engine NISSAN TIIDA 2011 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2011, Model line: TIIDA, Model: NISSAN TIIDA 2011Pages: 3787, PDF Size: 78.35 MB

Page 198 of 3787

TROUBLE DIAGNOSIS FOR SYMPTOMSAT-181

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

OD OFF indicator lamp does not come on for abou t 2 seconds when turning ignition switch to ON.

DIAGNOSTIC PROCEDURE

1.CHECK CAN COMMUNICATION LINE

Perform self-diagnosis. Refer to AT-77, "

CONSULT-III Function (TRANSMISSION)" .

Is a malfunction in CAN communication indicated in the results?

YES >> Check CAN communication line. Refer to AT- 8 7 .

NO >> GO TO 2.

2.CHECK TCM POWER SOURCE

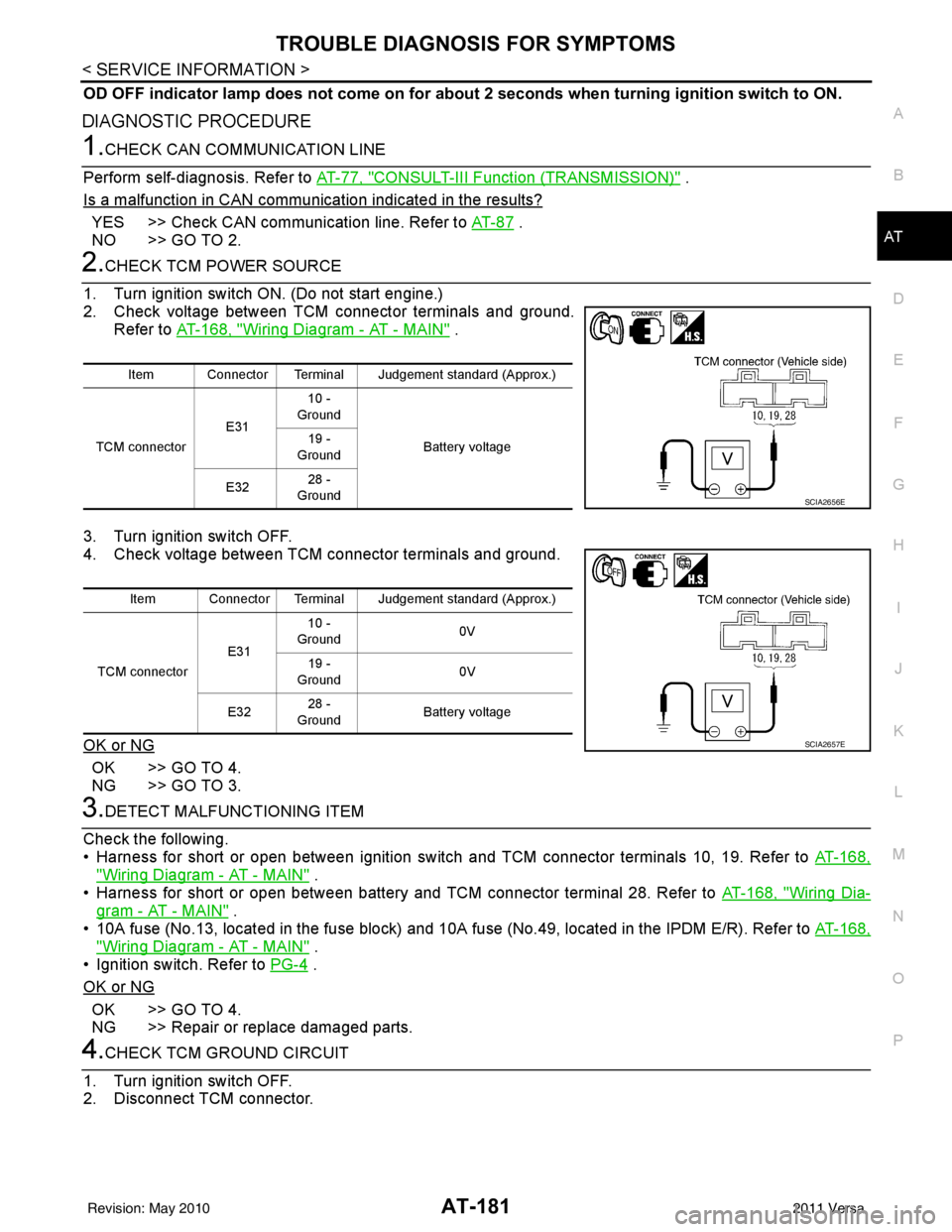

1. Turn ignition switch ON. (Do not start engine.)

2. Check voltage between TCM connector terminals and ground. Refer to AT-168, "

Wiring Diagram - AT - MAIN" .

3. Turn ignition switch OFF.

4. Check voltage between TCM connector terminals and ground.

OK or NG

OK >> GO TO 4.

NG >> GO TO 3.

3.DETECT MALFUNCTIONING ITEM

Check the following.

• Harness for short or open between ignition switch and TCM connector terminals 10, 19. Refer to AT-168,

"Wiring Diagram - AT - MAIN" .

• Harness for short or open between battery and TCM connector terminal 28. Refer to AT-168, "

Wiring Dia-

gram - AT - MAIN" .

• 10A fuse (No.13, located in the fuse block) and 10A fuse (No.49, located in the IPDM E/R). Refer to AT-168,

"Wiring Diagram - AT - MAIN" .

• Ignition switch. Refer to PG-4

.

OK or NG

OK >> GO TO 4.

NG >> Repair or replace damaged parts.

4.CHECK TCM GROUND CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect TCM connector.

Item Connector Terminal Judgement standard (Approx.)

TCM connector E3110 -

Ground

Battery voltage

19 -

Ground

E32 28 -

Ground

SCIA2656E

Item Connector Terminal Judgement standard (Approx.)

