bulb NISSAN TIIDA 2011 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2011, Model line: TIIDA, Model: NISSAN TIIDA 2011Pages: 3787, PDF Size: 78.35 MB

Page 58 of 3787

ON BOARD DIAGNOSTIC (OBD) SYSTEMAT-41

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

The OD OFF indicator lamp is located on the combination meter.

1. If the ignition switch stays ON after repair work, be su re to turn ignition switch OFF once. Wait at least 10

seconds and then turn it ON (engine stopped) again.

2. Perform “TCM SELF-DIAGNOSTIC PR OCEDURE (No Tools)”. Refer to AT-82, "

Diagnosis Procedure

without CONSULT-III". (The engine warm-up step can be skipped when performing the diagnosis only to

erase the DTC.)

3. Perform “OBD-II SELF-DIAGNOSTIC PROCEDURE (No tools)”. Refer to EC-95, "

Diagnosis Description"

(HR16DE), EC-542, "Emission-related Diagnostic Information" (MR18DE).

Malfunction Indicator Lamp (MIL)INFOID:0000000005928088

DESCRIPTION

The MIL is located on the instrument panel.

1. The MIL will light up when the ignition switch is turned ON with-

out the engine running. This is a bulb check.

• If the MIL does not light up, refer to DI-21, "

Schematic", EC-

450, "Wiring Diagram" (HR16DE), EC-1033, "Wiring Diagram"

(MR18DE).

2. When the engine is start ed, the MIL should go off.

• If the MIL remains on, the on board diagnostic system has detected an engine system malfunction.

