C11 NISSAN TIIDA 2011 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2011, Model line: TIIDA, Model: NISSAN TIIDA 2011Pages: 3787, PDF Size: 78.35 MB

Page 1 of 3787

-1

QUICK REFERENCE INDEX

AGENERAL INFORMATIONGIGeneral Information

BENGINEEMEngine Mechanical

LUEngine Lubrication System

COEngine Cooling System

ECEngine Control System

FLFuel System

EXExhaust System

ACCAccelerator Control System

CTRANSMISSION/

TRANSAXLECLClutch System

MTManual Transaxle

ATAutomatic Transaxle

CVTCVT

DDRIVELINE/AXLEFAXFront Axle

RAXRear Axle

ESUSPENSIONFSUFront Suspension

RSURear Suspension

WTRoad Wheels & Tires

FBRAKESBRBrake System

PBParking Brake System

BRCBrake Control System

GSTEERINGPSPower Steering System

STCSteering Control System

HRESTRAINTSSBSeat Belts

SRSSupplemental Restraint System (SRS)

IBODYBLBody, Lock & Security System

GWGlasses, Window System & Mirrors

RFRoof

EIExterior & Interior

IPInstrument Panel

SESeat

JAIR CONDITIONERMTCManual Air Conditioner

KELECTRICALSCStarting & Charging System

LTLighting System

DIDriver Information System

WWWiper, Washer & Horn

BCSBody Control System

LANLAN System

AVAudio Visual, Navigation & Telephone System

ACSAuto Cruise Control System

PGPower Supply, Ground & Circuit Elements

LMAINTENANCEMAMaintenance

Edition: May 2010

Revision: May 2010

Publication No. SM1E-1C11U0

B

D

© 2010 NISSAN NORTH AMERICA, INC.

All rights reserved. No part of this Service Manual may be reproduced or stored in a retrieval system, or transmitted in any

form, or by any means, electronic, mechanical, photo-copying, recording or otherwise, without the prior written permission

of Nissan North America Inc.

A

C

E

F

G

H

I

J

K

L

M

Page 910 of 3787

![NISSAN TIIDA 2011 Service Repair Manual TROUBLE DIAGNOSISBRC-21

< SERVICE INFORMATION > [ABS]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

Self-diagnostic item Malfunction detecting condition Check system

RR RH SENSOR-1

[C1101] Circuit of rear RH whee NISSAN TIIDA 2011 Service Repair Manual TROUBLE DIAGNOSISBRC-21

< SERVICE INFORMATION > [ABS]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

Self-diagnostic item Malfunction detecting condition Check system

RR RH SENSOR-1

[C1101] Circuit of rear RH whee](/img/5/57396/w960_57396-909.png)

TROUBLE DIAGNOSISBRC-21

< SERVICE INFORMATION > [ABS]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

Self-diagnostic item Malfunction detecting condition Check system

RR RH SENSOR-1

[C1101] Circuit of rear RH wheel sensor is open.

BRC-25, "

Wheel Sensor

System" (Note 1)

RR LH SENSOR-1

[C1102]

Circuit of rear LH wheel sensor is open.

FR RH SENSOR-1

[C1103] Circuit of front RH wheel sensor is open.

FR LH SENSOR-1

[C1104] Circuit of front LH wheel sensor is open.

RR RH SENSOR-2

[C1105] When the circuit in the rear RH wheel sensor is short-circuited or

when the sensor power voltage is outside the standard. When the

distance between the wheel sensor and sensor rotor is too large

and the sensor pulse cannot be recognized by the control unit.

RR LH SENSOR-2

[C1106] When the circuit in the rear LH wheel sensor is short-circuited or

when the sensor power voltage is outside the standard. When the

distance between the wheel sensor and sensor rotor is too large

and the sensor pulse cannot be recognized by the control unit.

FR RH SENSOR-2

[C1107] When the circuit in the front RH wheel sensor is short-circuited or

when the sensor power voltage is outside the standard. When the

distance between the wheel sensor and sensor rotor is too large

and the sensor pulse cannot be recognized by the control unit.

FR LH SENSOR-2

[C1108] When the circuit in the front LH wheel sensor is short-circuited or

when the sensor power voltage is outside the standard. When the

distance between the wheel sensor and sensor rotor is too large

and the sensor pulse cannot be recognized by the control unit.

ABS SENSOR

[ABNORMAL SIGNAL]

[ C 111 5 ] Wheel sensor input is abnormal.

BATTERY VOLTAGE

[ABNORMAL]

[C1109] ABS actuator and electric unit (con

trol unit) power voltage is too

low. BRC-28, "

ABS Control

Unit Power and Ground

Systems Inspection"

CONTROLLER FAILURE

[ C 111 0 ]

Internal malfunction of ABS actuator and electric unit (control unit) BRC-26, "ABS Control

Unit Inspection"

PUMP MOTOR

[ C 1111 ]During actuator motor operation with ON, when actuator motor

turns OFF or when control line fo

r actuator motor relay is open. BRC-27, "Actuator Mo-

tor, Motor Relay, and Cir-

cuit Inspection"During actuator motor operation with OFF, when actuator motor

turns ON or when control line for relay is shorted to ground.

