battery location NISSAN TIIDA 2011 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2011, Model line: TIIDA, Model: NISSAN TIIDA 2011Pages: 3787, PDF Size: 78.35 MB

Page 18 of 3787

AT-1

TRANSMISSION/TRANSAXLE

DE

F

G H

I

J

K L

M

SECTION AT

A

B

AT

N

O P

CONTENTS

AUTOMATIC TRANSAXLE

SERVICE INFORMATION .. ..........................5

INDEX FOR DTC ............................................ .....5

Alphabetical Index ............................................... ......5

DTC No. Index ..........................................................5

PRECAUTIONS ...................................................7

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

7

Precaution Necessary for Steering Wheel Rota-

tion After Battery Disconnect ............................... ......

7

Precaution for On Board Diagnosis (OBD) System

of A/T and Engine .....................................................

8

Precaution .................................................................8

Service Notice or Precaution .....................................9

PREPARATION ..................................................11

Special Service Tool ........................................... ....11

Commercial Service Tool ........................................14

A/T FLUID ...........................................................17

Checking A/T Fluid ..................................................17

Changing A/T Fluid .................................................17

A/T Fluid Cooler Cleaning .......................................18

A/T CONTROL SYSTEM ....................................21

Cross-Sectional View ..............................................21

Shift Mechanism .................................................. ....22

TCM Function ..........................................................30

CAN Communication ...............................................31

Input/Output Signal of TCM .....................................31

Line Pressure Control .............................................32

Shift Control ........................................................ ....33

Lock-up Control .......................................................34

Engine Brake Control (Overrun Clutch Control) ......35

Control Valve ....................................................... ....37

Centrifugal Cancel Mechanism ...............................37

ON BOARD DIAGNOSTIC (OBD) SYSTEM ......39

Introduction ......................................................... ....39

OBD-II Function for A/T System ..............................39

One or Two Trip Detection Logic of OBD-II ......... ....39

OBD-II Diagnostic Trouble Code (DTC) ..................39

Malfunction Indicator Lamp (MIL) ............................41

TROUBLE DIAGNOSIS ....................................42

DTC Inspection Priority Chart ..................................42

Fail-Safe ..................................................................42

How to Perform Trouble Diagnosis for Quick and

Accurate Repair .......................................................

43

A/T Electrical Parts Location ...................................49

Circuit Diagram ........................................................50

Inspections Before Trouble Diagnosis .....................51

Road Test ................................................................55

Check Before Engine Is Started ..............................56

Check at Idle ............................................................56

Cruise Test - Part 1 .................................................58

Cruise Test - Part 2 .................................................61

Cruise Test - Part 3 .................................................62

Vehicle Speed at Which Gear Shifting Occurs ........64

Vehicle Speed at Which Lock-up Occurs/Releas-

es .............................................................................

64

Symptom Chart ........................................................65

TCM Terminal and Reference Value .......................75

CONSULT-III Function (TRANSMISSION) .......... ....77

Diagnosis Procedure without CONSULT-III ............82

U1000 CAN COMM CIRCUIT ...........................87

Description ........................................................... ....87

On Board Diagnosis Logic .......................................87

Possible Cause ........................................................87

DTC Confirmation Procedure ..................................87

Wiring Diagram - AT - CAN .....................................88

Diagnosis Procedure ...............................................89

P0705 TRANSMISSION RANGE SWITCH A ...90

Description ...............................................................90

CONSULT-III Reference Value in Data Monitor

Mode .................................................................... ....

90

On Board Diagnosis Logic .......................................90

Possible Cause ........................................................90

DTC Confirmation Procedure ..................................90

Revision: May 2010 2011 Versa

Page 398 of 3787

AV-1

ELECTRICAL

C

DE

F

G H

I

J

L

M

SECTION AV

A

B

AV

N

O P

CONTENTS

AUDIO, VISUAL, NAVIGATION & TELEPHONE SYS- TEM

AUDIO WITHOUT NAVIGATION

SERVICE INFORMATION .. ..........................

3

PRECAUTIONS .............................................. .....3

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

3

Precaution Necessary for Steering Wheel Rota-

tion After Battery Disconnect ............................... ......

3

PREPARATION ...................................................5

Commercial Service Tool .................................... ......5

AUDIO .................................................................6

Component Parts Location .................................. ......6

System Description ...................................................6

Schematic .................................................................8

Wiring Diagram - AUDIO - .........................................9

Audio Unit (Base System) Harness Connector

Terminal Layout ......................................................

15

Terminal and Reference Value for Audio Unit

(Base System) .........................................................

15

Audio Unit (Premium System) Harness Connector

Terminal Layout ......................................................

16

Terminal and Reference Value for Audio Unit

(Premium System) ..................................................

16

IPod Adapter Harness Connector Terminal Layout

....

18

Terminal and Reference Value for IPod Adapter ....19

Trouble Diagnosis ...................................................20

Noise Inspection ......................................................21

Power Supply Circuit Inspection .............................22

Steering Switch Check (With Bluetooth) .................22

Sound Is Not Heard from Front Door Speaker

(Base System) .........................................................

24

Sound Is Not Heard from Rear Door Speaker

(Base System) .........................................................

25

Sound Is Not Heard from Front Door Speaker or

Tweeter (Premium System) ....................................

26

Sound Is Not Heard from Rear Door Speaker

(Premium System) ............................................... ....

