power distribution NISSAN TIIDA 2010 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2010, Model line: TIIDA, Model: NISSAN TIIDA 2010Pages: 3745, PDF Size: 73.67 MB

Page 1384 of 3745

![NISSAN TIIDA 2010 Service Repair Manual POWER SUPPLY AND GROUND CIRCUITEC-119

< COMPONENT DIAGNOSIS > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

Refer to

EC-114, "Diagnosis Procedure".

Is the inspection result normal?

YES >> Replace IPDM E/R NISSAN TIIDA 2010 Service Repair Manual POWER SUPPLY AND GROUND CIRCUITEC-119

< COMPONENT DIAGNOSIS > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

Refer to

EC-114, "Diagnosis Procedure".

Is the inspection result normal?

YES >> Replace IPDM E/R](/img/5/57397/w960_57397-1383.png)

POWER SUPPLY AND GROUND CIRCUITEC-119

< COMPONENT DIAGNOSIS > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

Refer to

EC-114, "Diagnosis Procedure".

Is the inspection result normal?

YES >> Replace IPDM E/R. Refer to PG-28, "Removal and Installation of IPDM E/R".

NO >> Repair open circuit or short to ground or short to power in harness or connectors.

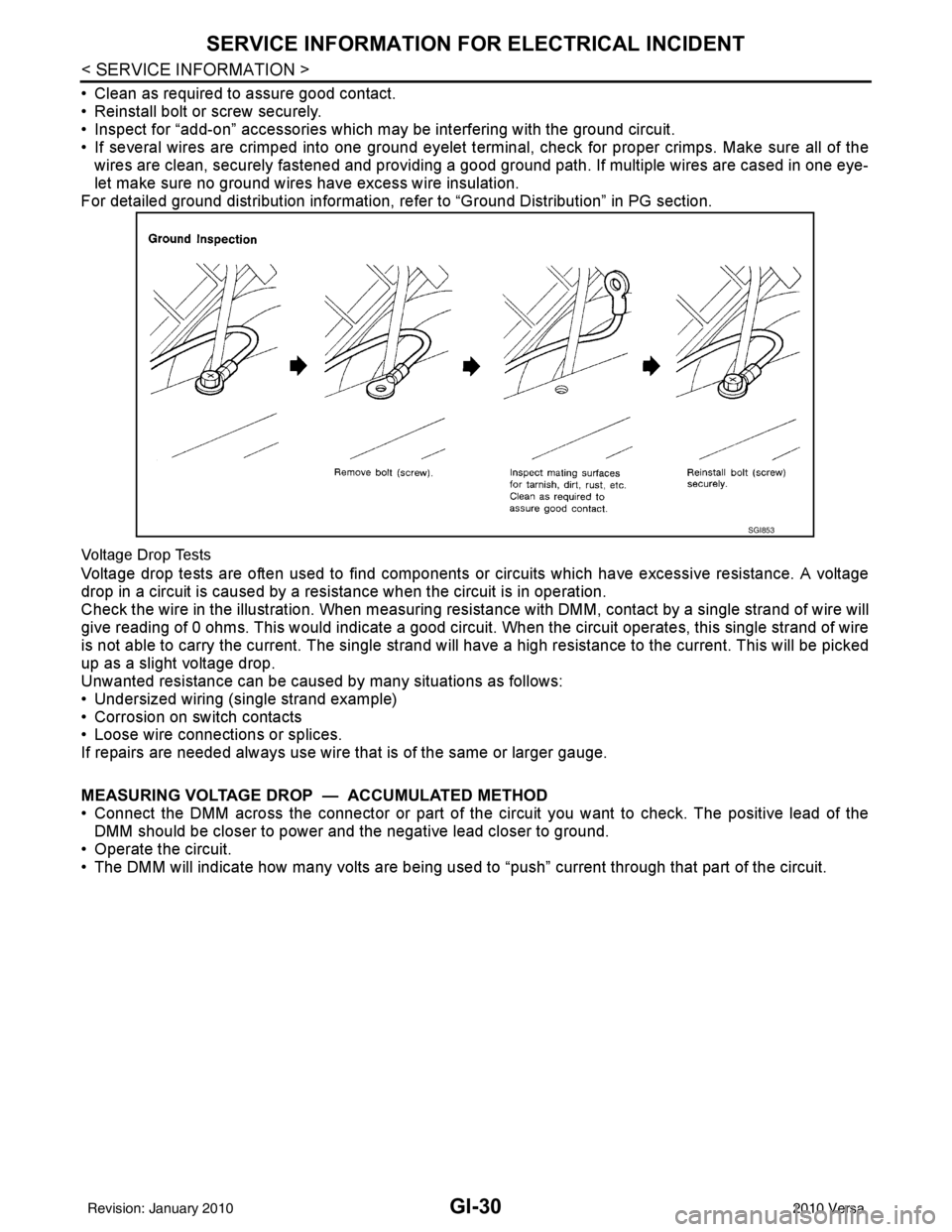

Ground InspectionINFOID:0000000005398287

Ground connections are very important to the proper oper ation of electrical and electronic circuits. Ground

connections are often exposed to moisture, dirt and other corrosive elements. The corrosion (rust) can

become an unwanted resistance. This unwanted resistance can change the way a circuit works.

Electronically controlled circuits are very sensitive to proper grounding. A loose or corroded ground can drasti-

cally affect an electronically controlled circuit. A poor or corroded ground can easily affect the circuit. Even

when the ground connection looks clean, there can be a thin film of rust on the surface.

When inspecting a ground connection follow these rules:

• Remove the ground bolt or screw.

• Inspect all mating surfaces for tarnish, dirt, rust, etc.

• Clean as required to assure good contact.

• Reinstall bolt or screw securely.

• Inspect for “add-on” accessories which may be interfering with the ground circuit.