FR LH IN ABS SOL

[C1120] Circuit of front LH IN ABS solenoid is open or shorted, or control

line is open or shorted to power supply or ground.

BRC-26, "

Solenoid Valve

System Inspection"

FR LH OUT ABS SOL

[C1121]Circuit of front LH OUT ABS solenoid is open or shorted, or control

line is open or shorted to power supply or ground.

FR RH IN ABS SOL

[C1122] Circuit of front RH IN ABS solenoid

is open or shorted, or control

line is open or shorted to power supply or ground.

FR RH OUT ABS SOL

[C1123] Circuit of front RH OUT ABS solenoid

is open or shorted, or con-

trol line is open or shorted to power supply or ground.

RR LH IN ABS SOL

[C1124] Circuit of rear LH IN ABS solenoid

is open or shorted, or control

line is open or shorted to power supply or ground.

RR LH OUT ABS SOL

[C1125] Circuit of rear LH OUT ABS solenoid is open or shorted, or control

line is open or shorted to power supply or ground.

RR RH IN ABS SOL

[C1126] Circuit of rear RH IN ABS solenoid is open or shorted, or control

line is open or shorted to power supply or ground.

RR RH OUT ABS SOL

[C1127] Circuit of rear RH OUT ABS solenoid

is open or shorted, or control

line is open or shorted to power supply or ground.

Revision: May 2010 2011 Versa

Page 950 of 3787

![NISSAN TIIDA 2011 Service Repair Manual TROUBLE DIAGNOSISBRC-61

< SERVICE INFORMATION > [VDC/TCS/ABS]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

6. The self-diagnostic results are displayed. • When “NO DTC IS DETECTED” is displayed, check the NISSAN TIIDA 2011 Service Repair Manual TROUBLE DIAGNOSISBRC-61

< SERVICE INFORMATION > [VDC/TCS/ABS]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

6. The self-diagnostic results are displayed. • When “NO DTC IS DETECTED” is displayed, check the](/img/5/57396/w960_57396-949.png)

TROUBLE DIAGNOSISBRC-61

< SERVICE INFORMATION > [VDC/TCS/ABS]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

6. The self-diagnostic results are displayed. • When “NO DTC IS DETECTED” is displayed, check the ABS warning lamp, SLIP indicator lamp and

VDC OFF indicator lamp.

7. Conduct the appropriate inspection from the display item list, and repair or replace the malfunctioning

component.

8. Start engine and drive at approximately 30 km /h (19 MPH) for approximately 1 minute.

CAUTION:

• When a wheel sensor “short-circuit” is detected, if the vehicle is not driven at 30 km/h (19 MPH)

for at least 1 minute, the ABS warn ing lamp will not turn off even if the malfunction is repaired.

9. Turn ignition switch OFF to prepare for erasing the memory.

10. Start the engine and touch “ABS”, “SELF-DIAG RESULTS”, “ERASE” in order on the CONSULT-III screen to erase the error memory.

If “ABS” is not indicated, go to GI-36, "

CONSULT-III Data Link Connector (DLC) Circuit".

CAUTION:

If the error memory is not erased, re -conduct the operation from step 5.

11. For the final inspection, drive at approximately 30 km/h (19 MPH) for approximately 1 minute and confirm

that the ABS warning lamp, SLIP indicator lamp, and VDC OFF indicator lamp are off.

Display Item List

Self-diagnostic item Malfunction detecting condition Check system

RR RH SENSOR 1

[C1101] Circuit of rear RH wheel sensor is open.

BRC-67, "

Wheel Sensor

System Inspection"

(Note 1)

RR LH SENSOR 1

[C1102]

Circuit of rear LH wheel sensor is open.

FR RH SENSOR 1

[C1103] Circuit of front RH wheel sensor is open.

FR LH SENSOR 1

[C1104] Circuit of front LH wheel sensor is open.

RR RH SENSOR 2

[C1105] Circuit of rear RH wheel sensor is shorted, or sensor power volt-

age is unusua

l. ABS actuator and electric unit (control unit) cannot

identify sensor pulses, because of large gap between wheel sen-

sor and sensor rotor.

RR LH SENSOR 2

[C1106] Circuit of rear LH wheel sensor is shorted, or sensor power volt-

age is unusua

l. ABS actuator and electric unit (control unit) cannot

identify sensor pulses, because of large gap between wheel sen-

sor and sensor rotor.

FR RH SENSOR 2

[C1107] Circuit of front RH wheel sensor is shorted, or sensor power volt-

age is unusua

l. ABS actuator and electric unit (control unit) cannot

identify sensor pulses, because of large gap between wheel sen-

sor and sensor rotor.

FR LH SENSOR 2

[C1108] Circuit of front LH wheel sensor is shorted, or sensor power volt-

age is unusua

l. ABS actuator and electric unit (control unit) cannot

identify sensor pulses, because of large gap between wheel sen-

sor and sensor rotor.

