ipdm NISSAN TIIDA 2011 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2011, Model line: TIIDA, Model: NISSAN TIIDA 2011Pages: 3787, PDF Size: 78.35 MB

Page 110 of 3787

P0705 TRANSMISSION RANGE SWITCH A

AT-93

< SERVICE INFORMATION >

D E

F

G H

I

J

K L

M A

B

AT

N

O P

NG >> GO TO 3.

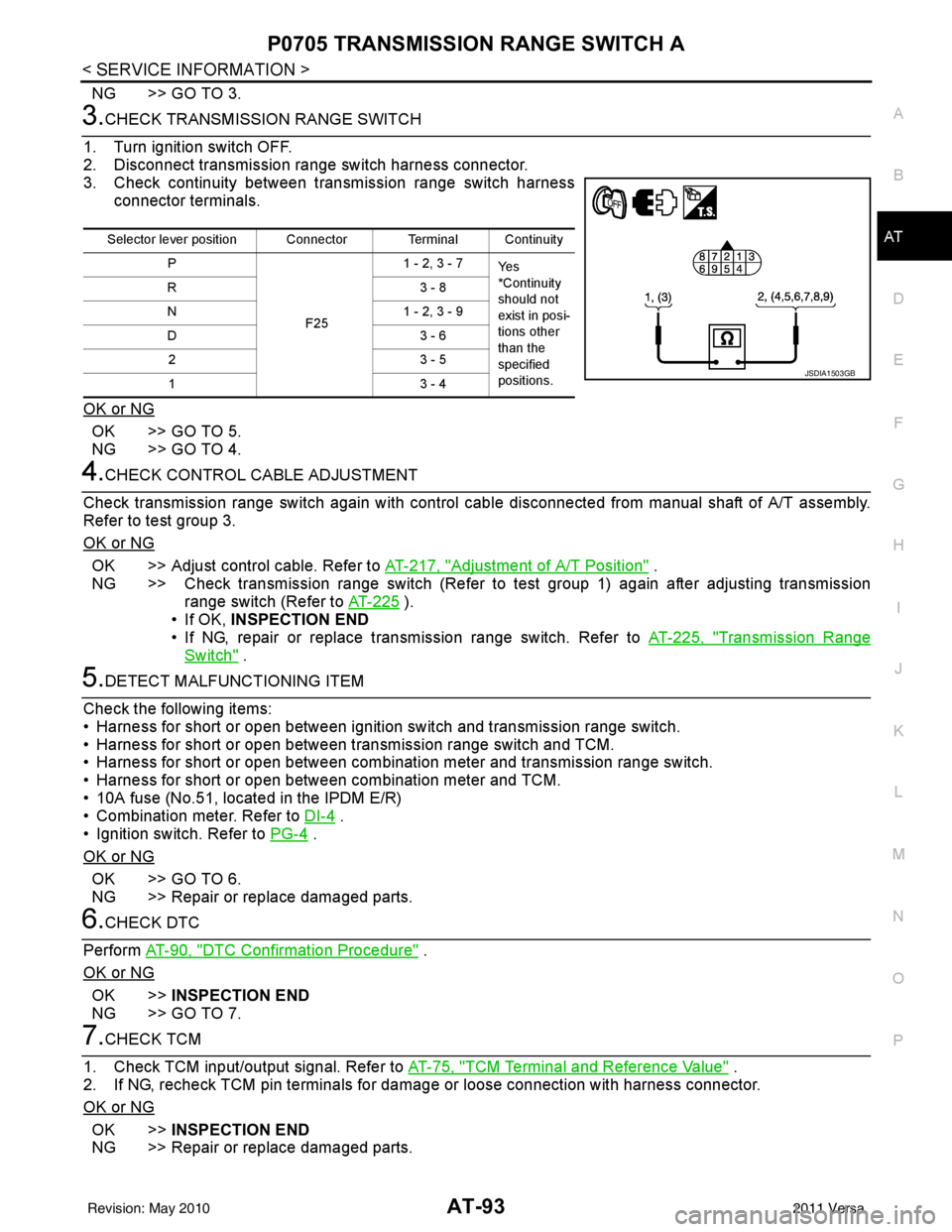

3.CHECK TRANSMISSION RANGE SWITCH

1. Turn ignition switch OFF.

2. Disconnect transmission range switch harness connector.

3. Check continuity between transmission range switch harness connector terminals.

OK or NG

OK >> GO TO 5.