27

Removal and Installation .........................................29

iPod® CONNECTOR ........................................31

Removal and Installation .........................................31

iPod® ADAPTER ..............................................32

Removal and Installation .........................................32

AUDIO ANTENNA .............................................33

Location of Antenna ............................................. ....33

Removal and Installation of Roof Antenna ..............33

TELEPHONE .....................................................35

Component Parts and Harness Connector Loca-

tion ...........................................................................

35

System Description ..................................................35

Wiring Diagram - H/PHON - ....................................37

Bluetooth Control Unit Harness Connector Termi-

nal Layout ............................................................ ....

39

Terminal and Reference Value for Bluetooth Con-

trol Unit ....................................................................

39

Bluetooth Control Unit Self-Diagnosis Function ......41

Workflow .............................................................. ....41

Power Supply and Ground Circuit Inspection for

Bluetooth Control Unit .............................................

42

Steering Wheel Audio Co ntrol Switch Does Not

Operate ................................................................ ....

43

Voice Activated Control Function Does Not Oper-

ate ........................................................................ ....

43

Removal and Installation .........................................46

AUDIO WITH NAVIGATION

SERVICE INFORMATION .. .........................

50

PRECAUTIONS .................................................50

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ....

50

Precaution Necessary for Steering Wheel Rota-

tion After Battery Disconnect ...................................

50

Revision: May 2010 2011 Versa

Page 512 of 3787

BL-2

Keyfob Function (Lock) Check ...............................82

Keyfob Function (Unlock) Check ............................82

ID Code Entry Procedure .................................... ...83

Keyfob Battery Replacement ............................... ...85

Removal and Installation of Remote Keyless Entry

Receiver .............................................................. ...

85

INTELLIGENT KEY SYSTEM ............................86

Component Parts and Harness Connector Loca-

tion ....................................................................... ...

86

System Description .................................................88

CAN Communication System Description ..............95

Schematic ............................................................ ...96

Wiring Diagram - I/KEY - ..................................... ...98

Intelligent Key Unit Har ness Connector Terminal

Layout .................................................................. ..

108

Terminal and Reference Value for Intelligent Key

Unit ........................................................................

108

Steering Lock Solenoid Harness Connector Ter-

minal Layout ..........................................................

110

Terminal and Reference Value for Steering Lock

Solenoid .................................................................

110

Terminal and Reference Value for BCM ................111

Trouble Diagnosis Procedure ................................115

CONSULT-III Functions (INTELLIGENT KEY) ......117

CONSULT-III Application Item ............................. ..117

Trouble Diagnosis Symptom Chart ........................119

CAN Communication System Inspection ...............126

Power Supply and Ground Circuit Inspection ........126

Key Switch (Intelligent Key Unit Input) Check .......127

Key Switch (BCM Input) Check .............................128

Ignition Knob Switch Check ................................. ..129

Door Switch Check (Hatchback) ............................131

Door Switch Check (Sedan) ..................................134

Door Request Switch Check ..................................135

Back Door Request Switch Check (Hatchback) ....137

Trunk Opener Request Switch Check (Sedan) ... ..138

Unlock Sensor Check ............................................140

Intelligent Key Warning Buzzer(s) Check ..............142

Outside Key Antenna (Dri ver Side and Passenger

Side) Check ......................................................... ..

143

Outside Key Antenna (Rear Bumper) Check .........144

Inside Key Antenna Check ....................................146

Steering Lock Solenoid Check ............................ ..147

Key Interlock Solenoid (With M/T) Check ..............149

Ignition Switch Position Check ............................ ..150

Stop Lamp Switch Check (With CVT or A/T) ....... ..150

Stop Lamp Switch Check (With M/T) .....................152

CVT or A/T Shift Selector (Park Position Switch)

Check .................................................................. ..

153

"P-SHIFT" Warning Lamp (With CVT or A/T)

Check ....................................................................

154

"LOCK" Warning Lamp (With M/T) Check .............155

"KEY" Warning Lamp (RED) Check ......................155

"KEY" Warning Lamp (G REEN) Check .................155

Check Warning Chime in Combination Meter ........156

Hazard Function Check .........................................156

Horn Function Check .... .........................................157

Headlamp Function Chec k ....................................157

Intelligent Key Battery Re placement .....................158

Remote Keyless Entry Func tion ............................158

Removal and Installation of Intelligent Key Unit ... .158

DOOR ...............................................................160

Fitting Adjustment ................................................ .160

Removal and Installation .......................................163

Back Door Stay Disposal ..................................... .166

FRONT DOOR LOCK .......................................167

Component Parts Location .................................. .167

Removal and Installation .......................................167

REAR DOOR LOCK ....................................... ..170

Component Parts Location .................................. .170

Removal and Installation .......................................170

BACK DOOR LOCK ....................................... ..173

Component Parts and Harness Connector Loca-

tion ....................................................................... .

173

System Description ...............................................173

Wiring Diagram - B/DOOR - ..................................174

Terminal and Reference Value for BCM ...............176

Terminal and Reference Value for Intelligent Key

Unit ....................................................................... .

180

CONSULT-III Function (BCM) ..............................182

Work Flow .............................................................183

Trouble Diagnosis Chart by Symptom ..................183

BCM Power Supply and Ground Circuit Inspection

.

183

Check Back Door Opener Switch Circuit (Without

Intelligent Key or Power Windows) ...................... .

