Front NISSAN TIIDA 2010 Service Manual Online

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2010, Model line: TIIDA, Model: NISSAN TIIDA 2010Pages: 3745, PDF Size: 73.67 MB

Page 524 of 3745

HOODBL-15

< SERVICE INFORMATION >

C

DE

F

G H

J

K L

M A

B

BL

N

O P

Installation

Installation is in the reverse order of removal.

CAUTION:

• Before installing hood hinge, apply anticorrosive

agent onto the surfaces that make contact with the

vehicle body.

• After installing, perform hood fitting adjustment. Refer to BL-13, "

Fitting Adjustment".

HOOD HINGE

Removal

1. Remove hood assembly. Refer to BL-14, "Removal and Installation".

2. Remove front fender. Refer to BL-21, "

Removal and Installation".

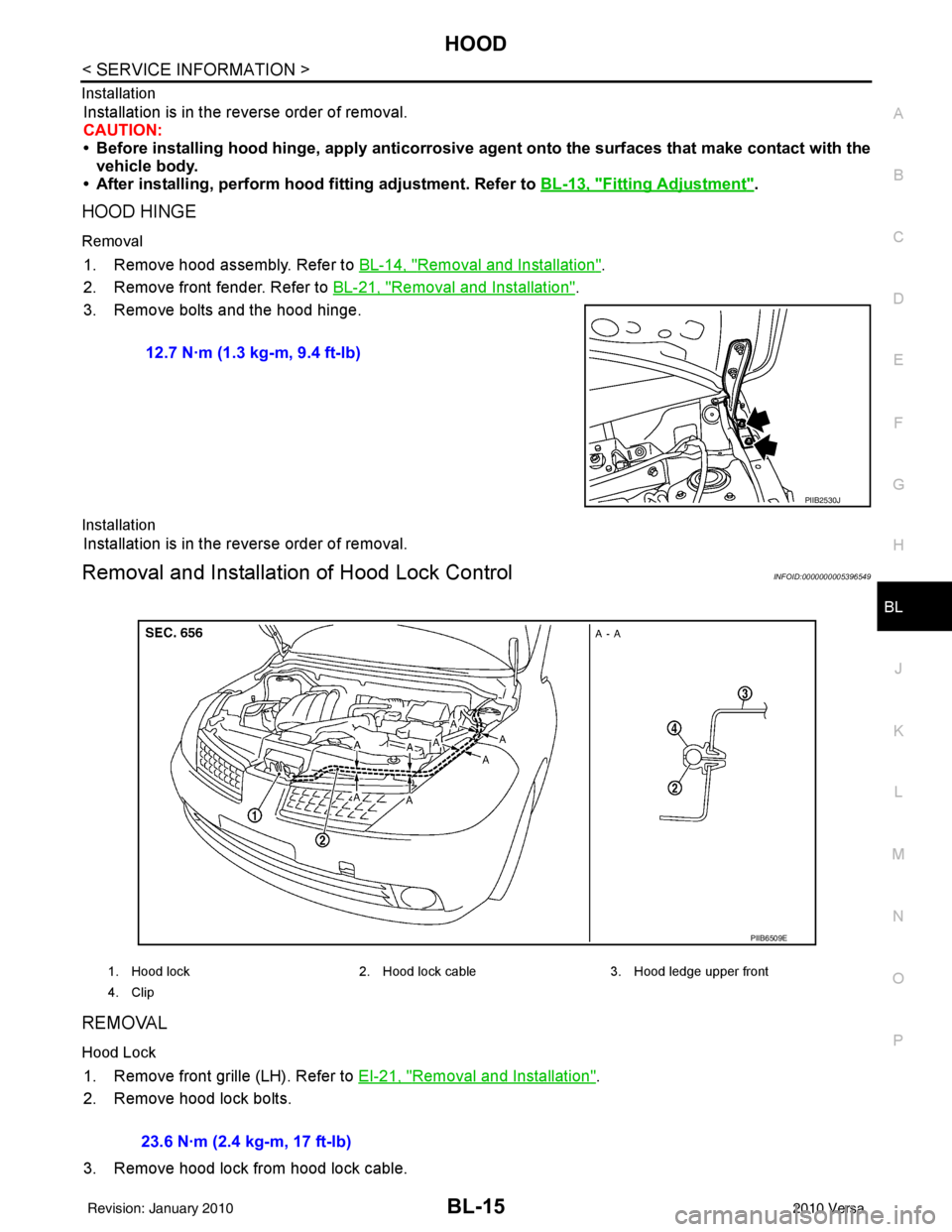

3. Remove bolts and the hood hinge.

Installation

Installation is in the reverse order of removal.