• If several wires are crimped into one ground eyelet terminal, check for proper crimps. Make sure all of the wires are clean, securely fastened and providing a good ground path. If multiple wires are cased in one eye-

let make sure no ground wires have excess wire insulation.

For detailed ground distribution information, refer to PG-30, "

Ground Distribution".

PBIB1870E

Revision: January 20102010 Versa

Page 1903 of 3745

![NISSAN TIIDA 2010 Service Repair Manual EC-638

< SERVICE INFORMATION >[MR18DE]

POWER SUPPLY AND GROUND CIRCUIT

Ground Inspection

INFOID:0000000005532432

Ground connections are very important to the proper operation of electrical and electro NISSAN TIIDA 2010 Service Repair Manual EC-638

< SERVICE INFORMATION >[MR18DE]

POWER SUPPLY AND GROUND CIRCUIT

Ground Inspection

INFOID:0000000005532432

Ground connections are very important to the proper operation of electrical and electro](/img/5/57397/w960_57397-1902.png)

EC-638

< SERVICE INFORMATION >[MR18DE]

POWER SUPPLY AND GROUND CIRCUIT

Ground Inspection

INFOID:0000000005532432

Ground connections are very important to the proper operation of electrical and electronic circuits. Ground

connections are often exposed to moisture, dirt and ot her corrosive elements. The corrosion (rust) can

become an unwanted resistance. This unwanted resistance can change the way a circuit works.

Electronically controlled circuits are very sensitive to proper grounding. A loose or corroded ground can drasti-

cally affect an electronically controlled circuit. A poor or corroded ground can easily affect the circuit. Even

when the ground connection looks clean, there can be a thin film of rust on the surface.

When inspecting a ground connection follow these rules:

• Remove the ground bolt or screw.

• Inspect all mating surfaces for tarnish, dirt, rust, etc.

• Clean as required to assure good contact.

• Reinstall bolt or screw securely.

• Inspect for “add-on” accessories which may be interfering with the ground circuit.

• If several wires are crimped into one ground eyelet terminal, check for proper crimps. Make sure all of the wires are clean, securely fastened and providing a good ground path. If multiple wires are cased in one eye-

let make sure no ground wires have excess wire insulation.

For detailed ground distribution information, refer to PG-30, "

Ground Distribution".

PBIB1870E

Revision: January 20102010 Versa

Page 2696 of 3745

GI-30

< SERVICE INFORMATION >

SERVICE INFORMATION FOR ELECTRICAL INCIDENT

• Clean as required to assure good contact.

• Reinstall bolt or screw securely.

• Inspect for “add-on” accessories which may be interfering with the ground circuit.

• If several wires are crimped into one ground eyelet terminal, check for proper crimps. Make sure all of thewires are clean, securely fastened and providing a good ground path. If multiple wires are cased in one eye-

let make sure no ground wires have excess wire insulation.

For detailed ground distribution information, refer to “Ground Distribution” in PG section.

Voltage Drop Tests

Voltage drop tests are often used to find components or circuits which have excessive resistance. A voltage

drop in a circuit is caused by a resistance when the circuit is in operation.

Check the wire in the illustration. When measuring resist ance with DMM, contact by a single strand of wire will

give reading of 0 ohms. This would indicate a good circuit. When the circuit operates, this single strand of wire

is not able to carry the current. The single strand will have a high resistance to the current. This will be picked

up as a slight voltage drop.

Unwanted resistance can be caused by many situations as follows:

• Undersized wiring (single strand example)

• Corrosion on switch contacts

• Loose wire connections or splices.

If repairs are needed always use wire that is of the same or larger gauge.

MEASURING VOLTAGE DROP — ACCUMULATED METHOD

• Connect the DMM across the connector or part of the circuit you want to check. The positive lead of the

DMM should be closer to power and the negative lead closer to ground.

• Operate the circuit.

• The DMM will indicate how many volts are being used to “push” current through that part of the circuit.