184

Check Back Door Opener Switch Circuit (Without

Intelligent Key, with Power Windows) .................. .

187

Check Back Door Opener Switch Circuit (With In-

telligent Key) ........................................................ .

189

Check Back Door Lock Assembly (Actuator) Cir-

cuit ........................................................................

191

Removal and Installation .......................................193

TRUNK LID ..................................................... ..195

Fitting Adjustment ................................................ .195

Trunk Lid Assembly ..............................................195

Trunk Lid Lock ......................................................196

Trunk Lid Striker ....................................................196

TRUNK LID OPENER .......................................198

Component Parts and Harness Connector Loca-

tion ....................................................................... .

198

System Description ...............................................198

Wiring Diagram - TLID - ........................................199

Terminal and Reference Value for BCM ...............201

Terminal and Reference Value for Intelligent Key

Unit ....................................................................... .

205

CONSULT-III Function (BCM) ..............................207

Work Flow .............................................................208

Trouble Diagnosis Chart by Symptom ..................208

BCM Power Supply and Ground Circuit Inspection

.

208

Revision: May 2010 2011 Versa

Page 568 of 3787

BL-58

< SERVICE INFORMATION >

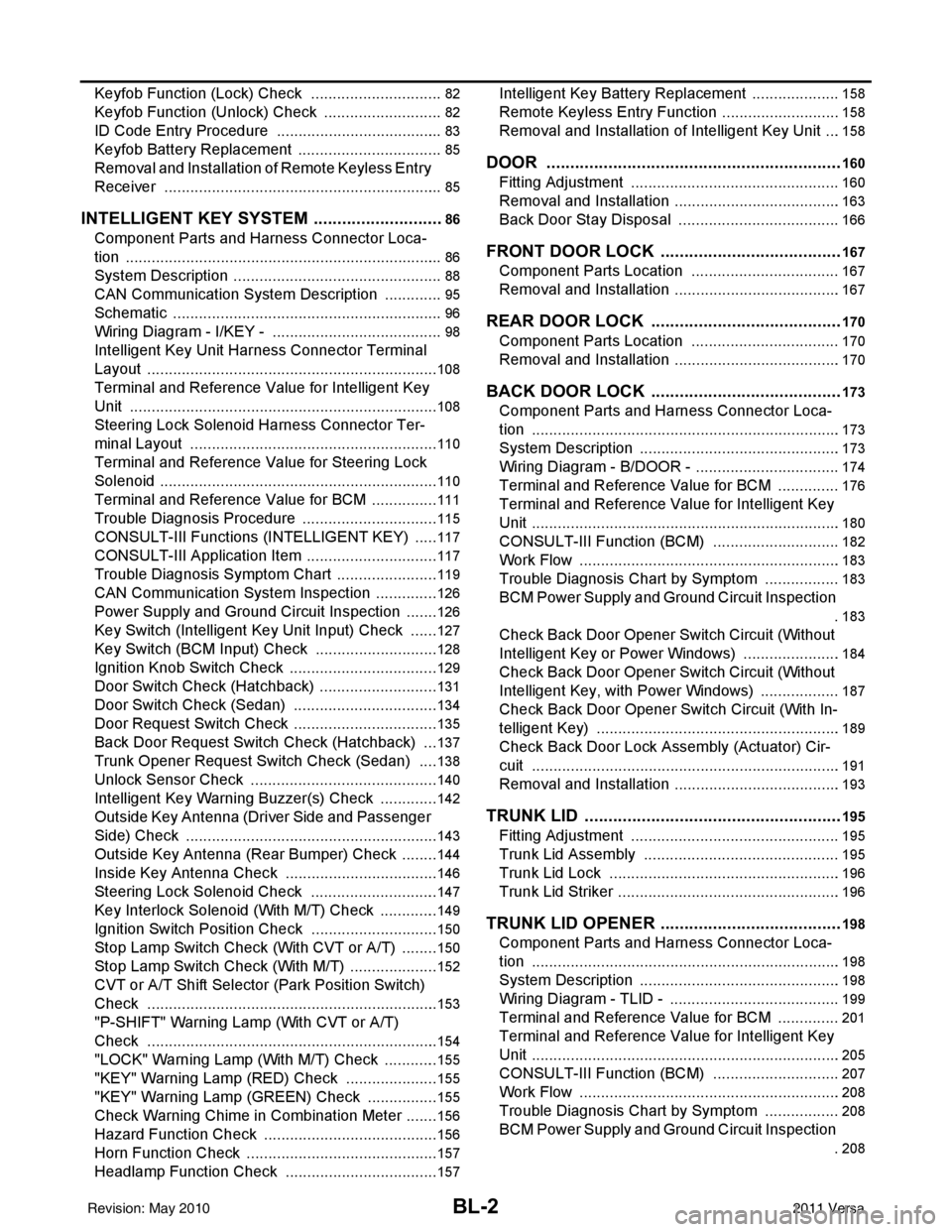

REMOTE KEYLESS ENTRY SYSTEM

REMOTE KEYLESS ENTRY SYSTEM

Component Parts and Harness Connector LocationINFOID:0000000005929302

System DescriptionINFOID:0000000005929303

INPUTS

Power is supplied at all times

• through 40A fusible link (letter g , located in the fuse and fusible link box)

• to BCM terminal 70

• through 10A fuse [No. 8, located in the fuse block (J/B)]

• to BCM terminal 57.

