Front NISSAN TIIDA 2010 Service Owner's Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2010, Model line: TIIDA, Model: NISSAN TIIDA 2010Pages: 3745, PDF Size: 73.67 MB

Page 247 of 3745

AT-230

< SERVICE INFORMATION >

ON-VEHICLE SERVICE

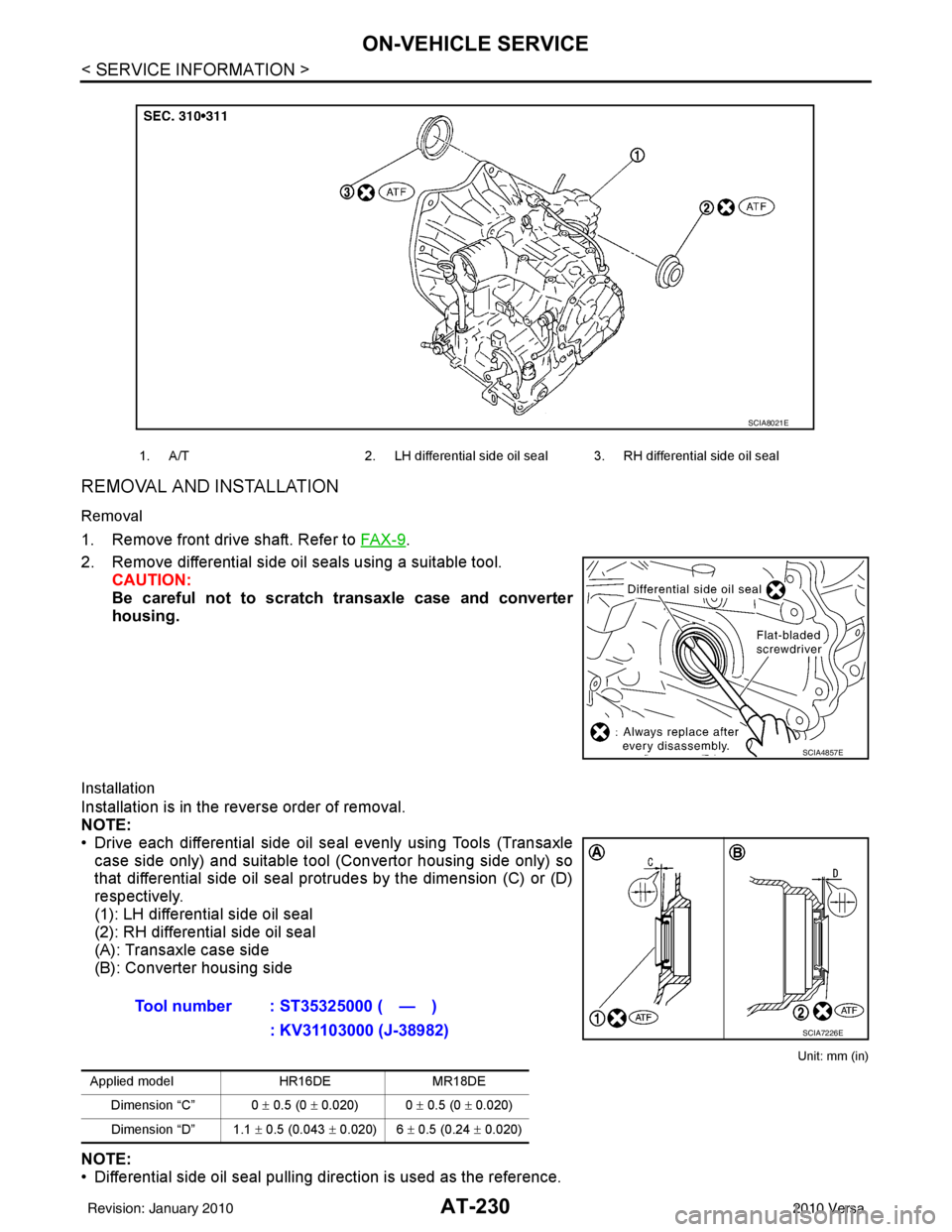

REMOVAL AND INSTALLATION

Removal

1. Remove front drive shaft. Refer to FA X - 9.

2. Remove differential side oil seals using a suitable tool. CAUTION:

Be careful not to scratch transaxle case and converter

housing.

Installation

Installation is in the reverse order of removal.

NOTE:

• Drive each differential side oil seal evenly using Tools (Transaxlecase side only) and suitable tool (Convertor housing side only) so

that differential side oil seal prot rudes by the dimension (C) or (D)

respectively.

(1): LH differential side oil seal

(2): RH differential side oil seal

(A): Transaxle case side

(B): Converter housing side

Unit: mm (in)

NOTE:

• Differential side oil seal pulling direction is used as the reference.

1. A/T 2. LH differential side oil seal 3. RH differential side oil seal

SCIA8021E

SCIA4857E

Tool number : ST35325000 ( — )

: KV31103000 (J-38982)

Applied model HR16DEMR18DE

Dimension “C” 0 ± 0.5 (0 ± 0.020) 0 ± 0.5 (0 ± 0.020)

Dimension “D” 1.1 ± 0.5 (0.043 ± 0.020) 6 ± 0.5 (0.24 ± 0.020)

