Electronic NISSAN TIIDA 2010 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2010, Model line: TIIDA, Model: NISSAN TIIDA 2010Pages: 3745, PDF Size: 73.67 MB

Page 1 of 3745

-1

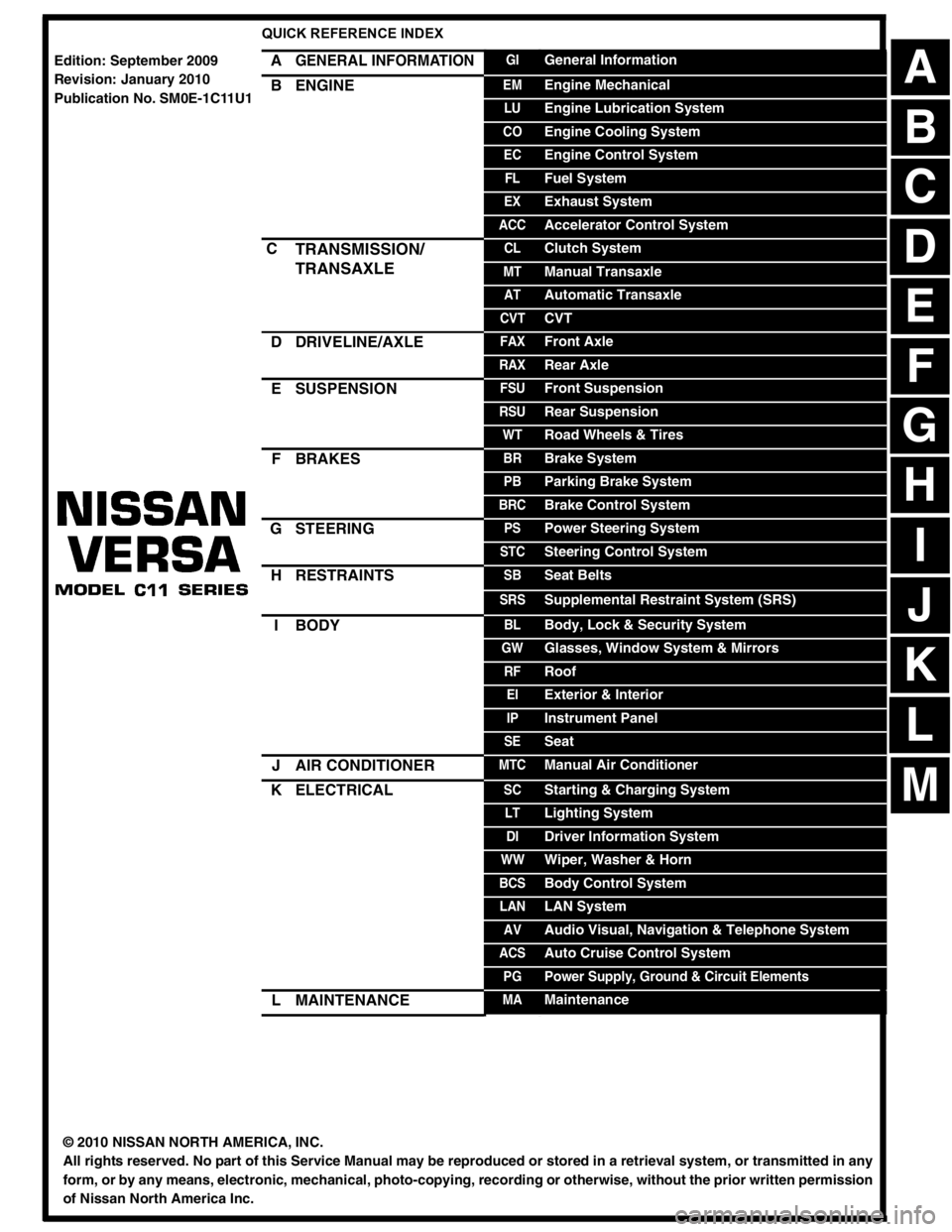

QUICK REFERENCE INDEX

AGENERAL INFORMATIONGIGeneral Information

BENGINEEMEngine Mechanical

LUEngine Lubrication System

COEngine Cooling System

ECEngine Control System

FLFuel System

EXExhaust System

ACCAccelerator Control System

CTRANSMISSION/

TRANSAXLECLClutch System

MTManual Transaxle

ATAutomatic Transaxle

CVTCVT

DDRIVELINE/AXLEFAXFront Axle

RAXRear Axle

ESUSPENSIONFSUFront Suspension

RSURear Suspension

WTRoad Wheels & Tires

FBRAKESBRBrake System

PBParking Brake System

BRCBrake Control System

GSTEERINGPSPower Steering System

STCSteering Control System

HRESTRAINTSSBSeat Belts

SRSSupplemental Restraint System (SRS)

IBODYBLBody, Lock & Security System

GWGlasses, Window System & Mirrors

RFRoof

EIExterior & Interior

IPInstrument Panel

SESeat

JAIR CONDITIONERMTCManual Air Conditioner

KELECTRICALSCStarting & Charging System

LTLighting System

DIDriver Information System

WWWiper, Washer & Horn

BCSBody Control System

LANLAN System

AVAudio Visual, Navigation & Telephone System

ACSAuto Cruise Control System

PGPower Supply, Ground & Circuit Elements

LMAINTENANCEMAMaintenance

Edition: September 2009

Revision: January 2010

Publication No. SM0E-1C11U1

B

D

© 2010 NISSAN NORTH AMERICA, INC.

