ground clearance NISSAN TIIDA 2010 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2010, Model line: TIIDA, Model: NISSAN TIIDA 2010Pages: 3745, PDF Size: 73.67 MB

Page 3366 of 3745

REFRIGERANT LINESMTC-87

< SERVICE INFORMATION >

C

DE

F

G H

I

K L

M A

B

MTC

N

O P

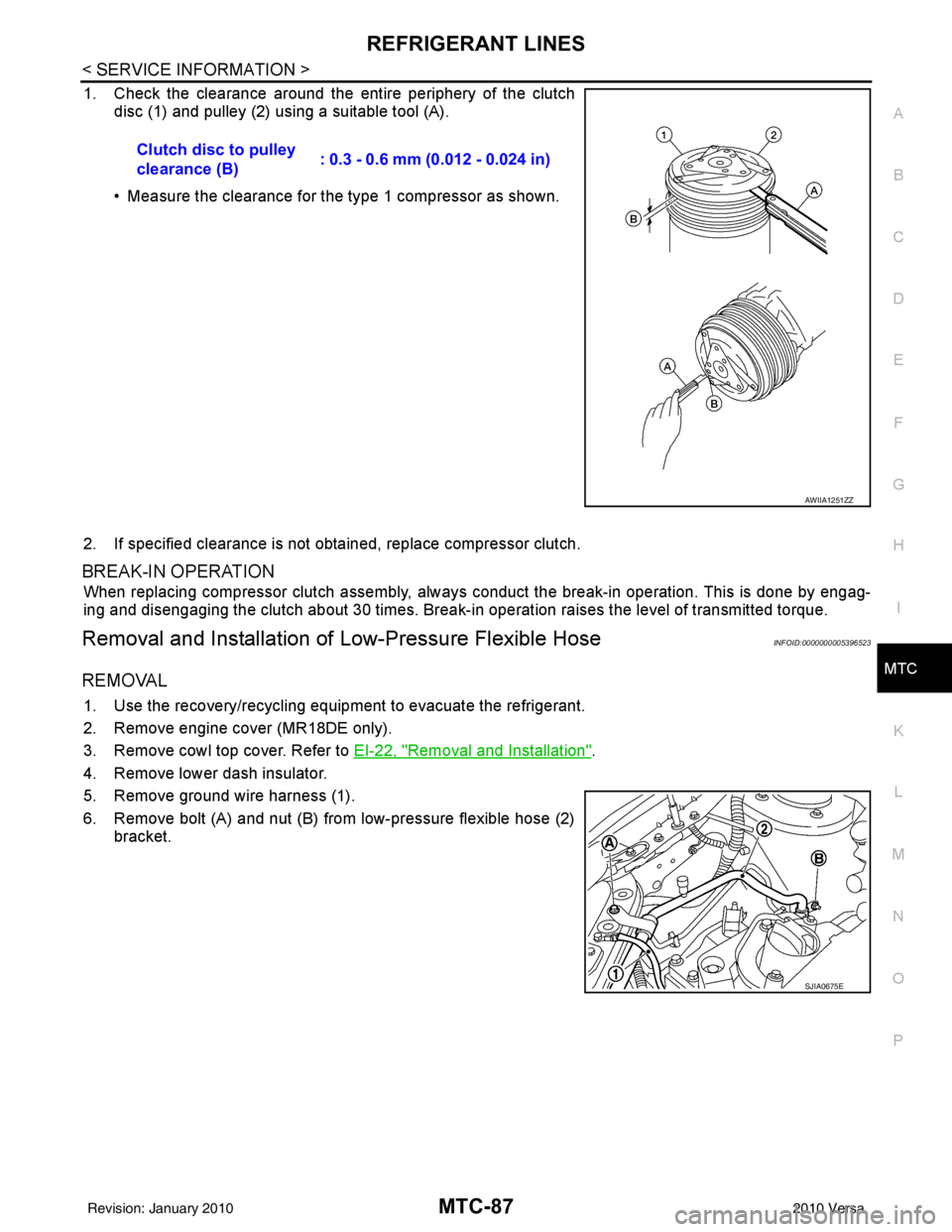

1. Check the clearance around the entire periphery of the clutch disc (1) and pulley (2) using a suitable tool (A).

• Measure the clearance for the type 1 compressor as shown.