BATTERY VOLTAGE

[ABNORMAL]

[C1109] ABS actuator and electric unit (con

trol unit) power voltage is too

low. BRC-75, "

ABS/TCS/VDC

Control Unit

Power and

Ground Systems Inspec-

tion"

CONTROLLER FAILURE

[ C 111 0 ] Internal malfunction of ABS actuat

or and electric unit (control

unit). BRC-68, "ABS/TCS/VDC

Control Unit Inspection"

PUMP MOTOR

[ C 1111 ]During actuator motor operation with ON, when actuator motor

turns OFF or when control line fo

r actuator motor relay is open. BRC-73, "Actuator Mo-

tor, Motor Relay, and Cir-

cuit Inspection"During actuator motor operation with OFF, when actuator motor

turns ON or when control line for relay is shorted to ground.

Revision: May 2010

2011 Versa

Page 951 of 3787

![NISSAN TIIDA 2011 Service Repair Manual BRC-62

< SERVICE INFORMATION >[VDC/TCS/ABS]

TROUBLE DIAGNOSIS

MAIN RELAY

[ C 111 4 ]During actuator relay OFF, when the actuator relay turns ON, or

when the control line for the relay is shorted to g NISSAN TIIDA 2011 Service Repair Manual BRC-62

< SERVICE INFORMATION >[VDC/TCS/ABS]

TROUBLE DIAGNOSIS

MAIN RELAY

[ C 111 4 ]During actuator relay OFF, when the actuator relay turns ON, or

when the control line for the relay is shorted to g](/img/5/57396/w960_57396-950.png)

BRC-62

< SERVICE INFORMATION >[VDC/TCS/ABS]

TROUBLE DIAGNOSIS

MAIN RELAY

[ C 111 4 ]During actuator relay OFF, when the actuator relay turns ON, or

when the control line for the relay is shorted to ground.

BRC-72, "Solenoid and

VDC Change-Over Valve

System Inspection"During actuator relay ON, when the actuator relay turns ON, or

when the control line for the relay is open.

ABS SENSOR

[ABNORMAL SIGNAL]

[ C 111 5 ] When wheel sensor input signal is malfunctioning. BRC-67, "

Wheel Sensor

System Inspection"

(NOTE 1)

STOP LAMP SW

[ C 111 6 ] Stop lamp switch or circuit malfunction. BRC-74, "

Stop Lamp

Switch System Inspec-

tion"

FR LH IN ABS SOL

[C1120]

Circuit of front LH IN ABS solenoid

is open or shorted, or control

line is open or shorted to power supply or ground.

BRC-72, "

Solenoid and

VDC Change-Over Valve

System Inspection"

FR LH OUT ABS SOL

[C1121]Circuit of front LH OUT ABS solenoid is open or shorted, or control

line is open or shorted to power supply or ground.

FR RH IN ABS SOL

[C1122] Circuit of front RH IN ABS solenoid is open or shorted, or control

line is open or shorted to power supply or ground.

FR RH OUT ABS SOL

[C1123] Circuit of front RH OUT ABS solenoid is open or shorted, or con-

trol line is open or shorted to power supply or ground.

RR LH IN ABS SOL

[C1124] Circuit of rear LH IN ABS solenoid

is open or shorted, or control

line is open or shorted to power supply or ground.

RR LH OUT ABS SOL

[C1125] Circuit of rear LH OUT ABS solenoid is open or shorted, or control

line is open or shorted to power supply or ground.

RR RH IN ABS SOL

[C1126] Circuit of rear RH IN ABS solenoid

is open or shorted, or control

line is open or shorted to power supply or ground.

RR RH OUT ABS SOL

[C1127] Circuit of rear RH OUT ABS solenoid is open or shorted, or control

line is open or shorted to power supply or ground.

ENGINE SIGNAL 1

[C1130] ECM judges th

e communication between ABS/TCS/VDC control

unit and ECM is abnormal.

BRC-68, "

Engine System

Inspection"

ENGINE SIGNAL 2

[C1131]ECM judges th

e communication between ABS/TCS/VDC control

unit and ECM is abnormal.

ENGINE SIGNAL 3

[C1132] ECM judges th

e communication between ABS/TCS/VDC control

unit and ECM is abnormal.

ENGINE SIGNAL 4

[C1133] ECM judges th

e communication between ABS/TCS/VDC control

unit and ECM is abnormal.

ENGINE SIGNAL 6

[C1136] ECM judges th

e communication between ABS/TCS/VDC control

unit and ECM is abnormal.

PRESS SEN CIRCUIT

[C1142] Pressure sensor signal line is open or shorted, or pressure sensor

is malfunctioning. BRC-77, "

Pressure Sen-

sor System Inspection"

ST ANGLE SEN CIRCUIT

[C1143]Neutral position of steering angle sensor is dislocated, or steering

angle sensor is malfunctioning.

BRC-69, "Steering Angle

Sensor System Inspec-

tion"ST ANGLE SEN SIGNAL

[C1144]Neutral position correction of steering angle sensor is not finished.

YAW RATE SENSOR

[C1145] Yaw rate sensor has generated an error, or yaw rate sensor signal

line is open or shorted.

BRC-70, "

Yaw Rate/

Side/Decel G Sensor

System Inspection"SIDE G-SEN CIRCUIT

[C1146]Lateral G-sensor is malfunctioning, or signal line of lateral G-sen-

sor is open or shorted.