SCIA7226E

Revision: January 20102010 Versa

Page 249 of 3745

AT-232

< SERVICE INFORMATION >

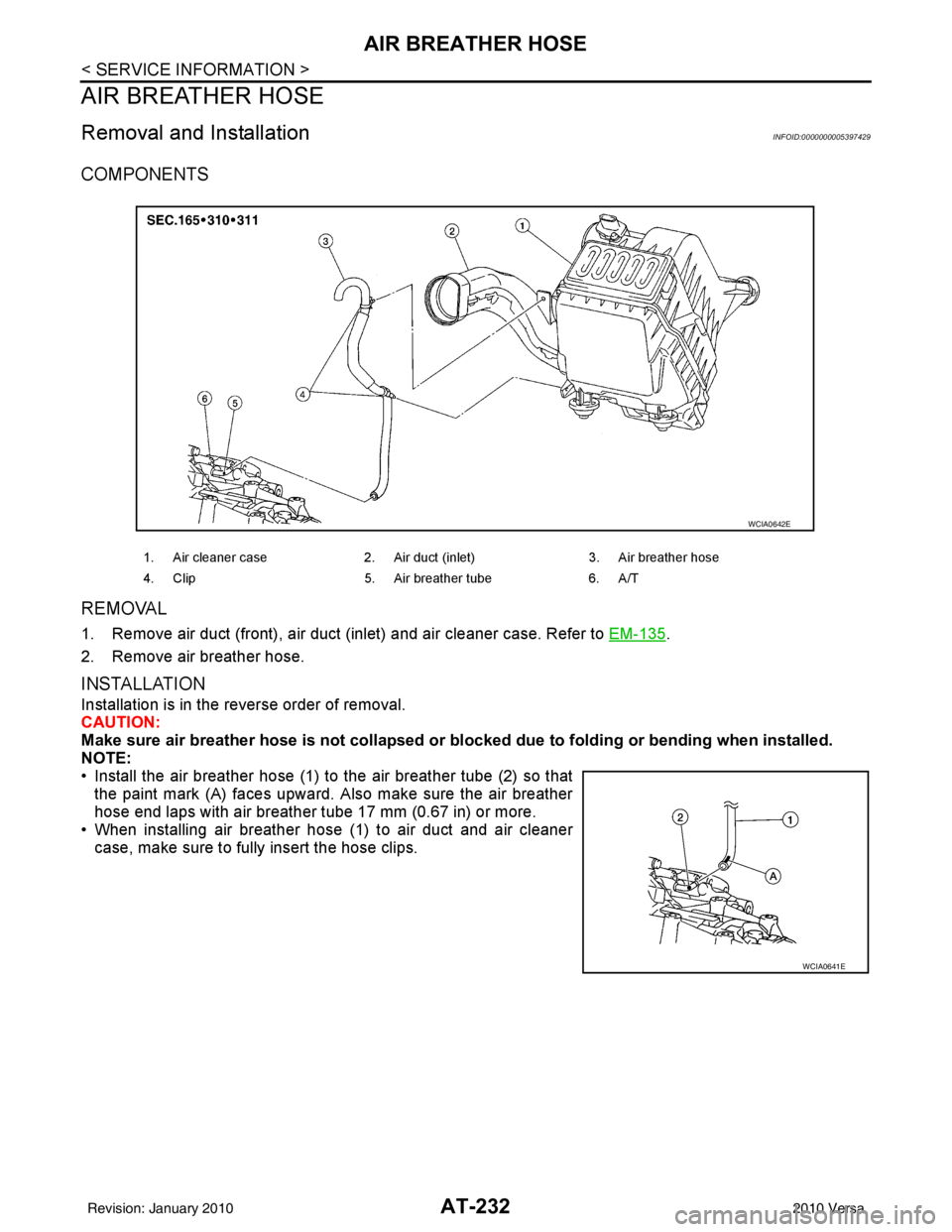

AIR BREATHER HOSE

AIR BREATHER HOSE

Removal and InstallationINFOID:0000000005397429

COMPONENTS

REMOVAL

1. Remove air duct (front), air duct (inlet) and air cleaner case. Refer to EM-135.

2. Remove air breather hose.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

Make sure air breather hose is not collapsed or bl ocked due to folding or bending when installed.

NOTE:

• Install the air breather hose (1) to the air breather tube (2) so that

the paint mark (A) faces upward. Also make sure the air breather

hose end laps with air breather tube 17 mm (0.67 in) or more.

• When installing air breather hose (1) to air duct and air cleaner

case, make sure to fully insert the hose clips.

