engine NISSAN TIIDA 2011 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2011, Model line: TIIDA, Model: NISSAN TIIDA 2011Pages: 3787, PDF Size: 78.35 MB

Page 516 of 3787

BL-6

< SERVICE INFORMATION >

PREPARATION

PREPARATION

Special Service ToolINFOID:0000000005929271

Commercial Service ToolINFOID:0000000005929272

Tool number

(Kent-Moore No.)

Tool nameDescription

—

(J-39570)

Chassis ear Locating the noise

—

(J-43980)

NISSAN Squeak and Rat-

tle Kit Repairing the cause of noise

—

(J-43241)

Remote Keyless Entry

Te s t e r Used to test key fobs

SIIA0993E

SIIA0994E

LEL946A

Tool name

Description

Engine ear Locating the noise

SIIA0995E

Revision: May 2010 2011 Versa

Page 518 of 3787

BL-8

< SERVICE INFORMATION >

SQUEAK AND RATTLE TROUBLE DIAGNOSES

If the noise can be duplicated easily during the test drive, to help identify the source of the noise, try to dupli-

cate the noise with the vehicle stopped by doing one or all of the following:

1) Close a door.

2) Tap or push/pull around the area where the noise appears to be coming from.

3) Rev the engine.

4) Use a floor jack to recreate vehicle “twist”.

5) At idle, apply engine load (electrical load, half-clutch on M/T model, drive position on A/T model).

6) Raise the vehicle on a hoist and hit a tire with a rubber hammer.

• Drive the vehicle and attempt to duplicate the conditions the customer states exist when the noise occurs.

• If it is difficult to duplicate the noise, drive the v ehicle slowly on an undulating or rough road to stress the

vehicle body.

CHECK RELATED SERVICE BULLETINS

After verifying the customer concern or symptom, chec k ASIST for Technical Service Bulletins (TSBs) related

to that concern or symptom.

If a TSB relates to the symptom, follo w the procedure to repair the noise.

LOCATE THE NOISE AND IDENTIFY THE ROOT CAUSE

1. Narrow down the noise to a general area.To help pinpoint the source of the noise, use a listening tool

(Chassis Ear: J-39570, Engine Ear: J-39565 and mechanic's stethoscope).

2. Narrow down the noise to a more specific area and identify the cause of the noise by:

• removing the components in the area that you suspect the noise is coming from.

Do not use too much force when removing clips and fasteners, otherwise clips and fasteners can be broken

or lost during the repair, resulting in the creation of new noise.

• tapping or pushing/pulling the component that you suspect is causing the noise.

Do not tap or push/pull the component with excessive force, otherwise the noise will be eliminated only tem-

porarily.

• feeling for a vibration with your hand by touching the component(s) that you suspect is (are) causing the

noise.

• placing a piece of paper between components that you suspect are causing the noise.

• looking for loose components and contact marks. Refer to BL-9, "

Generic Squeak and Rattle Troubleshooting".

REPAIR THE CAUSE

• If the cause is a loose component, tighten the component securely.

• If the cause is insufficient clearance between components:

- separate components by repositioning or loos ening and retightening the component, if possible.

- insulate components with a suitable insulator such as urethane pads, foam blocks, felt cloth tape or urethane tape. A NISSAN Squeak and Rattle Kit (J-43980) is av ailable through your authorized NISSAN Parts Depart-

ment.

CAUTION:

Do not use excessive force as many components are constructed of plastic and may be damaged.

Always check with the Parts Department for the latest parts information.

The following materials are contained in the NISSAN Squeak and Rattle Kit (J-43980). Each item can be

ordered separately as needed.

URETHANE PADS [1.5 mm (0.059 in) thick]

Insulates connectors, harness, etc.

76268-9E005: 100 ×135 mm (3.94× 5.31 in)/76884-71L01: 60 ×85 mm (2.36 ×3.35 in)/76884-71L02: 15 ×25

mm (0.59× 0.98 in)

INSULATOR (Foam blocks)

Insulates components from contact. Can be used to fill space behind a panel.

73982-9E000: 45 mm (1.77 in) thick, 50 ×50 mm (1.97 ×1.97 in)/73982-50Y00: 10 mm (0.39 in) thick,

50× 50 mm (1.97 ×1.97 in)

INSULATOR (Light foam block)

80845-71L00: 30 mm (1.18 in) thick, 30 ×50 mm (1.18 ×1.97 in)

FELT CLOTH TAPE

Used to insulate where movemen t does not occur. Ideal for instrument panel applications.

68370-4B000: 15 ×25 mm (0.59× 0.98 in) pad/68239-13E00: 5 mm (0.20 in ) wide tape roll. The following

materials not found in the kit can also be used to repair squeaks and rattles.

UHMW (TEFLON) TAPE

Insulates where slight movement is present. Ideal for inst rument panel applications.

Revision: May 2010 2011 Versa

Page 520 of 3787

BL-10

< SERVICE INFORMATION >

SQUEAK AND RATTLE TROUBLE DIAGNOSES

Most of these incidents can be repaired by adjusting, securing or insulating the item(s) or component(s) caus-

ing the noise.

SUNROOF/HEADLINING

Noises in the sunroof/headlining area c an often be traced to one of the following:

1. Sunroof lid, rail, linkage or seals making a rattle or light knocking noise

2. Sun visor shaft shaking in the holder

3. Front or rear windshield touching headliner and squeaking

Again, pressing on the components to stop the noise while duplicating the conditions can isolate most of these

incidents. Repairs usually consist of insulating with felt cloth tape.