TCM connector E3110 -

Ground 0V

19 -

Ground 0V

E32 28 -

Ground Battery voltage

SCIA2657E

Revision: May 2010

2011 Versa

Page 199 of 3787

AT-182

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS FOR SYMPTOMS

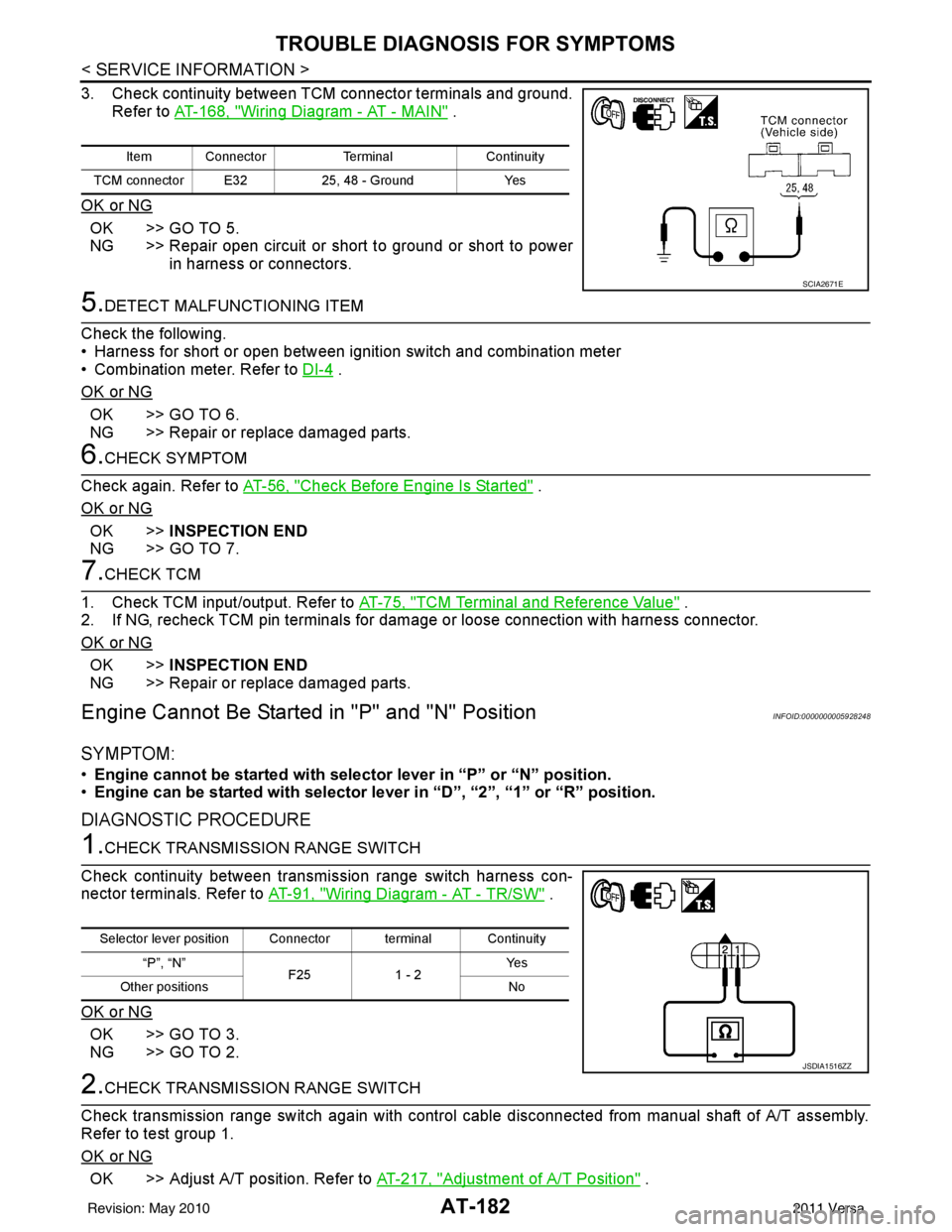

3. Check continuity between TCM connector terminals and ground.Refer to AT-168, "

Wiring Diagram - AT - MAIN" .

OK or NG

OK >> GO TO 5.

NG >> Repair open circuit or short to ground or short to power in harness or connectors.

5.DETECT MALFUNCTIONING ITEM

Check the following.

• Harness for short or open between ignition switch and combination meter

• Combination meter. Refer to DI-4

.

OK or NG

OK >> GO TO 6.

NG >> Repair or replace damaged parts.

6.CHECK SYMPTOM

Check again. Refer to AT-56, "

Check Before Engine Is Started" .

OK or NG

OK >> INSPECTION END

NG >> GO TO 7.

7.CHECK TCM

1. Check TCM input/output. Refer to AT-75, "

TCM Terminal and Reference Value" .

2. If NG, recheck TCM pin terminals for damage or loose connection with harness connector.

OK or NG

OK >> INSPECTION END

NG >> Repair or replace damaged parts.

Engine Cannot Be Started in "P" and "N" PositionINFOID:0000000005928248

SYMPTOM:

•Engine cannot be started with select or lever in “P” or “N” position.

• Engine can be started with selector lever in “D”, “2”, “1” or “R” position.

DIAGNOSTIC PROCEDURE

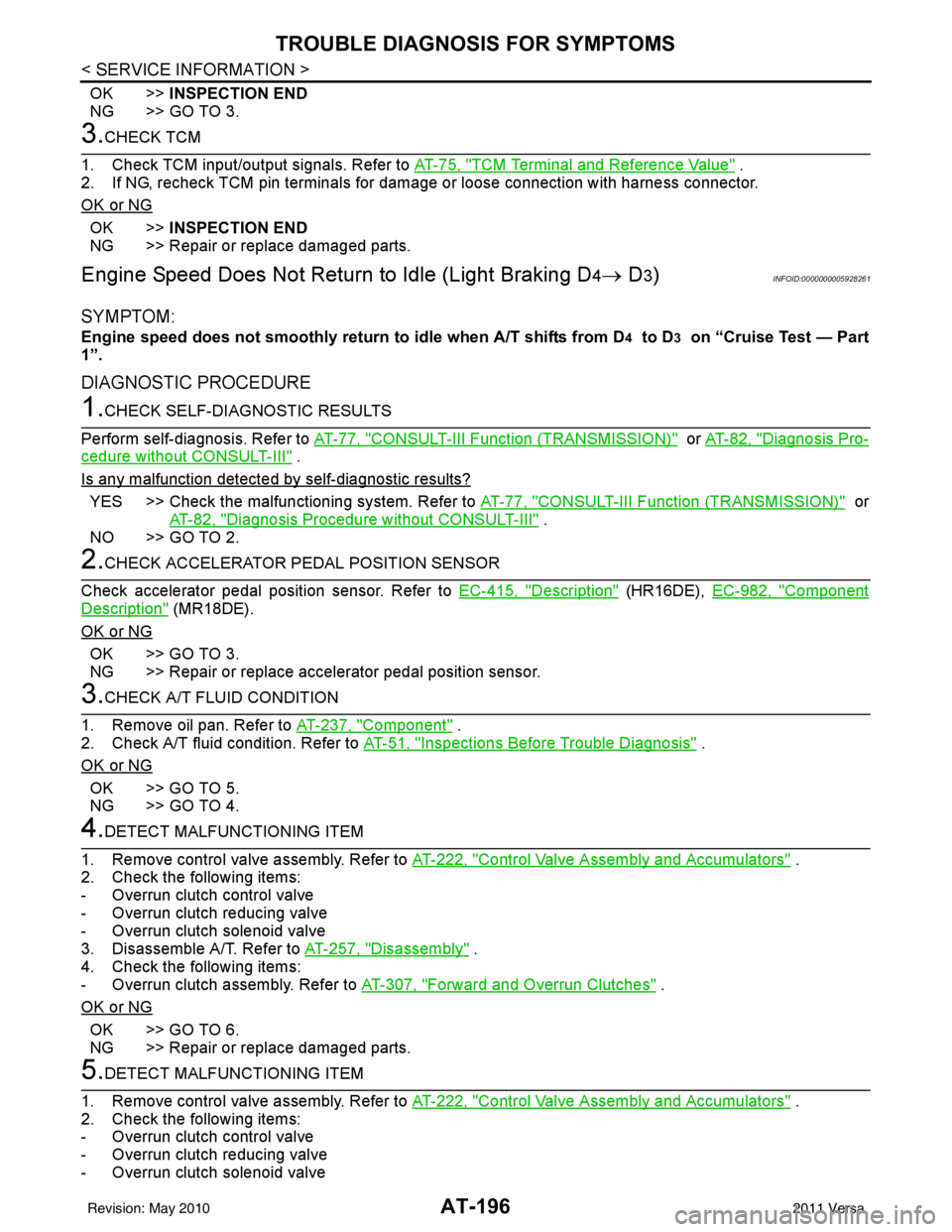

1.CHECK TRANSMISSION RANGE SWITCH

Check continuity between transmission range switch harness con-

nector terminals. Refer to AT-91, "

Wiring Diagram - AT - TR/SW" .

