belt NISSAN TIIDA 2011 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2011, Model line: TIIDA, Model: NISSAN TIIDA 2011Pages: 3787, PDF Size: 78.35 MB

Page 1 of 3787

-1

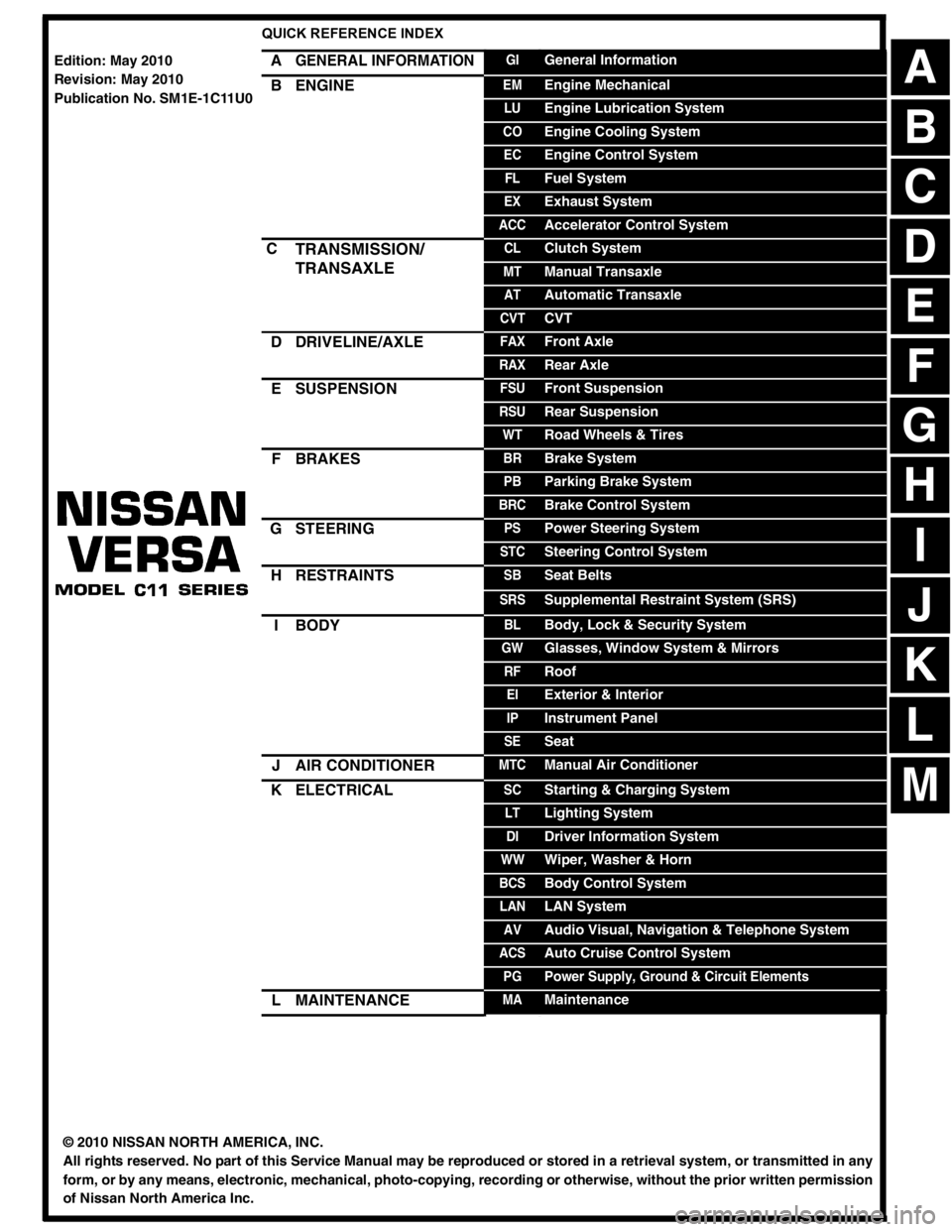

QUICK REFERENCE INDEX

AGENERAL INFORMATIONGIGeneral Information

BENGINEEMEngine Mechanical

LUEngine Lubrication System

COEngine Cooling System

ECEngine Control System

FLFuel System

EXExhaust System

ACCAccelerator Control System

CTRANSMISSION/

TRANSAXLECLClutch System

MTManual Transaxle

ATAutomatic Transaxle

CVTCVT

DDRIVELINE/AXLEFAXFront Axle

RAXRear Axle

ESUSPENSIONFSUFront Suspension

RSURear Suspension

WTRoad Wheels & Tires

FBRAKESBRBrake System

PBParking Brake System

BRCBrake Control System

GSTEERINGPSPower Steering System

STCSteering Control System

HRESTRAINTSSBSeat Belts

SRSSupplemental Restraint System (SRS)