OVERHEAD CONSOLE (FRONT AND REAR)

Overhead console noises are often caused by the c onsole panel clips not being engaged correctly. Most of

these incidents are repaired by pushing up on the c onsole at the clip locations until the clips engage.

In addition look for:

1. Loose harness or harness connectors.

2. Front console map/reading lamp lense loose.

3. Loose screws at console attachment points.

SEATS

When isolating seat noise it's important to note the pos ition the seat is in and the load placed on the seat when

the noise is present. These conditions should be duplicated when verifying and isolating the cause of the

noise.

Cause of seat noise include:

1. Headrest rods and holder

2. A squeak between the seat pad cushion and frame

3. The rear seatback lock and bracket

These noises can be isolated by moving or pressing on the suspected components while duplicating the con-

ditions under which the noise occurs. Most of thes e incidents can be repaired by repositioning the component

or applying urethane tape to the contact area.

UNDERHOOD

Some interior noise may be caused by components under the hood or on the engine wall. The noise is then

transmitted into the passenger compartment.

Causes of transmitted underhood noise include:

1. Any component mounted to the engine wall

2. Components that pass through the engine wall

3. Engine wall mounts and connectors

4. Loose radiator mounting pins

5. Hood bumpers out of adjustment

6. Hood striker out of adjustment

These noises can be difficult to isolate since they cannot be reached from the interior of the vehicle. The best

method is to secure, move or insulate one component at a time and test drive the \

vehicle. Also, engine RPM

or load can be changed to isolate the noise. Repairs can usually be made by moving, adjusting, securing, or

insulating the component causing the noise.

Revision: May 2010 2011 Versa

Page 526 of 3787

BL-16

< SERVICE INFORMATION >

HOOD

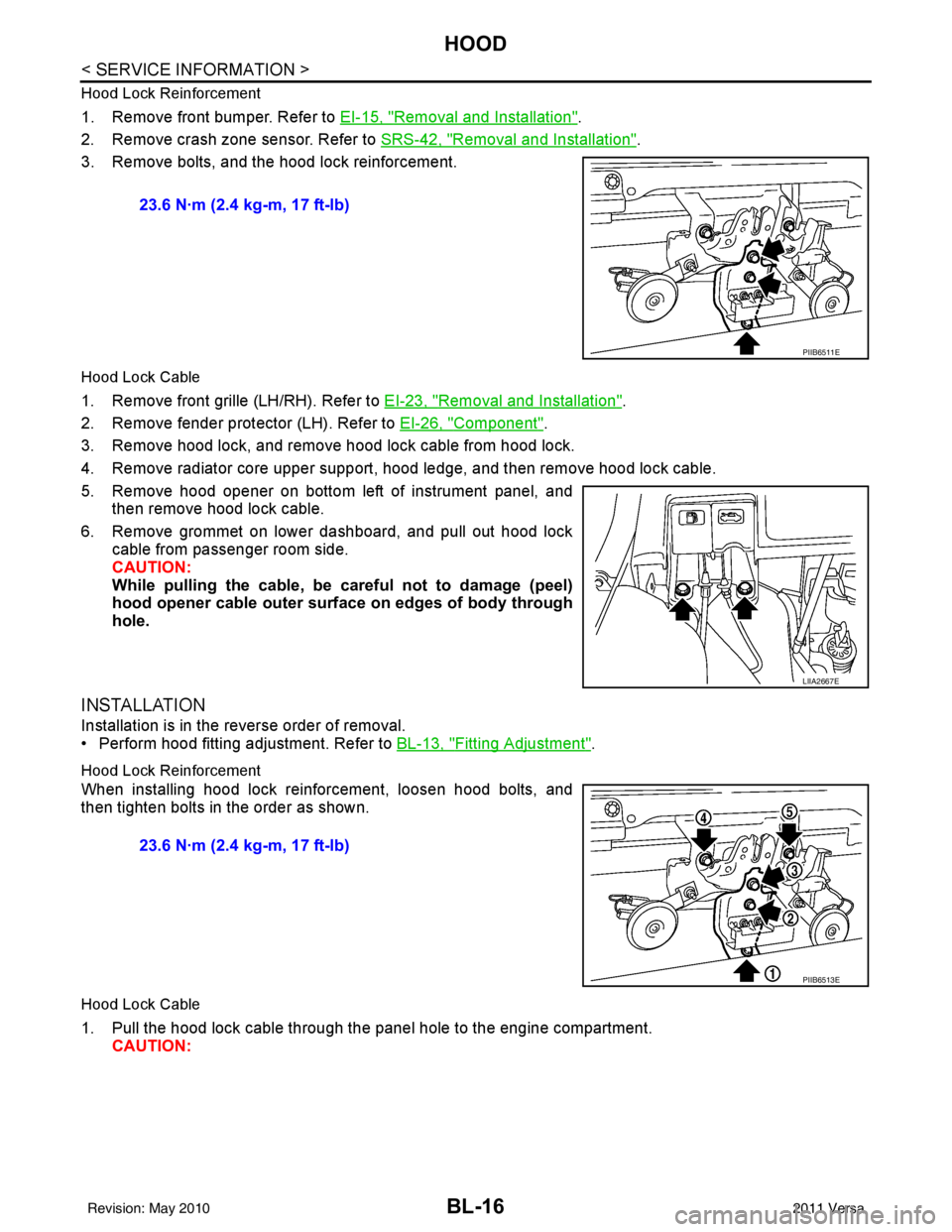

Hood Lock Reinforcement

1. Remove front bumper. Refer to EI-15, "Removal and Installation".

2. Remove crash zone sensor. Refer to SRS-42, "

Removal and Installation".

