brake NISSAN TIIDA 2011 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2011, Model line: TIIDA, Model: NISSAN TIIDA 2011Pages: 3787, PDF Size: 78.35 MB

Page 3500 of 3787

PS-6

< SERVICE INFORMATION >

STEERING WHEEL

STEERING WHEEL

On-Vehicle Inspection and ServiceINFOID:0000000006416714

CHECKING CONDITION OF INSTALLATION

• Check installation conditions of steering gear assembly, front suspension assembly, axle and steering col-

umn assembly.

• Check if movement exists when steering wheel is mo ved up and down, to the left and right and to the axial

direction.

• Check steering gear assembly bolts and nuts for looseness. Refer to PS-15, "

Removal and Installation".

CHECKING STEERING WHEEL PLAY

• Turn steering wheel so that front wheels come to the straight-ahead position. Start engine and lightly turn

steering wheel to the left and right until front wheels start to move. Measure steering wheel movement on the

outer circumference.

• When the measurement value is outside the standard val ue, check backlash for each joint of steering col-

umn assembly and installation condition of steering gear assembly.

CHECKING NEUTRAL POSITION STEERING WHEEL

• Make sure that steering gear assembly, steering column assembly and steering wheel are installed in the correct position.

• Perform neutral position inspection after wheel alignment. Refer to PS-2, "

Precaution for Supplemental

Restraint System (SRS) "AIR BAG" and "SEAT BELT PRE-TENSIONER"".

• Set vehicle to the straight-ahead position and c onfirm steering wheel is in the neutral position.

• Loosen outer socket lock nut and turn inner socket to left and right equally to make fine adjustments if steer-

ing wheel is not in the neutral position.

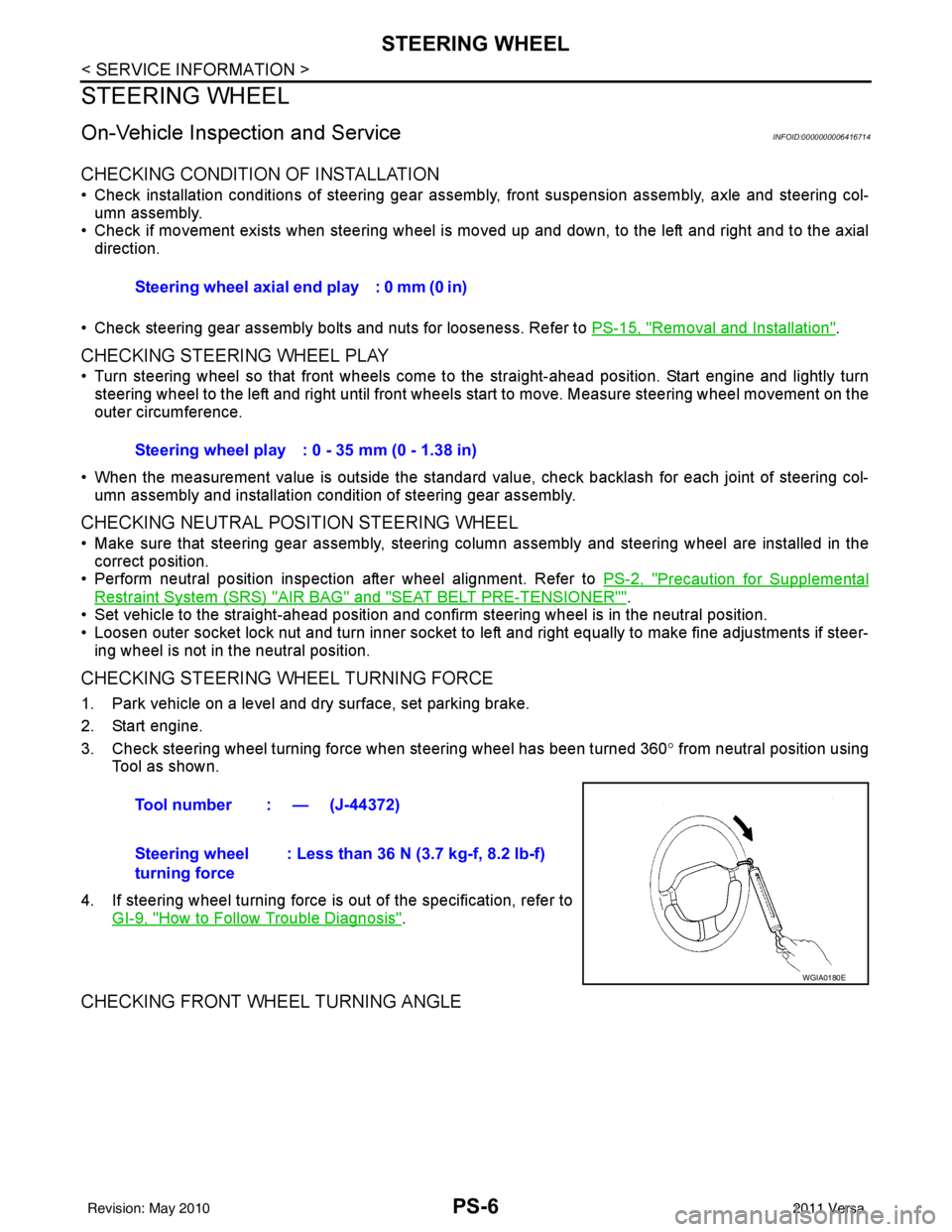

CHECKING STEERING WHEEL TURNING FORCE

1. Park vehicle on a level and dry surface, set parking brake.

2. Start engine.

3. Check steering wheel turning force when steering wheel has been turned 360 ° from neutral position using

Tool as shown.