OK or NG

OK >> GO TO 3.

NG >> GO TO 2.

2.CHECK TRANSMISSION RANGE SWITCH

Check transmission range switch again with control cabl e disconnected from manual shaft of A/T assembly.

Refer to test group 1.

OK or NG

OK >> Adjust A/T position. Refer to AT-217, "Adjustment of A/T Position" .

Item ConnectorTerminalContinuity

TCM connector E32 25, 48 - GroundYes

SCIA2671E

Selector lever position Connector terminal Continuity

“P”, “N” F251 - 2 Ye s

Other positions No

JSDIA1516ZZ

Revision: May 2010 2011 Versa

Page 213 of 3787

AT-196

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS FOR SYMPTOMS

OK >>INSPECTION END

NG >> GO TO 3.

3.CHECK TCM

1. Check TCM input/output signals. Refer to AT-75, "

TCM Terminal and Reference Value" .

2. If NG, recheck TCM pin terminals for damage or loose connection with harness connector.

OK or NG

OK >> INSPECTION END

NG >> Repair or replace damaged parts.

Engine Speed Does Not Return to Idle (Light Braking D4→ D3)INFOID:0000000005928261

SYMPTOM:

Engine speed does not smoothly return to idle when A/T shifts from D4 to D3 on “Cruise Test — Part

1”.

DIAGNOSTIC PROCEDURE

1.CHECK SELF-DIAGNOSTIC RESULTS

Perform self-diagnosis. Refer to AT-77, "

CONSULT-III Function (TRANSMISSION)" or AT-82, "Diagnosis Pro-

cedure without CONSULT-III" .

Is any malfunction detected by self-diagnostic results?

YES >> Check the malfunctioning system. Refer to AT-77, "CONSULT-III Function (TRANSMISSION)" or

AT-82, "

Diagnosis Procedure without CONSULT-III" .

NO >> GO TO 2.

2.CHECK ACCELERATOR PEDAL POSITION SENSOR

Check accelerator pedal position sensor. Refer to EC-415, "

Description" (HR16DE), EC-982, "Component

Description" (MR18DE).

OK or NG

OK >> GO TO 3.

NG >> Repair or replace accelerator pedal position sensor.

3.CHECK A/T FLUID CONDITION

1. Remove oil pan. Refer to AT-237, "

Component" .

2. Check A/T fluid condition. Refer to AT-51, "

Inspections Before Trouble Diagnosis" .

OK or NG

OK >> GO TO 5.

NG >> GO TO 4.

4.DETECT MALFUNCTIONING ITEM

1. Remove control valve assembly. Refer to AT-222, "

Control Valve Assembly and Accumulators" .

2. Check the following items:

- Overrun clutch control valve

- Overrun clutch reducing valve

- Overrun clutch solenoid valve

3. Disassemble A/T. Refer to AT-257, "

Disassembly" .

4. Check the following items:

- Overrun clutch assembly. Refer to AT-307, "

Forward and Overrun Clutches" .

OK or NG

OK >> GO TO 6.

NG >> Repair or replace damaged parts.

5.DETECT MALFUNCTIONING ITEM

1. Remove control valve assembly. Refer to AT-222, "

Control Valve Assembly and Accumulators" .

2. Check the following items:

- Overrun clutch control valve

- Overrun clutch reducing valve

- Overrun clutch solenoid valve

Revision: May 2010 2011 Versa

Page 214 of 3787

TROUBLE DIAGNOSIS FOR SYMPTOMSAT-197

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

OK or NG

OK >> GO TO 6.

NG >> Repair or replace damaged parts.

6.CHECK SYMPTOM

Check again. Refer to AT-58, "

Cruise Test - Part 1" .

OK or NG

OK >> INSPECTION END

NG >> GO TO 7.

7.CHECK TCM

1. Check TCM input/output signals. Refer to AT-75, "

TCM Terminal and Reference Value" .

2. If NG, recheck TCM pin terminals for dam age or loose connection with harness connector.

OK or NG

OK >> INSPECTION END

NG >> Repair or replace damaged parts.

A/T Does Not Shift: D4→ D3, When OD OFFINFOID:0000000005928262

SYMPTOM:

A/T does not shift from D4 to D3 when OD OFF (OD OFF indicator lamp is on) on “Cruise Test — Part

3”.

DIAGNOSTIC PROCEDURE

1.CHECK CAN COMMUNICATION LINE

Perform self-diagnosis. Refer to AT-77, "

CONSULT-III Function (TRANSMISSION)" or AT-82, "Diagnosis Pro-

cedure without CONSULT-III" .

Is a malfunction in CAN communication indicated in the results?

YES >> Check CAN communication line. Refer to AT- 8 7 .

NO >> GO TO 2.