3. Remove bolts, and the hood lock reinforcement.

Hood Lock Cable

1. Remove front grille (LH/RH). Refer to EI-23, "Removal and Installation".

2. Remove fender protector (LH). Refer to EI-26, "

Component".

3. Remove hood lock, and remove hood lock cable from hood lock.

4. Remove radiator core upper support, hood ledge, and then remove hood lock cable.

5. Remove hood opener on bottom left of instrument panel, and then remove hood lock cable.

6. Remove grommet on lower dashboard, and pull out hood lock cable from passenger room side.

CAUTION:

While pulling the cable, be car eful not to damage (peel)

hood opener cable outer surface on edges of body through

hole.

INSTALLATION

Installation is in the reverse order of removal.

• Perform hood fitting adjustment. Refer to BL-13, "

Fitting Adjustment".

Hood Lock Reinforcement

When installing hood lock reinforcement, loosen hood bolts, and

then tighten bolts in the order as shown.

Hood Lock Cable

1. Pull the hood lock cable through the panel hole to the engine compartment. CAUTION: 23.6 N·m (2.4 kg-m, 17 ft-lb)

PIIB6511E

LIIA2667E

23.6 N·m (2.4 kg-m, 17 ft-lb)

PIIB6513E

Revision: May 2010

2011 Versa

Page 598 of 3787

BL-88

< SERVICE INFORMATION >

INTELLIGENT KEY SYSTEM

System Description

INFOID:0000000005929328

• The Intelligent Key system is a system that makes it possible to lock and unlock the door locks (door lock/

unlock function), and start the engine (engine start func tion) by carrying around the Intelligent Key (without

some key operation), which operates based on the results of electronic ID verification using two-way com-

munications between the Intelligent Key and the vehicle (Intelligent Key unit).

• Vehicles equipped with a manual transmission include a key interlock solenoid located in the steering col- umn to prevent accidental shut-off of the ignition sw itch and locking of the steering wheel during driving con-

dition when the vehicle is moving.

CAUTION:

The driver should always carry the Intelligent Key

• Operation of the remote controller buttons on the Inte lligent Key also provides the same functions as the

remote control entry system. (Remote keyless entry functions)

• If an action that does not meet the operating conditions of the Intelligent Key system is taken, the buzzer

goes off to inform the driver. (Warning chime functions)

• When a door lock is locked or unlocked with request switch or remote controller button operation, the hazard

lamps flash and the buzzer (outside vehicle) sounds (Hazard and buzzer reminder function).

• Even if the Intelligent Key battery is completely discharged, the door locks can be locked and unlocked and the engine started with the mechanical key built into the Intelligent Key.

• The settings for each function can be changed with the CONSULT-III.

• If an Intelligent Key is lost, a new Intelligent Key can be registered. A maximum of 4 Intelligent Keys can be registered.

• It has been made possible to diagnose the system and r egister an Intelligent Key with the CONSULT-III.