SEF217U

Revision: May 2010 2011 Versa

Page 664 of 3787

BL-154

< SERVICE INFORMATION >

INTELLIGENT KEY SYSTEM

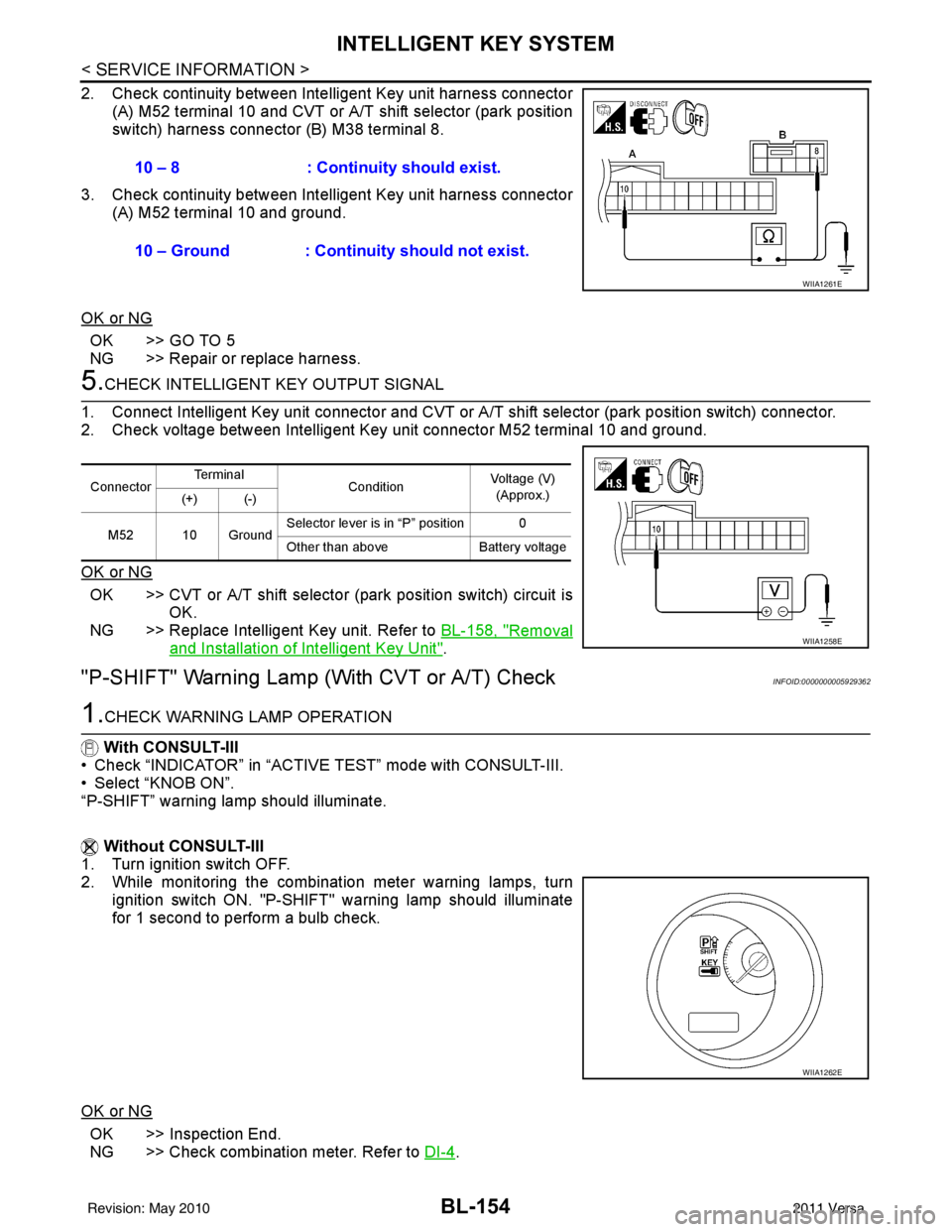

2. Check continuity between Intelligent Key unit harness connector

(A) M52 terminal 10 and CVT or A/T shift selector (park position

switch) harness connector (B) M38 terminal 8.

3. Check continuity between Inte lligent Key unit harness connector

(A) M52 terminal 10 and ground.

OK or NG

OK >> GO TO 5

NG >> Repair or replace harness.

5.CHECK INTELLIGENT KEY OUTPUT SIGNAL

1. Connect Intelligent Key unit connector and CVT or A/T shift selector (park position switch) connector.

2. Check voltage between Intelligent Key unit connector M52 terminal 10 and ground.

OK or NG

OK >> CVT or A/T shift selector (park position switch) circuit is

OK.

NG >> Replace Intelligent Key unit. Refer to BL-158, "

Removal

and Installation of Intelligent Key Unit".

"P-SHIFT" Warning Lamp (With CVT or A/T) CheckINFOID:0000000005929362

1.CHECK WARNING LAMP OPERATION

With CONSULT-III

• Check “INDICATOR” in “ACTIVE TEST” mode with CONSULT-III.

• Select “KNOB ON”.

“P-SHIFT” warning lamp should illuminate.

Without CONSULT-III

1. Turn ignition switch OFF.

2. While monitoring the combination meter warning lamps, turn

ignition switch ON. "P-SHIFT" warning lamp should illuminate

for 1 second to perform a bulb check.

OK or NG

OK >> Inspection End.

NG >> Check combination meter. Refer to DI-4

.

10 – 8 : Continuity should exist.

10 – Ground : Continuity should not exist.

WIIA1261E

Connector

Te r m i n a l

ConditionVoltage (V)

(Approx.)

(+) (-)