IBODYBLBody, Lock & Security System

GWGlasses, Window System & Mirrors

RFRoof

EIExterior & Interior

IPInstrument Panel

SESeat

JAIR CONDITIONERMTCManual Air Conditioner

KELECTRICALSCStarting & Charging System

LTLighting System

DIDriver Information System

WWWiper, Washer & Horn

BCSBody Control System

LANLAN System

AVAudio Visual, Navigation & Telephone System

ACSAuto Cruise Control System

PGPower Supply, Ground & Circuit Elements

LMAINTENANCEMAMaintenance

Edition: May 2010

Revision: May 2010

Publication No. SM1E-1C11U0

B

D

© 2010 NISSAN NORTH AMERICA, INC.

All rights reserved. No part of this Service Manual may be reproduced or stored in a retrieval system, or transmitted in any

form, or by any means, electronic, mechanical, photo-copying, recording or otherwise, without the prior written permission

of Nissan North America Inc.

A

C

E

F

G

H

I

J

K

L

M

Page 4 of 3787

2011

QUICK REFERENCE INDEX: VERSA

QUICK REFERENCE INDEX: VERSA

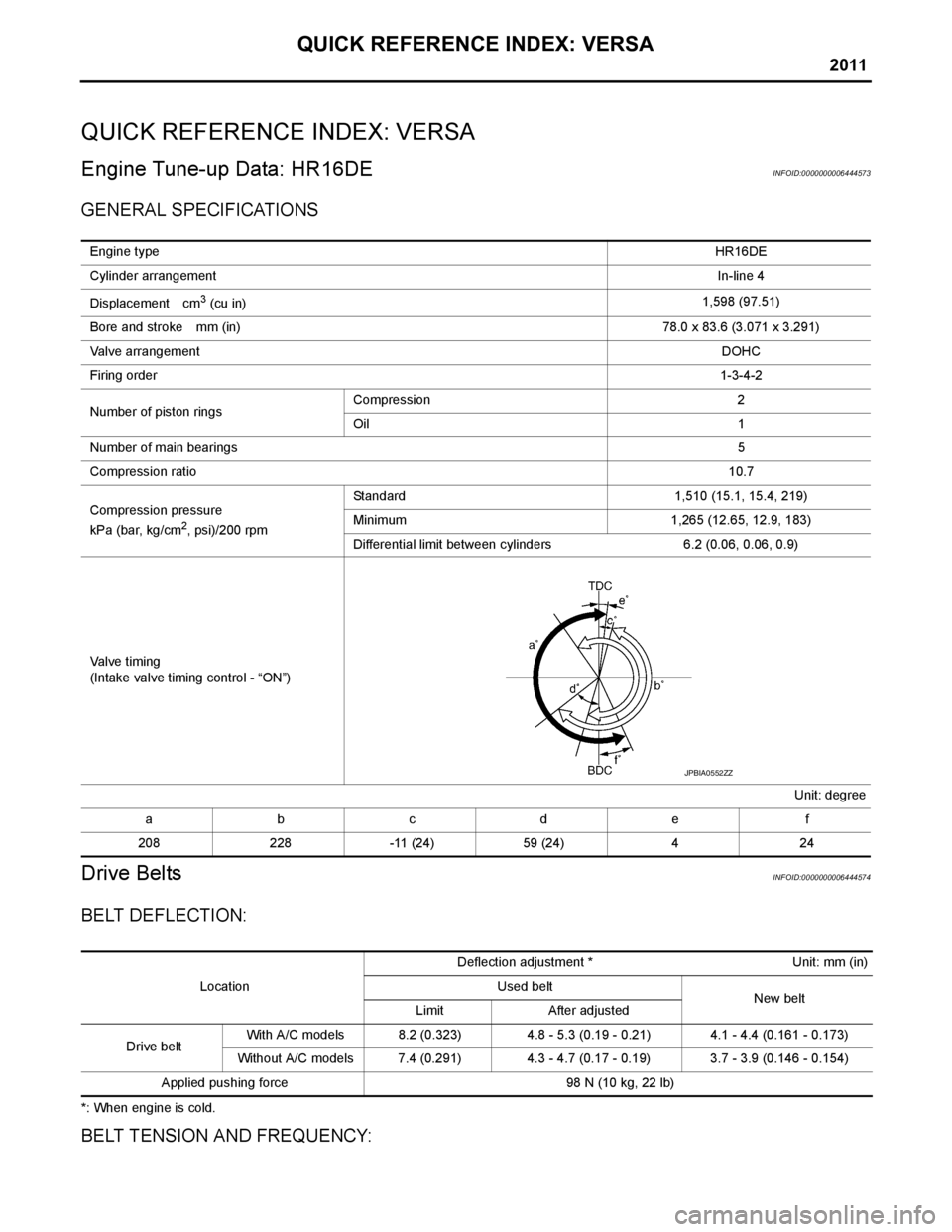

Engine Tune-up Data: HR16DEINFOID:0000000006444573