Self-diagnostic item Malfunction detecting condition Check system

Revision: May 2010

2011 Versa

Page 952 of 3787

![NISSAN TIIDA 2011 Service Repair Manual TROUBLE DIAGNOSISBRC-63

< SERVICE INFORMATION > [VDC/TCS/ABS]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

Note 1. If wheel sensor 2 for each wheel is indicated, check ABS actuator and electric unit (control un NISSAN TIIDA 2011 Service Repair Manual TROUBLE DIAGNOSISBRC-63

< SERVICE INFORMATION > [VDC/TCS/ABS]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

Note 1. If wheel sensor 2 for each wheel is indicated, check ABS actuator and electric unit (control un](/img/5/57396/w960_57396-951.png)

TROUBLE DIAGNOSISBRC-63

< SERVICE INFORMATION > [VDC/TCS/ABS]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

Note 1. If wheel sensor 2 for each wheel is indicated, check ABS actuator and electric unit (control unit) power

supply voltage in addition to wheel sensor circuit check.

Note 2. If multiple malfunctions are detected including CAN communication line [U1000], perform diagnosis for

CAN communication line first.

DATA MONITOR

Display Item List

USV LINE [FL-RR]

[C1147] Front side VDC switch-over solenoid valve (cut valve) is open or

shorted, or control line is open or shorted to power supply or

ground.

BRC-72, "

Solenoid and

VDC Change-Over Valve

System Inspection"

USV LINE [FR-RL]

[C1148]Rear side VDC switch-over solenoid valve (cut valve) is open or

shorted, or control line is open or shorted to power supply or

ground.

HSV LINE [FL-RR]

[C1149] Front side VDC switch-over solenoid valve (suction valve) is open

or shorted, or control line is open or shorted to power supply or

ground.

HSV LINE [FR-RL]

[C1150] Rear side VDC switch-over solenoid valve (suction valve) is open

or shorted, or control line is open or shorted to power supply or

ground.

EMERGENCY BRAKE

[C1153] When ABS actuator and el

ectric unit (control unit) is malfunction-

ing. (Pressure increase is too much or too little) BRC-68, "

ABS/TCS/VDC

Control Unit Inspection"

PNP POS SIG

[C1154]Transmission range switch signal or communication line between

the ABS actuator and electric unit (control unit) and TCM is open

or shorted. BRC-78, "Transmission

Range Switch System In-

spection"

BR FLUID LEVEL LOW

[C1155]

Brake fluid level drops or circuit between ABS actuator and elec-

tric unit (control unit) and brake fluid level switch is open or

shorted. BRC-76, "Brake Fluid

Level Switch System In-

spection"

ST ANG SEN COM CIR

[C1156]

CAN communication line or steering angle sensor has generated

an error. BRC-79, "

CAN Commu-

nication System Inspec-

tion"

(Note 2)

VARIANT CODING

[C1170] In case where VARIANT CODING is different. BRC-68, "

ABS/TCS/VDC

Control Unit Inspection"

CAN COMM CIRCUIT

[U1000]• CAN communication line is open or shorted.

• ABS actuator and electric unit (control unit) internal malfunction

• Battery voltage for ECM is suddenly interrupted for approxi-

mately 0.5 seconds or more. BRC-79, "

CAN Commu-

nication System Inspec-

tion"

(Note 2)

Self-diagnostic item

Malfunction detecting condition Check system

Item

(Unit) Data monitor item selection

Remarks

ECU INPUT

SIGNALS MAIN

SIGNALS SELECTION

FROM MENU

FR LH SENSOR

(km/h, mph) ××× Wheel speed (km/h, mph) calculated by front LH

wheel sensor signal is displayed.

FR RH SENSOR

(km/h, mph) ××× Wheel speed (km/h, mph) calculated by front RH

wheel sensor signal is displayed.

RR LH SENSOR

(km/h, mph) ×××

Wheel speed (km/h, mph) calculated by rear LH

wheel sensor signal is displayed.

RR RH SENSOR

(km/h, mph) ××× Wheel speed (km/h, mph) calculated by rear RH

wheel sensor signal is displayed.

FR RH IN SOL

(On/Off) —

×× Front RH IN ABS solenoid (On/Off) status is dis-

played.

FR RH OUT SOL

(On/Off) —

×× Front RH OUT ABS solenoid (On/Off) status is

displayed.

FR LH IN SOL

(On/Off) —

×× Front LH IN ABS solenoid (On/Off) status is dis-

played.

Revision: May 2010

2011 Versa

Page 1271 of 3787

DI-32

< SERVICE INFORMATION >

WARNING LAMPS

Oil Pressure Warning Lamp Does Not Turn Off (Oil Pressure Is Normal)

INFOID:0000000005929182

NOTE:

For oil pressure inspection, refer to LU-17, "

Inspection".

1.CHECK OIL PRESSURE WARNING LAMP OPERATION

Activate IPDM E/R auto active test. Refer to PG-20, "

Auto Active Test".

Does oil pressure warning lamp blink?

YES >> GO TO 2.

NO >> GO TO 5.