M52 10 Ground Selector lever is in “P” position 0

Other than above

Battery voltage

WIIA1258E

WIIA1262E

Revision: May 2010 2011 Versa

Page 665 of 3787

INTELLIGENT KEY SYSTEMBL-155

< SERVICE INFORMATION >

C

DE

F

G H

J

K L

M A

B

BL

N

O P

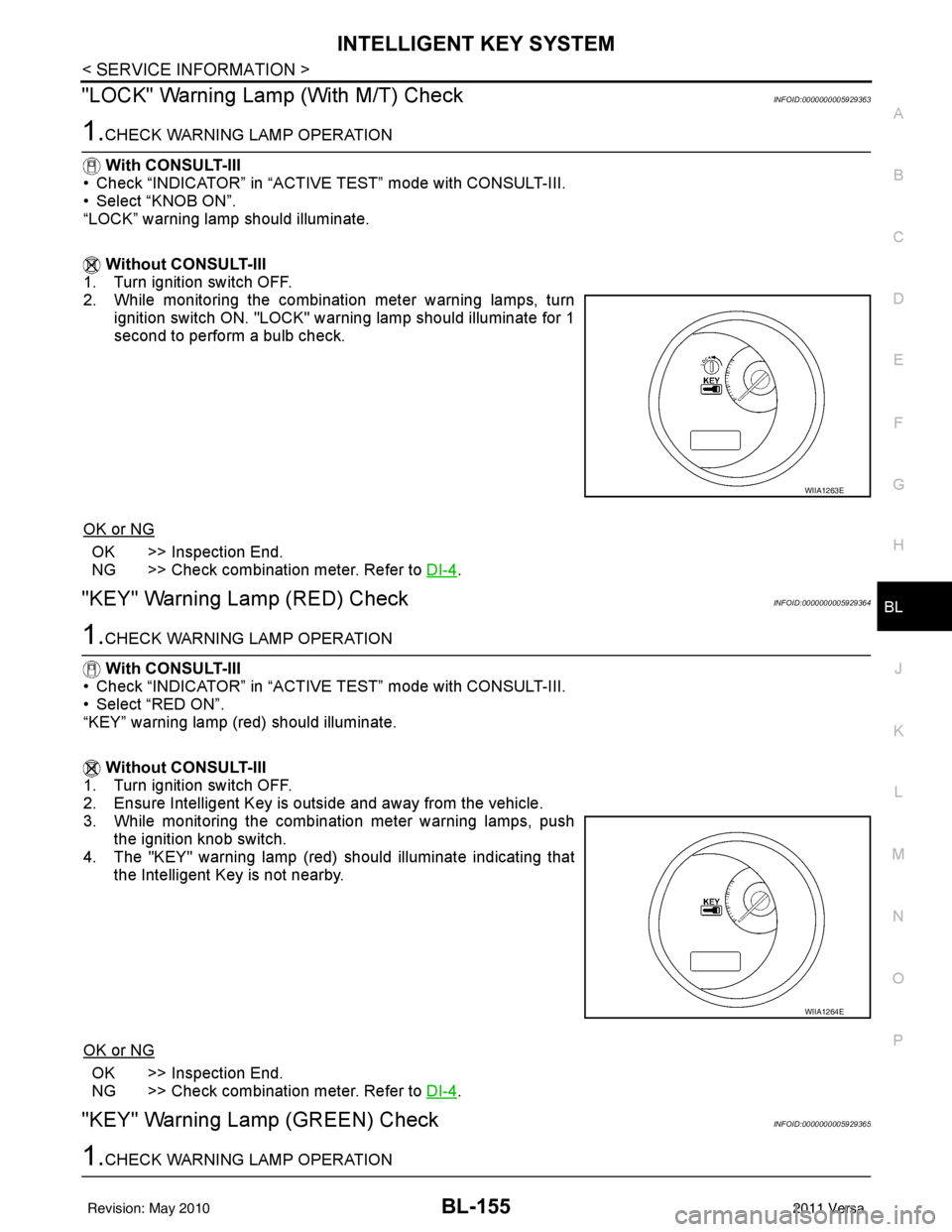

"LOCK" Warning Lamp (With M/T) CheckINFOID:0000000005929363

1.CHECK WARNING LAMP OPERATION

With CONSULT-III

• Check “INDICATOR” in “ACTIVE TEST” mode with CONSULT-III.

• Select “KNOB ON”.

“LOCK” warning lamp should illuminate.

Without CONSULT-III

1. Turn ignition switch OFF.

2. While monitoring the combination meter warning lamps, turn

ignition switch ON. "LOCK" warning lamp should illuminate for 1

second to perform a bulb check.

OK or NG

OK >> Inspection End.

NG >> Check combination meter. Refer to DI-4

.

"KEY" Warning Lamp (RED) CheckINFOID:0000000005929364

1.CHECK WARNING LAMP OPERATION

With CONSULT-III

• Check “INDICATOR” in “ACTIVE TEST” mode with CONSULT-III.

• Select “RED ON”.

“KEY” warning lamp (red) should illuminate.

Without CONSULT-III

1. Turn ignition switch OFF.

2. Ensure Intelligent Key is outside and away from the vehicle.

3. While monitoring the combination meter warning lamps, push the ignition knob switch.

4. The "KEY" warning lamp (red) should illuminate indicating that the Intelligent Key is not nearby.

OK or NG

OK >> Inspection End.

NG >> Check combination meter. Refer to DI-4

.

"KEY" Warning Lamp (GREEN) CheckINFOID:0000000005929365

1.CHECK WARNING LAMP OPERATION

WIIA1263E

WIIA1264E

Revision: May 2010 2011 Versa

Page 1084 of 3787

![NISSAN TIIDA 2011 Service Repair Manual ON BOARD DIAGNOSTIC (OBD) SYSTEMCVT-29

< SERVICE INFORMATION > [RE0F08B]

D

E

F

G H

I

J

K L

M A

B

CVT

N

O P

The MIL is located on the instrument panel.

1. The MIL will light up when the ignition switch NISSAN TIIDA 2011 Service Repair Manual ON BOARD DIAGNOSTIC (OBD) SYSTEMCVT-29

< SERVICE INFORMATION > [RE0F08B]

D

E

F

G H

I

J

K L

M A

B

CVT

N

O P

The MIL is located on the instrument panel.

1. The MIL will light up when the ignition switch](/img/5/57396/w960_57396-1083.png)

ON BOARD DIAGNOSTIC (OBD) SYSTEMCVT-29

< SERVICE INFORMATION > [RE0F08B]

D

E

F

G H

I

J

K L

M A

B

CVT

N

O P

The MIL is located on the instrument panel.

1. The MIL will light up when the ignition switch is turned ON with- out the engine running. This is a bulb check.

• If the MIL does not light up, refer to DI-21, "

Schematic", or see

EC-1033, "

Wiring Diagram".

