srs NISSAN TIIDA 2010 Service User Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2010, Model line: TIIDA, Model: NISSAN TIIDA 2010Pages: 3745, PDF Size: 73.67 MB

Page 446 of 3745

![NISSAN TIIDA 2010 Service User Guide PRECAUTIONSAV-49

< SERVICE INFORMATION > [AUDIO WITH NAVIGATION]

C

D

E

F

G H

I

J

L

M A

B

AV

N

O P

SERVICE INFORMATION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEA NISSAN TIIDA 2010 Service User Guide PRECAUTIONSAV-49

< SERVICE INFORMATION > [AUDIO WITH NAVIGATION]

C

D

E

F

G H

I

J

L

M A

B

AV

N

O P

SERVICE INFORMATION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEA](/img/5/57397/w960_57397-445.png)

PRECAUTIONSAV-49

< SERVICE INFORMATION > [AUDIO WITH NAVIGATION]

C

D

E

F

G H

I

J

L

M A

B

AV

N

O P

SERVICE INFORMATION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000005924391

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severi ty of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and w hether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SRS and SB section of this Service Man-

ual.

WARNING:

• To avoid rendering the SRS inoper ative, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including in correct removal and installation of the SRS can lead to personal

injury caused by unintentional act ivation of the system. For removal of Spiral Cable and Air Bag

Module, see the SRS section.

• Do not use electrical test equipm ent on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identi fied by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Un it or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or el ectric power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers, always switch the Ignition OFF, disconnect the battery, and wait at least 3 minutes before performing any service.

Precaution Necessary for Steering Wheel Rotation After Battery Disconnect

INFOID:0000000005975904

NOTE:

• This Procedure is applied only to models with Intelligent Key system and NATS (NISSAN ANTI-THEFT SYS-

TEM).

• Remove and install all control units after disconnecti ng both battery cables with the ignition knob in the

″ LOCK ″ position.

• Always use CONSULT-III to perform self-diagnosis as a part of each function inspection after finishing work.

If DTC is detected, perform trouble diagnosis according to self-diagnostic results.

For models equipped with the Intelligent Key system and NATS , an electrically controlled steering lock mech-

anism is adopted on the key cylinder.

For this reason, if the battery is disconnected or if the battery is discharged, the steering wheel will lock and

steering wheel rotation will become impossible.

If steering wheel rotation is required when battery power is interrupted, follow the procedure below before

starting the repair operation.

OPERATION PROCEDURE

1. Connect both battery cables. NOTE:

Supply power using jumper cables if battery is discharged.

2. Use the Intelligent Key or mechanical key to turn the ignition switch to the ″ACC ″ position. At this time, the

steering lock will be released.

3. Disconnect both battery cables. The steering lock will remain released and the steering wheel can be

rotated.

4. Perform the necessary repair operation.

Revision: January 20102010 Versa

Page 466 of 3745

![NISSAN TIIDA 2010 Service User Guide AUDIOAV-69

< SERVICE INFORMATION > [AUDIO WITH NAVIGATION]

C

D

E

F

G H

I

J

L

M A

B

AV

N

O P

2.SPIRAL CABLE CHECK

1. Disconnect combination switch (spiral cable) connector M31.

2. Check continuity betw NISSAN TIIDA 2010 Service User Guide AUDIOAV-69

< SERVICE INFORMATION > [AUDIO WITH NAVIGATION]

C

D

E

F

G H

I

J

L

M A

B

AV

N

O P

2.SPIRAL CABLE CHECK

1. Disconnect combination switch (spiral cable) connector M31.

2. Check continuity betw](/img/5/57397/w960_57397-465.png)

AUDIOAV-69

< SERVICE INFORMATION > [AUDIO WITH NAVIGATION]

C

D

E

F

G H

I

J

L

M A

B

AV

N

O P

2.SPIRAL CABLE CHECK

1. Disconnect combination switch (spiral cable) connector M31.

2. Check continuity between combination switch (spiral cable) ter- minals.

OK or NG

OK >> GO TO 4.

NG >> Replace combination switch (spiral cable). Refer to SRS-37, "

Removal and Installation".

3.CHECK STEERING SWITCH RESISTANCE

Check resistance between combination switch (spiral cable) connector M31 terminals.

