Engine cooling system NISSAN TIIDA 2011 Service Manual PDF

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2011, Model line: TIIDA, Model: NISSAN TIIDA 2011Pages: 3787, PDF Size: 78.35 MB

Page 2573 of 3787

![NISSAN TIIDA 2011 Service Manual PDF OIL SEALEM-183

< SERVICE INFORMATION > [MR18DE]

C

D

E

F

G H

I

J

K L

M A

EM

NP

O

• Front fender protector (RH). Refer to EI-26.

• Drive belt. Refer to EM-132, "

Component".

• Crankshaft pulley. NISSAN TIIDA 2011 Service Manual PDF OIL SEALEM-183

< SERVICE INFORMATION > [MR18DE]

C

D

E

F

G H

I

J

K L

M A

EM

NP

O

• Front fender protector (RH). Refer to EI-26.

• Drive belt. Refer to EM-132, "

Component".

• Crankshaft pulley.](/img/5/57396/w960_57396-2572.png)

OIL SEALEM-183

< SERVICE INFORMATION > [MR18DE]

C

D

E

F

G H

I

J

K L

M A

EM

NP

O

• Front fender protector (RH). Refer to EI-26.

• Drive belt. Refer to EM-132, "

Component".

• Crankshaft pulley. Refer to EM-159, "

Component".

2. Remove front oil seal using a suitable tool. CAUTION:

Be careful not to damage front cover and crankshaft.

INSTALLATION

1. Apply new engine oil to new front oil seal joint surface and seal lip.

2. Install front oil seal so that each seal lip is oriented as shown.

• Install front oil seal (2) using a suitable tool with outer diameter57 mm (2.24 in) and inner diameter 45 mm (1.77 in) (A) to the

dimension as shown.

CAUTION:

• Be careful not to damage front cover and crankshaft.

• Press-fit oil seal straight to avoid causing burrs or tilting.

• Do not touch grease applied on oil seal lip.

3. Installation of the remaining components is in the reverse order of removal.

InspectionINFOID:0000000006413293

INSPECTION AFTER INSTALLATION

• Before starting engine, check oil/fluid levels incl uding engine coolant and engine oil. If less than required

quantity, fill to the specified level. Refer to MA-14, "

Fluids and Lubricants".

• Use procedure below to check for fuel leakage.

• Turn ignition switch ON (with engine stopped). With fuel pressure applied to fuel piping, check for fuel leak- age at connection points.

• Start engine. With engine speed increased, check again for fuel leakage at connection points.

• Run engine to check for unusual noise and vibration.

• Warm up engine thoroughly to make sure there is no leak age of fuel, exhaust gas, or any oils/fluids including

engine oil and engine coolant.

• Bleed air from passages in lines and hoses, such as in cooling system.

• After cooling down engine, again check oil/fluid levels including engine oil and engine coolant. Refill to spec-

ified level, if necessary.

• Summary of the inspection items:

A : Dust seal lip

B: Oil seal lip

: Engine front

: Engine rear

PBIC3485J

1 : Front cover: Engine front

Within 0.3 mm (0.012 in) toward engine front

Within 0.5 mm (0.020 in) toward engine rear

PBIC3729E

Item Before starting engine Engine runningAfter engine stopped

Engine coolant LevelLeakage Level

Engine oil LevelLeakage Level

Revision: May 2010 2011 Versa

Page 2575 of 3787

![NISSAN TIIDA 2011 Service Manual PDF OIL SEALEM-185

< SERVICE INFORMATION > [MR18DE]

C

D

E

F

G H

I

J

K L

M A

EM

NP

O

• Install rear oil seal (1) to the position as shown.

NOTE:

The standard surface of the dimens

ion is the rear end sur NISSAN TIIDA 2011 Service Manual PDF OIL SEALEM-185

< SERVICE INFORMATION > [MR18DE]

C

D

E

F

G H

I

J

K L

M A

EM

NP

O

• Install rear oil seal (1) to the position as shown.

NOTE:

The standard surface of the dimens

ion is the rear end sur](/img/5/57396/w960_57396-2574.png)

OIL SEALEM-185

< SERVICE INFORMATION > [MR18DE]

C

D

E

F

G H

I

J

K L

M A

EM

NP

O

• Install rear oil seal (1) to the position as shown.

NOTE:

The standard surface of the dimens

ion is the rear end surface of

cylinder block.

3. Installation of the remaining components is in the reverse order of removal.

InspectionINFOID:0000000006413292

INSPECTION AFTER INSTALLATION

• Before starting engine, check oil/fluid levels incl uding engine coolant and engine oil. If less than required

quantity, fill to the specified level. Refer to MA-14, "

Fluids and Lubricants".

• Use procedure below to check for fuel leakage.

