high beam NISSAN TIIDA 2010 Service User Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2010, Model line: TIIDA, Model: NISSAN TIIDA 2010Pages: 3745, PDF Size: 73.67 MB

Page 3019 of 3745

LT-24

< SERVICE INFORMATION >

HEADLAMP (FOR USA)

Aiming Adjustment

INFOID:0000000005394892

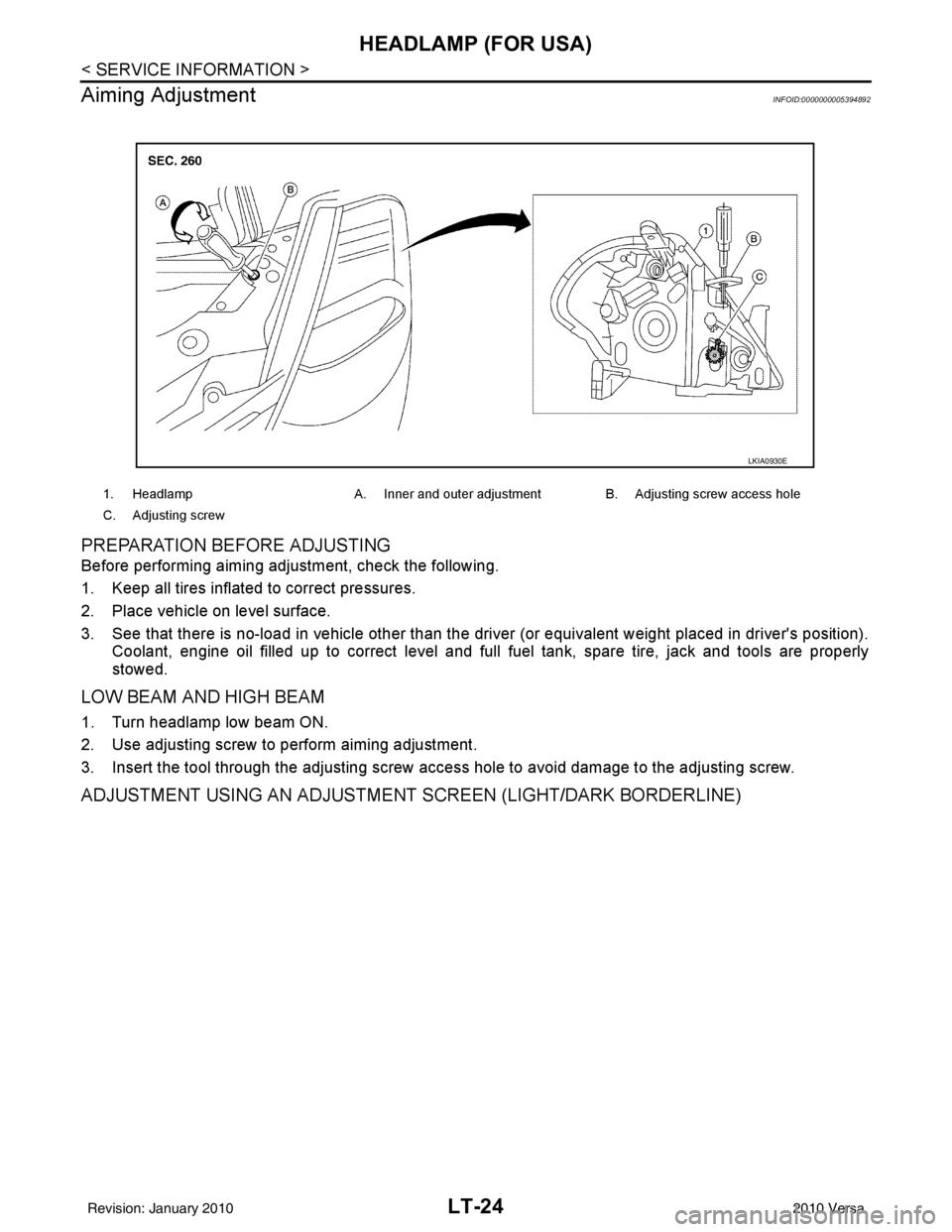

PREPARATION BEFORE ADJUSTING

Before performing aiming adjustment, check the following.

1. Keep all tires inflated to correct pressures.

2. Place vehicle on level surface.

3. See that there is no-load in vehicle other than the driver (or equivalent weight placed in driver's position). Coolant, engine oil filled up to correct level and full fuel tank, spare tire, jack and tools are properly

stowed.

LOW BEAM AND HIGH BEAM

1. Turn headlamp low beam ON.

2. Use adjusting screw to perform aiming adjustment.

3. Insert the tool through the adjusting screw access hole to avoid damage to the adjusting screw.

ADJUSTMENT USING AN ADJUSTMENT SCREEN (LIGHT/DARK BORDERLINE)