NG >> GO TO 4.

4.CHECK CONTROL CABLE ADJUSTMENT

Check transmission range switch again with control cabl e disconnected from manual shaft of A/T assembly.

Refer to test group 3.

OK or NG

OK >> Adjust control cable. Refer to AT-217, "Adjustment of A/T Position" .

NG >> Check transmission range switch (Refer to test group 1) again after adjusting transmission range switch (Refer to AT-225

).

• If OK, INSPECTION END

• If NG, repair or replace transmission range switch. Refer to AT-225, "

Transmission Range

Switch" .

5.DETECT MALFUNCTIONING ITEM

Check the following items:

• Harness for short or open between ignition switch and transmission range switch.

• Harness for short or open between transmission range switch and TCM.

• Harness for short or open between combination meter and transmission range switch.

• Harness for short or open between combination meter and TCM.

• 10A fuse (No.51, located in the IPDM E/R)

• Combination meter. Refer to DI-4

.

• Ignition switch. Refer to PG-4

.

OK or NG

OK >> GO TO 6.

NG >> Repair or replace damaged parts.

6.CHECK DTC

Perform AT-90, "

DTC Confirmation Procedure" .

OK or NG

OK >> INSPECTION END

NG >> GO TO 7.

7.CHECK TCM

1. Check TCM input/output signal. Refer to AT-75, "

TCM Terminal and Reference Value" .

2. If NG, recheck TCM pin terminals for dam age or loose connection with harness connector.

OK or NG

OK >> INSPECTION END

NG >> Repair or replace damaged parts.

Selector lever position Connector Terminal Continuity

P

F251 - 2, 3 - 7

Ye s

*Continuity

should not

exist in posi-

tions other

than the

specified

positions.