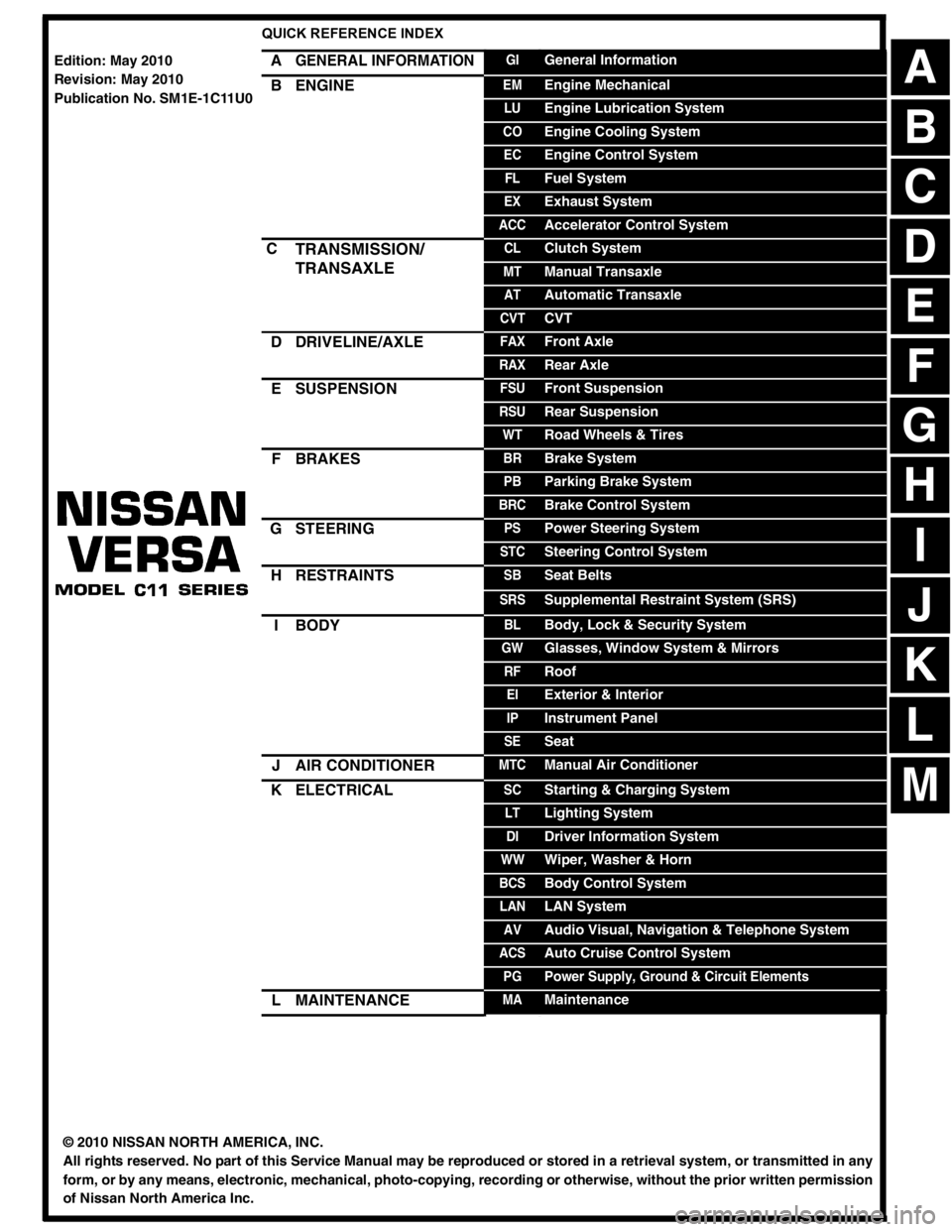

2.CHECK IPDM E/R OUTPUT SIGNAL

1. Turn ignition switch OFF.

2. Disconnect oil pressure switch connector.

3. Turn ignition switch ON.

4. Check voltage between oil pressure switch harness connector and ground.

OK or NG

OK >> GO TO 3.

NG >> GO TO 4.

3.CHECK OIL PRESSURE SWITCH

1. Turn ignition switch OFF.

2. Check oil pressure switch. Refer to DI-32, "

Component Inspection".

OK or NG

OK >> Replace IPDM E/R. Refer to PG-28, "Removal and Installation of IPDM E/R".

NG >> Replace oil pressure switch.

