233 NISSAN TIIDA 2010 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2010, Model line: TIIDA, Model: NISSAN TIIDA 2010Pages: 3745, PDF Size: 73.67 MB

Page 21 of 3745

AT-4

Transmission Range Switch ..................................225

Output Speed Sensor ............................................227

Input Speed Sensor ...............................................228

Differential Side Oil Seal ........................................229

AIR BREATHER HOSE ...................................232

Removal and Installation ..................................... ..232

TRANSAXLE ASSEMBLY ..............................233

Removal and Installation ..................................... ..233

OVERHAUL .................................................... .237

Component .......................................................... ..237

Oil Channel ............................................................250

Location of Adjusting Shims, Needle Bearings and

Thrust Washers .....................................................

253

Location of Snap Rings .........................................255

DISASSEMBLY .............................................. .257

Disassembly ........................................................ ..257

REPAIR FOR COMPONENT PARTS ..............275

Manual Shaft ....................................................... ..275

Oil Pump ................................................................278

Control Valve Assembly ........................................281

Control Valve Upper Body .....................................290

Control Valve Lower Body ................................... ..294

Reverse Clutch ......................................................297

High Clutch ............................................................302

Forward and Overrun Clutches .............................307

Low & Reverse Brake ............................................314

Rear Internal Gear and Forward Clutch Hub .........318

Output Shaft, Output Gear, Idler Gear, Reduction

Pinion Gear and Bearing Retainer .........................

322

Band Servo Piston Assembly ................................331

Final Drive .............................................................337

ASSEMBLY .....................................................344

Assembly (1) ........................................................ ..344

Adjustment (1) (For HR16DE Engine Models) ..... .345

Adjustment (1) (For MR18DE Engine Models) .....349

Assembly (2) .........................................................355

Adjustment (2) .......................................................360

Assembly (3) .........................................................363

SERVICE DATA AND SPECIFICATIONS

(SDS) ................................................................

373

General Specification ........................................... .373

Vehicle Speed at Which Gear Shifting Occurs .....373

Vehicle Speed at When Lock-up Occurs/Releases

.

373

Stall Speed ............................................................374

Line Pressure ........................................................374

Adjusting shims, Needle Bearings, Thrust Wash-

ers and Snap Rings ..............................................

374

Control Valves .......................................................375

Accumulator ..........................................................376

Clutches and Brakes .............................................376

Final Drive .............................................................378

Planetary Carrier ...................................................378

Oil Pump ...............................................................378

Input Shaft .............................................................378

Reduction Pinion Gear ..........................................378

Band Servo ...........................................................378

Output Shaft ..........................................................379

Bearing Retainer ...................................................379

Total End Play ...................................................... .379

Reverse Clutch End Play ......................................379

Removal and Installation .......................................379

Shift Solenoid Valves ........................................... .379

Solenoid Valves ....................................................380

A/T Fluid Temperature Sensor ..............................380

Output Speed Sensor ...........................................380

Dropping Resistor .................................................380

Input Speed Sensor ..............................................380

Revision: January 20102010 Versa

Page 56 of 3745

ON BOARD DIAGNOSTIC (OBD) SYSTEMAT-39

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

ON BOARD DIAGNOSTIC (OBD) SYSTEM

IntroductionINFOID:0000000005397230

A/T system has two self-diagnostic systems.

The first is emission-related on board diagnostic system (OBD-II) performed by the TCM in combination with

the ECM. The malfunction is indicated by the MIL (malf unction indicator lamp) and is stored as a DTC in the

ECM memory but not the TCM memory.

The second is the TCM original self-diagnosis indicated by the OD OFF indicator lamp. The malfunction is

stored in the TCM memory. The detected items are ov erlapped with OBD-II self-diagnostic items. For detail,

refer to AT-77, "

CONSULT-III Function (TRANSMISSION)" .

OBD-II Function for A/T SystemINFOID:0000000005397231

The ECM provides emission-related on board diagnostic (O BD-II) functions for the A/T system. One function

is to receive a signal from the TCM used with OBD-rela ted parts of the A/T system. The signal is sent to the

ECM when a malfunction occurs in the corresponding OBD-re lated part. The other function is to indicate a

diagnostic result by means of the MIL (malfunction indica tor lamp) on the instrument panel. Sensors, switches

and solenoid valves are used as sensing elements.

The MIL automatically illuminates in One or Two Trip Detection Logic when a malfunction is sensed in relation

to A/T system parts.

One or Two Trip Detection Logic of OBD-IIINFOID:0000000005397232

ONE TRIP DETECTION LOGIC

If a malfunction is sensed during the first test drive, the MIL will illuminate and the malfunction will be stored in

the ECM memory as a DTC. The TCM is not provided with such a memory function.

TWO TRIP DETECTION LOGIC

When a malfunction is sensed during the first test drive, it is stored in the ECM memory as a 1st trip DTC

(diagnostic trouble code) or 1st trip freeze frame data. At this point, the MIL will not illuminate. — 1st trip

If the same malfunction as that experienced during the fi rst test drive is sensed during the second test drive,

the MIL will illuminate. — 2nd trip

The “trip” in the “One or Two Trip Detection Logic” m eans a driving mode in which self-diagnosis is performed

during vehicle operation.

