Trunk lid assembly NISSAN TIIDA 2011 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2011, Model line: TIIDA, Model: NISSAN TIIDA 2011Pages: 3787, PDF Size: 78.35 MB

Page 498 of 3787

BCS-8

< SERVICE INFORMATION >

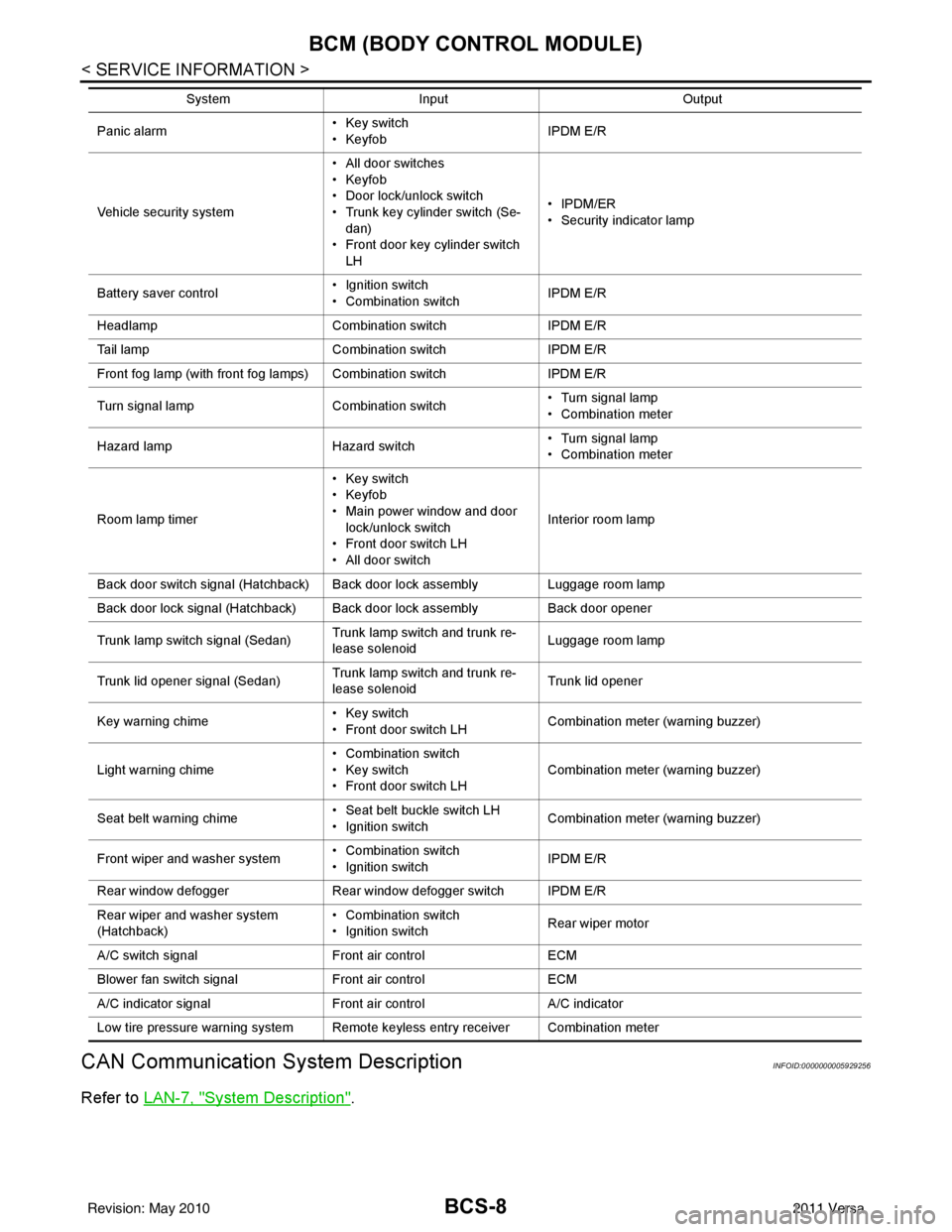

BCM (BODY CONTROL MODULE)

CAN Communication System Description

INFOID:0000000005929256

Refer to LAN-7, "System Description".

Panic alarm •Key switch

•KeyfobIPDM E/R

Vehicle security system • All door switches

•Keyfob

• Door lock/unlock switch

• Trunk key cylinder switch (Se-

dan)

• Front door key cylinder switch LH • IPDM/ER

• Security indicator lamp

Battery save r control • Ignition switch

• Combination switch

IPDM E/R

Headlamp Combination switch IPDM E/R

Tail lamp Combination switchIPDM E/R

Front fog lamp (with front fog lamps) Combination switch IPDM E/R

Turn signal lamp Combination switch• Turn signal lamp

• Combination meter

Hazard lamp Hazard switch• Turn signal lamp

• Combination meter

Room lamp timer •Key switch

•Keyfob

• Main power window and door

lock/unlock switch

• Front door switch LH

• All door switch Interior room lamp

Back door switch signal (Hatchback) Back door lock assembly Luggage room lamp

Back door lock signal (Hatchback) Back door lock assembly Back door opener

Trunk lamp switch signal (Sedan) Trunk lamp switch and trunk re-

lease solenoidLuggage room lamp

Trunk lid opener signal (Sedan) Trunk lamp switch and trunk re-

lease solenoid

Trunk lid opener

Key warning chime •Key switch

• Front door switch LHCombination meter (warning buzzer)

Light warning chime • Combination switch

•Key switch

• Front door switch LHCombination meter (warning buzzer)

Seat belt warning chime • Seat belt buckle switch LH

• Ignition switch

Combination meter (warning buzzer)

Front wiper and washer system • Combination switch

• Ignition switchIPDM E/R

Rear window defogger Rear window defogger switch IPDM E/R

Rear wiper and washer system

(Hatchback) • Combination switch

• Ignition switch

Rear wiper motor

A/C switch signal Front air controlECM

Blower fan switch signal Front air controlECM

A/C indicator signal Front air controlA/C indicator

Low tire pressure warning system Remote keyless entry receiver Combination meter System

Input Output

Revision: May 2010 2011 Versa

Page 512 of 3787

BL-2

Keyfob Function (Lock) Check ...............................82

Keyfob Function (Unlock) Check ............................82

ID Code Entry Procedure .................................... ...83

Keyfob Battery Replacement ............................... ...85

Removal and Installation of Remote Keyless Entry

Receiver .............................................................. ...

85

INTELLIGENT KEY SYSTEM ............................86

Component Parts and Harness Connector Loca-

tion ....................................................................... ...

86

System Description .................................................88

CAN Communication System Description ..............95

Schematic ............................................................ ...96

Wiring Diagram - I/KEY - ..................................... ...98

Intelligent Key Unit Har ness Connector Terminal

Layout .................................................................. ..