1. Air cleaner case 2. Air duct (inlet) 3. Air breather hose

4. Clip 5. Air breather tube 6. A/T

WCIA0642E

WCIA0641E

Revision: January 20102010 Versa

Page 251 of 3745

AT-234

< SERVICE INFORMATION >

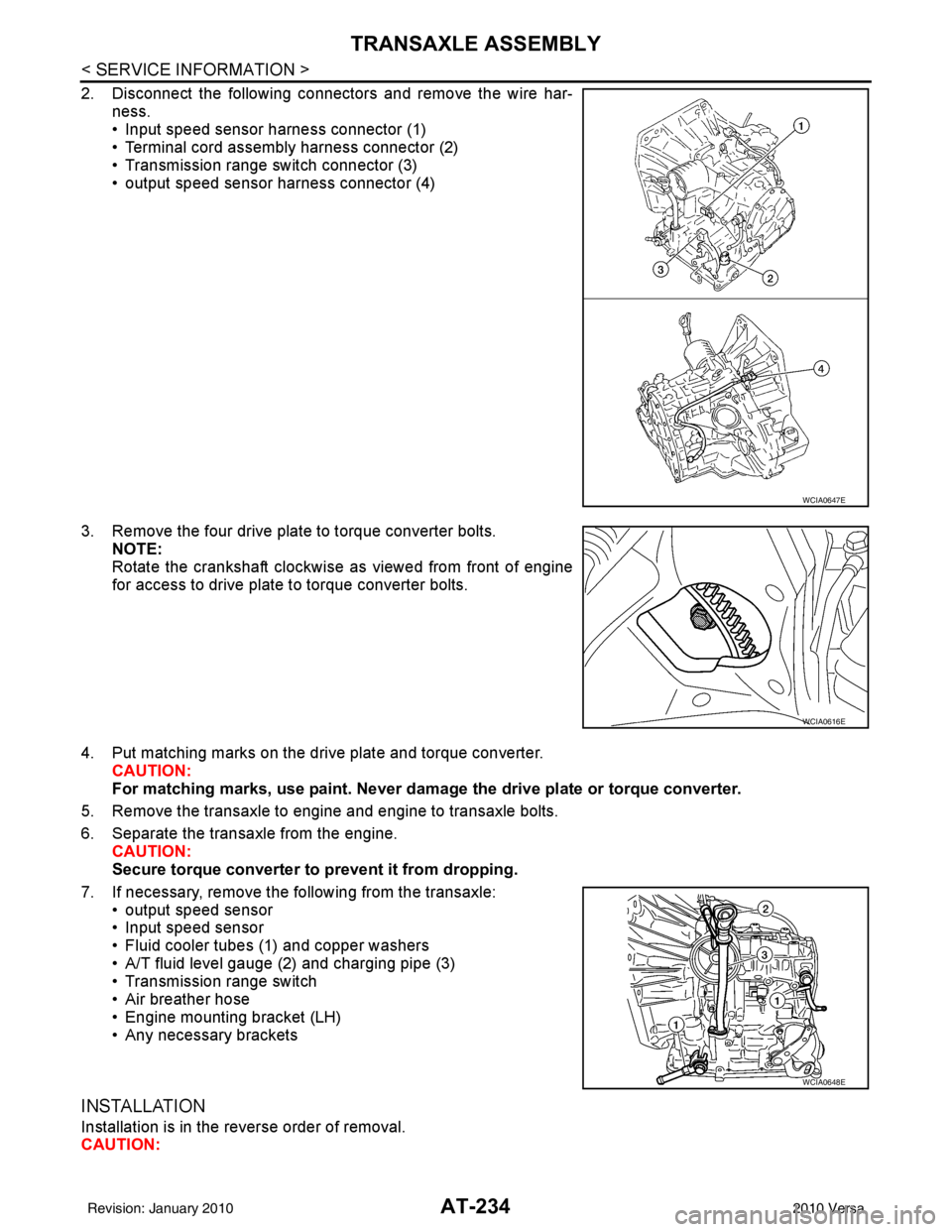

TRANSAXLE ASSEMBLY

2. Disconnect the following connectors and remove the wire har-ness.

• Input speed sensor harness connector (1)

• Terminal cord assembly harness connector (2)

• Transmission range switch connector (3)

• output speed sensor harness connector (4)

3. Remove the four drive plate to torque converter bolts. NOTE:

Rotate the crankshaft clockwise as viewed from front of engine

for access to drive plate to torque converter bolts.

4. Put matching marks on the drive plate and torque converter. CAUTION:

For matching marks, use paint. Never dama ge the drive plate or torque converter.

5. Remove the transaxle to engine and engine to transaxle bolts.

6. Separate the transaxle from the engine. CAUTION:

Secure torque converter to prevent it from dropping.

7. If necessary, remove the following from the transaxle: • output speed sensor

• Input speed sensor

• Fluid cooler tubes (1) and copper washers

• A/T fluid level gauge (2) and charging pipe (3)

• Transmission range switch

• Air breather hose

• Engine mounting bracket (LH)

• Any necessary brackets

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

WCIA0647E

WCIA0616E

WCIA0648E

Revision: January 20102010 Versa

Page 252 of 3745

TRANSAXLE ASSEMBLYAT-235

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

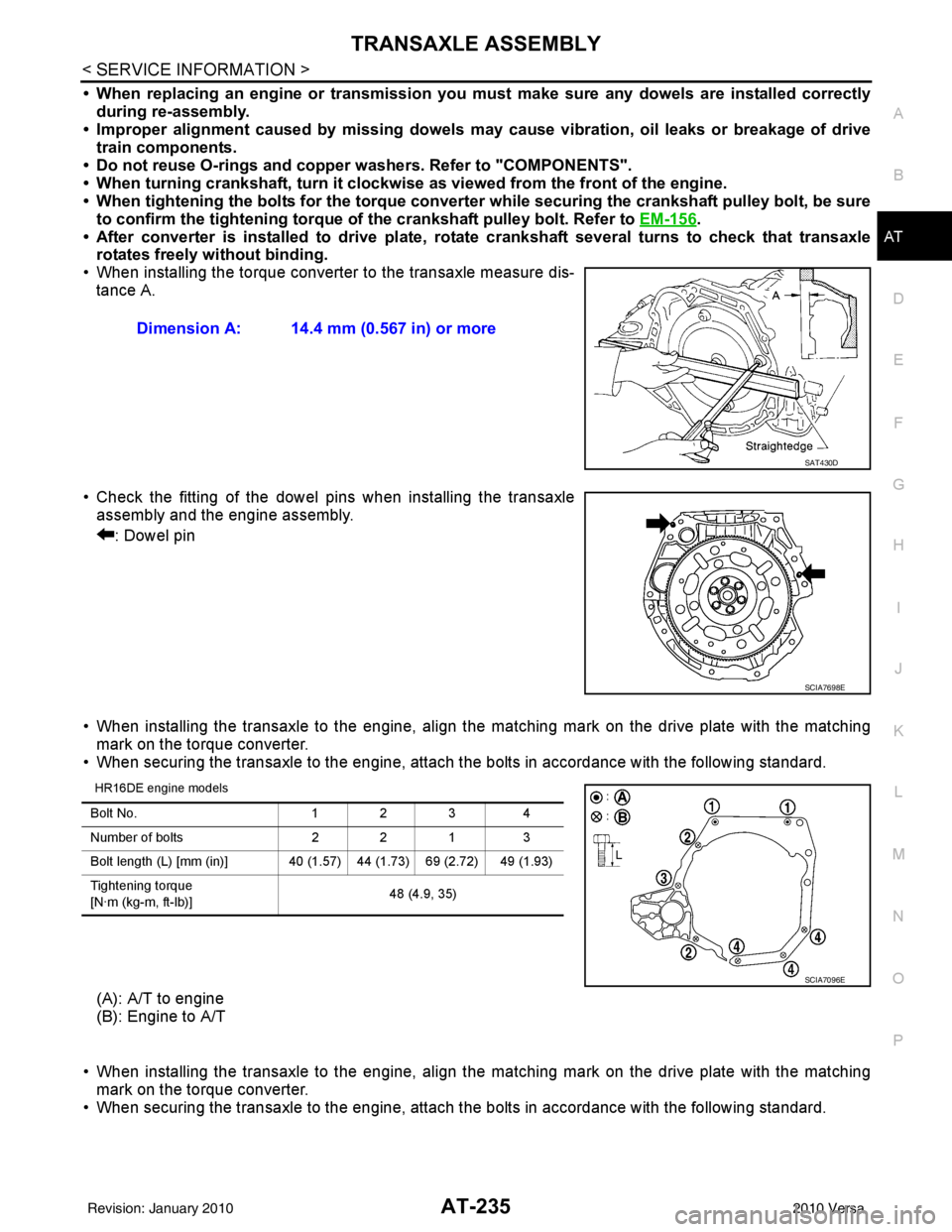

• When replacing an engine or transmission you must make sure any dowels are installed correctly during re-assembly.