OBD-II Diagnostic Trouble Code (DTC)INFOID:0000000005397233

HOW TO READ DTC AND 1ST TRIP DTC

DTC and 1st trip DTC can be read by the following methods.

( with CONSULT-III or GST) CONSULT-III or GST (Generic Scan Tool) Examples: P0705, P0720 etc.

These DTC are prescribed by SAE J2012.

(CONSULT-III also displays the malfunctioning component or system.)

• 1st trip DTC No. is the same as DTC No.

• Output of the diagnostic trouble code indicates that the indicated circuit has a malfunction. How-

ever, in case of the Mode II and GST, they do not indicate whether the malfunction is still occurring or

occurred in the past and returned to normal.

CONSULT-III can identify them as shown below, therefore, CONS ULT-III (if available) is recom-

mended.

DTC or 1st trip DTC of a malfunction is displayed in SELF-DIAGNOSTIC RESULTS mode for “ENGINE” with

CONSULT-III. Time data indicates how many times the vehicle was driven after the last detection of a DTC.

If the DTC is being detected curr ently, the time data will be “0”.

If a 1st trip DTC is stored in the ECM, the time data will be “1t”.

Freeze Frame Data and 1st Trip Freeze Frame Data

The ECM has a memory function, which stores the driv ing condition such as fuel system status, calculated

load value, engine coolant temperature, short term f uel trim, long term fuel trim, engine speed and vehicle

speed at the moment the ECM detects a malfunction.

Revision: January 20102010 Versa

Page 114 of 3745

P0710 TRANSMISSION FLUID TEMPERATURE SENSOR AAT-97

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

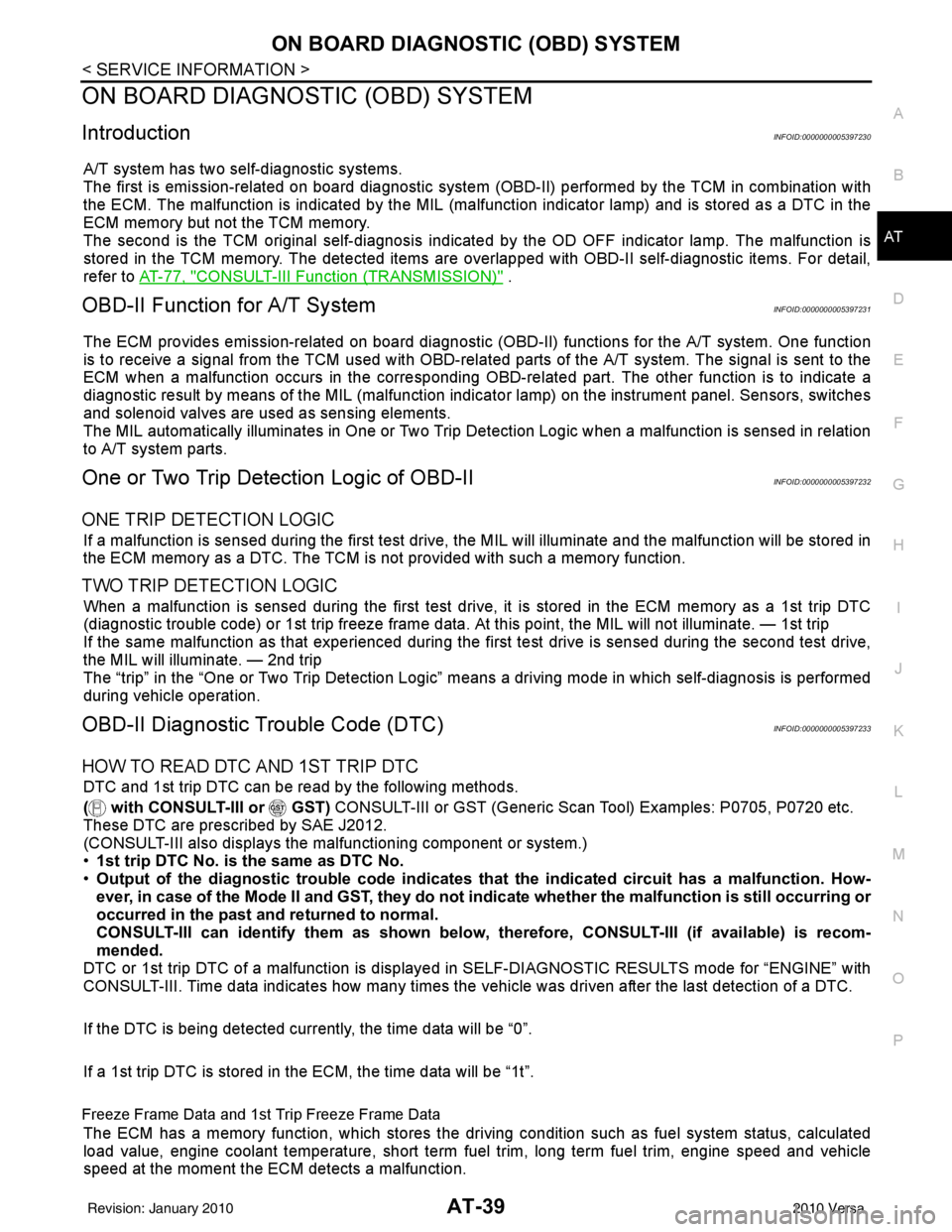

With CONSULT-III

1. Start engine.

2. Select “TCM INPUT SIGNALS” in “DATA MONI TOR” mode for “TRANSMISSION” with CONSULT-III.

3. Read out the value of “FLUID TEMP SE”.

Without CONSULT-III

1. Start engine.

2. Check voltage TCM connector terminals while warming up A/T.

OK or NG

OK >> GO TO 7.