108

Terminal and Reference Value for Intelligent Key

Unit ........................................................................

108

Steering Lock Solenoid Harness Connector Ter-

minal Layout ..........................................................

110

Terminal and Reference Value for Steering Lock

Solenoid .................................................................

110

Terminal and Reference Value for BCM ................111

Trouble Diagnosis Procedure ................................115

CONSULT-III Functions (INTELLIGENT KEY) ......117

CONSULT-III Application Item ............................. ..117

Trouble Diagnosis Symptom Chart ........................119

CAN Communication System Inspection ...............126

Power Supply and Ground Circuit Inspection ........126

Key Switch (Intelligent Key Unit Input) Check .......127

Key Switch (BCM Input) Check .............................128

Ignition Knob Switch Check ................................. ..129

Door Switch Check (Hatchback) ............................131

Door Switch Check (Sedan) ..................................134

Door Request Switch Check ..................................135

Back Door Request Switch Check (Hatchback) ....137

Trunk Opener Request Switch Check (Sedan) ... ..138

Unlock Sensor Check ............................................140

Intelligent Key Warning Buzzer(s) Check ..............142

Outside Key Antenna (Dri ver Side and Passenger

Side) Check ......................................................... ..

143

Outside Key Antenna (Rear Bumper) Check .........144

Inside Key Antenna Check ....................................146

Steering Lock Solenoid Check ............................ ..147

Key Interlock Solenoid (With M/T) Check ..............149

Ignition Switch Position Check ............................ ..150

Stop Lamp Switch Check (With CVT or A/T) ....... ..150

Stop Lamp Switch Check (With M/T) .....................152

CVT or A/T Shift Selector (Park Position Switch)

Check .................................................................. ..

153

"P-SHIFT" Warning Lamp (With CVT or A/T)

Check ....................................................................

154

"LOCK" Warning Lamp (With M/T) Check .............155

"KEY" Warning Lamp (RED) Check ......................155

"KEY" Warning Lamp (G REEN) Check .................155

Check Warning Chime in Combination Meter ........156

Hazard Function Check .........................................156

Horn Function Check .... .........................................157

Headlamp Function Chec k ....................................157

Intelligent Key Battery Re placement .....................158

Remote Keyless Entry Func tion ............................158

Removal and Installation of Intelligent Key Unit ... .158

DOOR ...............................................................160

Fitting Adjustment ................................................ .160

Removal and Installation .......................................163

Back Door Stay Disposal ..................................... .166

FRONT DOOR LOCK .......................................167

Component Parts Location .................................. .167

Removal and Installation .......................................167

REAR DOOR LOCK ....................................... ..170

Component Parts Location .................................. .170

Removal and Installation .......................................170

BACK DOOR LOCK ....................................... ..173

Component Parts and Harness Connector Loca-

tion ....................................................................... .

173

System Description ...............................................173

Wiring Diagram - B/DOOR - ..................................174

Terminal and Reference Value for BCM ...............176

Terminal and Reference Value for Intelligent Key

Unit ....................................................................... .

180

CONSULT-III Function (BCM) ..............................182

Work Flow .............................................................183

Trouble Diagnosis Chart by Symptom ..................183

BCM Power Supply and Ground Circuit Inspection

.

183

Check Back Door Opener Switch Circuit (Without

Intelligent Key or Power Windows) ...................... .

184

Check Back Door Opener Switch Circuit (Without

Intelligent Key, with Power Windows) .................. .

187

Check Back Door Opener Switch Circuit (With In-

telligent Key) ........................................................ .

189

Check Back Door Lock Assembly (Actuator) Cir-

cuit ........................................................................

191

Removal and Installation .......................................193

TRUNK LID ..................................................... ..195

Fitting Adjustment ................................................ .195

Trunk Lid Assembly ..............................................195

Trunk Lid Lock ......................................................196

Trunk Lid Striker ....................................................196

TRUNK LID OPENER .......................................198

Component Parts and Harness Connector Loca-

tion ....................................................................... .

198

System Description ...............................................198

Wiring Diagram - TLID - ........................................199

Terminal and Reference Value for BCM ...............201

Terminal and Reference Value for Intelligent Key

Unit ....................................................................... .

205

CONSULT-III Function (BCM) ..............................207

Work Flow .............................................................208

Trouble Diagnosis Chart by Symptom ..................208

BCM Power Supply and Ground Circuit Inspection

.

