Time NISSAN TIIDA 2011 Service Workshop Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2011, Model line: TIIDA, Model: NISSAN TIIDA 2011Pages: 3787, PDF Size: 78.35 MB

Page 515 of 3787

PRECAUTIONSBL-5

< SERVICE INFORMATION >

C

DE

F

G H

J

K L

M A

B

BL

N

O P

5. When the repair work is completed, return the ignition switch to the ″LOCK ″ position before connecting

the battery cables. (At this time, the steering lock mechanism will engage.)

6. Perform a self-diagnosis check of al l control units using CONSULT-III.

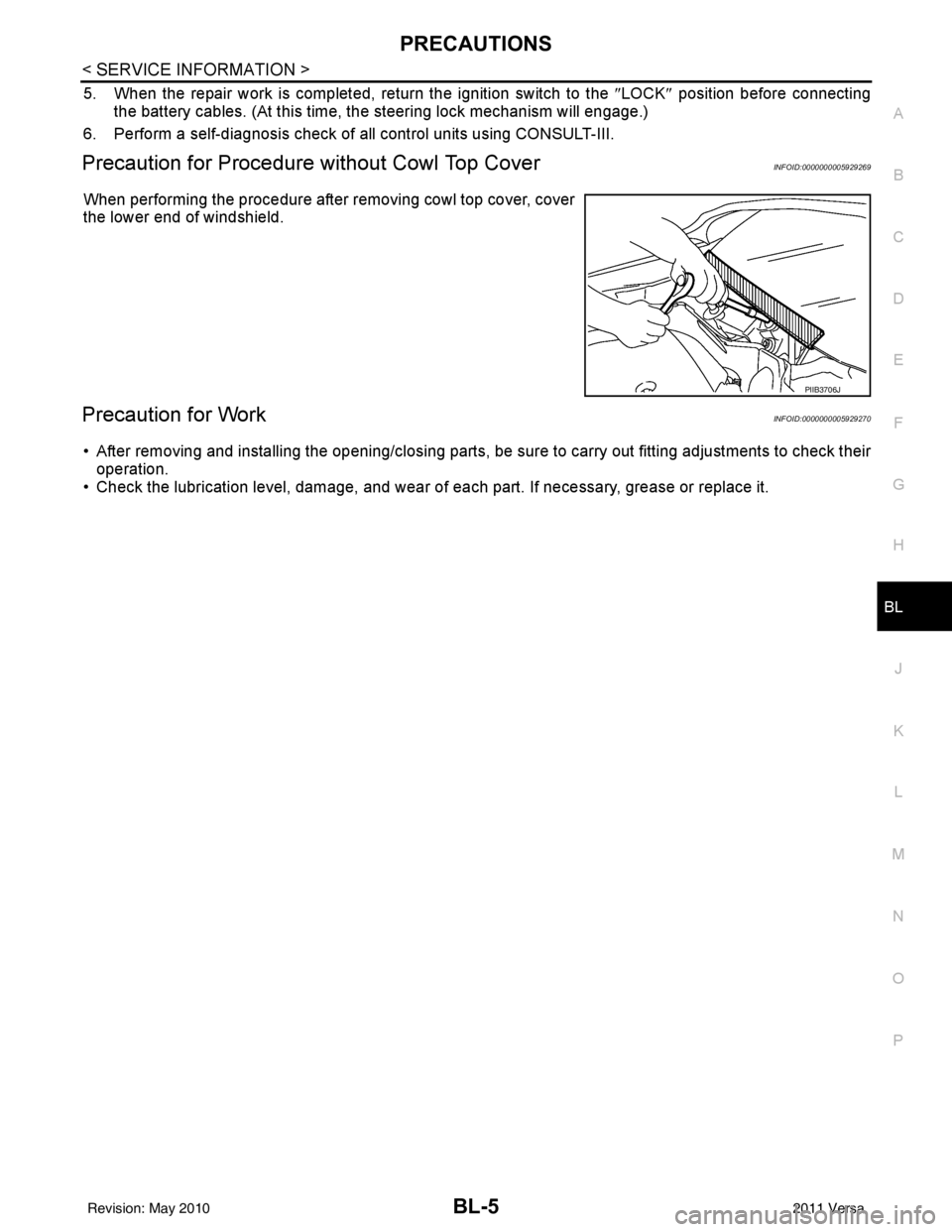

Precaution for Procedure without Cowl Top CoverINFOID:0000000005929269

When performing the procedure after removing cowl top cover, cover

the lower end of windshield.

Precaution for WorkINFOID:0000000005929270

• After removing and installing the opening/closing parts, be sure to carry out fitting adjustments to check their

operation.

• Check the lubrication level, damage, and wear of each part. If necessary, grease or replace it.

PIIB3706J

Revision: May 2010 2011 Versa

Page 520 of 3787

BL-10

< SERVICE INFORMATION >

SQUEAK AND RATTLE TROUBLE DIAGNOSES

Most of these incidents can be repaired by adjusting, securing or insulating the item(s) or component(s) caus-

ing the noise.

SUNROOF/HEADLINING

Noises in the sunroof/headlining area c an often be traced to one of the following:

1. Sunroof lid, rail, linkage or seals making a rattle or light knocking noise

2. Sun visor shaft shaking in the holder

3. Front or rear windshield touching headliner and squeaking

Again, pressing on the components to stop the noise while duplicating the conditions can isolate most of these

incidents. Repairs usually consist of insulating with felt cloth tape.

OVERHEAD CONSOLE (FRONT AND REAR)

Overhead console noises are often caused by the c onsole panel clips not being engaged correctly. Most of

these incidents are repaired by pushing up on the c onsole at the clip locations until the clips engage.

In addition look for:

1. Loose harness or harness connectors.

2. Front console map/reading lamp lense loose.

3. Loose screws at console attachment points.

SEATS

When isolating seat noise it's important to note the pos ition the seat is in and the load placed on the seat when

the noise is present. These conditions should be duplicated when verifying and isolating the cause of the

noise.

Cause of seat noise include:

1. Headrest rods and holder

2. A squeak between the seat pad cushion and frame

3. The rear seatback lock and bracket

These noises can be isolated by moving or pressing on the suspected components while duplicating the con-

ditions under which the noise occurs. Most of thes e incidents can be repaired by repositioning the component

or applying urethane tape to the contact area.