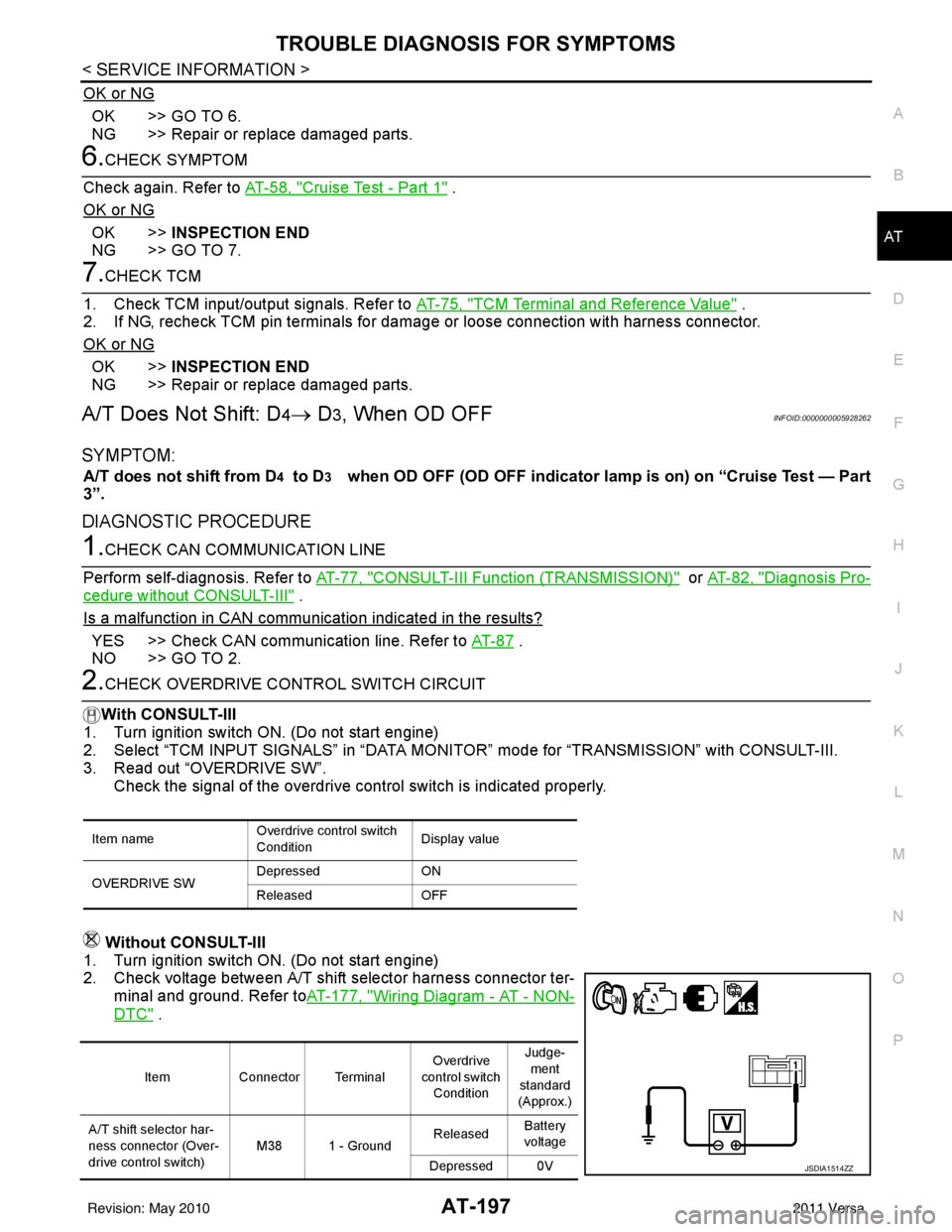

2.CHECK OVERDRIVE CO NTROL SWITCH CIRCUIT

With CONSULT-III

1. Turn ignition switch ON. (Do not start engine)

2. Select “TCM INPUT SIGNALS” in “DATA MONI TOR” mode for “TRANSMISSION” with CONSULT-III.

3. Read out “OVERDRIVE SW”. Check the signal of the overdrive control switch is indicated properly.

Without CONSULT-III

1. Turn ignition switch ON. (Do not start engine)

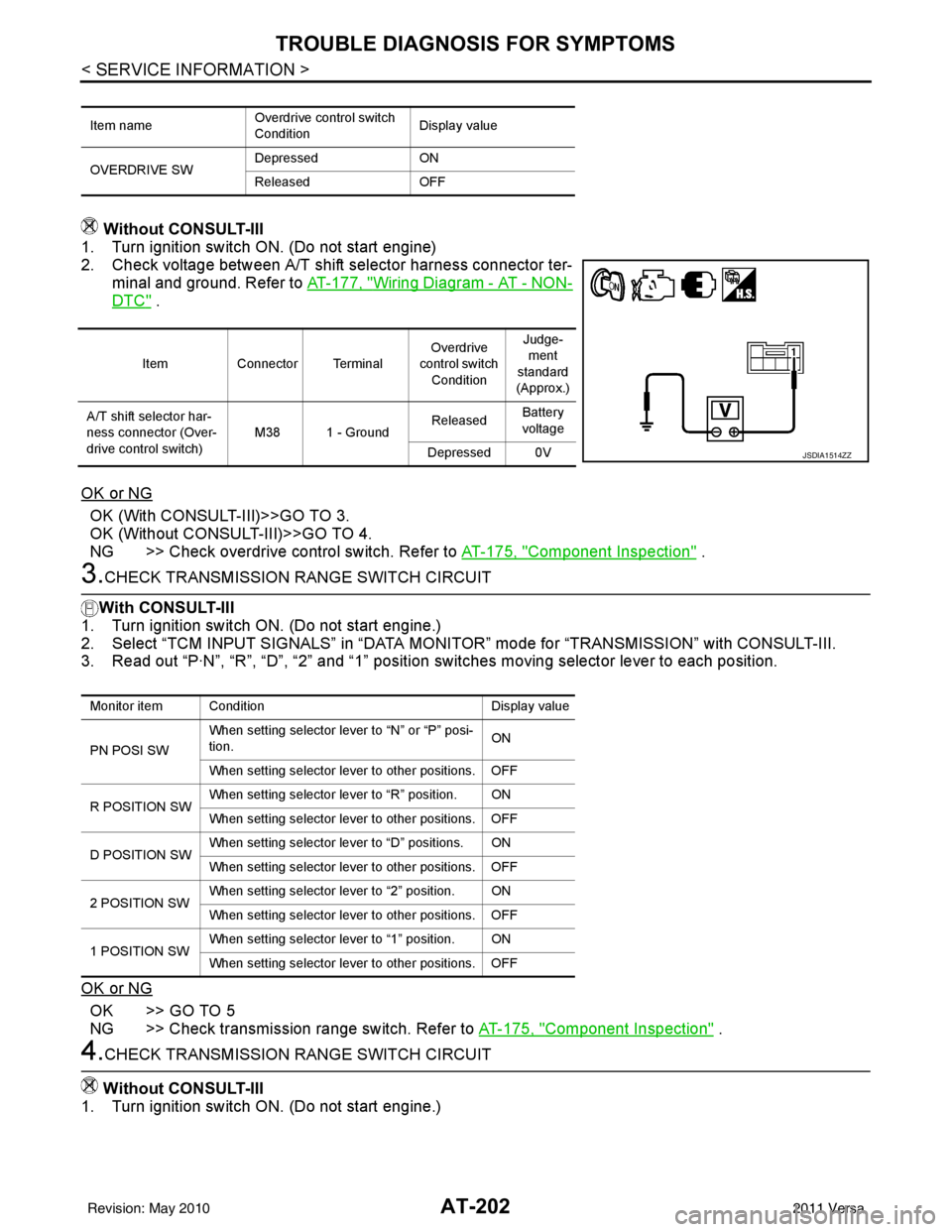

2. Check voltage between A/T shift selector harness connector ter- minal and ground. Refer to AT-177, "

Wiring Diagram - AT - NON-

DTC" .

Item name Overdrive control switch

ConditionDisplay value

OVERDRIVE SW Depressed

ON

Released OFF

ItemConnector Terminal Overdrive

control switch Condition Judge-

ment

standard

(Approx.)

A/T shift selector har-

ness connector (Over-

drive control switch) M38 1 - Ground

Released

Battery

voltage

Depressed 0V

JSDIA1514ZZ

Revision: May 2010 2011 Versa

Page 215 of 3787

AT-198

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS FOR SYMPTOMS

OK or NG

OK >> Go to AT-190, "A/T Does Not Shift: D2→ D3" .

NG >> Check overdrive control switch. Refer to AT-175, "

Component Inspection" .

A/T Does Not Shift: D3→ 22, When Selector Lever "D" → "2" PositionINFOID:0000000005928263

SYMPTOM:

A/T does not shift from D3 to 22 when changing selector lever from “D” to “2” position on “Cruise

Test — Part 3”.

DIAGNOSTIC PROCEDURE

1.CHECK SYMPTOM

Check symptom. Refer to AT-58, "

Cruise Test - Part 1" or AT-61, "Cruise Test - Part 2" .

Is

“A/T Does Not Shift: D1 → D2 or Does Not Kickdown: D4→ D2” OK?

YES (With CONSULT-III) >>GO TO 2.

YES (Without CONSULT-III) >>GO TO 3.

NO >> Go to AT-189, "

A/T Does Not Shift: D1→ D2or Does Not Kickdown: D4→ D2" .