208

Revision: May 2010 2011 Versa

Page 705 of 3787

TRUNK LIDBL-195

< SERVICE INFORMATION >

C

DE

F

G H

J

K L

M A

B

BL

N

O P

TRUNK LID

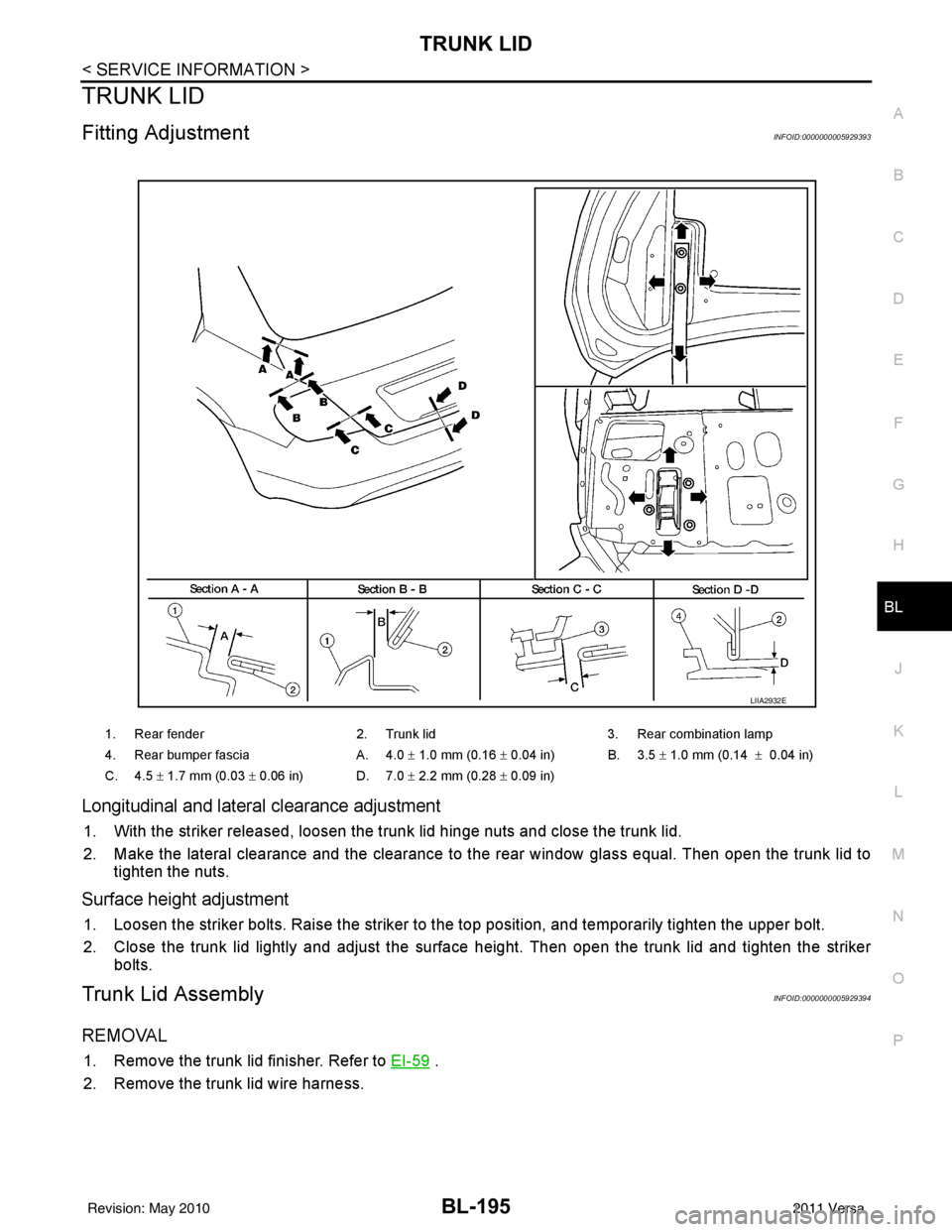

Fitting AdjustmentINFOID:0000000005929393

Longitudinal and latera l clearance adjustment

1. With the striker released, loosen the trunk lid hinge nuts and close the trunk lid.

2. Make the lateral clearance and the clearance to the rear window glass equal. Then open the trunk lid to

tighten the nuts.

Surface height adjustment

1. Loosen the striker bolts. Raise the striker to t he top position, and temporarily tighten the upper bolt.

2. Close the trunk lid lightly and adjust the surface height. Then open the trunk lid and tighten the striker bolts.

Trunk Lid AssemblyINFOID:0000000005929394

REMOVAL

1. Remove the trunk lid finisher. Refer to EI-59 .

2. Remove the trunk lid wire harness.

1. Rear fender 2. Trunk lid3. Rear combination lamp

4. Rear bumper fascia A. 4.0 ± 1.0 mm (0.16 ± 0.04 in) B. 3.5 ± 1.0 mm (0.14 ± 0.04 in)

C. 4.5 ± 1.7 mm (0.03 ± 0.06 in) D. 7.0 ± 2.2 mm (0.28 ± 0.09 in)

LIIA2932E

Revision: May 2010 2011 Versa

Page 706 of 3787

BL-196

< SERVICE INFORMATION >

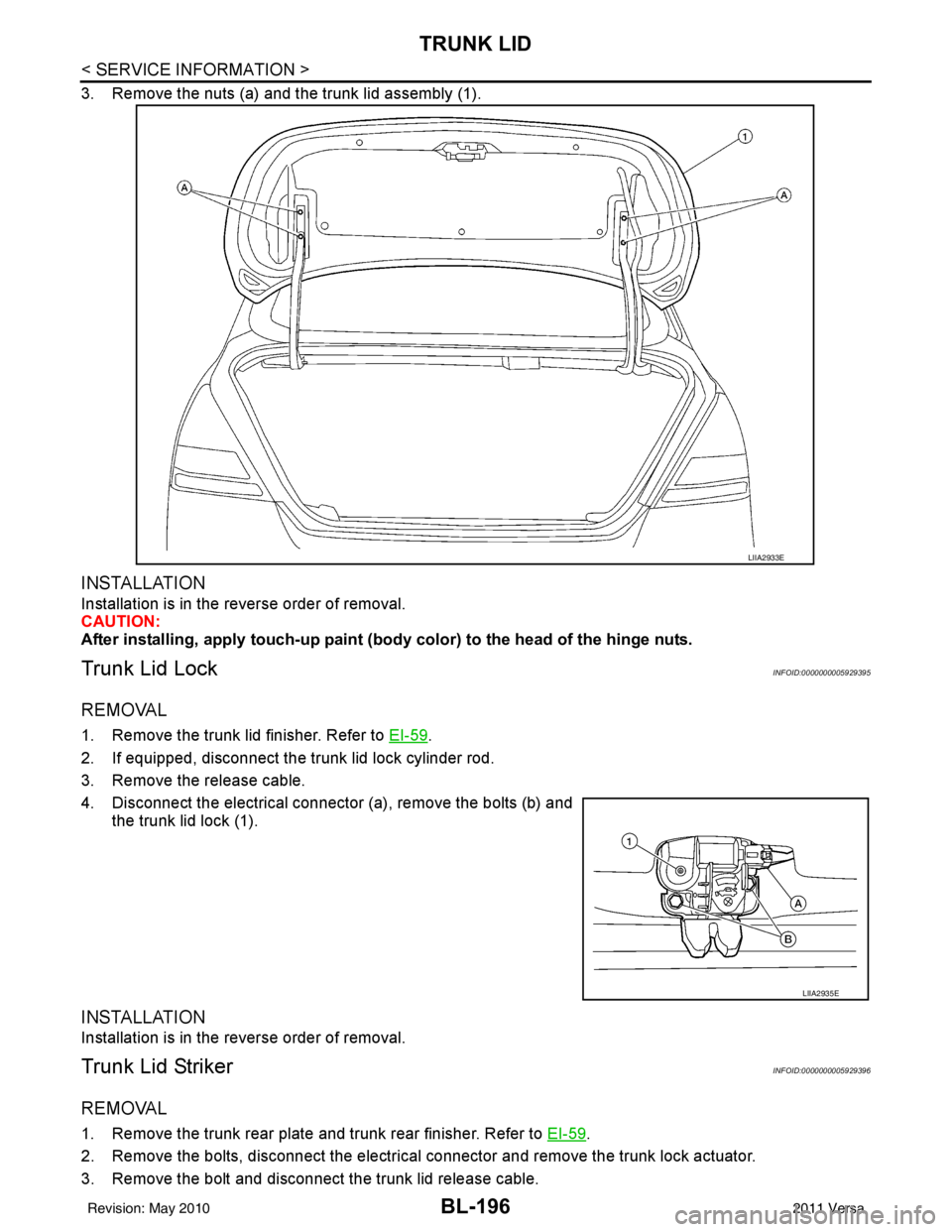

TRUNK LID

3. Remove the nuts (a) and the trunk lid assembly (1).

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

After installing, apply touch-up paint (body color) to the head of the hinge nuts.