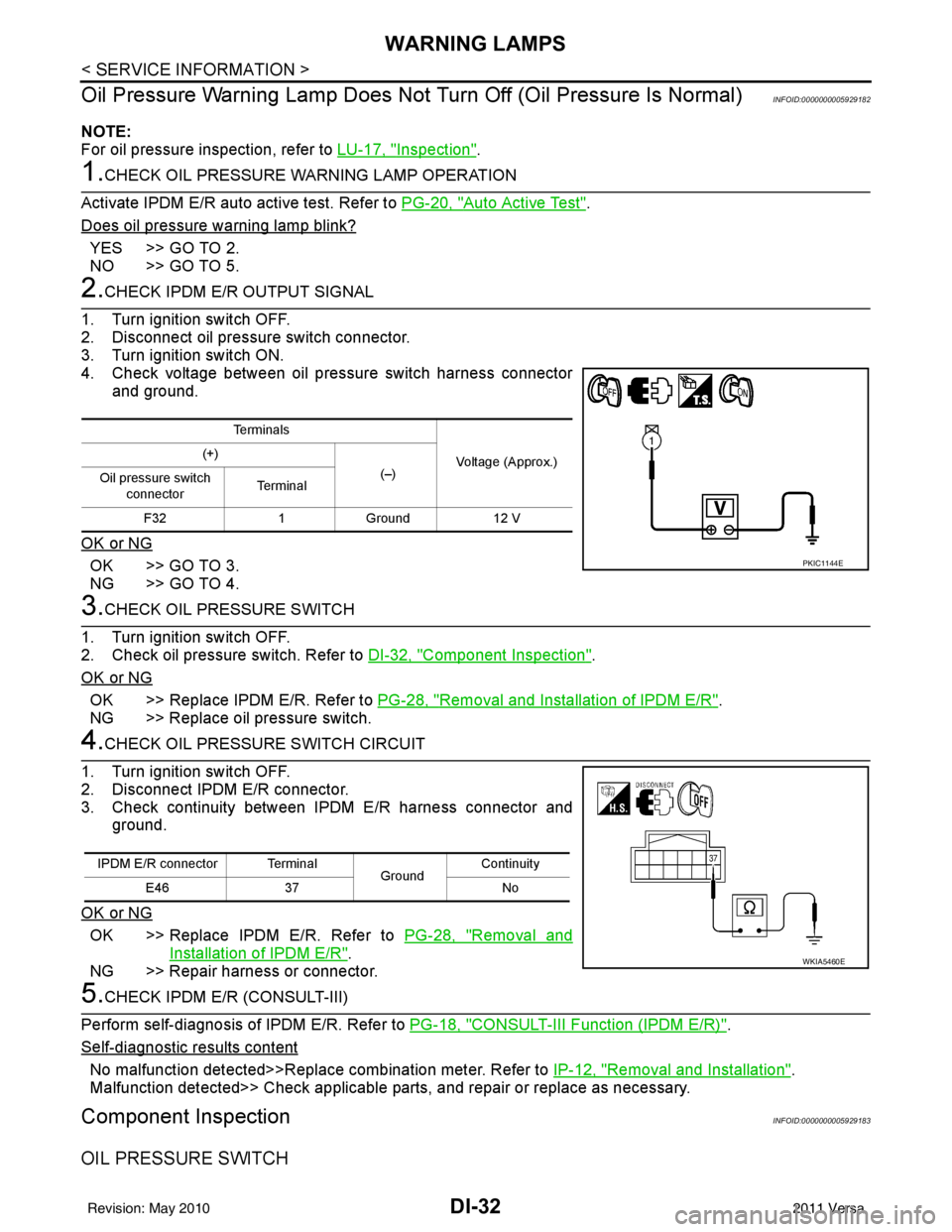

4.CHECK OIL PRESSURE SWITCH CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect IPDM E/R connector.

3. Check continuity between IPDM E/R harness connector and ground.

OK or NG

OK >> Replace IPDM E/R. Refer to PG-28, "Removal and

Installation of IPDM E/R".

NG >> Repair harness or connector.

5.CHECK IPDM E/R (CONSULT-III)

Perform self-diagnosis of IPDM E/R. Refer to PG-18, "

CONSULT-III Function (IPDM E/R)".

Self

-diagnostic results content

No malfunction detected>>Replace combination meter. Refer to IP-12, "Removal and Installation".

Malfunction detected>> Check applicable parts, and repair or replace as necessary.

Component InspectionINFOID:0000000005929183

OIL PRESSURE SWITCH

Te r m i n a l s

Voltage (Approx.)

(+)

(–)

Oil pressure switch

connector Te r m i n a l

F32 1Ground 12 V

PKIC1144E

IPDM E/R connector Terminal

GroundContinuity

E46 37 No

WKIA5460E

Revision: May 2010 2011 Versa

Page 1407 of 3787

![NISSAN TIIDA 2011 Service Repair Manual DIAGNOSIS SYSTEM (ECM)EC-113

< FUNCTION DIAGNOSIS > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

DTC WORK SUPPORT Mode

*: DTC P1442 and P1456 does not apply to C11 model

s but appears in DTC Work Support NISSAN TIIDA 2011 Service Repair Manual DIAGNOSIS SYSTEM (ECM)EC-113

< FUNCTION DIAGNOSIS > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

DTC WORK SUPPORT Mode

*: DTC P1442 and P1456 does not apply to C11 model

s but appears in DTC Work Support](/img/5/57396/w960_57396-1406.png)

DIAGNOSIS SYSTEM (ECM)EC-113

< FUNCTION DIAGNOSIS > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

DTC WORK SUPPORT Mode

*: DTC P1442 and P1456 does not apply to C11 model

s but appears in DTC Work Support Mode screens.