4. If steering wheel turning force is out of the specification, refer to GI-9, "

How to Follow Trouble Diagnosis".

CHECKING FRONT WHEEL TURNING ANGLE

Steering wheel axial end play : 0 mm (0 in)

Steering wheel play : 0 - 35 mm (0 - 1.38 in)

Tool number : — (J-44372)

Steering wheel

turning force : Less than 36 N (3.7 kg-f, 8.2 lb-f)

WGIA0180E

Revision: May 2010

2011 Versa

Page 3520 of 3787

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTINGRAX-5

< SERVICE INFORMATION >

CEF

G H

I

J

K L

M A

B

RAX

N

O P

NOISE, VIBRATION AND HARSHN ESS (NVH) TROUBLESHOOTING

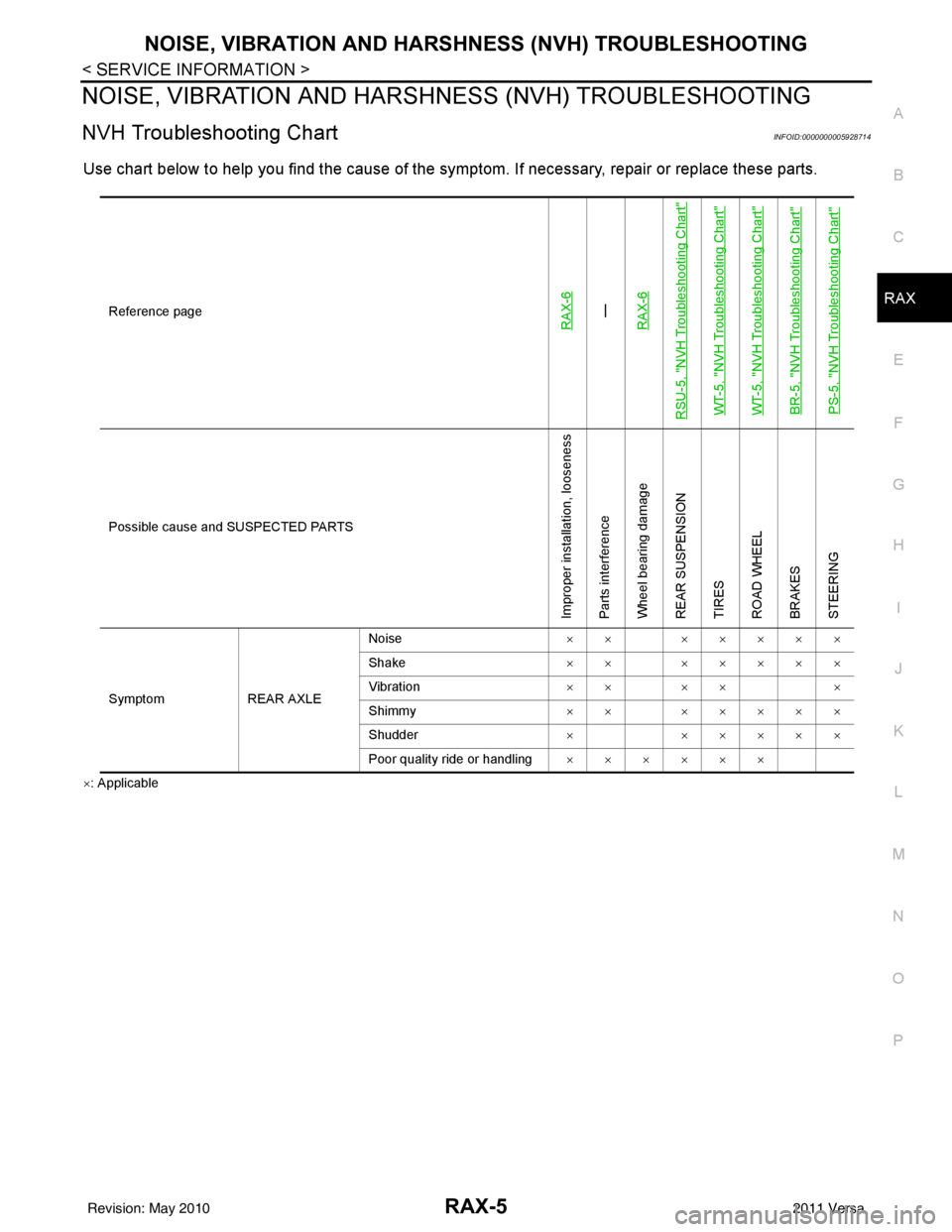

NVH Troubleshooting ChartINFOID:0000000005928714

Use chart below to help you find the cause of the symptom. If necessary, repair or replace these parts.