UNDERHOOD

Some interior noise may be caused by components under the hood or on the engine wall. The noise is then

transmitted into the passenger compartment.

Causes of transmitted underhood noise include:

1. Any component mounted to the engine wall

2. Components that pass through the engine wall

3. Engine wall mounts and connectors

4. Loose radiator mounting pins

5. Hood bumpers out of adjustment

6. Hood striker out of adjustment

These noises can be difficult to isolate since they cannot be reached from the interior of the vehicle. The best

method is to secure, move or insulate one component at a time and test drive the \

vehicle. Also, engine RPM

or load can be changed to isolate the noise. Repairs can usually be made by moving, adjusting, securing, or

insulating the component causing the noise.

Revision: May 2010 2011 Versa

Page 533 of 3787

POWER DOOR LOCK SYSTEMBL-23

< SERVICE INFORMATION >

C

DE

F

G H

J

K L

M A

B

BL

N

O P

System DescriptionINFOID:0000000005929283

Power is supplied at all times

• through 40A fusible link (letter g, located in the fuse and fusible link box)

• to BCM terminal 70

• through 10A fuse [No. 8, located in the fuse block (J/B)]

• to BCM terminal 57

• through 10A fuse [No. 14, located in the fuse block (J/B)]

• to key switch terminal 2 (without Intelligent Key system)

• through 10A fuse [No. 31, located in the fuse block (J/B)]

• to key switch and ignition knob switch terminals 2 and 4 (with Intelligent Key system).

When key switch is ON (key is inserted in ignition key cylinder), power is supplied

• through key switch terminal 1 (without Intelligent Key system) or key switch and ignition knob terminal 1 (with Intelligent Key system)

• to BCM terminal 37.

Ground is supplied

• to BCM terminal 67

• through body grounds M57 and M61.

LOCK OPERATION

When the door is locked with main power window and door lock/unlock switch, ground is supplied

• to BCM terminal 45

• through main power window and door lock and unlock switch terminals 17 and 18

• through body grounds M57 and M61.

When the door is locked with power window and door lock/unlock switch RH, ground is supplied

• to BCM terminal 45

• through power window and door lock and unlock switch RH terminals 1 and 3

• through body grounds M57 and M61.

When the door is locked with front door lock assemb ly LH (key cylinder switch), ground is supplied

• to BCM terminal 8

• through front door lock assembly LH (key cylinder switch) terminals 4 and 6

• through body grounds M57 and M61.

UNLOCK OPERATION

When the door is unlocked with main power window and door lock/unlock switch, ground is supplied

• to BCM terminal 46

• through main power window and door lock/unlock switch terminals 6 and 17

• through body grounds M57 and M61.

When the door is unlocked with power window and door lock/unlock switch RH, ground is supplied

• to BCM terminal 46

• through power window and door lock and unlock switch RH terminals 2 and 3

• through body grounds M57 and M61.

When the door is unlocked with front door lock assemb ly LH (key cylinder switch), ground is supplied

• to BCM terminal 7

• through front door lock assembly LH (key cylinder switch) terminals 4 and 5

1. BCM M18, M19, M20

(view with glove box removed) 2. Intelligent Key unit M52

(if equipped) 3. Front door lock assembly LH (key cyl-

inder switch) D14

4. Front door switch LH B8, RH B108 5. Front door lock assembly LH (actuator) D14

Front door lock assembly RH (actuator)

D1146. Rear door switch LH B6, RH B116

7. Rear door lock actuator LH D205 RH D305 8. Key switch and ignition knob switch M73

(with A/T or CVT and Intelligent Key) 9. Key switch and ignition knob switch

M73 (with M/T and Intelligent Key)

10. Key switch and key lock solenoid M27 (without Intelligent key) 11. Main power window and door lock/un-

lock switch D7, D8

Power window and door lock/unlock

switch RH D105 12. Fuse block (with Intelligent Key)

(view with instrument panel LH re-

moved)

13. Passenger select unlock relay M2 (with Intelligent Key) 14. Back door lock assembly (back door

switch) D405 (hatchback view with back

door open) 15. Combination meter M24

Revision: May 2010

2011 Versa

Page 534 of 3787

BL-24

< SERVICE INFORMATION >

POWER DOOR LOCK SYSTEM

• through body grounds M57 and M61.

When the front door switch LH is ON (door is OPEN), ground is supplied

• to BCM terminal 47

• through front door switch LH terminal 2

• through front door switch LH case ground.

When the front door switch RH is ON (door is OPEN), ground is supplied

• to BCM terminal 12

• through front door switch RH terminal 2

• through front door switch RH case ground.

When the rear door switch LH is ON (door is OPEN), ground is supplied

• to BCM terminal 48

• through rear door switch LH terminal 1

• through rear door switch LH case ground.

When the rear door switch RH is ON (door is OPEN), ground is supplied

• to BCM terminal 13

• through rear door switch RH terminal 1

• through rear door switch RH case ground.

When the back door lock assembly (back door switch) ( hatchback) is ON (back door is OPEN), ground is sup-

plied

• to BCM terminal 43

• through back door lock assembly (back door switch) terminals 3 and 4

• through body grounds B117, B132 and D402.

OUTLINE

Functions available by operating the inside door lock and unlock switches

• Interlocked with the locking operation of door lock and unlock switch, door lock actuators of all doors are

locked.

• Interlocked with the unlocking operation of door lock and unlock switch, door lock actuators of all doors are

unlocked.

Functions available by operating the front door lock assembly LH (key cylinder switch)

• Interlocked with the locking operation of front door lock assembly LH (key cylinder switch), door lock actua-

tors of all doors are locked.

• When front door lock assembly LH (key cylinder switch) is unlocked, front door lock assembly LH (actuator)

is unlocked.

• When front door lock assembly LH (key cylinder swit ch) is unlocked for the second time within 5 seconds

after the first operation, front door lock assembly RH (actuator), rear door lock actuator LH and rear door

lock actuator RH are unlocked.

Key reminder door system

When door lock and unlock switch is operated to lock doors with ignition key inserted in key cylinder and any

door open, all door lock actuators are locked and then unlocked.