1. Headlamp A. Inner and outer adjustment B. Adjusting screw access hole

C. Adjusting screw

LKIA0930E

Revision: January 20102010 Versa

Page 3020 of 3745

HEADLAMP (FOR USA)LT-25

< SERVICE INFORMATION >

C

DE

F

G H

I

J

L

M A

B

LT

N

O P

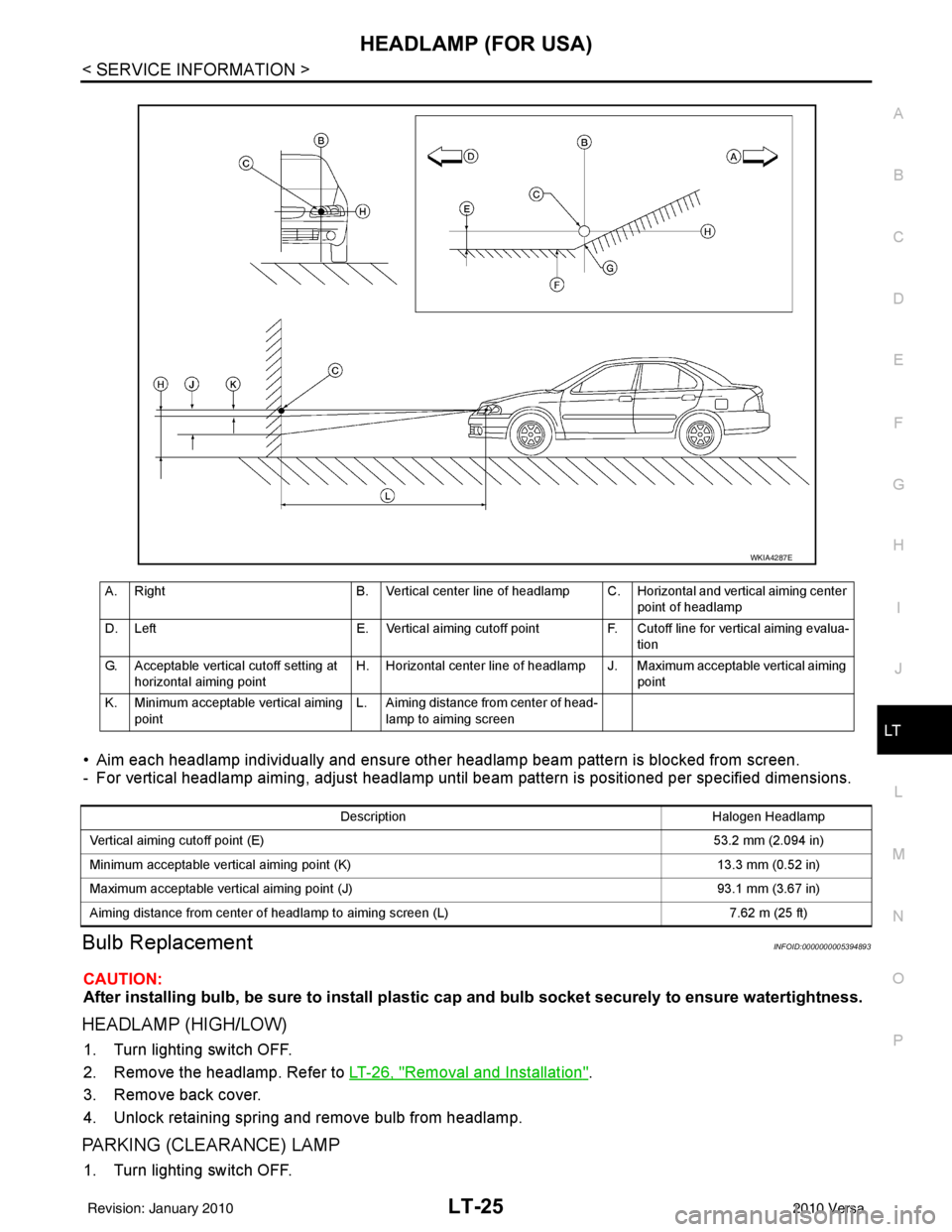

• Aim each headlamp individually and ensure other headlamp beam pattern is blocked from screen.

- For vertical headlamp aiming, adjust headlamp until beam pattern is positioned per specified dimensions.

Bulb ReplacementINFOID:0000000005394893

CAUTION:

After installing bulb, be sure to install plastic cap and bulb socket securely to ensure watertightness.

HEADLAMP (HIGH/LOW)

1. Turn lighting switch OFF.

2. Remove the headlamp. Refer to LT-26, "

Removal and Installation".

3. Remove back cover.

4. Unlock retaining spring and remove bulb from headlamp.

PARKING (CLEARANCE) LAMP

1. Turn lighting switch OFF.

A. Right B. Vertical center line of headlamp C. Horizontal and vertical aiming center

point of headlamp

D. Left E. Vertical aiming cutoff pointF. Cutoff line for vertical aiming evalua-

tion

G. Acceptable vertical cutoff setting at horizontal aiming point H. Horizontal center line of headlamp J. Maximum acceptable vertical aiming

point

K. Minimum acceptable vertical aiming point L. Aiming distance from center of head-

lamp to aiming screen

WKIA4287E

Description Halogen Headlamp

Vertical aiming cutoff point (E) 53.2 mm (2.094 in)

Minimum acceptable vertical aiming point (K) 13.3 mm (0.52 in)

Maximum acceptable vertical aiming point (J) 93.1 mm (3.67 in)

Aiming distance from center of headlamp to aiming screen (L) 7.62 m (25 ft)

Revision: January 20102010 Versa

Page 3024 of 3745

![NISSAN TIIDA 2010 Service User Guide HEADLAMP (FOR CANADA) - DAYTIME LIGHT SYSTEM -

LT-29

< SERVICE INFORMATION >

C

D E

F

G H

I

J

L

M A

B

LT

N

O P

• through 10A fuse [No. 3, located in fuse block (J/B)]

• to combination meter termina NISSAN TIIDA 2010 Service User Guide HEADLAMP (FOR CANADA) - DAYTIME LIGHT SYSTEM -

LT-29

< SERVICE INFORMATION >

C

D E

F

G H

I

J

L

M A

B

LT

N

O P

• through 10A fuse [No. 3, located in fuse block (J/B)]

• to combination meter termina](/img/5/57397/w960_57397-3023.png)

HEADLAMP (FOR CANADA) - DAYTIME LIGHT SYSTEM -

LT-29

< SERVICE INFORMATION >

C

D E

F

G H

I

J

L

M A

B

LT

N

O P

• through 10A fuse [No. 3, located in fuse block (J/B)]

• to combination meter terminal 28.

With the ignition switch in the ACC or ON position, power is supplied

• through 10A fuse [No. 20, located in fuse block (J/B)]

• to BCM terminal 11.

Ground is supplied

• to BCM terminal 67 and

• to combination meter terminals 21, 22 and 23

• through grounds M57 and M61,

• to IPDM E/R terminals 39 and 59

• through grounds E15 and E24,

HEADLAMP OPERATION

Low Beam Operation

With the lighting switch in 2ND position, the BCM re ceives an input signal requesting the headlamps to illumi-

nate. This input signal is communicated to the IPDM E/R via the CAN communication lines. The CPU located

in the IPDM E/R controls the headlamp low relay coil, which when energized, directs power

• through 15A fuse (No. 41, located in IPDM E/R)

• through IPDM E/R terminal 54

• to daytime light relay 2 terminals 1 and 5 (energizing the relay),

• through daytime light relay 2 terminal 3

• to front combination lamp RH terminal 3, and

• through 15A fuse (No. 40, located in IPDM E/R)

• through IPDM E/R terminal 52

• to front combination lamp LH terminal 3.

Ground is supplied

• to front combination lamp LH terminal 2

• through grounds E15 and E24,

• to headlamp RH terminal 2 via

• daytime light relay 1 terminals 3 and 4

• through grounds E15 and E24.