Trunk Lid LockINFOID:0000000005929395

REMOVAL

1. Remove the trunk lid finisher. Refer to EI-59.

2. If equipped, disconnect the trunk lid lock cylinder rod.

3. Remove the release cable.

4. Disconnect the electrical connector (a), remove the bolts (b) and the trunk lid lock (1).

INSTALLATION

Installation is in the reverse order of removal.

Trunk Lid StrikerINFOID:0000000005929396

REMOVAL

1. Remove the trunk rear plate and trunk rear finisher. Refer to EI-59.

2. Remove the bolts, disconnect the electrical connector and remove the trunk lock actuator.

3. Remove the bolt and disconnect the trunk lid release cable.

LIIA2933E

LIIA2935E

Revision: May 2010 2011 Versa

Page 708 of 3787

BL-198

< SERVICE INFORMATION >

TRUNK LID OPENER

TRUNK LID OPENER

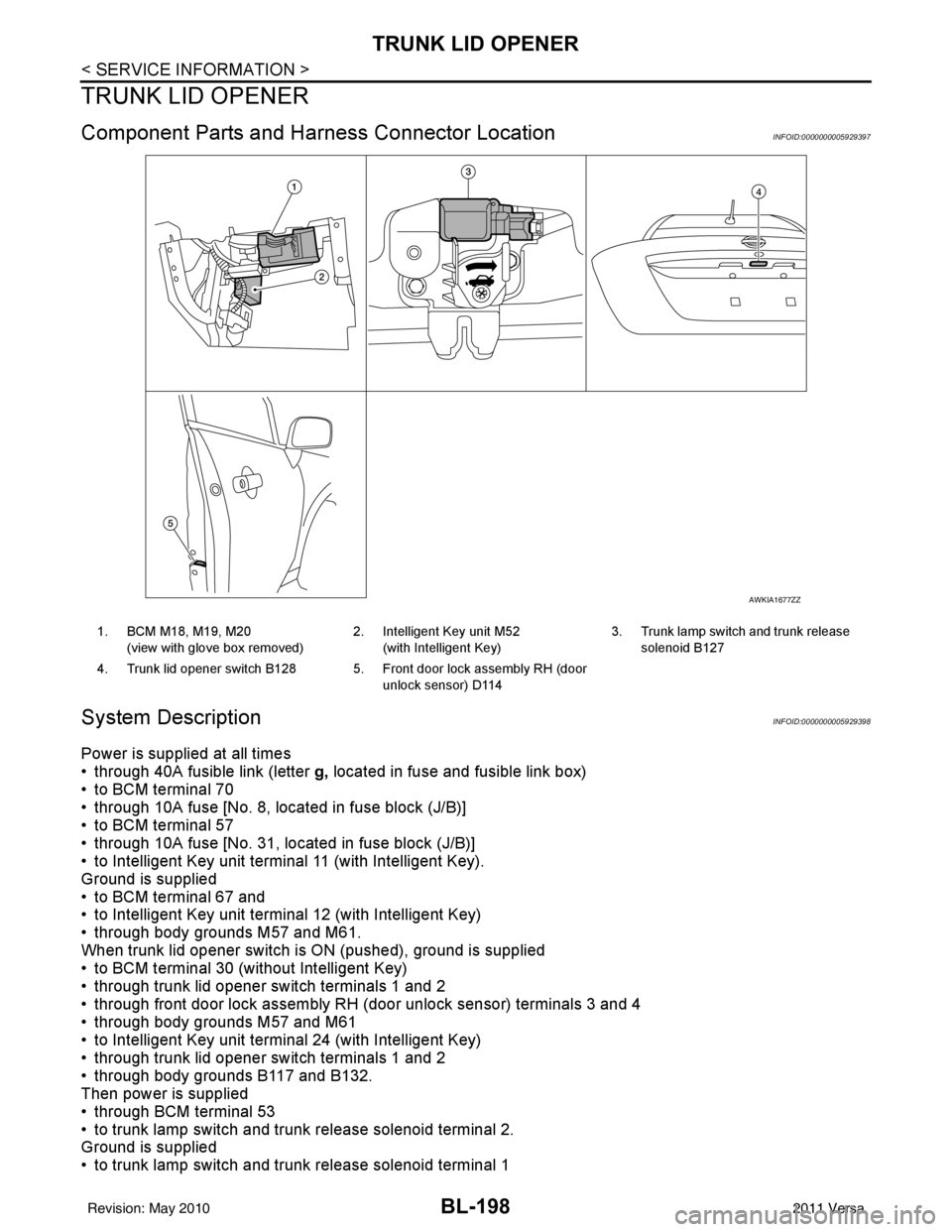

Component Parts and Harness Connector LocationINFOID:0000000005929397

System DescriptionINFOID:0000000005929398

Power is supplied at all times

• through 40A fusible link (letter g, located in fuse and fusible link box)

• to BCM terminal 70

• through 10A fuse [No. 8, located in fuse block (J/B)]

• to BCM terminal 57

• through 10A fuse [No. 31, located in fuse block (J/B)]

• to Intelligent Key unit terminal 11 (with Intelligent Key).

Ground is supplied

• to BCM terminal 67 and

• to Intelligent Key unit terminal 12 (with Intelligent Key)

• through body grounds M57 and M61.

When trunk lid opener switch is ON (pushed), ground is supplied

• to BCM terminal 30 (without Intelligent Key)

• through trunk lid opener switch terminals 1 and 2

• through front door lock assembly RH (door unlock sensor) terminals 3 and 4

• through body grounds M57 and M61

• to Intelligent Key unit terminal 24 (with Intelligent Key)

• through trunk lid opener switch terminals 1 and 2

• through body grounds B117 and B132.

Then power is supplied

• through BCM terminal 53

• to trunk lamp switch and trunk release solenoid terminal 2.