All rights reserved. No part of this Service Manual may be reproduced or stored in a retrieval system, or transmitted in any

form, or by any means, electronic, mechanical, photo-copying, recording or otherwise, without the prior written permission

of Nissan North America Inc.

A

C

E

F

G

H

I

J

K

L

M

Page 49 of 3745

AT-32

< SERVICE INFORMATION >

A/T CONTROL SYSTEM

*1: Output speed sensor

*2: Spare for accelerator pedal position signal

*3: If these input and output signals are different, the TCM triggers the fail-safe function.

*4: Used as a condition for starting self-diagnostics; if self-diagnosis are not started, it is judged that there is some kind of error.

*5: Input by CAN communications.

*6: Output by CAN communications.

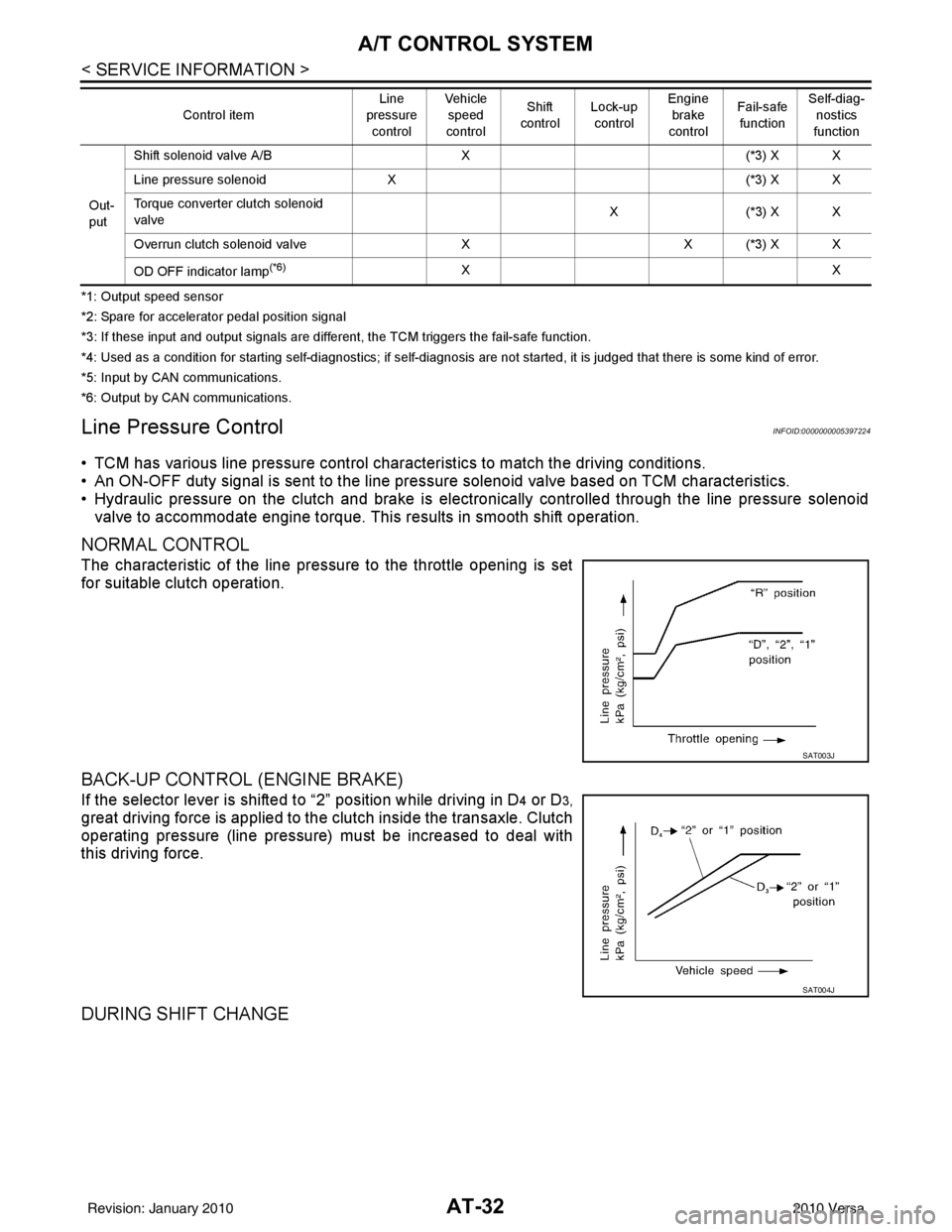

Line Pressure ControlINFOID:0000000005397224

• TCM has various line pressure control char acteristics to match the driving conditions.