• Turn ignition switch ON (with engine stopped). With fuel pressure applied to fuel piping, check for fuel leak-

age at connection points.

• Start engine. With engine speed increased, check again for fuel leakage at connection points.

• Run engine to check for unusual noise and vibration.

• Warm up engine thoroughly to make sure there is no leak age of fuel, exhaust gas, or any oils/fluids including

engine oil and engine coolant.

• Bleed air from passages in lines and hoses, such as in cooling system.

• After cooling down engine, again check oil/fluid levels including engine oil and engine coolant. Refill to spec- ified level, if necessary.

• Summary of the inspection items:

*Power steering fluid, brake fluid, etc. A : Rear end surface of cylinder block

PBIC3761E

Item

Before starting engine Engine runningAfter engine stopped

Engine coolant LevelLeakage Level

Engine oil LevelLeakage Level

Transmission/

transaxle fluid A/T and CVT Models

LeakageLevel/Leakage Leakage

M/T Models Level/Leakage LeakageLevel/Leakage

Other oils and fluids* LevelLeakage Level

Fuel LeakageLeakageLeakage

Exhaust gas —Leakage —

Revision: May 2010 2011 Versa

Page 2577 of 3787

![NISSAN TIIDA 2011 Service Manual PDF CYLINDER HEADEM-187

< SERVICE INFORMATION > [MR18DE]

C

D

E

F

G H

I

J

K L

M A

EM

NP

O

• If the engine speed is out of the specified range, check battery liquid for proper gravity. Check engine

speed NISSAN TIIDA 2011 Service Manual PDF CYLINDER HEADEM-187

< SERVICE INFORMATION > [MR18DE]

C

D

E

F

G H

I

J

K L

M A

EM

NP

O

• If the engine speed is out of the specified range, check battery liquid for proper gravity. Check engine

speed](/img/5/57396/w960_57396-2576.png)

CYLINDER HEADEM-187

< SERVICE INFORMATION > [MR18DE]

C

D

E

F

G H

I

J

K L

M A

EM

NP

O

• If the engine speed is out of the specified range, check battery liquid for proper gravity. Check engine

speed again with normal battery gravity.

• If compression pressure is below minimum value, check valve clearances and parts associated with

combustion chamber (Valve, valve seat, piston, pi ston ring, cylinder bore, cylinder head, cylinder head

gasket). After the checking, measure the compression pressure again.

• If one cylinder has low compression pressure, pour small amount of engine oil into the spark plug hole

of the cylinder to re-check it for compression.

- If the added engine oil improves the compression, piston rings may be worn out or damaged. Check pis- ton rings and replace if necessary.

- If the compression pressure remains at low level despite the addition of engine oil, valves may be mal- functioning. Check valves for damage. Replace valve or valve seat accordingly.

• If two adjacent cylinders have respectively low compression pressure and their compression remains low even after the addition of engine oil, cylinder head gasket is leaking. In such a case, replace cylinder

head gasket.

9. After inspection is completed, install removed parts.

10. Start the engine, and confirm that the engine runs smoothly.

11. Perform trouble diagnosis. If DTC appears, erase it. Refer to EC-585, "

Trouble Diagnosis Introduction".

InspectionINFOID:0000000006413294

INSPECTION AFTER INSTALLATION

• Before starting engine, check oil/fluid levels including engine coolant and engine oil. If less than required

quantity, fill to the specified level. Refer to MA-14, "

Fluids and Lubricants".

• Use procedure below to check for fuel leakage.

• Turn ignition switch ON (with engine stopped). With fuel pressure applied to fuel piping, check for fuel leak-

age at connection points.

• Start engine. With engine speed increased, check again for fuel leakage at connection points.

• Run engine to check for unusual noise and vibration.

• Warm up engine thoroughly to make sure there is no leak age of fuel, exhaust gas, or any oils/fluids including

engine oil and engine coolant.

• Bleed air from passages in lines and hoses, such as in cooling system.

• After cooling down engine, again check oil/fluid levels including engine oil and engine coolant. Refill to spec- ified level, if necessary.