Removal and Installation of Hood Lock ControlINFOID:0000000005396549

REMOVAL

Hood Lock

1. Remove front grille (LH). Refer to EI-21, "Removal and Installation".

2. Remove hood lock bolts.

3. Remove hood lock from hood lock cable. 12.7 N·m (1.3 kg-m, 9.4 ft-lb)

PIIB2530J

1. Hood lock

2. Hood lock cable 3. Hood ledge upper front

4. Clip

PIIB6509E

23.6 N·m (2.4 kg-m, 17 ft-lb)

Revision: January 20102010 Versa

Page 525 of 3745

BL-16

< SERVICE INFORMATION >

HOOD

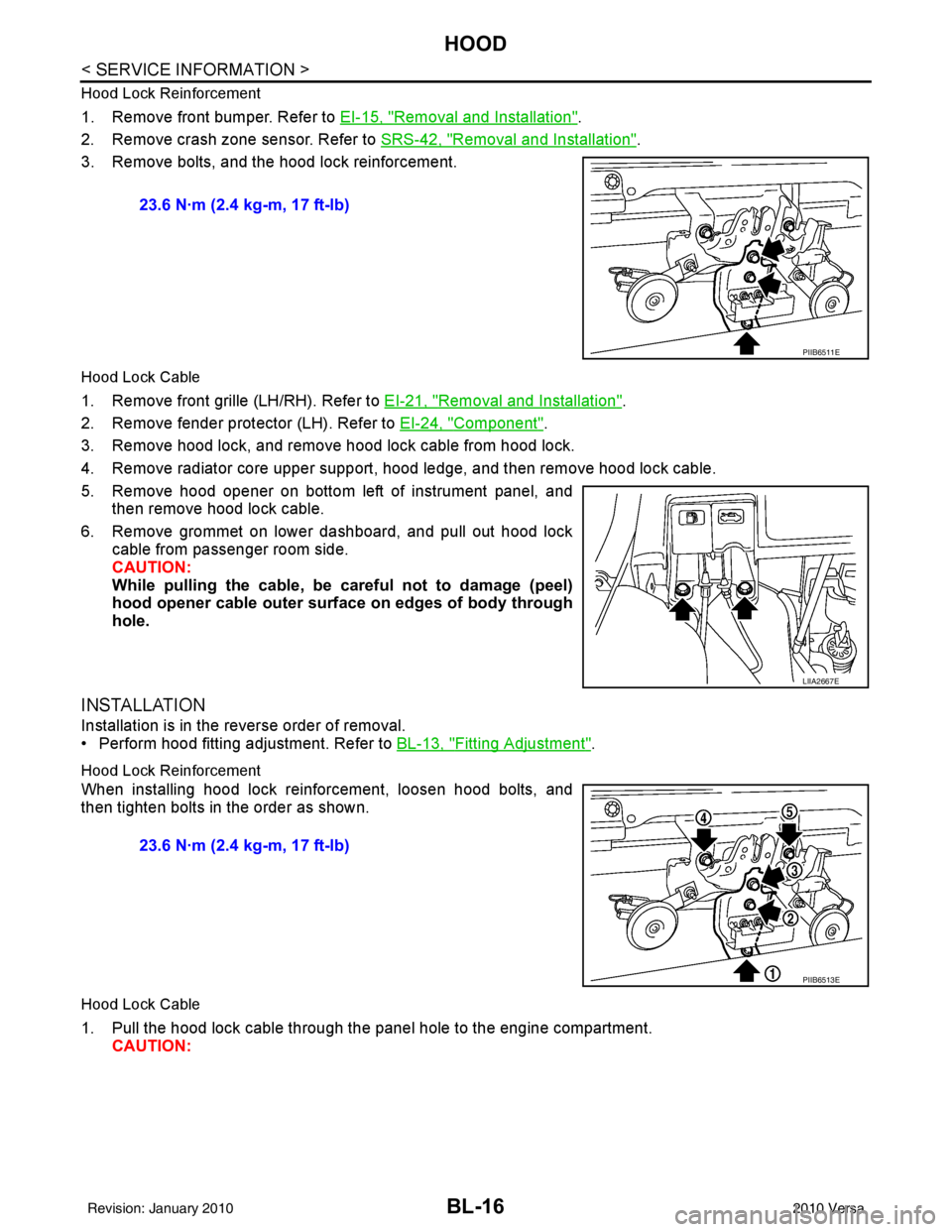

Hood Lock Reinforcement

1. Remove front bumper. Refer to EI-15, "Removal and Installation".

2. Remove crash zone sensor. Refer to SRS-42, "

Removal and Installation".

3. Remove bolts, and the hood lock reinforcement.

Hood Lock Cable

1. Remove front grille (LH/RH). Refer to EI-21, "Removal and Installation".

2. Remove fender protector (LH). Refer to EI-24, "

Component".

3. Remove hood lock, and remove hood lock cable from hood lock.

4. Remove radiator core upper support, hood ledge, and then remove hood lock cable.

5. Remove hood opener on bottom left of instrument panel, and then remove hood lock cable.

6. Remove grommet on lower dashboard, and pull out hood lock cable from passenger room side.

CAUTION:

While pulling the cable, be car eful not to damage (peel)

hood opener cable outer surface on edges of body through

hole.

INSTALLATION

Installation is in the reverse order of removal.

• Perform hood fitting adjustment. Refer to BL-13, "

Fitting Adjustment".

Hood Lock Reinforcement

When installing hood lock reinforcement, loosen hood bolts, and

then tighten bolts in the order as shown.

Hood Lock Cable

1. Pull the hood lock cable through the panel hole to the engine compartment. CAUTION: 23.6 N·m (2.4 kg-m, 17 ft-lb)

PIIB6511E

LIIA2667E

23.6 N·m (2.4 kg-m, 17 ft-lb)

PIIB6513E

Revision: January 20102010 Versa

Page 526 of 3745

HOODBL-17

< SERVICE INFORMATION >

C

DE

F

G H

J

K L

M A

B

BL

N

O P

Be careful not to bend the cable too much, keeping the

radius 100 mm (3.94 in) or more.