• Improper alignment caused by missing dowels may cause vibration, oil leaks or breakage of drive

train components.

• Do not reuse O-rings and copper washers. Refer to "COMPONENTS".

• When turning crankshaft, turn it clockwise as viewed from the front of the engine.

• When tightening the bolts for th e torque converter while securing the crankshaft pulley bolt, be sure

to confirm the tightening torque of the crankshaft pulley bolt. Refer to EM-156

.

• After converter is installed to drive plate, ro tate crankshaft several turns to check that transaxle

rotates freely without binding.

• When installing the torque converter to the transaxle measure dis- tance A.

• Check the fitting of the dowel pins when installing the transaxle assembly and the engine assembly.

: Dowel pin

• When installing the transaxle to the engine, align the matching mark on the drive plate with the matching mark on the torque converter.

• When securing the transaxle to the engine, attach the bolts in accordance with the following standard.

HR16DE engine models

(A): A/T to engine

(B): Engine to A/T

• When installing the transaxle to the engine, align the matching mark on the drive plate with the matching mark on the torque converter.

• When securing the transaxle to the engine, attach the bolts in accordance with the following standard. Dimension A: 14.4 mm (0.567 in) or more

SAT430D

SCIA7698E

Bolt No.

1 2 34

Number of bolts 2 2 13

Bolt length (L) [mm (in)] 40 (1.5 7) 44 (1.73) 69 (2.72) 49 (1.93)

Tightening torque

[N·m (kg-m, ft-lb)] 48 (4.9, 35)