SGI853

Revision: January 20102010 Versa

Page 2768 of 3745

REAR WINDOW DEFOGGERGW-51

< SERVICE INFORMATION >

C

DE

F

G H

J

K L

M A

B

GW

N

O P

REAR WINDOW DEFOGGER

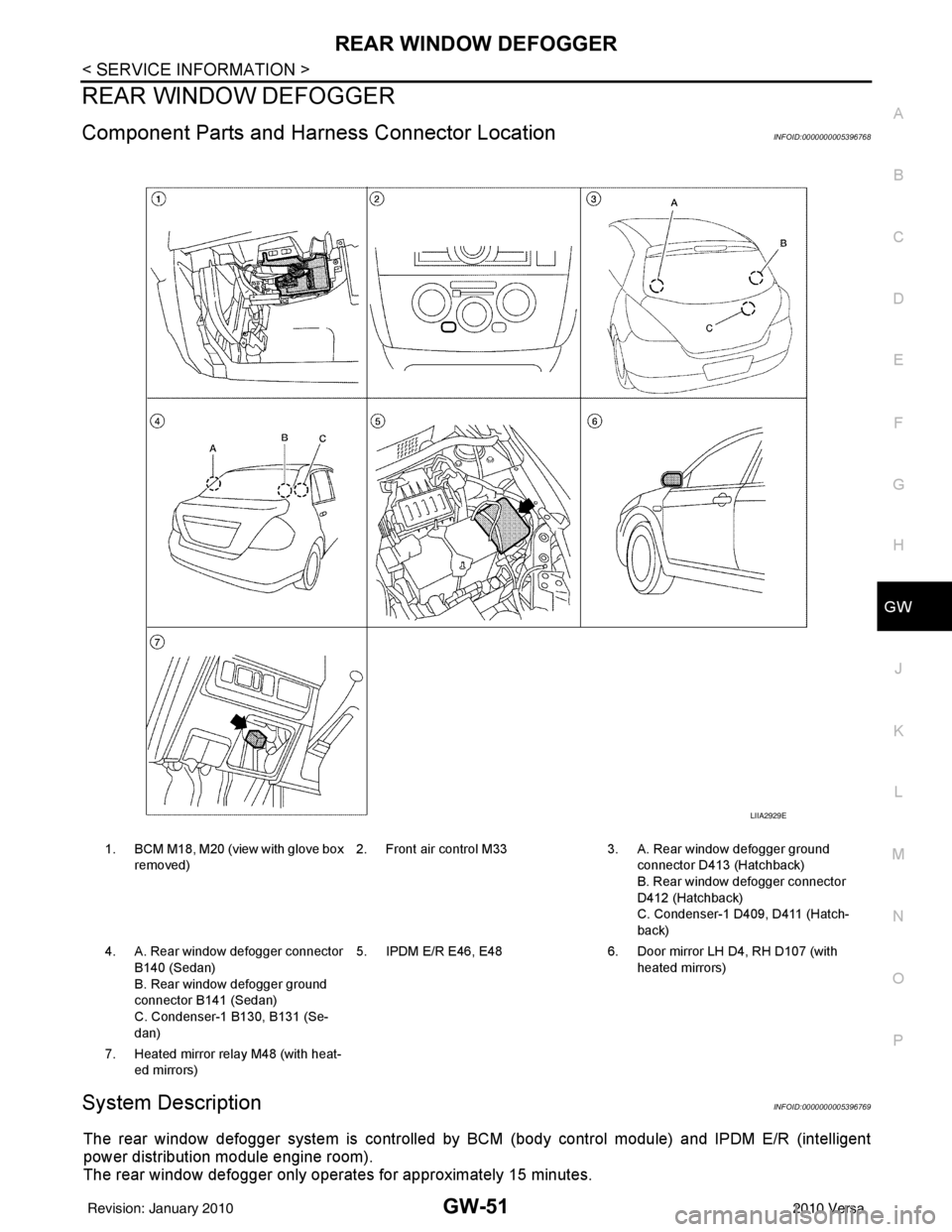

Component Parts and Har ness Connector LocationINFOID:0000000005396768

System DescriptionINFOID:0000000005396769

The rear window defogger system is controlled by BCM (body control module) and IPDM E/R (intelligent

power distribution module engine room).

The rear window defogger only operates for approximately 15 minutes.

1. BCM M18, M20 (view with glove box

removed) 2. Front air control M33 3. A. Rear window defogger ground

connector D413 (Hatchback)

B. Rear window defogger connector

D412 (Hatchback)

C. Condenser-1 D409, D411 (Hatch-

back)

4. A. Rear window defogger connector B140 (Sedan)

B. Rear window defogger ground

connector B141 (Sedan)

C. Condenser-1 B130, B131 (Se-

dan) 5. IPDM E/R E46, E48

6. Door mirror LH D4, RH D107 (with

heated mirrors)