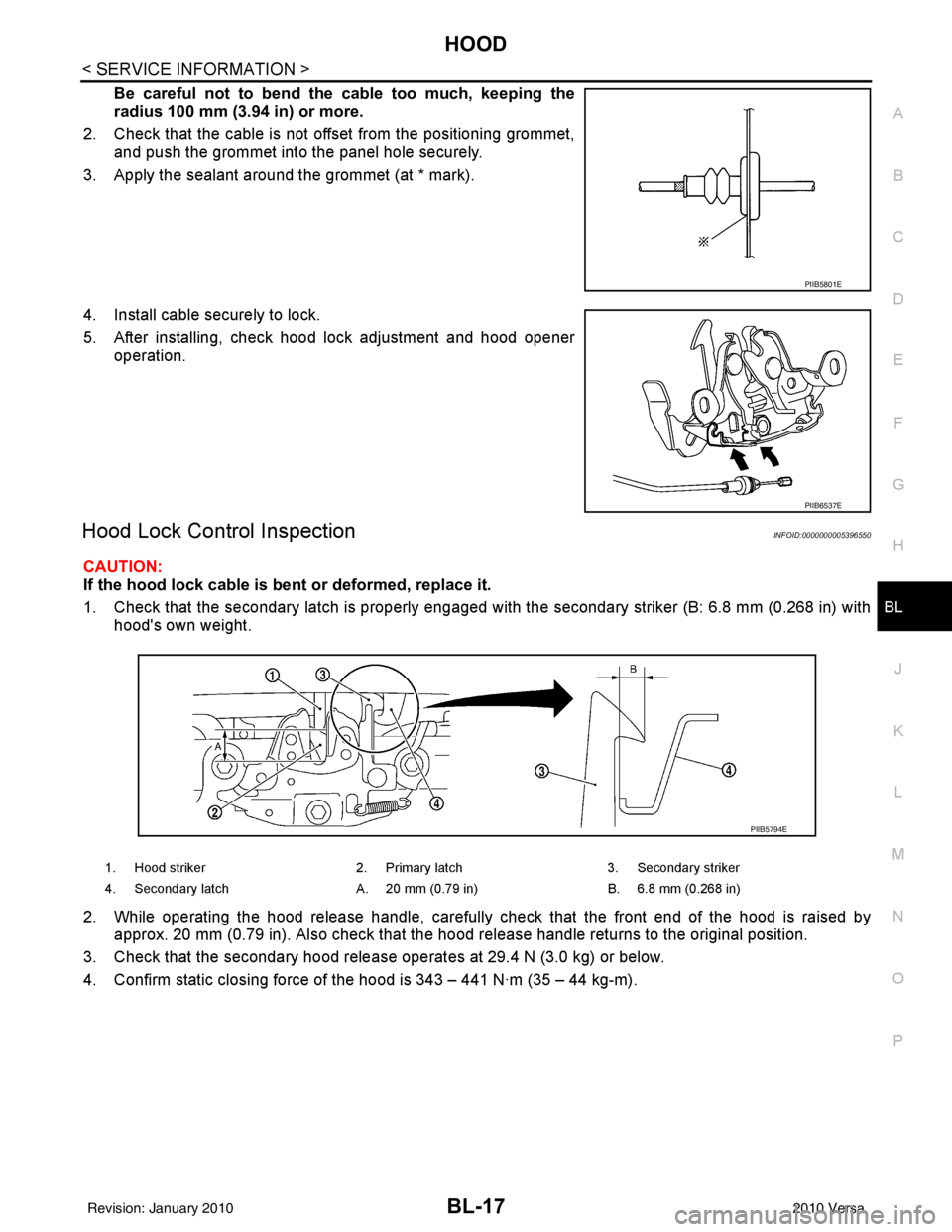

2. Check that the cable is not of fset from the positioning grommet,

and push the grommet into the panel hole securely.

3. Apply the sealant around the grommet (at * mark).

4. Install cable securely to lock.

5. After installing, check hood lock adjustment and hood opener operation.

Hood Lock Control InspectionINFOID:0000000005396550

CAUTION:

If the hood lock cable is bent or deformed, replace it.

1. Check that the secondary latch is properly engaged with the secondary striker (B: 6.8 mm (0.268 in) with

hood's own weight.

2. While operating the hood release handle, carefully check that the front end of the hood is raised by

approx. 20 mm (0.79 in). Also check that the hood release handle returns to the original position.