SCIA7096E

Revision: January 20102010 Versa

Page 258 of 3745

OVERHAULAT-241

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

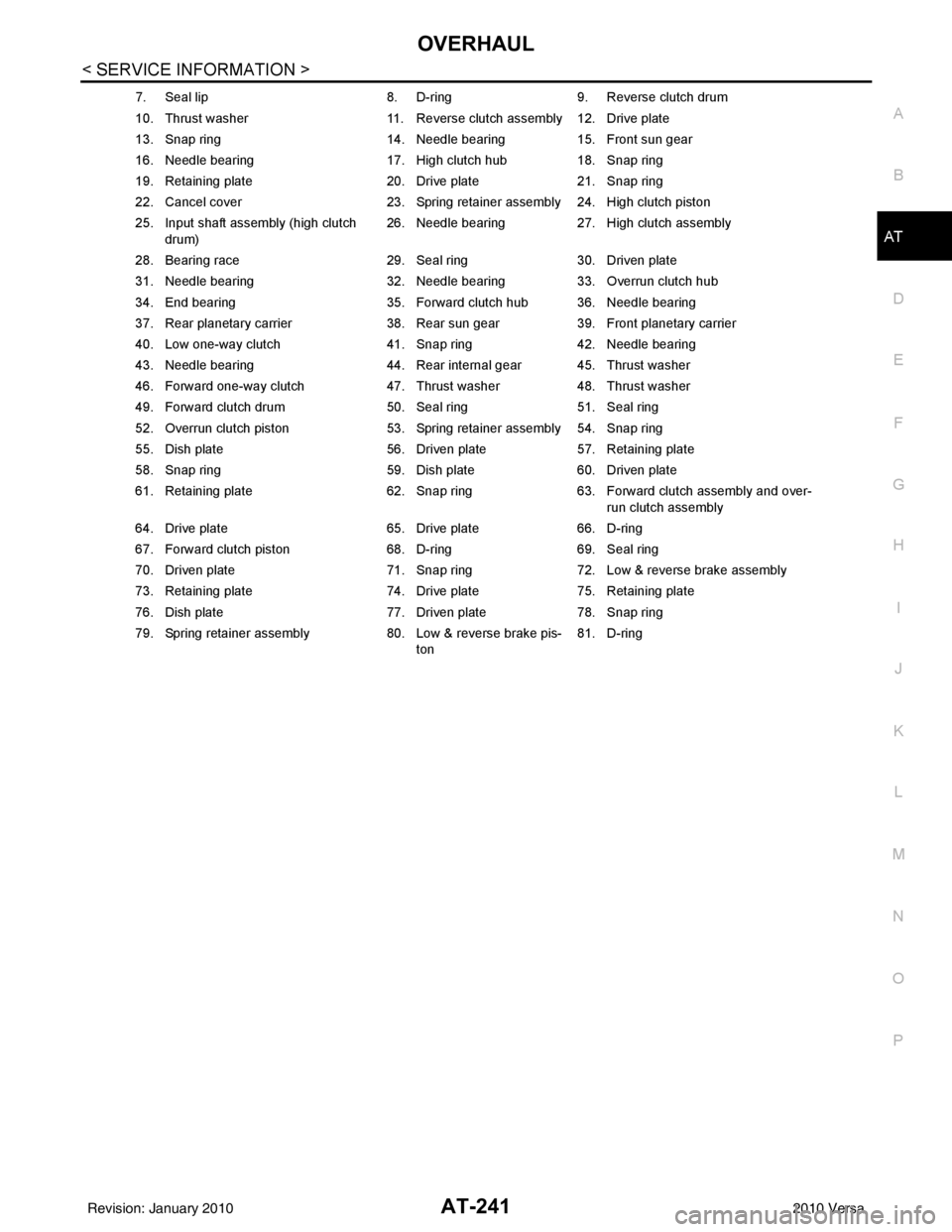

7. Seal lip 8. D-ring9. Reverse clutch drum

10. Thrust washer 11. Reverse clutch assembly 12. Drive plate

13. Snap ring 14. Needle bearing15. Front sun gear

16. Needle bearing 17. High clutch hub18. Snap ring

19. Retaining plate 20. Drive plate21. Snap ring

22. Cancel cover 23. Spring retainer assembly 24. High clutch piston

25. Input shaft assembly (high clutch drum) 26. Needle bearing

27. High clutch assembly

28. Bearing race 29. Seal ring30. Driven plate

31. Needle bearing 32. Needle bearing33. Overrun clutch hub

34. End bearing 35. Forward clutch hub 36. Needle bearing

37. Rear planetary carrier 38. Rear sun gear39. Front planetary carrier

40. Low one-way clutch 41. Snap ring42. Needle bearing

43. Needle bearing 44. Rear internal gear 45. Thrust washer

46. Forward one-way clutch 47. Thrust washer48. Thrust washer

49. Forward clutch drum 50. Seal ring51. Seal ring

52. Overrun clutch piston 53. Spring retainer assembly 54. Snap ring

55. Dish plate 56. Driven plate57. Retaining plate

58. Snap ring 59. Dish plate60. Driven plate

61. Retaining plate 62. Snap ring63. Forward clutch assembly and over-

run clutch assembly