GENERAL SPECIFICATIONS

Drive BeltsINFOID:0000000006444574

BELT DEFLECTION:

*: When engine is cold.

BELT TENSION AND FREQUENCY:

Engine typeHR16DE

Cylinder arrangement In-line 4

Displacement cm

3 (cu in) 1,598 (97.51)

Bore and stroke mm (in) 78.0 x 83.6 (3.071 x 3.291)

Valve arrangement DOHC

Firing order 1-3-4-2

Number of piston rings Compression

2

Oil 1

Number of main bearings 5

Compression ratio 10.7

Compression pressure

kPa (bar, kg/cm

2, psi)/200 rpm Standard 1,510 (15.1, 15.4, 219)

Minimum

1,265 (12.65, 12.9, 183)

Differential limit between cylinders 6.2 (0.06, 0.06, 0.9)

Valve timing

(Intake valve timing control - “ON”) Unit: degree

abcde f

208 228-11 (24) 59 (24) 424

JPBIA0552ZZ

Location Deflection adjustment *

Unit: mm (in)

Used belt New belt

Limit After adjusted

Drive belt With A/C models 8.2 (0.323) 4.8 - 5.3 (0.19 - 0.21) 4.1 - 4.4 (0.161 - 0.173)

Without A/C models 7.4 (0.291) 4.3 - 4.7 (0.17 - 0.19) 3.7 - 3.9 (0.146 - 0.154)

Applied pushing force 98 N (10 kg, 22 lb)