3. Check that the secondary hood release operates at 29.4 N (3.0 kg) or below.

4. Confirm static closing force of the hood is 343 – 441 N·m (35 – 44 kg-m).

PIIB5801E

PIIB6537E

1. Hood striker 2. Primary latch 3. Secondary striker

4. Secondary latch A. 20 mm (0.79 in) B. 6.8 mm (0.268 in)

PIIB5794E

Revision: January 20102010 Versa

Page 528 of 3745

RADIATOR CORE SUPPORTBL-19

< SERVICE INFORMATION >

C

DE

F

G H

J

K L

M A

B

BL

N

O P

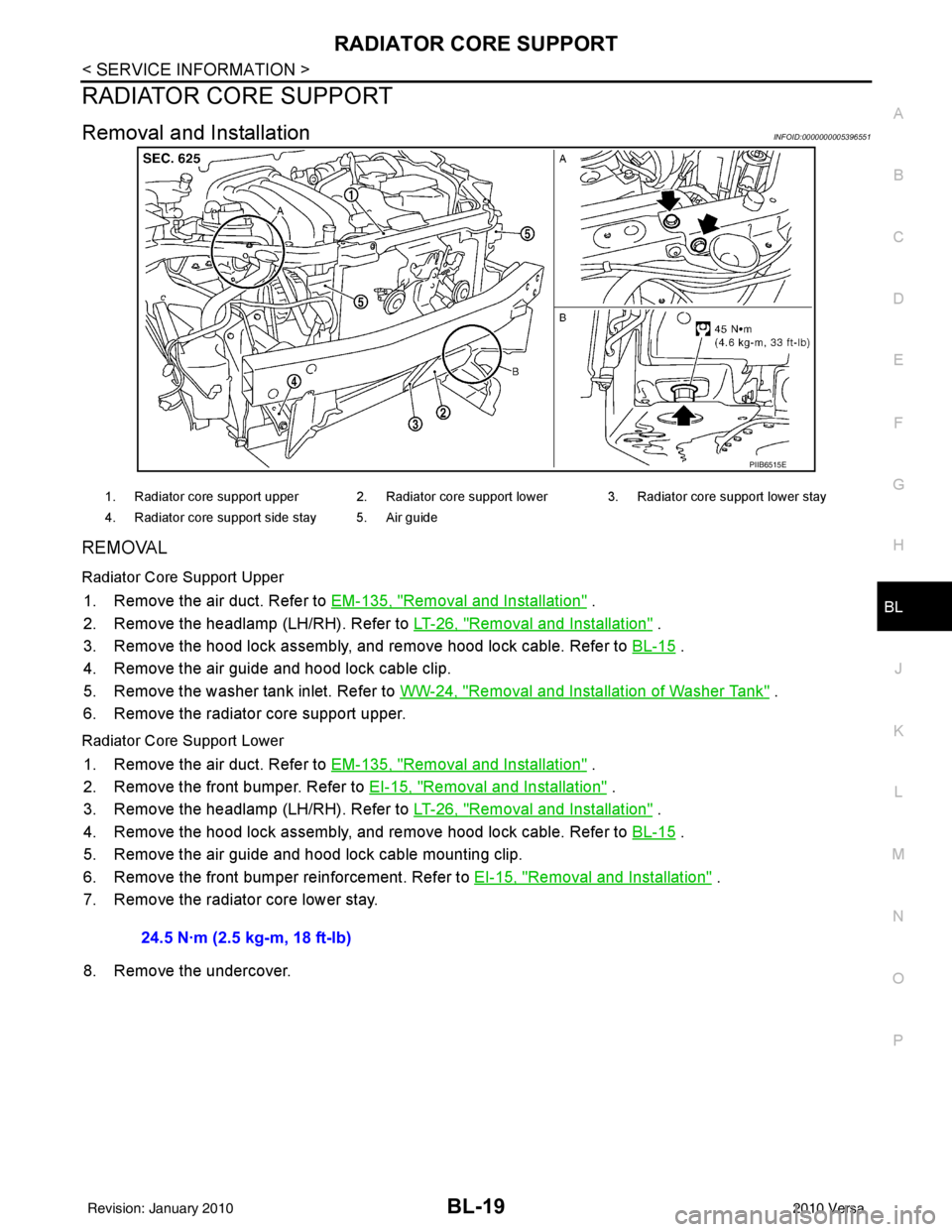

RADIATOR CORE SUPPORT

Removal and InstallationINFOID:0000000005396551

REMOVAL

Radiator Core Support Upper

1. Remove the air duct. Refer to EM-135, "Removal and Installation" .

2. Remove the headlamp (LH/RH). Refer to LT-26, "

Removal and Installation" .

3. Remove the hood lock assembly, and remove hood lock cable. Refer to BL-15

.

4. Remove the air guide and hood lock cable clip.

5. Remove the washer tank inlet. Refer to WW-24, "

Removal and Installation of Washer Tank" .

6. Remove the radiator core support upper.

Radiator Core Support Lower

1. Remove the air duct. Refer to EM-135, "Removal and Installation" .

2. Remove the front bumper. Refer to EI-15, "

Removal and Installation" .

3. Remove the headlamp (LH/RH). Refer to LT-26, "

Removal and Installation" .

4. Remove the hood lock assembly, and remove hood lock cable. Refer to BL-15

.

5. Remove the air guide and hood lock cable mounting clip.

6. Remove the front bumper reinforcement. Refer to EI-15, "

Removal and Installation" .