NG >> GO TO 2.

2.DETECT MALFUNCTIONING ITEMS

Check the following.

• Harness for short or open between TCM, ECM and terminal cord assembly

• Ground circuit for ECM, Refer to EC-115

(HR16DE), EC-633 (MR18DE).

OK or NG

OK >> GO TO 3.

NG >> Repair or replace damaged parts.

3. CHECK FLUID TEMPERATURE SENSOR CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect the TCM connector.

3. Check resistance between TCM connector terminals.

OK or NG

OK >> GO TO 7.

NG >> GO TO 4.

4. CHECK HARNESS BETWEEN TCM AND TERMINAL CORD ASSEMBLY HARNESS CONNECTOR

1. Turn ignition switch OFF.

2. Disconnect terminal cord assemb ly harness connector and TCM connector.

Item name Condition Display value

(Approx.)

FLUID TEMP

SE When A/T fluid temperature is 20

°C (68 °F). 1.5 V

When A/T fluid temperature is 80 °C (176 °F). 0.5 V

Item Connec-

tor Terminal

Condition Judge-

ment stan- dard

(Approx.)

A/T fluid

temperature

sensor E32 47 - 42 When A/T fluid tempera-

ture is 20 °C (68 °F). 1.5 V

When A/T fluid tempera- ture is 80 °C (176 °F). 0.5 V

SCIA2658E

Item Connector Terminal Te m p e r a -

ture [ °C ( °F)] Resistance

(Approx.)