Page 5 of 3787

QUICK REFERENCE INDEX: VERSA

2011

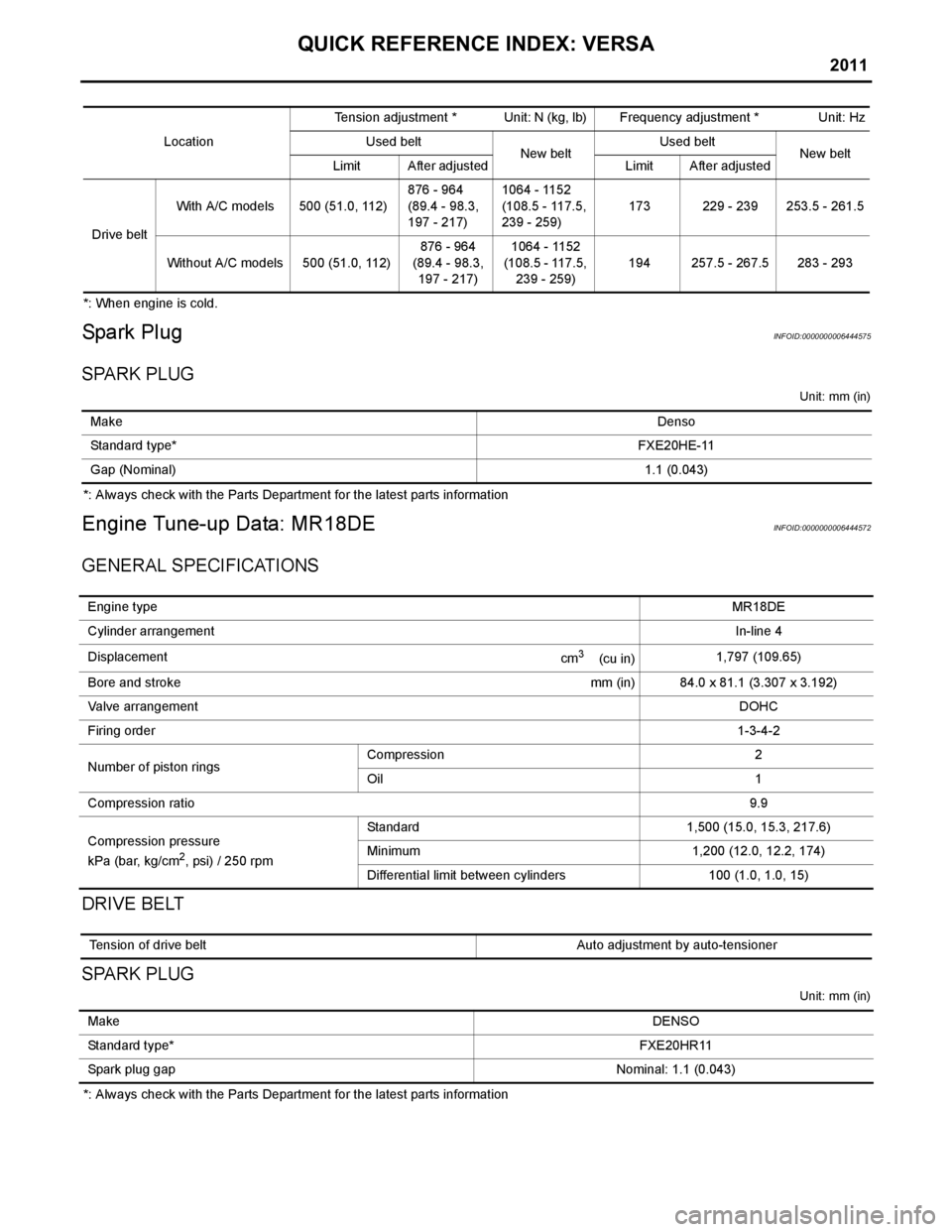

*: When engine is cold.

Spark PlugINFOID:0000000006444575

SPARK PLUG

Unit: mm (in)

*: Always check with the Parts Department for the latest parts information

Engine Tune-up Data: MR18DEINFOID:0000000006444572

GENERAL SPECIFICATIONS

DRIVE BELT

SPARK PLUG

Unit: mm (in)

*: Always check with the Parts Department for the latest parts informationLocation

Tension adjustment * Unit: N (kg, lb) Frequency adjustment * Unit: Hz

Used belt New beltUsed belt

New belt

Limit After adjusted Limit After adjusted

Drive belt With A/C models 500 (51.0, 112)

876 - 964

(89.4 - 98.3,

197 - 217)1064 - 1152

(108.5 - 117.5,

239 - 259)

173 229 - 239 253.5 - 261.5

Without A/C models 500 (51.0, 112) 876 - 964

(89.4 - 98.3, 197 - 217) 1064 - 1152

(108.5 - 117.5, 239 - 259) 194 257.5 - 267.5 283 - 293

Make

Denso

Standard type* FXE20HE-11

Gap (Nominal) 1.1 (0.043)

Engine type MR18DE

Cylinder arrangement In-line 4

Displacement cm

3 (cu in)1,797 (109.65)

Bore and stroke mm (in) 84.0 x 81.1 (3.307 x 3.192)

Valve arrangement DOHC

Firing order 1-3-4-2

Number of piston rings Compression

2

Oil 1

Compression ratio 9.9

Compression pressure

kPa (bar, kg/cm

2, psi) / 250 rpm Standard 1,500 (15.0, 15.3, 217.6)

Minimum

1,200 (12.0, 12.2, 174)

Differential limit between cylinders 100 (1.0, 1.0, 15)

Tension of drive belt Auto adjustment by auto-tensioner

Make DENSO

Standard type* FXE20HR11

Spark plug gap Nominal: 1.1 (0.043)

Page 12 of 3787

ACC-1

ENGINE

C

DE

F

G H

I

J

K L

M

SECTION ACC

A

ACC

N

O P

CONTENTS

ACCELERATOR CONTROL SYSTEM

SERVICE INFORMATION .. ..........................2

PRECAUTIONS .............................................. .....2

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

2

Precaution Necessary for Steering Wheel Rota-

tion After Battery Disconnect ............................... .....