×: Applicable Reference page

RAX-6—

RAX-6

RSU-5, "

NVH Troubleshooting Chart

"

WT-5, "

NVH Troubleshooting Chart

"

WT-5, "

NVH Troubleshooting Chart

"

BR-5, "

NVH Troubleshooting Chart

"

PS-5, "

NVH Troubleshooting Chart

"

Possible cause and SUSPECTED PARTS

Improper installation, looseness

Parts interference

Wheel bearing damage

REAR SUSPENSION

TIRES

ROAD WHEEL

BRAKES

STEERING

Symptom REAR AXLENoise

×× ×××××

Shake ×× ×××××

Vibration ×× ×× ×

Shimmy ×× ×××××

Shudder ××××××

Poor quality ride or handling ××××××

Revision: May 2010 2011 Versa

Page 3522 of 3787

WHEEL HUBRAX-7

< SERVICE INFORMATION >

CEF

G H

I

J

K L

M A

B

RAX

N

O P

Do not pull on wheel sensor harness.

3. Remove the brake drum only. Refer to BR-36, "

Removal and Installation of Drum Brake Assembly".

4. Remove wheel hub and bearing assembly bolts, and then remove wheel hub and bearing assembly from vehicle.

5. Suspend back plate with suitable wire, or if necessary, remove back plate using the following procedure. 1. Remove parking brake rear cable from back plate. Refer to PB-6, "

Removal and Installation".

2. Separate brake tube from wheel cylinder. Refer to BR-12, "

Rear Brake Tube and Hose".

INSPECTION AFTER REMOVAL

Check for any deformity, cracks, or other damage on the wheel hub assembly, replace if necessary.

CAUTION:

The wheel hub assembly does not requ ire maintenance. If any of the following symptoms are noted,

replace the wheel hub assembly.

• Growling noise is emitted from the wheel hub bearing during operation.

• Wheel hub bearing drags or turns roughly.

INSTALLATION

Installation is in the reverse order of removal.

Revision: May 2010 2011 Versa

Page 3558 of 3787

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTINGRSU-5

< SERVICE INFORMATION >

C

DF

G H

I

J

K L

M A

B

RSU

N

O P

NOISE, VIBRATION AND HARSHN ESS (NVH) TROUBLESHOOTING

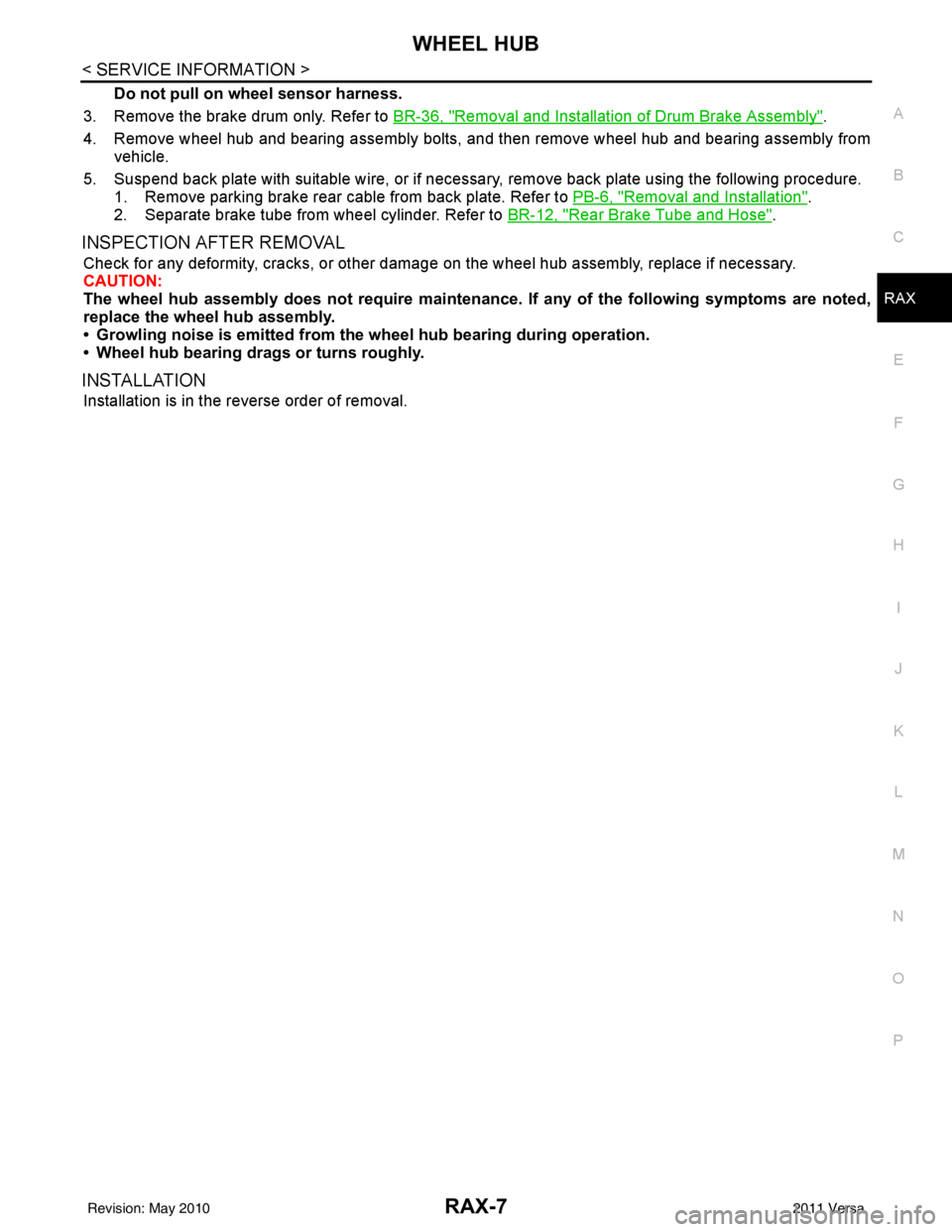

NVH Troubleshooting ChartINFOID:0000000005931083

Use chart below to help you find the cause of the symptom. If necessary, repair or replace these parts.