A/T fluid

temperature

sensor E32

47 - 42 20 (68) 2.5 k

Ω

80 (176) 0.3 k Ω

SCIA2338E

Revision: January 20102010 Versa

Page 176 of 3745

BATT/FLUID TEMP SENAT-159

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

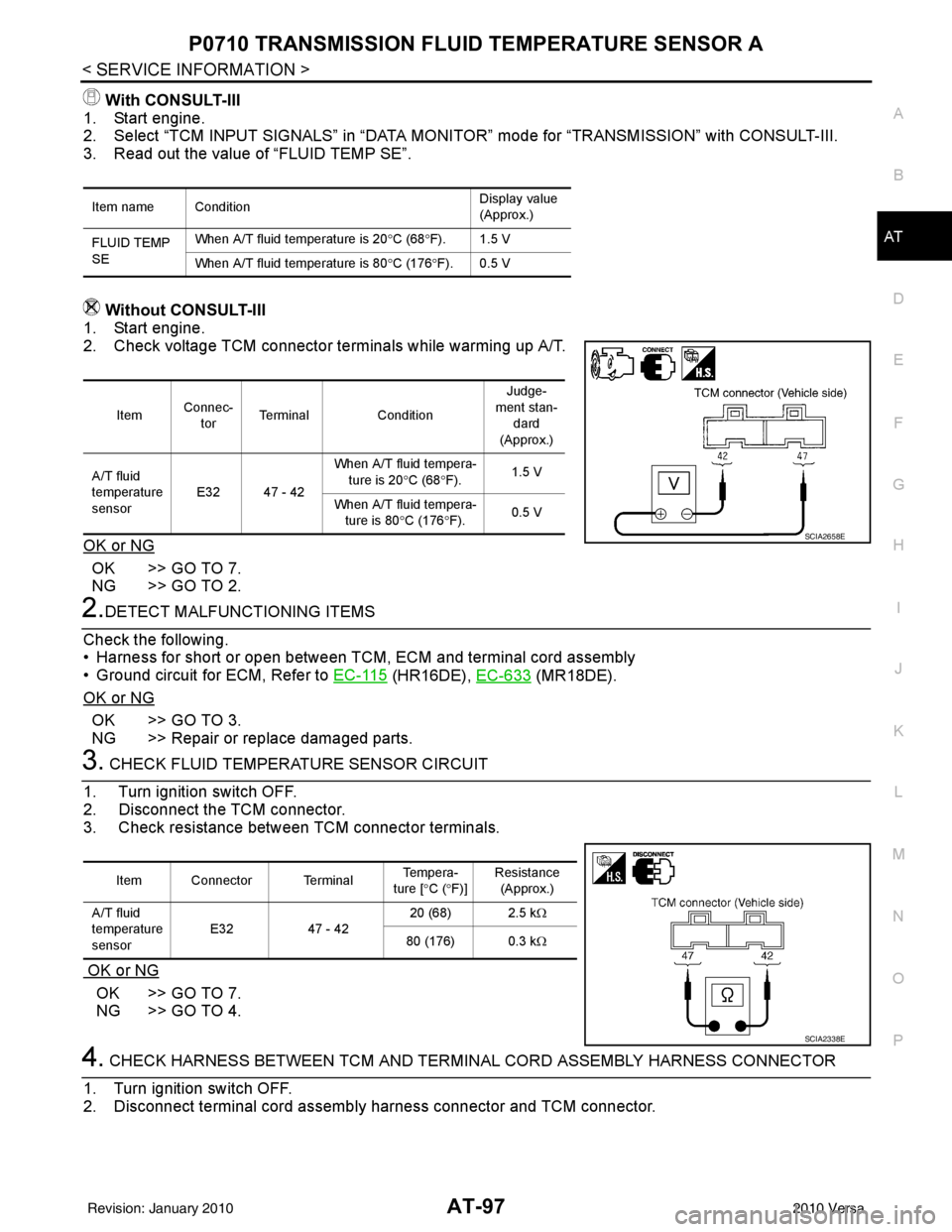

2. Check voltage TCM connector terminals while warming up A/T.

OK or NG

OK >> GO TO 9.

NG >> GO TO 4.

4.DETECT MALFUNCTIONING ITEM

Check the following items:

• Harness for short or open between TCM, ECM and terminal cord assembly

• Ground circuit for ECM Refer to EC-115, "

Wiring Diagram" (HR16DE), EC-633, "Wiring Diagram" (MR18DE).

OK or NG

OK >> GO TO 5.

NG >> Repair or replace damaged parts.

5. CHECK FLUID TEMPERATURE SENSOR CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect the TCM connector.

3. Check resistance between terminals.

OK or NG

OK >> GO TO 9.

NG >> GO TO 6.

6. CHECK HARNESS BETWEEN TCM AND TERMINAL CORD ASSEMBLY HARNESS CONNECTOR

1. Turn ignition switch OFF.

2. Disconnect terminal cord assemb ly harness connector and TCM connector.

3. Check continuity between terminal cord assembly harness con- nector terminal and TCM connector terminal.

4. If OK, check harness for short to ground and short to power.

5. If OK, check continuity between ground and transaxle assembly.

6. Reinstall any part removed.

OK or NG

Item Connec-

tor Terminal

Condition Judge-

ment stan-

dard

(Approx.)

A/T fluid

temperature

sensor E32 47 - 42 When A/T fluid tempera-

ture is 20

°C (68 °F). 1.5 V

When A/T fluid tempera-

ture is 80 °C (176 °F). 0.5 V

SCIA2658E

Item Connector Terminal Te m p e r a -

ture ° C (°F) Resistance

(Approx.)

A/T fluid

temperature

sensor E32

47 - 42AT- 3 8 0 , "

A/T Fluid Tempera-

ture Sensor"