R3

- 8

N 1 - 2, 3 - 9

D3 - 6

23 - 5

13 - 4

JSDIA1503GB

Revision: May 2010 2011 Versa

Page 121 of 3787

AT-104

< SERVICE INFORMATION >

P0720 OUTPUT SPEED SENSOR

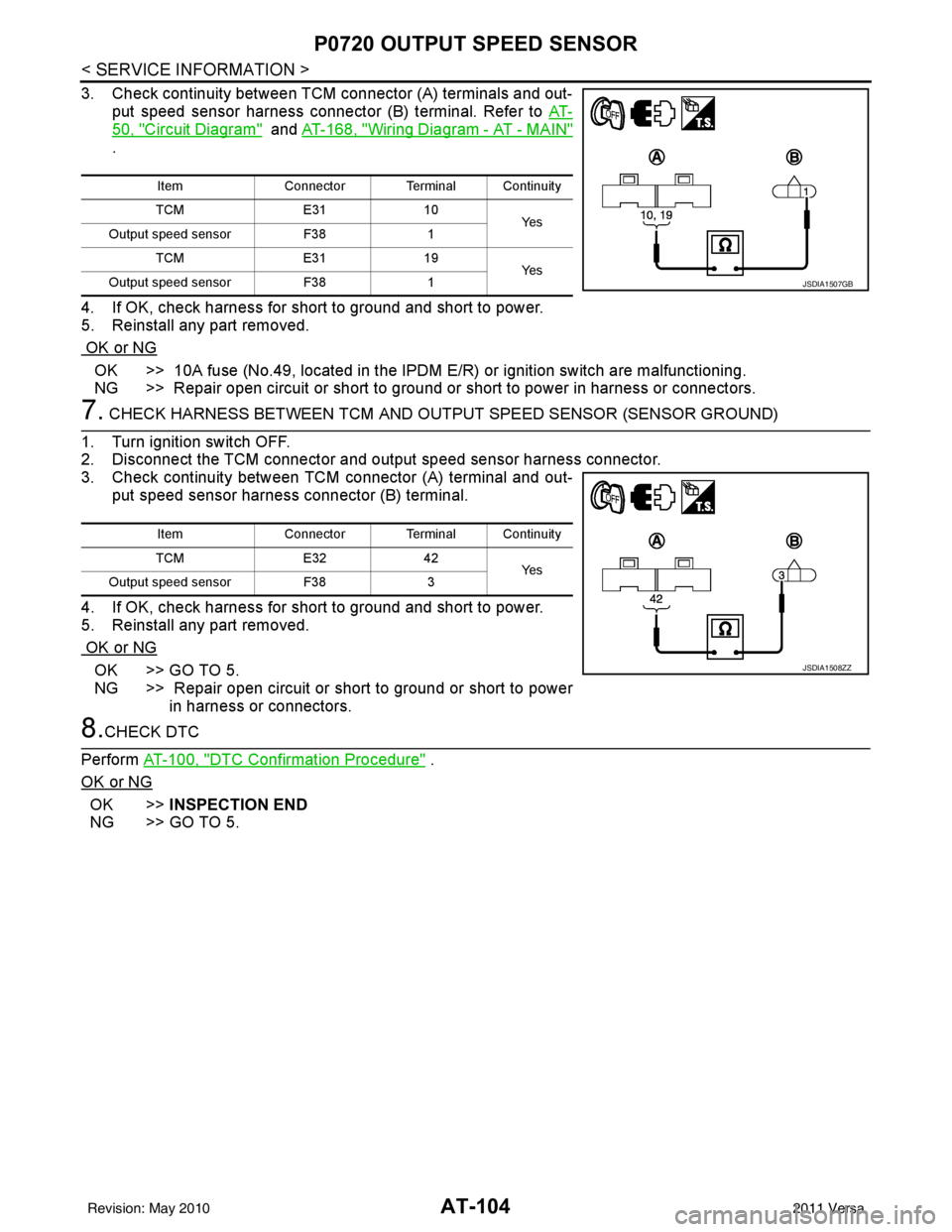

3. Check continuity between TCM connector (A) terminals and out-put speed sensor harness connector (B) terminal. Refer to AT-

50, "Circuit Diagram" and AT-168, "Wiring Diagram - AT - MAIN"

.

4. If OK, check harness for short to ground and short to power.

5. Reinstall any part removed.

OK or NG

OK >> 10A fuse (No.49, located in the IPDM E/R) or ignition switch are malfunctioning.

NG >> Repair open circuit or short to ground or short to power in harness or connectors.

7. CHECK HARNESS BETWEEN TCM AND OUTPUT SPEED SENSOR (SENSOR GROUND)

1. Turn ignition switch OFF.

2. Disconnect the TCM connector and output speed sensor harness connector.

3. Check continuity between TCM connector (A) terminal and out-

put speed sensor harness connector (B) terminal.

4. If OK, check harness for short to ground and short to power.

5. Reinstall any part removed.

OK or NG

OK >> GO TO 5.

NG >> Repair open circuit or short to ground or short to power in harness or connectors.

8.CHECK DTC

Perform AT-100, "

DTC Confirmation Procedure" .

OK or NG

OK >> INSPECTION END

NG >> GO TO 5.