OK or NG

OK >> Inspection End.

NG >> Replace steering wheel audio control switch. Refer to AV-72, "

Removal and Installation".

Sound Is Not Heard from Front Door Speaker or Front TweeterINFOID:0000000005988550

1.HARNESS CHECK

1. Disconnect AV control unit connector and front door speaker and front tweeter connector (LH or RH).

16 - 32 : Continuity should exist.

17 - 31 : Continuity should exist.

20 - 24 : Continuity should exist.

WKIA4424E

Terminal Signal name

ConditionResistance

(Ω)

(Approx.)

16 17 Seek (down) Depress Seek down switch.

165

Phone/ Send Depress Phone/ Send switch. 0

Volume (down) Depress volume down switch. 652

20 17 Seek (up) Depress Seek up switch.

165

Phone/ End Depress Phone/ End switch. 0

Volume (up) Depress volume up switch. 652

LKIA0191E

Revision: January 20102010 Versa

Page 490 of 3745

BCS-1

ELECTRICAL

C

DE

F

G H

I

J

L

M

SECTION BCS

A

B

BCS

N

O P

CONTENTS

BODY CONTROL SYSTEM

SERVICE INFORMATION .. ..........................2

PRECAUTIONS .............................................. .....2

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

2

Precaution Necessary for Steering Wheel Rota-

tion After Battery Disconnect ............................... ......

2

BCM (BODY CONTROL MODULE) ....................4

System Description ............................................. ......4

CAN Communication System Description .................8

Schematic ............................................................ .....9

BCM Terminal Arrangement ....................................11

Terminal and Reference Value for BCM ..................12

BCM Power Supply and Ground Circuit Inspection

....

16

CONSULT-III Function (BCM) .................................17

CAN Communication Inspection Using CON-

SULT-III (Self-Diagnosis) ..................................... ....

18

Configuration ...........................................................19

Removal and Installation of BCM ............................19

Revision: January 20102010 Versa

Page 491 of 3745

BCS-2

< SERVICE INFORMATION >

PRECAUTIONS

SERVICE INFORMATION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000005715841

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and w hether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SRS and SB section of this Service Man-

ual.

WARNING:

• To avoid rendering the SRS inopera tive, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including incorrect removal and installation of the SRS can lead to personal

injury caused by unintent ional activation of the system. For re moval of Spiral Cable and Air Bag

Module, see the SRS section.

• Do not use electrical test equipmen t on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harn esses can be identified by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Unit or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or electri c power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers , always switch the Ignition OFF, disconnect the

battery, and wait at least 3 minu tes before performing any service.

Precaution Necessary for Steering W heel Rotation After Battery Disconnect

INFOID:0000000005976476

NOTE:

• This Procedure is applied only to models with Intelligent Key system and NATS (NISSAN ANTI-THEFT SYS-

TEM).

• Remove and install all control units after disconnecting both battery cables with the ignition knob in the

″LOCK ″ position.

• Always use CONSULT-III to perform self-diagnosis as a part of each function inspection after finishing work.

If DTC is detected, perform trouble diagnosis according to self-diagnostic results.

For models equipped with the Intelligent Key system and NATS, an electrically controlled steering lock mech-

anism is adopted on the key cylinder.

For this reason, if the battery is disconnected or if the battery is discharged, the steering wheel will lock and

steering wheel rotation will become impossible.

If steering wheel rotation is required when battery pow er is interrupted, follow the procedure below before

starting the repair operation.

OPERATION PROCEDURE

1. Connect both battery cables. NOTE:

Supply power using jumper cables if battery is discharged.

2. Use the Intelligent Key or mechanical key to turn the ignition switch to the ″ACC ″ position. At this time, the

steering lock will be released.

3. Disconnect both battery cables. The steering lock will remain released and the steering wheel can be rotated.

4. Perform the necessary repair operation.

Revision: January 20102010 Versa

Page 510 of 3745

BL-1

BODY

C

DE

F

G H

J

K L

M

SECTION BL

A

B

BL

N

O P

CONTENTS

BODY, LOCK & SECURITY SYSTEM

SERVICE INFORMATION .. ..........................4

PRECAUTIONS .............................................. .....4

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

4

Precaution Necessary for Steering Wheel Rota-

tion After Battery Disconnect ............................... ......