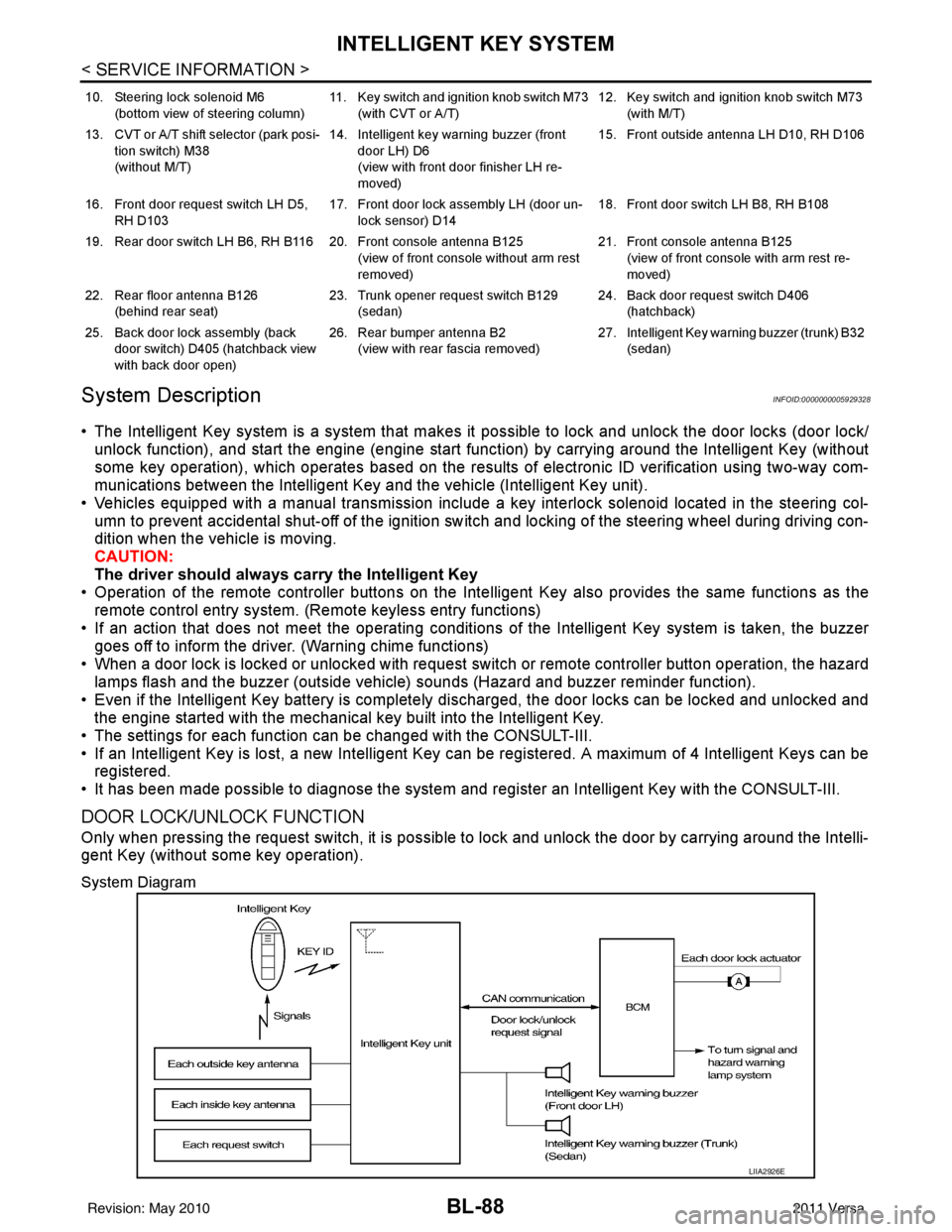

DOOR LOCK/UNLOCK FUNCTION

Only when pressing the request switch, it is possible to lock and unlock the door by carrying around the Intelli-

gent Key (without some key operation).

System Diagram

10. Steering lock solenoid M6

(bottom view of steering column) 11. Key switch and ignition knob switch M73

(with CVT or A/T) 12. Key switch and ignition knob switch M73

(with M/T)

13. CVT or A/T shift selector (park posi- tion switch) M38

(without M/T) 14. Intelligent key warning buzzer (front

door LH) D6

(view with front door finisher LH re-

moved) 15. Front outside antenna LH D10, RH D106

16. Front door request switch LH D5, RH D103 17. Front door lock assembly LH (door un-

lock sensor) D14 18. Front door switch LH B8, RH B108

19. Rear door switch LH B6, RH B116 20. Front console antenna B125 (view of front console without arm rest

removed)21. Front console antenna B125

(view of front console with arm rest re-

moved)

22. Rear floor antenna B126 (behind rear seat) 23. Trunk opener request switch B129

(sedan) 24. Back door request switch D406

(hatchback)

25. Back door lock assembly (back door switch) D405 (hatchback view

with back door open) 26. Rear bumper antenna B2

(view with rear fascia removed) 27. Intelligent Key warn

ing buzzer (trunk) B32

(sedan)

LIIA2926E

Revision: May 2010 2011 Versa

Page 602 of 3787

BL-92

< SERVICE INFORMATION >

INTELLIGENT KEY SYSTEM

The headlamp flashes and the horn sounds intermittently.

The alarm automatically turns off:

• After 25 seconds

• When Intelligent Key unit receives any signal from remote controller of Intelligent Key

• When door request switch is pressed (Intelligent Key is outside vehicle)

Panic alarm function's press and holding time value can be changed in “PANIC ALARM DELAY” mode in

“WORK SUPPORT”. Refer to BL-117, "

CONSULT-III Application Item".

List of Operation Related Parts

Parts marked with × are the parts related to operation.

ENGINE START FUNCTION

When the registered Intelligent Key is carried, the engine can be started without inserting the key.

When ignition knob switch is ON (press ignition switch ), Intelligent Key unit searches Intelligent Key in the

vehicle using inside key antenna.

Then Intelligent Key is inside the vehicle, it performs the following operation.

• Illuminate green “KEY” warning lamp in combination meter.

• Released steering lock and ignition switch can be turned from OFF to ACC, ON or START position.

NOTE:

If Intelligent Key is not registered, “KEY” warning lamp in combination meter illuminates red.

• Intelligent Key sends engine start signal to BCM via CAN communication line.

When ignition switch turns to START position, BCM sends starter request signal to IPDM E/R. Then, engine

starts.

Remote keyless entry functions

Intelligent Key

Key switch

Ignition knob switch

Door request switch

Door switch

Back door lock assembly (back door switch)

Door lock actuator

Intelligent Key warning buzzer

Intelligent Key unit

CAN communication system

BCM

Hazard warning lamp

Horn

IPDM E/R

Head lamp

Door lock/unlock function by Intelligent Key button × ××× ×××

Hazard and buzzer reminder function ×××××

Auto door lock function ×× ××× ×××

Panic alarm function ×××× ××× ×××

WIIA1282E

Revision: May 2010 2011 Versa

Page 603 of 3787

INTELLIGENT KEY SYSTEMBL-93

< SERVICE INFORMATION >

C

DE

F

G H

J

K L

M A

B

BL

N

O P

Even if Intelligent Key battery runs down, Intelligent key unit can start engine with mechanical key built Intelli-

gent Key. For details, refer toBL-246

.

All of the originally supplied Intelligent Key IDs (exc ept for key) have been registered in Intelligent Key system.

If requested by the vehicle owner, a maximum of four Intelligent Key IDs can be registered into the Intelligent

Key system components.