AUTOMATIC DOOR LOCKS (LOCK OPERATION)

The interlock door lock function is the function that locks all doors linked with the vehicle speed.

Vehicle Speed Sensing Auto Door Lock*1

All doors are locked when the vehicle speed reaches 24 km/h (15 MPH) or more.

BCM outputs the lock signal to all door lock actuators when it detects that the ignition switch is turned ON, all

doors are closed and the vehicle speed received from the combination meter via CAN communication

becomes 15 MPH (24 km/h) or more.

If a door is opened and closed at any time during one ignition cycle (OFF → ON), even after initial auto door

lock has taken place, the BCM will relock all doors when the vehicle speed reaches 15 MPH (24 km/h) or more

again.

Setting change of Automatic Door Locks (LOCK) Function

The lock operation setting of the autom atic door locks function can be changed.

With CONSULT-III

The ON/OFF switching of the automatic door locks (LOC K) function and the type selection of the automatic

door locks (LOCK) function can be performed at the WO RK SUPPORT setting of CONSULT-III. Refer to BL-

41, "CONSULT-III Function (BCM)".

Without CONSULT- III

The automatic door locks (LOCK) function can be swit ched ON/OFF by performing the following operation.

Revision: May 2010 2011 Versa

Page 551 of 3787

POWER DOOR LOCK SYSTEMBL-41

< SERVICE INFORMATION >

C

DE

F

G H

J

K L

M A

B

BL

N

O P

1: With Intelligent Key

2: Without Intelligent Key

3: Hatchback without Intelligent Key

4: Sedan without Intelligent Key

5: Hatchback

6: Sedan

7: With power door locks

8: With power windows

Work FlowINFOID:0000000005929290

1. Check the symptom and customer's requests.

2. Understand the outline of system. Refer to BL-23, "

System Description" .

3. According to the trouble diagnosis chart, repair or replace the cause of the malfunction. Refer to BL-119,

"Trouble Diagnosis Symptom Chart" .

4. Does power door lock system operate normally? OK: GO TO 5, NG: GO TO 3.

5. Inspection End.

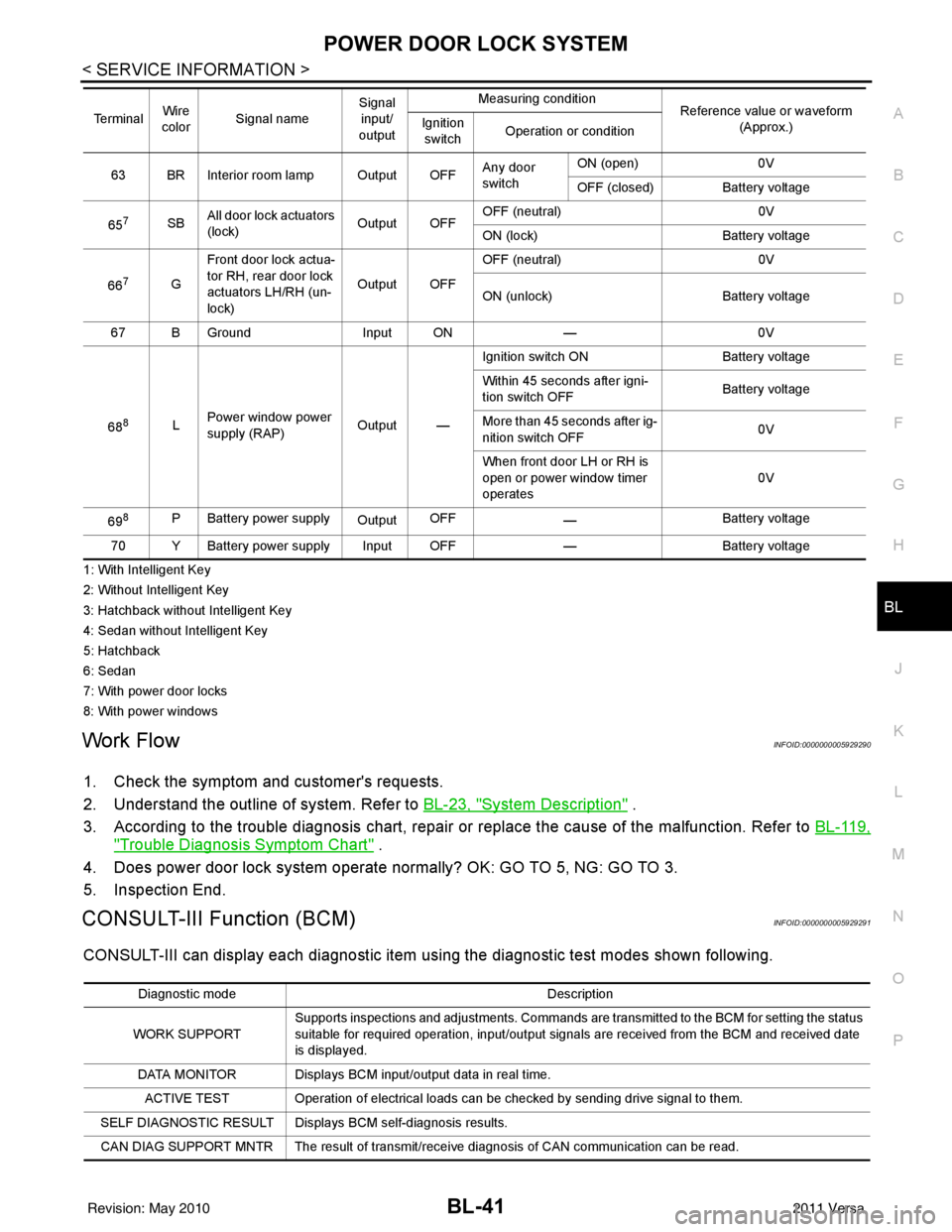

CONSULT-III Function (BCM)INFOID:0000000005929291

CONSULT-III can display each diagnostic item using the diagnostic test modes shown following.