7. Remove the radiator core lower stay.

8. Remove the undercover.

PIIB6515E

1. Radiator core support upper 2. Radiator core support lower 3. Radiator core support lower stay

4. Radiator core support side stay 5. Air guide

24.5 N·m (2.5 kg-m, 18 ft-lb)

Revision: January 20102010 Versa

Page 530 of 3745

FRONT FENDERBL-21

< SERVICE INFORMATION >

C

DE

F

G H

J

K L

M A

B

BL

N

O P

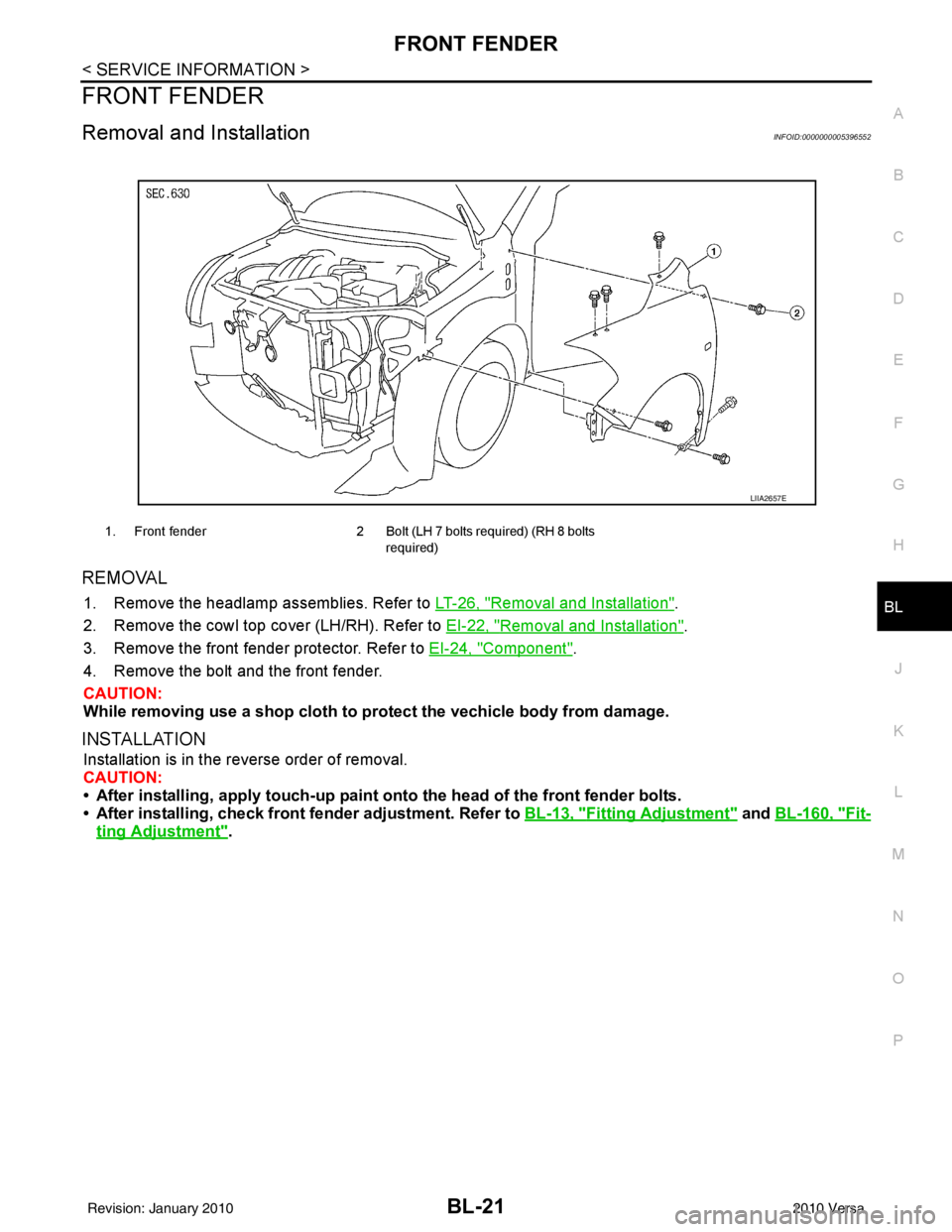

FRONT FENDER

Removal and InstallationINFOID:0000000005396552

REMOVAL

1. Remove the headlamp assemblies. Refer to LT-26, "Removal and Installation".

2. Remove the cowl top cover (LH/RH). Refer to EI-22, "

Removal and Installation".

3. Remove the front fender protector. Refer to EI-24, "

Component".

4. Remove the bolt and the front fender.

CAUTION:

While removing use a shop cloth to pr otect the vechicle body from damage.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

• After installing, apply touch-up paint on to the head of the front fender bolts.

• After installing, check front fender adjustment. Refer to BL-13, "

Fitting Adjustment" and BL-160, "Fit-

ting Adjustment".

1. Front fender 2 Bolt (LH 7 bolts required) (RH 8 bolts

required)

LIIA2657E

Revision: January 20102010 Versa

Page 531 of 3745

BL-22

< SERVICE INFORMATION >

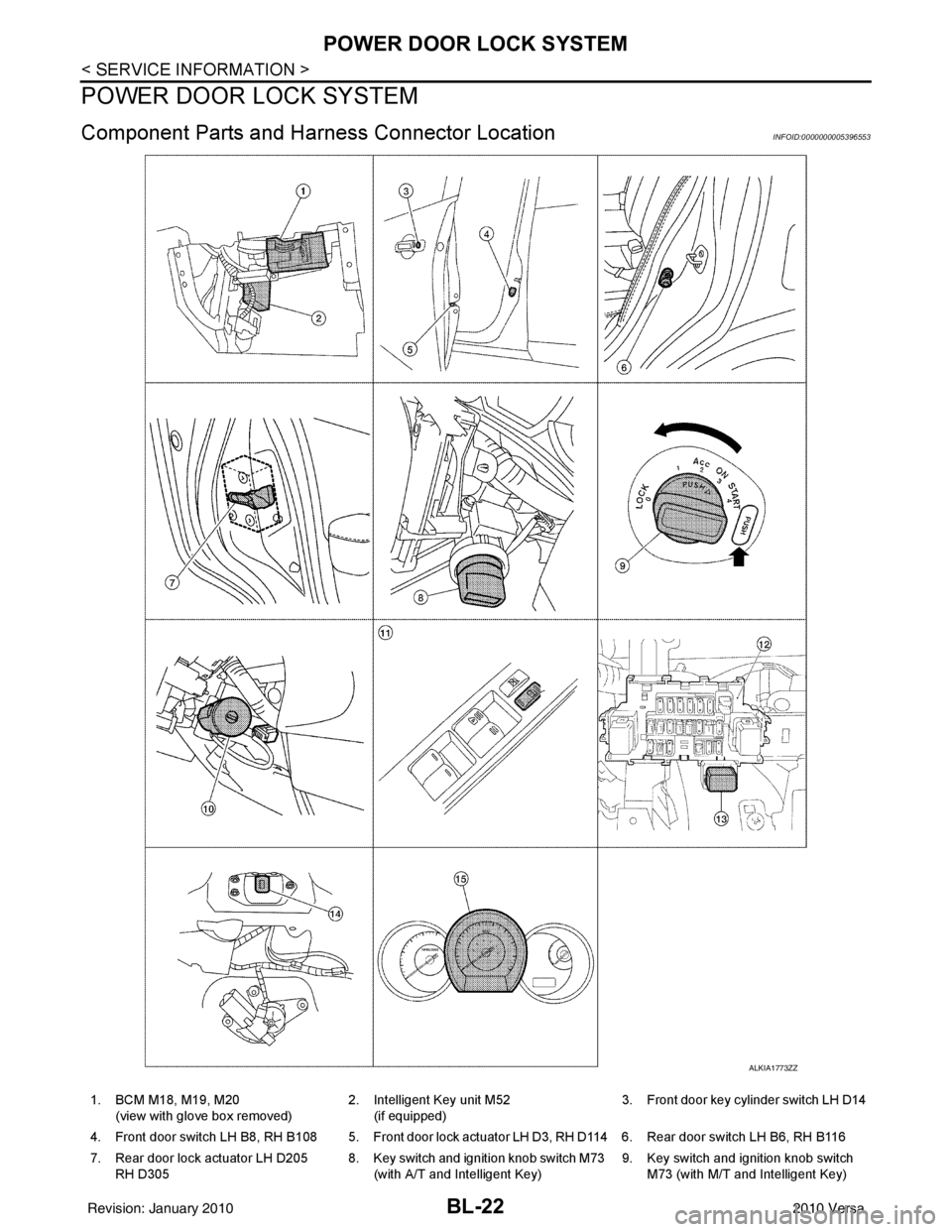

POWER DOOR LOCK SYSTEM

POWER DOOR LOCK SYSTEM

Component Parts and Harness Connector LocationINFOID:0000000005396553

ALKIA1773ZZ

1. BCM M18, M19, M20

(view with glove box removed) 2. Intelligent Key unit M52

(if equipped) 3. Front door key cylinder switch LH D14

4. Front door switch LH B8, RH B108 5. Front door lock actuator LH D3, RH D114 6. Rear door switch LH B6, RH B116

7. Rear door lock actuator LH D205 RH D305 8. Key switch and ignition knob switch M73

(with A/T and Intelligent Key) 9. Key switch and ignition knob switch

M73 (with M/T and Intelligent Key)