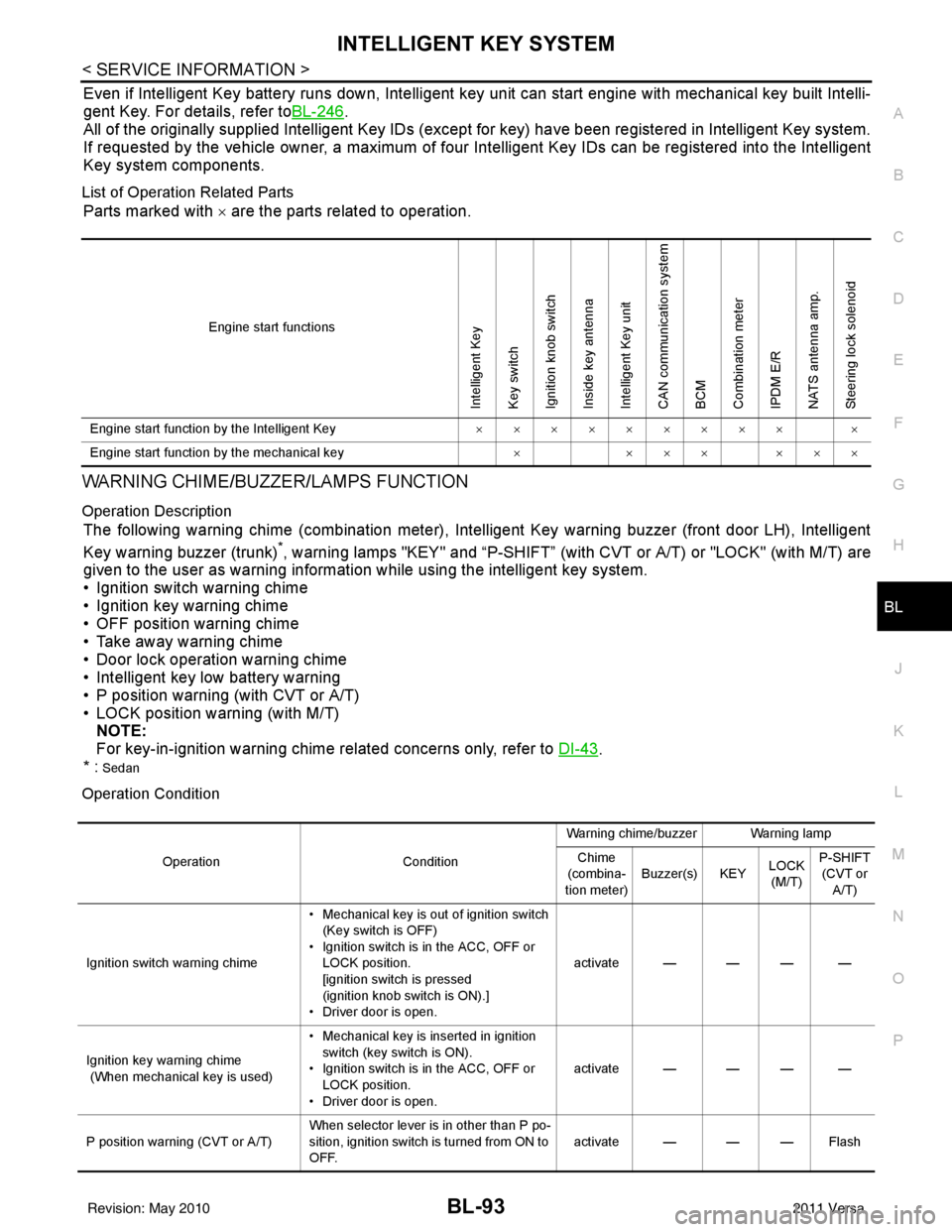

List of Operation Related Parts

Parts marked with × are the parts related to operation.

WARNING CHIME/BUZZER/LAMPS FUNCTION

Operation Description

The following warning chime (combination meter), Intelligent Key warning buzzer (front door LH), Intelligent

Key warning buzzer (trunk)

*, warning lamps "KEY" and “P-SHIFT” (with CVT or A/T) or "LOCK" (with M/T) are

given to the user as warning informati on while using the intelligent key system.

• Ignition switch warning chime

• Ignition key warning chime

• OFF position warning chime

• Take away warning chime

• Door lock operation warning chime

• Intelligent key low battery warning

• P position warning (with CVT or A/T)

• LOCK position warning (with M/T) NOTE:

For key-in-ignition warning chime related concerns only, refer to DI-43

.

* :

Sedan

Operation Condition

Engine start functions

Intelligent Key

Key switch

Ignition knob switch

Inside key antenna

Intelligent Key unit

CAN communication system

BCM

Combination meter

IPDM E/R

NATS antenna amp.

Steering lock solenoid

Engine start function by the Intelligent Key ××××××××× ×

Engine start function by the mechanical key ×××× ×××

Operation ConditionWarning chime/buzzer Warning lamp

Chime

(combina-

tion meter) Buzzer(s) KEY

LOCK

(M/T) P-SHIFT

(CVT or A/T)

Ignition switch warning chime • Mechanical key is out of ignition switch

(Key switch is OFF)

• Ignition switch is in the ACC, OFF or LOCK position.

[ignition switch is pressed

(ignition knob switch is ON).]

• Driver door is open. activate — — — —

Ignition key warning chime

(When mechanical key is used) • Mechanical key is inserted in ignition

switch (key switch is ON).

• Ignition switch is in the ACC, OFF or

LOCK position.