With power and ground supplied, low beam headlamps illuminate.

High Beam/Flash-to-Pass Operation

With the lighting switch in 2ND position and high beam s witch in the HIGH position, the BCM receives input

signal requesting the headlamp high beams to illuminate. The flash-to-pass feature can be used any time and

also sends a signal to the BCM. This input signal is communicated to the IPDM E/R and the combination

meter via the CAN communication lines. The CPU locat ed in the IPDM E/R controls the headlamp high relay

coil, which when energized, directs power

• through 10A fuse (No. 34, located in IPDM E/R)

• through IPDM E/R terminal 56

• to front combination lamp RH terminal 1, and

• through 10A fuse (No. 35, located in IPDM E/R)

• through IPDM E/R terminal 55

• to front combination lamp LH terminal 1.

Ground is supplied

• to front combination lamp LH terminal 2

• through grounds E15 and E24, and

• to front combination lamp RH terminal 2 via

• daytime light relay 1 terminals 3 and 4

• through grounds E15 and E24.

With power and ground supplied, the high beam headlamps illuminate.

The BCM sends a signal to the combination meter requesting the high beam indicator lamp to turn ON.

Daytime Light System Operation

With the lighting switch in the OFF or 1ST position (parking lamps ON), the BCM receives inputs requesting

the headlights off. If the parking brake is released and the engine is running, the BCM then sends a signal, via

the CAN communication lines, requesting the IPDM E/R to activate the daytime light system. The CPU located

in the IPDM E/R controls the daytime light relay 1 coil, which when energized, directs power

• from daytime light relay 1 terminal 3

• to front combination lamp RH terminal 2,

• through front combination lamp RH high beam terminal 1

Revision: January 20102010 Versa

Page 3025 of 3745

LT-30

< SERVICE INFORMATION >

HEADLAMP (FOR CANADA) - DAYTIME LIGHT SYSTEM -

• to IPDM E/R terminal 56,

• through 10A fuse (No. 34, located in IPDM E/R) and

• through both de-energized headlamp high relays

• to 10A fuse (No. 35, located in IPDM E/R),

• through IPDM E/R terminal 55

• to front combination lamp LH terminal high beam 1.

Ground is supplied

• to front combination lamp LH terminal 2

• through grounds E15 and E24,

• to daytime light relay 1 terminal 1

• through IPDM E/R terminal 6.

With power and ground supplied, high beam headlamps illuminate at reduced intensity.

COMBINATION SWITCH READING FUNCTION

Refer to BCS-4, "System Description" .

EXTERIOR LAMP BATTERY SAVER CONTROL

Refer to LT-75, "System Description" .

CAN Communication System DescriptionINFOID:0000000005394898

Refer to LAN-7, "System Description" .

Revision: January 20102010 Versa

Page 3031 of 3745

LT-36

< SERVICE INFORMATION >

HEADLAMP (FOR CANADA) - DAYTIME LIGHT SYSTEM -

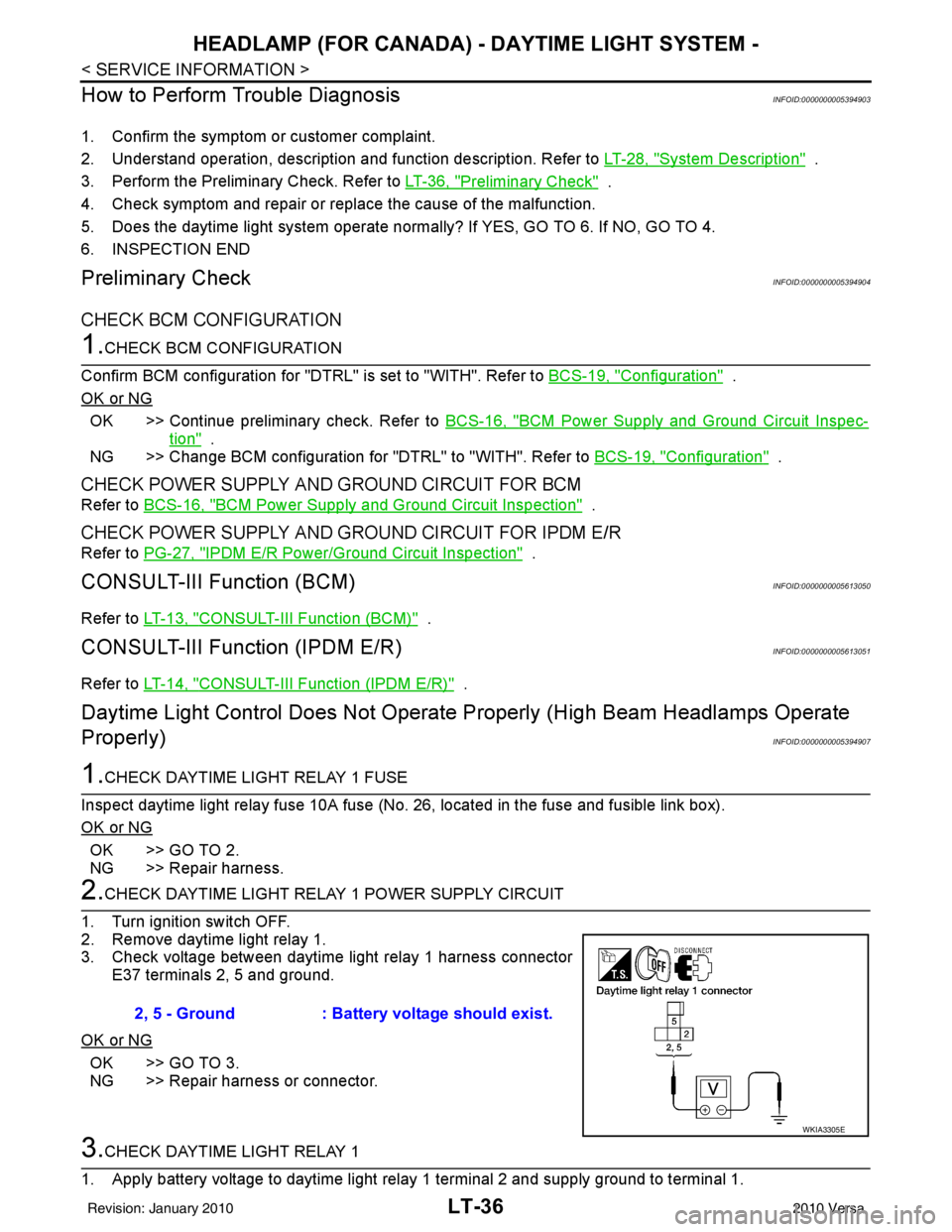

How to Perform Trouble Diagnosis

INFOID:0000000005394903

1. Confirm the symptom or customer complaint.

2. Understand operation, description and function description. Refer to LT-28, "

System Description" .