63 BR Interior room lamp Output OFF Any door

switchON (open)

0V

OFF (closed) Battery voltage

65

7SB All door lock actuators

(lock) Output OFFOFF (neutral)

0V

ON (lock) Battery voltage

66

7G Front door lock actua-

tor RH, rear door lock

actuators LH/RH (un-

lock) Output OFFOFF (neutral)

0V

ON (unlock) Battery voltage

67 B Ground Input ON—0V

68

8L Power window power

supply (RAP)

Output —Ignition switch ON

Battery voltage

Within 45 seconds after igni-

tion switch OFF Battery voltage

More than 45 seconds after ig-

nition switch OFF 0V

When front door LH or RH is

open or power window timer

operates 0V

69

8P Battery power supply OutputOFF

— Battery voltage

70 Y Battery power supply Input OFF —Battery voltage

Te r m i n a l

Wire

color Signal name Signal

input/

output Measuring condition

Reference value or waveform

(Approx.)

Ignition

switch Operation or condition

Diagnostic mode

Description

WORK SUPPORT Supports inspections and adjustments. Commands are transmitted to the BCM for setting the status

suitable for required operation, input/output signals are received from the BCM and received date

is displayed.

DATA MONITOR Displays BCM input/output data in real time. ACTIVE TEST Operation of electrical loads can be checked by sending drive signal to them.

SELF DIAGNOSTIC RESULT Displays BCM self-diagnosis results.

CAN DIAG SUPPORT MNTR The result of transmit/receive diagnosis of CAN communication can be read.

Revision: May 2010 2011 Versa

Page 568 of 3787

BL-58

< SERVICE INFORMATION >

REMOTE KEYLESS ENTRY SYSTEM

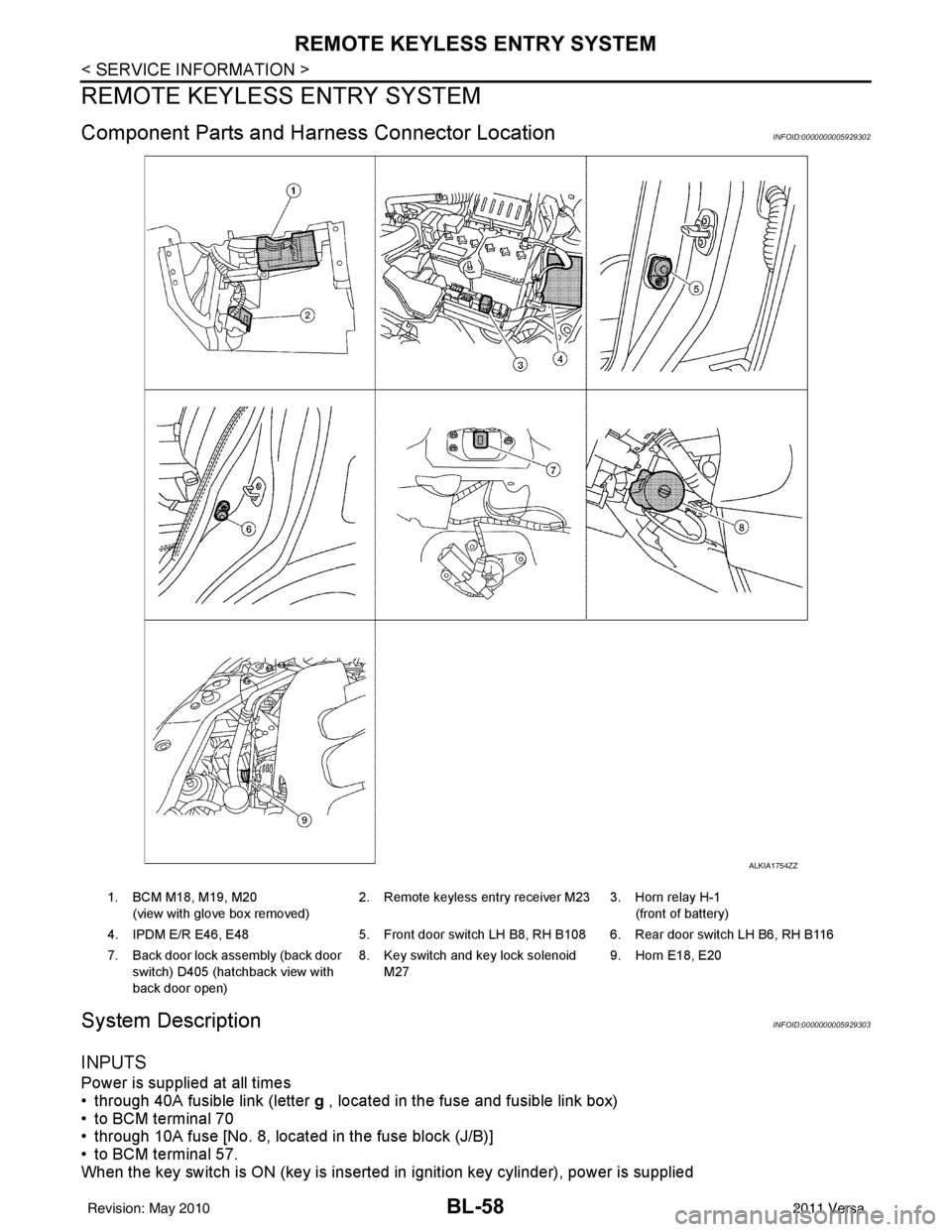

REMOTE KEYLESS ENTRY SYSTEM

Component Parts and Harness Connector LocationINFOID:0000000005929302

System DescriptionINFOID:0000000005929303

INPUTS

Power is supplied at all times

• through 40A fusible link (letter g , located in the fuse and fusible link box)

• to BCM terminal 70

• through 10A fuse [No. 8, located in the fuse block (J/B)]

• to BCM terminal 57.