×: ApplicableReference page

RSU-8RSU-9RSU-9RSU-9RSU-11RSU-8RSU-6

RSU-5, "

NVH Troubleshooting Chart

"

WT-5, "

NVH Troubleshooting Chart

"

WT-5, "

NVH Troubleshooting Chart

"

BR-5, "

NVH Troubleshooting Chart

"

PS-5, "

NVH Troubleshooting Chart

"

Possible cause and SUSPECTED PARTS

Improper installation, looseness

Shock absorber deformation, damage or deflection

Bushing or mounting deterioration

Parts interference

Spring fatigue

Suspension looseness

Incorrect wheel alignment

REAR AXLE

TIRES

ROAD WHEEL

BRAKES

STEERING

Symptom

Noise

×××××× ×××××

Shake ×××× × ×××××

Vibration ××××× ×× ×

Shimmy ×××× ××××××

Shudder ××× ×××××

Poor quality ride or handling ××××× ××××

Revision: May 2010 2011 Versa

Page 3561 of 3787

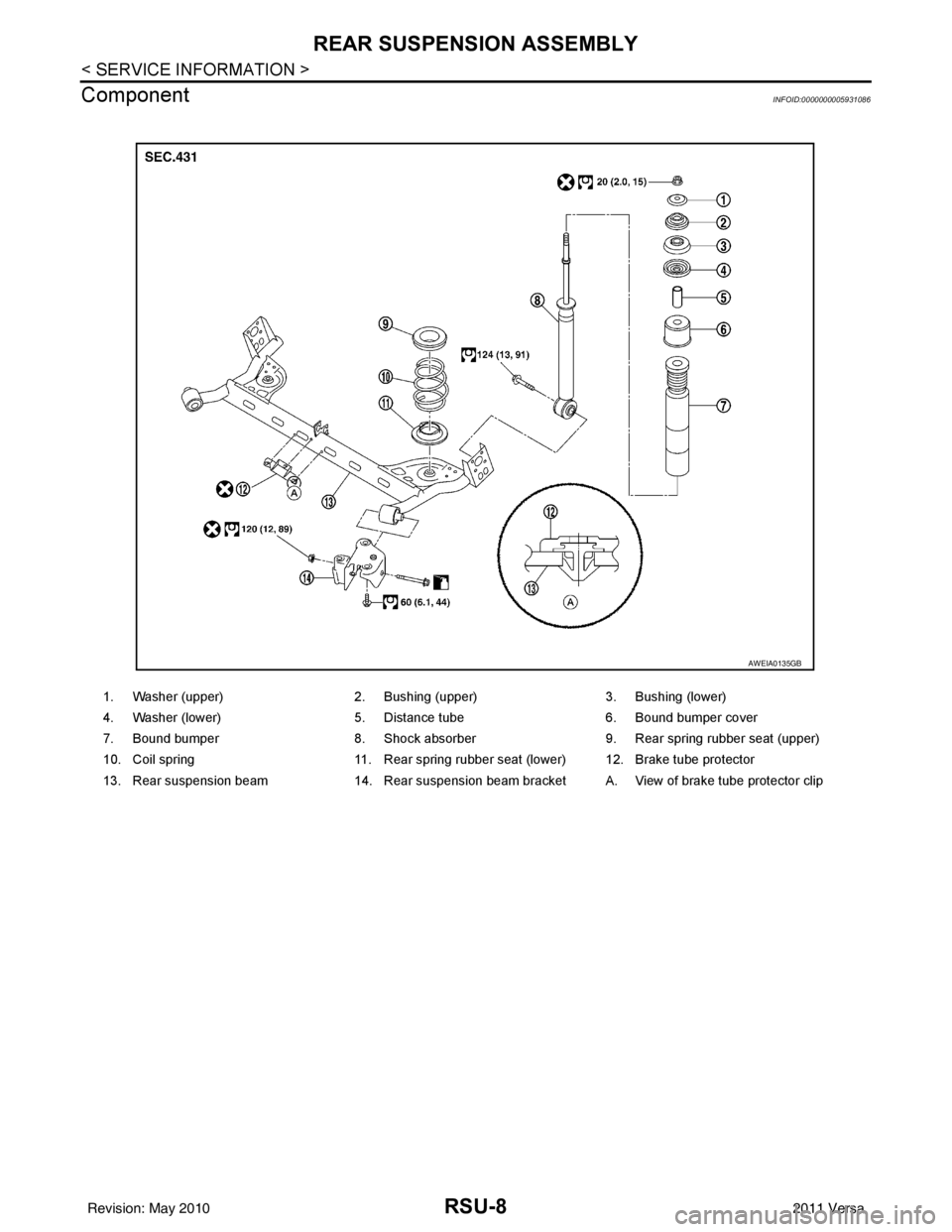

RSU-8

< SERVICE INFORMATION >

REAR SUSPENSION ASSEMBLY

Component

INFOID:0000000005931086

1. Washer (upper) 2. Bushing (upper)3. Bushing (lower)

4. Washer (lower) 5. Distance tube6. Bound bumper cover

7. Bound bumper 8. Shock absorber 9. Rear spring rubber seat (upper)

10. Coil spring 11. Rear spring rubber seat (lower) 12. Brake tube protector

13. Rear suspension beam 14. Rear suspension beam bracket A. View of brake tube protector clip

AWEIA0135GB

Revision: May 2010 2011 Versa

Page 3565 of 3787

RSU-12

< SERVICE INFORMATION >