SCIA2338E

Item

Connector Terminal Continuity

TCM E3242

Ye s

Terminal cord assembly

harness connector F30

7

TCM E3247

Ye s

Terminal cord assembly

harness connector F30

6

SCIA2660E

Revision: January 20102010 Versa

Page 250 of 3745

TRANSAXLE ASSEMBLYAT-233

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

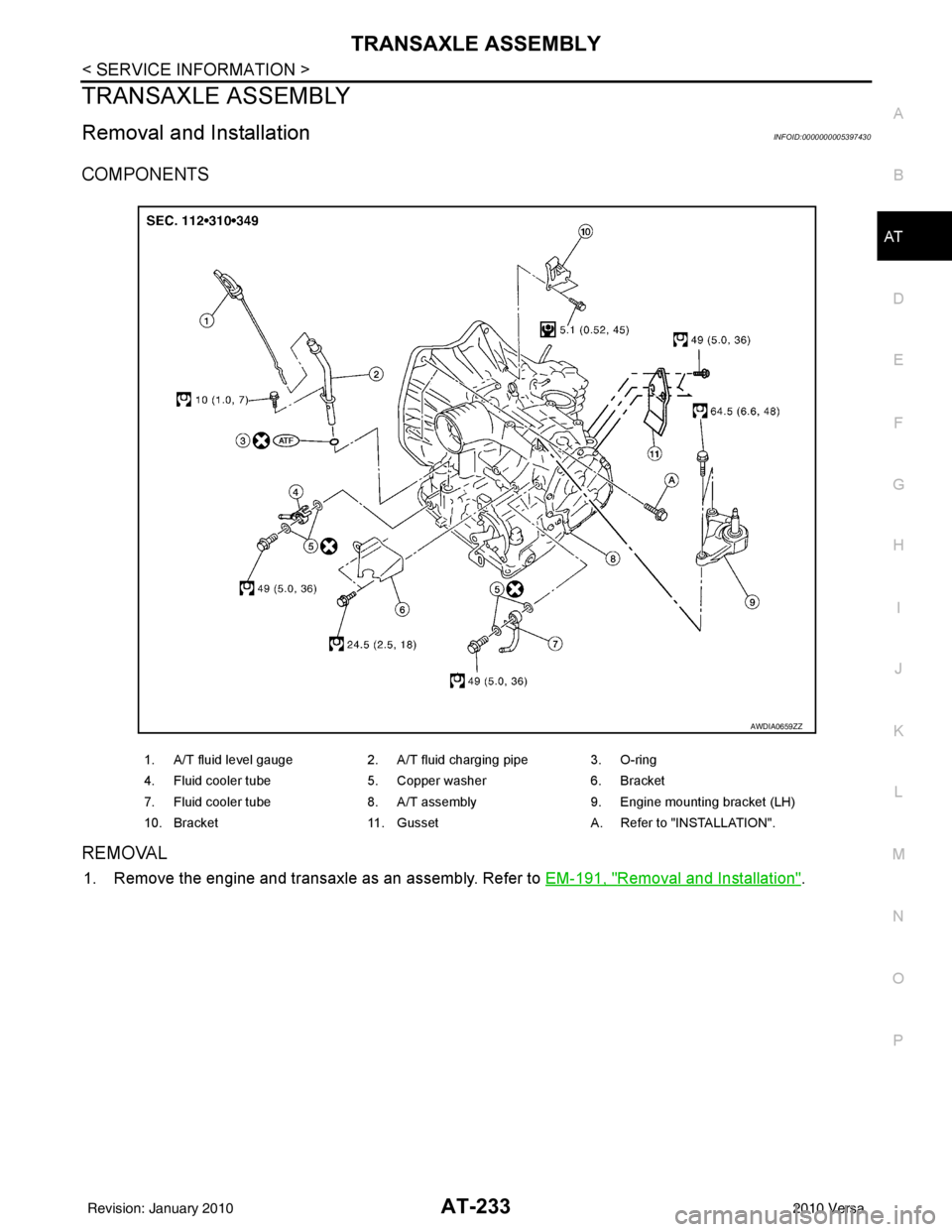

TRANSAXLE ASSEMBLY

Removal and InstallationINFOID:0000000005397430

COMPONENTS

REMOVAL

1. Remove the engine and transaxle as an assembly. Refer to EM-191, "Removal and Installation".

1. A/T fluid level gauge2. A/T fluid charging pipe 3. O-ring

4. Fluid cooler tube 5. Copper washer 6. Bracket

7. Fluid cooler tube 8. A/T assembly9. Engine mounting bracket (LH)

10. Bracket 11. Gusset A. Refer to "INSTALLATION".

AWDIA0659ZZ

Revision: January 20102010 Versa

Page 512 of 3745

BL-3

C

DE

F

G H

J

K L

M A

B

BL

N

O P

Check Trunk Lid Opener S

witch Circuit (Without

Intelligent Key, with Power Windows) ................. ..

210

Check Trunk Lid Opener Switch Circuit (With Intel-

ligent Key) ........................................................... ..

212

Check Trunk Release Solenoid Circuit .................214

FUEL FILLER LID OPENER ............................217

Removal and Installation of Fuel Filler Lid Opener ..217

VEHICLE SECURITY (THEFT WARNING)

SYSTEM ...........................................................

218

Component Parts and Harness Connector Loca-

tion ...................................................................... ..

218

System Description ...............................................219

CAN Communication System Description .............221

Schematic .............................................................222

Wiring Diagram - VEHSEC - .................................223

Terminal and Reference Value for BCM ...............227

Terminal and Reference Value for Intelligent Key

Unit ...................................................................... ..

231

CONSULT-III Function (BCM) ...............................233

Trouble Diagnosis .................................................235

Preliminary Check .................................................235

Symptom Chart .....................................................237

Diagnosis Procedure 1 ..........................................238

Diagnosis Procedure 2 ..........................................241

Diagnosis Procedure 3 ..........................................242

Diagnosis Procedure 4 ..........................................242

Diagnosis Procedure 5 ..........................................242

Diagnosis Procedure 6 ..........................................242

Diagnosis Procedure 7 ..........................................242

Diagnosis Procedure 8 ..........................................244

Diagnosis Procedure 9 ........................................ ..245

NATS (Nissan Anti-Theft System) ................248

Component Parts and Harness Connector Loca-

tion .........................................................................