4

Precaution for Procedure without Cowl Top Cover ......5

Precaution for Work ..................................................5

PREPARATION ...................................................6

Special Service Tool ........................................... ......6

Commercial Service Tool ..........................................6

SQUEAK AND RATTLE TROUBLE DIAG-

NOSES ................................................................

7

Work Flow ........................................................... ......7

Generic Squeak and Rattle Troubleshooting ............9

Diagnostic Worksheet .............................................11

HOOD .................................................................13

Fitting Adjustment ............................................... ....13

Removal and Installation .........................................14

Removal and Installation of Hood Lock Control .. ....15

Hood Lock Control Inspection .................................17

RADIATOR CORE SUPPORT ....................... ....19

Removal and Installation .........................................19

FRONT FENDER ................................................21

Removal and Installation .........................................21

POWER DOOR LOCK SYSTEM .................... ....22

Component Parts and Harness Connector Loca-

tion ...................................................................... ....

22

System Description .................................................23

CAN Communication System Description ...............25

Schematic ...............................................................26

Wiring Diagram - D/LOCK - .....................................27

Schematic ...............................................................31

Wiring Diagram - D/LOCK - .....................................32

Terminal and Reference Value for BCM ..................37

Work Flow ............................................................ ....41

CONSULT-III Function (BCM) .................................41

Trouble Diagnosis Symptom Chart ...................... ....43

BCM Power Supply and Ground Circuit Inspection

....

43

Door Switch Check (Hatchback) ..............................44

Door Switch Check (Sedan) ....................................47

Key Switch (Insert) Check .......................................48

Door Lock and Unlock Switch Check ......................49

Front Door Lock Assembly LH (Actuator) Check .....52

Door Lock Actuator Check (Front RH and Rear

LH/RH) ................................................................. ....

53

Front Door Key Cylinder Switch LH Check ..............54

Passenger Select Unlock Relay Circuit Inspection

(With Intelligent Key) ........................................... ....

55

REMOTE KEYLESS ENTRY SYSTEM .............58

Component Parts and Harness Connector Loca-

tion ...........................................................................

58

System Description ..................................................58

CAN Communication System Description ...............60

Schematic ................................................................61

Wiring Diagram - KEYLES - ....................................62

Terminal and Reference Value for BCM ..................65

How to Perform Trouble Diagnosis ...................... ....69

Preliminary Check ...................................................69

CONSULT-III Function (BCM) .................................69

Work Flow ............................................................ ....71

Trouble Diagnosis Symptom Chart ..........................71

Keyfob Battery and Function Check ........................72

ACC Switch Check ..................................................74

Door Switch Check (Hatchback) ..............................74

Door Switch Check (Sedan) ....................................76

Key Switch (Insert) Check .......................................78

Hazard Function Check ...........................................78

Horn Function Check ...............................................79

Interior Lamp and Ignition Keyhole Illumination

Function Check ........................................................

79

Remote Keyless Entry Receiver Check ...................80

Keyfob Function (Lock) Check ............................ ....82

Revision: January 20102010 Versa

Page 513 of 3745

BL-4

< SERVICE INFORMATION >

PRECAUTIONS

SERVICE INFORMATION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000005777020

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and w hether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SRS and SB section of this Service Man-

ual.

WARNING:

• To avoid rendering the SRS inopera tive, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including incorrect removal and installation of the SRS can lead to personal

injury caused by unintent ional activation of the system. For re moval of Spiral Cable and Air Bag

Module, see the SRS section.

• Do not use electrical test equipmen t on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harn esses can be identified by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Unit or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or electri c power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers , always switch the Ignition OFF, disconnect the

battery, and wait at least 3 minu tes before performing any service.

Precaution Necessary for Steering W heel Rotation After Battery Disconnect

INFOID:0000000006044768

NOTE:

• This Procedure is applied only to models with Intelligent Key system and NATS (NISSAN ANTI-THEFT SYS-

TEM).

• Remove and install all control units after disconnecting both battery cables with the ignition knob in the

″LOCK ″ position.

• Always use CONSULT-III to perform self-diagnosis as a part of each function inspection after finishing work.

If DTC is detected, perform trouble diagnosis according to self-diagnostic results.