2. If specified clearance is not obt ained, replace compressor clutch.

BREAK-IN OPERATION

When replacing compressor clutch assembly, always conduct the break-in operation. This is done by engag-

ing and disengaging the clutch about 30 times. Break-in operation raises the level of transmitted torque.

Removal and Installation of Low-Pressure Flexible HoseINFOID:0000000005396523

REMOVAL

1. Use the recovery/recycling equipment to evacuate the refrigerant.

2. Remove engine cover (MR18DE only).

3. Remove cowl top cover. Refer to EI-22, "

Removal and Installation".

4. Remove lower dash insulator.

5. Remove ground wire harness (1).

6. Remove bolt (A) and nut (B) from low-pressure flexible hose (2) bracket.Clutch disc to pulley

clearance (B)

: 0.3 - 0.6 mm (0.012 - 0.024 in)

AWIIA1251ZZ

SJIA0675E

Revision: January 20102010 Versa

Page 3677 of 3745

![NISSAN TIIDA 2010 Service Repair Manual PRECAUTIONSSTC-31

< PRECAUTION > [EPS]

C

D

E

F

H I

J

K L

M A

B

STC

N

O P

5. When the repair work is completed, return the ignition switch to the ″LOCK ″ position before connecting

the battery cab NISSAN TIIDA 2010 Service Repair Manual PRECAUTIONSSTC-31

< PRECAUTION > [EPS]

C

D

E

F

H I

J

K L

M A

B

STC

N

O P

5. When the repair work is completed, return the ignition switch to the ″LOCK ″ position before connecting

the battery cab](/img/5/57397/w960_57397-3676.png)

PRECAUTIONSSTC-31

< PRECAUTION > [EPS]

C

D

E

F

H I

J

K L

M A

B

STC

N

O P

5. When the repair work is completed, return the ignition switch to the ″LOCK ″ position before connecting

the battery cables. (At this time, the steering lock mechanism will engage.)

6. Perform a self-diagnosis check of al l control units using CONSULT-III.

Service Notice or Precaution for EPS SystemINFOID:0000000005602354

CAUTION:

Check or confirm the following item wh en performing the trouble diagnosis.

• Check any possible causes by interviewing the symptom and it’s condition from the customer if any

malfunction, such as EPS warn ing lamp turns ON, occurs.

• Check if air pressure and size of tires are proper, the specified part is used for the steering wheel,

and control unit is genuine part.

• Check if the connection of steer ing column assembly and steering gear assembly is proper (there is

not looseness of mounting bolts, damage of rods, boots or sealants, and leakage of grease, etc).

• Check if the wheel alignment is adjusted properly.

• Check if there is any damage or modification to su spension or body resulting in increased weight or

altered ground clearance.

• Check if installation conditions of each link and suspension are proper.

• Check if the battery voltage is proper

• Check connection conditions of each connector are proper.

• Before connecting or disconnect ing the EPS control unit har-

ness connector, turn ignition switch “OFF” and disconnect

battery ground cable. Because battery voltage is applied to

EPS control unit even if igniti on switch is turned “OFF”.

• When connecting or disconnect ing pin connectors into or

from EPS control unit, take care not to damage pin terminals

(bend or break).

When connecting pin connectors, make sure that there are no

bends or breaks on EPS control unit pin terminal.

• Before replacing EPS control unit, perform EPS control unit input/output signal inspectio n and make sure whether EPS

control unit functions properly or not. Refer to STC-20, "

Ref-

erence Value".

SEF289H

SEF291H

SDIA1848E

Revision: January 20102010 Versa