• Summary of the inspection items:

*Power steering fluid, brake fluid, etc. Item

Before starting engine Engine runningAfter engine stopped

Engine coolant LevelLeakage Level

Engine oil LevelLeakage Level

Transmission/

transaxle fluid A/T and CVT Models

LeakageLevel/Leakage Leakage

M/T Models Level/Leakage LeakageLevel/Leakage

Other oils and fluids* LevelLeakage Level

Fuel LeakageLeakageLeakage

Exhaust gas —Leakage —

Revision: May 2010 2011 Versa

Page 2590 of 3787

![NISSAN TIIDA 2011 Service Manual PDF EM-200

< SERVICE INFORMATION >[MR18DE]

ENGINE ASSEMBLY

35. Separate the engine and the transaxle and mount the engine on a suitable engine stand. Refer to

AT-233

(A/T models), CVT-180, "Removal and I NISSAN TIIDA 2011 Service Manual PDF EM-200

< SERVICE INFORMATION >[MR18DE]

ENGINE ASSEMBLY

35. Separate the engine and the transaxle and mount the engine on a suitable engine stand. Refer to

AT-233

(A/T models), CVT-180, "Removal and I](/img/5/57396/w960_57396-2589.png)

EM-200

< SERVICE INFORMATION >[MR18DE]

ENGINE ASSEMBLY

35. Separate the engine and the transaxle and mount the engine on a suitable engine stand. Refer to

AT-233

(A/T models), CVT-180, "Removal and Installation" (CVT models) or MT-61, "Removal and Installation"

(M/T models).

INSTALLATION

Installation is in the reverse order of removal.

Note the following during installation:

• When installation directions are specified, install parts according to the directions. Refer to EM-197, "

Com-

ponent".

• Do not allow engine oil to get on engine mounting insulator. Be careful not to damage engine mounting insu-

lator.

• Prior to installing the upper torque rod, apply a light coat of silicone lubricant (A) to the washer facing side of the bushing inner tube as

shown.

NOTE:

• Apply silicone lubricant (A) by dabbing the outward facing tubesurface with a sponge or suitable tool.

• Do not apply excess lubricant.

• Make sure that each mounting insulator is seated properly, and tighten nuts and bolts.

• Tighten engine mounting insulator (RH) bolts in the numerical order shown.

INSPECTION AFTER INSTALLATION

• Before starting engine, check oil/fluid levels incl uding engine coolant and engine oil. If less than required

quantity, fill to the specified level. Refer to MA-14, "

Fluids and Lubricants".

• Use procedure below to check for fuel leakage.

• Turn ignition switch ON (with engine stopped). With fuel pressure applied to fuel piping, check for fuel leak- age at connection points.

• Start engine. With engine speed increased, che ck again for fuel leakage at connection points.

• Run engine to check for unusual noise and vibration.

• Warm up engine thoroughly to make sure there is no leakage of fuel, exhaust gas, or any oils/fluids including

engine oil and engine coolant.

• Bleed air from passages in lines and hoses, such as in cooling system.

• After cooling down engine, again check oil/fluid levels including engine oil and engine coolant. Refill to spec- ified level, if necessary.

• Summary of the inspection items:

: Vehicle front

LBIA0470E

: Vehicle front

WBIA0785E

Item Before starting engine Engine runningAfter engine stopped

Engine coolant LevelLeakage Level

Engine oil LevelLeakage Level

Transmission/

transaxle fluid A/T and CVT Models

LeakageLevel/Leakage Leakage

M/T Models Level/Leakage LeakageLevel/Leakage

Revision: May 2010 2011 Versa

Page 2858 of 3787

![NISSAN TIIDA 2011 Service Manual PDF LAN-12

< SERVICE INFORMATION >[CAN FUNDAMENTAL]

TROUBLE DIAGNOSIS

NOTE:

• When data link connector branch line is open, transmission and reception of CAN communication signals

are not affected. Ther NISSAN TIIDA 2011 Service Manual PDF LAN-12

< SERVICE INFORMATION >[CAN FUNDAMENTAL]

TROUBLE DIAGNOSIS

NOTE:

• When data link connector branch line is open, transmission and reception of CAN communication signals

are not affected. Ther](/img/5/57396/w960_57396-2857.png)

LAN-12

< SERVICE INFORMATION >[CAN FUNDAMENTAL]

TROUBLE DIAGNOSIS

NOTE:

• When data link connector branch line is open, transmission and reception of CAN communication signals

are not affected. Therefore, no symptoms occur. However, be sure to repair malfunctioning circuit.

• The model (all units on CAN communication system are Diag on CAN) cannot perform CAN diagnosis with

CONSULT-III if the following error occu rs. The error is judged by the symptom.

Example: Main Line Between Data Link Connector and ABS Actuator and Electric Un it (Control Unit) Open Circuit

Unit name Symptom

ECM

Normal operation.

BCM

EPS control unit

Combination meter

ABS actuator and electric unit (control unit)

TCM

IPDM E/R

Error Difference of symptom

Data link connector branch line open circuit Normal operation.

CAN-H, CAN-L harness short-circuit Most of the units which are connected to the CAN communication

system enter fail-safe mode or are deactivated.

SKIB8740E

Unit name

Symptom

ECM Engine torque limiting is affected, and shift harshness increases.

BCM • Reverse warning chime does not sound.

• The front wiper moves under continuous operation mode even though the front wip-

er switch being in the intermittent position.