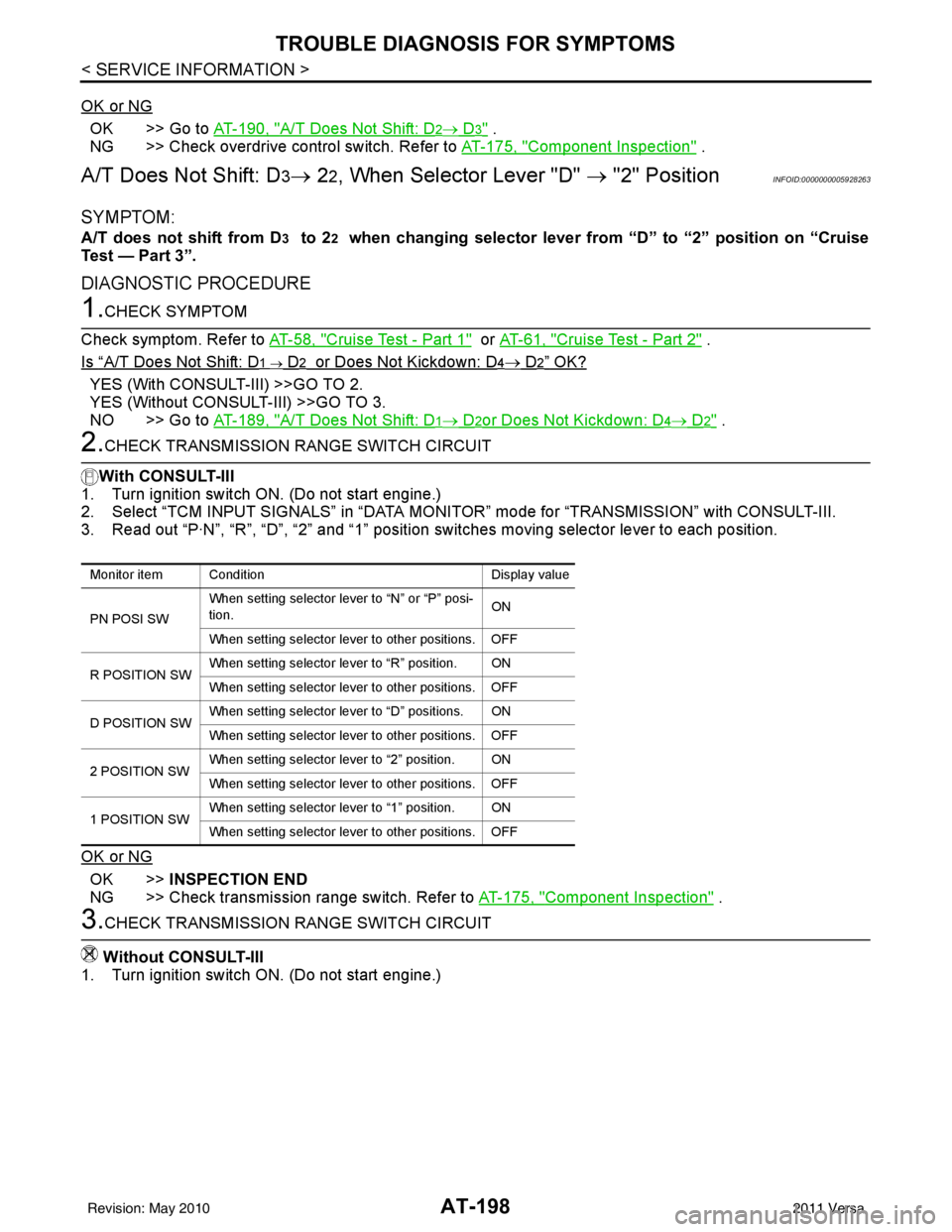

2.CHECK TRANSMISSION RANGE SWITCH CIRCUIT

With CONSULT-III

1. Turn ignition switch ON. (Do not start engine.)

2. Select “TCM INPUT SIGNALS” in “DATA MONITOR” mode for “TRANSMISSION” with CONSULT-III.

3. Read out “P·N”, “R”, “D”, “2” and “1” position switches moving selector lever to each position.

OK or NG

OK >> INSPECTION END

NG >> Check transmission range switch. Refer to AT-175, "

Component Inspection" .

3.CHECK TRANSMISSION RANGE SWITCH CIRCUIT

Without CONSULT-III

1. Turn ignition switch ON. (Do not start engine.)

Monitor item Condition Display value

PN POSI SW When setting selector le

ver to “N” or “P” posi-

tion. ON

When setting selector lever to other positions. OFF

R POSITION SW When setting selector lever to “R” position. ON

When setting selector lever to other positions. OFF

D POSITION SW When setting selector lever to “D” positions. ON

When setting selector lever to other positions. OFF

2 POSITION SW When setting selector lever to “2” position. ON

When setting selector lever to other positions. OFF

1 POSITION SW When setting selector lever to “1” position. ON

When setting selector lever to other positions. OFF

Revision: May 2010

2011 Versa

Page 216 of 3787

TROUBLE DIAGNOSIS FOR SYMPTOMSAT-199

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

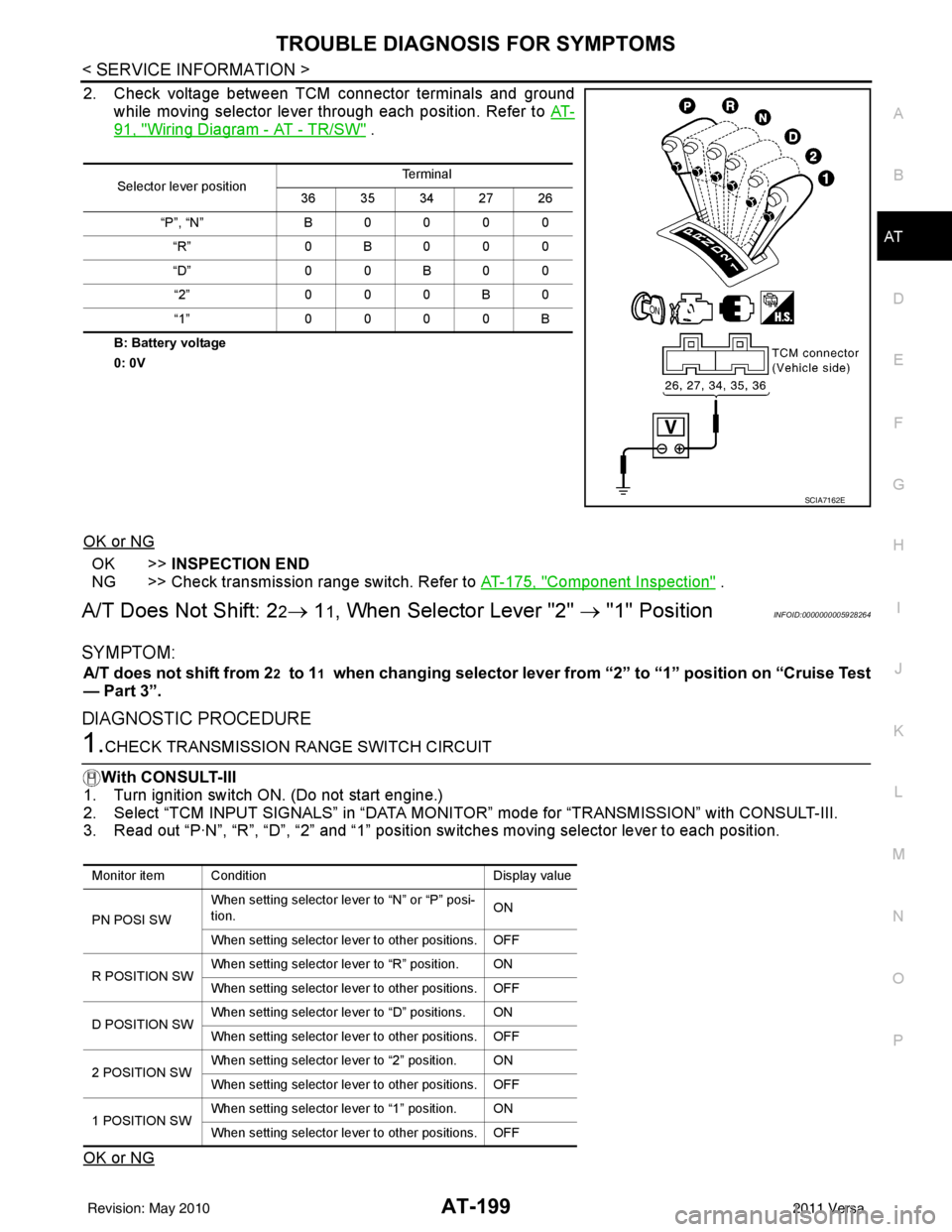

2. Check voltage between TCM connector terminals and ground while moving selector lever through each position. Refer to AT-

91, "Wiring Diagram - AT - TR/SW" .