When the key switch is ON (key is inserted in ignition key cylinder), power is supplied

ALKIA1754ZZ

1. BCM M18, M19, M20

(view with glove box removed) 2. Remote keyless entry receiver M23 3. Horn relay H-1

(front of battery)

4. IPDM E/R E46, E48 5. Front door switch LH B8, RH B108 6. Rear door switch LH B6, RH B116

7. Back door lock assembly (back door switch) D405 (hatchback view with

back door open) 8. Key switch and key lock solenoid

M27 9. Horn E18, E20

Revision: May 2010

2011 Versa

Page 579 of 3787

REMOTE KEYLESS ENTRY SYSTEMBL-69

< SERVICE INFORMATION >

C

DE

F

G H

J

K L

M A

B

BL

N

O P

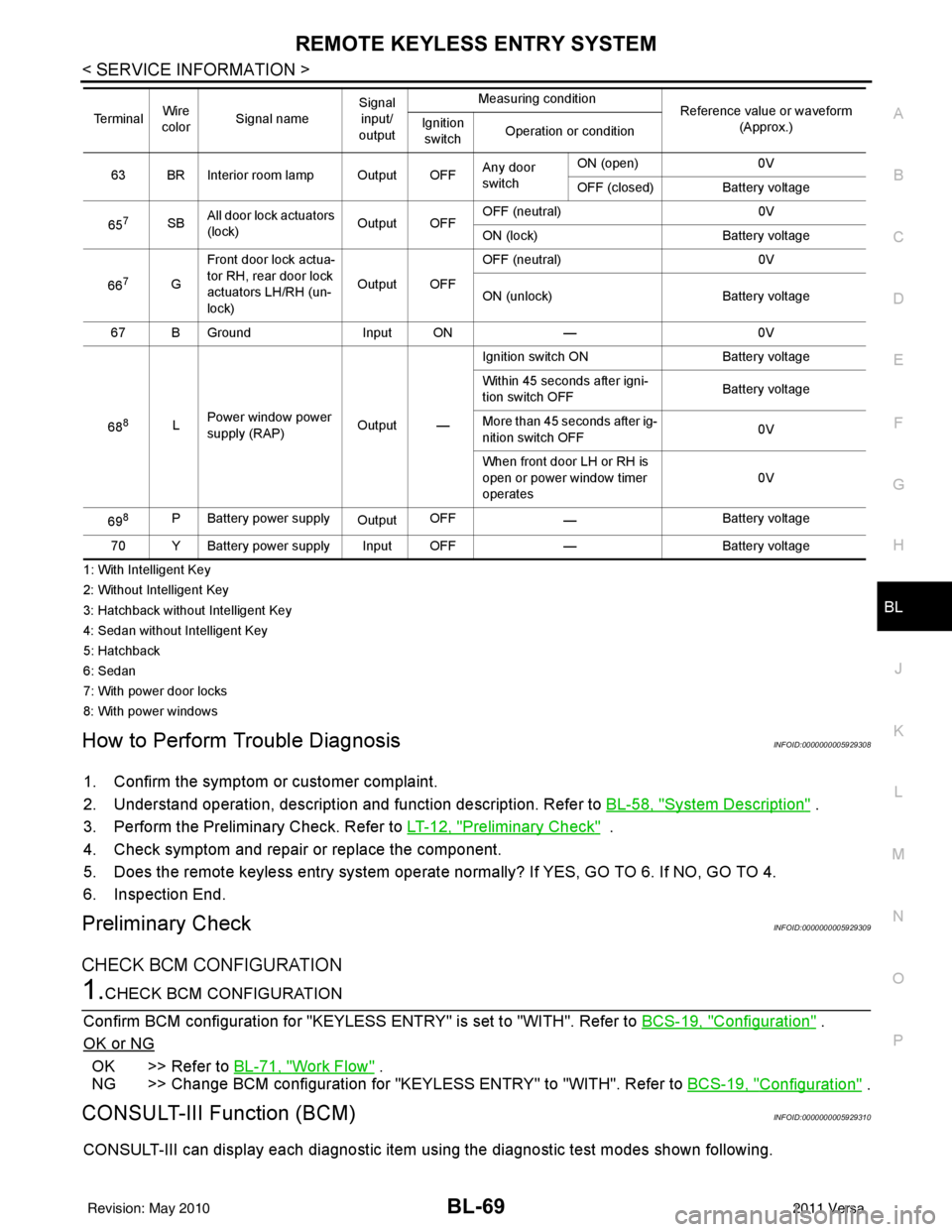

1: With Intelligent Key

2: Without Intelligent Key

3: Hatchback without Intelligent Key

4: Sedan without Intelligent Key

5: Hatchback

6: Sedan

7: With power door locks

8: With power windows

How to Perform Trouble DiagnosisINFOID:0000000005929308

1. Confirm the symptom or customer complaint.

2. Understand operation, description and function description. Refer to BL-58, "

System Description" .

3. Perform the Preliminary Check. Refer to LT-12, "

Preliminary Check" .

4. Check symptom and repair or replace the component.

5. Does the remote keyless entry system operate normally? If YES, GO TO 6. If NO, GO TO 4.

6. Inspection End.

Preliminary CheckINFOID:0000000005929309

CHECK BCM CONFIGURATION

1.CHECK BCM CONFIGURATION

Confirm BCM configuration for "KEYLESS ENTRY" is set to "WITH". Refer to BCS-19, "

Configuration" .

OK or NG

OK >> Refer to BL-71, "Work Flow" .

NG >> Change BCM configuration for "KEYLESS ENTRY" to "WITH". Refer to BCS-19, "

Configuration" .

CONSULT-III Function (BCM)INFOID:0000000005929310

CONSULT-III can display each diagnostic item using the diagnostic test modes shown following.

63 BR Interior room lamp Output OFFAny door

switchON (open)

0V

OFF (closed) Battery voltage

65

7SB All door lock actuators

(lock) Output OFFOFF (neutral)

0V

ON (lock) Battery voltage

66

7G Front door lock actua-

tor RH, rear door lock

actuators LH/RH (un-

lock) Output OFFOFF (neutral)

0V

ON (unlock) Battery voltage

67 B Ground Input ON—0V

68

8L Power window power

supply (RAP)

Output —Ignition switch ON

Battery voltage

Within 45 seconds after igni-

tion switch OFF Battery voltage

More than 45 seconds after ig-

nition switch OFF 0V

When front door LH or RH is

open or power window timer

operates 0V

69

8P Battery power supply OutputOFF

— Battery voltage

70 Y Battery power supply Input OFF —Battery voltage

Te r m i n a l

Wire

color Signal name Signal

input/

output Measuring condition

Reference value or waveform

(Approx.)