For models equipped with the Intelligent Key system and NATS, an electrically controlled steering lock mech-

anism is adopted on the key cylinder.

For this reason, if the battery is disconnected or if the battery is discharged, the steering wheel will lock and

steering wheel rotation will become impossible.

If steering wheel rotation is required when battery pow er is interrupted, follow the procedure below before

starting the repair operation.

OPERATION PROCEDURE

1. Connect both battery cables. NOTE:

Supply power using jumper cables if battery is discharged.

2. Use the Intelligent Key or mechanical key to turn the ignition switch to the ″ACC ″ position. At this time, the

steering lock will be released.

3. Disconnect both battery cables. The steering lock will remain released and the steering wheel can be rotated.

4. Perform the necessary repair operation.

Revision: January 20102010 Versa

Page 525 of 3745

BL-16

< SERVICE INFORMATION >

HOOD

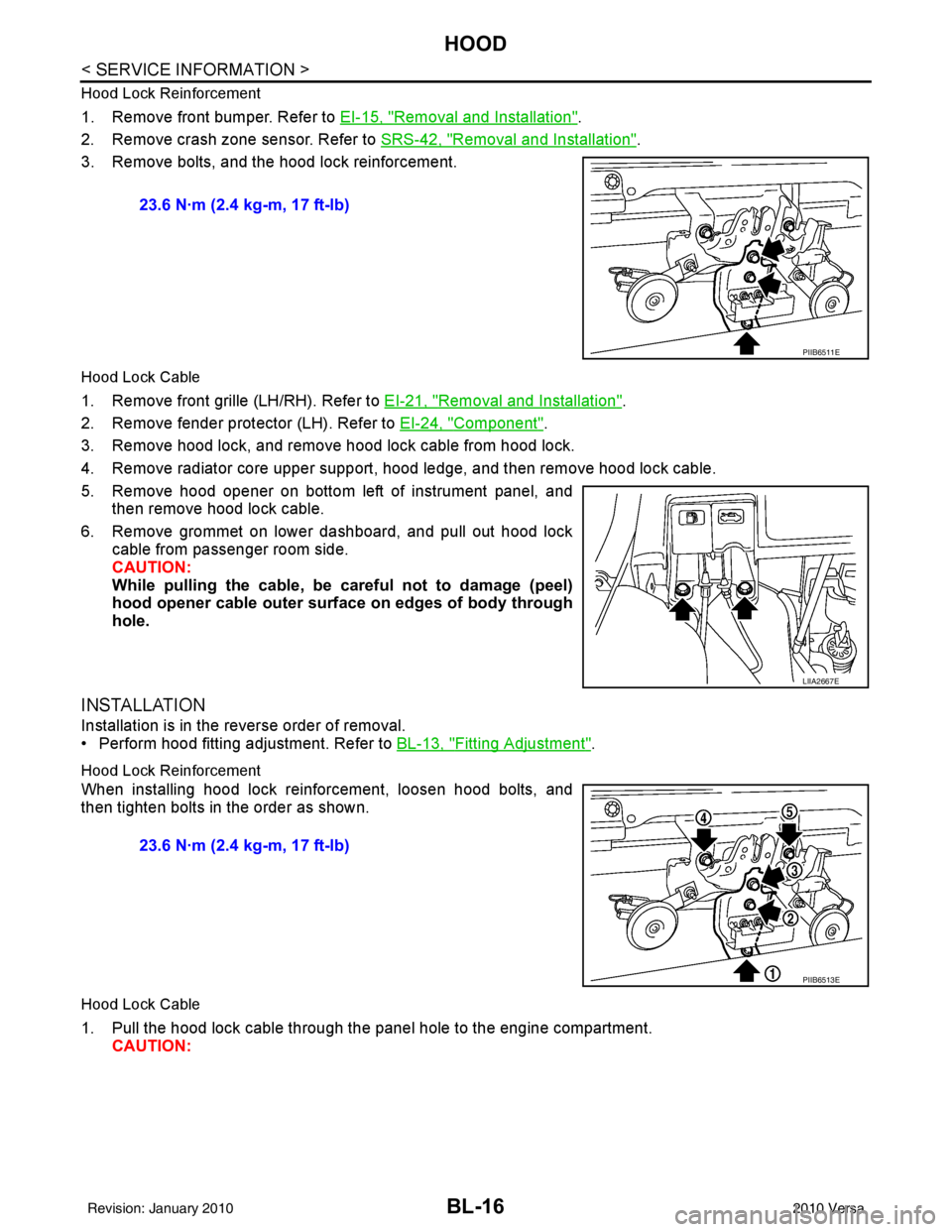

Hood Lock Reinforcement

1. Remove front bumper. Refer to EI-15, "Removal and Installation".

2. Remove crash zone sensor. Refer to SRS-42, "

Removal and Installation".