B: Battery voltage

0: 0V

OK or NG

OK >>INSPECTION END

NG >> Check transmission range switch. Refer to AT-175, "

Component Inspection" .

A/T Does Not Shift: 22→ 11, When Selector Lever "2" → "1" PositionINFOID:0000000005928264

SYMPTOM:

A/T does not shift from 22 to 11 when changing selector lever from “2” to “1” position on “Cruise Test

— Part 3”.

DIAGNOSTIC PROCEDURE

1.CHECK TRANSMISSION RANGE SWITCH CIRCUIT

With CONSULT-III

1. Turn ignition switch ON. (Do not start engine.)

2. Select “TCM INPUT SIGNALS” in “DATA MONI TOR” mode for “TRANSMISSION” with CONSULT-III.

3. Read out “P·N”, “R”, “D”, “2” and “1” position switches moving selector lever to each position.

OK or NG

Selector lever position Te r m i n a l

36 35 34 27 26

“P”, “N” B 0 0 0 0

“R” 0B000

“D” 0 0 B 0 0

“2” 0 0 0 B 0

“1” 0 0 0 0 B

SCIA7162E

Monitor item Condition Display value

PN POSI SW When setting selector le

ver to “N” or “P” posi-

tion. ON

When setting selector lever to other positions. OFF

R POSITION SW When setting selector lever to “R” position. ON

When setting selector lever to other positions. OFF

D POSITION SW When setting selector lever to “D” positions. ON

When setting selector lever to other positions. OFF

2 POSITION SW When setting selector lever to “2” position. ON

When setting selector lever to other positions. OFF

1 POSITION SW When setting selector lever to “1” position. ON

When setting selector lever to other positions. OFF

Revision: May 2010

2011 Versa

Page 217 of 3787

AT-200

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS FOR SYMPTOMS

OK >> GO TO 3

NG >> Check transmission range switch. Refer to AT-175, "

Component Inspection" .

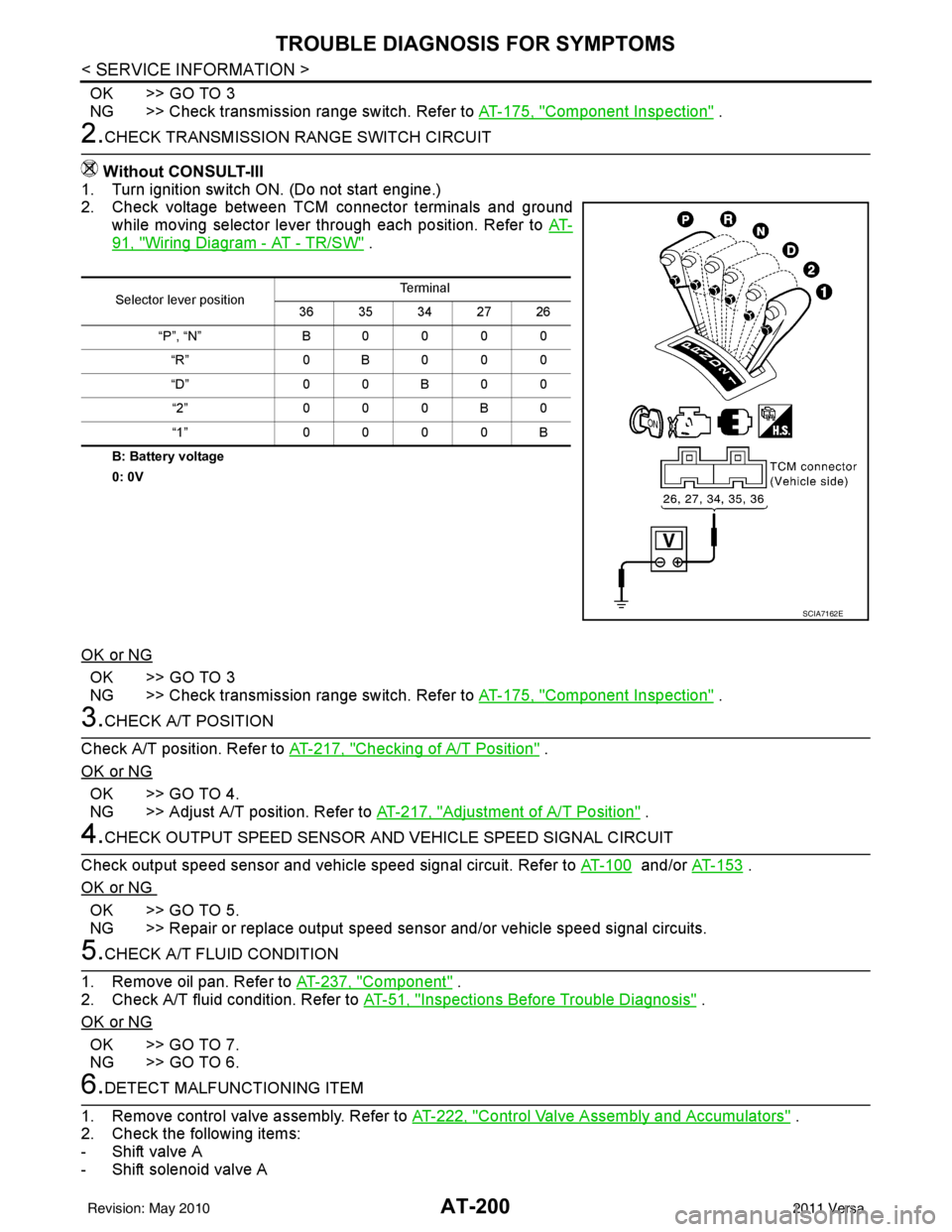

2.CHECK TRANSMISSION RANGE SWITCH CIRCUIT

Without CONSULT-III

1. Turn ignition switch ON. (Do not start engine.)

2. Check voltage between TCM connector terminals and ground

while moving selector lever through each position. Refer to AT-

91, "Wiring Diagram - AT - TR/SW" .

B: Battery voltage

0: 0V

OK or NG

OK >> GO TO 3

NG >> Check transmission range switch. Refer to AT-175, "

Component Inspection" .

3.CHECK A/T POSITION

Check A/T position. Refer to AT-217, "

Checking of A/T Position" .

OK or NG

OK >> GO TO 4.

NG >> Adjust A/T position. Refer to AT-217, "

Adjustment of A/T Position" .