Ignition

switch Operation or condition

Revision: May 2010

2011 Versa

Page 580 of 3787

BL-70

< SERVICE INFORMATION >

REMOTE KEYLESS ENTRY SYSTEM

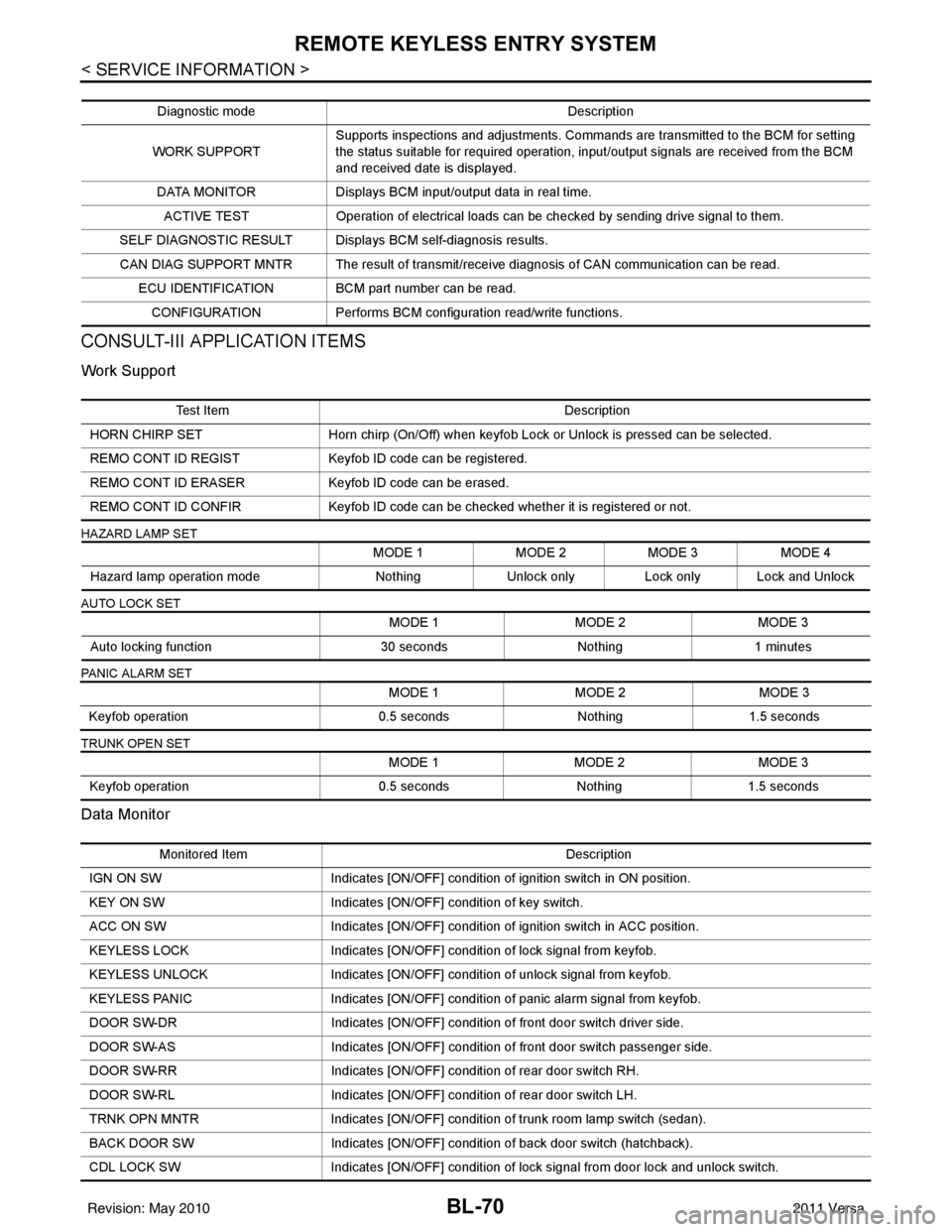

CONSULT-III APPLICATION ITEMS

Work Support

HAZARD LAMP SET

AUTO LOCK SET

PANIC ALARM SET

TRUNK OPEN SET

Data Monitor

Diagnostic modeDescription

WORK SUPPORT Supports inspections and adjustments. Commands are transmitted to the BCM for setting

the status suitable for required operation, input/output signals are received from the BCM

and received date is displayed.

DATA MONITOR Displays BCM input/output data in real time.

ACTIVE TEST Operation of electrical loads can be checked by sending drive signal to them.

SELF DIAGNOSTIC RESULT Displays BCM self-diagnosis results. CAN DIAG SUPPORT MNTR The result of transmit/receive diagnosis of CAN communication can be read. ECU IDENTIFICATION BCM part number can be read.CONFIGURATION Performs BCM configuration read/write functions.

Te s t I t e m D e s c r i p t i o n

HORN CHIRP SET Horn chirp (On/Off) when keyfob Lock or Unlock is pressed can be selected.

REMO CONT ID REGIST Keyfob ID code can be registered.

REMO CONT ID ERASER Keyfob ID code can be erased.

REMO CONT ID CONFIR Keyfob ID code can be checked whether it is registered or not.

MODE 1 MODE 2MODE 3 MODE 4

Hazard lamp operation mode NothingUnlock only Lock only Lock and Unlock

MODE 1 MODE 2MODE 3

Auto locking function 30 secondsNothing1 minutes

MODE 1 MODE 2MODE 3

Keyfob operation 0.5 secondsNothing1.5 seconds

MODE 1 MODE 2MODE 3

Keyfob operation 0.5 secondsNothing1.5 seconds

Monitored Item Description

IGN ON SW Indicates [ON/OFF] condition of ignition switch in ON position.

KEY ON SW Indicates [ON/OFF] condition of key switch.

ACC ON SW Indicates [ON/OFF] condition of ignition switch in ACC position.

KEYLESS LOCK Indicates [ON/OFF] condition of lock signal from keyfob.

KEYLESS UNLOCK Indicates [ON/OFF] condition of unlock signal from keyfob.

KEYLESS PANIC Indicates [ON/OFF] condition of panic alarm signal from keyfob.