2

ACCELERATOR CONTROL SYSTEM ..............4

Component ...............................................................4

Removal and Installation ..........................................4

Revision: May 2010 2011 Versa

Page 13 of 3787

ACC-2

< SERVICE INFORMATION >

PRECAUTIONS

SERVICE INFORMATION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000006405207

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and w hether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SRS and SB section of this Service Man-

ual.

WARNING:

• To avoid rendering the SRS inopera tive, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including incorrect removal and installation of the SRS can lead to personal

injury caused by unintent ional activation of the system. For re moval of Spiral Cable and Air Bag

Module, see the SRS section.

• Do not use electrical test equipmen t on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harn esses can be identified by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Unit or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or electri c power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers , always switch the Ignition OFF, disconnect the

battery, and wait at least 3 minu tes before performing any service.

Precaution Necessary for Steering W heel Rotation After Battery Disconnect

INFOID:0000000005928708

NOTE:

• This Procedure is applied only to models with Intelligent Key system and NATS (NISSAN ANTI-THEFT SYS-

TEM).

• Remove and install all control units after disconnecting both battery cables with the ignition knob in the

″LOCK ″ position.

• Always use CONSULT-III to perform self-diagnosis as a part of each function inspection after finishing work.

If DTC is detected, perform trouble diagnosis according to self-diagnostic results.

For models equipped with the Intelligent Key system and NATS, an electrically controlled steering lock mech-

anism is adopted on the key cylinder.

For this reason, if the battery is disconnected or if the battery is discharged, the steering wheel will lock and

steering wheel rotation will become impossible.

If steering wheel rotation is required when battery pow er is interrupted, follow the procedure below before

starting the repair operation.

OPERATION PROCEDURE

1. Connect both battery cables. NOTE:

Supply power using jumper cables if battery is discharged.

2. Use the Intelligent Key or mechanical key to turn the ignition switch to the ″ACC ″ position. At this time, the

steering lock will be released.

3. Disconnect both battery cables. The steering lock will remain released and the steering wheel can be rotated.

4. Perform the necessary repair operation.

Revision: May 2010 2011 Versa

Page 16 of 3787

ACS-1

ELECTRICAL

C

DE

F

G H

I

J

L

M

SECTION ACS

A

B

ACS

N

O P

CONTENTS

AUTO CRUISE CONTROL SYSTEM

SERVICE INFORMATION .. ..........................2

AUTOMATIC SPEED CONTROL DEVICE

(ASCD) ........................................................... .....

2

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. .....

2

Description ................................................................2

Revision: May 2010 2011 Versa

Page 17 of 3787

ACS-2

< SERVICE INFORMATION >

AUTOMATIC SPEED CONTROL DEVICE (ASCD)

SERVICE INFORMATION

AUTOMATIC SPEED CONTROL DEVICE (ASCD)

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000005929265

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and w hether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SRS and SB section of this Service Man-

ual.

WARNING:

• To avoid rendering the SRS inopera tive, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including incorrect removal and installation of the SRS can lead to personal

injury caused by unintent ional activation of the system. For re moval of Spiral Cable and Air Bag

Module, see the SRS section.

• Do not use electrical test equipmen t on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harn esses can be identified by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Unit or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or electri c power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers , always switch the Ignition OFF, disconnect the

battery, and wait at least 3 minu tes before performing any service.

DescriptionINFOID:0000000005929266

Regarding the information for ASCD system, refer to EC-523, "System Description".

