicle on a flat and solid surface.

2. Open fuel door and unscrew the fuel filler cap to release the pressure inside the fuel tank.

3. Release the fuel pressure from the fuel lines. Refer to EC-496, "

Inspection" (HR16DE), EC-582, "Fuel

Pressure Check" (MR18DE).

4. Remove rear seat bottom. Refer to SE-16, "

Removal and Installation" (60:40 Split - Hatchback), SE-22,

"Removal and Installation" (60:40 Split - Sedan), or SE-26, "Removal and Installation" (Fixed).

5. Turn the three retainers 90 ° in a clockwise direction and remove the fuel pump inspection hole cover.

1. Lock ring (Locking tab style shown) 2. Fuel pump 3. O-ring

4. Fuel tank 5. Fuel tank band (LH) 6. Fuel tank band (RH)

7. EVAP hose 8. Hose clamp 9. Fuel filler hose

10. Hose clamp 11. Fuel filler pipe shield 12. Fuel filler tube

13. Grommet 14. Fuel filler cap Front of vehicle

WCIA0591E

Revision: January 20102010 Versa

Page 2643 of 3745

FUEL TANKFL-13

< SERVICE INFORMATION >

C

DE

F

G H

I

J

K L

M A

FL

NP

O

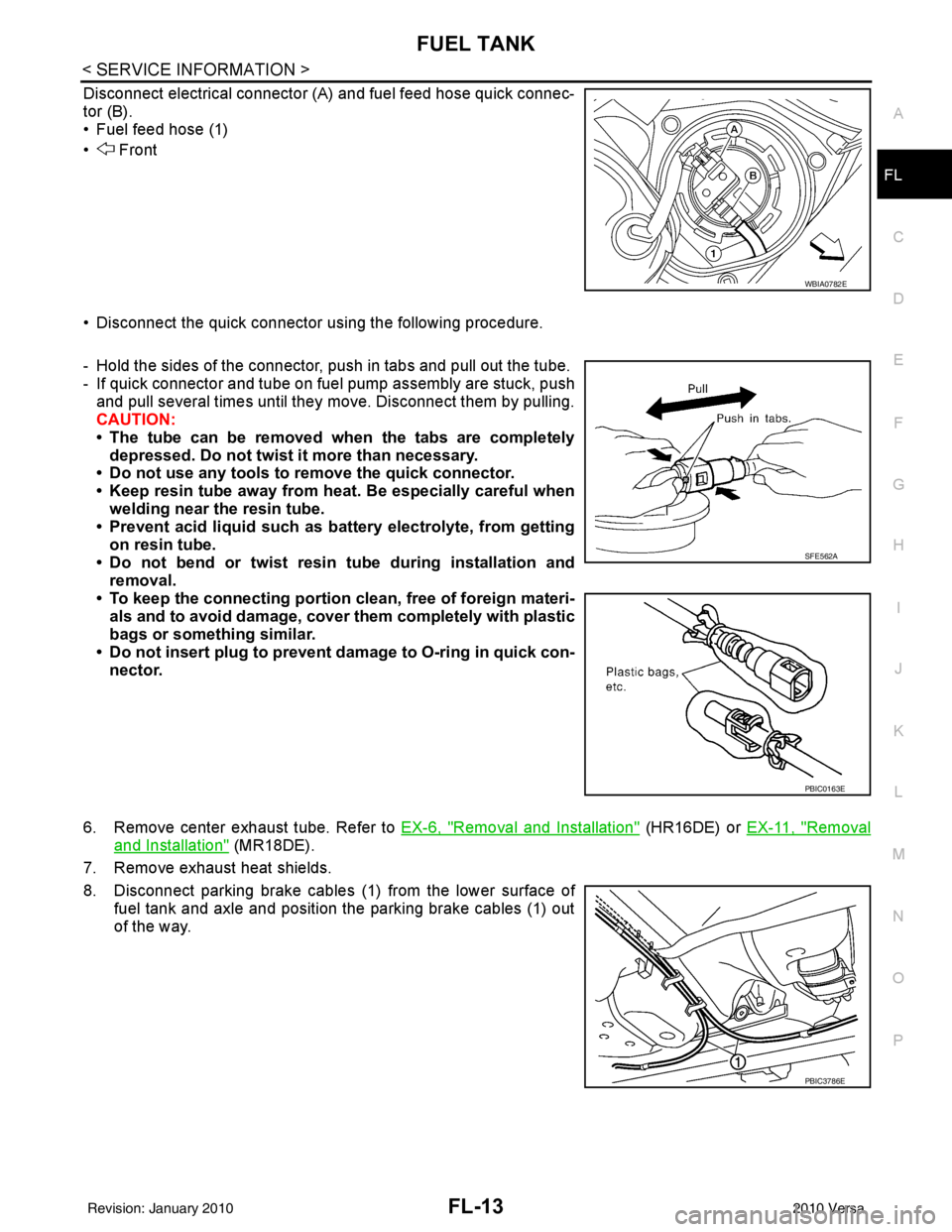

Disconnect electrical connector (A

) and fuel feed hose quick connec-

tor (B).

• Fuel feed hose (1)

• Front

• Disconnect the quick connector using the following procedure.

- Hold the sides of the connector, push in tabs and pull out the tube.

- If quick connector and tube on fuel pump assembly are stuck, push and pull several times until they move. Disconnect them by pulling.

CAUTION:

• The tube can be removed when the tabs are completely depressed. Do not twist it more than necessary.

• Do not use any tools to remove the quick connector.

• Keep resin tube away from heat. Be especially careful when welding near the resin tube.

• Prevent acid liquid such as ba ttery electrolyte, from getting

on resin tube.

• Do not bend or twist resin tube during installation and removal.

• To keep the connecting portion clean, free of foreign materi- als and to avoid damage, cover them completely with plastic

bags or something similar.

• Do not insert plug to prevent damage to O-ring in quick con-

nector.

6. Remove center exhaust tube. Refer to EX-6, "

Removal and Installation" (HR16DE) or EX-11, "Removal

and Installation" (MR18DE).

7. Remove exhaust heat shields.

8. Disconnect parking brake cables (1) from the lower surface of

fuel tank and axle and position the parking brake cables (1) out

of the way.