3. Remove bolts, and the hood lock reinforcement.

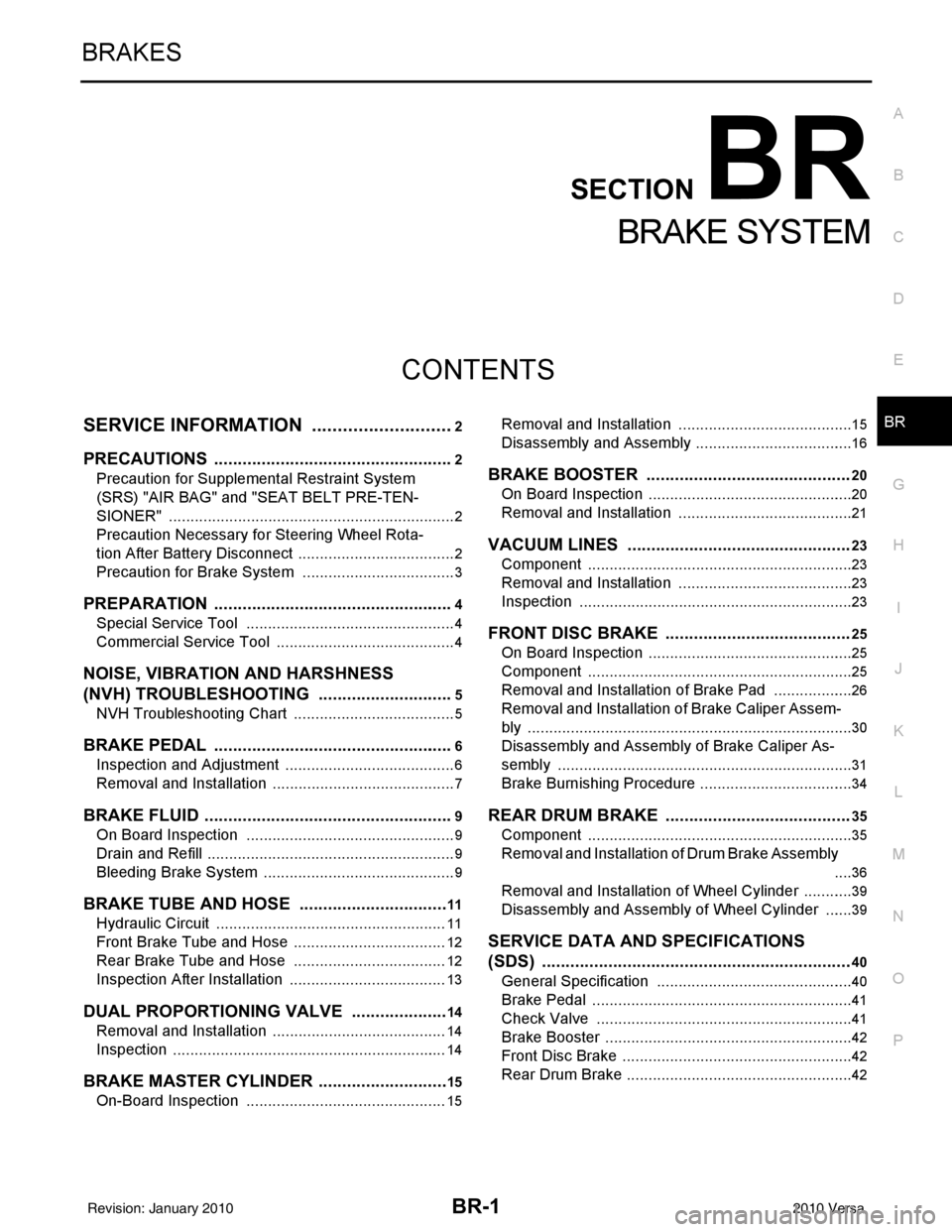

Hood Lock Cable

1. Remove front grille (LH/RH). Refer to EI-21, "Removal and Installation".

2. Remove fender protector (LH). Refer to EI-24, "

Component".