Revision: May 2010 2011 Versa

Page 18 of 3787

AT-1

TRANSMISSION/TRANSAXLE

DE

F

G H

I

J

K L

M

SECTION AT

A

B

AT

N

O P

CONTENTS

AUTOMATIC TRANSAXLE

SERVICE INFORMATION .. ..........................5

INDEX FOR DTC ............................................ .....5

Alphabetical Index ............................................... ......5

DTC No. Index ..........................................................5

PRECAUTIONS ...................................................7

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

7

Precaution Necessary for Steering Wheel Rota-

tion After Battery Disconnect ............................... ......

7

Precaution for On Board Diagnosis (OBD) System

of A/T and Engine .....................................................

8

Precaution .................................................................8

Service Notice or Precaution .....................................9

PREPARATION ..................................................11

Special Service Tool ........................................... ....11

Commercial Service Tool ........................................14

A/T FLUID ...........................................................17

Checking A/T Fluid ..................................................17

Changing A/T Fluid .................................................17

A/T Fluid Cooler Cleaning .......................................18

A/T CONTROL SYSTEM ....................................21

Cross-Sectional View ..............................................21

Shift Mechanism .................................................. ....22

TCM Function ..........................................................30

CAN Communication ...............................................31

Input/Output Signal of TCM .....................................31

Line Pressure Control .............................................32

Shift Control ........................................................ ....33

Lock-up Control .......................................................34

Engine Brake Control (Overrun Clutch Control) ......35

Control Valve ....................................................... ....37

Centrifugal Cancel Mechanism ...............................37

ON BOARD DIAGNOSTIC (OBD) SYSTEM ......39

Introduction ......................................................... ....39

OBD-II Function for A/T System ..............................39

One or Two Trip Detection Logic of OBD-II ......... ....39

OBD-II Diagnostic Trouble Code (DTC) ..................39

Malfunction Indicator Lamp (MIL) ............................41

TROUBLE DIAGNOSIS ....................................42

DTC Inspection Priority Chart ..................................42

Fail-Safe ..................................................................42

How to Perform Trouble Diagnosis for Quick and

Accurate Repair .......................................................

43

A/T Electrical Parts Location ...................................49

Circuit Diagram ........................................................50

Inspections Before Trouble Diagnosis .....................51

Road Test ................................................................55

Check Before Engine Is Started ..............................56

Check at Idle ............................................................56

Cruise Test - Part 1 .................................................58

Cruise Test - Part 2 .................................................61

Cruise Test - Part 3 .................................................62

Vehicle Speed at Which Gear Shifting Occurs ........64

Vehicle Speed at Which Lock-up Occurs/Releas-

es .............................................................................

64

Symptom Chart ........................................................65

TCM Terminal and Reference Value .......................75

CONSULT-III Function (TRANSMISSION) .......... ....77

Diagnosis Procedure without CONSULT-III ............82

U1000 CAN COMM CIRCUIT ...........................87

Description ........................................................... ....87

On Board Diagnosis Logic .......................................87

Possible Cause ........................................................87

DTC Confirmation Procedure ..................................87

Wiring Diagram - AT - CAN .....................................88

Diagnosis Procedure ...............................................89

P0705 TRANSMISSION RANGE SWITCH A ...90

Description ...............................................................90

CONSULT-III Reference Value in Data Monitor

Mode .................................................................... ....

90

On Board Diagnosis Logic .......................................90

Possible Cause ........................................................90

DTC Confirmation Procedure ..................................90

Revision: May 2010 2011 Versa

Page 24 of 3787

PRECAUTIONSAT-7

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000006413332

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severi ty of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and w hether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SRS and SB section of this Service Man-

ual.

WARNING:

• To avoid rendering the SRS inoper ative, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including in correct removal and installation of the SRS can lead to personal

injury caused by unintentional act ivation of the system. For removal of Spiral Cable and Air Bag

Module, see the SRS section.

• Do not use electrical test equipm ent on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identi fied by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Un it or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or el ectric power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers, always switch the Ignition OFF, disconnect the battery, and wait at least 3 minutes before performing any service.

Precaution Necessary for Steering Wheel Rotation After Battery Disconnect

INFOID:0000000005928064

NOTE:

• This Procedure is applied only to models with Intelligent Key system and NVIS /IVIS (NISSAN/INFINITI

VEHICLE IMMOBILIZER SYSTEM - NATS).

• Remove and install all control units after disconnecti ng both battery cables with the ignition knob in the

″ LOCK ″ position.