4.CHECK OUTPUT SPEED SENSOR AND VEHICLE SPEED SIGNAL CIRCUIT

Check output speed sensor and vehicle speed signal circuit. Refer to AT-100

and/or AT-153 .

OK or NG

OK >> GO TO 5.

NG >> Repair or replace output speed sens or and/or vehicle speed signal circuits.

5.CHECK A/T FLUID CONDITION

1. Remove oil pan. Refer to AT-237, "

Component" .

2. Check A/T fluid condition. Refer to AT-51, "

Inspections Before Trouble Diagnosis" .

OK or NG

OK >> GO TO 7.

NG >> GO TO 6.

6.DETECT MALFUNCTIONING ITEM

1. Remove control valve assembly. Refer to AT-222, "

Control Valve Assembly and Accumulators" .

2. Check the following items:

- Shift valve A

- Shift solenoid valve A

Selector lever position Te r m i n a l

36 35 34 27 26

“P”, “N” B0000 “R” 0B000

“D” 0 0 B 0 0

“2” 000B0

“1” 0000B

SCIA7162E

Revision: May 2010 2011 Versa

Page 218 of 3787

TROUBLE DIAGNOSIS FOR SYMPTOMSAT-201

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

- Overrun clutch control valve

- Overrun clutch solenoid valve

3. Disassemble A/T. Refer to AT-257, "

Disassembly" .

4. Check the following items:

- Servo piston assembly

- Brake band

OK or NG

OK >> GO TO 7.

NG >> Repair or replace damaged parts.

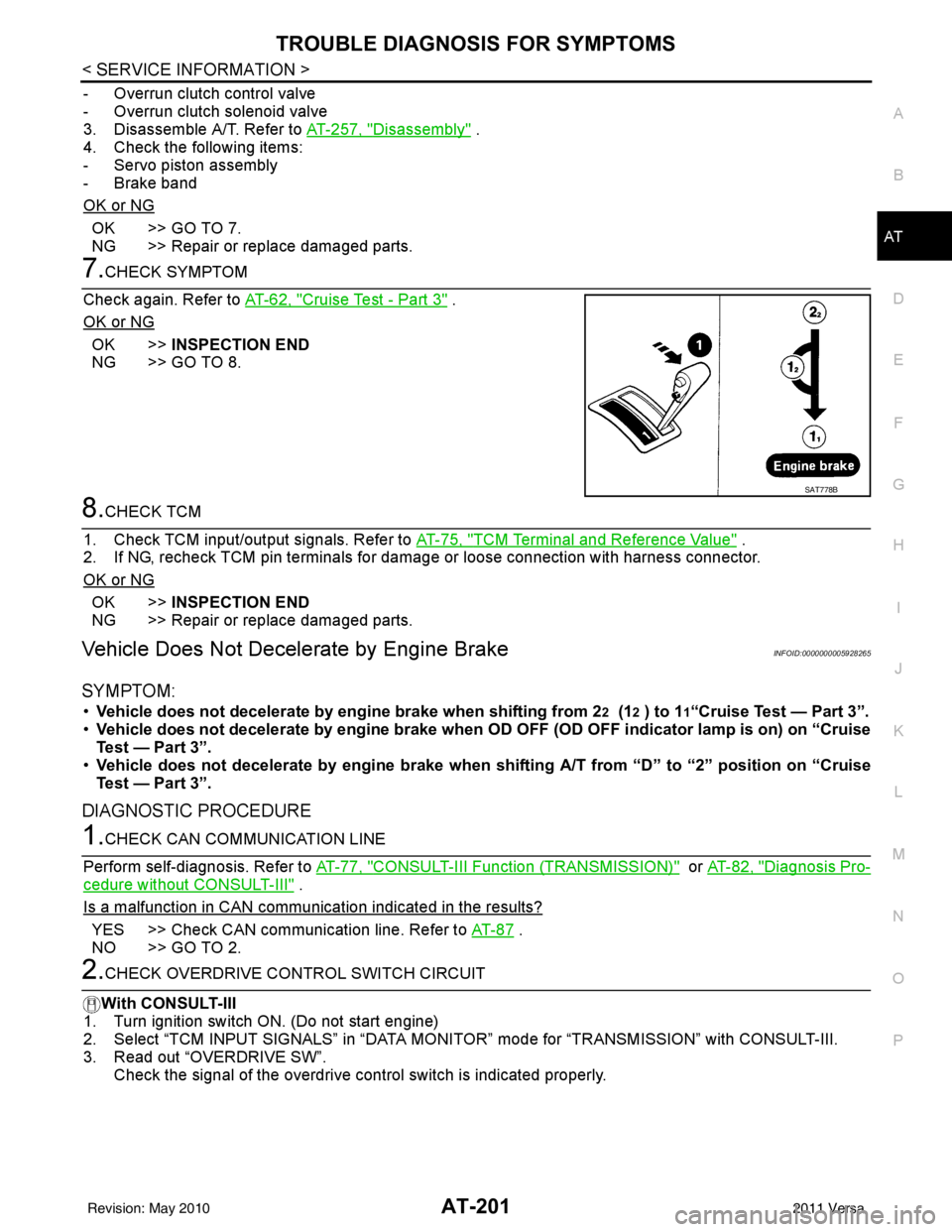

7.CHECK SYMPTOM

Check again. Refer to AT-62, "

Cruise Test - Part 3" .

OK or NG

OK >> INSPECTION END

NG >> GO TO 8.

8.CHECK TCM

1. Check TCM input/output signals. Refer to AT-75, "

TCM Terminal and Reference Value" .

2. If NG, recheck TCM pin terminals for dam age or loose connection with harness connector.

OK or NG

OK >> INSPECTION END

NG >> Repair or replace damaged parts.

Vehicle Does Not Decelerate by Engine BrakeINFOID:0000000005928265

SYMPTOM:

• Vehicle does not decelerate by engine brake when shifting from 22 (12 ) to 11“Cruise Test — Part 3”.

• Vehicle does not decelerate by engi ne brake when OD OFF (OD OFF indicator lamp is on) on “Cruise

Test — Part 3”.

• Vehicle does not decelerate by engi ne brake when shifting A/T from “D” to “2” position on “Cruise

Test — Part 3”.

DIAGNOSTIC PROCEDURE

1.CHECK CAN COMMUNICATION LINE

Perform self-diagnosis. Refer to AT-77, "

CONSULT-III Function (TRANSMISSION)" or AT-82, "Diagnosis Pro-

cedure without CONSULT-III" .

Is a malfunction in CAN communication indicated in the results?

YES >> Check CAN communication line. Refer to AT- 8 7 .

NO >> GO TO 2.

2.CHECK OVERDRIVE CO NTROL SWITCH CIRCUIT

With CONSULT-III

1. Turn ignition switch ON. (Do not start engine)

2. Select “TCM INPUT SIGNALS” in “DATA MONI TOR” mode for “TRANSMISSION” with CONSULT-III.

3. Read out “OVERDRIVE SW”.

Check the signal of the overdrive control switch is indicated properly.

SAT778B

Revision: May 2010 2011 Versa

Page 219 of 3787

AT-202

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS FOR SYMPTOMS

Without CONSULT-III

1. Turn ignition switch ON. (Do not start engine)

2. Check voltage between A/T shift selector harness connector ter-

minal and ground. Refer to AT-177, "

Wiring Diagram - AT - NON-

DTC" .

OK or NG

OK (With CONSULT-III)>>GO TO 3.