• Driver door is open. activate — — — —

P position warning (CVT or A/T) When selector lever is in other than P po-

sition, ignition switch is turned from ON to

OFF. activate — — — Flash

Revision: May 2010

2011 Versa

Page 625 of 3787

INTELLIGENT KEY SYSTEMBL-115

< SERVICE INFORMATION >

C

DE

F

G H

J

K L

M A

B

BL

N

O P

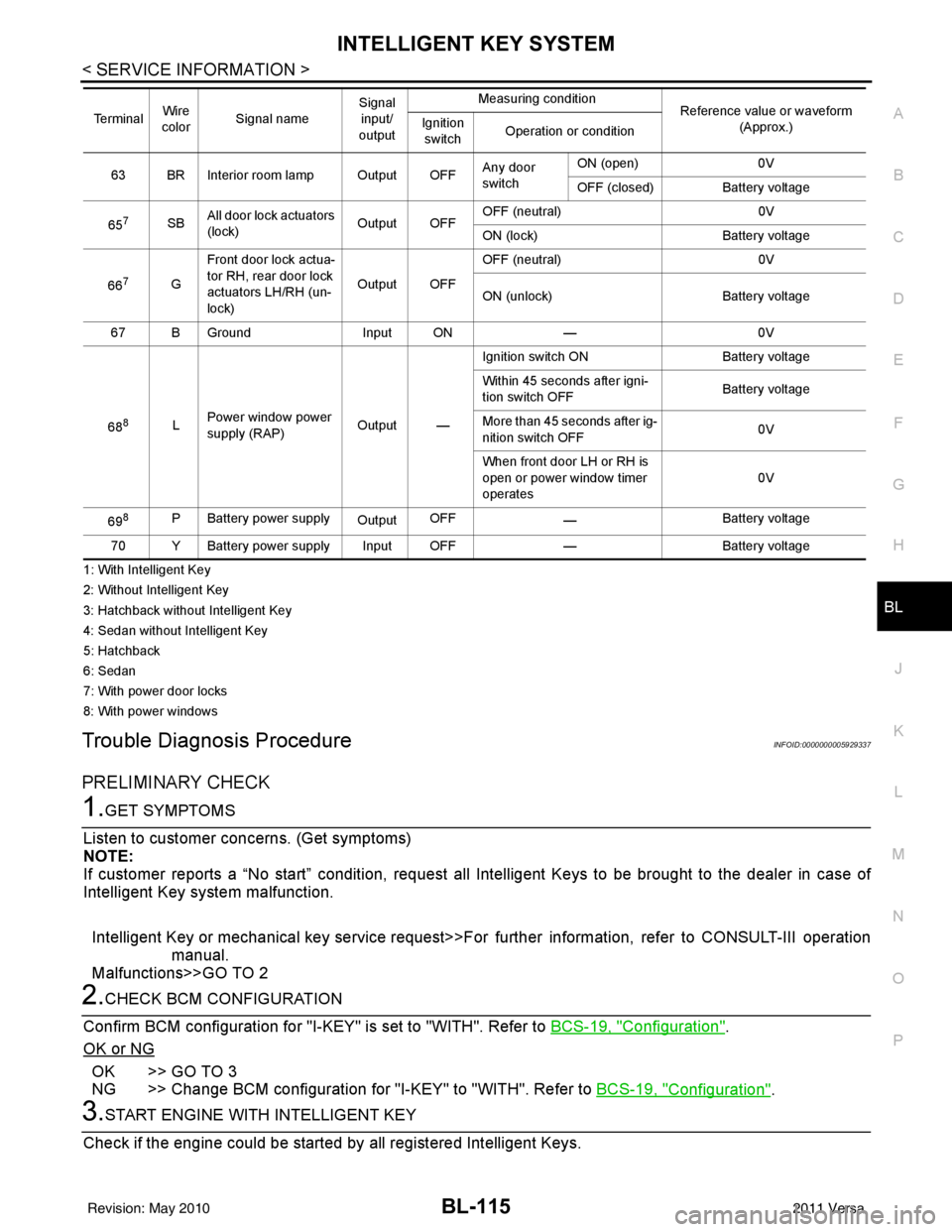

1: With Intelligent Key

2: Without Intelligent Key

3: Hatchback without Intelligent Key

4: Sedan without Intelligent Key

5: Hatchback

6: Sedan

7: With power door locks

8: With power windows

Trouble Diagnosis ProcedureINFOID:0000000005929337

PRELIMINARY CHECK

1.GET SYMPTOMS

Listen to customer c oncerns. (Get symptoms)

NOTE:

If customer reports a “No start” condition, request all Intelligent Keys to be brought to the dealer in case of

Intelligent Key system malfunction.

Intelligent Key or mechanical key service request>>For further information, refer to CONSULT-III operation

manual.

Malfunctions>>GO TO 2

2.CHECK BCM CONFIGURATION

Confirm BCM configuration for "I- KEY" is set to "WITH". Refer to BCS-19, "

Configuration".

OK or NG

OK >> GO TO 3

NG >> Change BCM configuration for "I-KEY" to "WITH". Refer to BCS-19, "

Configuration".

3.START ENGINE WITH INTELLIGENT KEY

Check if the engine could be started by all registered Intelligent Keys.

63 BR Interior room lamp Output OFF Any door

switchON (open)

0V

OFF (closed) Battery voltage

65

7SB All door lock actuators

(lock) Output OFFOFF (neutral)

0V

ON (lock) Battery voltage

66

7G Front door lock actua-

tor RH, rear door lock

actuators LH/RH (un-

lock) Output OFFOFF (neutral)

0V

ON (unlock) Battery voltage

67 B Ground Input ON—0V

68

8L Power window power

supply (RAP)

Output —Ignition switch ON

Battery voltage

Within 45 seconds after igni-

tion switch OFF Battery voltage

More than 45 seconds after ig-

nition switch OFF 0V

When front door LH or RH is

open or power window timer

operates 0V

69

8P Battery power supply OutputOFF

— Battery voltage

70 Y Battery power supply Input OFF —Battery voltage

Te r m i n a l

Wire

color Signal name Signal

input/

output Measuring condition

Reference value or waveform

(Approx.)