248

System Description ................................................248

System Composition ..............................................249

ECM Re-communicating Function .........................249

Wiring Diagram - NATS - .......................................251

Terminal and Reference Value for BCM ................252

CONSULT-III Function ........................................ ..256

Trouble Diagnosis Procedure ................................257

Trouble Diagnosis ..................................................259

Diagnosis Procedure 1 ..........................................260

Diagnosis Procedure 2 ..........................................262

Diagnosis Procedure 3 ..........................................263

Diagnosis Procedure 4 ..........................................264

Diagnosis Procedure 5 ..........................................265

Diagnosis Procedure 6 ..........................................266

How to Replace NATS Antenna Amp ....................266

BODY REPAIR ................................................267

Body Exterior Paint Color ......................................267

Body Component Parts .........................................269

Corrosion Protection ..............................................274

Body Sealing .........................................................278

Body Construction .................................................284

Body Alignment .....................................................286

Handling Precaution for Plastics ............................303

Precaution in Repairing High Strength Steel .........307

Foam Repair ..........................................................310

Replacement Operation .........................................313

Revision: January 20102010 Versa

Page 742 of 3745

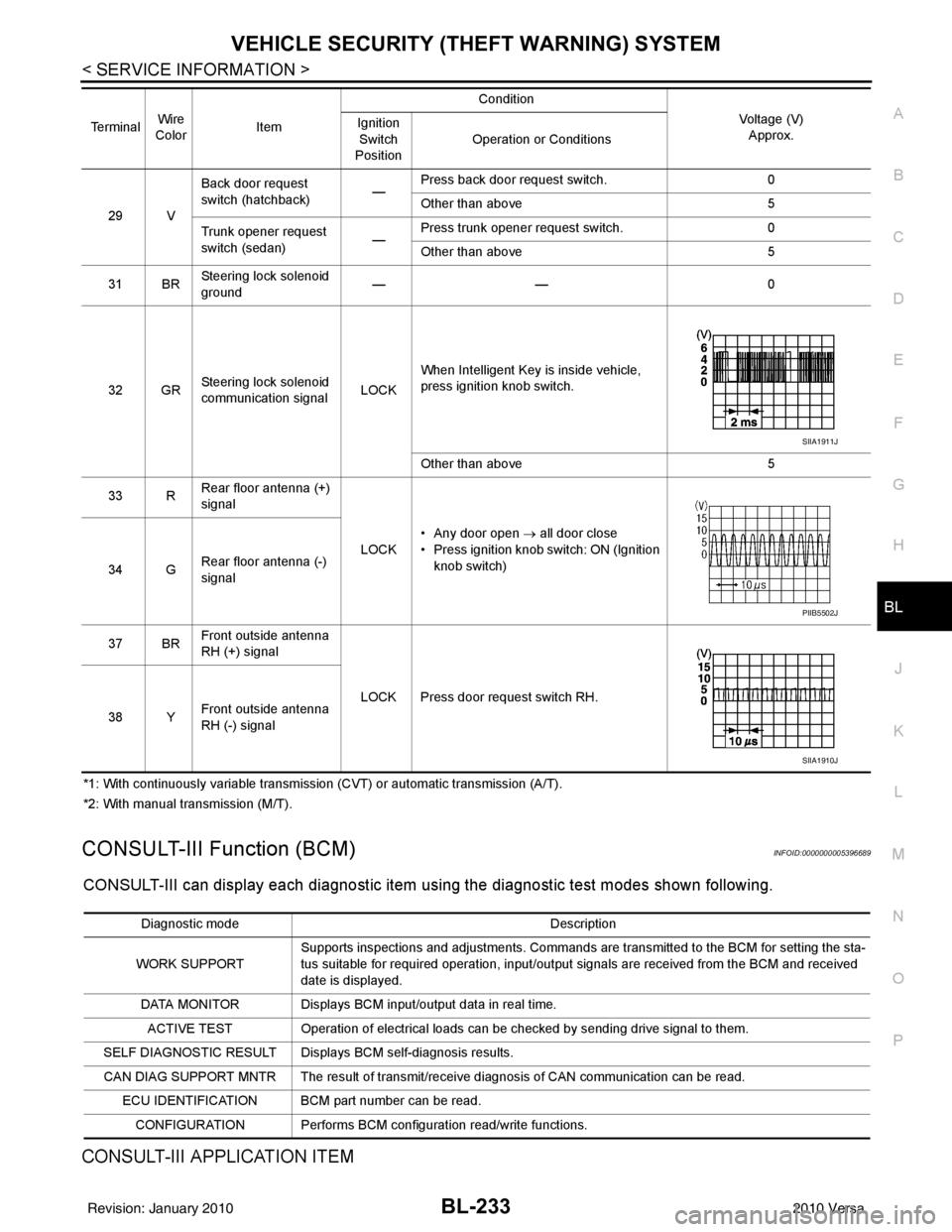

VEHICLE SECURITY (THEFT WARNING) SYSTEMBL-233

< SERVICE INFORMATION >

C

DE

F

G H

J

K L

M A

B

BL

N

O P

*1: With continuously variable transmission (CVT) or automatic transmission (A/T).

*2: With manual transmission (M/T).

CONSULT-III Function (BCM)INFOID:0000000005396689

CONSULT-III can display each diagnostic item using the diagnostic test modes shown following.

CONSULT-III APPLICATION ITEM

29 V Back door request

switch (hatchback)

—Press back door request switch.

0

Other than above 5

Trunk opener request

switch (sedan) —Press trunk opener request switch.

0

Other than above 5

31 BR Steering lock solenoid

ground ——

0

32 GR Steering lock solenoid

communication signal LOCKWhen Intelligent Key is inside vehicle,

press ignition knob switch.

Other than above

5

33 R Rear floor antenna (+)

signal

LOCK• Any door open

→ all door close

• Press ignition knob switch: ON (Ignition

knob switch)

34 G Rear floor antenna (-)

signal

37 BR Front outside antenna

RH (+) signal

LOCK Press door request switch RH.

38 Y Front outside antenna

RH (-) signal

Terminal

Wire

Color Item Condition

Voltage (V)Approx.

Ignition

Switch

Position Operation or Conditions

SIIA1911J

PIIB5502J

SIIA1910J

Diagnostic mode

Description

WORK SUPPORT Supports inspections and adjustments. Commands are transmitted to the BCM for setting the sta-

tus suitable for required operation, input/output signals are received from the BCM and received

date is displayed.

DATA MONITOR Displays BCM input/output data in real time. ACTIVE TEST Operation of electrical loads can be checked by sending drive signal to them.

SELF DIAGNOSTIC RESULT Displays BCM self-diagnosis results.