Item Connector Terminal Continuity

TCM E3110

Ye s

Output speed sensor F381

TCM E3119

Ye s

Output speed sensor F381

JSDIA1507GB

Item Connector Terminal Continuity

TCM E3242

Ye s

Output speed sensor F383

JSDIA1508ZZ

Revision: May 2010 2011 Versa

Page 175 of 3787

AT-158

< SERVICE INFORMATION >

BATT/FLUID TEMP SEN

Diagnosis Procedure

INFOID:0000000005928223

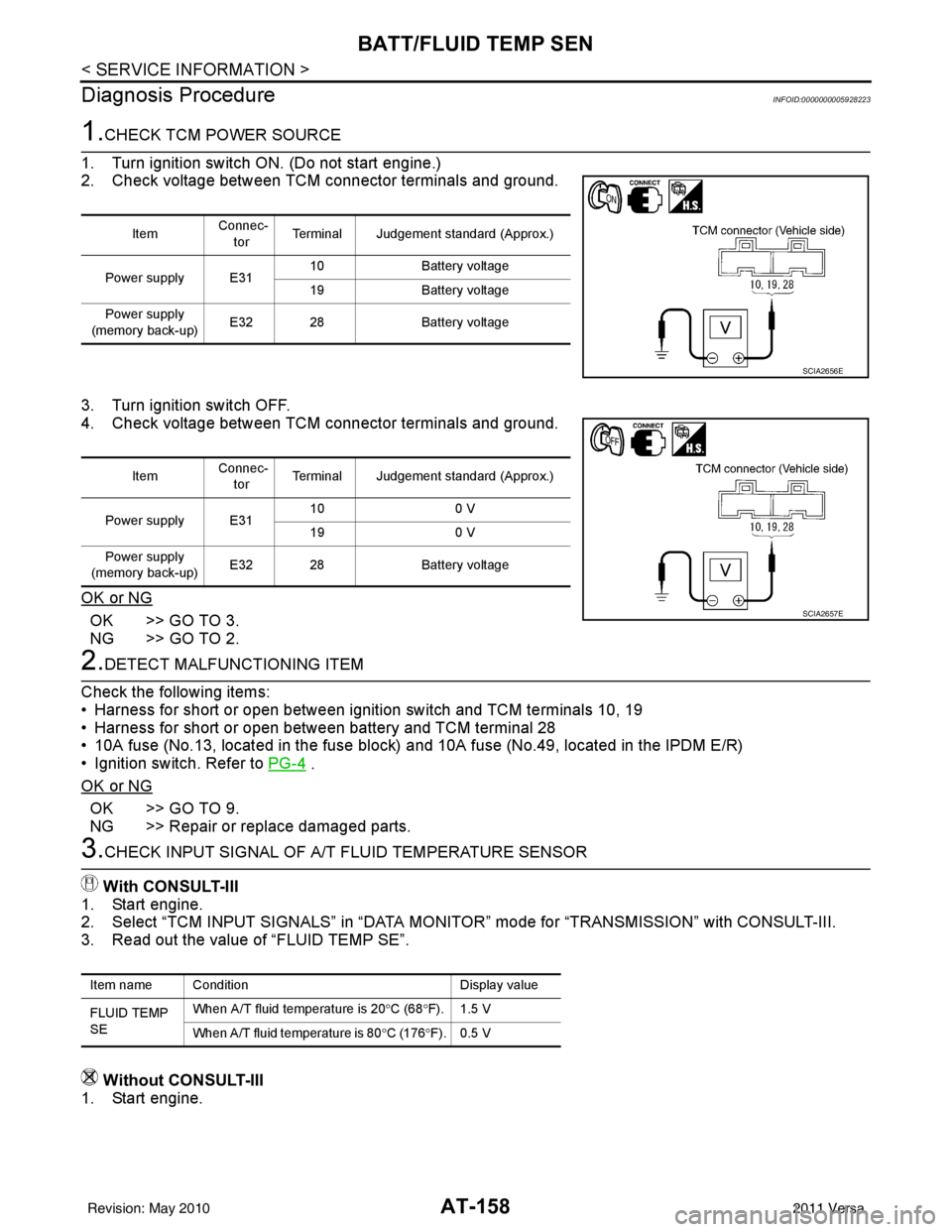

1.CHECK TCM POWER SOURCE

1. Turn ignition switch ON. (Do not start engine.)

2. Check voltage between TCM connector terminals and ground.

3. Turn ignition switch OFF.

4. Check voltage between TCM connector terminals and ground.

OK or NG

OK >> GO TO 3.

NG >> GO TO 2.

2.DETECT MALFUNCTIONING ITEM

Check the following items:

• Harness for short or open between ignition switch and TCM terminals 10, 19

• Harness for short or open between battery and TCM terminal 28

• 10A fuse (No.13, located in the fuse block) and 10A fuse (No.49, located in the IPDM E/R)

• Ignition switch. Refer to PG-4

.

OK or NG

OK >> GO TO 9.

NG >> Repair or replace damaged parts.

3.CHECK INPUT SIGNAL OF A/ T FLUID TEMPERATURE SENSOR

With CONSULT-III

1. Start engine.

2. Select “TCM INPUT SIGNALS” in “DATA MONITOR” mode for “TRANSMISSION” with CONSULT-III.

3. Read out the value of “FLUID TEMP SE”.

Without CONSULT-III

1. Start engine.

Item Connec-

tor Terminal Judgement standard (Approx.)

Power supply E31 10

Battery voltage

19 Battery voltage

Power supply

(memory back-up) E32 28

Battery voltage

SCIA2656E

Item Connec-

tor Terminal Judgement standard (Approx.)