Ground is supplied

• to trunk lamp switch and trunk release solenoid terminal 1

AWKIA1677ZZ

1. BCM M18, M19, M20

(view with glove box removed) 2. Intelligent Key unit M52

(with Intelligent Key) 3. Trunk lamp switch and trunk release

solenoid B127

4. Trunk lid opener switch B128 5. Front door lock assembly RH (door unlock sensor) D114

Revision: May 2010 2011 Versa

Page 718 of 3787

BL-208

< SERVICE INFORMATION >

TRUNK LID OPENER

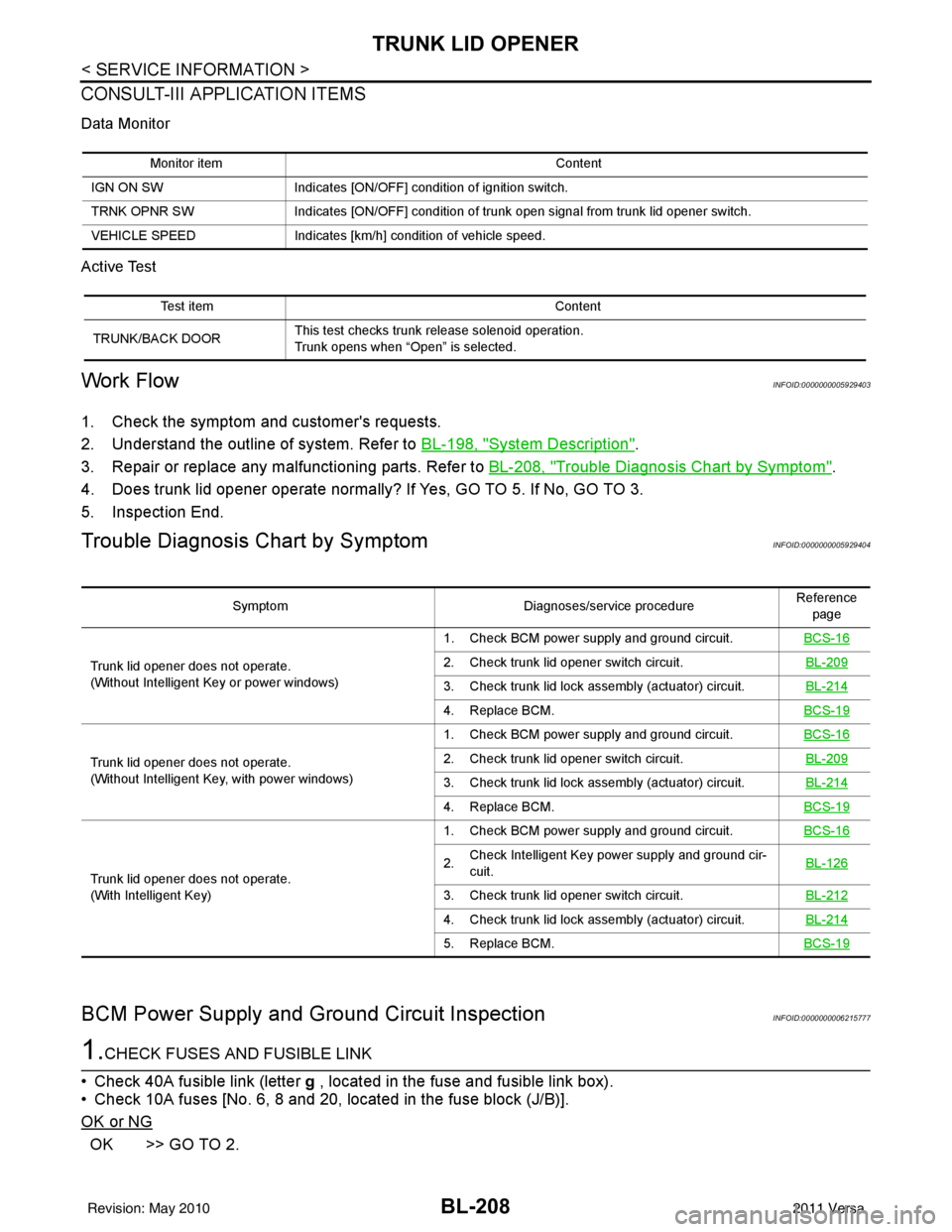

CONSULT-III APPLICATION ITEMS

Data Monitor

Active Test

Work FlowINFOID:0000000005929403

1. Check the symptom and customer's requests.

2. Understand the outline of system. Refer to BL-198, "

System Description".

3. Repair or replace any malfunctioning parts. Refer to BL-208, "

Trouble Diagnosis Chart by Symptom".

4. Does trunk lid opener operate normally? If Yes, GO TO 5. If No, GO TO 3.

5. Inspection End.

Trouble Diagnosis Chart by SymptomINFOID:0000000005929404

BCM Power Supply and Ground Circuit InspectionINFOID:0000000006215777

1.CHECK FUSES AND FUSIBLE LINK

• Check 40A fusible link (letter g , located in the fuse and fusible link box).

• Check 10A fuses [No. 6, 8 and 20, lo cated in the fuse block (J/B)].

OK or NG

OK >> GO TO 2.

Monitor item Content

IGN ON SW Indicates [ON/OFF] condition of ignition switch.

TRNK OPNR SW Indicates [ON/OFF] condition of trun k open signal from trunk lid opener switch.

VEHICLE SPEED Indicates [km/h] condition of vehicle speed.

Test item Content

TRUNK/BACK DOOR This test checks trunk release solenoid operation.

Trunk opens when “Open” is selected.

Symptom

Diagnoses/service procedureReference

page

Trunk lid opener does not operate.

(Without Intelligent Key or power windows) 1. Check BCM power supply and ground circuit.

BCS-16

2. Check trunk lid opener switch circuit. BL-209

3. Check trunk lid lock assembly (actuator) circuit.BL-214

4. Replace BCM.BCS-19

Trunk lid opener does not operate.

(Without Intelligent Key, with power windows)1. Check BCM power supply and ground circuit.

BCS-162. Check trunk lid opener switch circuit. BL-209

3. Check trunk lid lock assembly (actuator) circuit.BL-214

4. Replace BCM.BCS-19

Trunk lid opener does not operate.

(With Intelligent Key)1. Check BCM power supply and ground circuit.

BCS-16

2.Check Intelligent Key power supply and ground cir-

cuit.