DOOR SW-DR Indicates [ON/OFF] condition of front door switch driver side.

DOOR SW-AS Indicates [ON/OFF] condition of front door switch passenger side.

DOOR SW-RR Indicates [ON/OFF] condition of rear door switch RH.

DOOR SW-RL Indicates [ON/OFF] condition of rear door switch LH.

TRNK OPN MNTR Indicates [ON/OFF] condition of trunk room lamp switch (sedan).

BACK DOOR SW Indicates [ON/OFF] condition of back door switch (hatchback).

CDL LOCK SW Indicates [ON/OFF] condition of lock signal from door lock and unlock switch.

Revision: May 2010 2011 Versa

Page 594 of 3787

BL-84

< SERVICE INFORMATION >

REMOTE KEYLESS ENTRY SYSTEM

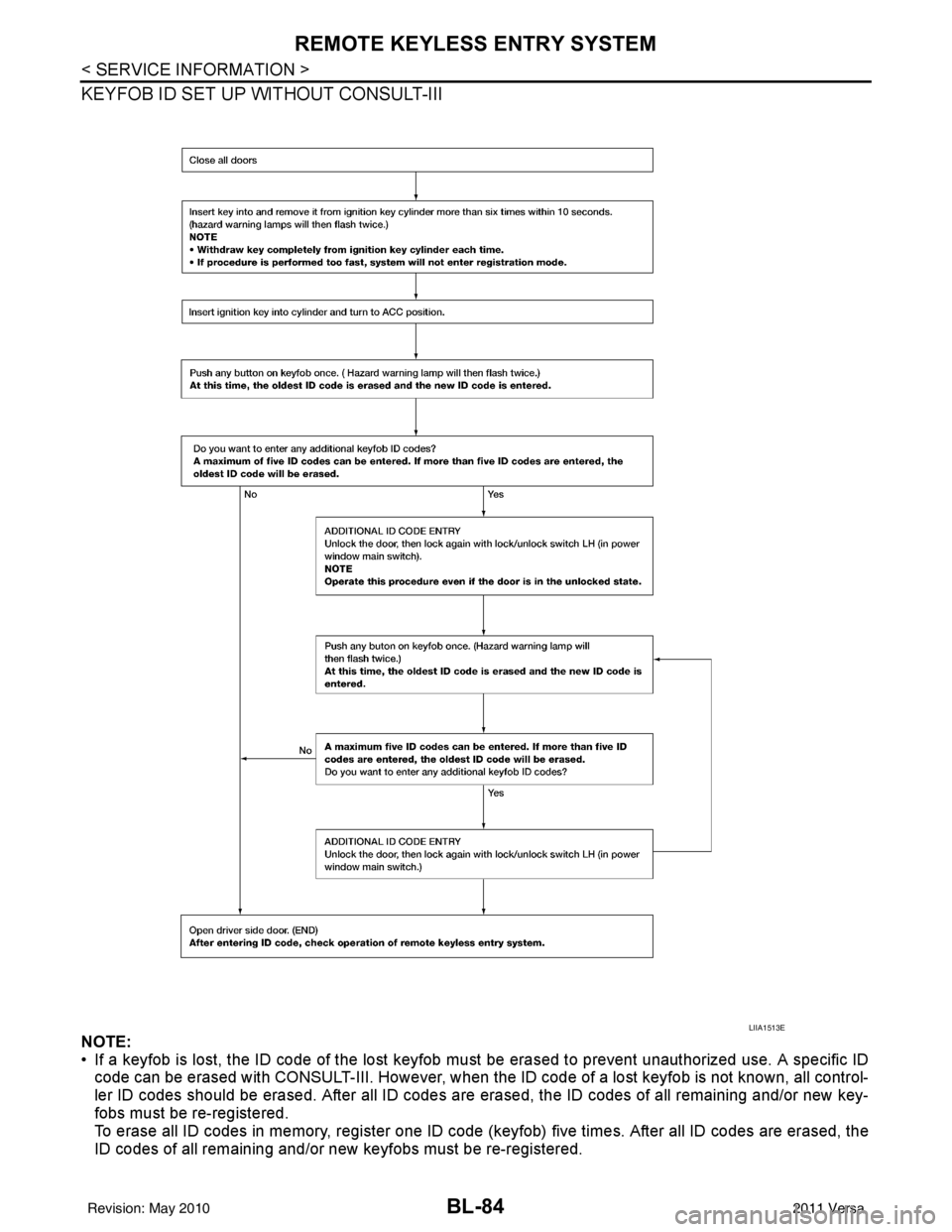

KEYFOB ID SET UP WITHOUT CONSULT-III

NOTE:

• If a keyfob is lost, the ID code of the lost keyfob must be erased to prevent unauthorized use. A specific ID

code can be erased with CONSULT-III. However, when the ID code of a lost keyfob is not known, all control-

ler ID codes should be erased. After all ID codes are erased, the ID codes of all remaining and/or new key-

fobs must be re-registered.

To erase all ID codes in memory, register one ID code (keyfob) five times. After all ID codes are erased, the

ID codes of all remaining and/or new keyfobs must be re-registered.