2. When the engine is start ed, the MIL should go off.

If the MIL remains on, the on board diagnostic system has

detected an engine system malfunction.

SEF217U

Revision: May 2010 2011 Versa

Page 1397 of 3787

![NISSAN TIIDA 2011 Service Repair Manual DIAGNOSIS SYSTEM (ECM)EC-103

< FUNCTION DIAGNOSIS > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

PERMANENT DTC SET TIMING

The setting timing of permanent DTC is stored in ECM

with the lighting of MIL whe NISSAN TIIDA 2011 Service Repair Manual DIAGNOSIS SYSTEM (ECM)EC-103

< FUNCTION DIAGNOSIS > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

PERMANENT DTC SET TIMING

The setting timing of permanent DTC is stored in ECM

with the lighting of MIL whe](/img/5/57396/w960_57396-1396.png)

DIAGNOSIS SYSTEM (ECM)EC-103

< FUNCTION DIAGNOSIS > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

PERMANENT DTC SET TIMING

The setting timing of permanent DTC is stored in ECM

with the lighting of MIL when a DTC is confirmed.

DIAGNOSIS DESCRIPTION : Malfunction Indicator Lamp (MIL)INFOID:0000000006314669

DESCRIPTION

The MIL is located on the instrument panel.

1. The MIL will light up when the ignition switch is turned ON with-

out the engine running. This is a bulb check.

If the MIL does not light up, refer to EC-449, "

Component Func-

tion Check".

2. When the engine is start ed, the MIL should go off.

If the MIL remains on, the on board diagnostic system has

detected an engine system malfunction.

On Board Diagnosis FunctionINFOID:0000000006314670

ON BOARD DIAGNOSIS ITEM

The on board diagnostic system has the following functions.

BULB CHECK MODE

Description

This function allows damage inspection in the MIL bulb (blown, open circuit, etc.).

Operation Procedure

1. Turn ignition switch ON.

2. The MIL on the instrument panel should stay ON.

If it remains OFF, check MIL circuit. Refer to EC-451, "

Diagnosis Procedure".

SRT STATUS MODE

Description

This function allows to read if ECM has completed the self-diagnoses of major emission control systems and

components. For SRT, refer to EC-101, "

DIAGNOSIS DESCRIPTION : System Readiness Test (SRT) Code".

Operation Procedure

1. Turn ignition switch ON and wait 20 seconds.

2. SRT status is indicated as shown blow.

• ECM continues to illuminate MIL if all SRT codes are set.

SEF217U

Diagnostic test mode Function

Bulb check MIL can be checked.

SRT status ECM can read if SRT codes are set.

Malfunction warning If ECM detects a malfunction, it illuminates or blinks MIL to inform the driver that a malfunction has

been detected.

Self-diagnostic results DTCs or 1st trip DTCs stored in ECM can be read.

Accelerator pedal released po-

sition learning ECM can learn the accelerator pedal released position. Refer to EC-25, "

ACCELERATOR PEDAL

RELEASED POSITION LEARNING : Description".

Throttle valve closed position

learning ECM can learn the throttle valve closed position. Refer to

EC-25, "

THROTTLE VALVE CLOSED PO-

SITION LEARNING : Description".

Idle air volume learning ECM can learn the idle air volume. Refer to EC-25, "

IDLE AIR VOLUME LEARNING : Description".

Mixture ratio self-learning value

clear Mixture ratio self-learning value can be erased. Refer to

EC-27, "

MIXTURE RATIO SELF-LEARNING

VALUE CLEAR : Description".

Revision: May 2010 2011 Versa

Page 1743 of 3787

![NISSAN TIIDA 2011 Service Repair Manual MALFUNCTION INDICATOR LAMPEC-449

< COMPONENT DIAGNOSIS > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

MALFUNCTION INDICATOR LAMP

DescriptionINFOID:0000000005930135

The Malfunction Indicator Lamp (MIL) is NISSAN TIIDA 2011 Service Repair Manual MALFUNCTION INDICATOR LAMPEC-449

< COMPONENT DIAGNOSIS > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

MALFUNCTION INDICATOR LAMP

DescriptionINFOID:0000000005930135

The Malfunction Indicator Lamp (MIL) is](/img/5/57396/w960_57396-1742.png)

MALFUNCTION INDICATOR LAMPEC-449

< COMPONENT DIAGNOSIS > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

MALFUNCTION INDICATOR LAMP

DescriptionINFOID:0000000005930135

The Malfunction Indicator Lamp (MIL) is located on the combination

meter.

The MIL will light up when the ignition switch is turned ON without

the engine running. This is a bulb check.