When the key switch is ON (key is inserted in ignition key cylinder), power is supplied

ALKIA1754ZZ

1. BCM M18, M19, M20

(view with glove box removed) 2. Remote keyless entry receiver M23 3. Horn relay H-1

(front of battery)

4. IPDM E/R E46, E48 5. Front door switch LH B8, RH B108 6. Rear door switch LH B6, RH B116

7. Back door lock assembly (back door switch) D405 (hatchback view with

back door open) 8. Key switch and key lock solenoid

M27 9. Horn E18, E20

Revision: May 2010

2011 Versa

Page 812 of 3787

BL-302

< SERVICE INFORMATION >

BODY REPAIR

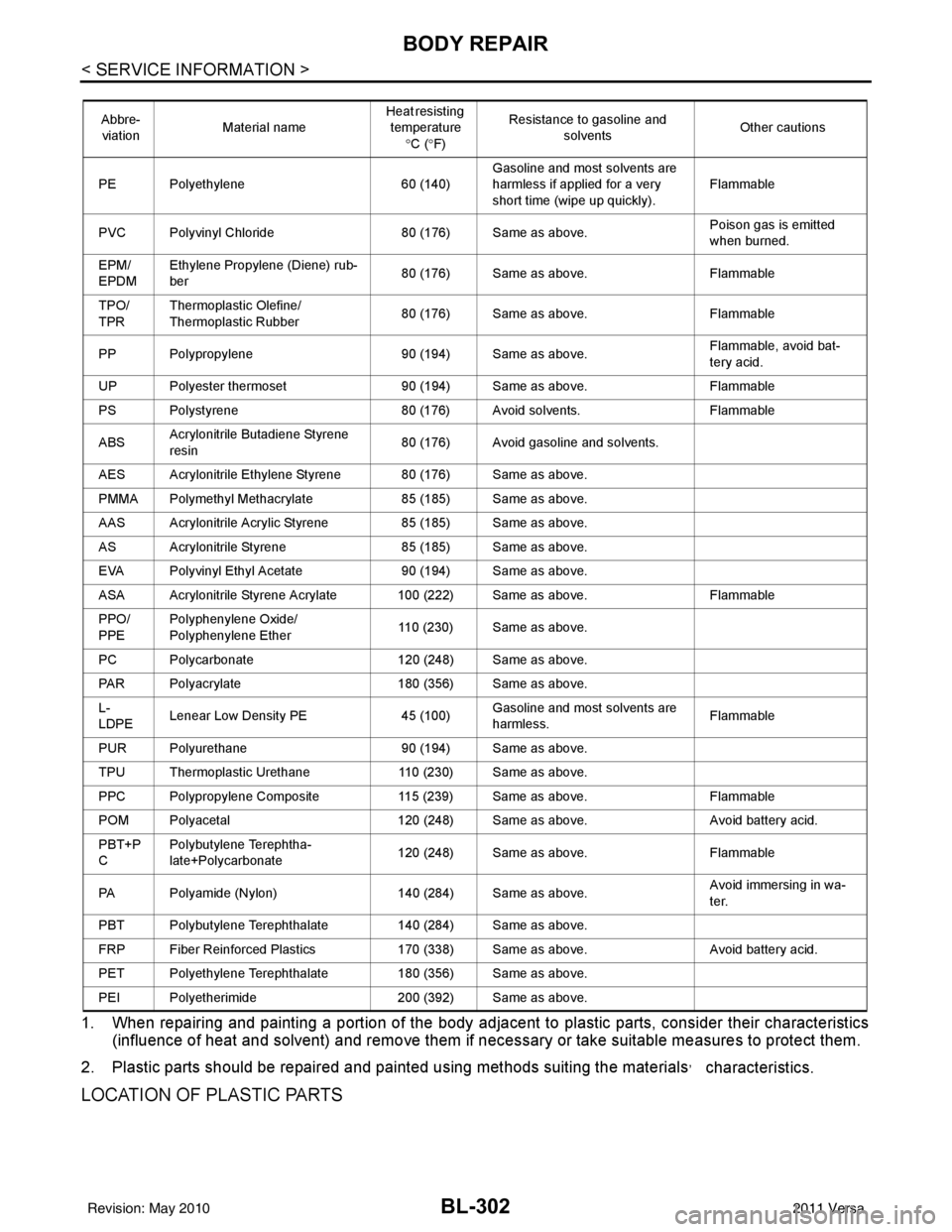

1. When repairing and painting a portion of the body adjacent to plastic parts, consider their characteristics

(influence of heat and solvent) and remove them if neces sary or take suitable measures to protect them.

2. Plastic parts should be repaired and painted using methods suiting the materials

, characteristics.

LOCATION OF PLASTIC PARTS

Abbre- viation Material name Heat resisting

temperature °C ( °F) Resistance to gasoline and

solvents Other cautions

PE Polyethylene 60 (140)Gasoline and most solvents are

harmless if applied for a very

short time (wipe up quickly). Flammable

PVC Polyvinyl Chloride 80 (176) Same as above. Poison gas is emitted

when burned.

EPM/

EPDM Ethylene Propylene (Diene) rub-

ber

80 (176) Same as above.

Flammable

TPO/

TPR Thermoplastic Olefine/

Thermoplastic Rubber

80 (176) Same as above.

Flammable

PP Polypropylene 90 (194) Same as above. Flammable, avoid bat-

tery acid.