BL-126

3. Check trunk lid opener switch circuit.

BL-212

4. Check trunk lid lock assembly (actuator) circuit.BL-214

5. Replace BCM.BCS-19

Revision: May 2010 2011 Versa

Page 719 of 3787

TRUNK LID OPENERBL-209

< SERVICE INFORMATION >

C

DE

F

G H

J

K L

M A

B

BL

N

O P

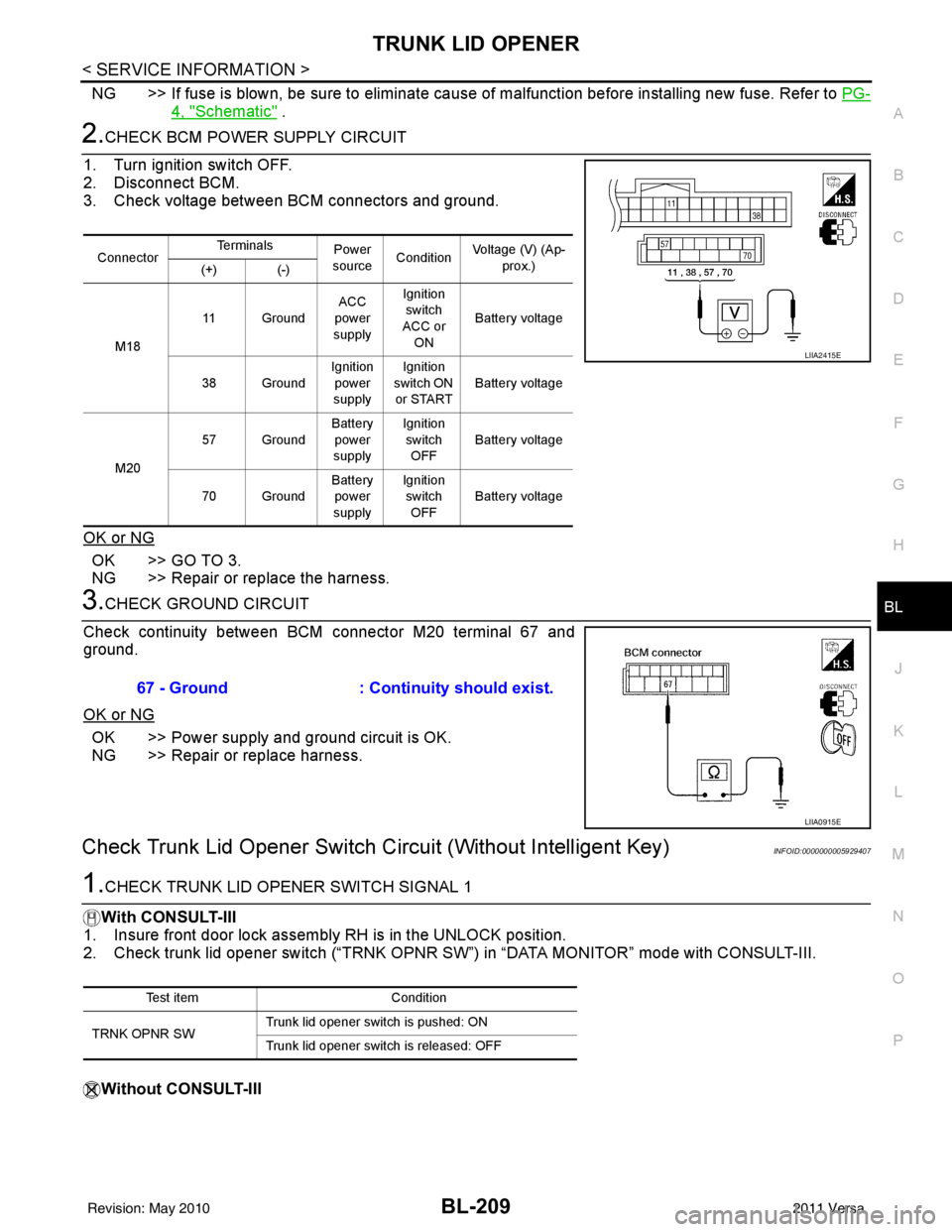

NG >> If fuse is blown, be sure to eliminate cause of malfunction before installing new fuse. Refer to PG-

4, "Schematic" .

2.CHECK BCM POWER SUPPLY CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect BCM.

3. Check voltage between BCM connectors and ground.

OK or NG

OK >> GO TO 3.

NG >> Repair or replace the harness.

3.CHECK GROUND CIRCUIT

Check continuity between BCM connector M20 terminal 67 and

ground.

OK or NG

OK >> Power supply and ground circuit is OK.

NG >> Repair or replace harness.

Check Trunk Lid Opener Switch Cir cuit (Without Intelligent Key)INFOID:0000000005929407

1.CHECK TRUNK LID OPENER SWITCH SIGNAL 1

With CONSULT-III

1. Insure front door lock assembly RH is in the UNLOCK position.

2. Check trunk lid opener switch (“TRNK OPNR SW”) in “DATA MONITOR” mode with CONSULT-III.

Without CONSULT-III

Connector Te r m i n a l s

Power

source Condition Voltage (V) (Ap-

prox.)

(+) (-)

M18 11 Ground

ACC

power

supply Ignition

switch

ACC or

ON Battery voltage

38 Ground Ignition

power

supply Ignition

switch ON or START Battery voltage

M20 57 Ground

Battery

power

supply Ignition

switch OFF Battery voltage

70 Ground Battery

power

supply Ignition

switch

OFF Battery voltage

LIIA2415E

67 - Ground

: Continuity should exist.