REAR SUSPENSION BEAM

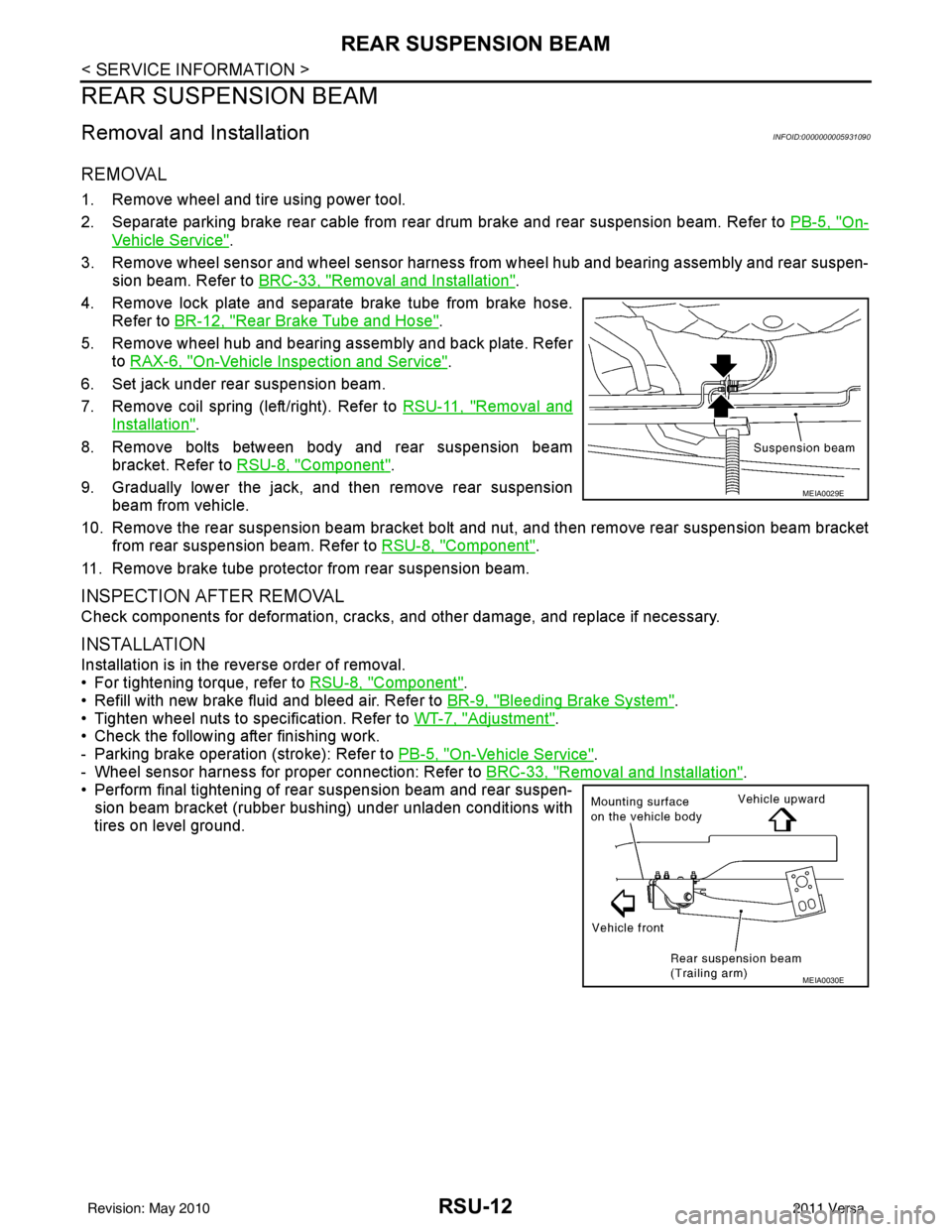

REAR SUSPENSION BEAM

Removal and InstallationINFOID:0000000005931090

REMOVAL

1. Remove wheel and tire using power tool.

2. Separate parking brake rear cable from rear drum brake and rear suspension beam. Refer to PB-5, "

On-

Vehicle Service".

3. Remove wheel sensor and wheel sensor harness from wheel hub and bearing assembly and rear suspen-

sion beam. Refer to BRC-33, "

Removal and Installation".

4. Remove lock plate and separate brake tube from brake hose. Refer to BR-12, "

Rear Brake Tube and Hose".

5. Remove wheel hub and bearing assembly and back plate. Refer to RAX-6, "

On-Vehicle Inspection and Service".

6. Set jack under rear suspension beam.

7. Remove coil spring (left/right). Refer to RSU-11, "

Removal and

Installation".

8. Remove bolts between body and rear suspension beam bracket. Refer to RSU-8, "

Component".

9. Gradually lower the jack, and then remove rear suspension beam from vehicle.

10. Remove the rear suspension beam bracket bolt and nut, and then remove rear suspension beam bracket

from rear suspension beam. Refer to RSU-8, "

Component".

11. Remove brake tube protector from rear suspension beam.

INSPECTION AFTER REMOVAL

Check components for deformation, cracks, and other damage, and replace if necessary.