EPS control unit The steering effort increases.

Combination meter • The shift position indicator and OD OFF indicator turn OFF.

• The speedometer is inoperative.

• The odo/trip meter stops.

ABS actuator and electric unit (control unit) Normal operation.

TCM No impact on operation.

IPDM E/R When the ignition switch is ON,

• The headlamps (Lo) turn ON.

• The cooling fan continues to rotate.

Revision: May 2010

2011 Versa

Page 2859 of 3787

![NISSAN TIIDA 2011 Service Manual PDF TROUBLE DIAGNOSISLAN-13

< SERVICE INFORMATION > [CAN FUNDAMENTAL]

C

D

E

F

G H

I

J

L

M A

B

LAN

N

O P

Example: CAN-H, CAN-L Harness Short Circuit

CAN Diagnosis with CONSULT-IIIINFOID:0000000005928521

CA NISSAN TIIDA 2011 Service Manual PDF TROUBLE DIAGNOSISLAN-13

< SERVICE INFORMATION > [CAN FUNDAMENTAL]

C

D

E

F

G H

I

J

L

M A

B

LAN

N

O P

Example: CAN-H, CAN-L Harness Short Circuit

CAN Diagnosis with CONSULT-IIIINFOID:0000000005928521

CA](/img/5/57396/w960_57396-2858.png)

TROUBLE DIAGNOSISLAN-13

< SERVICE INFORMATION > [CAN FUNDAMENTAL]

C

D

E

F

G H

I

J

L

M A

B

LAN

N

O P

Example: CAN-H, CAN-L Harness Short Circuit

CAN Diagnosis with CONSULT-IIIINFOID:0000000005928521

CAN diagnosis on CONSULT-III extracts the root

cause by receiving the following information.

• Response to the system call

• Control unit diagnosis information

• Self-diagnosis

• CAN diagnostic support monitor

SKIB8741E

Unit name Symptom

ECM • Engine torque limiting is affected, and shift harshness increases.

• Engine speed drops.

BCM • Reverse warning chime does not sound.

• The front wiper moves under continuous operation mode even though the front

wiper switch being in the intermittent position.

• The room lamp does not turn ON.

• The engine does not start (if an error or malfunction occurs while turning the igni- tion switch OFF.)

• The steering lock does not release (if an error or malfunction occurs while turning the ignition switch OFF.)

EPS control unit The steering effort increases.

Combination meter • The tachometer and the speedometer do not move.

• Warning lamps turn ON.

• Indicator lamps do not turn ON.

ABS actuator and electric unit (control unit) Normal operation.

TCM No impact on operation.

IPDM E/R When the ignition switch is ON,

• The headlamps (Lo) turn ON.

• The cooling fan continues to rotate.

Revision: May 2010

2011 Versa

Page 2873 of 3787

![NISSAN TIIDA 2011 Service Manual PDF CAN COMMUNICATION SYSTEMLAN-27

< SERVICE INFORMATION > [CAN]

C

D

E

F

G H

I

J

L

M A

B

LAN

N

O P

CAN Communication Signal ChartINFOID:0000000005928534

Refer to LAN-16, "How to Use CAN Communication Sig NISSAN TIIDA 2011 Service Manual PDF CAN COMMUNICATION SYSTEMLAN-27

< SERVICE INFORMATION > [CAN]

C

D

E

F

G H

I

J

L

M A

B

LAN

N

O P

CAN Communication Signal ChartINFOID:0000000005928534

Refer to LAN-16, "How to Use CAN Communication Sig](/img/5/57396/w960_57396-2872.png)

CAN COMMUNICATION SYSTEMLAN-27

< SERVICE INFORMATION > [CAN]

C

D

E

F

G H

I

J

L

M A

B

LAN

N

O P

CAN Communication Signal ChartINFOID:0000000005928534

Refer to LAN-16, "How to Use CAN Communication Signal Chart" for how to use CAN communication signal

chart.

NOTE:

Refer to LAN-22, "

Abbreviation List" for the abbreviations of the connecting units.