7. Heated mirror relay M48 (with heat- ed mirrors)

LIIA2929E

Revision: January 20102010 Versa

Page 3023 of 3745

LT-28

< SERVICE INFORMATION >

HEADLAMP (FOR CANADA) - DAYTIME LIGHT SYSTEM -

HEADLAMP (FOR CANADA) - DAYTIME LIGHT SYSTEM -

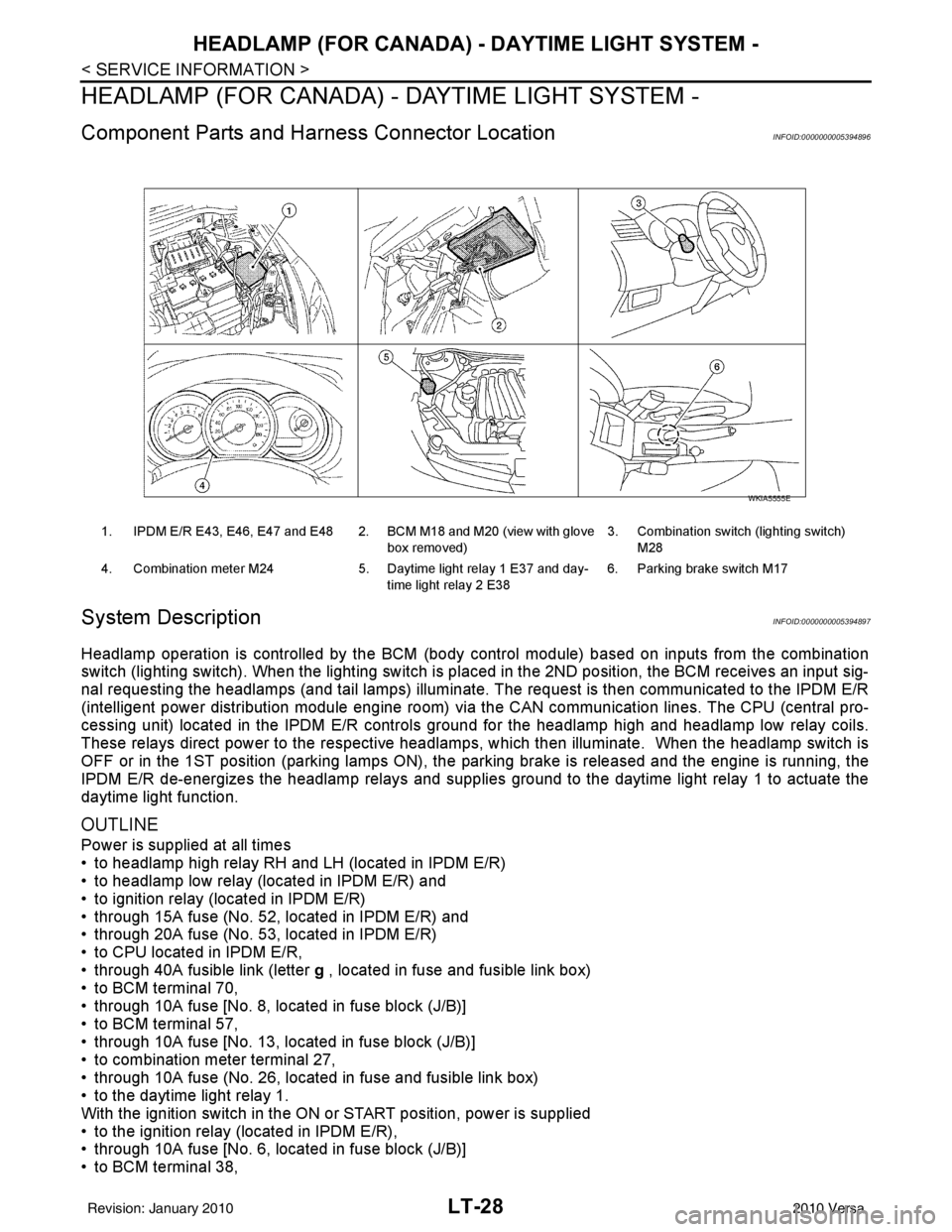

Component Parts and Harness Connector LocationINFOID:0000000005394896

System DescriptionINFOID:0000000005394897

Headlamp operation is controlled by the BCM (body c ontrol module) based on inputs from the combination

switch (lighting switch). When the lighting switch is pl aced in the 2ND position, the BCM receives an input sig-

nal requesting the headlamps (and tail lamps) illuminate. The request is then communicated to the IPDM E/R

(intelligent power distribution module engine room) vi a the CAN communication lines. The CPU (central pro-

cessing unit) located in the IPDM E/R controls ground for the headlamp high and headlamp low relay coils.

These relays direct power to the respective headlamps , which then illuminate. When the headlamp switch is

OFF or in the 1ST position (parking lamps ON), the parking brake is released and the engine is running, the

IPDM E/R de-energizes the headlamp relays and supplies ground to the daytime light relay 1 to actuate the

daytime light function.

OUTLINE

Power is supplied at all times

• to headlamp high relay RH and LH (located in IPDM E/R)

• to headlamp low relay (located in IPDM E/R) and

• to ignition relay (located in IPDM E/R)

• through 15A fuse (No. 52, located in IPDM E/R) and

• through 20A fuse (No. 53, located in IPDM E/R)

• to CPU located in IPDM E/R,

• through 40A fusible link (letter g , located in fuse and fusible link box)

• to BCM terminal 70,

• through 10A fuse [No. 8, located in fuse block (J/B)]

• to BCM terminal 57,

• through 10A fuse [No. 13, located in fuse block (J/B)]

• to combination meter terminal 27,

• through 10A fuse (No. 26, located in fuse and fusible link box)

• to the daytime light relay 1.

With the ignition switch in the ON or START position, power is supplied

• to the ignition relay (located in IPDM E/R),

• through 10A fuse [No. 6, located in fuse block (J/B)]

• to BCM terminal 38,

1. IPDM E/R E43, E46, E47 and E48 2. BCM M18 and M20 (view with glove

box removed)3. Combination switch (lighting switch)