UP Polyester thermoset 90 (194) Same as above. Flammable

PS Polystyrene 80 (176) Avoid solvents. Flammable

ABS Acrylonitrile Butadiene Styrene

resin

80 (176) Avoid gasoline and solvents.

AES Acrylonitrile Ethylene Styrene 80 (176) Same as above.

PMMA Polymethyl Methacrylate 85 (185) Same as above.

AAS Acrylonitrile Acrylic Styrene 85 (185) Same as above.

AS Acrylonitrile Styrene 85 (185) Same as above.

EVA Polyvinyl Ethyl Acetate 90 (194) Same as above.

ASA Acrylonitrile Styrene Acrylate 100 (222) Same as above. Flammable

PPO/

PPE Polyphenylene Oxide/

Polyphenylene Ether

110 (230) Same as above.

PC Polycarbonate 120 (248) Same as above.

PAR Polyacrylate 180 (356) Same as above.

L-

LDPE Lenear Low Density PE

45 (100)Gasoline and most solvents are

harmless. Flammable

PUR Polyurethane 90 (194) Same as above.

TPU Thermoplastic Urethane 110 (230) Same as above.

PPC Polypropylene Composite 115 (239) Same as above. Flammable

POM Polyacetal 120 (248) Same as above. Avoid battery acid.

PBT+P

C Polybutylene Terephtha-

late+Polycarbonate

120 (248) Same as above.

Flammable

PA Polyamide (Nylon) 140 (284) Same as above. Avoid immersing in wa-

ter.

PBT Polybutylene Terephthalate 140 (284) Same as above.

FRP Fiber Reinforced Plastics 170 (338) Same as above. Avoid battery acid.

PET Polyethylene Terephthalate 180 (356) Same as above.

PEI Polyetherimide 200 (392) Same as above.

Revision: May 2010 2011 Versa

Page 1028 of 3787

![NISSAN TIIDA 2011 Service Repair Manual CO-28

< SERVICE INFORMATION >[MR18DE]

PRECAUTIONS

5. When the repair work is completed, return the ignition switch to the

″LOCK ″ position before connecting

the battery cables. (At this time, the NISSAN TIIDA 2011 Service Repair Manual CO-28

< SERVICE INFORMATION >[MR18DE]

PRECAUTIONS

5. When the repair work is completed, return the ignition switch to the

″LOCK ″ position before connecting

the battery cables. (At this time, the](/img/5/57396/w960_57396-1027.png)

CO-28

< SERVICE INFORMATION >[MR18DE]

PRECAUTIONS

5. When the repair work is completed, return the ignition switch to the

″LOCK ″ position before connecting

the battery cables. (At this time, the steering lock mechanism will engage.)

6. Perform a self-diagnosis check of a ll control units using CONSULT-III.

Precaution for Liquid GasketINFOID:0000000005930801

REMOVAL OF LIQUID GASKET SEALING

• After removing nuts and bolts, separate the mating surface, using Tool and remove old liquid gasket sealing.

CAUTION:

Be careful not to damage the mating surfaces.

• Tap Tool to insert it (1), and then slide it by tapping on the side (2)

as shown.

• In areas where Tool is difficult to use, use plastic hammer to lightly tap the parts, to remove it.

CAUTION:

If for some unavoidable reason suitable tool such as screw-

driver is used, be careful no t to damage the mating surfaces.

LIQUID GASKET APPLICATION PROCEDURE

1. Remove old liquid gasket adhering to the liquid gasket applica-

tion surface and the mating surface, using scraper.

• Remove liquid gasket completely from the groove of the liquid

gasket application surface, bolts, and bolt holes.

2. Thoroughly clean the mating surfaces and remove adhering moisture, grease and foreign materials.

3. Attach liquid gasket tube to Tool.

Use Genuine RTV Silicone Seal ant or equivalent. Refer to GI-42, "

Recommended Chemical Prod-

uct and Sealant".

4. Apply liquid gasket without breaks to the specif ied location with the specified dimensions.

• If there is a groove for the liquid gasket application, apply liquid gasket to the groove. Tool number : KV10111100 (J-37228)

WBIA0566E

Tool number : WS39930000 ( — )