Test modeTest itemCorresponding DTC No. Reference page

EVAPORATIVE SYSTEM EVP SML LEAK P044

2/P1442* P0455EC-333

EVP V/S LEAK P0456/P1456* P0442

EC-288P0456EC-339

A/F SEN1 A/F SEN1 (B1) P1278/P1279 P0133

EC-201A/F SEN1 (B1) P1276P0130EC-185

HO2S2 HO2S2 (B1) P1146

P0138EC-215HO2S2 (B1) P1147 P0137EC-207

HO2S2 (B1) P139 P0139EC-224

Revision: May 2010 2011 Versa

Page 1793 of 3787

![NISSAN TIIDA 2011 Service Repair Manual FUEL PRESSUREEC-499

< ON-VEHICLE MAINTENANCE > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

ON-VEHICLE MAINTENANCE

FUEL PRESSURE

InspectionINFOID:0000000005930166

FUEL PRESSURE RELEASE

With CONSULT-III

1 NISSAN TIIDA 2011 Service Repair Manual FUEL PRESSUREEC-499

< ON-VEHICLE MAINTENANCE > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

ON-VEHICLE MAINTENANCE

FUEL PRESSURE

InspectionINFOID:0000000005930166

FUEL PRESSURE RELEASE

With CONSULT-III

1](/img/5/57396/w960_57396-1792.png)

FUEL PRESSUREEC-499

< ON-VEHICLE MAINTENANCE > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

ON-VEHICLE MAINTENANCE

FUEL PRESSURE

InspectionINFOID:0000000005930166

FUEL PRESSURE RELEASE

With CONSULT-III

1. Turn ignition switch ON.

2. Perform “FUEL PRESSURE RELEASE” in

“WORK SUPPORT” mode with CONSULT-III.

3. Start engine.

4. After engine stalls, crank it two or three times to release all fuel pressure.

5. Turn ignition switch OFF.

Without CONSULT-III

1. Remove fuel pump fuse located in IPDM E/R.

2. Start engine.

3. After engine stalls, crank it two or three times to release all fuel pressure.

4. Turn ignition switch OFF.

5. Reinstall fuel pump fuse after servicing fuel system.

FUEL PRESSURE CHECK

CAUTION:

Before disconnecting fuel line, release fuel pressure from fuel line to eliminate danger.

NOTE:

• Prepare pans or saucers under the disconnected fuel line because the fuel may spill out. The fuel

pressure cannot be completely released because C11 models do not have fuel return system.

• The fuel hose connection method used when taking fuel pressure check must not be used for other

purposes.

• Be careful not to scratch or put debris around connection area when servicing, so that the quick

connector maintains seal abil ity with O-rings inside.

• Do not perform fuel pressure check with electrical systems operating (i.e. lights, rear defogger, A/C,

etc.) Fuel pressure gauge may indicate false readin gs due to varying engine load and changes in

manifold vacuum.

1. Release fuel pressure to zero. Refer to "FUEL PRESSURE RELEASE".

2. Prepare fuel hose for fuel pressure check B and fuel tube adapter (KV10118400) D, then connect fuel pressure gauge A.

• : To quick connector

• : To fuel tube (engine side)

• C: Clamp

• Use suitable fuel hose for fuel pressure check (genuine

NISSAN fuel hose without quick connector).

• To avoid unnecessary force or tension to hose, use moder-

ately long fuel hose for fuel pressure check.

• Do not use the fuel hose for checking fuel pressure with dam- age or cracks on it.

• Use Pressure Gauge to check fuel pressure.

3. Remove fuel hose. Refer to EM-154, "

Removal and Installation".

• Do not twist or kink fuel hose because it is plastic hose.

PBIB2982E

Revision: May 2010 2011 Versa

Page 1877 of 3787

![NISSAN TIIDA 2011 Service Repair Manual BASIC SERVICE PROCEDUREEC-583

< SERVICE INFORMATION > [MR18DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

1. Remove fuel pump fuse (1) located in IPDM E/R (2).

• : Vehicle front

2. Start engine.

3. After engin NISSAN TIIDA 2011 Service Repair Manual BASIC SERVICE PROCEDUREEC-583

< SERVICE INFORMATION > [MR18DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

1. Remove fuel pump fuse (1) located in IPDM E/R (2).

• : Vehicle front

2. Start engine.

3. After engin](/img/5/57396/w960_57396-1876.png)

BASIC SERVICE PROCEDUREEC-583

< SERVICE INFORMATION > [MR18DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

1. Remove fuel pump fuse (1) located in IPDM E/R (2).

• : Vehicle front

2. Start engine.

3. After engine stalls, crank it two or three times to release all fuel pressure.

4. Turn ignition switch OFF.

5. Reinstall fuel pump fuse after servicing fuel system.

FUEL PRESSURE CHECK

CAUTION:

Before disconnecting fuel line, release fuel pressure from fuel line to eliminate danger.

NOTE:

• Prepare pans or saucers under the disconnected fuel line because the fuel may spill out. The fuel

pressure cannot be completely released because C11 models do not have fuel return system.

• The fuel hose connection method used when taking fuel pressure check must not be used for other

purposes.

• Be careful not to scratch or put debris around connection area when servicing, so that the quick

connector maintains seal abil ity with O-rings inside.