3. Perform the Preliminary Check. Refer to LT-36, "

Preliminary Check" .

4. Check symptom and repair or replace the cause of the malfunction.

5. Does the daytime light syst em operate normally? If YES, GO TO 6. If NO, GO TO 4.

6. INSPECTION END

Preliminary CheckINFOID:0000000005394904

CHECK BCM CONFIGURATION

1.CHECK BCM CONFIGURATION

Confirm BCM configuration for "DTRL" is set to "WITH". Refer to BCS-19, "

Configuration" .

OK or NG

OK >> Continue preliminary check. Refer to BCS-16, "BCM Power Supply and Ground Circuit Inspec-

tion" .

NG >> Change BCM configuration for "DTRL" to "WITH". Refer to BCS-19, "

Configuration" .

CHECK POWER SUPPLY AND GROUND CIRCUIT FOR BCM

Refer to BCS-16, "BCM Power Supply and Ground Circuit Inspection" .

CHECK POWER SUPPLY AND GROUND CIRCUIT FOR IPDM E/R

Refer to PG-27, "IPDM E/R Power/Ground Circuit Inspection" .

CONSULT-III Function (BCM)INFOID:0000000005613050

Refer to LT-13, "CONSULT-III Function (BCM)" .

CONSULT-III Function (IPDM E/R)INFOID:0000000005613051

Refer to LT-14, "CONSULT-III Function (IPDM E/R)" .

Daytime Light Control Does Not Operate Properly (High Beam Headlamps Operate

Properly)

INFOID:0000000005394907

1.CHECK DAYTIME LIGHT RELAY 1 FUSE

Inspect daytime light relay fuse 10A fuse (No. 26, located in the fuse and fusible link box).

OK or NG

OK >> GO TO 2.

NG >> Repair harness.

2.CHECK DAYTIME LIGHT RELAY 1 POWER SUPPLY CIRCUIT

1. Turn ignition switch OFF.

2. Remove daytime light relay 1.

3. Check voltage between daytime light relay 1 harness connector E37 terminals 2, 5 and ground.

OK or NG

OK >> GO TO 3.

NG >> Repair harness or connector.

3.CHECK DAYTIME LIGHT RELAY 1

1. Apply battery voltage to daytime light relay 1 terminal 2 and supply ground to terminal 1. 2, 5 - Ground

: Battery voltage should exist.

WKIA3305E

Revision: January 20102010 Versa

Page 3033 of 3745

LT-38

< SERVICE INFORMATION >

HEADLAMP (FOR CANADA) - DAYTIME LIGHT SYSTEM -

Aiming Adjustment

INFOID:0000000005394908

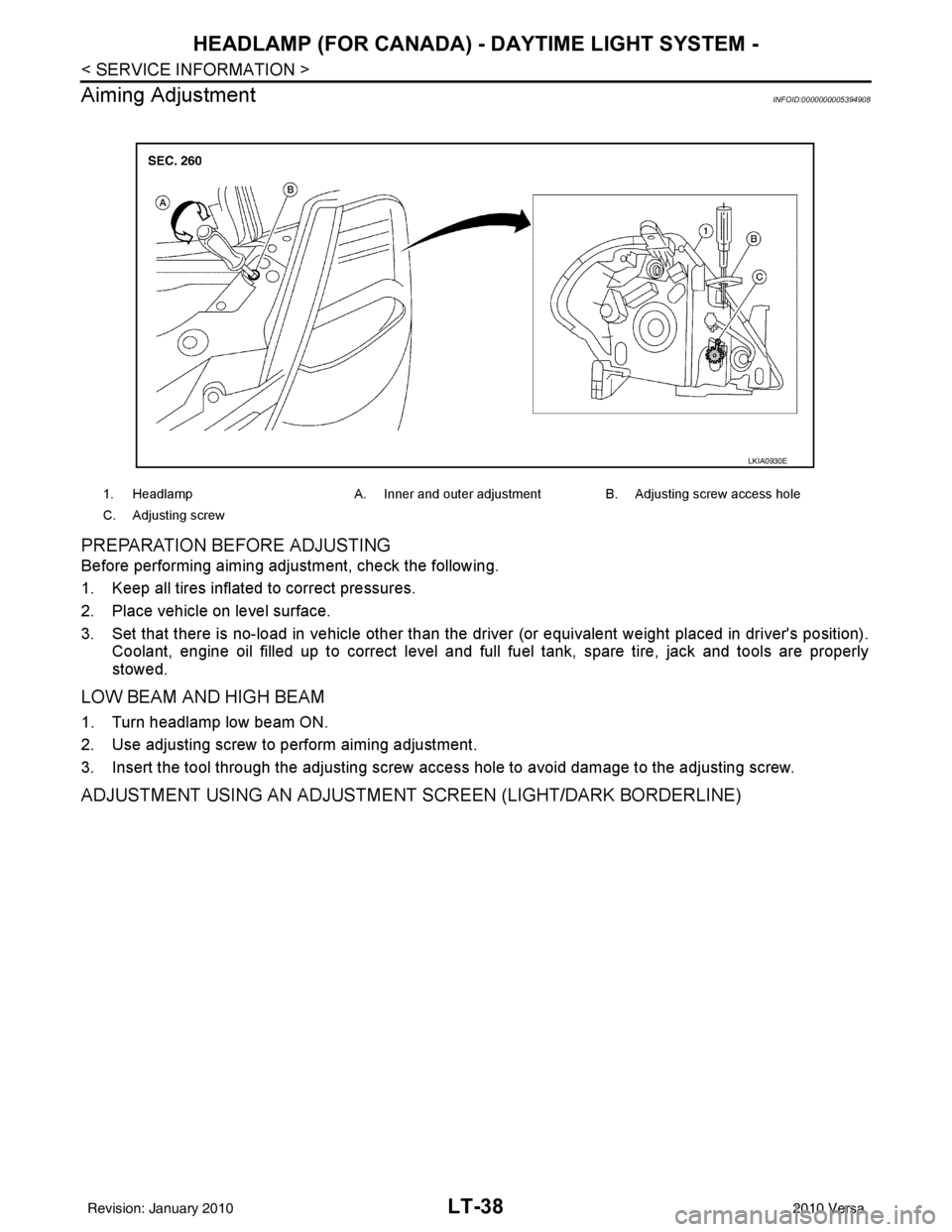

PREPARATION BEFORE ADJUSTING

Before performing aiming adjustment, check the following.