Revision: January 20102010 Versa

Page 532 of 3745

POWER DOOR LOCK SYSTEMBL-23

< SERVICE INFORMATION >

C

DE

F

G H

J

K L

M A

B

BL

N

O P

System DescriptionINFOID:0000000005396554

Power is supplied at all times

• through 40A fusible link (letter g , located in the fuse and fusible link box)

• to BCM terminal 70

• through 10A fuse [No. 8, located in the fuse block (J/B)]

• to BCM terminal 57

• through 10A fuse [No. 14, located in the fuse block (J/B)]

• to key switch terminal 2 (without Intelligent Key system)

• through 10A fuse [No. 31, located in the fuse block (J/B)]

• to key switch and ignition knob switch terminals 2 and 4 (with Intelligent Key system).

When key switch is ON (key is inserted in ignition key cylinder), power is supplied

• through key switch terminal 1 (without Intelligent Key system) or key switch and ignition knob terminal 1 (with Intelligent Key system)

• to BCM terminal 37.

Ground is supplied

• to BCM terminal 67

• through body grounds M57 and M61.

LOCK OPERATION

When the door is locked with main power window and door lock/unlock switch, ground is supplied

• to BCM terminal 45

• through main power window and door lock and unlock switch terminals 17 and 18

• through body grounds M57 and M61.

When the door is locked with power window and door lock/unlock switch RH, ground is supplied

• to BCM terminal 45

• through power window and door lock and unlock switch RH terminals 1 and 3

• through body grounds M57 and M61.

When the door is locked with front door ke y cylinder switch LH, ground is supplied

• to BCM terminal 8

• through front door key cylinder switch LH terminals 1 and 2

• through body grounds M57 and M61.

UNLOCK OPERATION

When the door is unlocked with main power window and door lock/unlock switch, ground is supplied

• to BCM terminal 46

• through main power window and door lock/unlock switch terminals 6 and 17

• through body grounds M57 and M61.

When the door is unlocked with power window and door lock/unlock switch RH, ground is supplied

• to BCM terminal 46

• through power window and door lock and unlock switch RH terminals 2 and 3

• through body grounds M57 and M61.

When the door is unlocked with front door ke y cylinder switch LH, ground is supplied

• to BCM terminal 7

• through front door key cylinder switch LH terminals 2 and 3

• through body grounds M57 and M61.

When the front door switch LH is ON (door is OPEN), ground is supplied

• to BCM terminal 47

• through front door switch LH terminal 2

• through front door switch LH case ground.

When the front door switch RH is ON (door is OPEN), ground is supplied

• to BCM terminal 12

• through front door switch RH terminal 2

• through front door switch RH case ground.

10. Key switch and key lock solenoid M27

(without Intelligent key) 11. Main power window and door lock/un-

lock switch D7, D8

Power window and door lock/unlock

switch RH D105 12. Fuse block (with Intelligent Key)

(view with instrument panel LH re-

moved)

13. Passenger select unlock relay M2 (with Intelligent Key) 14. Back door lock assembly (back door

switch) D405 (hatchback view with back

door open) 15. Combination meter M24

Revision: January 20102010 Versa

Page 533 of 3745

BL-24

< SERVICE INFORMATION >

POWER DOOR LOCK SYSTEM

When the rear door switch LH is ON (door is OPEN), ground is supplied

• to BCM terminal 48

• through rear door switch LH terminal 1

• through rear door switch LH case ground.

When the rear door switch RH is ON (door is OPEN), ground is supplied

• to BCM terminal 13

• through rear door switch RH terminal 1

• through rear door switch RH case ground.

When the back door switch (hatchback) is ON (back door is OPEN), ground is supplied

• to BCM terminal 43

• through back door switch terminals 3 and 4

• through body grounds B117, B132 and D402.

OUTLINE

Functions available by operating the inside door lock and unlock switches

• Interlocked with the locking operation of door lock and unlock switch, door lock actuators of all doors and

trunk (sedan) are locked.

• Interlocked with the unlocking operation of door lock and unlock switch, door lock actuators of all doors and

trunk (sedan) are unlocked.

Functions available by operating t he front door key cylinder switch LH

• Interlocked with the locking operation of front door key cylinder switch LH, door lock actuators of all doors

and trunk (sedan) are locked.

• When front door key cylinder switch LH is unlo cked, front door lock actuator LH is unlocked.

• When front door key cylinder switch LH is unlocked for the second time within 5 seconds after the first oper- ation, door lock actuators on all doors and trunk (sedan) are unlocked.

Key reminder door system

When door lock and unlock switch is operated to lock doors with ignition key inserted in key cylinder and any

door open, all door lock actuators are locked and then unlocked.

AUTOMATIC DOOR LOCKS (LOCK OPERATION)

The interlock door lock function is the function that locks all doors linked with the vehicle speed.

Vehicle Speed Sensing Auto Door Lock*1

All doors are locked when the vehicle speed reaches 24 km/h (15 MPH) or more.

BCM outputs the lock signal to all door lock actuators when it detects that the ignition switch is turned ON, all

doors are closed and the vehicle speed received from the combination meter via CAN communication

becomes 15 MPH (24 km/h) or more.

If a door is opened and closed at any time during one ignition cycle (OFF → ON), even after initial auto door

lock has taken place, the BCM will relock all doors when the vehicle speed reaches 15 MPH (24 km/h) or more

again.

Setting change of Automatic Door Locks (LOCK) Function

The lock operation setting of the autom atic door locks function can be changed.