• An ON-OFF duty signal is sent to the line pres sure solenoid valve based on TCM characteristics.

• Hydraulic pressure on the clutch and brake is electronically controlled through the line pressure solenoid valve to accommodate engine torque. This results in smooth shift operation.

NORMAL CONTROL

The characteristic of the line pressure to the throttle opening is set

for suitable clutch operation.

BACK-UP CONTROL (ENGINE BRAKE)

If the selector lever is shifted to “2” position while driving in D4 or D3,

great driving force is applied to the clutch inside the transaxle. Clutch

operating pressure (line pressure) must be increased to deal with

this driving force.

DURING SHIFT CHANGE

Out-

put Shift solenoid valve A/B

X(*3) X X

Line pressure solenoid X (*3) X X

Torque converter clutch solenoid

valve X(

*3 ) X X

Overrun clutch solenoid valve XX (*3) X X

OD OFF indicator lamp

(*6)XX

Control item

Line

pressure

control Vehicle

speed

control Shift

control Lock-up

control Engine

brake

control Fail-safe

function Self-diag-

nostics

function

SAT003J

SAT004J

Revision: January 20102010 Versa

Page 50 of 3745

A/T CONTROL SYSTEMAT-33

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

The line pressure is temporarily reduced corresponding to a change

in engine torque when shifting gears (that is, when the shift solenoid

valve is switched for clutch operation) to reduce shifting shock.

AT LOW FLUID TEMPERATURE

• A/T fluid viscosity and frictional characteristics of t he clutch facing change with A/T fluid temperature. Clutch

engaging or band-contacting pressure is compensated for, according to A/T fluid temperature, to stabilize

shifting quality.

• The line pressure is reduced below 60 °C (140° F) to prevent shift-

ing shock due to high viscosity of A/T fluid when temperature is

low.

• Line pressure is increased to a maximum irrespective of the throt- tle opening when A/T fluid temperature drops to −10° C (14° F). This

pressure rise is adopted to prevent a delay in clutch and brake

operation due to extreme drop of A/T fluid viscosity at low temper-

ature.

Shift ControlINFOID:0000000005397225

The shift is regulated entirely by electronic cont rol to accommodate vehicle speed and varying engine opera-

tions. This is accomplished by electrical signals trans mitted by the output speed sensor and the ECM (acceler-

ator pedal position sensor). This results in improved acceleration performance and fuel economy.

CONTROL OF SHIFT SOLENOID VALVES A AND B

The TCM activates shift solenoid valves A and B according to sig-

nals from the accelerator pedal position sensor and output speed

sensor to select the optimum gear position on the basis of the shift

schedule memorized in the TCM.

The shift solenoid valve performs simple ON-OFF operation. When

set to “ON”, the drain circuit closes and pilot pressure is applied to

the shift valve.