M28

4. Combination meter M24 5. Daytime light relay 1 E37 and day-

time light relay 2 E38 6. Parking brake switch M17

WKIA5555E

Revision: January 20102010 Versa

Page 3037 of 3745

LT-42

< SERVICE INFORMATION >

FRONT FOG LAMP

FRONT FOG LAMP

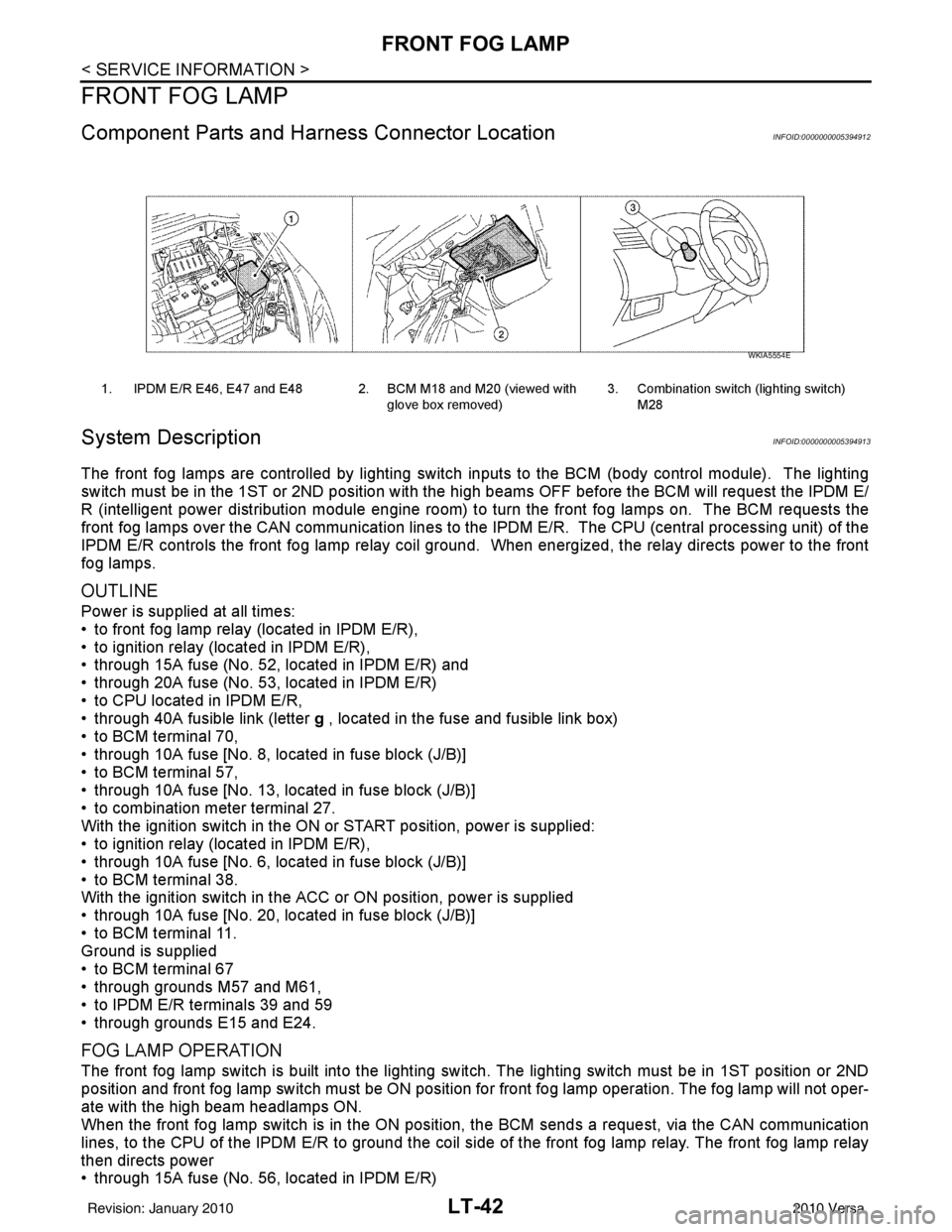

Component Parts and Harness Connector LocationINFOID:0000000005394912

System DescriptionINFOID:0000000005394913

The front fog lamps are controlled by lighting switch inputs to the BCM (body control module). The lighting

switch must be in the 1ST or 2ND position with t he high beams OFF before the BCM will request the IPDM E/

R (intelligent power distribution module engine room) to turn the front fog lamps on. The BCM requests the

front fog lamps over the CAN communication lines to the IPDM E/R. The CPU (central processing unit) of the

IPDM E/R controls the front fog lamp relay coil ground. When energized, the relay directs power to the front

fog lamps.

OUTLINE

Power is supplied at all times:

• to front fog lamp relay (located in IPDM E/R),

• to ignition relay (located in IPDM E/R),

• through 15A fuse (No. 52, located in IPDM E/R) and

• through 20A fuse (No. 53, located in IPDM E/R)

• to CPU located in IPDM E/R,

• through 40A fusible link (letter g , located in the fuse and fusible link box)

• to BCM terminal 70,

• through 10A fuse [No. 8, located in fuse block (J/B)]

• to BCM terminal 57,

• through 10A fuse [No. 13, located in fuse block (J/B)]

• to combination meter terminal 27.

With the ignition switch in the ON or START position, power is supplied:

• to ignition relay (located in IPDM E/R),

• through 10A fuse [No. 6, located in fuse block (J/B)]

• to BCM terminal 38.

With the ignition switch in the ACC or ON position, power is supplied

• through 10A fuse [No. 20, located in fuse block (J/B)]

• to BCM terminal 11.

Ground is supplied

• to BCM terminal 67

• through grounds M57 and M61,

• to IPDM E/R terminals 39 and 59

• through grounds E15 and E24.

FOG LAMP OPERATION

The front fog lamp switch is built into the lighting s witch. The lighting switch must be in 1ST position or 2ND

position and front fog lamp switch must be ON position fo r front fog lamp operation. The fog lamp will not oper-

ate with the high beam headlamps ON.

When the front fog lamp switch is in the ON positi on, the BCM sends a request, via the CAN communication

lines, to the CPU of the IPDM E/R to ground the coil side of the front fog lamp relay. The front fog lamp relay

then directs power

• through 15A fuse (No. 56, located in IPDM E/R)

1. IPDM E/R E46, E47 and E48 2. BCM M18 and M20 (viewed with

glove box removed)3. Combination switch (lighting switch)