With CONSULT-III

The ON/OFF switching of the automatic door locks (LOC K) function and the type selection of the automatic

door locks (LOCK) function can be performed at the WO RK SUPPORT setting of CONSULT-III. Refer to BL-

41, "CONSULT-III Function (BCM)".

Without CONSULT- III

The automatic door locks (LOCK) function can be swit ched ON/OFF by performing the following operation.

1. Close all doors (door switch OFF).

2. Turn ignition switch ON.

3. Within 20 seconds of turning the ignition switch ON, press and hold the door lock and unlock switch to the LOCK position for more than 5 seconds.

4. The switching is completed when the hazard lamps blink.

5. The ignition switch must be turned OFF and ON again between each setting change.

OFF → ON : 2 blinks

ON → OFF : 1 blink

Revision: January 20102010 Versa

Page 546 of 3745

POWER DOOR LOCK SYSTEMBL-37

< SERVICE INFORMATION >

C

DE

F

G H

J

K L

M A

B

BL

N

O P

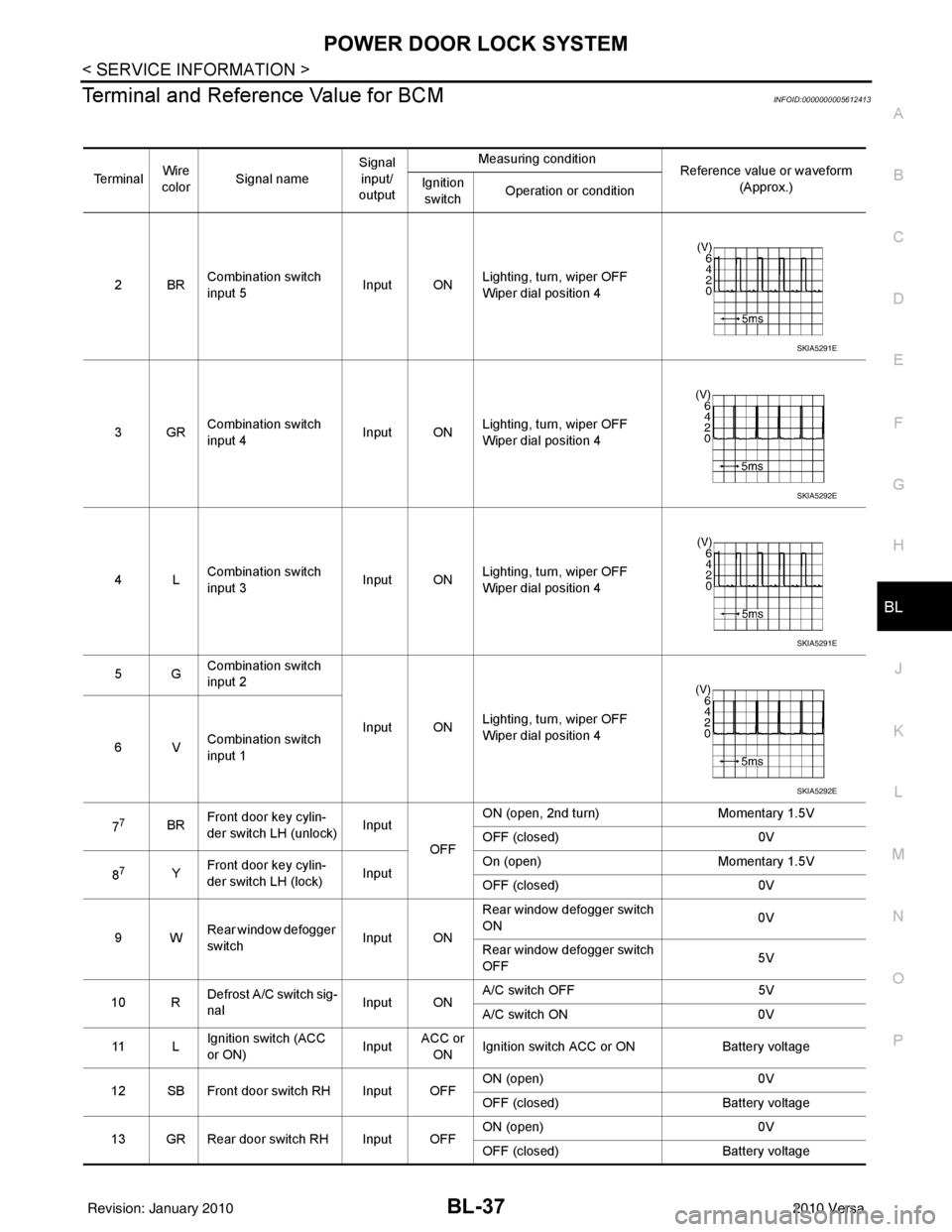

Terminal and Reference Value for BCMINFOID:0000000005612413

Te r m i n a l Wire

color Signal name Signal

input/

output Measuring condition

Reference value or waveform

(Approx.)

Ignition

switch Operation or condition

2BR Combination switch

input 5

Input ONLighting, turn, wiper OFF

Wiper dial position 4

3GR Combination switch

input 4 Input ONLighting, turn, wiper OFF

Wiper dial position 4

4L Combination switch

input 3

Input ONLighting, turn, wiper OFF

Wiper dial position 4

5G Combination switch

input 2

Input ONLighting, turn, wiper OFF

Wiper dial position 4

6V Combination switch

input 1

7

7BR Front door key cylin-

der switch LH (unlock) Input

OFFON (open, 2nd turn)

Momentary 1.5V

OFF (closed) 0V

8

7Y Front door key cylin-

der switch LH (lock) InputOn (open)