1. Keep all tires inflated to correct pressures.

2. Place vehicle on level surface.

3. Set that there is no-load in vehicle other than the driv er (or equivalent weight placed in driver's position).

Coolant, engine oil filled up to correct level and full fuel tank, spare tire, jack and tools are properly

stowed.

LOW BEAM AND HIGH BEAM

1. Turn headlamp low beam ON.

2. Use adjusting screw to perform aiming adjustment.

3. Insert the tool through the adjusting screw access hole to avoid damage to the adjusting screw.

ADJUSTMENT USING AN ADJUSTMENT SCREEN (LIGHT/DARK BORDERLINE)

1. Headlamp A. Inner and outer adjustment B. Adjusting screw access hole

C. Adjusting screw

LKIA0930E

Revision: January 20102010 Versa

Page 3034 of 3745

HEADLAMP (FOR CANADA) - DAYTIME LIGHT SYSTEM -

LT-39

< SERVICE INFORMATION >

C

D E

F

G H

I

J

L

M A

B

LT

N

O P

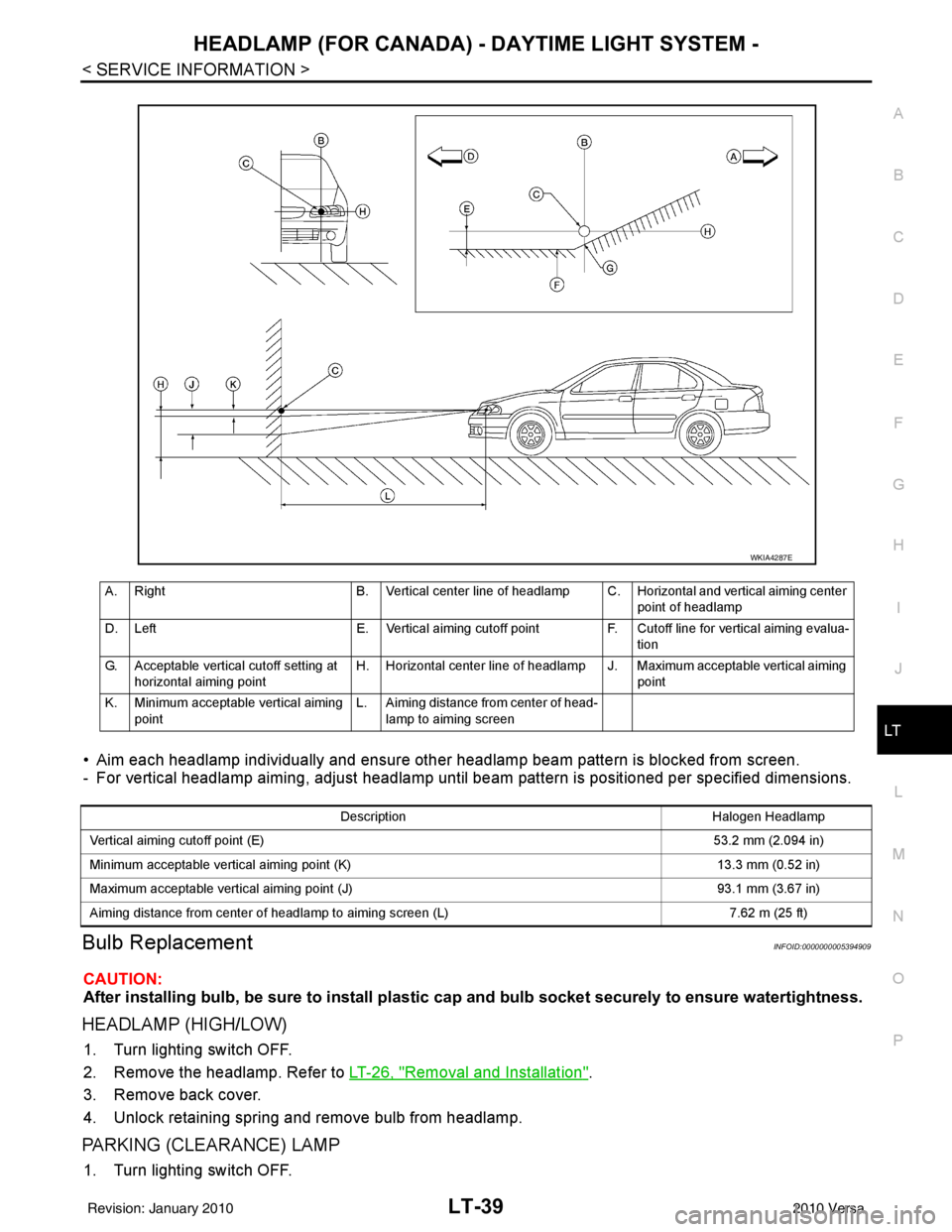

• Aim each headlamp individually and ensure other headlamp beam pattern is blocked from screen.

- For vertical headlamp aiming, adjust headlamp until beam pattern is positioned per specified dimensions.

Bulb ReplacementINFOID:0000000005394909

CAUTION:

After installing bulb, be sure to install plastic cap and bulb socket securely to ensure watertightness.

HEADLAMP (HIGH/LOW)

1. Turn lighting switch OFF.

2. Remove the headlamp. Refer to LT-26, "

Removal and Installation".