When the engine is started, the MIL should go off. If the MIL remains

on, the on board diagnostic syste

m has detected an engine system

malfunction.

For details, refer to EC-451, "

Diagnosis Procedure".

Component Function CheckINFOID:0000000005930136

1.CHECK MIL FUNCTION

1. Turn ignition switch ON.

2. Make sure that MIL lights up.

Is the inspection result normal?

YES >> INSPECTION END

NO >> Go to EC-451, "

Diagnosis Procedure".

SEF217U

Revision: May 2010 2011 Versa

Page 1860 of 3787

![NISSAN TIIDA 2011 Service Repair Manual EC-566

< SERVICE INFORMATION >[MR18DE]

ON BOARD DIAGNOSTIC (OBD) SYSTEM

The MIL is located on the instrument panel.

1. The MIL will light up when the ignition switch is turned ON with-

out the engine NISSAN TIIDA 2011 Service Repair Manual EC-566

< SERVICE INFORMATION >[MR18DE]

ON BOARD DIAGNOSTIC (OBD) SYSTEM

The MIL is located on the instrument panel.

1. The MIL will light up when the ignition switch is turned ON with-

out the engine](/img/5/57396/w960_57396-1859.png)

EC-566

< SERVICE INFORMATION >[MR18DE]

ON BOARD DIAGNOSTIC (OBD) SYSTEM

The MIL is located on the instrument panel.

1. The MIL will light up when the ignition switch is turned ON with-

out the engine running. This is a bulb check.

If the MIL does not light up, refer to DI-21

or see EC-1033.

2. When the engine is started, the MIL should go off. If the MIL remains on, the on board diagnostic system has

detected an engine system malfunction.

ON BOARD DIAGNOSTIC SYSTEM FUNCTION

The on board diagnostic system has the following three functions.

When there is an open circuit on MIL circuit, the ECM cannot warn the driver by MIL lighting up when there is

malfunction on engine control system.

Therefore, when electrical controlled throttle and part of ECM related diagnoses are continuously detected as

NG for 5 trips, ECM warns the driver that engine cont rol system malfunctions and MIL circuit is open by means

of operating fail-safe function.

The fail-safe function also operates when above diagnoses except MIL circuit are detected, and demands the

driver to repair the malfunction.

MIL Flashing Without DTC

When any SRT codes are not set, MIL may fl ash without DTC. For the details, refer to EC-542, "Emission-

related Diagnostic Information".

HOW TO SWITCH DIAGNOSTIC TEST MODE

NOTE:

•It is better to count the ti me accurately with a clock.

SEF217U

Diagnostic Test

Mode KEY and ENG.

Statu s Function

Explanation of Function

Mode I Ignition switch in

ON position

Engine stopped BULB CHECK

This function checks the MIL bulb for damage (blown, open

circuit, etc.).

If the MIL does not come on, check MIL circuit.

Engine running MALFUNCTION WARNING This is a usual driving condition. When a malfunction is de-

tected twice in two consecutive driving cycles (two trip de-

tection logic), the MIL will light up to inform the driver that a

malfunction has been detected.

The following malfunctions will light up or blink the MIL in

the 1st trip.

• Misfire (Possible three way catalyst damage)

• One trip detection diagnoses

Mode II Ignition switch in

ON position

Engine stopped SELF-DIAGNOSTIC

RESULTS

This function allows DTCs an

d 1st trip DTCs to be read.

Engine operating condition in fail-safe mode Engine speed will not rise more than 2,500 rpm due to the fuel cut

Revision: May 2010 2011 Versa

Page 1861 of 3787

![NISSAN TIIDA 2011 Service Repair Manual ON BOARD DIAGNOSTIC (OBD) SYSTEMEC-567

< SERVICE INFORMATION > [MR18DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

•

It is impossible to switch the di agnostic mode when an accelerator pedal position sensor ci NISSAN TIIDA 2011 Service Repair Manual ON BOARD DIAGNOSTIC (OBD) SYSTEMEC-567

< SERVICE INFORMATION > [MR18DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

•

It is impossible to switch the di agnostic mode when an accelerator pedal position sensor ci](/img/5/57396/w960_57396-1860.png)

ON BOARD DIAGNOSTIC (OBD) SYSTEMEC-567

< SERVICE INFORMATION > [MR18DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

•

It is impossible to switch the di agnostic mode when an accelerator pedal position sensor circuit has

a malfunction.

• Always ECM returns to Diagnostic Test Mode I after ignition switch is turned OFF.

How to Set Diagnostic Test Mode II (Self-diagnostic Results)

1. Confirm that accelerator pedal is fully released, turn ignition switch ON and wait 3 seconds.

2. Repeat the following procedure quick ly five times within 5 seconds.

a. Fully depress the accelerator pedal.

b. Fully release the accelerator pedal.