M28

WKIA5554E

Revision: January 20102010 Versa

Page 3070 of 3745

PARKING, LICENSE PLATE AND TAIL LAMPS

LT-75

< SERVICE INFORMATION >

C

D E

F

G H

I

J

L

M A

B

LT

N

O P

PARKING, LICENSE PLATE AND TAIL LAMPS

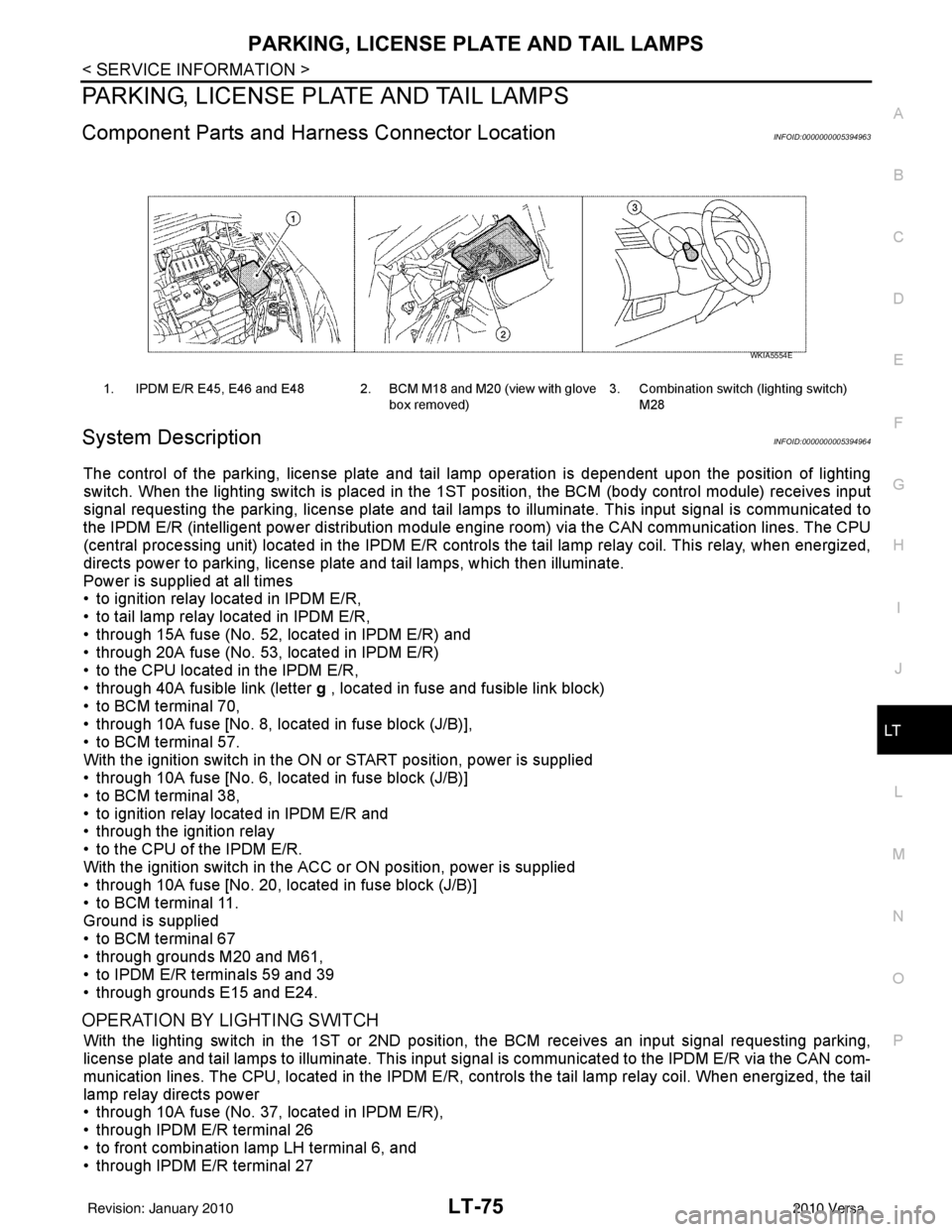

Component Parts and Har ness Connector LocationINFOID:0000000005394963

System DescriptionINFOID:0000000005394964

The control of the parking, license plate and tail lamp operation is dependent upon the position of lighting

switch. When the lighting switch is placed in the 1ST position, the BCM (body control module) receives input

signal requesting the parking, license plate and tail lamps to illuminate. This input signal is communicated to

the IPDM E/R (intelligent power distribution module engine room) via the CAN communication lines. The CPU

(central processing unit) located in the IPDM E/R contro ls the tail lamp relay coil. This relay, when energized,

directs power to parking, license plate and tail lamps, which then illuminate.

Power is supplied at all times

• to ignition relay located in IPDM E/R,

• to tail lamp relay located in IPDM E/R,

• through 15A fuse (No. 52, located in IPDM E/R) and

• through 20A fuse (No. 53, located in IPDM E/R)

• to the CPU located in the IPDM E/R,

• through 40A fusible link (letter g , located in fuse and fusible link block)

• to BCM terminal 70,

• through 10A fuse [No. 8, located in fuse block (J/B)],

• to BCM terminal 57.

With the ignition switch in the ON or START position, power is supplied

• through 10A fuse [No. 6, located in fuse block (J/B)]

• to BCM terminal 38,

• to ignition relay located in IPDM E/R and

• through the ignition relay

• to the CPU of the IPDM E/R.

With the ignition switch in the ACC or ON position, power is supplied

• through 10A fuse [No. 20, located in fuse block (J/B)]

• to BCM terminal 11.

Ground is supplied

• to BCM terminal 67

• through grounds M20 and M61,

• to IPDM E/R terminals 59 and 39

• through grounds E15 and E24.

OPERATION BY LIGHTING SWITCH

With the lighting switch in the 1ST or 2ND positi on, the BCM receives an input signal requesting parking,

license plate and tail lamps to illuminate. This input si gnal is communicated to the IPDM E/R via the CAN com-

munication lines. The CPU, located in the IPDM E/R, c ontrols the tail lamp relay coil. When energized, the tail

lamp relay directs power

• through 10A fuse (No. 37, located in IPDM E/R),

• through IPDM E/R terminal 26

• to front combination lamp LH terminal 6, and

• through IPDM E/R terminal 27

1. IPDM E/R E45, E46 and E48 2. BCM M18 and M20 (view with glove

box removed)3. Combination switch (lighting switch)

M28

WKIA5554E

Revision: January 20102010 Versa

Page 3105 of 3745

LT-110

< SERVICE INFORMATION >

ILLUMINATION

ILLUMINATION

System DescriptionINFOID:0000000005394998

The control of the illumination lamps operation is dependent upon the position of the lighting switch. When the

lighting switch is placed in the 1ST or 2ND position, the BCM (body con\

trol module) receives input signal

requesting the illumination lamps to illuminate. This i nput signal is communicated to IPDM E/R (intelligent

power distribution module engine room) across CAN communication lines. CPU (central processing unit)

located in the IPDM E/R controls the tail lamp relay coil. This relay, when energized, directs power to the illu-

mination lamps, which then illuminate.

Power is supplied at all times

• to ignition relay, located in IPDM E/R,

• to tail lamp relay, located in IPDM E/R,

• through 15A fuse (No. 52, located in IPDM E/R) and

• through 20A fuse (No. 53, located in IPDM E/R)

• to CPU located in IPDM E/R,

• through 40A fusible link (letter g, located in fuse and fusible link box)

• to BCM terminal 70, and

• through 10A fuse [No. 8, located in fuse block (J/B)]

• to BCM terminal 57.

With the ignition switch in the ON or START position, power is supplied

• to ignition relay, located in IPDM E/R, and

• through 10A fuse [No. 6, located in fuse block (J/B)]

• to BCM terminal 38.

With the ignition switch in the ACC or ON position, power is supplied

• through 10A fuse [No. 20, located in fuse block (J/B)]

• to BCM terminal 11.

Ground is supplied

• to BCM terminal 67

• through grounds M57 and M61

• to IPDM E/R terminals 39 and 59, and

• through grounds E15 and E24.