3. Remove back cover.

4. Unlock retaining spring and remove bulb from headlamp.

PARKING (CLEARANCE) LAMP

1. Turn lighting switch OFF.

A. Right B. Vertical center line of headlamp C. Horizontal and vertical aiming center

point of headlamp

D. Left E. Vertical aiming cutoff pointF. Cutoff line for vertical aiming evalua-

tion

G. Acceptable vertical cutoff setting at horizontal aiming point H. Horizontal center line of headlamp J. Maximum acceptable vertical aiming

point

K. Minimum acceptable vertical aiming point L. Aiming distance from center of head-

lamp to aiming screen

WKIA4287E

Description Halogen Headlamp

Vertical aiming cutoff point (E) 53.2 mm (2.094 in)

Minimum acceptable vertical aiming point (K) 13.3 mm (0.52 in)

Maximum acceptable vertical aiming point (J) 93.1 mm (3.67 in)

Aiming distance from center of headlamp to aiming screen (L) 7.62 m (25 ft)

Revision: January 20102010 Versa

Page 3037 of 3745

LT-42

< SERVICE INFORMATION >

FRONT FOG LAMP

FRONT FOG LAMP

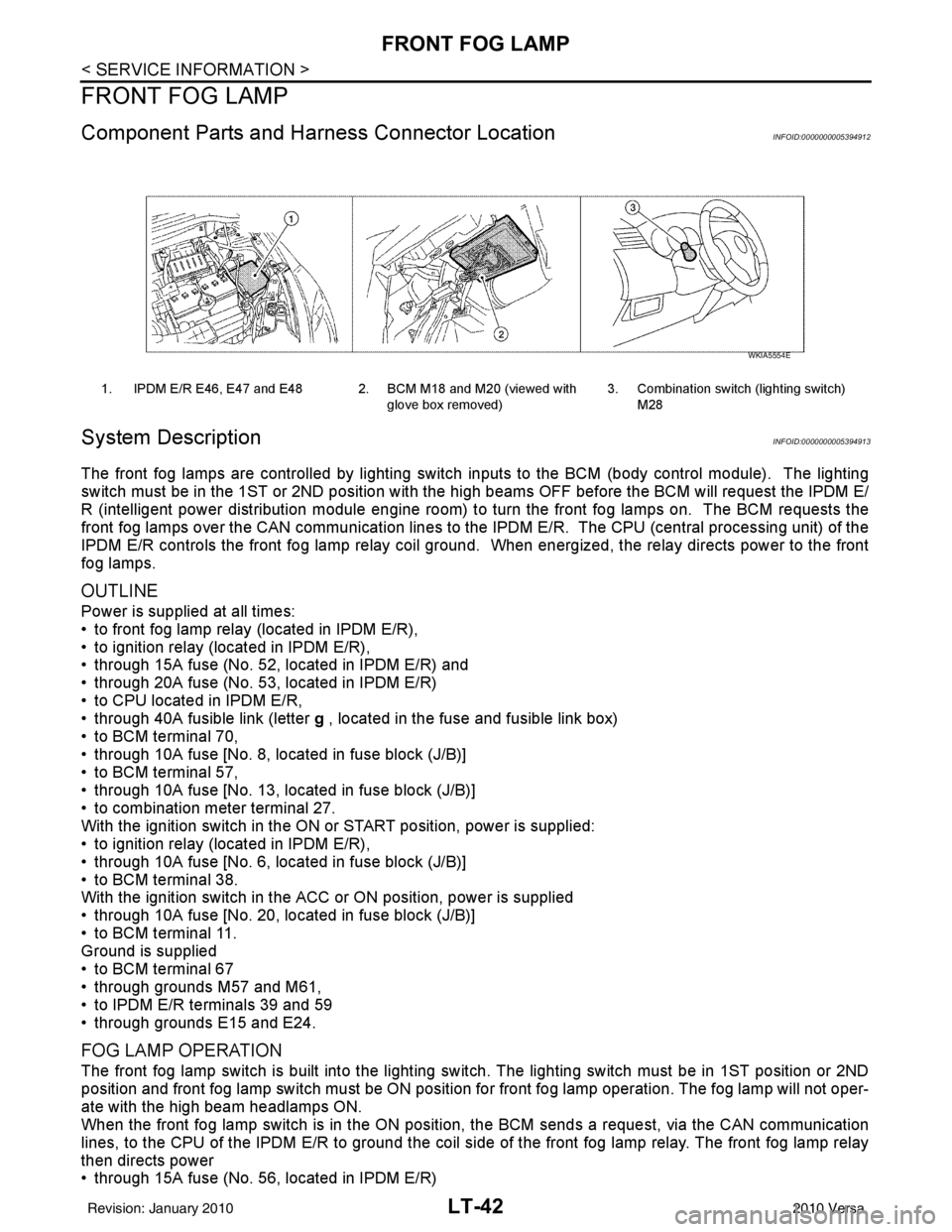

Component Parts and Harness Connector LocationINFOID:0000000005394912

System DescriptionINFOID:0000000005394913

The front fog lamps are controlled by lighting switch inputs to the BCM (body control module). The lighting

switch must be in the 1ST or 2ND position with t he high beams OFF before the BCM will request the IPDM E/

R (intelligent power distribution module engine room) to turn the front fog lamps on. The BCM requests the

front fog lamps over the CAN communication lines to the IPDM E/R. The CPU (central processing unit) of the

IPDM E/R controls the front fog lamp relay coil ground. When energized, the relay directs power to the front

fog lamps.

OUTLINE

Power is supplied at all times:

• to front fog lamp relay (located in IPDM E/R),

• to ignition relay (located in IPDM E/R),

• through 15A fuse (No. 52, located in IPDM E/R) and

• through 20A fuse (No. 53, located in IPDM E/R)

• to CPU located in IPDM E/R,

• through 40A fusible link (letter g , located in the fuse and fusible link box)

• to BCM terminal 70,

• through 10A fuse [No. 8, located in fuse block (J/B)]

• to BCM terminal 57,

• through 10A fuse [No. 13, located in fuse block (J/B)]

• to combination meter terminal 27.

With the ignition switch in the ON or START position, power is supplied:

• to ignition relay (located in IPDM E/R),

• through 10A fuse [No. 6, located in fuse block (J/B)]

• to BCM terminal 38.

With the ignition switch in the ACC or ON position, power is supplied

• through 10A fuse [No. 20, located in fuse block (J/B)]

• to BCM terminal 11.

Ground is supplied

• to BCM terminal 67

• through grounds M57 and M61,

• to IPDM E/R terminals 39 and 59

• through grounds E15 and E24.

FOG LAMP OPERATION

The front fog lamp switch is built into the lighting s witch. The lighting switch must be in 1ST position or 2ND

position and front fog lamp switch must be ON position fo r front fog lamp operation. The fog lamp will not oper-

ate with the high beam headlamps ON.