OK (Without CONSULT-III)>>GO TO 4.

NG >> Check overdrive control switch. Refer to AT-175, "

Component Inspection" .

3.CHECK TRANSMISSION RANGE SWITCH CIRCUIT

With CONSULT-III

1. Turn ignition switch ON. (Do not start engine.)

2. Select “TCM INPUT SIGNALS” in “DATA MONITOR” mode for “TRANSMISSION” with CONSULT-III.

3. Read out “P·N”, “R”, “D”, “2” and “1” position switches moving selector lever to each position.

OK or NG

OK >> GO TO 5

NG >> Check transmission range switch. Refer to AT-175, "

Component Inspection" .

4.CHECK TRANSMISSION RANGE SWITCH CIRCUIT

Without CONSULT-III

1. Turn ignition switch ON. (Do not start engine.)

Item name Overdrive control switch

ConditionDisplay value

OVERDRIVE SW Depressed

ON

Released OFF

ItemConnector Terminal Overdrive

control switch

Condition Judge-

ment

standard

(Approx.)

A/T shift selector har-

ness connector (Over-

drive control switch) M38 1 - Ground

Released

Battery

voltage

Depressed 0V

JSDIA1514ZZ

Monitor item Condition Display value

PN POSI SW When setting selector le

ver to “N” or “P” posi-

tion. ON

When setting selector lever to other positions. OFF

R POSITION SW When setting selector lever to “R” position. ON

When setting selector lever to other positions. OFF

D POSITION SW When setting selector lever to “D” positions. ON

When setting selector lever to other positions. OFF

2 POSITION SW When setting selector lever to “2” position. ON

When setting selector lever to other positions. OFF

1 POSITION SW When setting selector lever to “1” position. ON

When setting selector lever to other positions. OFF

Revision: May 2010

2011 Versa

Page 226 of 3787

A/T SHIFT LOCK SYSTEMAT-209

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

• Selector lever can be moved fr om “P” position with ignition key in ON position and brake pedal

released.

• Selector lever can be moved from “P” position when ignition switch is removed from key cylinder.

SYMPTOM 2:

• Ignition key cannot be removed when sel ector lever is set to “P” position.

• Ignition key can be removed wh en selector lever is set to any position except “P” position.

1.CHECK KEY INTERLOCK CABLE

Check key interlock cable for damage.

OK or NG

OK >> GO TO 2.

NG >> Repair key interlock cable. Refer to AT-219, "

Removal and Installation" .

2.CHECK A/T POSITION

Check A/T position. Refer to AT-217, "

Checking of A/T Position" .

OK or NG

OK >> GO TO 3.

NG >> Adjust control cable. Refer to AT-217, "

Adjustment of A/T Position" .

3.CHECK SHIFT LOCK SOLENOID AND PARK POSITION SWITCH

1. Turn ignition switch ON. (Do not start engine.)

2. Selector lever is set in “P” position.

3. Check operation sound.

OK or NG

OK >> INSPECTION END

NG - 1 >> With intelligent key: GO TO 4.

NG - 2 >> Without intelligent key: GO TO 5.

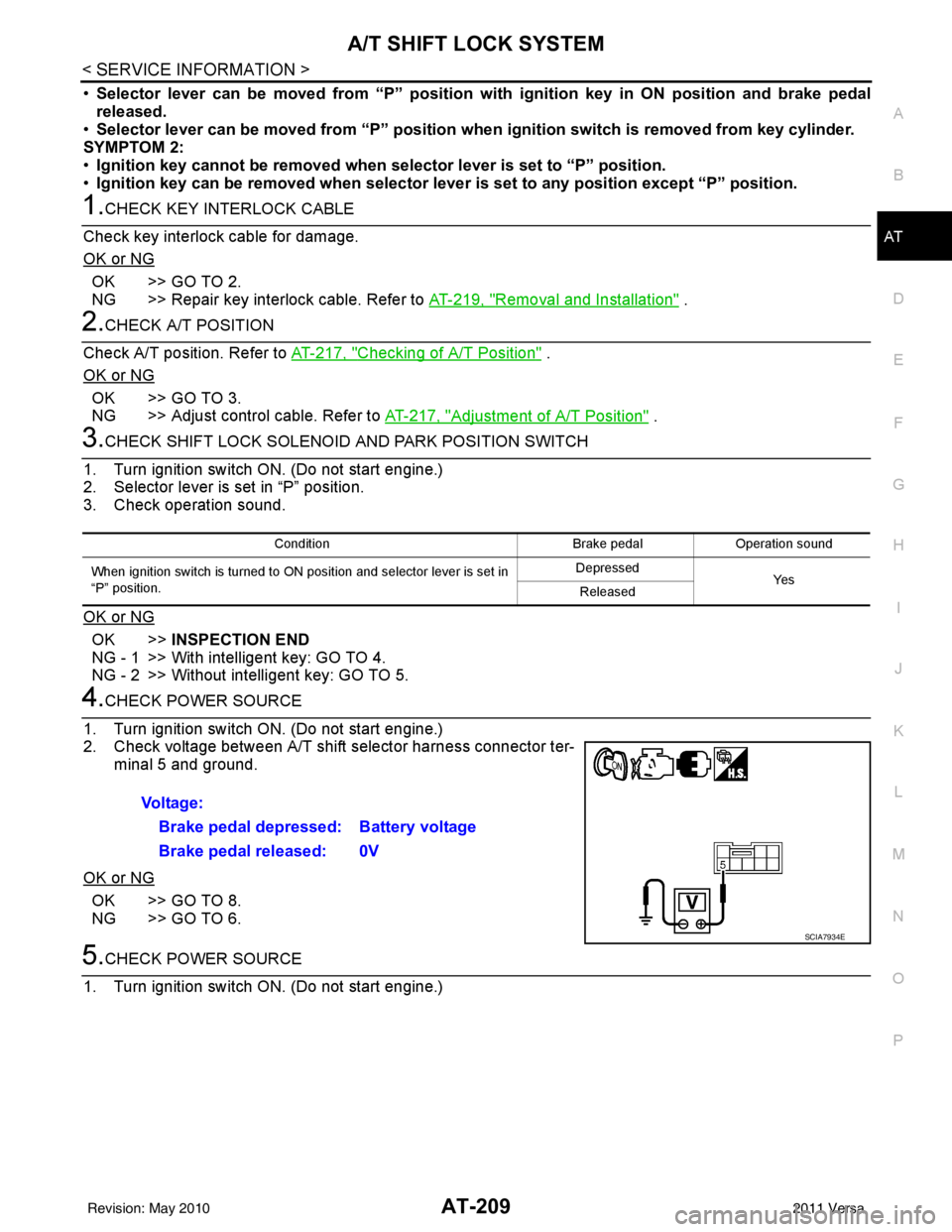

4.CHECK POWER SOURCE

1. Turn ignition switch ON. (Do not start engine.)

2. Check voltage between A/T shift selector harness connector ter- minal 5 and ground.

OK or NG

OK >> GO TO 8.

NG >> GO TO 6.

5.CHECK POWER SOURCE

1. Turn ignition switch ON. (Do not start engine.)

Condition Brake pedalOperation sound

When ignition switch is turned to ON position and selector lever is set in

“P” position. Depressed

Ye s

Released

Voltage:

Brake pedal depressed: Battery voltage

Brake pedal released: 0V

SCIA7934E

Revision: May 2010 2011 Versa