RELATION BETWEEN SHIFT SOLENOID VALVES A AND B AND GEAR POSITIONS

SCIA4828E

SCIA4829E

SCIA4830E

SAT008J

Revision: January 20102010 Versa

Page 59 of 3745

AT-42

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS

TROUBLE DIAGNOSIS

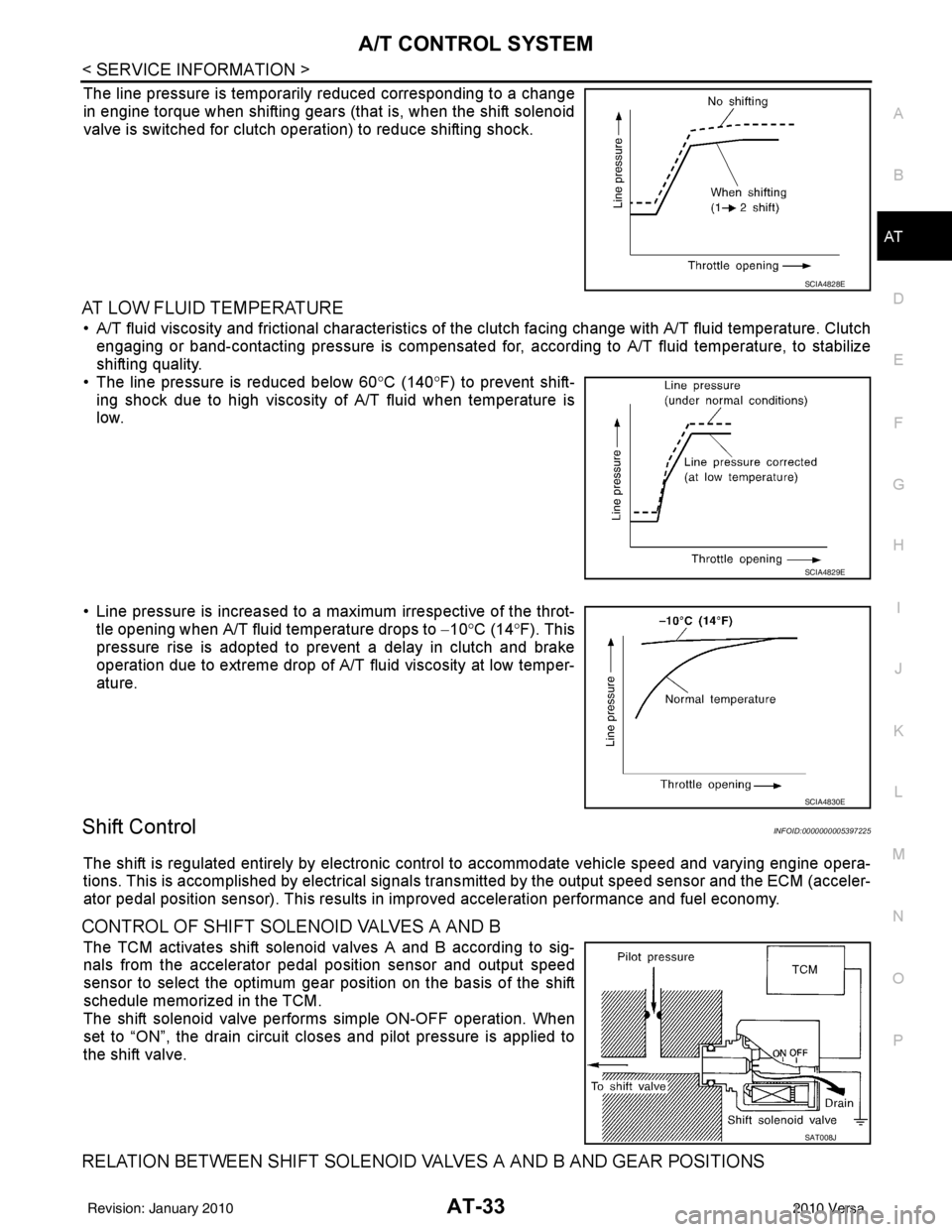

DTC Inspection Priority ChartINFOID:0000000005397235

If some DTCs are displayed at the same time, perform inspections one by one based on the following priority

chart.

NOTE:

If DTC “CAN COMM CIRCUIT” is displayed with other DTCs, first perform the trouble diagnosis for

DTC “CAN COMM CIRCUIT”. Refer to AT- 8 7

.

Fail-SafeINFOID:0000000005397236

The TCM has an electronic Fail-safe mode. This allows t he vehicle to be driven even if a major electrical input/

output device circuit is damaged.

Under Fail-Safe, the vehicle always runs in 3GR, even wit h a shift lever position of “1”, “2” or “D”. The cus-

tomer may complain of sluggish or poor acceleration.

Always follow the “ AT-43, "

How to Perform Trouble Diagnosis for Quick and Accurate Repair" ”.

The SELF-DIAGNOSIS results will be as follows:

• The first SELF-DIAGNOSIS will indicate damage to the vehicle speed signal or the output speed sensor.

• During the next SELF-DIAGNOSIS, performed after checking the sensor, no damages will be indicated.

FAIL-SAFE FUNCTION

The following fail-safe functions allow vehicles to be driven even when sensor, switch or solenoid malfunction

occurs.

Output Speed Sensor

Vehicle speed signal is input from combination meter.

Accelerator Pedal Position Signal and Throttle Position Signal

TCM controls the throttle opening angle to a predetermined fixed position to enable driving if a malfunctioning

signal is input to TCM.

Transmission Range Switch

When the multiple transmission range switch signals are input to TCM, the priority of selector lever position

becomes “D”, “N”, “R”, “2” and “1” in order by internal TCM determination.

The use of 4GR is inhibited until normal operation resumes. Because the hydraulic circuit of the control valve

is switched by manual valve according to the selector lever position, however, actual operating condition of

vehicle becomes as follows.

Shift Solenoid Valve A and B

If non-standard solenoid signal is sent to TCM, use of certain gears is limited. Refer to chart shown below.

Priority Detected items

1 CAN communication line

2 Except above

Actual lever positionTransmission range switch input signal Running status

“P” “P” position and other position signals P

“R” “R” position and other position signals R

“N” “N” position and other position signals N

“D” “D” position and other position signals D

1 ⇔ D2 ⇔ D3 ⇔ D4

“2” “2” position and other position signals (Except “1” position)

21 ⇔ 22 ⇔ 23

“2” position and “1” position signals 21 ⇔ 22

“1” “1” position and other position signals (Except “2” position)

11 ⇔ 12 ⇔ 13

“1” position and “2” position signals 11 ⇔ 12

Revision: January 20102010 Versa

Page 104 of 3745

U1000 CAN COMM CIRCUITAT-87

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

U1000 CAN COMM CIRCUIT

DescriptionINFOID:0000000005397253

CAN (Controller Area Network) is a serial communication line for real time application. It is an on-vehicle mul-

tiplex communication line with high data communica tion speed and excellent malfunction detection ability.