INSTALLATION

Installation is in the reverse order of removal.

• For tightening torque, refer to RSU-8, "

Component".

• Refill with new brake fluid and bleed air. Refer to BR-9, "

Bleeding Brake System".

• Tighten wheel nuts to specification. Refer to WT-7, "

Adjustment".

• Check the following after finishing work.

- Parking brake operation (stroke): Refer to PB-5, "

On-Vehicle Service".

- Wheel sensor harness for proper connection: Refer to BRC-33, "

Removal and Installation".

• Perform final tightening of rear suspension beam and rear suspen-

sion beam bracket (rubber bushing) under unladen conditions with

tires on level ground.

MEIA0029E

MEIA0030E

Revision: May 2010 2011 Versa

Page 3576 of 3787

SB-10

< ON-VEHICLE REPAIR >

SEAT BELTS

Grasp the shoulder webbing and pull it forward quickly. The retractor should lock and prevent the belt from

extending further.

ALR Function Stationary Check

1. Pull out entire length of seat belt from retractor until a click is heard.

2. Retract the webbing partially. A clicking noise should be heard as the webbing retracts, indicating that the

retractor is in the Automatic Locking Retractors (ALR) mode.

3. Grasp the seat belt and try to pull out the retractor. The webbing must lock and not extend any further. If NG, replace the retractor assembly.

4. Allow the entire length of the webbing to re tract to cancel the automatic locking mode.

ELR Function Moving Check

WARNING:

Perform the following test in a safe, open area clear of other vehicles and obstructions (for example, a

large, empty parking lot). Road surface must be p aved and dry. DO NOT perform the following test on

wet or gravel roads or on public streets and highw ays. This could result in an accident and serious

personal injury. The driver and passenger must be prepared to brace themselves in the event the

retractor does not lock.

1. Fasten driver's seat belt. Buckle a passenger in to the seat for the belt that is to be tested.

2. Proceed to the designated safe area.

3. Drive the vehicle at approximately 16 km/h ( 10 MPH). Notify any passengers of a pending sudden stop

and the driver and passenger must be prepared to brac e themselves in the event the retractor does not

lock, apply brakes firmly and make a very hard stop.

During the stop, seat belts should lock and not be extended. If the seat belt retractor assembly does not lock,

perform the retractor off-vehicle check.