64. Drive plate 65. Drive plate66. D-ring

67. Forward clutch piston 68. D-ring69. Seal ring

70. Driven plate 71. Snap ring72. Low & reverse brake assembly

73. Retaining plate 74. Drive plate75. Retaining plate

76. Dish plate 77. Driven plate78. Snap ring

79. Spring retainer assembly 80. Low & reverse brake pis-

ton 81. D-ring

Revision: January 20102010 Versa

Page 264 of 3745

OVERHAULAT-247

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

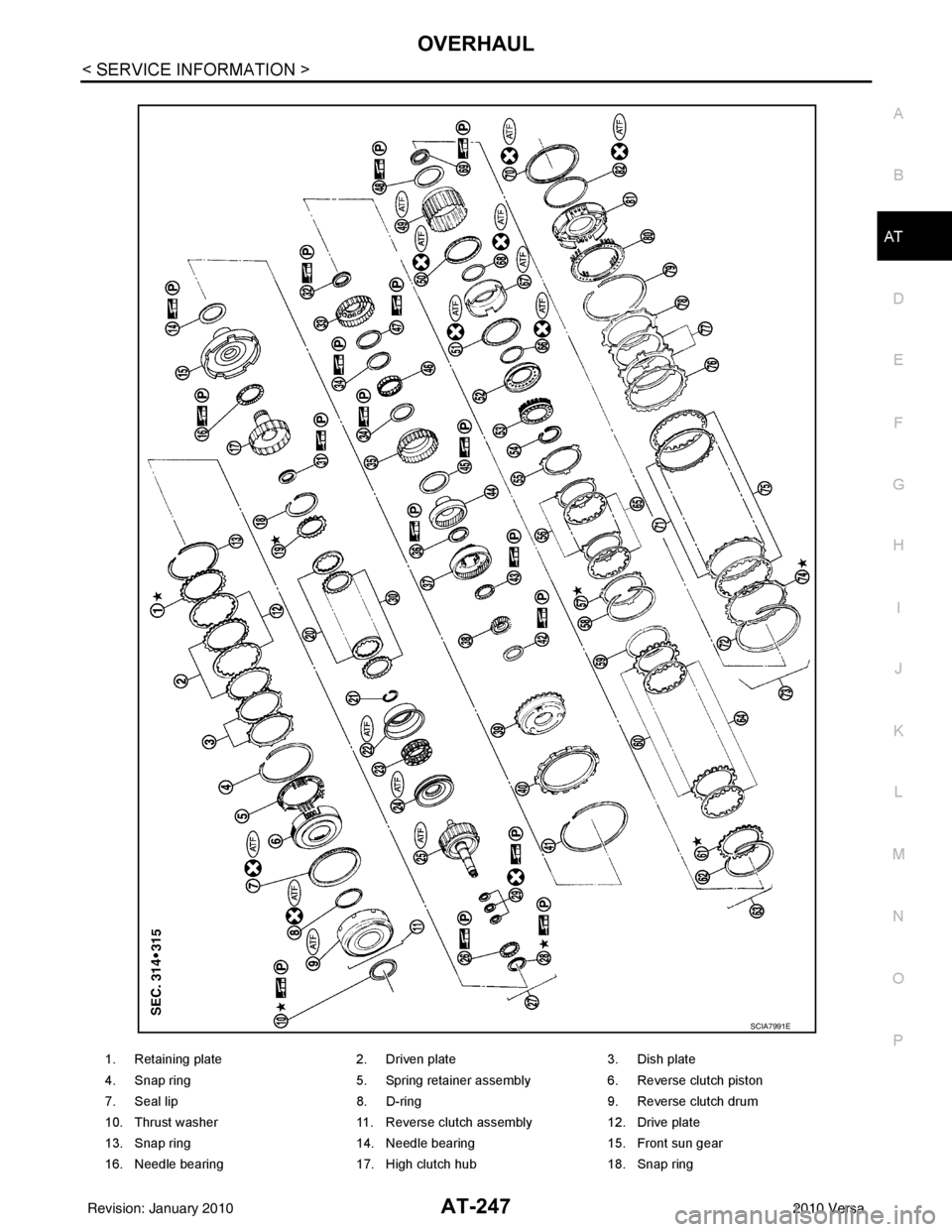

1. Retaining plate 2. Driven plate3. Dish plate

4. Snap ring 5. Spring retainer assembly6. Reverse clutch piston

7. Seal lip 8. D-ring9. Reverse clutch drum

10. Thrust washer 11. Reverse clutch assembly 12. Drive plate

13. Snap ring 14. Needle bearing15. Front sun gear

16. Needle bearing 17. High clutch hub18. Snap ring

SCIA7991E

Revision: January 20102010 Versa

Page 265 of 3745

AT-248

< SERVICE INFORMATION >

OVERHAUL

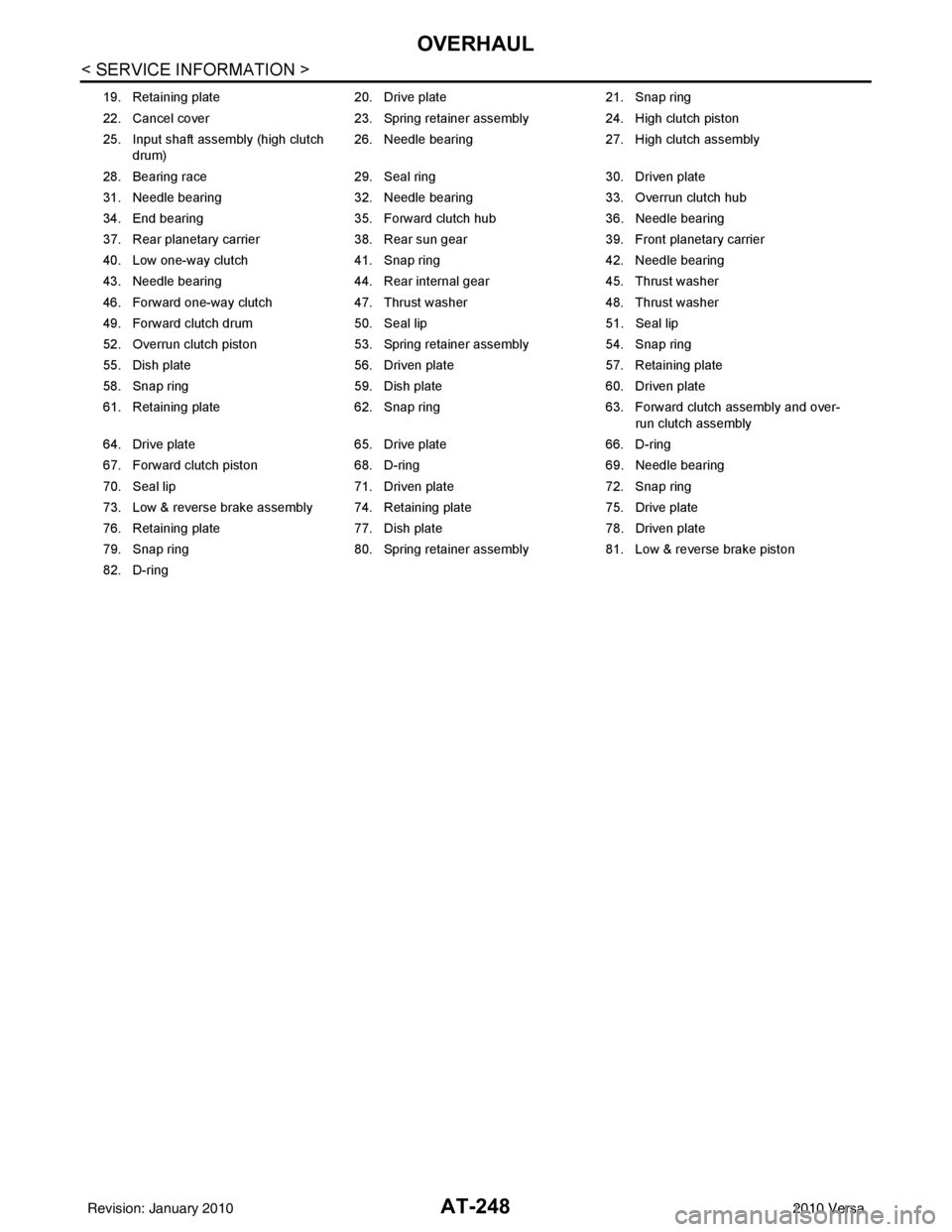

19. Retaining plate20. Drive plate21. Snap ring

22. Cancel cover 23. Spring retainer assembly 24. High clutch piston

25. Input shaft assembly (high clutch drum) 26. Needle bearing

27. High clutch assembly

28. Bearing race 29. Seal ring30. Driven plate

31. Needle bearing 32. Needle bearing33. Overrun clutch hub

34. End bearing 35. Forward clutch hub 36. Needle bearing