Power supply E31 10

0 V

19 0 V

Power supply

(memory back-up) E32 28

Battery voltage

SCIA2657E

Item name Condition Display value

FLUID TEMP

SE When A/T fluid temperature is 20

°C (68 °F). 1.5 V

When A/T fluid temperature is 80 °C (176 °F). 0.5 V

Revision: May 2010 2011 Versa

Page 183 of 3787

AT-166

< SERVICE INFORMATION >

INPUT SPEED SENSOR A

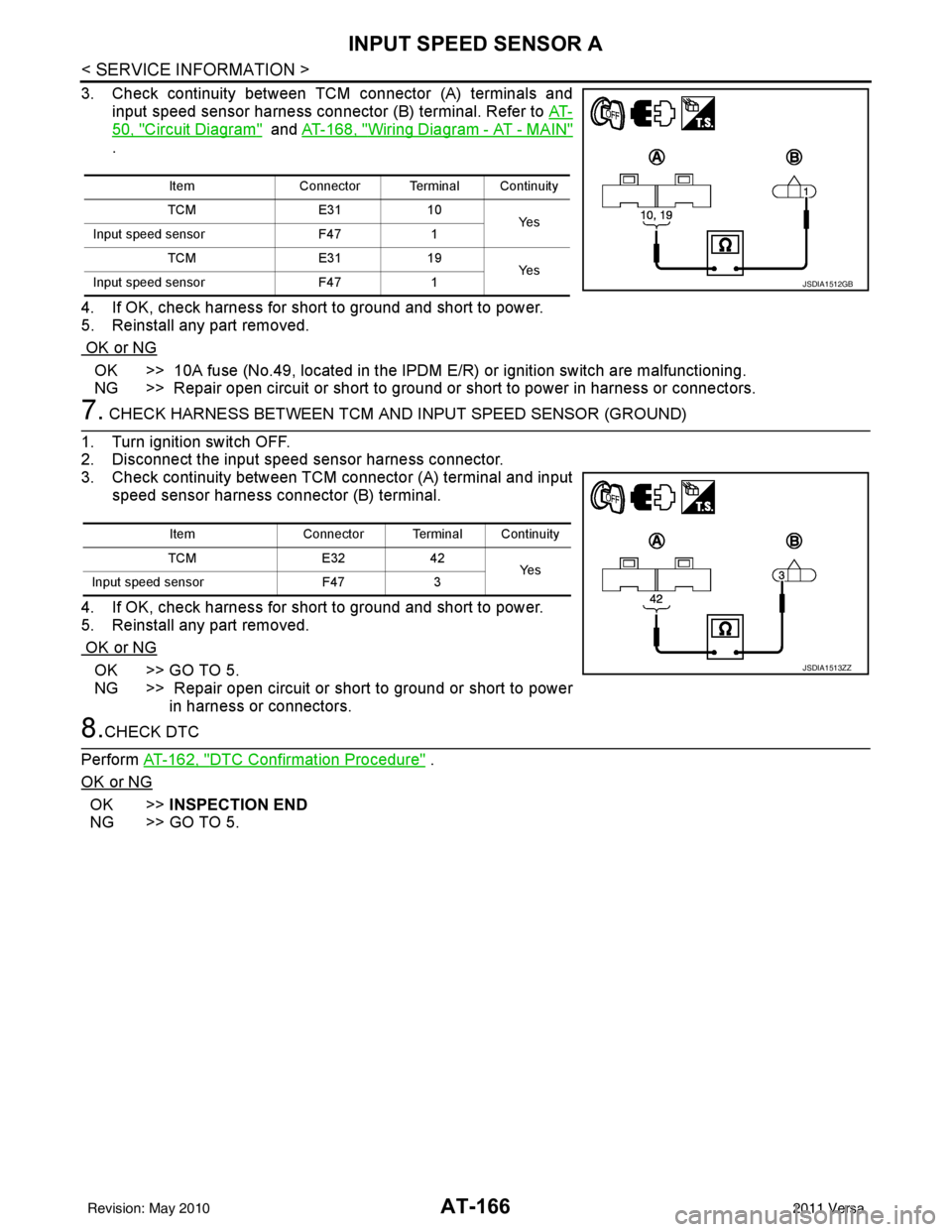

3. Check continuity between TCM connector (A) terminals and

input speed sensor harness connector (B) terminal. Refer to AT-

50, "Circuit Diagram" and AT-168, "Wiring Diagram - AT - MAIN"

.

4. If OK, check harness for short to ground and short to power.

5. Reinstall any part removed.

OK or NG

OK >> 10A fuse (No.49, located in the IPDM E/R) or ignition switch are malfunctioning.