Many electronic control units are equipped onto a vehicle, and each control unit shares information and links

with other control units during operation (not independent). In CAN communication, control units are con-

nected with 2 communication lines (CAN H line, CAN L li ne) allowing a high rate of information transmission

with less wiring. Each control unit transmits/recei ves data but selectively reads required data only.

On Board Diagnosis LogicINFOID:0000000005397254

• This is an OBD-II self-diagnostic item.

• Diagnostic trouble code “U1000 CAN COMM CIRCUIT” wit h CONSULT-III or 12th judgement flicker without

CONSULT-III is detected when TCM cannot communicate to other control units.

Possible CauseINFOID:0000000005397255

Harness or connector

(CAN communication line is open or shorted.)

DTC Confirmation ProcedureINFOID:0000000005397256

CAUTION:

If performing this “DTC Confirmation Procedure” again, always turn ignition switch OFF and wait at

least 10 seconds before continuing.

After the repair, perform the following procedure to confirm the malfunction is eliminated.

WITH CONSULT-III

1. Turn ignition switch ON.

2. Select “DATA MONITOR” mode for “TRANSMISSION” with CONSULT-III.

3. Touch “START”.

4. Wait at least 6 seconds or start engine and wait for at least 6 seconds.

5. If DTC is detected, go to AT-89, "

Diagnosis Procedure".

WITH GST

Follow the procedure “WITH CONSULT-III”.

WITHOUT CONSULT-III

1. Turn ignition switch ON.

2. Wait at least 6 seconds or start engine and wait at least 6 seconds.

3. Perform self-diagnosis. Refer to AT-82, "

Diagnosis Procedure without CONSULT-III".

4. If DTC is detected, go to AT-89, "

Diagnosis Procedure".