37. Rear planetary carrier 38. Rear sun gear 39. Front planetary carrier

40. Low one-way clutch 41. Snap ring42. Needle bearing

43. Needle bearing 44. Rear internal gear 45. Thrust washer

46. Forward one-way clutch 47. Thrust washer48. Thrust washer

49. Forward clutch drum 50. Seal lip51. Seal lip

52. Overrun clutch piston 53. Spring retainer assembly54. Snap ring

55. Dish plate 56. Driven plate57. Retaining plate

58. Snap ring 59. Dish plate60. Driven plate

61. Retaining plate 62. Snap ring63. Forward clutch assembly and over-

run clutch assembly

64. Drive plate 65. Drive plate 66. D-ring

67. Forward clutch piston 68. D-ring 69. Needle bearing

70. Seal lip 71. Driven plate 72. Snap ring

73. Low & reverse brake assembly 74. Retaining plate 75. Drive plate

76. Retaining plate 77. Dish plate78. Driven plate

79. Snap ring 80. Spring retainer assembly 81. Low & reverse brake piston

82. D-ring

Revision: January 20102010 Versa

Page 283 of 3745

AT-266

< SERVICE INFORMATION >

DISASSEMBLY

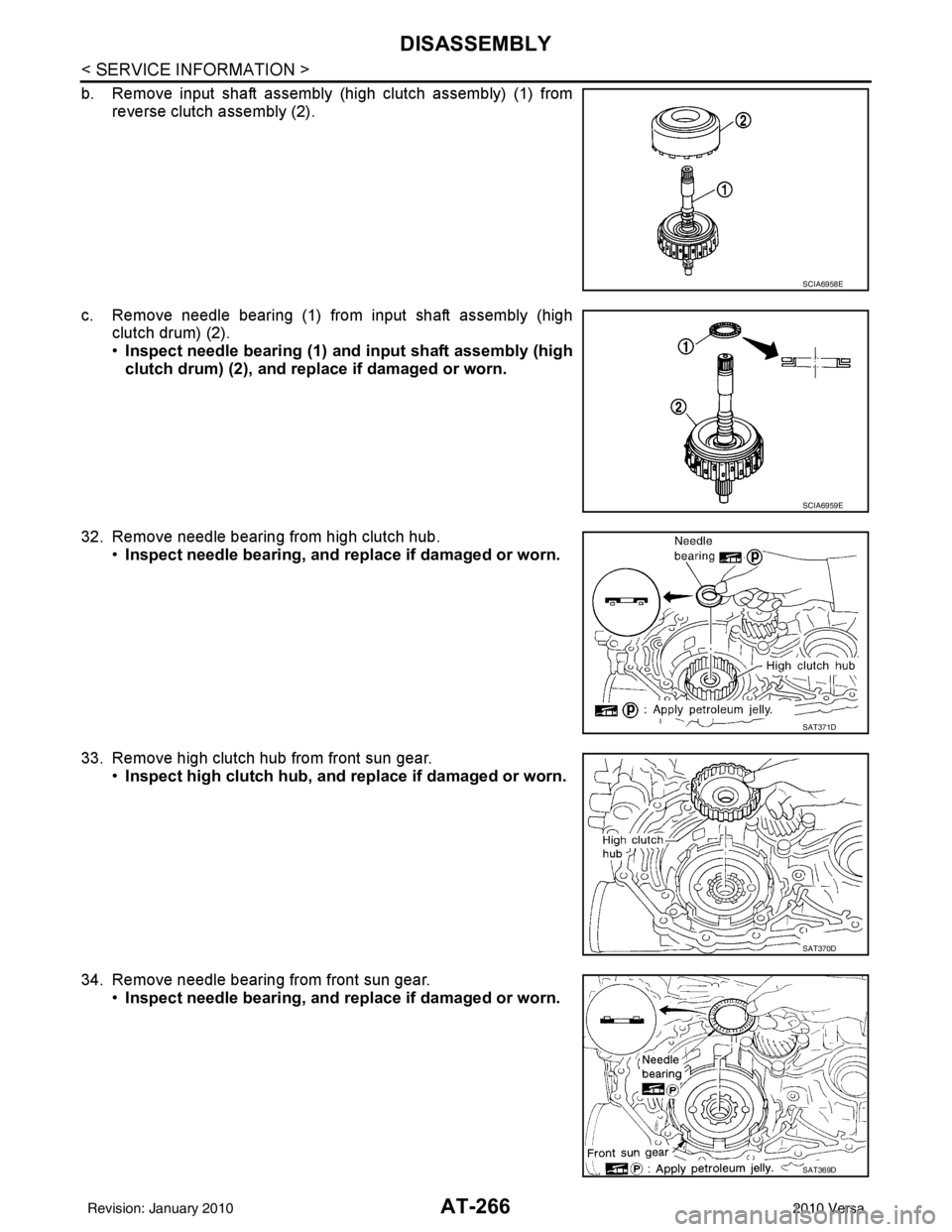

b. Remove input shaft assembly (high clutch assembly) (1) fromreverse clutch assembly (2).

c. Remove needle bearing (1) from input shaft assembly (high clutch drum) (2).

•Inspect needle bearing (1) and input shaft assembly (high

clutch drum) (2), and re place if damaged or worn.