3. Remove hood lock, and remove hood lock cable from hood lock.

4. Remove radiator core upper support, hood ledge, and then remove hood lock cable.

5. Remove hood opener on bottom left of instrument panel, and then remove hood lock cable.

6. Remove grommet on lower dashboard, and pull out hood lock cable from passenger room side.

CAUTION:

While pulling the cable, be car eful not to damage (peel)

hood opener cable outer surface on edges of body through

hole.

INSTALLATION

Installation is in the reverse order of removal.

• Perform hood fitting adjustment. Refer to BL-13, "

Fitting Adjustment".

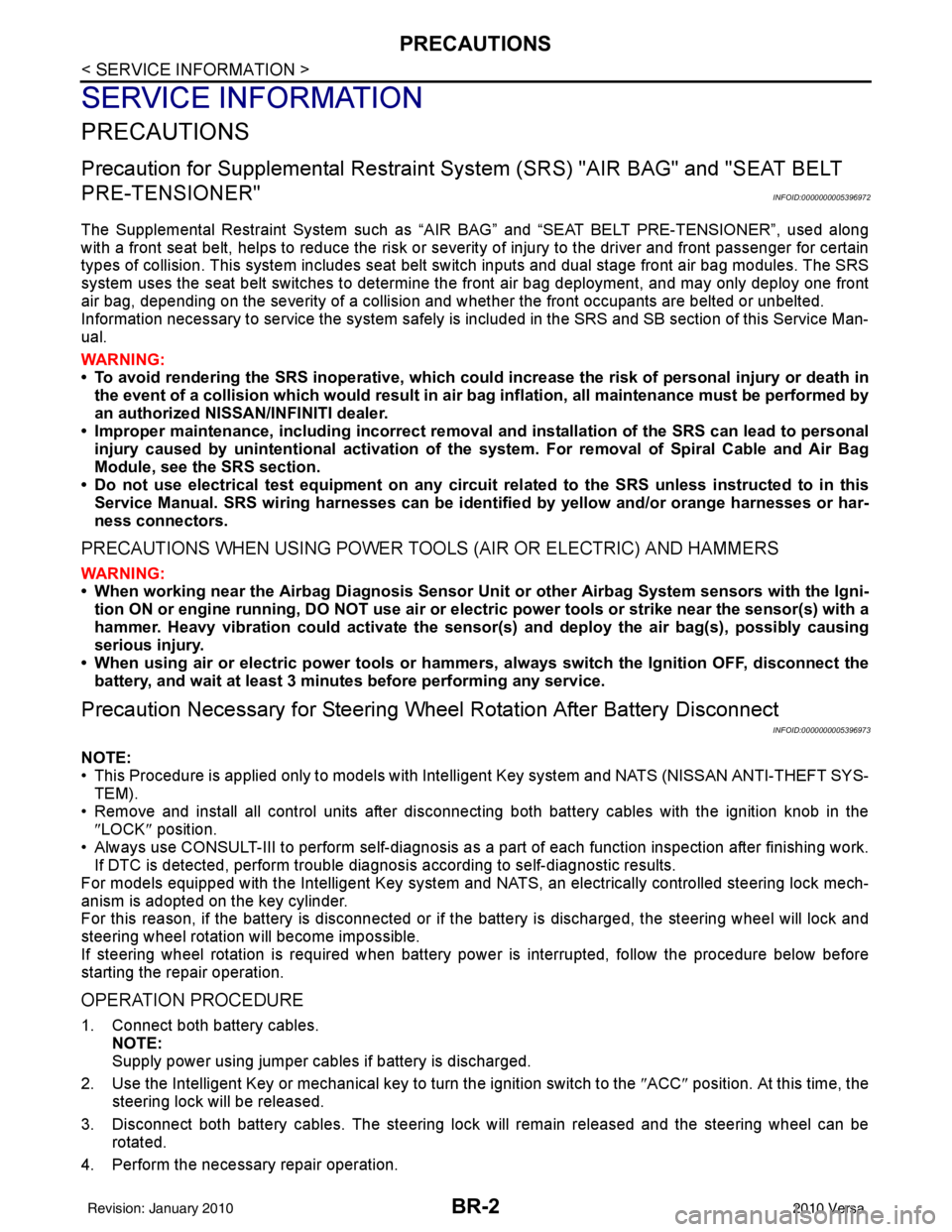

Hood Lock Reinforcement

When installing hood lock reinforcement, loosen hood bolts, and

then tighten bolts in the order as shown.