Momentary 1.5V

OFF (closed) 0V

9W Rear window defogger

switch Input ONRear window defogger switch

ON

0V

Rear window defogger switch

OFF 5V

10 R Defrost A/C switch sig-

nal

Input ONA/C switch OFF

5V

A/C switch ON 0V

11 L Ignition switch (ACC

or ON) InputACC or

ON Ignition switch ACC or ON

Battery voltage

12 SB Front door switch RH Input OFF ON (open)

0V

OFF (closed) Battery voltage

13 GR Rear door switch RH Input OFF ON (open)

0V

OFF (closed) Battery voltage

SKIA5291E

SKIA5292E

SKIA5291E

SKIA5292E

Revision: January 20102010 Versa

Page 547 of 3745

BL-38

< SERVICE INFORMATION >

POWER DOOR LOCK SYSTEM

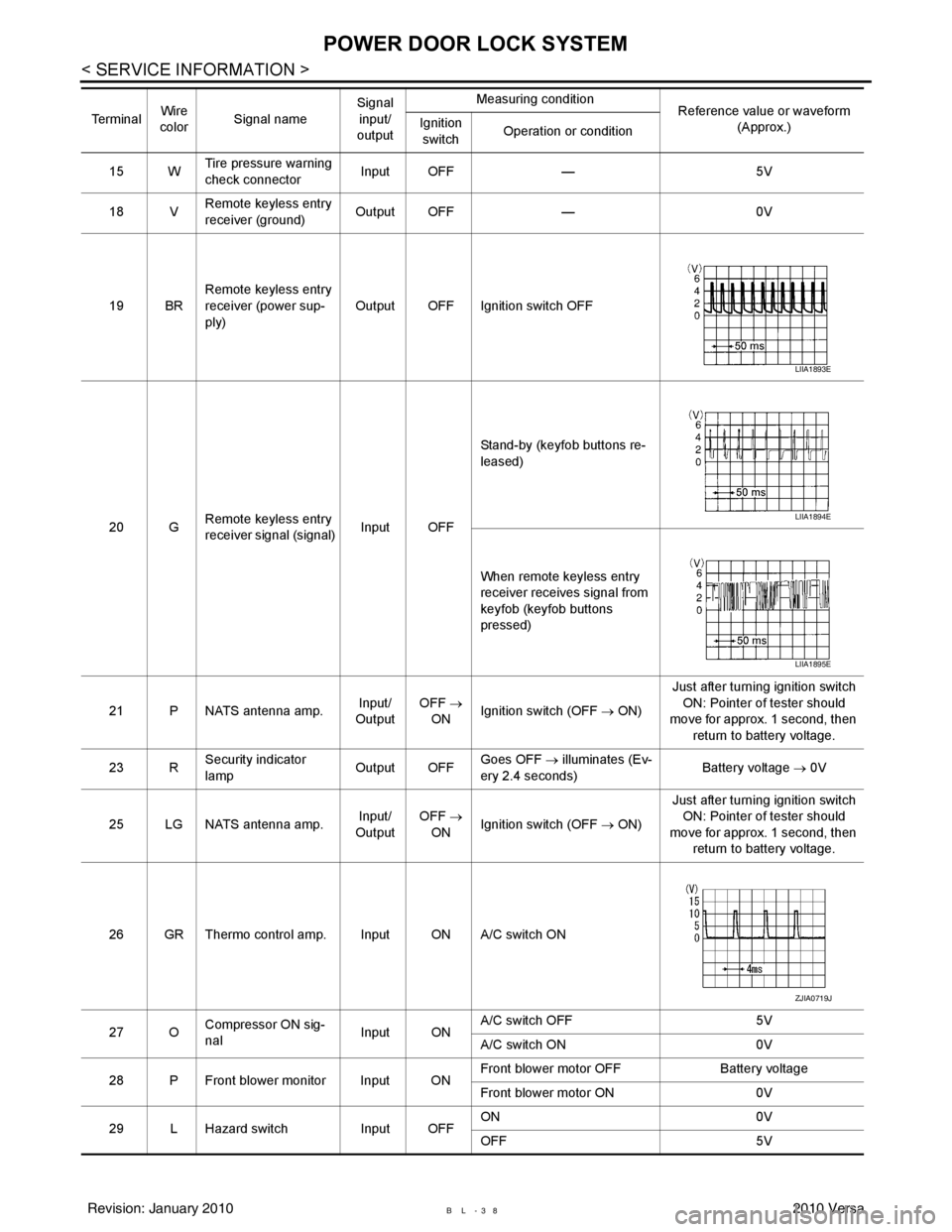

15 WTire pressure warning

check connector

Input OFF

—5V

18 V Remote keyless entry

receiver (ground) Output OFF

—0V

19 BR Remote keyless entry

receiver (power sup-

ply) Output OFF Ignition switch OFF

20 G Remote keyless entry

receiver signal (signal)

Input OFFStand-by (keyfob buttons re-

leased)

When remote keyless entry

receiver receives signal from

keyfob (keyfob buttons

pressed)

21 P NATS antenna amp. Input/

Output OFF

→

ON Ignition switch (OFF

→ ON)Just after turning ignition switch

ON: Pointer of tester should

move for approx. 1 second, then

return to battery voltage.

23 R Security indicator

lamp Output OFF

Goes OFF

→ illuminates (Ev-

ery 2.4 seconds) Battery voltage

→ 0V

25 LG NATS antenna amp. Input/

Output OFF

→

ON Ignition switch (OFF

→ ON)Just after turning ignition switch

ON: Pointer of tester should

move for approx. 1 second, then return to battery voltage.

26 GR Thermo control amp. Input ON A/C switch ON

27 O Compressor ON sig-

nal Input ONA/C switch OFF

5V

A/C switch ON 0V

28 P Front blower monitor Input ON Front blower motor OFF

Battery voltage

Front blower motor ON 0V

29 L Hazard switch Input OFFON

0V

OFF 5V

Te r m i n a l

Wire

color Signal name Signal

input/

output Measuring condition

Reference value or waveform

(Approx.)

Ignition

switch Operation or condition

LIIA1893E

LIIA1894E

LIIA1895E

ZJIA0719J

Revision: January 20102010 Versa