NG >> Repair open circuit or short to ground or short to power in harness or connectors.

7. CHECK HARNESS BETWEEN TCM AND INPUT SPEED SENSOR (GROUND)

1. Turn ignition switch OFF.

2. Disconnect the input speed sensor harness connector.

3. Check continuity between TCM connector (A) terminal and input speed sensor harness connector (B) terminal.

4. If OK, check harness for short to ground and short to power.

5. Reinstall any part removed.

OK or NG

OK >> GO TO 5.

NG >> Repair open circuit or short to ground or short to power in harness or connectors.

8.CHECK DTC

Perform AT-162, "

DTC Confirmation Procedure" .

OK or NG

OK >> INSPECTION END

NG >> GO TO 5.

Item Connector Terminal Continuity

TCM E3110

Ye s

Input speed sensor F471

TCM E3119

Ye s

Input speed sensor F471

JSDIA1512GB

Item Connector Terminal Continuity

TCM E3242

Ye s

Input speed sensor F473

JSDIA1513ZZ

Revision: May 2010 2011 Versa

Page 186 of 3787

MAIN POWER SUPPLY AND GROUND CIRCUITAT-169

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

Diagnosis ProcedureINFOID:0000000005928238

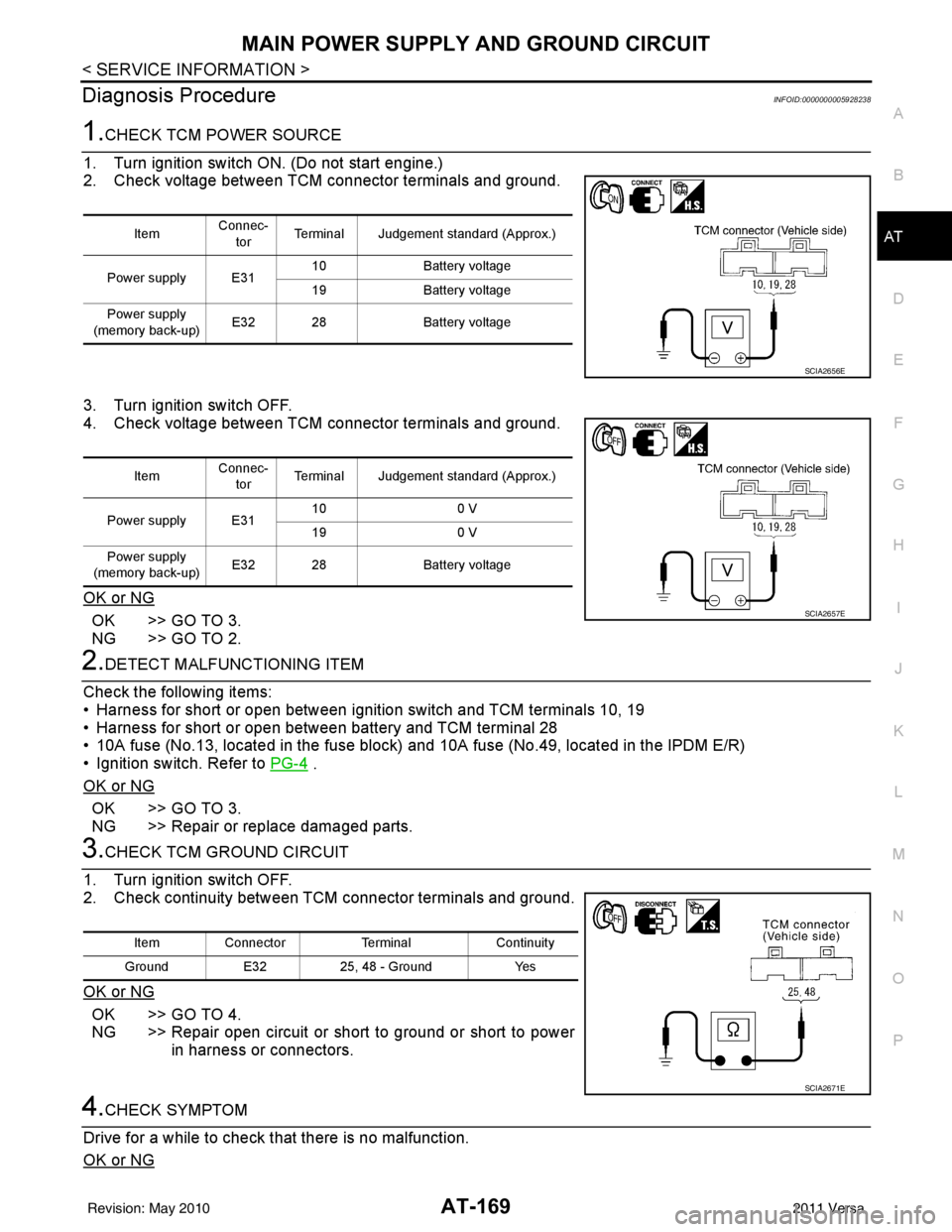

1.CHECK TCM POWER SOURCE

1. Turn ignition switch ON. (Do not start engine.)

2. Check voltage between TCM connector terminals and ground.

3. Turn ignition switch OFF.

4. Check voltage between TCM connector terminals and ground.

OK or NG

OK >> GO TO 3.

NG >> GO TO 2.

2.DETECT MALFUNCTIONING ITEM

Check the following items:

• Harness for short or open between ignition switch and TCM terminals 10, 19

• Harness for short or open between battery and TCM terminal 28

• 10A fuse (No.13, located in the fuse block) and 10A fuse (No.49, located in the IPDM E/R)

• Ignition switch. Refer to PG-4

.

OK or NG

OK >> GO TO 3.

NG >> Repair or replace damaged parts.

3.CHECK TCM GROUND CIRCUIT

1. Turn ignition switch OFF.

2. Check continuity between TCM connector terminals and ground.

OK or NG

OK >> GO TO 4.

NG >> Repair open circuit or short to ground or short to power in harness or connectors.

4.CHECK SYMPTOM

Drive for a while to check that there is no malfunction.

OK or NG

Item Connec-

tor Terminal Judgement standard (Approx.)

Power supply E31 10

Battery voltage

19 Battery voltage

Power supply

(memory back-up) E32 28

Battery voltage

SCIA2656E

ItemConnec-

tor Terminal Judgement standard (Approx.)