32. Remove needle bearing from high clutch hub. •Inspect needle bearing, and replace if damaged or worn.

33. Remove high clutch hub from front sun gear. •Inspect high clutch hub, and replace if damaged or worn.

34. Remove needle bearing from front sun gear. •Inspect needle bearing, and replace if damaged or worn.

SCIA6958E

SCIA6959E

SAT371D

SAT370D

SAT369D

Revision: January 20102010 Versa

Page 284 of 3745

DISASSEMBLYAT-267

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

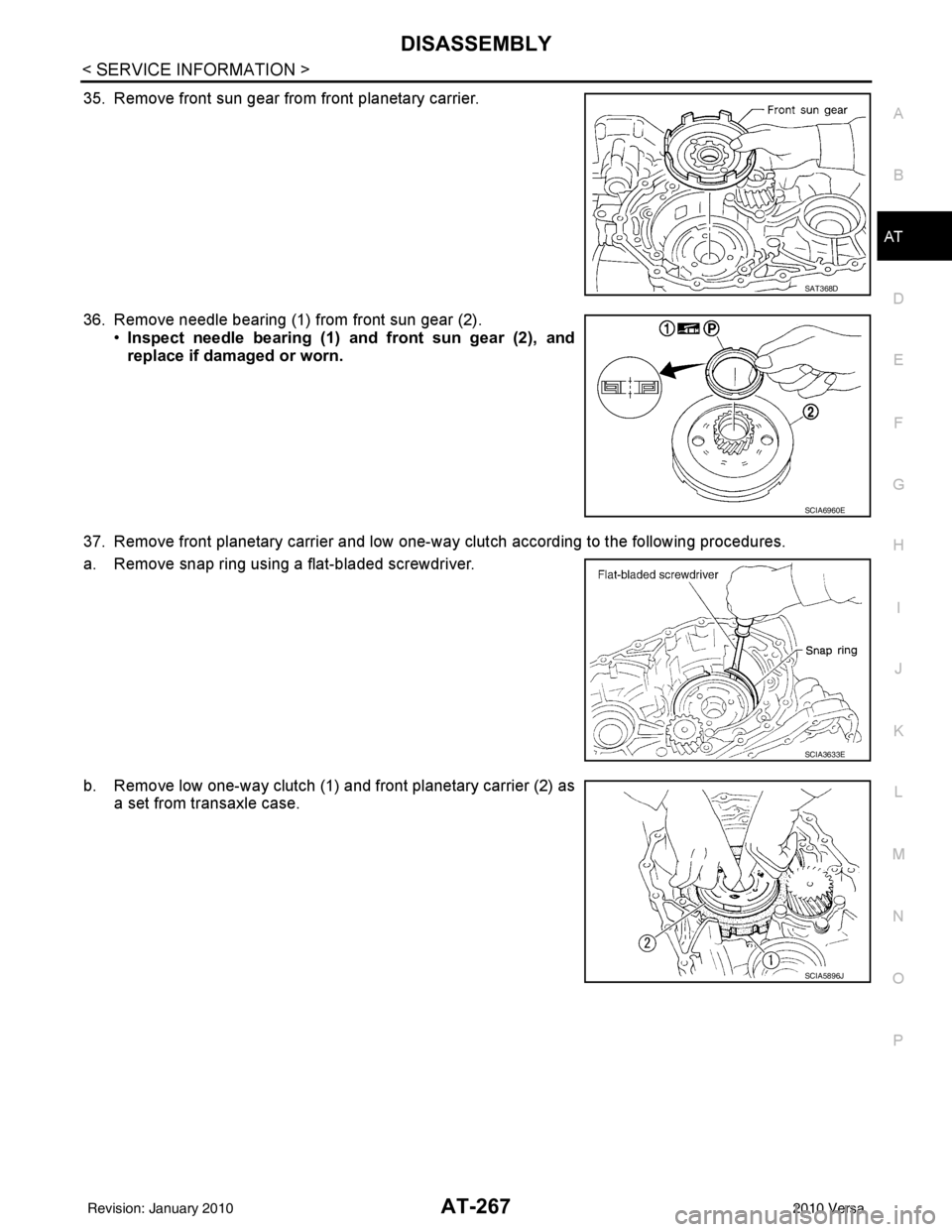

35. Remove front sun gear from front planetary carrier.

36. Remove needle bearing (1) from front sun gear (2). •Inspect needle bearing (1) an d front sun gear (2), and

replace if damaged or worn.

37. Remove front planetary carrier and low one-way clutch according to the following procedures.

a. Remove snap ring using a flat-bladed screwdriver.

b. Remove low one-way clutch (1) and front planetary carrier (2) as a set from transaxle case.

SAT368D

SCIA6960E

SCIA3633E

SCIA5896J

Revision: January 20102010 Versa

Page 285 of 3745

AT-268

< SERVICE INFORMATION >

DISASSEMBLY

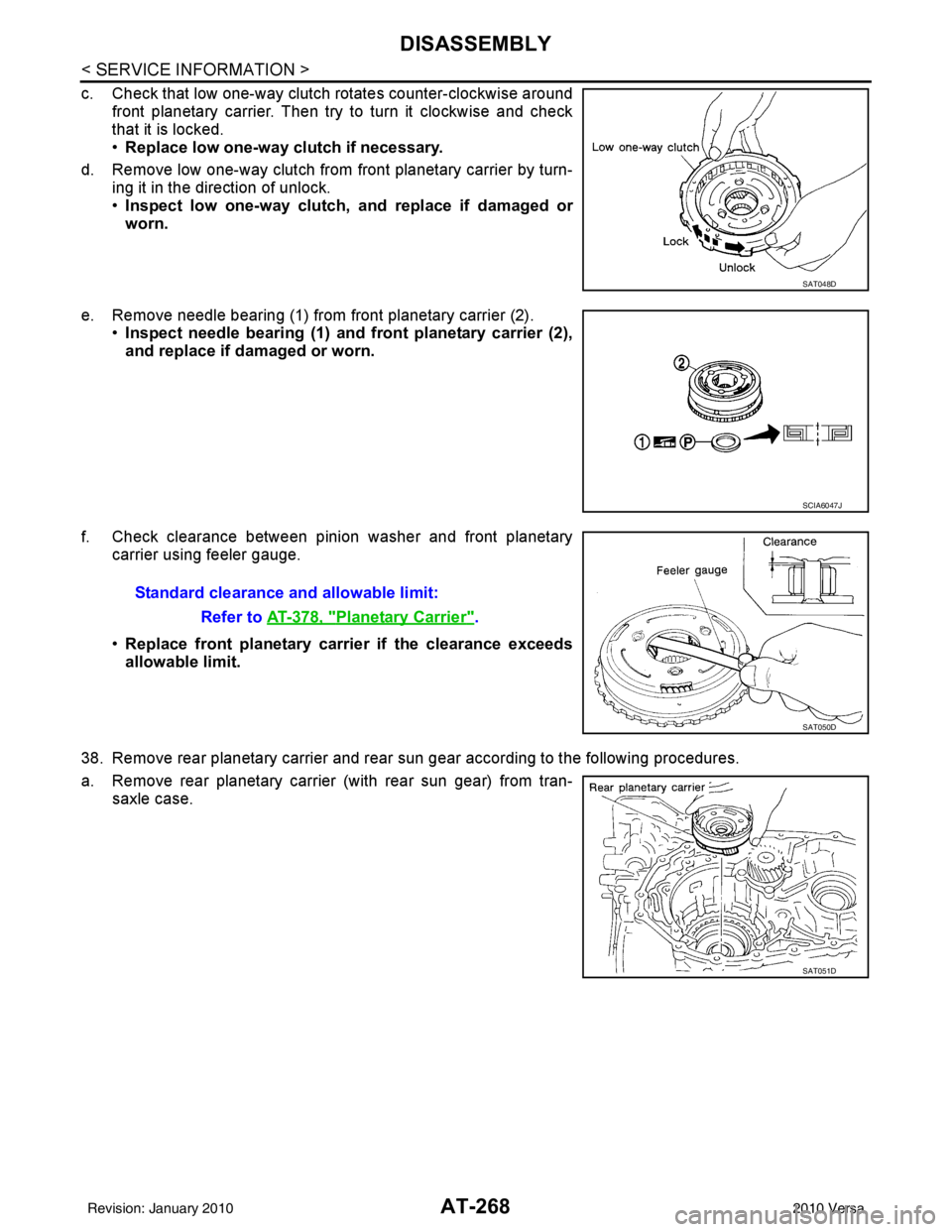

c. Check that low one-way clutch rotates counter-clockwise aroundfront planetary carrier. Then try to turn it clockwise and check

that it is locked.

•Replace low one-way clutch if necessary.

d. Remove low one-way clutch from front planetary carrier by turn- ing it in the direction of unlock.

•Inspect low one-way clutch, and replace if damaged or

worn.

e. Remove needle bearing (1) from front planetary carrier (2). •Inspect needle bearing (1) and front planetary carrier (2),

and replace if damaged or worn.

f. Check clearance between pinion washer and front planetary carrier using feeler gauge.

•Replace front planetary carrier if the clearance exceeds

allowable limit.

38. Remove rear planetary carrier and rear sun gear according to the following procedures.

a. Remove rear planetary carrier (with rear sun gear) from tran- saxle case.

SAT048D

SCIA6047J

Standard clearance and allowable limit:

Refer to AT-378, "

Planetary Carrier".

SAT050D

SAT051D

Revision: January 20102010 Versa