PBIC0003E

WBIA0567E

Revision: May 2010

2011 Versa

Page 1056 of 3787

CVT-1

TRANSMISSION/TRANSAXLE

DE

F

G H

I

J

K L

M

SECTION CVT

A

B

CVT

N

O P

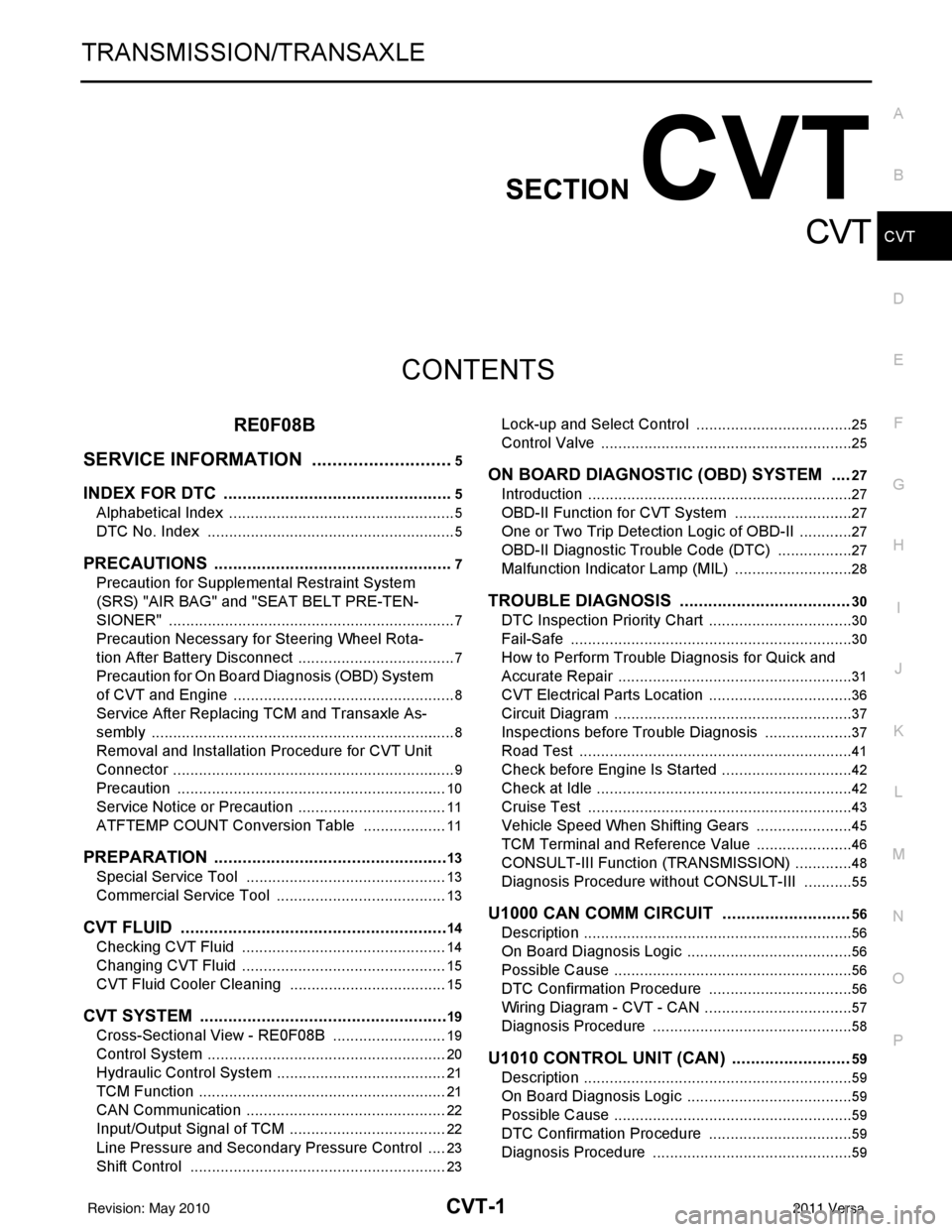

CONTENTS

CVT

RE0F08B

SERVICE INFORMATION .. ..........................

5

INDEX FOR DTC ............................................ .....5

Alphabetical Index ............................................... ......5

DTC No. Index ..........................................................5

PRECAUTIONS ...................................................7

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

7

Precaution Necessary for Steering Wheel Rota-

tion After Battery Disconnect ............................... ......

7

Precaution for On Board Diagnosis (OBD) System

of CVT and Engine ....................................................

8

Service After Replacing TCM and Transaxle As-

sembly .......................................................................

8

Removal and Installation Procedure for CVT Unit

Connector ............................................................ ......

9

Precaution ...............................................................10

Service Notice or Precaution ...................................11

ATFTEMP COUNT Conversion Table ....................11

PREPARATION .............................................. ....13

Special Service Tool ........................................... ....13

Commercial Service Tool ........................................13

CVT FLUID .........................................................14

Checking CVT Fluid ............................................ ....14

Changing CVT Fluid ................................................15

CVT Fluid Cooler Cleaning .....................................15

CVT SYSTEM ................................................. ....19

Cross-Sectional View - RE0F08B ....................... ....19

Control System .................................................... ....20

Hydraulic Control System ........................................21

TCM Function ...................................................... ....21

CAN Communication ...............................................22

Input/Output Signal of TCM .....................................22

Line Pressure and Secondary Pressure Control .....23

Shift Control ............................................................23

Lock-up and Select Control .....................................25

Control Valve ....................................................... ....25

ON BOARD DIAGNOSTIC (OBD) SYSTEM ....27

Introduction ..............................................................27

OBD-II Function for CVT System ............................27

One or Two Trip Detection Logic of OBD-II .............27

OBD-II Diagnostic Trouble Code (DTC) ..................27

Malfunction Indicator Lamp (MIL) ............................28

TROUBLE DIAGNOSIS ....................................30

DTC Inspection Priority Chart ..................................30

Fail-Safe ..................................................................30

How to Perform Trouble Diagnosis for Quick and

Accurate Repair .......................................................