Power supply E31 10

0 V

19 0 V

Power supply

(memory back-up) E32 28

Battery voltage

SCIA2657E

Item Connector TerminalContinuity

Ground E3225, 48 - Ground Yes

SCIA2671E

Revision: May 2010 2011 Versa

Page 190 of 3787

TR SW, OD SW AND CLOSED THROTTLE, WIDE OPEN THROTTLE POSITION

SIGNAL CIRCUIT

AT-173

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

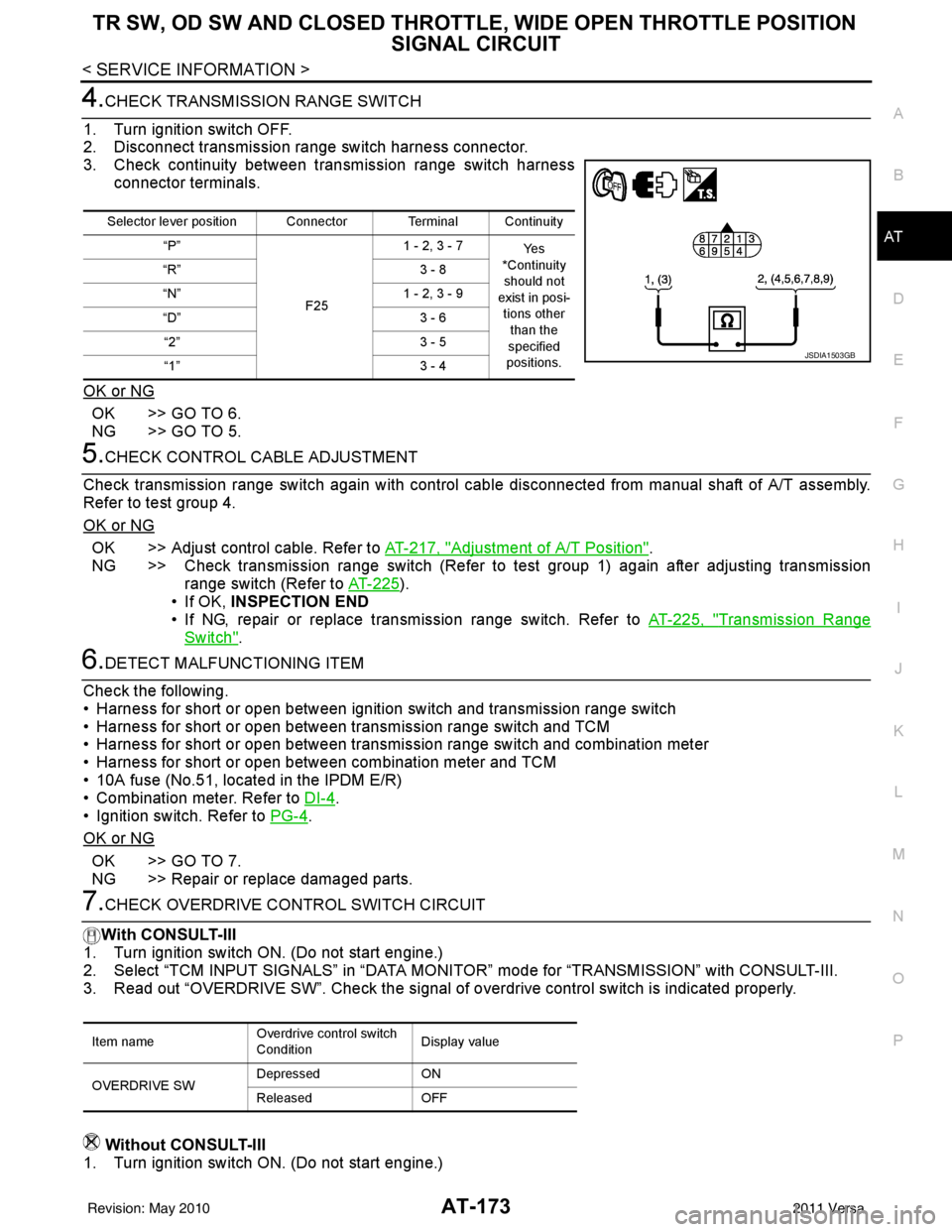

4.CHECK TRANSMISSION RANGE SWITCH

1. Turn ignition switch OFF.

2. Disconnect transmission range switch harness connector.

3. Check continuity between transmission range switch harness connector terminals.

OK or NG

OK >> GO TO 6.

NG >> GO TO 5.

5.CHECK CONTROL CABLE ADJUSTMENT

Check transmission range switch again with control cabl e disconnected from manual shaft of A/T assembly.

Refer to test group 4.

OK or NG

OK >> Adjust control cable. Refer to AT-217, "Adjustment of A/T Position".

NG >> Check transmission range switch (Refer to test group 1) again after adjusting transmission range switch (Refer to AT-225

).

• If OK, INSPECTION END

• If NG, repair or replace transmission range switch. Refer to AT-225, "

Transmission Range

Switch".

6.DETECT MALFUNCTIONING ITEM

Check the following.

• Harness for short or open between ignition switch and transmission range switch