CAN DIAG SUPPORT MNTR The result of transmit/receive diagnosis of CAN communication can be read. ECU IDENTIFICATION BCM part number can be read.CONFIGURATION Performs BCM configuration read/write functions.

Revision: January 20102010 Versa

Page 752 of 3745

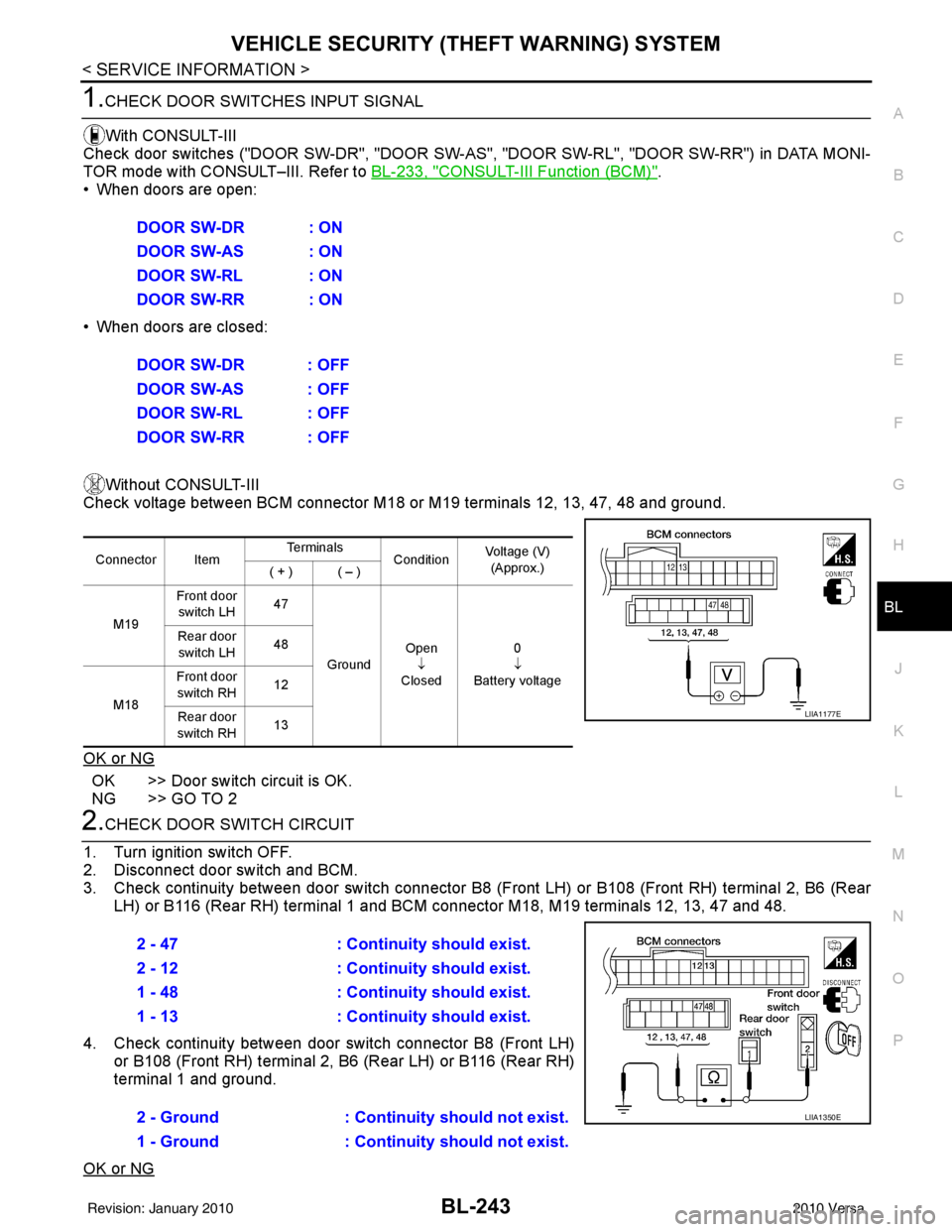

VEHICLE SECURITY (THEFT WARNING) SYSTEMBL-243

< SERVICE INFORMATION >

C

DE

F

G H

J

K L

M A

B

BL

N

O P

1.CHECK DOOR SWITCHES INPUT SIGNALWith CONSULT-III

Check door switches ("DOOR SW-DR", "DOOR SW-AS" , "DOOR SW-RL", "DOOR SW-RR") in DATA MONI-

TOR mode with CONSULT–III. Refer to BL-233, "

CONSULT-III Function (BCM)".

• When doors are open:

• When doors are closed:

Without CONSULT-III

Check voltage between BCM connector M18 or M19 terminals 12, 13, 47, 48 and ground.

OK or NG

OK >> Door switch circuit is OK.

NG >> GO TO 2

2.CHECK DOOR SWITCH CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect door switch and BCM.

3. Check continuity between door switch connector B8 (F ront LH) or B108 (Front RH) terminal 2, B6 (Rear

LH) or B116 (Rear RH) terminal 1 and BCM connector M18, M19 terminals 12, 13, 47 and 48.

4. Check continuity between door switch connector B8 (Front LH) or B108 (Front RH) terminal 2, B6 (Rear LH) or B116 (Rear RH)

terminal 1 and ground.