Ignition

switch Operation or condition

Revision: May 2010

2011 Versa

Page 626 of 3787

BL-116

< SERVICE INFORMATION >

INTELLIGENT KEY SYSTEM

The engine cannot be started by some Intelligent Keys>>Intelligent Key is low battery or malfunction. Refer

to BL-158, "

Intelligent Key Battery Replacement".

The engine cannot be started by all Intelligent Keys >> GO TO 4

The engine can be started by all Intelligent Keys >> GO TO 5

4.CHECK “KEY” WARNING LAMP ILLUMINATION

When pushing the ignition switch, check if “KEY” warning lamp in combination meter illuminates.

KEY warning lamp illuminates green >> Refer to BL-119, "

Trouble Diagnosis Symptom Chart".

KEY warning lamp illuminates red >> Refer to BL-119, "

Trouble Diagnosis Symptom Chart".

Does not illuminate>>GO TO BL-119, "

Trouble Diagnosis Symptom Chart".

5.START ENGINE WITH MECHANICAL KEY

Check if the engine could be started by all registered mechanical keys.

No start by some mechanical keys >> Register mechanical key. Refer to CONSULT-III operation manual.

Engine starts by mechanical or Intelligent Key >> Refer to BL-119, "

Trouble Diagnosis Symptom Chart".

No start by mechanical key or Intelligent Key >> Refer to NATS BL-255, "

Trouble Diagnosis Procedure".

Engine starts with Intelligent Key or mechanical key >> GO TO "WORK FLOW".

The engine can be started by all mechanical keys >> GO TO 6

6.PERFORM SELF-DIAGNOSIS

1. Turn ignition switch to ON by carrying the Intelligent Key.

2. Perform self-diagnosis of Intel ligent Key system with CONSULT-III.

DTC is displayed >> Refer to BL-117, "

CONSULT-III Application Item".

DTC is not displayed >> Refer to BL-119, "

Trouble Diagnosis Symptom Chart".

WORK FLOW

Before performing the work flow, carry out prel iminary check. Refer to "PRELIMINARY CHECK".

1.CHECK FUNCTION OF INTELLIGENT KEY SYSTEM

Check if the function related to Intelligent Key system operates normally.

All functions of Intelligent Key system do not operate >> Refer to BL-119, "

Trouble Diagnosis Symptom

Chart".

Specific function of Intelligent Ke y system does not operate >> GO TO 2

2.CHECK POWER DOOR LOCK OPERATION

Check if door lock/unlock function operates with door lock and unlock switch.

OK or NG

OK >> GO TO 3

NG >> Refer to BL-22

.

3.CHECK DOOR REQUEST SWITCH OPERATION

Check if door lock/unlock function operates with request switch.

OK or NG

OK >> GO TO 4

NG >> Refer to BL-119, "

Trouble Diagnosis Symptom Chart".

4.CHECK REMOTE K EYLESS FUNCTION

Check if the following function responds with Intelligent Key button.

• Door lock/unlock function

• Panic alarm function

OK or NG

OK >> GO TO 5

NG >> Refer to BL-119, "

Trouble Diagnosis Symptom Chart".