ILLUMINATION OPERATION BY LIGHTING SWITCH

With the lighting switch in the 1ST or 2ND position, BCM receives input signal requesting the illumination

lamps to illuminate. This input signal is communica ted to IPDM E/R across CAN communication lines. CPU

located in the IPDM E/R controls the tail lamp relay coil, which, when energized, directs power

• through 10A fuse (No. 37, located in IPDM E/R)

• through IPDM E/R terminal 29

• to illumination control switch terminal 1

• to VDC OFF switch terminal 3 (with VDC)

• to audio unit (with audio unit) or AV control unit (with premium audio system) terminal 9

• to front air control terminal 5

• to A/T shift selector terminal 3 (with 4-speed A/T)

• to CVT shift selector terminal 3 (with CVT)

• to hazard switch terminal 3

• to combination meter terminal 12

• to door mirror remote control switch terminal 16

• to combination switch (spiral cable) terminal 26 (with steering wheel audio control switches)

• to steering wheel audio control switches through combination switch (spiral cable) terminal 18 (with steering wheel audio control switches).

Ground is supplied

• to VDC OFF switch terminal 4 (with VDC)

• to illumination control switch terminal 3, and

• through grounds M57 and M61.

The illumination control switch controls illumination intensity by varying the ground to the following

• through illumination control switch terminal 2

• to audio unit (with audio unit) or AV control unit (with premium audio system) terminal 8

• to front air control terminal 6

• to A/T shift selector terminal 4 (with 4-speed A/T)

• to CVT shift selector terminal 3 (with CVT)

Revision: January 20102010 Versa

Page 3384 of 3745

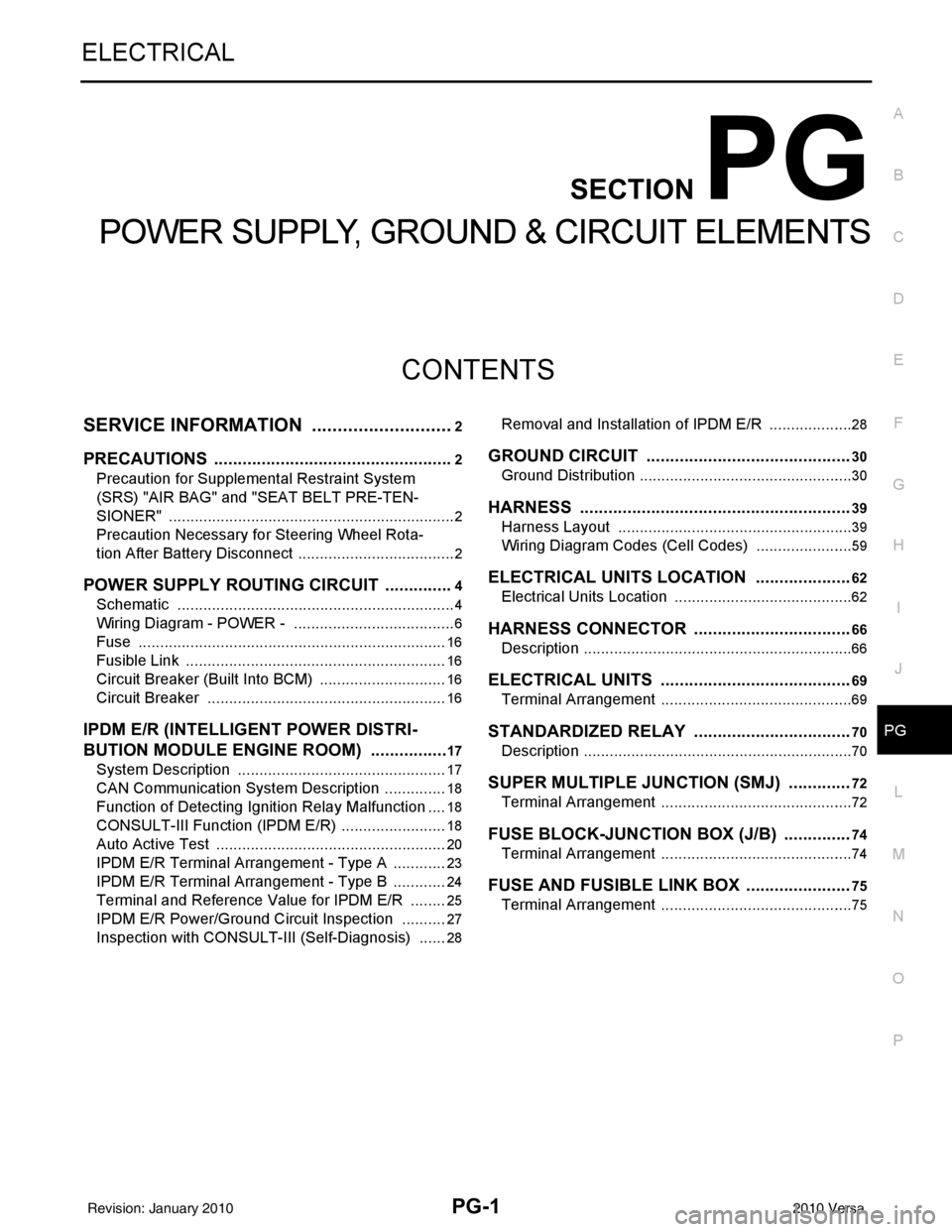

PG-1

ELECTRICAL

C

DE

F

G H

I

J

L

M

SECTION PG

A

B

PG

N

O P

CONTENTS

POWER SUPPLY, GROUND & CIRCUIT ELEMENTS

SERVICE INFORMATION .. ..........................2

PRECAUTIONS .............................................. .....2

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

2

Precaution Necessary for Steering Wheel Rota-

tion After Battery Disconnect ............................... ......