T: Transmit R: Receive

Signal name/Connecting unitECM

BCM

EPS

I-KEY M&A

STRG ABS

TCM

*1

TCM

*2

IPDM-E

A/C compressor request signal T R

Accelerator pedal position signal T

R

*3RR

ASCD CRUISE lamp signal T R

ASCD SET lamp signal T R

Closed throttle position signal T R R

Cooling fan motor operation signal T R

Engine coolant temperature signal TR

Engine speed signal TR

R

*3R

Engine status signal T R R R

Fuel consumption monitor signal T R

Malfunction indicator lamp signal TR

Wide open throttle position signal T R R

A/C switch signal R T

Blower fan motor switch signal R T

Buzzer output signal TR

TR

Day time running light request signal

*4TR

Door lock/unlock status signal TR

Door switch signal TR R R

Front wiper request signal T R

High beam request signal TR R

Horn chirp signal T R

Ignition switch signal T R

Low beam request signal T R

Position lights request signal TR R

Rear window defogger switch signal T R

Sleep/wake up signal TRR

R

RT

Theft warning horn request signal T R

Tire pressure signal

*5TR

Trunk open/close status signal TR

Turn indicator signal TR

EPS operation signal TR

EPS warning lamp signal TR

Door lock/unlock/trunk open request signal RT

Hazard request signal RT

Ignition knob switch signal RT

Revision: May 2010 2011 Versa

Page 3176 of 3787

PREPARATIONMA-5

< SERVICE INFORMATION >

C

DE

F

G H

I

J

K

M A

B

MA

N

O P

PREPARATION

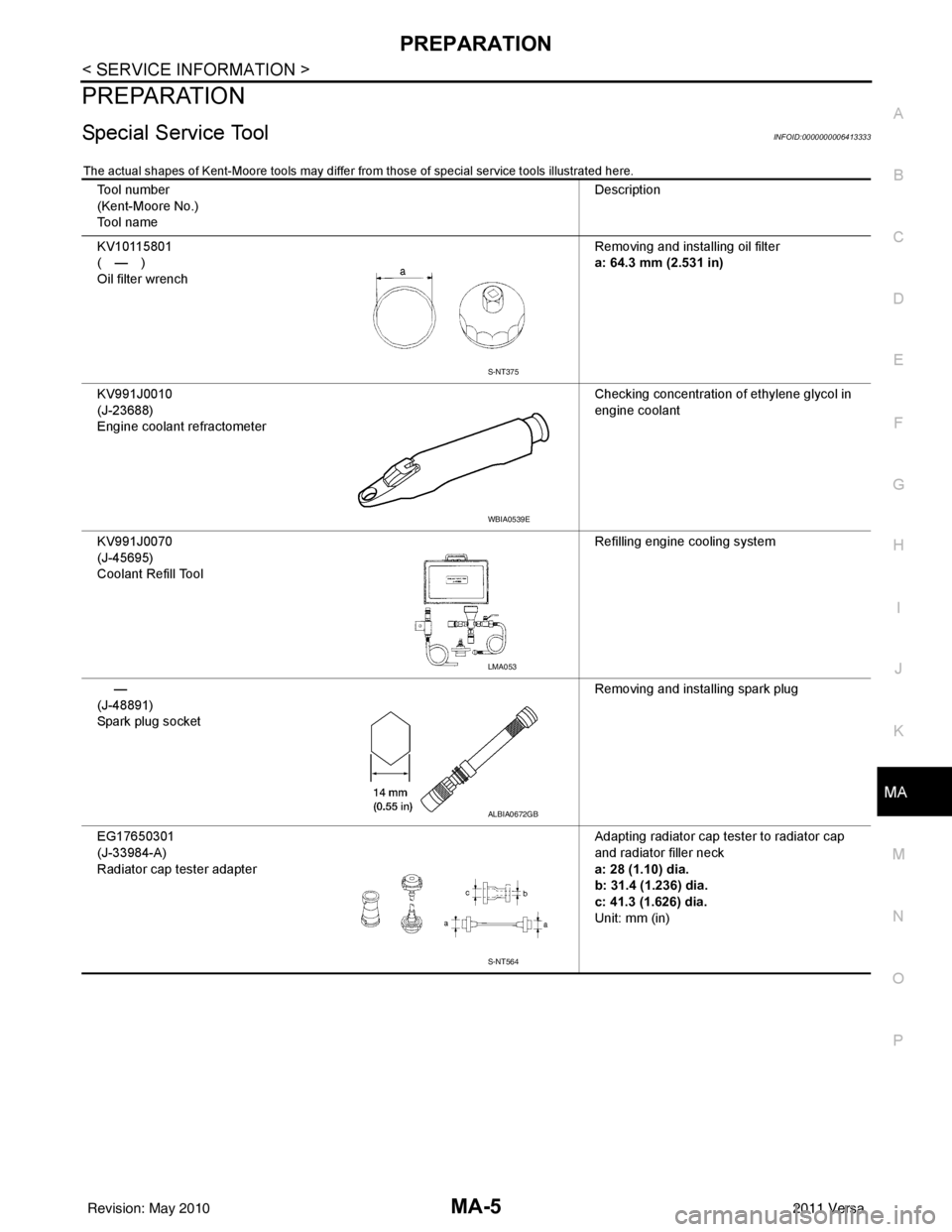

Special Service ToolINFOID:0000000006413333

The actual shapes of Kent-Moore tools may differ from those of special service tools illustrated here.