When the front fog lamp switch is in the ON positi on, the BCM sends a request, via the CAN communication

lines, to the CPU of the IPDM E/R to ground the coil side of the front fog lamp relay. The front fog lamp relay

then directs power

• through 15A fuse (No. 56, located in IPDM E/R)

1. IPDM E/R E46, E47 and E48 2. BCM M18 and M20 (viewed with

glove box removed)3. Combination switch (lighting switch)

M28

WKIA5554E

Revision: January 20102010 Versa

Page 3044 of 3745

FRONT FOG LAMPLT-49

< SERVICE INFORMATION >

C

DE

F

G H

I

J

L

M A

B

LT

N

O P

1. Check continuity between front fog lamp harness connector and ground.

OK or NG

OK >> Replace IPDM E/R. Refer to PG-28, "Removal and

Installation of IPDM E/R" .

NG >> Repair harness or connector.

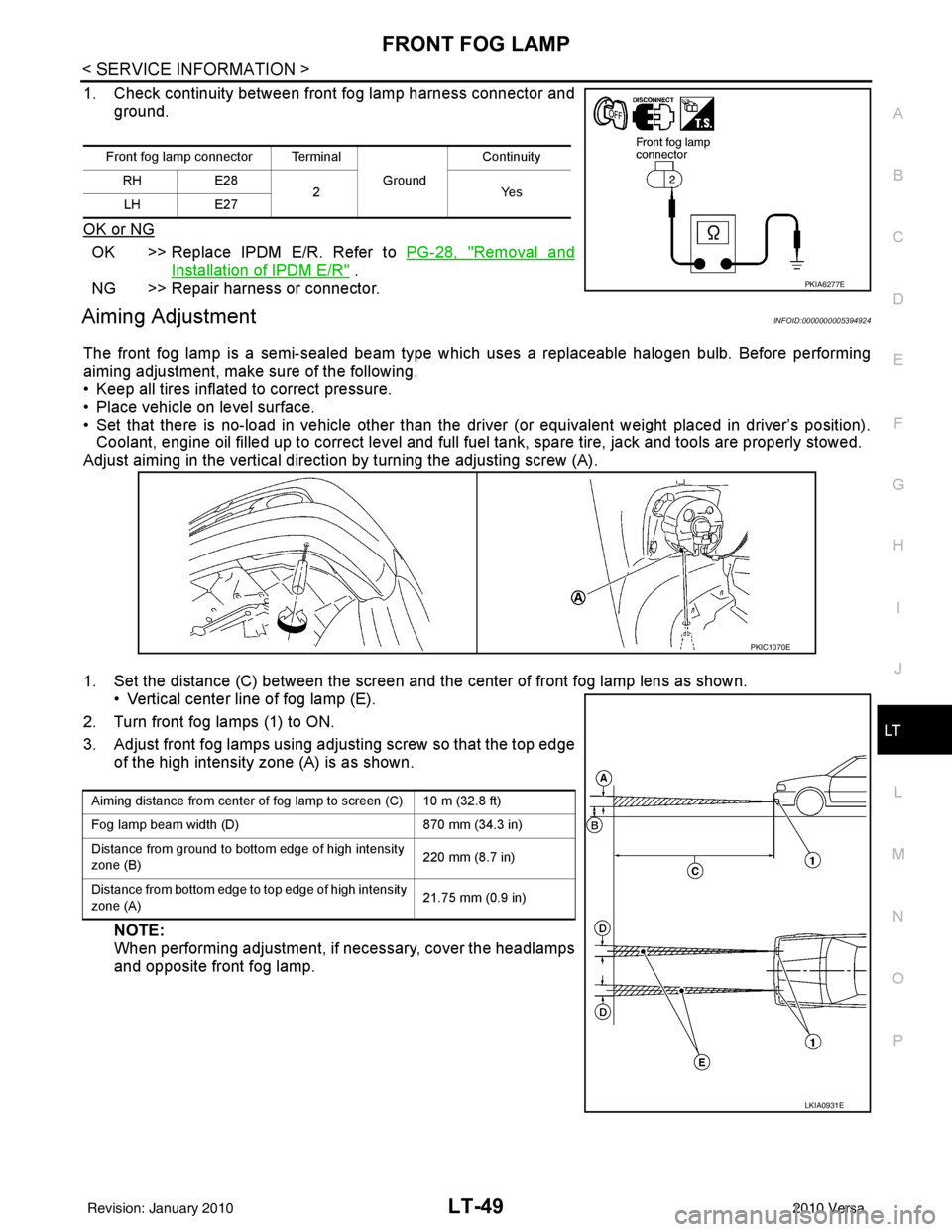

Aiming AdjustmentINFOID:0000000005394924

The front fog lamp is a semi-sealed beam type whic h uses a replaceable halogen bulb. Before performing

aiming adjustment, make sure of the following.

• Keep all tires inflated to correct pressure.

• Place vehicle on level surface.

• Set that there is no-load in vehicle other than the driver (or equivalent weight placed in driver’s position). Coolant, engine oil filled up to correct level and full fuel tank, spare tire, jack and tools are properly stowed.

Adjust aiming in the vertical direction by turning the adjusting screw (A).

1. Set the distance (C) between the screen and the c enter of front fog lamp lens as shown.

• Vertical center line of fog lamp (E).

2. Turn front fog lamps (1) to ON.

3. Adjust front fog lamps using adjusting screw so that the top edge of the high intensity zone (A) is as shown.

NOTE:

When performing adjustment, if necessary, cover the headlamps

and opposite front fog lamp.