31

CVT Electrical Parts Location ..................................36

Circuit Diagram ........................................................37

Inspections before Trouble Diagnosis .....................37

Road Test ................................................................41

Check before Engine Is Started ...............................42

Check at Idle ............................................................42

Cruise Test ..............................................................43

Vehicle Speed When Shifting Gears .......................45

TCM Terminal and Reference Value .......................46

CONSULT-III Function (TRANSMISSION) .......... ....48

Diagnosis Procedure without CONSULT-III ............55

U1000 CAN COMM CIRCUIT ...........................56

Description ........................................................... ....56

On Board Diagnosis Logic .......................................56

Possible Cause ........................................................56

DTC Confirmation Procedure ..................................56

Wiring Diagram - CVT - CAN ...................................57

Diagnosis Procedure ...............................................58

U1010 CONTROL UNIT (CAN) .........................59

Description ...............................................................59

On Board Diagnosis Logic .......................................59

Possible Cause ........................................................59

DTC Confirmation Procedure ..................................59

Diagnosis Procedure ...............................................59

Revision: May 2010 2011 Versa

Page 1647 of 3787

![NISSAN TIIDA 2011 Service Repair Manual P0506 ISC SYSTEMEC-353

< COMPONENT DIAGNOSIS > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

P0506 ISC SYSTEM

DescriptionINFOID:0000000005930017

The ECM controls the engine idle speed to a specified level NISSAN TIIDA 2011 Service Repair Manual P0506 ISC SYSTEMEC-353

< COMPONENT DIAGNOSIS > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

P0506 ISC SYSTEM

DescriptionINFOID:0000000005930017

The ECM controls the engine idle speed to a specified level](/img/5/57396/w960_57396-1646.png)

P0506 ISC SYSTEMEC-353

< COMPONENT DIAGNOSIS > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

P0506 ISC SYSTEM

DescriptionINFOID:0000000005930017

The ECM controls the engine idle speed to a specified level through the fine adjustment of the air, which is let

into the intake manifold, by operating the electric thrott

le control actuator. The operating of the throttle valve is

varied to allow for optimum control of the engine idli ng speed. The crankshaft position sensor (POS) detects

the actual engine speed and sends a signal to the ECM.

The ECM controls the electric throttle control actuator so that the engine speed coincides with the target value

memorized in the ECM. The target engine speed is the lowest speed at which the engine can operate steadily.

The optimum value stored in the ECM is determined by taking into consideration various engine conditions,

such as during warming up, deceleration, and engine load (air conditioner, power steering and cooling fan

operation, etc.).

DTC LogicINFOID:0000000005930018

DTC DETECTION LOGIC

NOTE:

If DTC P0506 is displayed with ot her DTC, first perform the trouble diagnosis for the other DTC.

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If DTC Confirmation Procedure has been previously conducted, always turn ignition switch OFF and wait at

least 10 seconds before conducting the next test.

If the target idle speed is ou t of the specified value, perform EC-26, "

IDLE AIR VOLUME LEARNING :

Special Repair Requirement", before conducting DTC Confirmation Procedure.

TESTING CONDITION:

• Before performing the following procedure, confirm that battery voltage is more than 11 V at idle.

• Always perform the test at a temperature above −10° C(14° F).

>> GO TO 2.

2.PERFORM DTC CONFIRMATION PROCEDURE

1. Start engine and warm it up to normal operating temperature.

2. Turn ignition switch OFF and wait at least 10 seconds.

3. Start engine and run it for at least 1 minute at idle speed.

4. Check 1st trip DTC.

Is 1st trip DTC detected?

YES >> Go to EC-353, "Diagnosis Procedure".

NO >> INSPECTION END

Diagnosis ProcedureINFOID:0000000005930019

1.CHECK INTAKE AIR LEAK

1. Start engine and let it idle.

2. Listen for an intake air leak after the mass air flow sensor.

Is intake air leak detected?

YES >> Discover air leak location and repair.

NO >> GO TO 2.

2.REPLACE ECM

1. Stop engine.

2. Replace ECM.

DTC No. Trouble diagnosis name DTC detecting conditionPossible cause

P0506 Idle speed control system

RPM lower than expected The idle speed is less than the target idle

speed by 100 rpm or more. • Electric throttle control actuator

• Intake air leak

Revision: May 2010

2011 Versa

Page 1940 of 3787

![NISSAN TIIDA 2011 Service Repair Manual EC-646

< SERVICE INFORMATION >[MR18DE]

DTC P0011 IVT CONTROL

On Board Diagn osis Logic

INFOID:0000000006341768

FA I L - S A F E M O D E

ECM enters in fail-safe mode when the malfunction is detected.

NISSAN TIIDA 2011 Service Repair Manual EC-646

< SERVICE INFORMATION >[MR18DE]

DTC P0011 IVT CONTROL

On Board Diagn osis Logic

INFOID:0000000006341768

FA I L - S A F E M O D E

ECM enters in fail-safe mode when the malfunction is detected.](/img/5/57396/w960_57396-1939.png)

EC-646

< SERVICE INFORMATION >[MR18DE]

DTC P0011 IVT CONTROL

On Board Diagn osis Logic

INFOID:0000000006341768

FA I L - S A F E M O D E

ECM enters in fail-safe mode when the malfunction is detected.

DTC Confirmation ProcedureINFOID:0000000006341769

CAUTION:

Always drive at a safe speed.

NOTE:

•If DTC P0011 is displayed with DTC P0075, first perform trouble diagnosis for DTC P0075.

See EC-659

.

• If DTC Confirmation Procedure has been previously conducted, always turn ignition switch OFF and wait at

least 10 seconds before conducting the next test.

TESTING CONDITION:

Before performing the following procedure, confi rm that battery voltage is between 10 V and 16 V at

idle.