Tool number

(Kent-Moore No.)

Tool name Description

KV10115801

(—)

Oil filter wrench Removing and installing oil filter

a: 64.3 mm (2.531 in)

KV991J0010

(J-23688)

Engine coolant refractometer Checking concentration of ethylene glycol in

engine coolant

KV991J0070

(J-45695)

Coolant Refill Tool Refilling engine cooling system

—

(J-48891)

Spark plug socket Removing and installing spark plug

EG17650301

(J-33984-A)

Radiator cap tester adapter Adapting radiator cap tester to radiator cap

and radiator filler neck

a: 28 (1.10) dia.

b: 31.4 (1.236) dia.

c: 41.3 (1.626) dia.

Unit: mm (in)

S-NT375

WBIA0539E

LMA053

ALBIA0672GB

S-NT564

Revision: May 2010

2011 Versa

Page 3185 of 3787

MA-14

< SERVICE INFORMATION >

RECOMMENDED FLUIDS AND LUBRICANTS

RECOMMENDED FLUIDS AND LUBRICANTS

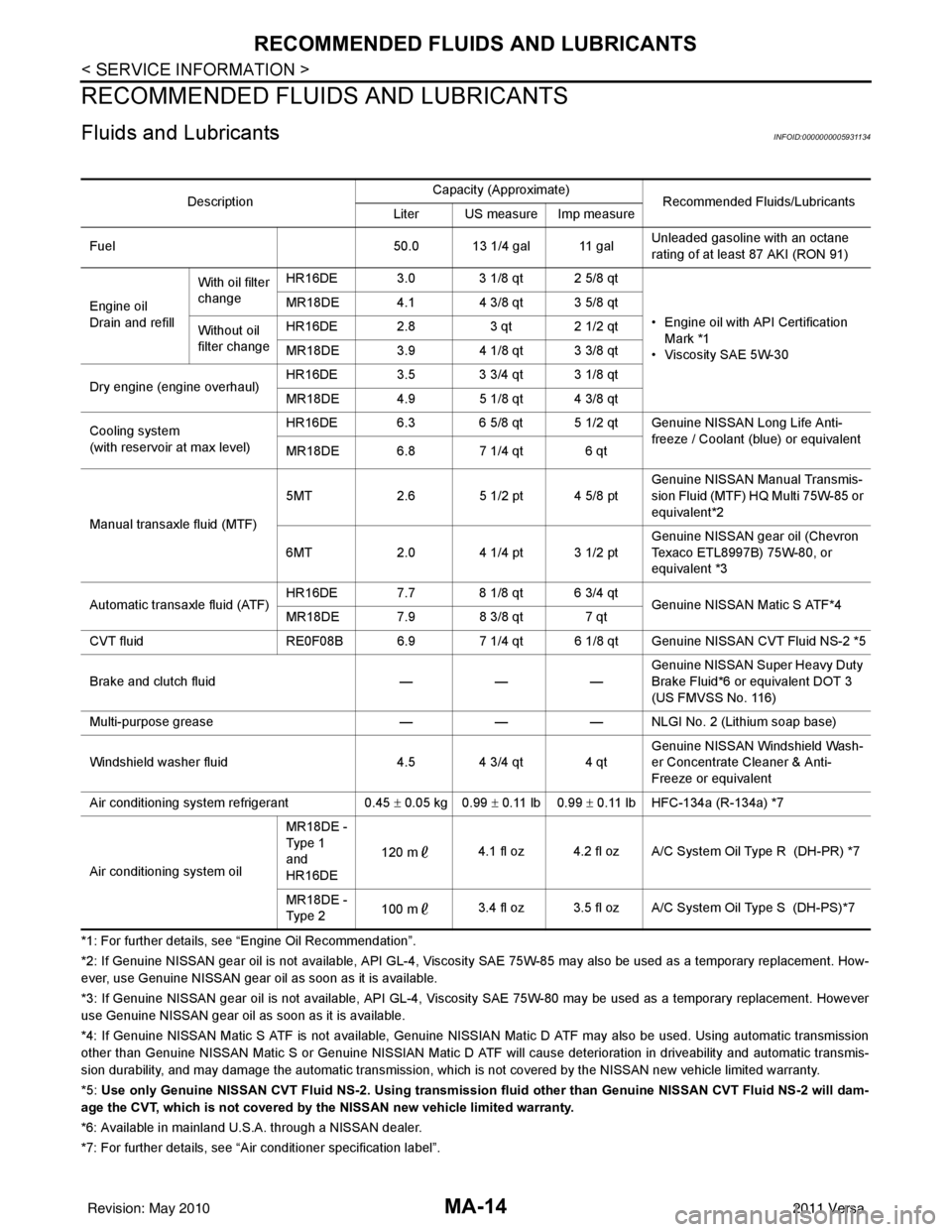

Fluids and LubricantsINFOID:0000000005931134

*1: For further details, see “Engine Oil Recommendation”.