• Do not perform fuel pressure check with electrical systems operating (i.e. lights, rear defogger, A/C,

etc.) Fuel pressure gauge may indicate false readin gs due to varying engine load and changes in

manifold vacuum.

1. Release fuel pressure to zero. Refer to "FUEL PRESSURE RELEASE".

2. Prepare fuel hose for fuel pressure check B and fuel tube adapter (KV10118400) D, then connect fuel pressure gauge A.

• : To quick connector

• : To fuel tube (engine side)

• C: Clamp

• Use suitable fuel hose for fuel pressure check (genuineNISSAN fuel hose without quick connector).

• To avoid unnecessary force or tension to hose, use moder- ately long fuel hose for fuel pressure check.

• Do not use the fuel hose for checking fuel pressure with dam- age or cracks on it.

• Use Pressure Gauge to check fuel pressure.

3. Remove fuel hose. Refer to EM-154, "

Removal and Installation".

• Do not twist or kink fuel hose because it is plastic hose.

4. Connect fuel hose for fuel pressure check (1) to fuel tube (engine side) with clamp (2) as shown in the figure.

• No.2 spool (5)

• Wipe off oil or dirt from hose insertion part using cloth moist-ened with gasoline.

• Apply proper amount of gasoline between top of the fuel tube (3) and No.1 spool (4).

• Insert fuel hose for fuel pressure check until it touches the No.1 spool on fuel tube.

• Use NISSAN genuine hose clamp (part number: 16439 N4710

or 16439 40U00).

• When reconnecting fuel line, always use new clamps.

• Use a torque driver to tighten clamps.

• Install hose clamp to the positi on within 1 - 2 mm (0.04 - 0.08 in).

• Make sure that clamp screw does not contact adjacent parts.

PBIB2958E

Tightening torque: 1 - 1.5 N·m (0.1 - 0.15 kg-m, 9 - 13 in-lb)

PBIB2982E

PBIB2983E

Revision: May 2010 2011 Versa

Page 1912 of 3787

![NISSAN TIIDA 2011 Service Repair Manual EC-618

< SERVICE INFORMATION >[MR18DE]

TROUBLE DIAGNOSIS

*: Leaving cooling fan OFF with CONSULT-III while engine is running may cause the engine to overheat.

DTC & SRT CONFIRMATION MODE

SRT STATUS Mo NISSAN TIIDA 2011 Service Repair Manual EC-618

< SERVICE INFORMATION >[MR18DE]

TROUBLE DIAGNOSIS

*: Leaving cooling fan OFF with CONSULT-III while engine is running may cause the engine to overheat.

DTC & SRT CONFIRMATION MODE

SRT STATUS Mo](/img/5/57396/w960_57396-1911.png)

EC-618

< SERVICE INFORMATION >[MR18DE]

TROUBLE DIAGNOSIS

*: Leaving cooling fan OFF with CONSULT-III while engine is running may cause the engine to overheat.

DTC & SRT CONFIRMATION MODE

SRT STATUS Mode

For details, refer to EC-542, "Emission-related Diagnostic Information".

PERMANENT DTC STATUS Mode

For details, refer to

EC-542, "Emission-related Diagnostic Information".

NOTE:

This mode is not used in regions that permanent DTCs are not regulated by law.

SRT WORK SUPPORT Mode

This mode enables a technician to drive a vehicle to set the SRT while monitoring the SRT status.

PERMANENT DTC WORK SUPPORT Mode

This mode enables a technician to drive a vehicle to comp lete the driving pattern that is reguired for erasing

permanent DTC.

NOTE:

This mode is not used in regions that permanent DTCs are not regulated by law.

DTC WORK SUPPORT Mode

*: DTC P1442 and P1456 does not apply to C11 models but appears in DTC Work Support Mode screens.

Generic Scan Tool (GST) FunctionINFOID:0000000006341740

DESCRIPTION

VENT CON-

TROL/V• Ignition switch: ON

(Engine stopped)

• Turn solenoid valve “ON” and “OFF” with the CONSULT-III and

listen to operating sound. Solenoid valve makes an operating

sound.

• Harness and connectors

• EVAP canister vent control valve

V/T ASSIGN AN-

GLE • Engine: Return to the original

trouble condition

• Change intake valve timing using CONSULT-III. If trouble symptom disappears, see

CHECK ITEM.

• Harness and connectors

• Intake valve timing control sole-

noid valve

Test item

Condition JudgmentCheck item (Remedy)

Test mode Test itemCorresponding DTC No. Reference

EVAPORATIVE SYS-

TEM PURG FLOW P0441

P0441EC-810

EVP SML LEAK P0442/P1442* P0442

EC-815P0455EC-866

EVP V/S LEAK P0456/P1456* P0456EC-873

PURG VOL CN/V P1444 P0443EC-822

A/F SEN1 A/F SEN1 (B1) P1276

P0130EC-704A/F SEN1 (B1) P1278/P1279 ——

HO2S2 HO2S2 (B1) P0139

P0139EC-741

HO2S2 (B1) P1146 P0138EC-731

HO2S2 (B1) P1147 P0137EC-722

Revision: May 2010 2011 Versa