WITH CONSULT-III

1. Turn ignition switch ON and select “DATA MONITOR” mode with CONSULT-III.

2. Start engine and warm it up to the normal operating temperature.

3. Maintain the following conditions for at least 6 consecutive seconds. Hold the accelerator pedal as steady as possible.

4. Let engine idle for 10 seconds.

5. If 1st trip DTC is detected, go to EC-647, "

Diagnosis Procedure".

If 1st trip DTC is not detected, go to next step.

6. Maintain the following conditions for at least 10 consecutive seconds.

7. If 1st trip DTC is detected, go to EC-647, "

Diagnosis Procedure".

DTC No. Trouble diagnosis name DTC detecting condition Possible cause

P0011

0011 Intake valve timing control

performance There is a gap between angle of target and

phase-control angle degree. • Crankshaft position sensor (POS)

• Camshaft position

sensor (PHASE)

• Intake valve timing control solenoid valve

• Accumulation of debris to the signal pick-up portion of the camshaft

• Timing chain installation

• Foreign matter caught in the oil groove for in- take valve timing control

Detected items Engine operating condition in fail-safe mode

Intake valve timing control The signal is not energized to the solenoid valve and the valve control does not function

ENG SPEED1,200 - 2,000 rpm (A constant rotati on is maintained.)

COOLAN TEMP/S More than 60 °C (140 °F)

B/FUEL SCHDL More than 3.87 msec

Shift lever P or N position (A/T, CVT)

Neutral position (M/T)

ENG SPEED 1,200 - 3,175 rpm (A constant rotation is maintained.)

COOLAN TEMP/S More than 65 °C (149 °F)

Shift lever 1st or 2nd position

Driving location Driving vehicle uphill

(Increased engine load will help maintain the driving

conditions required for this test.)

Revision: May 2010

2011 Versa

Page 2183 of 3787

![NISSAN TIIDA 2011 Service Repair Manual DTC P0506 ISC SYSTEMEC-889

< SERVICE INFORMATION > [MR18DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

DTC P0506 ISC SYSTEM

DescriptionINFOID:0000000006342064

NOTE:

If DTC P0506 is displayed with ot

her DTC, fir NISSAN TIIDA 2011 Service Repair Manual DTC P0506 ISC SYSTEMEC-889

< SERVICE INFORMATION > [MR18DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

DTC P0506 ISC SYSTEM

DescriptionINFOID:0000000006342064

NOTE:

If DTC P0506 is displayed with ot

her DTC, fir](/img/5/57396/w960_57396-2182.png)

DTC P0506 ISC SYSTEMEC-889

< SERVICE INFORMATION > [MR18DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

DTC P0506 ISC SYSTEM

DescriptionINFOID:0000000006342064

NOTE:

If DTC P0506 is displayed with ot

her DTC, first perform the trouble diagnosis for the other DTC.

The ECM controls the engine idle speed to a specified level through the fine adjustment of the air, which is let

into the intake manifold, by operating the electric thrott le control actuator. The operating of the throttle valve is

varied to allow for optimum control of the engine id ling speed. The ECM calculates the actual engine speed

from signals of crankshaft position sensor (POS) and camshaft position sensor (PHASE).

The ECM controls the electric throttle control actuator so that the engine speed coincides with the target value

memorized in the ECM. The target engine speed is the lowest speed at which the engine can operate steadily.

The optimum value stored in the ECM is determined by taking into consideration various engine conditions,

such as during warming up, deceleration, and engine load (air conditioner, power steering and cooling fan

operation, etc.).

On Board Diagnosis LogicINFOID:0000000006342065

DTC Confirmation ProcedureINFOID:0000000006342066

NOTE:

• If DTC Confirmation Procedure has been previously conduc ted, always turn ignition switch OFF and wait at

least 10 seconds before conducting the next test.

• If the target idle speed is ou t of the specified value, perform EC-580, "

Idle Air Volume Learning",

before conducting DTC Confirmation Procedure. For the target idle speed, refer to the EC-1035

.

TESTING CONDITION:

• Before performing the following procedure, confirm that battery voltage is more than 11 V at idle.

• Always perform the test at a temperature above −10° C (14° F).

1. Open engine hood.

2. Start engine and warm it up to normal operating temperature.

3. Turn ignition switch OFF and wait at least 10 seconds.

4. Start engine and run it for at least 1 minute at idle speed.

5. Check 1st trip DTC.

6. If 1st trip DTC is detected, go to EC-889, "

Diagnosis Procedure".

Diagnosis ProcedureINFOID:0000000006342067

1.CHECK INTAKE AIR LEAK

1. Start engine and let it idle.

2. Listen for an intake air leak after the mass air flow sensor.

OK or NG

OK >> GO TO 2.

NG >> Discover air leak location and repair.

2.REPLACE ECM

1. Stop engine.

2. Replace ECM.

3. Perform initialization of NVIS (NATS) system and registration of all NVIS (NATS) ignition key IDs.

Refer to BL-247, "

ECM Re-communicating Function".

4. Perform EC-580, "

VIN Registration".

5. Perform EC-580, "

Accelerator Pedal Released Position Learning".

6. Perform EC-580, "

Throttle Valve Closed Position Learning".

DTC No. Trouble diagnosis name DTC detecting condition Possible cause

P0506

0506 Idle speed control sys-

tem RPM lower than ex-

pected The idle speed is less than the target idle speed

by 100 rpm or more.

• Electric throttle control actuator

• Intake air leak

Revision: May 2010

2011 Versa