Revision: January 20102010 Versa

Page 597 of 3745

BL-88

< SERVICE INFORMATION >

INTELLIGENT KEY SYSTEM

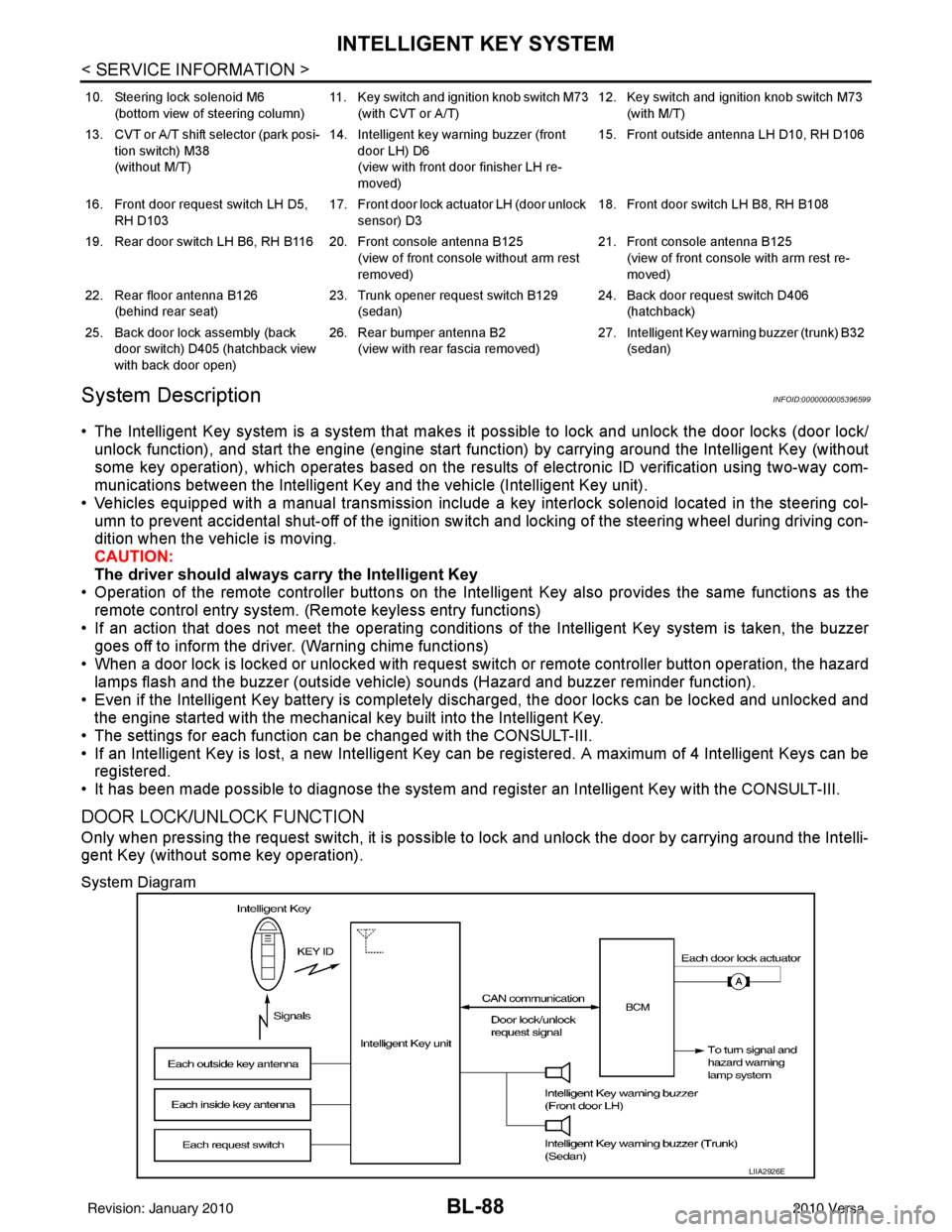

System Description

INFOID:0000000005396599

• The Intelligent Key system is a system that makes it possible to lock and unlock the door locks (door lock/

unlock function), and start the engine (engine start func tion) by carrying around the Intelligent Key (without

some key operation), which operates based on the results of electronic ID verification using two-way com-

munications between the Intelligent Key and the vehicle (Intelligent Key unit).

• Vehicles equipped with a manual transmission include a key interlock solenoid located in the steering col- umn to prevent accidental shut-off of the ignition sw itch and locking of the steering wheel during driving con-

dition when the vehicle is moving.

CAUTION:

The driver should always carry the Intelligent Key

• Operation of the remote controller buttons on the Inte lligent Key also provides the same functions as the

remote control entry system. (Remote keyless entry functions)

• If an action that does not meet the operating conditions of the Intelligent Key system is taken, the buzzer

goes off to inform the driver. (Warning chime functions)

• When a door lock is locked or unlocked with request switch or remote controller button operation, the hazard

lamps flash and the buzzer (outside vehicle) sounds (Hazard and buzzer reminder function).

• Even if the Intelligent Key battery is completely discharged, the door locks can be locked and unlocked and the engine started with the mechanical key built into the Intelligent Key.

• The settings for each function can be changed with the CONSULT-III.

• If an Intelligent Key is lost, a new Intelligent Key can be registered. A maximum of 4 Intelligent Keys can be registered.

• It has been made possible to diagnose the system and r egister an Intelligent Key with the CONSULT-III.

DOOR LOCK/UNLOCK FUNCTION

Only when pressing the request switch, it is possible to lock and unlock the door by carrying around the Intelli-

gent Key (without some key operation).

System Diagram

10. Steering lock solenoid M6

(bottom view of steering column) 11. Key switch and ignition knob switch M73

(with CVT or A/T) 12. Key switch and ignition knob switch M73

(with M/T)

13. CVT or A/T shift selector (park posi- tion switch) M38

(without M/T) 14. Intelligent key warning buzzer (front

door LH) D6

(view with front door finisher LH re-

moved) 15. Front outside antenna LH D10, RH D106

16. Front door request switch LH D5, RH D103 17. Front door lock actuator LH (door unlock

sensor) D3 18. Front door switch LH B8, RH B108

19. Rear door switch LH B6, RH B116 20. Front console antenna B125 (view of front console without arm rest

removed)21. Front console antenna B125

(view of front console with arm rest re-

moved)

22. Rear floor antenna B126 (behind rear seat) 23. Trunk opener request switch B129

(sedan) 24. Back door request switch D406

(hatchback)

25. Back door lock assembly (back door switch) D405 (hatchback view

with back door open) 26. Rear bumper antenna B2

(view with rear fascia removed) 27. Intelligent Key warn

ing buzzer (trunk) B32

(sedan)

LIIA2926E

Revision: January 20102010 Versa

Page 897 of 3745

![NISSAN TIIDA 2010 Service Repair Manual SYSTEM DESCRIPTIONBRC-7

< SERVICE INFORMATION > [ABS]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

SYSTEM DESCRIPTION

System ComponentINFOID:0000000005397026

ABS FunctionINFOID:0000000005397027

• The Anti-Lock NISSAN TIIDA 2010 Service Repair Manual SYSTEM DESCRIPTIONBRC-7

< SERVICE INFORMATION > [ABS]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

SYSTEM DESCRIPTION

System ComponentINFOID:0000000005397026

ABS FunctionINFOID:0000000005397027

• The Anti-Lock](/img/5/57397/w960_57397-896.png)

SYSTEM DESCRIPTIONBRC-7

< SERVICE INFORMATION > [ABS]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

SYSTEM DESCRIPTION

System ComponentINFOID:0000000005397026

ABS FunctionINFOID:0000000005397027

• The Anti-Lock Brake System detects wheel revolution while braking and improves handling stability during sudden braking by electrically preventing wheel lockup. Maneuverability is also improved for avoiding obsta-

cles during emergency braking.

• If the electrical system malfunctions, the Fail-Safe function is activated, t he ABS becomes inoperative and

the ABS warning lamp turns on.

• The electrical system can be diagnosed using CONSULT-III.

• During ABS operation, the brake pedal may vibrate lightly and a mechanical noise may be heard. This is normal.