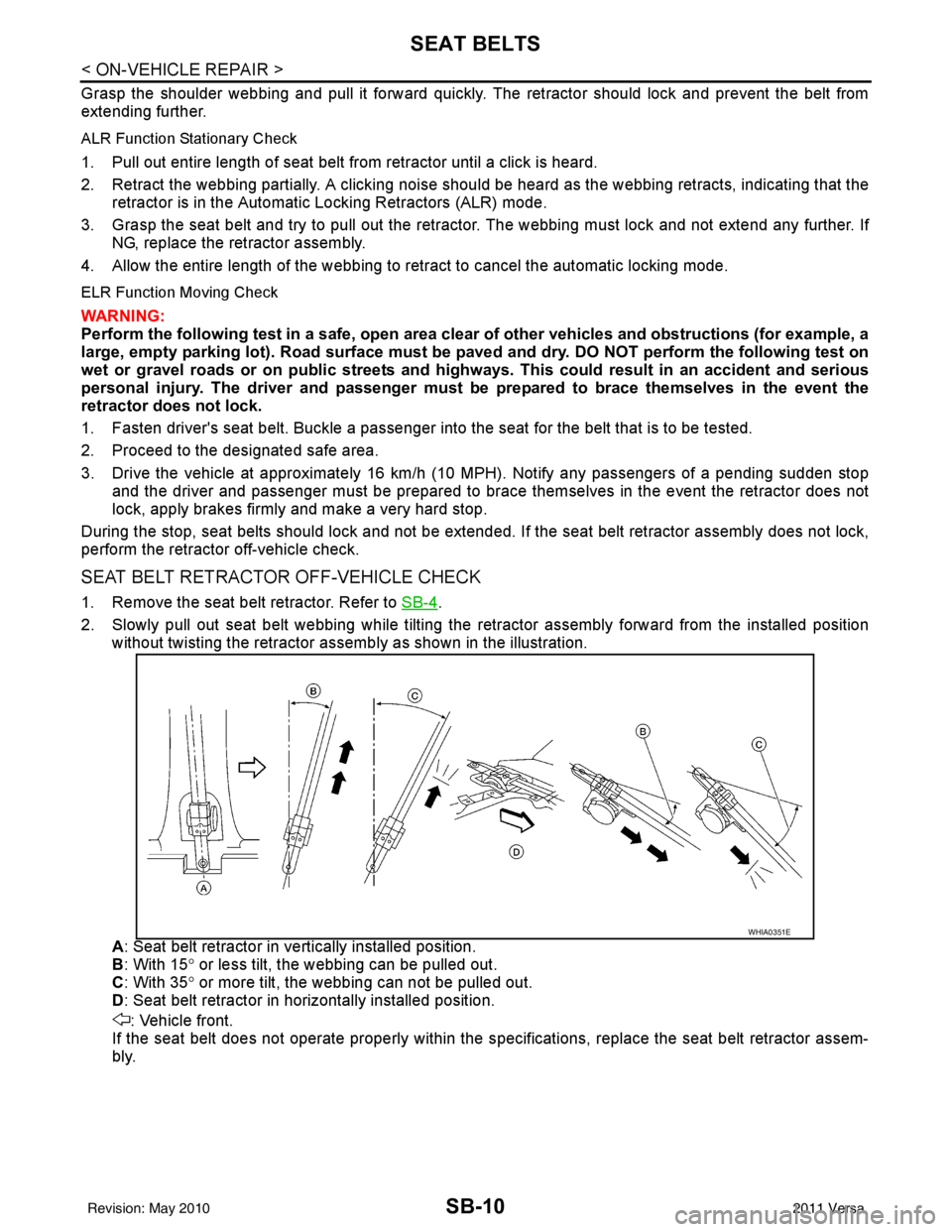

SEAT BELT RETRACTOR OFF-VEHICLE CHECK

1. Remove the seat belt retractor. Refer to SB-4.

2. Slowly pull out seat belt webbing while tilting the re tractor assembly forward from the installed position

without twisting the retractor assemb ly as shown in the illustration.

A : Seat belt retractor in ve rtically installed position.

B : With 15 ° or less tilt, the webbing can be pulled out.

C : With 35 ° or more tilt, the webbing can not be pulled out.

D : Seat belt retractor in horizontally installed position.

: Vehicle front.

If the seat belt does not operate properly within the s pecifications, replace the seat belt retractor assem-

bly.