*2: If Genuine NISSAN gear oil is not available, API GL-4, Viscosity SAE 75W-85 may also be used as a temporary replacement. How-

ever, use Genuine NISSAN gear oil as soon as it is available.

*3: If Genuine NISSAN ge ar oil is not available, API GL-4, Viscosity SAE 75W-80 may be used as a temporary replacement. However

use Genuine NISSAN gear oil as soon as it is available.

*4: If Genuine NISSAN Matic S ATF is not available, Genuine NISSIAN Matic D ATF may also be used. Using automatic transmission

other than Genuine NISSAN Matic S or Genuine NISSIAN Matic D ATF will cause deteri oration in driveability and automatic transmis-

sion durability, and may damage the automatic transmission, which is not covered by th e NISSAN new vehicle limited warranty.

*5: Use only Genuine NISSAN CVT Fluid NS-2. Using transmission fluid other than Genuine NISSAN CVT Fluid NS-2 will dam-

age the CVT, which is not covered by the NISSAN new vehicle limited warranty.

*6: Available in mainland U.S.A. through a NISSAN dealer.

*7: For further details, see “Air conditioner specification label”. Description

Capacity (Approximate)

Recommended Fluids/Lubricants

Liter US measure Imp measure

Fuel 50.0 13 1/4 gal 11 galUnleaded gasoline with an octane

rating of at least 87 AKI (RON 91)

Engine oil

Drain and refill With oil filter

change

HR16DE 3.0 3 1/8 qt 2 5/8 qt

• Engine oil with API Certification Mark *1

• Viscosity SAE 5W-30

MR18DE 4.1 4 3/8 qt 3 5/8 qt

Without oil

filter change HR16DE 2.8

3 qt 2 1/2 qt

MR18DE 3.9 4 1/8 qt 3 3/8 qt

Dry engine (engine overhaul) HR16DE 3.5 3 3/4 qt 3 1/8 qt

MR18DE 4.9 5 1/8 qt 4 3/8 qt

Cooling system

(with reservoir at max level) HR16DE 6.3 6 5/8 qt 5 1/2 qt Genuine NISSAN Long Life Anti-

freeze / Coolant (blue) or equivalent

MR18DE 6.8 7 1/4 qt 6 qt

Manual transaxle fluid (MTF) 5MT

2.6 5 1/2 pt 4 5/8 pt Genuine NISSAN Manual Transmis-

sion Fluid (MTF) HQ Multi 75W-85 or

equivalent*2

6MT 2.0 4 1/4 pt 3 1/2 pt Genuine NISSAN gear oil (Chevron

Texaco ETL8997B) 75W-80, or

equivalent *3

Automatic transaxle fluid (ATF) HR16DE 7.7 8 1/8 qt 6 3/4 qt

Genuine NISSAN Matic S ATF*4

MR18DE 7.9 8 3/8 qt 7 qt

CVT fluid RE0F08B 6.9 7 1/4 qt 6 1/8 qt Genuine NISSAN CVT Fluid NS-2 *5

Brake and clutch fluid ———Genuine NISSAN Super Heavy Duty

Brake Fluid*6 or equivalent DOT 3

(US FMVSS No. 116)

Multi-purpose grease ——— NLGI No. 2 (Lithium soap base)

Windshield washer fluid 4.5 4 3/4 qt 4 qtGenuine NISSAN Windshield Wash-

er Concentrate Cleaner & Anti-

Freeze or equivalent

Air conditioning system refrigerant 0.45 ± 0.05 kg 0.99 ± 0.11 lb 0.99 ± 0.11 lb HFC-134a (R-134a) *7