LIIA0915E

Test item Condition

TRNK OPNR SW Trunk lid opener switch is pushed: ON

Trunk lid opener switch is released: OFF

Revision: May 2010

2011 Versa

Page 720 of 3787

BL-210

< SERVICE INFORMATION >

TRUNK LID OPENER

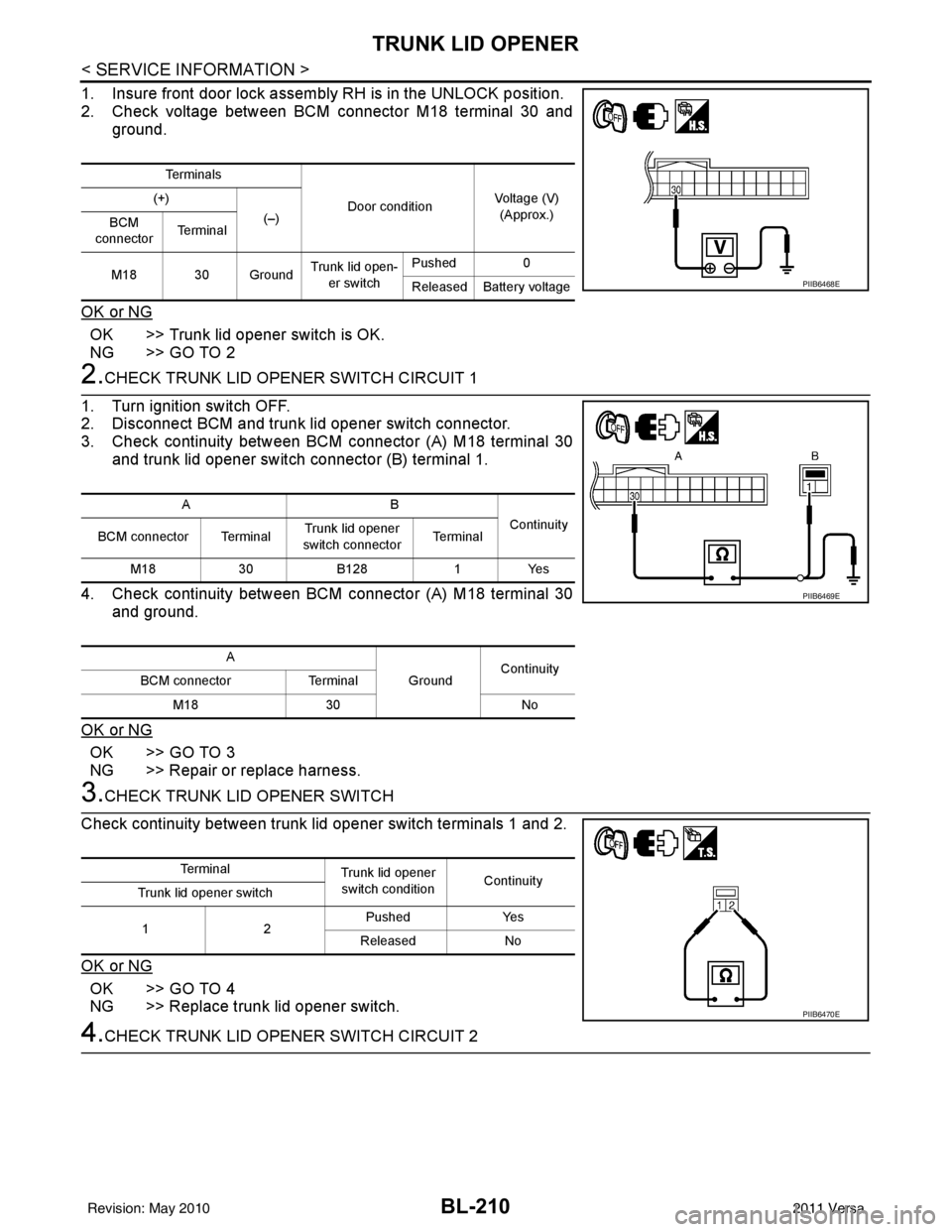

1. Insure front door lock assembly RH is in the UNLOCK position.

2. Check voltage between BCM connector M18 terminal 30 andground.

OK or NG

OK >> Trunk lid opener switch is OK.

NG >> GO TO 2

2.CHECK TRUNK LID OPENER SWITCH CIRCUIT 1

1. Turn ignition switch OFF.

2. Disconnect BCM and trunk lid opener switch connector.

3. Check continuity between BCM connector (A) M18 terminal 30 and trunk lid opener switch connector (B) terminal 1.

4. Check continuity between BCM connector (A) M18 terminal 30 and ground.

OK or NG

OK >> GO TO 3

NG >> Repair or replace harness.

3.CHECK TRUNK LID OPENER SWITCH

Check continuity between trunk lid opener switch terminals 1 and 2.

OK or NG

OK >> GO TO 4

NG >> Replace trunk lid opener switch.

4.CHECK TRUNK LID OPENER SWITCH CIRCUIT 2

Te r m i n a l s

Door conditionVoltage (V)

(Approx.)

(+)

(–)

BCM

connector Te r m i n a l

M18 30 Ground Trunk lid open-

er switch Pushed

0

Released Battery voltage

PIIB6468E

AB Continuity

BCM connector Terminal Trunk lid opener

switch connector Te r m i n a l

M18 30B128 1Yes

A GroundContinuity

BCM connector Terminal

M18 30 No

PIIB6469E

Te r m i n a l

Trunk lid opener

switch condition Continuity

Trunk lid opener switch

12 Pushed

Yes

Released No

PIIB6470E

Revision: May 2010 2011 Versa

Page 721 of 3787

TRUNK LID OPENERBL-211

< SERVICE INFORMATION >

C

DE

F

G H

J

K L

M A

B

BL

N

O P

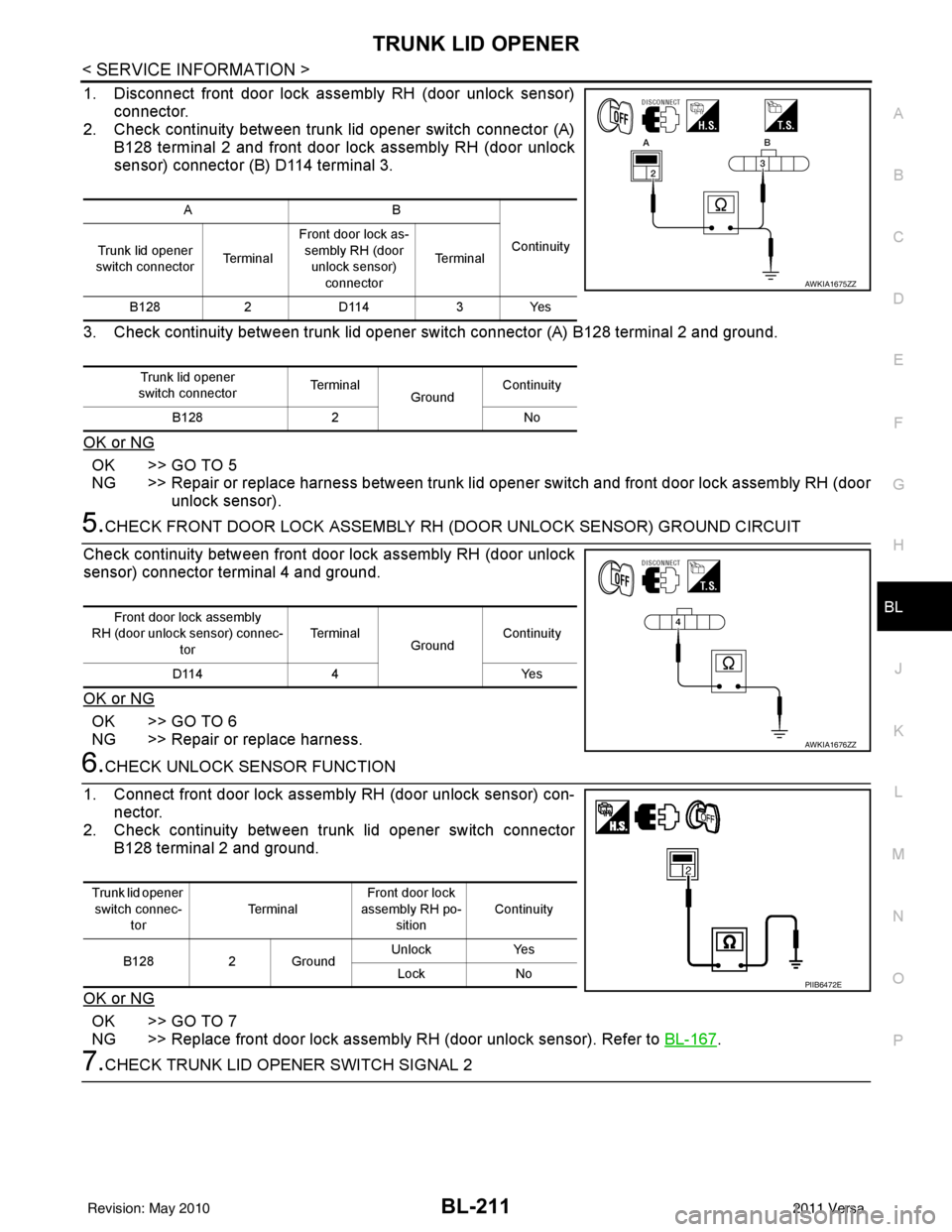

1. Disconnect front door lock asse mbly RH (door unlock sensor)

connector.