3. Wait 7 seconds, fully depress the accelerator pedal and keep it for approx. 10 seconds until the MIL starts

blinking.

4. Fully release the accelerator pedal. ECM has entered to Diagnostic Test Mode II (Self-diagnostic results).

How to Erase Diagnostic Test Mode II (Self-diagnostic Results)

1. Set ECM in Diagnostic Test Mode II (Self-diagnostic results).Refer to "How to Set Diagnostic Test Mode II (Self-diagnostic Results)".

2. Fully depress the accelerator pedal and keep it for more than 10 seconds. The emission-related diagnostic information has been erased from the backup memory in the ECM.

3. Fully release the accelerator pedal, and confirm the DTC 0000 is displayed.

DIAGNOSTIC TEST MODE I — BULB CHECK

In this mode, the MIL on the instrument panel should stay ON. If it remains OFF, check the bulb.

Refer to DI-21

or EC-1033.

DIAGNOSTIC TEST MODE I — MALFUNCTION WARNING

These DTC numbers are clarified in Diagnostic Test Mode II (SELF-DIAGNOSTIC RESULTS)

DIAGNOSTIC TEST MODE II — SELF-DIAGNOSTIC RESULTS

In this mode, the DTC and 1st trip DTC are indicated by the number of blinks of the MIL as shown below.

The DTC and 1st trip DTC are displayed at the same time. If the MIL does not illuminate in diagnostic test

mode I (Malfunction warning), all displayed items are 1st trip DTCs. If onl y one code is displayed when the MIL

illuminates in diagnostic test mode II (SELF-DIAGNOSTIC RESULTS), it is a DTC; if two or more codes are

displayed, they may be either DTCs or 1st trip DTCs. DTC No. is same as that of 1st trip DTC. These uniden-

PBIB0092E

MIL Condition

ON When the malfunction is detected.