Air conditioning system oil MR18DE -

Typ e 1

and

HR16DE

120 m

4.1 fl oz 4.2 fl oz A/C System Oil Type R (DH-PR) *7

MR18DE -

Typ e 2 100 m

3.4 fl oz 3.5 fl oz A/C System Oil Type S (DH-PS)*7

Revision: May 2010

2011 Versa

Page 3186 of 3787

RECOMMENDED FLUIDS AND LUBRICANTSMA-15

< SERVICE INFORMATION >

C

DE

F

G H

I

J

K

M A

B

MA

N

O P

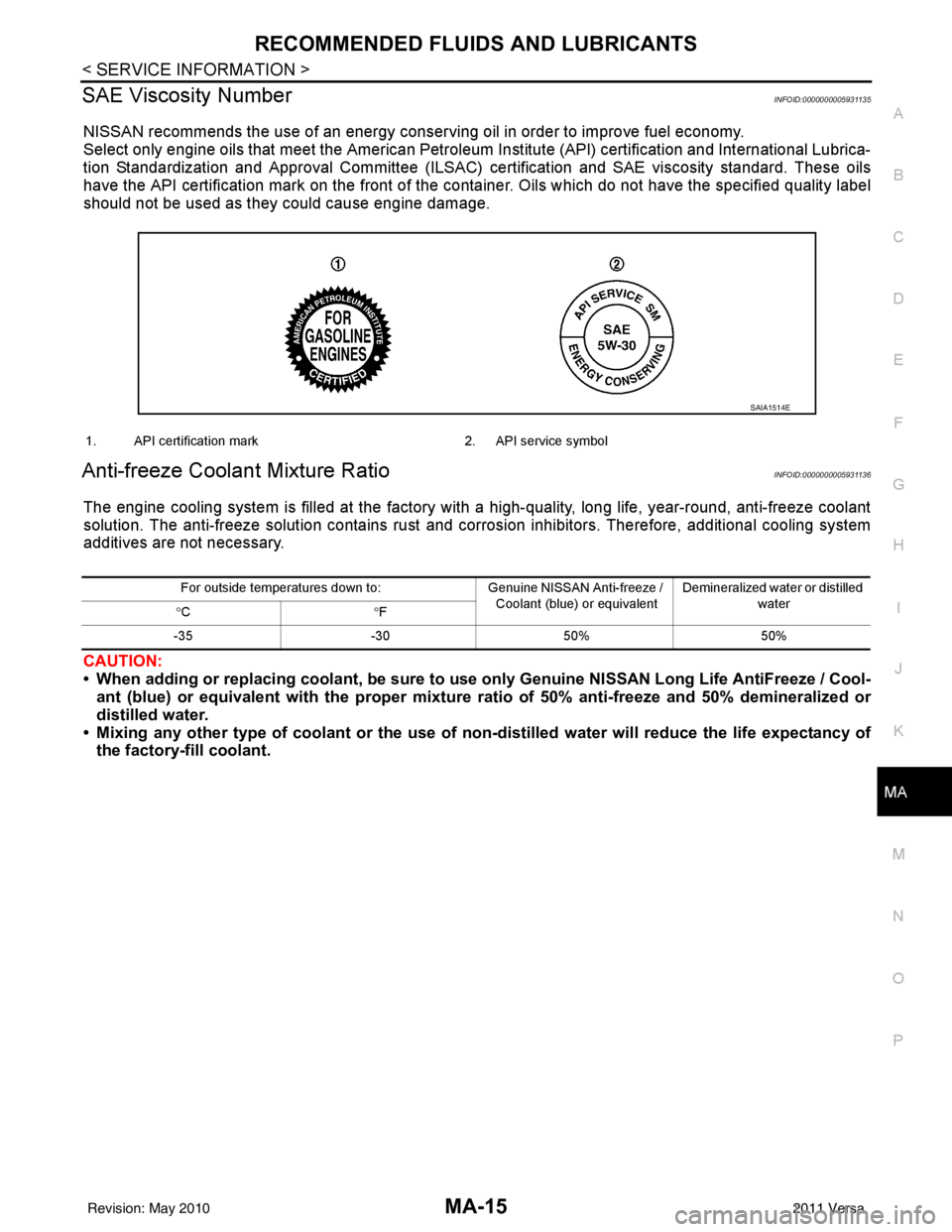

SAE Viscosity NumberINFOID:0000000005931135

NISSAN recommends the use of an energy conser ving oil in order to improve fuel economy.

Select only engine oils that meet the American Petroleum Institute (API) certification and International Lubrica-

tion Standardization and Approval Committee (ILSAC) ce rtification and SAE viscosity standard. These oils

have the API certification mark on the front of the container. Oils which do not have the specified quality label

should not be used as they could cause engine damage.

Anti-freeze Coolant Mixture RatioINFOID:0000000005931136

The engine cooling system is filled at the factory wit h a high-quality, long life, year-round, anti-freeze coolant

solution. The anti-freeze solution contains rust and corrosion inhibitors. Therefore, additional cooling system

additives are not necessary.

CAUTION:

• When adding or replacing coolant, be sure to u se only Genuine NISSAN Long Life AntiFreeze / Cool-

ant (blue) or equivalent with the proper mixture ratio of 50% an ti-freeze and 50% demineralized or

distilled water.

• Mixing any other type of coolant or the use of non-distilled water will reduce the life expectancy of

the factory-fi ll coolant.

SAIA1514E

1. API certification mark 2. API service symbol

For outside temperatures down to :Genuine NISSAN Anti-freeze /

Coolant (blue) or equivalent Demineralized water or distilled

water

° C °F

-35 -3050% 50%

Revision: May 2010 2011 Versa