WHIA0351E

Revision: May 2010 2011 Versa

Page 3723 of 3787

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTINGWT-5

< SERVICE INFORMATION >

C

DF

G H

I

J

K L

M A

B

WT

N

O P

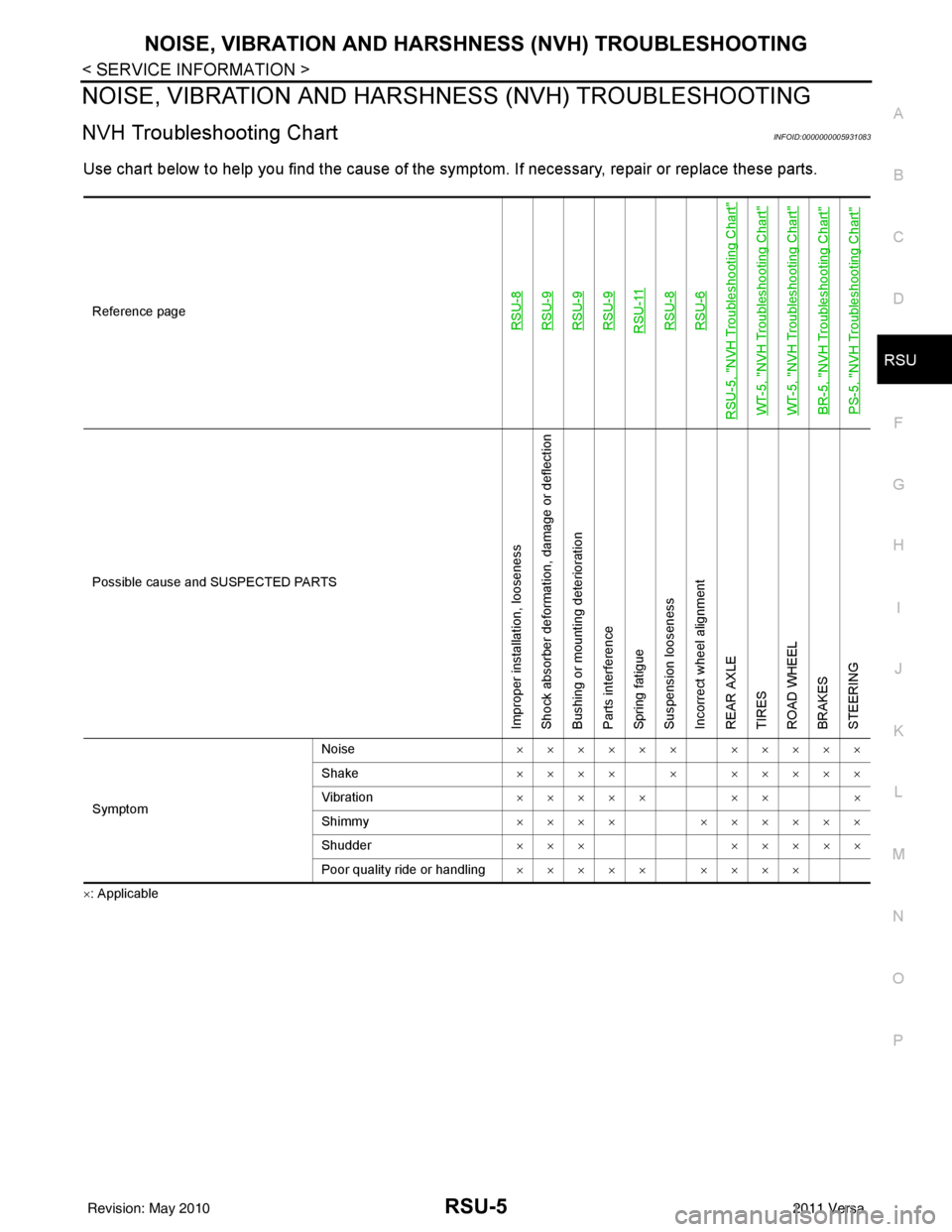

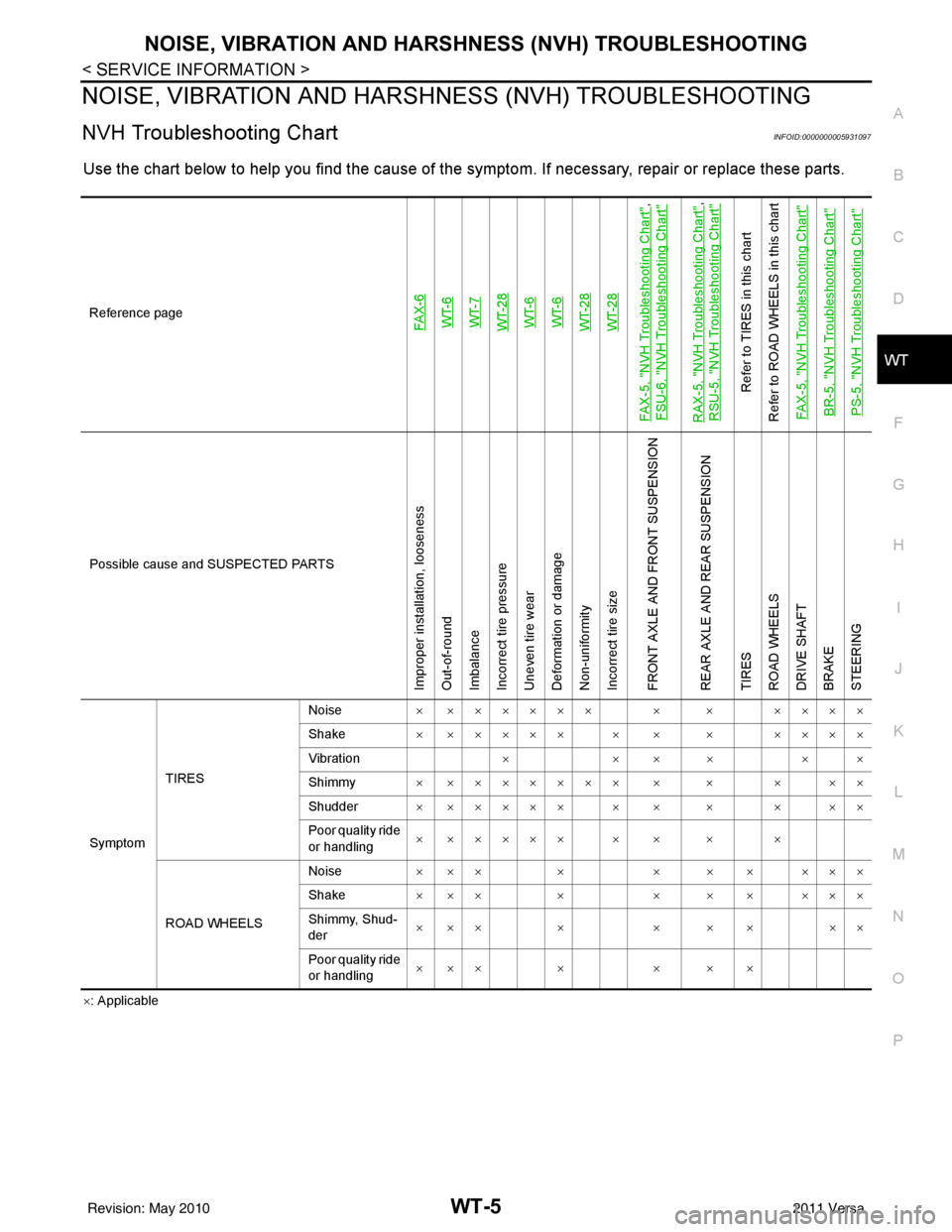

NOISE, VIBRATION AND HARSHN ESS (NVH) TROUBLESHOOTING

NVH Troubleshooting ChartINFOID:0000000005931097

Use the chart below to help you find t he cause of the symptom. If necessary, repair or replace these parts.

×: Applicable

Reference page

FAX-6WT-6

WT-7

WT-28WT-6

WT-6

WT-28WT-28

FAX-5, "

NVH Troubleshooting Chart

",

FSU-6, "

NVH Troubleshooting Chart

"

RAX-5, "

NVH Troubleshooting Chart

",

RSU-5, "

NVH Troubleshooting Chart

"

Refer to TIRES in this chart

Refer to ROAD WHEELS in this chart

FAX-5, "

NVH Troubleshooting Chart

"

BR-5, "

NVH Troubleshooting Chart

"

PS-5, "

NVH Troubleshooting Chart

"

Possible cause and SUSPECTED PARTS

Improper installation, looseness

Out-of-round

Imbalance

Incorrect tire pressure

Uneven tire wear

Deformation or damage

Non-uniformity

Incorrect tire size

FRONT AXLE AND FRONT SUSPENSION

REAR AXLE AND REAR SUSPENSION

TIRES

ROAD WHEELS

DRIVE SHAFT

BRAKE

STEERING

Symptom TIRES Noise

× ×××××× × × ××××

Shake × ××××× × × × ××××

Vibration ××××××

Shimmy × ××××××× × × × ××

Shudder × ××××× × × × × ××

Poor quality ride

or handling × ××××× × × × ×

ROAD WHEELS Noise

× ×× × × × × ×××

Shake × ×× × × × × ×××

Shimmy, Shud-

der ××× × × × × ××

Poor quality ride

or handling ××× × × × ×

Revision: May 2010

2011 Versa