WBIA0782E

SFE562A

PBIC0163E

PBIC3786E

Revision: January 20102010 Versa

Page 2644 of 3745

FL-14

< SERVICE INFORMATION >

FUEL TANK

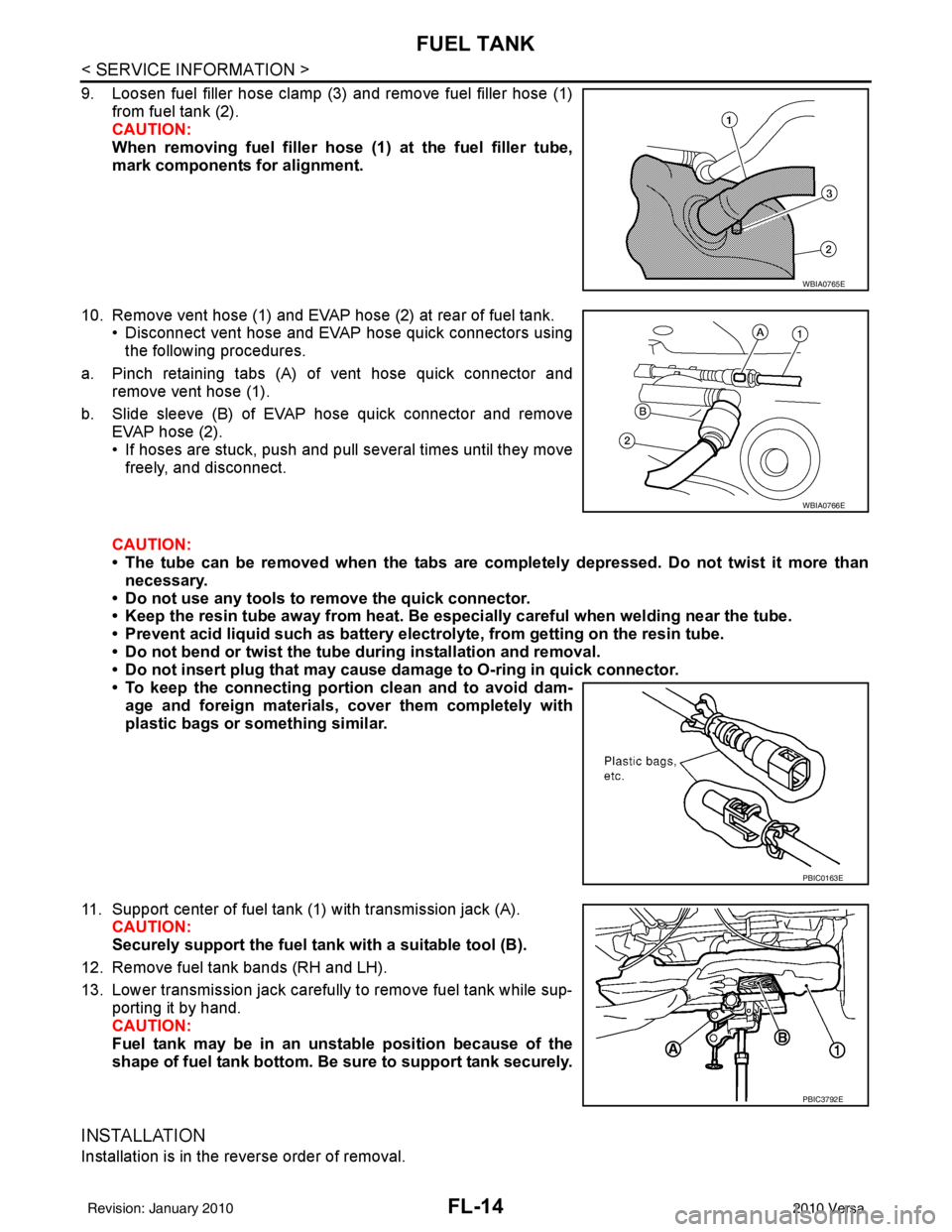

9. Loosen fuel filler hose clamp (3) and remove fuel filler hose (1)from fuel tank (2).

CAUTION:

When removing fuel filler hose (1) at the fuel filler tube,

mark components for alignment.

10. Remove vent hose (1) and EVAP hose (2) at rear of fuel tank. • Disconnect vent hose and EVAP hose quick connectors using

the following procedures.

a. Pinch retaining tabs (A) of vent hose quick connector and remove vent hose (1).

b. Slide sleeve (B) of EVAP hose quick connector and remove EVAP hose (2).

• If hoses are stuck, push and pull several times until they movefreely, and disconnect.

CAUTION:

• The tube can be removed when the tabs are completely depressed. Do not twist it more than necessary.

• Do not use any tools to remove the quick connector.

• Keep the resin tube away from heat. Be especially careful when we lding near the tube.

• Prevent acid liquid such as battery electro lyte, from getting on the resin tube.

• Do not bend or twist the tube during installation and removal.

• Do not insert plug that may cause da mage to O-ring in quick connector.

• To keep the connecting portio n clean and to avoid dam-

age and foreign materials, cover them completely with

plastic bags or something similar.

11. Support center of fuel tank (1) with transmission jack (A). CAUTION:

Securely support the fuel tank with a suitable tool (B).

12. Remove fuel tank bands (RH and LH).

13. Lower transmission jack carefully to remove fuel tank while sup- porting it by hand.

CAUTION:

Fuel tank may be in an unst able position because of the

shape of fuel tank bottom. Be sure to support tank securely.

INSTALLATION

Installation is in the reverse order of removal.

WBIA0765E

WBIA0766E

PBIC0163E

PBIC3792E

Revision: January 20102010 Versa