• Always use CONSULT-III to perform self-diagnosis as a part of each function inspection after finishing work.

If DTC is detected, perform trouble diagnosis according to self-diagnostic results.

For models equipped with the Intelligent Key system and NVIS/IVIS, an electrically controlled steering lock

mechanism is adopted on the key cylinder.

For this reason, if the battery is disconnected or if the battery is discharged, the steering wheel will lock and

steering wheel rotation will become impossible.

If steering wheel rotation is required when battery power is interrupted, follow the procedure below before

starting the repair operation.

OPERATION PROCEDURE

1. Connect both battery cables. NOTE:

Supply power using jumper cables if battery is discharged.

2. Use the Intelligent Key or mechanical key to turn the ignition switch to the ″ACC ″ position. At this time, the

steering lock will be released.

3. Disconnect both battery cables. The steering lock will remain released and the steering wheel can be

rotated.

4. Perform the necessary repair operation.

5. When the repair work is completed, return the ignition switch to the ″LOCK ″ position before connecting

the battery cables. (At this time, the steering lock mechanism will engage.)

Revision: May 2010 2011 Versa

Page 398 of 3787

AV-1

ELECTRICAL

C

DE

F

G H

I

J

L

M

SECTION AV

A

B

AV

N

O P

CONTENTS

AUDIO, VISUAL, NAVIGATION & TELEPHONE SYS- TEM

AUDIO WITHOUT NAVIGATION

SERVICE INFORMATION .. ..........................

3

PRECAUTIONS .............................................. .....3

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

3

Precaution Necessary for Steering Wheel Rota-

tion After Battery Disconnect ............................... ......

3

PREPARATION ...................................................5

Commercial Service Tool .................................... ......5

AUDIO .................................................................6

Component Parts Location .................................. ......6

System Description ...................................................6

Schematic .................................................................8

Wiring Diagram - AUDIO - .........................................9

Audio Unit (Base System) Harness Connector

Terminal Layout ......................................................

15

Terminal and Reference Value for Audio Unit

(Base System) .........................................................

15

Audio Unit (Premium System) Harness Connector

Terminal Layout ......................................................

16

Terminal and Reference Value for Audio Unit

(Premium System) ..................................................

16

IPod Adapter Harness Connector Terminal Layout

....

18

Terminal and Reference Value for IPod Adapter ....19

Trouble Diagnosis ...................................................20

Noise Inspection ......................................................21

Power Supply Circuit Inspection .............................22

Steering Switch Check (With Bluetooth) .................22

Sound Is Not Heard from Front Door Speaker

(Base System) .........................................................

24

Sound Is Not Heard from Rear Door Speaker

(Base System) .........................................................

25

Sound Is Not Heard from Front Door Speaker or

Tweeter (Premium System) ....................................

26

Sound Is Not Heard from Rear Door Speaker

(Premium System) ............................................... ....

27

Removal and Installation .........................................29

iPod® CONNECTOR ........................................31

Removal and Installation .........................................31

iPod® ADAPTER ..............................................32

Removal and Installation .........................................32

AUDIO ANTENNA .............................................33

Location of Antenna ............................................. ....33

Removal and Installation of Roof Antenna ..............33

TELEPHONE .....................................................35

Component Parts and Harness Connector Loca-

tion ...........................................................................

35

System Description ..................................................35

Wiring Diagram - H/PHON - ....................................37

Bluetooth Control Unit Harness Connector Termi-

nal Layout ............................................................ ....

39

Terminal and Reference Value for Bluetooth Con-

trol Unit ....................................................................

39

Bluetooth Control Unit Self-Diagnosis Function ......41

Workflow .............................................................. ....41

Power Supply and Ground Circuit Inspection for

Bluetooth Control Unit .............................................

42

Steering Wheel Audio Co ntrol Switch Does Not

Operate ................................................................ ....

43

Voice Activated Control Function Does Not Oper-

ate ........................................................................ ....

43

Removal and Installation .........................................46

AUDIO WITH NAVIGATION

SERVICE INFORMATION .. .........................

50

PRECAUTIONS .................................................50

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ....

50

Precaution Necessary for Steering Wheel Rota-

tion After Battery Disconnect ...................................

50

Revision: May 2010 2011 Versa