OFF No malfunction

Revision: May 2010 2011 Versa

Page 2735 of 3787

SERVICE INFORMATION FOR ELECTRICAL INCIDENTGI-31

< SERVICE INFORMATION >

C

DE

F

G H

I

J

K L

M B

GI

N

O P

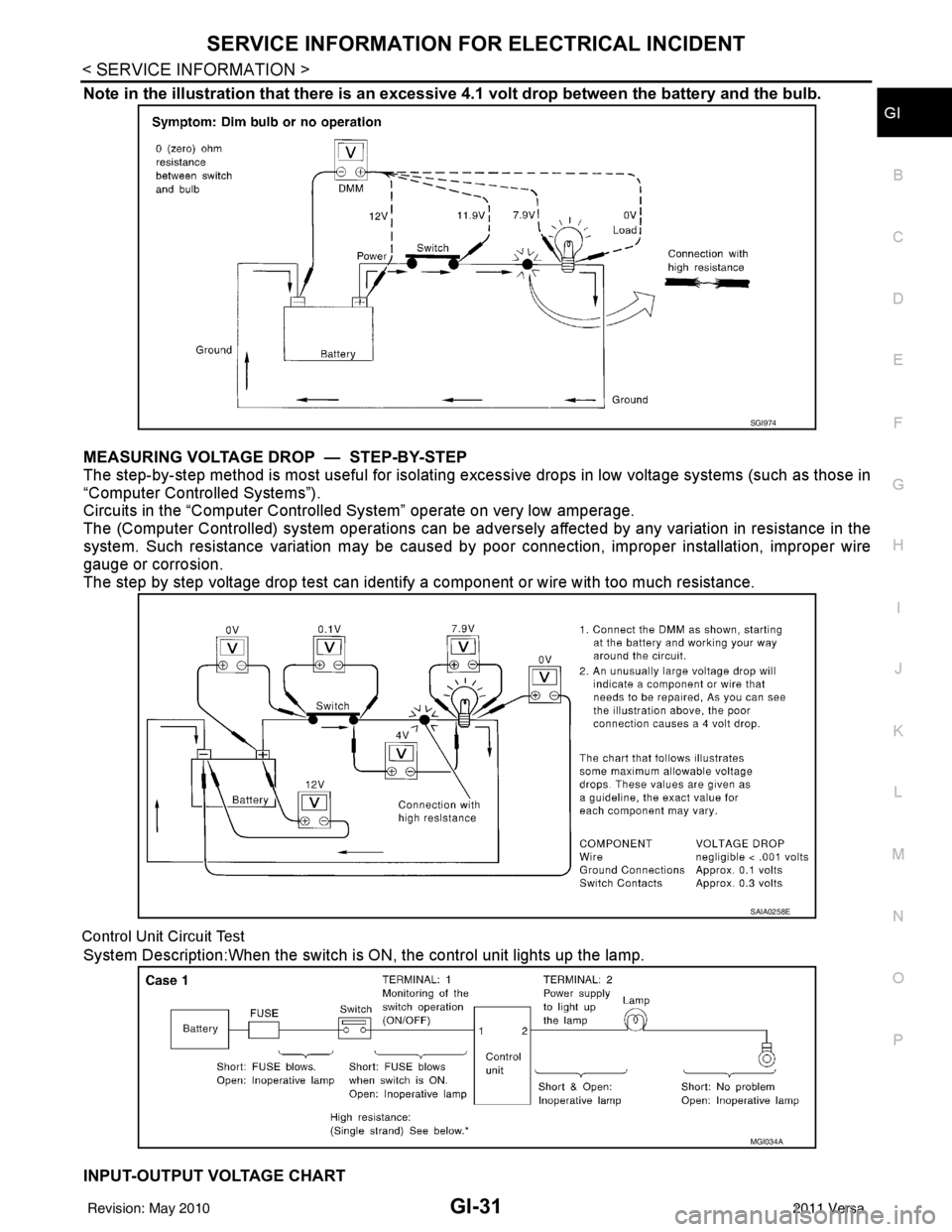

Note in the illustration that there is an excessi ve 4.1 volt drop between the battery and the bulb.

MEASURING VOLTAGE DRO P — STEP-BY-STEP

The step-by-step method is most useful for isolating excessive drops in low voltage systems (such as those in

“Computer Controlled Systems”).

Circuits in the “Computer Controlled System” operate on very low amperage.

The (Computer Controlled) system oper ations can be adversely affected by any variation in resistance in the

system. Such resistance variation may be caused by poor connection, improper installation, improper wire

gauge or corrosion.

The step by step voltage drop test can identify a component or wire with too much resistance.

Control Unit Circuit Test

System Description:When the switch is ON, the control unit lights up the lamp.