LIIA1513E

Revision: May 2010 2011 Versa

Page 599 of 3787

INTELLIGENT KEY SYSTEMBL-89

< SERVICE INFORMATION >

C

DE

F

G H

J

K L

M A

B

BL

N

O P

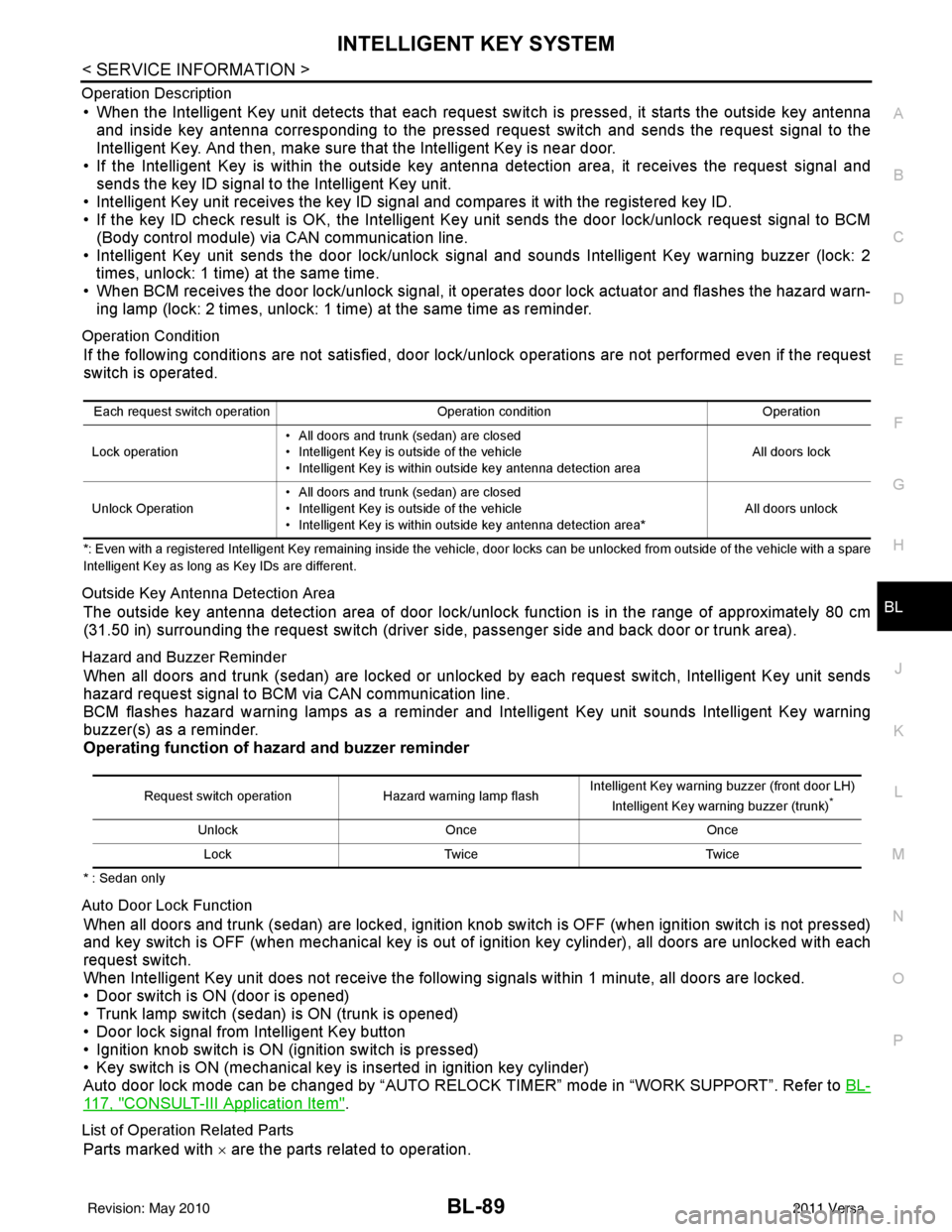

Operation Description

• When the Intelligent Key unit detects that each request sw

itch is pressed, it starts the outside key antenna

and inside key antenna corresponding to the pressed request switch and sends the request signal to the

Intelligent Key. And then, make sure that the Intelligent Key is near door.

• If the Intelligent Key is within the outside key antenna detection area, it receives the request signal and sends the key ID signal to the Intelligent Key unit.

• Intelligent Key unit receives the key ID signal and compares it with the registered key ID.

• If the key ID check result is OK, the Intelligent Ke y unit sends the door lock/unlock request signal to BCM

(Body control module) via CAN communication line.

• Intelligent Key unit sends the door lock/unlock signal and sounds Intelligent Key warning buzzer (lock: 2 times, unlock: 1 time) at the same time.

• When BCM receives the door lock/unlock signal, it oper ates door lock actuator and flashes the hazard warn-

ing lamp (lock: 2 times, unlock: 1 time) at the same time as reminder.

Operation Condition

If the following conditions are not satisfied, door lock/unlock operations are not performed even if the request

switch is operated.

*: Even with a registered Intelligent Key remaining inside the vehicle, door locks can be unlocked from outside of the vehicle with a spare

Intelligent Key as long as Key IDs are different.

Outside Key Antenna Detection Area

The outside key antenna detection area of door lock/unloc k function is in the range of approximately 80 cm

(31.50 in) surrounding the request switch (driver side, passenger side and back door or trunk area).

Hazard and Buzzer Reminder

When all doors and trunk (sedan) are locked or unlocked by each request switch, Intelligent Key\

unit sends

hazard request signal to BCM via CAN communication line.

BCM flashes hazard warning lamps as a reminder and Intelligent Key unit sounds Intelligent Key warning

buzzer(s) as a reminder.

Operating function of hazard and buzzer reminder

* : Sedan only

Auto Door Lock Function

When all doors and trunk (sedan) are locked, ignition knob sw itch is OFF (when ignition switch is not pressed)

and key switch is OFF (when mechanical key is out of ignition key cylinder), all doors are unlocked with each

request switch.

When Intelligent Key unit does not receive the following signals within 1 minute, all doors are locked.

• Door switch is ON (door is opened)

• Trunk lamp switch (sedan) is ON (trunk is opened)

• Door lock signal from Intelligent Key button

• Ignition knob switch is ON (ignition switch is pressed)

• Key switch is ON (mechanical key is inserted in ignition key cylinder)

Auto door lock mode can be changed by “AUTO RELOCK TIMER” mode in “WORK SUPPORT”. Refer to BL-

117, "CONSULT-III Application Item".

List of Operation Related Parts

Parts marked with × are the parts related to operation.

Each request switch operation Operation conditionOperation

Lock operation • All doors and trunk (sedan) are closed

• Intelligent Key is outside of the vehicle

• Intelligent Key is within outside key antenna detection area All doors lock

Unlock Operation • All doors and trunk (sedan) are closed

• Intelligent Key is outside of the vehicle

• Intelligent Key is within outside key antenna detection area*

All doors unlock

Request switch operation

Hazard warning lamp flashIntelligent Key warning buzzer (front door LH)

Intelligent Key warning buzzer (trunk)*

Unlock Once Once

Lock Twice Twice

Revision: May 2010 2011 Versa