Hood Lock Cable

1. Pull the hood lock cable through the panel hole to the engine compartment. CAUTION: 23.6 N·m (2.4 kg-m, 17 ft-lb)

PIIB6511E

LIIA2667E

23.6 N·m (2.4 kg-m, 17 ft-lb)

PIIB6513E

Revision: January 20102010 Versa

Page 849 of 3745

BR-1

BRAKES

C

DE

G H

I

J

K L

M

SECTION BR

A

B

BR

N

O P

CONTENTS

BRAKE SYSTEM

SERVICE INFORMATION .. ..........................2

PRECAUTIONS .............................................. .....2

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

2

Precaution Necessary for Steering Wheel Rota-

tion After Battery Disconnect ............................... ......

2

Precaution for Brake System ....................................3

PREPARATION ...................................................4

Special Service Tool ........................................... ......4

Commercial Service Tool ..........................................4

NOISE, VIBRATION AND HARSHNESS

(NVH) TROUBLESHOOTING .............................

5

NVH Troubleshooting Chart ................................ ......5

BRAKE PEDAL .............................................. .....6

Inspection and Adjustment .................................. ......6

Removal and Installation ...........................................7

BRAKE FLUID ................................................ .....9

On Board Inspection ........................................... ......9

Drain and Refill ..........................................................9

Bleeding Brake System .............................................9

BRAKE TUBE AND HOSE ................................11

Hydraulic Circuit .................................................. ....11

Front Brake Tube and Hose ....................................12

Rear Brake Tube and Hose ....................................12

Inspection After Installation .....................................13

DUAL PROPORTIONING VALVE .....................14

Removal and Installation .........................................14

Inspection ............................................................ ....14

BRAKE MASTER CYLINDER ........................ ....15

On-Board Inspection ........................................... ....15

Removal and Installation ..................................... ....15

Disassembly and Assembly .....................................16

BRAKE BOOSTER ...........................................20

On Board Inspection ............................................ ....20

Removal and Installation .........................................21

VACUUM LINES ...............................................23

Component ..............................................................23

Removal and Installation .........................................23

Inspection ................................................................23

FRONT DISC BRAKE .......................................25

On Board Inspection ............................................ ....25

Component ..............................................................25

Removal and Installation of Brake Pad ...................26

Removal and Installation of Brake Caliper Assem-

bly ........................................................................ ....

30

Disassembly and Assembly of Brake Caliper As-

sembly .....................................................................

31

Brake Burnishing Procedure ....................................34

REAR DRUM BRAKE .......................................35

Component .......................................................... ....35

Removal and Installation of Drum Brake Assembly

....

36

Removal and Installation of Wheel Cylinder ............39

Disassembly and Assembly of Wheel Cylinder .......39

SERVICE DATA AND SPECIFICATIONS

(SDS) .................................................................

40

General Specification ..............................................40

Brake Pedal .............................................................41

Check Valve ............................................................41

Brake Booster ..........................................................42

Front Disc Brake ......................................................42

Rear Drum Brake .....................................................42

Revision: January 20102010 Versa

Page 850 of 3745

BR-2

< SERVICE INFORMATION >

PRECAUTIONS

SERVICE INFORMATION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000005396972

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and w hether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SRS and SB section of this Service Man-

ual.

WARNING:

• To avoid rendering the SRS inopera tive, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including incorrect removal and installation of the SRS can lead to personal

injury caused by unintent ional activation of the system. For re moval of Spiral Cable and Air Bag

Module, see the SRS section.

• Do not use electrical test equipmen t on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harn esses can be identified by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Unit or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or electri c power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers , always switch the Ignition OFF, disconnect the

battery, and wait at least 3 minu tes before performing any service.