Front fog lamp connector Terminal

Ground Continuity

RH E28

2Y es

LH E27

PKIA6277E

PKIC1070E

Aiming distance from center of fog lamp to screen (C) 10 m (32.8 ft)

Fog lamp beam width (D) 870 mm (34.3 in)

Distance from ground to bottom edge of high intensity

zone (B) 220 mm (8.7 in)

Distance from bottom edge to top edge of high intensity

zone (A) 21.75 mm (0.9 in)

LKIA0931E

Revision: January 20102010 Versa

Page 3402 of 3745

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM)

PG-19

< SERVICE INFORMATION >

C

D E

F

G H

I

J

L

M A

B

PG

N

O P

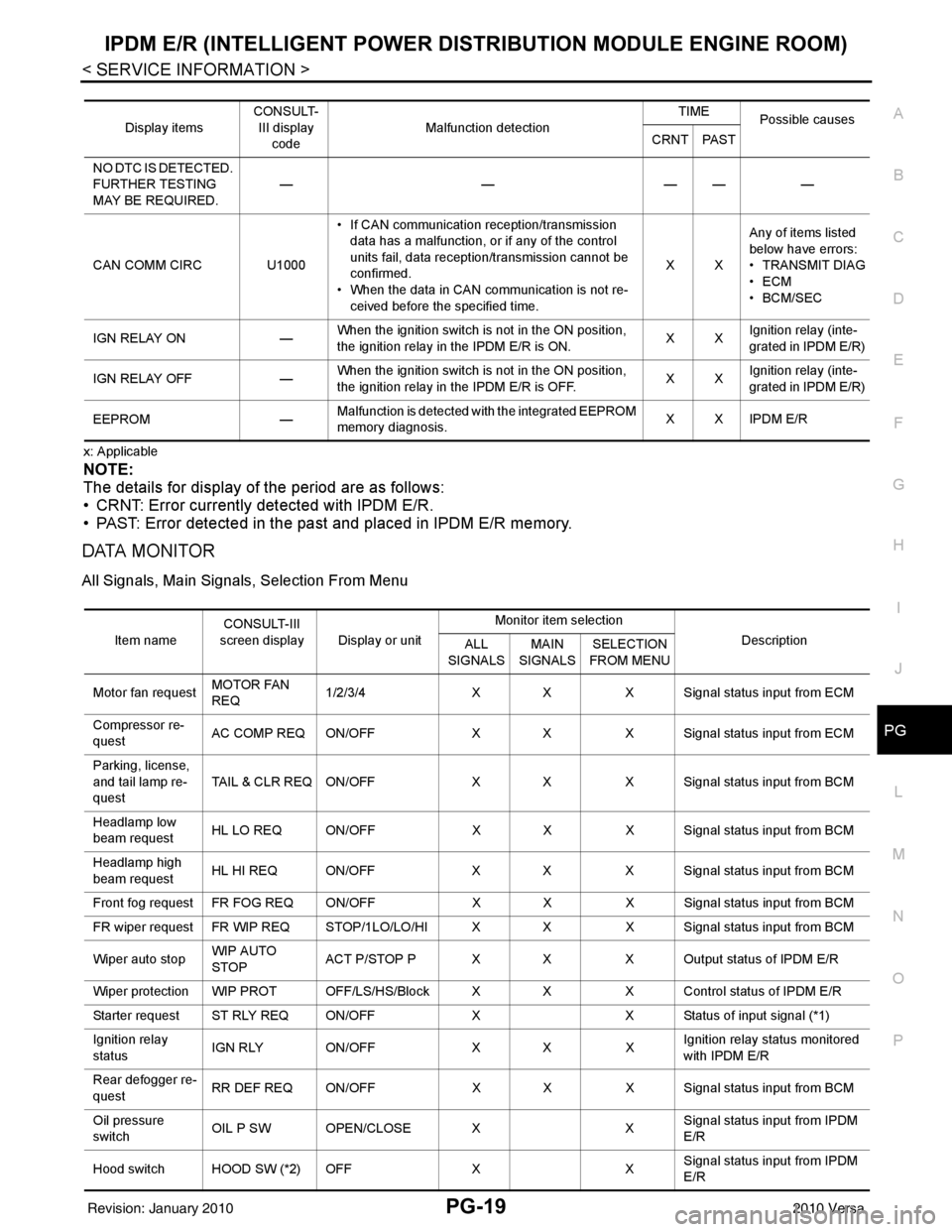

x: Applicable

NOTE:

The details for display of the period are as follows:

• CRNT: Error currently detected with IPDM E/R.

• PAST: Error detected in the past and placed in IPDM E/R memory.

DATA MONITOR

All Signals, Main Signals, Selection From Menu

Display items CONSULT-

III display code Malfunction detection TIME

Possible causes

CRNT PAST

NO DTC IS DETECTED.

FURTHER TESTING

MAY BE REQUIRED. ———

——

CAN COMM CIRC U1000 • If CAN communication reception/transmission

data has a malfunction, or if any of the control

units fail, data reception/transmission cannot be

confirmed.

• When the data in CAN communication is not re-

ceived before the specified time. XX

Any of items listed

below have

errors:

• TRANSMIT DIAG

•ECM

• BCM/SEC

IGN RELAY ON —When the ignition switch is not in the ON position,

the ignition relay in the IPDM E/R is ON. XX

Ignition relay (inte-

grated in IPDM E/R)

IGN RELAY OFF —When the ignition switch is not in the ON position,

the ignition relay in the IPDM E/R is OFF. XXIgnition relay (inte-

grated in IPDM E/R)

EEPROM —Malfunction is detected with the integrated EEPROM

memory diagnosis.

X X IPDM E/R

Item nameCONSULT-III

screen display Display or unit Monitor item selection

Description

ALL

SIGNALS MAIN

SIGNALS SELECTION

FROM MENU

Motor fan request MOTOR FAN

REQ1/2/3/4

X X X Signal status input from ECM

Compressor re-

quest AC COMP REQ ON/OFF

X XX Signal status input from ECM

Parking, license,

and tail lamp re-

quest TAIL & CLR REQ ON/OFF

X XX Signal status input from BCM

Headlamp low

beam request HL LO REQ ON/OFF

X XX Signal status input from BCM

Headlamp high

beam request HL HI REQ ON/OFF

X XX Signal status input from BCM

Front fog request FR FOG REQ ON/OFF X XX Signal status input from BCM

FR wiper request FR WIP REQ STOP/1LO/LO/HI X X X Signal status input from BCM

Wiper auto stop WIP AUTO

STOPACT P/STOP P X X

X Output status of IPDM E/R

Wiper protection WIP PROT OFF/LS/HS/Block X X X Control status of IPDM E/R

Starter request ST RLY REQ ON/OFF XX Status of input signal (*1)

Ignition relay

status IGN RLY ON/OFF

X XXIgnition relay status monitored

with IPDM E/R

Rear defogger re-

quest RR DEF REQ ON/OFF

X XX Signal status input from BCM

Oil pressure

switch OIL P SW OPEN/CLOSE X

XSignal status input from IPDM

E/R

Hood switch HOOD SW (*2) OFF XXSignal status input from IPDM

E/R

Revision: January 20102010 Versa