• Just after starting the vehicle, the brake pedal may vibrate or motor operating noises may be heard from the

engine compartment. This is normal due to the self check operation.

• Stopping distance may be longer than that of vehicles without ABS when vehicle drives on rough, gravel, or

snow-covered (fresh, deep snow) roads.

EBD FunctionINFOID:0000000005397028

• Electronic Brake Distribution is a function that detects subtle slippages between the front and rear wheels during braking, and it improves handling stability by elec tronically controlling the brake fluid pressure which

results in reduced rear wheel slippage.

• If the electrical system malfunctions, the Fail-Safe function is activated, the EBD and ABS become inopera- tive, and the ABS warning lamp and brake warning lamp are turned on.

• The electrical system can be diagnosed using CONSULT-III.

• During EBD operation, the brake pedal may vibrate lightly and a mechanical noise may be heard. This is

normal.

• Just after starting the vehicle, the brake pedal may vibrate or motor operating noises may be heard from the

engine compartment. This is normal due to the self check operation.

Fail-Safe FunctionINFOID:0000000005397029

CAUTION:

If the Fail-Safe function is activated, perform the Self Diagnosis for ABS system.

ABS/EBD SYSTEM

In case of an electrical malfunction with the ABS, the ABS warning lamp wi ll turn on. In case of an electrical

malfunction with the EBD system, the brake warni ng lamp and the ABS warning lamp will turn on.

The system will revert to one of the follo wing conditions of the Fail-Safe function.

1. For ABS malfunction, only the EBD is operative and t he condition of the vehicle is the same condition of

vehicles without ABS system.

WFIA0118E

Revision: January 20102010 Versa

Page 900 of 3745

![NISSAN TIIDA 2010 Service Repair Manual BRC-10

< SERVICE INFORMATION >[ABS]

TROUBLE DIAGNOSIS

TROUBLE DIAGNOSIS

How to Perform Trouble Diagnosis

for Quick and Accurate RepairINFOID:0000000005397032

INTRODUCTION

The ABS system has an electr NISSAN TIIDA 2010 Service Repair Manual BRC-10

< SERVICE INFORMATION >[ABS]

TROUBLE DIAGNOSIS

TROUBLE DIAGNOSIS

How to Perform Trouble Diagnosis

for Quick and Accurate RepairINFOID:0000000005397032

INTRODUCTION

The ABS system has an electr](/img/5/57397/w960_57397-899.png)

BRC-10

< SERVICE INFORMATION >[ABS]

TROUBLE DIAGNOSIS

TROUBLE DIAGNOSIS

How to Perform Trouble Diagnosis

for Quick and Accurate RepairINFOID:0000000005397032

INTRODUCTION

The ABS system has an electronic control unit to control major func-

tions. The control unit accepts input signals from sensors and con-

trols actuator operation. It is also important to check for air leaks in

the booster or brake and vacuum lines, lack of brake fluid, or other

malfunctions in the brake system.

It is much more difficult to diagnose a malfunction that occurs inter-

mittently rather than continuously. Most intermittent conditions are

caused by poor electrical connections or damaged wiring. In this

case, careful checking of suspicious circuits may help prevent the

replacement of good parts.

A visual check only may not find t he cause of the malfunction, so a

road test should be performed.

Before undertaking actual checks, take just a few minutes to talk with

a customer who approaches with an ABS complaint. The customer

is a very good source of informati on, especially for intermittent condi-

tions. Through the talks with the customer, find out what symptoms

are present and under what conditions they occur.

Start your diagnosis by looking for “conventional” malfunctions first.

This is one of the best ways to troubleshoot brake malfunctions on

an ABS equipped vehicle. Also check related Service Bulletins for

information.

SEF233G

SEF234G

Revision: January 20102010 Versa

Page 933 of 3745

![NISSAN TIIDA 2010 Service Repair Manual SYSTEM DESCRIPTIONBRC-43

< SERVICE INFORMATION > [VDC/TCS/ABS]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

SYSTEM DESCRIPTION

System ComponentINFOID:0000000005612142

ABS FunctionINFOID:0000000005612143

• The NISSAN TIIDA 2010 Service Repair Manual SYSTEM DESCRIPTIONBRC-43

< SERVICE INFORMATION > [VDC/TCS/ABS]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

SYSTEM DESCRIPTION

System ComponentINFOID:0000000005612142

ABS FunctionINFOID:0000000005612143

• The](/img/5/57397/w960_57397-932.png)

SYSTEM DESCRIPTIONBRC-43

< SERVICE INFORMATION > [VDC/TCS/ABS]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

SYSTEM DESCRIPTION

System ComponentINFOID:0000000005612142

ABS FunctionINFOID:0000000005612143

• The Anti-Lock Brake System detects wheel revolution while braking and improves handling stability during sudden braking by electrically preventing wheel lockup. Maneuverability is also improved for avoiding obsta-

cles.

• If the electrical system malfunctions, the Fail-Safe function is activated, t he ABS becomes inoperative and

the ABS warning lamp turns on.

• The electrical system can be diagnosed using CONSULT-III.