2

POWER SUPPLY ROUTING CIRCUIT ...............4

Schematic ........................................................... ......4

Wiring Diagram - POWER - ......................................6

Fuse ........................................................................16

Fusible Link .............................................................16

Circuit Breaker (Built Into BCM) ..............................16

Circuit Breaker ........................................................16

IPDM E/R (INTELLIGENT POWER DISTRI-

BUTION MODULE ENGINE ROOM) .................

17

System Description ............................................. ....17

CAN Communication System Description ...............18

Function of Detecting Ignition Relay Malfunction ....18

CONSULT-III Function (IPDM E/R) ..................... ....18

Auto Active Test ......................................................20

IPDM E/R Terminal Arrangement - Type A .............23

IPDM E/R Terminal Arrangement - Type B .............24

Terminal and Reference Value for IPDM E/R .........25

IPDM E/R Power/Ground Circuit Inspection ...........27

Inspection with CONSULT-III (Self-Diagnosis) .......28

Removal and Installation of IPDM E/R ................ ....28

GROUND CIRCUIT ...........................................30

Ground Distribution .............................................. ....30

HARNESS .........................................................39

Harness Layout ................................................... ....39

Wiring Diagram Codes (Cell Codes) .......................59

ELECTRICAL UNITS LOCATION ....................62

Electrical Units Location ..........................................62

HARNESS CONNECTOR .................................66

Description ...............................................................66

ELECTRICAL UNITS ........................................69

Terminal Arrangement .............................................69

STANDARDIZED RELAY .................................70

Description ...............................................................70

SUPER MULTIPLE JUNCTION (SMJ) .............72

Terminal Arrangement .............................................72

FUSE BLOCK-JUNCTION BOX (J/B) ..............74

Terminal Arrangement .............................................74

FUSE AND FUSIBLE LINK BOX ......................75

Terminal Arrangement .............................................75

Revision: January 20102010 Versa

Page 3387 of 3745

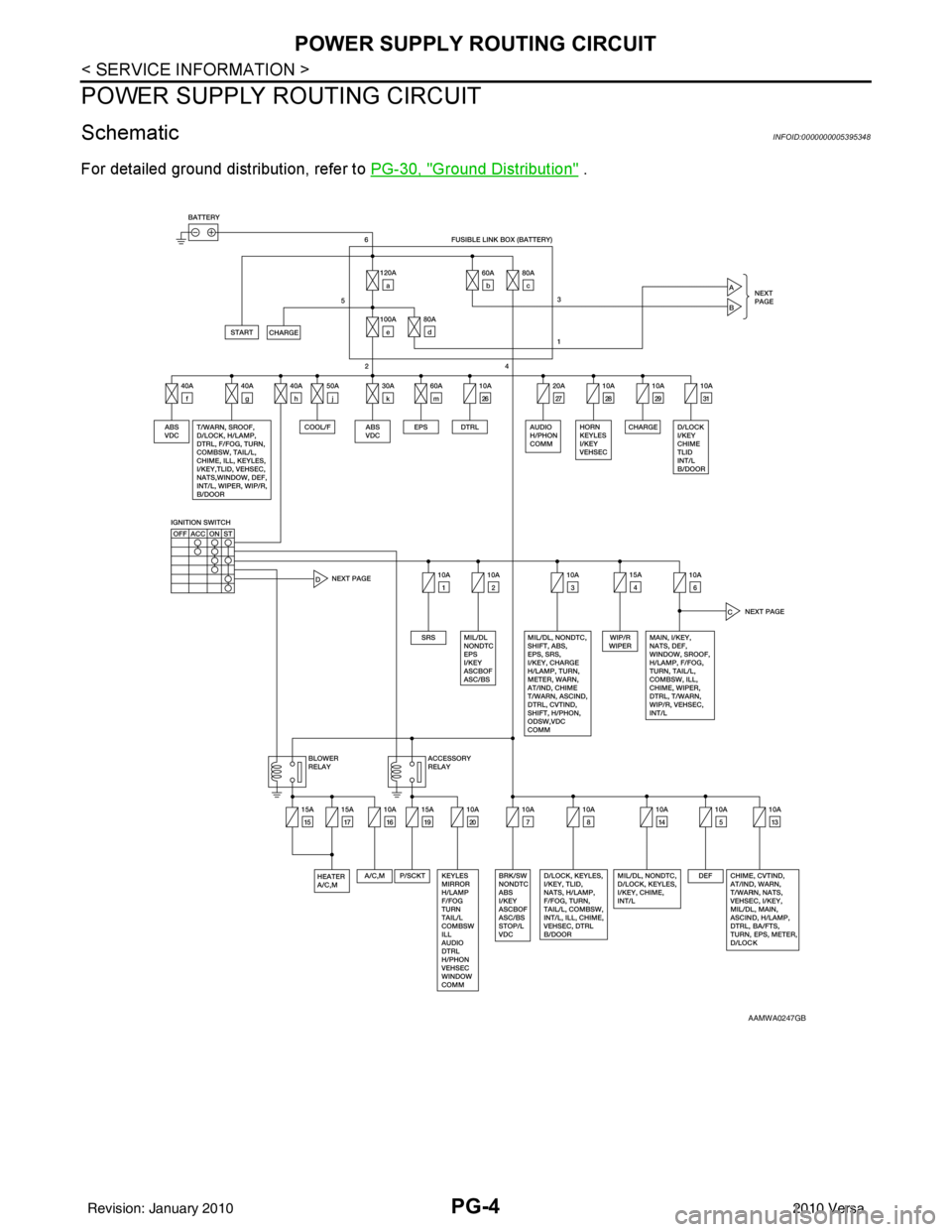

PG-4

< SERVICE INFORMATION >

POWER SUPPLY ROUTING CIRCUIT

POWER SUPPLY ROUTING CIRCUIT

SchematicINFOID:0000000005395348

For detailed ground distribution, refer to PG-30, "Ground Distribution" .

AAMWA0247GB

Revision: January 20102010 Versa