OK or NG

DOOR SW-DR : ON

DOOR SW-AS : ON

DOOR SW-RL : ON

DOOR SW-RR : ON

DOOR SW-DR : OFF

DOOR SW-AS : OFF

DOOR SW-RL : OFF

DOOR SW-RR : OFF

Connector Item Te r m i n a l s

ConditionVoltage (V)

(Approx.)

( + ) ( – )

M19 Front door

switch LH 47

Ground Open

↓

Closed 0

↓

Battery voltage

Rear door

switch LH 48

M18 Front door

switch RH 12

Rear door

switch RH 13

LIIA1177E

2 - 47

: Continuity should exist.

2 - 12 : Continuity should exist.

1 - 48 : Continuity should exist.

1 - 13 : Continuity should exist.

2 - Ground : Continuity should not exist.

1 - Ground : Continuity should not exist.

LIIA1350E

Revision: January 20102010 Versa

Page 900 of 3745

![NISSAN TIIDA 2010 Service Repair Manual BRC-10

< SERVICE INFORMATION >[ABS]

TROUBLE DIAGNOSIS

TROUBLE DIAGNOSIS

How to Perform Trouble Diagnosis

for Quick and Accurate RepairINFOID:0000000005397032

INTRODUCTION

The ABS system has an electr NISSAN TIIDA 2010 Service Repair Manual BRC-10

< SERVICE INFORMATION >[ABS]

TROUBLE DIAGNOSIS

TROUBLE DIAGNOSIS

How to Perform Trouble Diagnosis

for Quick and Accurate RepairINFOID:0000000005397032

INTRODUCTION

The ABS system has an electr](/img/5/57397/w960_57397-899.png)

BRC-10

< SERVICE INFORMATION >[ABS]

TROUBLE DIAGNOSIS

TROUBLE DIAGNOSIS

How to Perform Trouble Diagnosis

for Quick and Accurate RepairINFOID:0000000005397032

INTRODUCTION

The ABS system has an electronic control unit to control major func-

tions. The control unit accepts input signals from sensors and con-

trols actuator operation. It is also important to check for air leaks in

the booster or brake and vacuum lines, lack of brake fluid, or other

malfunctions in the brake system.

It is much more difficult to diagnose a malfunction that occurs inter-

mittently rather than continuously. Most intermittent conditions are

caused by poor electrical connections or damaged wiring. In this

case, careful checking of suspicious circuits may help prevent the

replacement of good parts.

A visual check only may not find t he cause of the malfunction, so a

road test should be performed.

Before undertaking actual checks, take just a few minutes to talk with

a customer who approaches with an ABS complaint. The customer

is a very good source of informati on, especially for intermittent condi-

tions. Through the talks with the customer, find out what symptoms

are present and under what conditions they occur.

Start your diagnosis by looking for “conventional” malfunctions first.

This is one of the best ways to troubleshoot brake malfunctions on

an ABS equipped vehicle. Also check related Service Bulletins for

information.

SEF233G

SEF234G

Revision: January 20102010 Versa

Page 937 of 3745

![NISSAN TIIDA 2010 Service Repair Manual TROUBLE DIAGNOSISBRC-47

< SERVICE INFORMATION > [VDC/TCS/ABS]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

TROUBLE DIAGNOSIS

How to Perform Trouble Diagnosis for Quick and Accurate RepairINFOID:0000000005612151

NISSAN TIIDA 2010 Service Repair Manual TROUBLE DIAGNOSISBRC-47

< SERVICE INFORMATION > [VDC/TCS/ABS]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

TROUBLE DIAGNOSIS

How to Perform Trouble Diagnosis for Quick and Accurate RepairINFOID:0000000005612151](/img/5/57397/w960_57397-936.png)

TROUBLE DIAGNOSISBRC-47

< SERVICE INFORMATION > [VDC/TCS/ABS]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

TROUBLE DIAGNOSIS

How to Perform Trouble Diagnosis for Quick and Accurate RepairINFOID:0000000005612151

INTRODUCTION

The ABS/TCS/VDC system has an el ectronic control unit to control

major functions. The control unit accepts input signals from sensors

and controls actuator operation. It is also important to check for con-

ventional malfunctions such as air leaks in the booster or lines, lack

of brake fluid, or other malfunctions with the brake system.

It is much more difficult to diagnose a malfunction that occurs inter-

mittently rather than continuously. Most intermittent malfunctions are

caused by poor electrical connections or wiring. In this case, careful

checking of suspicious circuits may help prevent the replacement of

good parts.

A visual check only may not find t he cause of the malfunction, so a

road test should be performed.

Before undertaking actual checks, take just a few minutes to talk with

a customer who approaches with an ABS/TCS/VDC complaint. The

customer is a very good source of information, especially for inter-

mittent malfunctions. Through the talks with the customer, find out

what symptoms are present and under what conditions they occur.

Start your diagnosis by looking fo r “conventional” malfunctions first.

This is one of the best ways to troubleshoot brake malfunctions on

an ABS/TCS/VDC equipped vehicle. Also check related Service Bul-

letins for information.

SEF233G

SEF234G

Revision: January 20102010 Versa