• During ABS operation, the brake pedal may vibrate lightly and a mechanical noise may be heard. This is normal.

• Just after starting the vehicle, the brake pedal may vibrate or a motor operating noise may be heard from engine compartment. This is a normal status of operation check.

• Stopping distance may be longer than that of vehicles without ABS when vehicle drives on rough, gravel, or snow-covered (fresh, deep snow) roads.

EBD FunctionINFOID:0000000005612144

• Electronic Brake Distribution is a function that detects subtle slippages between the front and rear wheelsduring braking, and it improves handling stability by elec tronically controlling the brake fluid pressure which

results in reduced rear wheel slippage.

• If the electrical system malfunctions, the Fail-Safe function is activated, the EBD and ABS become inopera- tive, and the ABS warning lamp and BRAKE warning lamp are turned on.

• The electrical system can be diagnosed using CONSULT-III.

• During EBD operation, the brake pedal may vibrate lightly and a mechanical noise may be heard. This is

normal.

• Just after starting the vehicle, the brake pedal may vibrate or a motor operating noise may be heard from engine compartment. This is a normal status of operation check.

• Stopping distance may be longer than that of vehicles without EBD when vehicle drives on rough, gravel, or

snow-covered (fresh, deep snow) roads.

AWFIA0604GB

Revision: January 20102010 Versa

Page 1063 of 3745

![NISSAN TIIDA 2010 Service Repair Manual CVT-30

< SERVICE INFORMATION >[RE0F08B]

TROUBLE DIAGNOSIS

TROUBLE DIAGNOSIS

DTC Inspection Priority ChartINFOID:0000000005397785

If some DTCs are displayed at the same time, perform inspections one by NISSAN TIIDA 2010 Service Repair Manual CVT-30

< SERVICE INFORMATION >[RE0F08B]

TROUBLE DIAGNOSIS

TROUBLE DIAGNOSIS

DTC Inspection Priority ChartINFOID:0000000005397785

If some DTCs are displayed at the same time, perform inspections one by](/img/5/57397/w960_57397-1062.png)

CVT-30

< SERVICE INFORMATION >[RE0F08B]

TROUBLE DIAGNOSIS

TROUBLE DIAGNOSIS

DTC Inspection Priority ChartINFOID:0000000005397785

If some DTCs are displayed at the same time, perform inspections one by one based on the following priority

chart.

NOTE:

If DTC “U1000” is displayed with other DTCs, first perform the trouble diagnosis for DTC “U1000”.

Refer to

CVT-56

.

Fail-SafeINFOID:0000000005397786

The TCM has an electrical fail-safe mode. This mode make s it possible to operate even if there is an error in a

main electronic control input/output signal circuit.

FAIL-SAFE FUNCTION

If any malfunction occurs in a sensor or solenoid, this function controls the CVT to make driving possible.

Secondary Speed Sensor

The shift pattern is changed in accordance with thrott le position when an unexpected signal is sent from the

secondary speed sensor to the TCM. T he overdrive-off mode is inhibited, and the transaxle is put in “D”.

Primary Speed Sensor

The shift pattern is changed in accordance with thro ttle position and secondary speed (vehicle speed) when

an unexpected signal is sent from the primary speed sensor to the TCM. The overdrive-off mode is inhibited,

and the transaxle is put in “D”.

Transmission Range Switch

If an unexpected signal is sent from the transmission range switch to the TCM, the transaxle is put in “D”.

CVT Fluid Temperature Sensor

If an unexpected signal is sent from the CVT fluid temperature sensor to the TCM, the gear ratio in use before

receiving the unexpected signal is maintained or t he gear ratio is controlled to keep engine speed under 3500

rpm.

Secondary Pressure Sensor

• If an unexpected signal is sent from the secondary pressure sensor to the TCM, the secondary pressure

feedback control is stopped and the offset value obtai ned before the non-standard condition occurs is used

to control line pressure.

• If secondary pressure sensor error signal is input to TCM, secondary pressure feedback control stops, but line pressure is controlled normally.

Line Pressure Solenoid

If an unexpected signal is sent from the solenoid to the TCM, the line pressure solenoid is turned OFF to

achieve the maximum fluid pressure.

Secondary Pressure Solenoid

If an unexpected signal is sent from the solenoid to t he TCM, the secondary pressure solenoid is turned OFF

to achieve the maximum fluid pressure.

Torque Converter Clutch Solenoid

If an unexpected signal is sent from the solenoid to t he TCM, the torque converter clutch solenoid is turned

OFF to cancel the lock-up.

Step Motor

If an unexpected signal is sent from the step motor to the TCM, the step motor coil phases “A” through “D” are

all turned OFF to hold the gear ratio used right before the non-standard condition occurred.

CVT Lock-up Select Solenoid

If an unexpected signal is sent from the solenoid to the TCM, the CVT lock-up select solenoid is turned OFF to

cancel the lock-up.

Priority Detected items (DTC)

1 U1000

2 Except above

Revision: January 20102010 Versa