2. Check continuity between trunk lid opener switch connector (A)

B128 terminal 2 and front door lock assembly RH (door unlock

sensor) connector (B) D114 terminal 3.

3. Check continuity between trunk lid opener switch connector (A) B128 terminal 2 and ground.

OK or NG

OK >> GO TO 5

NG >> Repair or replace harness between trunk lid opener switch and front door lock assembly RH (door unlock sensor).

5.CHECK FRONT DOOR LOCK ASSEMBLY RH (DOOR UNLOCK SENSOR) GROUND CIRCUIT

Check continuity between front door lock assembly RH (door unlock

sensor) connector terminal 4 and ground.

OK or NG

OK >> GO TO 6

NG >> Repair or replace harness.

6.CHECK UNLOCK SENSOR FUNCTION

1. Connect front door lock assembly RH (door unlock sensor) con- nector.

2. Check continuity between trunk lid opener switch connector

B128 terminal 2 and ground.

OK or NG

OK >> GO TO 7

NG >> Replace front door lock assembly RH (door unlock sensor). Refer to BL-167

.

7.CHECK TRUNK LID OPENER SWITCH SIGNAL 2

AB

Continuity

Trunk lid opener

switch connector Te r m i n a lFront door lock as-

sembly RH (door unlock sensor) connector Te r m i n a l

B128 2D114 3Yes

Trunk lid opener

switch connector Te r m i n a l

GroundContinuity

B128 2 No

AWKIA1675ZZ

Front door lock assembly

RH (door unlock sensor) connec- tor Te r m i n a l

GroundContinuity

D114 4 Yes

AWKIA1676ZZ

Trunk lid opener

switch connec-

tor Te r m i n a l

Front door lock

assembly RH po-

sition Continuity

B128 2 Ground Unlock

Yes

Lock No

PIIB6472E

Revision: May 2010 2011 Versa

Page 726 of 3787

BL-216

< SERVICE INFORMATION >

FUEL FILLER LID OPENER

FUEL FILLER LID OPENER

Removal and Installation of Fuel Filler Lid OpenerINFOID:0000000005929410

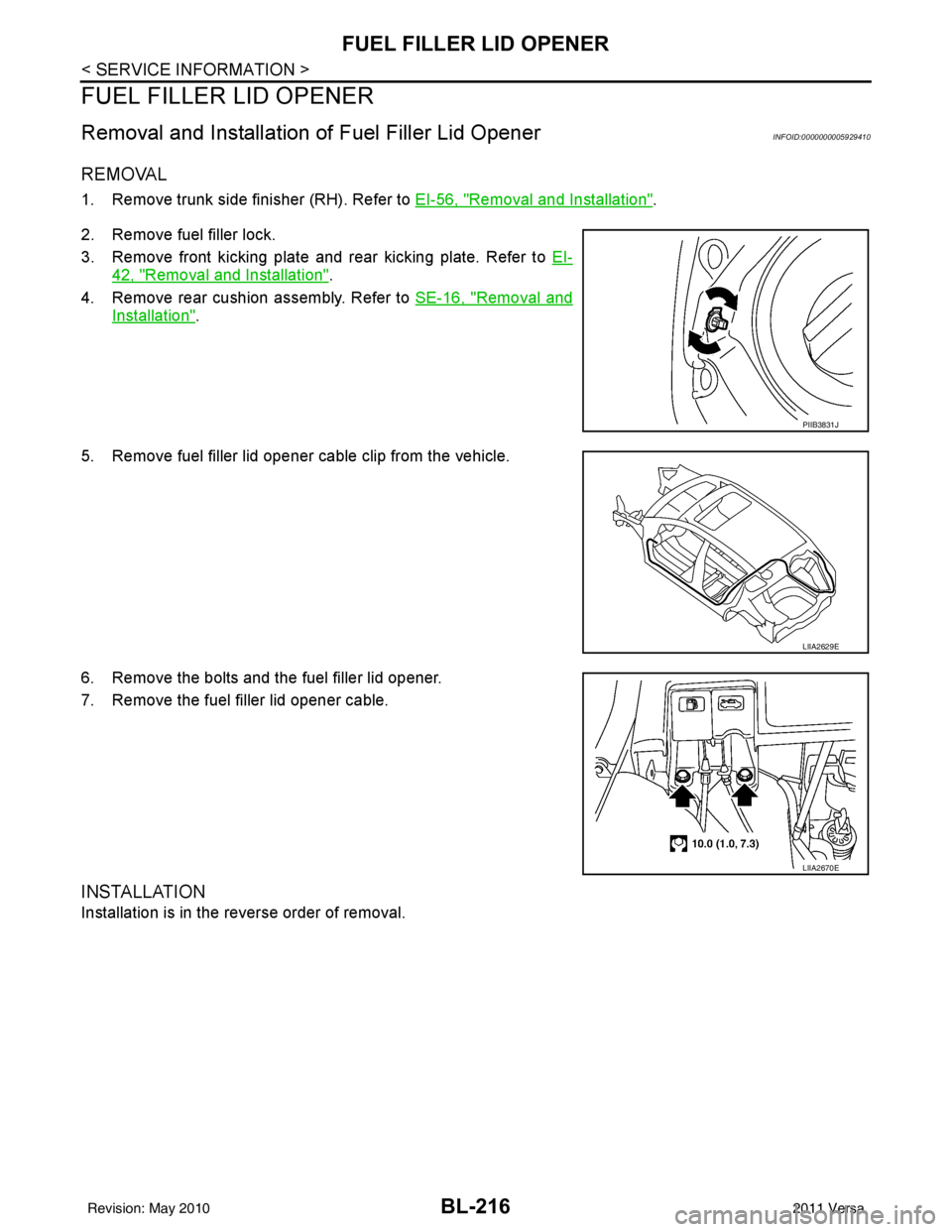

REMOVAL

1. Remove trunk side finisher (RH). Refer to EI-56, "Removal and Installation".

2. Remove fuel filler lock.

3. Remove front kicking plate and rear kicking plate. Refer to EI-

42, "Removal and Installation".

4. Remove rear cushion assembly. Refer to SE-16, "

Removal and

Installation".

5. Remove fuel filler lid opener cable clip from the vehicle.

6. Remove the bolts and the fuel filler lid opener.

7. Remove the fuel filler lid opener cable.

INSTALLATION

Installation is in the reverse order of removal.

PIIB3831J

LIIA2629E

LIIA2670E

Revision: May 2010 2011 Versa