INPUT-OUTPUT VOLTAGE CHART

SGI974

SAIA0258E

MGI034A

Revision: May 2010 2011 Versa

Page 3033 of 3787

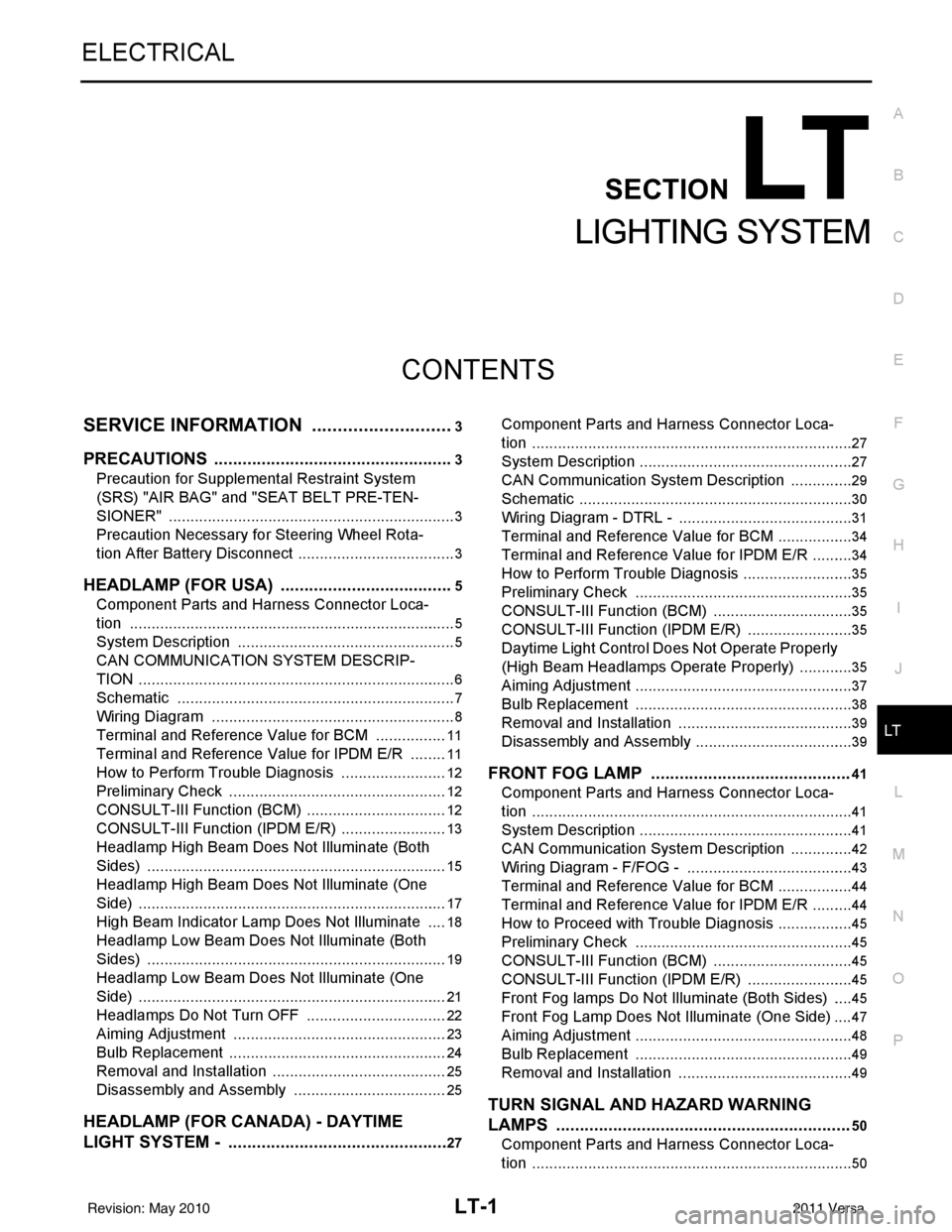

LT-1

ELECTRICAL

C

DE

F

G H

I

J

L

M

SECTION LT

A

B

LT

N

O P

CONTENTS

LIGHTING SYSTEM

SERVICE INFORMATION .. ..........................3

PRECAUTIONS .............................................. .....3

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

3

Precaution Necessary for Steering Wheel Rota-

tion After Battery Disconnect ............................... ......

3

HEADLAMP (FOR USA) .....................................5

Component Parts and Harness Connector Loca-

tion ...................................................................... ......

5

System Description ...................................................5

CAN COMMUNICATION SYSTEM DESCRIP-

TION .................................................................... ......

6

Schematic .................................................................7

Wiring Diagram .........................................................8

Terminal and Reference Value for BCM .................11

Terminal and Reference Value for IPDM E/R .........11

How to Perform Trouble Diagnosis .........................12

Preliminary Check ...................................................12

CONSULT-III Function (BCM) .................................12

CONSULT-III Function (IPDM E/R) .........................13

Headlamp High Beam Does Not Illuminate (Both

Sides) .................................................................. ....

15

Headlamp High Beam Does Not Illuminate (One

Side) .................................................................... ....

17

High Beam Indicator Lamp Does Not Illuminate .....18

Headlamp Low Beam Does Not Illuminate (Both

Sides) .................................................................. ....

19

Headlamp Low Beam Does Not Illuminate (One

Side) .................................................................... ....

21

Headlamps Do Not Turn OFF .................................22

Aiming Adjustment ..................................................23

Bulb Replacement ...................................................24

Removal and Installation .........................................25

Disassembly and Assembly ................................ ....25

HEADLAMP (FOR CANADA) - DAYTIME

LIGHT SYSTEM - ........................................... ....

27

Component Parts and Harness Connector Loca-

tion ....................................................................... ....

27

System Description ..................................................27

CAN Communication System Description ...............29

Schematic ................................................................30

Wiring Diagram - DTRL - .........................................31

Terminal and Reference Value for BCM ..................34

Terminal and Reference Value for IPDM E/R ...... ....34

How to Perform Trouble Diagnosis ..........................35

Preliminary Check ...................................................35

CONSULT-III Function (BCM) .................................35

CONSULT-III Function (IPDM E/R) ..................... ....35

Daytime Light Control Does Not Operate Properly

(High Beam Headlamps Operate Properly) .............

35

Aiming Adjustment ...................................................37

Bulb Replacement ...................................................38

Removal and Installation .........................................39

Disassembly and Assembly .....................................39

FRONT FOG LAMP ..........................................41

Component Parts and Harness Connector Loca-

tion ...........................................................................

41

System Description ..................................................41

CAN Communication System Description ...............42

Wiring Diagram - F/FOG - .......................................43

Terminal and Reference Value for BCM ..................44

Terminal and Reference Value for IPDM E/R ...... ....44

How to Proceed with Trouble Diagnosis ..................45

Preliminary Check ............................................... ....45

CONSULT-III Function (BCM) .................................45

CONSULT-III Function (IPDM E/R) ..................... ....45

Front Fog lamps Do Not Illuminate (Both Sides) .....45

Front Fog Lamp Does Not Illuminate (One Side) ....47

Aiming Adjustment ...................................................48

Bulb Replacement ...................................................49

Removal and Installation .........................................49

TURN SIGNAL AND HAZARD WARNING

LAMPS ..............................................................

50

Component Parts and Harness Connector Loca-

tion ...........................................................................

50

Revision: May 2010 2011 Versa