Precaution Necessary for Steering W heel Rotation After Battery Disconnect

INFOID:0000000005396973

NOTE:

• This Procedure is applied only to models with Intelligent Key system and NATS (NISSAN ANTI-THEFT SYS-

TEM).

• Remove and install all control units after disconnecting both battery cables with the ignition knob in the

″LOCK ″ position.

• Always use CONSULT-III to perform self-diagnosis as a part of each function inspection after finishing work.

If DTC is detected, perform trouble diagnosis according to self-diagnostic results.

For models equipped with the Intelligent Key system and NATS, an electrically controlled steering lock mech-

anism is adopted on the key cylinder.

For this reason, if the battery is disconnected or if the battery is discharged, the steering wheel will lock and

steering wheel rotation will become impossible.

If steering wheel rotation is required when battery pow er is interrupted, follow the procedure below before

starting the repair operation.

OPERATION PROCEDURE

1. Connect both battery cables. NOTE:

Supply power using jumper cables if battery is discharged.

2. Use the Intelligent Key or mechanical key to turn the ignition switch to the ″ACC ″ position. At this time, the

steering lock will be released.

3. Disconnect both battery cables. The steering lock will remain released and the steering wheel can be rotated.

4. Perform the necessary repair operation.

Revision: January 20102010 Versa

Page 891 of 3745

BRC-1

BRAKES

C

DE

G H

I

J

K L

M

SECTION BRC

A

B

BRC

N

O P

CONTENTS

BRAKE CONTROL SYSTEM

ABS

SERVICE INFORMATION .. ..........................

3

PRECAUTIONS .............................................. .....3

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

3

Precaution Necessary for Steering Wheel Rota-

tion After Battery Disconnect ............................... ......

3

Precaution for Brake System ....................................4

Precaution for Brake Control .....................................4

Precaution for CAN System ................................ ......4

PREPARATION ...................................................6

Special Service Tool ........................................... ......6

Commercial Service Tool ..........................................6

SYSTEM DESCRIPTION .....................................7

System Component ............................................. ......7

ABS Function ............................................................7

EBD Function ............................................................7

Fail-Safe Function .....................................................7

Hydraulic Circuit Diagram .........................................8

CAN COMMUNICATION ................................ .....9

System Description ............................................. ......9

TROUBLE DIAGNOSIS .....................................10

How to Perform Trouble Diagnosis for Quick and

Accurate Repair ......................................................

10

Component Parts and Harness Connector Loca-

tion ...................................................................... ....

13

Schematic ...............................................................14

Wiring Diagram - ABS - ...........................................15

Basic Inspection .................................................. ....18

Warning Lamp and Indicator Timing .......................19

Control Unit Input/Output Signal Standard ..............19

CONSULT-III Function (ABS) .................................20

TROUBLE DIAGNOSIS FOR SELF-DIAG-

NOSTIC ITEMS ..................................................

26

Wheel Sensor System ......................................... ....26

ABS Control Unit Inspection ....................................27

Solenoid Valve System Inspection ..........................27

Actuator Motor, Motor Relay, and Circuit Inspec-

tion ....................................................................... ....

28

ABS Control Unit Power and Ground Systems In-

spection ...................................................................

29

CAN Communication System Inspection .................30

TROUBLE DIAGNOSES FOR SYMPTOMS .....31

ABS Works Frequently ............................................31

Unexpected Pedal Action ........................................31

Long Stopping Distance ..........................................32

ABS Does Not Work ................................................32

Pedal Vibration or ABS Operation Noise .................32

WHEEL SENSORS ...........................................34

Removal and Installation ..................................... ....34

SENSOR ROTOR ..............................................36

Removal and Installation .........................................36

ACTUATOR AND ELECTRIC UNIT (ASSEM-

BLY) ..................................................................

37

Removal and Installation .........................................37

VDC/TCS/ABS

SERVICE INFORMATION .. .........................

39

PRECAUTIONS .................................................39

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ....

39

Precaution Necessary for Steering Wheel Rota-

tion After Battery Disconnect ...................................

39

Precaution for Brake System ...................................40

Precaution for Brake Control ...................................40

Precaution for CAN System .....................................41

PREPARATION .................................................42

Special Service Tool ................................................42

Commercial Service Tool ........................................42

Revision: January 20102010 Versa