Revision: May 2010 2011 Versa

Page 629 of 3787

INTELLIGENT KEY SYSTEMBL-119

< SERVICE INFORMATION >

C

DE

F

G H

J

K L

M A

B

BL

N

O P

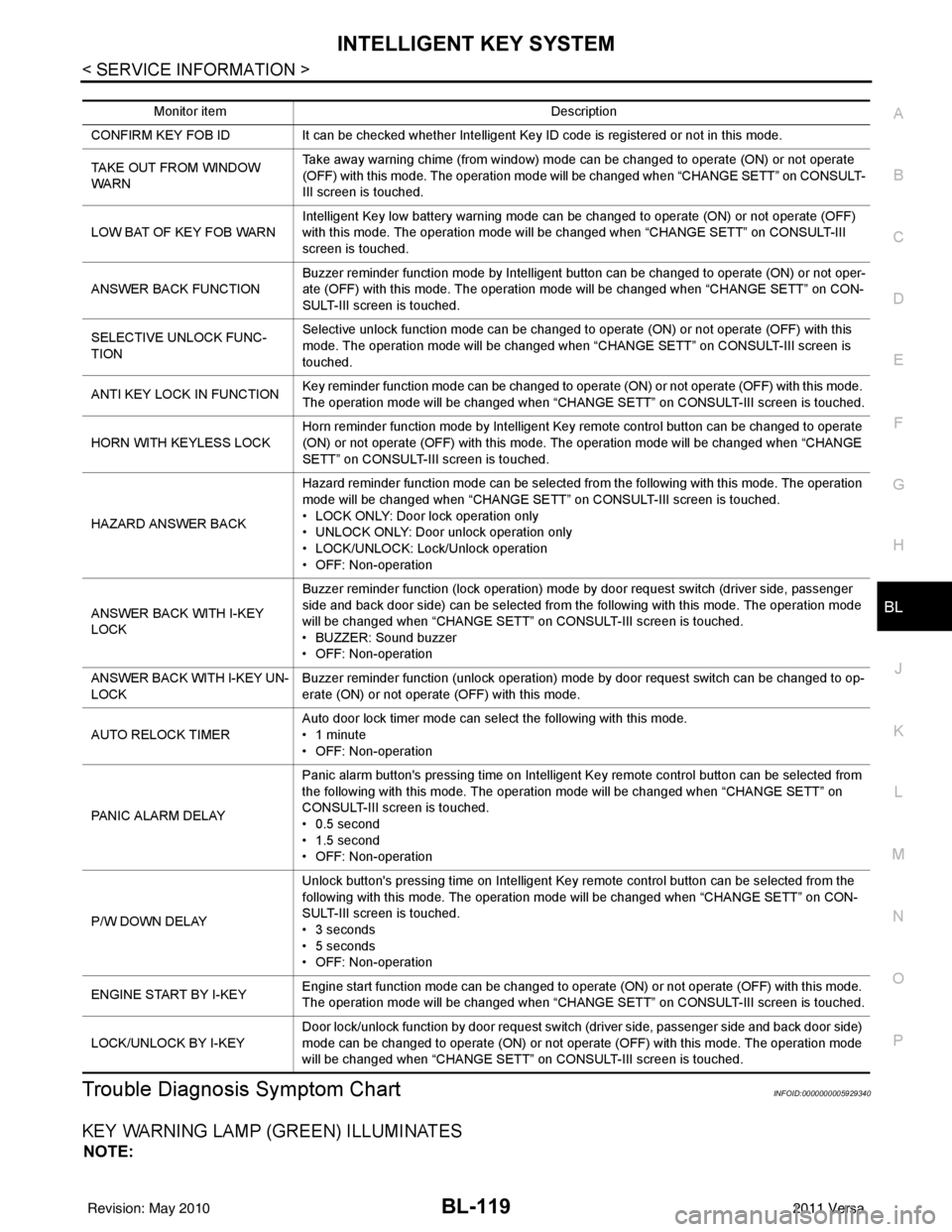

Trouble Diagnosis Symptom ChartINFOID:0000000005929340

KEY WARNING LAMP (GREEN) ILLUMINATES

NOTE:

Monitor item Description

CONFIRM KEY FOB ID It can be checked whether Intelligent Key ID code is registered or not in this mode.

TAKE OUT FROM WINDOW

WARN Take away warning chime (from window) mode can be changed to operate (ON) or not operate

(OFF) with this mode. The operation mode will be changed when “CHANGE SETT” on CONSULT-

III screen is touched.

LOW BAT OF KEY FOB WARN Intelligent Key low battery warning mode can be changed to operate (ON) or not operate (OFF)

with this mode. The operation mode will be changed when “CHANGE

SETT” on CONSULT-III

screen is touched.

ANSWER BACK FUNCTION Buzzer reminder function mode by Intelligent button can be changed to operate (ON) or not oper-

ate (OFF) with this mode. The operation mode will be changed when “CHANGE SETT” on CON-

SULT-III screen is touched.

SELECTIVE UNLOCK FUNC-

TION Selective unlock function mode can be changed to operate (ON) or not operate (OFF) with this

mode. The operation mode will be changed when “CHANGE SETT” on CONSULT-III screen is

touched.

ANTI KEY LOCK IN FUNCTION Key reminder function mode can be changed to operate (ON) or not operate (OFF) with this mode.

The operation mode will be changed when “CHANGE SETT” on CONSULT-III screen is touched.

HORN WITH KEYLESS LOCK Horn reminder function mode by Intelligent Key remote control button can be changed to operate

(ON) or not operate (OFF) with this mode. The operation mode will be changed when “CHANGE

SETT” on CONSULT-III screen is touched.

HAZARD ANSWER BACK Hazard reminder function mode can be selected from the following with this mode. The operation

mode will be changed when “CHANGE SE

TT” on CONSULT-III screen is touched.

• LOCK ONLY: Door lock operation only

• UNLOCK ONLY: Door unlock operation only

• LOCK/UNLOCK: Lock/Unlock operation

• OFF: Non-operation

ANSWER BACK WITH I-KEY

LOCK Buzzer reminder function (lock operation) mode by door request switch (driver side, passenger

side and back door side) can be selected from the following with this mode. The operation mode

will be changed when “

CHANGE SETT” on CONSULT- III screen is touched.

• BUZZER: Sound buzzer

• OFF: Non-operation

ANSWER BACK WITH I-KEY UN-

LOCK Buzzer reminder function (unlock operation) mode by door request switch can be changed to op-

erate (ON) or not operate (OFF) with this mode.

AUTO RELOCK TIMER Auto door lock timer mode can select the following with this mode.

• 1 minute

• OFF: Non-operation

PANIC ALARM DELAY Panic alarm button's pressing time on Intelligent Key remote control button can be selected from

the following with this mode. The operation mode will be changed when “CHANGE SETT” on

CONSULT-III screen is touched.

• 0.5 second

• 1.5 second

• OFF: Non-operation

P/W DOWN DELAY Unlock button's pressing time on Intelligent Key remote control button can be selected from the

following with this mode. The operation mode will be changed when “CHANGE SETT” on CON-

SULT-III screen is touched.

• 3 seconds

• 5 seconds

• OFF: Non-operation

ENGINE START BY I-KEY Engine start function mode can be changed to operate (ON) or not operate (OFF) with this mode.

The operation mode will be changed when “CHANGE SETT” on CONSULT-III screen is touched.

LOCK/UNLOCK BY I-KEY Door lock/unlock function by door request switch (driver side, passenger side and back door side)

mode can be changed to operate (ON) or not operate (OFF) with this mode. The operation mode

will be changed when “

CHANGE SETT” on CONSULT- III screen is touched.

Revision: May 2010 2011 Versa