• Harness for short or open between transmission range switch and TCM

• Harness for short or open between transmission range switch and combination meter

• Harness for short or open between combination meter and TCM

• 10A fuse (No.51, located in the IPDM E/R)

• Combination meter. Refer to DI-4

.

• Ignition switch. Refer to PG-4

.

OK or NG

OK >> GO TO 7.

NG >> Repair or replace damaged parts.

7.CHECK OVERDRIVE CO NTROL SWITCH CIRCUIT

With CONSULT-III

1. Turn ignition switch ON. (Do not start engine.)

2. Select “TCM INPUT SIGNALS” in “DATA MONI TOR” mode for “TRANSMISSION” with CONSULT-III.

3. Read out “OVERDRIVE SW”. Check the signal of ov erdrive control switch is indicated properly.

Without CONSULT-III

1. Turn ignition switch ON. (Do not start engine.)

Selector lever position Connector Terminal Continuity

“P”

F251 - 2, 3 - 7

Ye s

*Continuity should not

exist in posi-

tions other than the

specified

positions.

“R”

3 - 8

“N” 1 - 2, 3 - 9

“D” 3 - 6

“2” 3 - 5

“1” 3 - 4

JSDIA1503GB

Item nameOverdrive control switch

ConditionDisplay value

OVERDRIVE SW Depressed

ON

Released OFF

Revision: May 2010 2011 Versa

Page 198 of 3787

TROUBLE DIAGNOSIS FOR SYMPTOMSAT-181

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

OD OFF indicator lamp does not come on for abou t 2 seconds when turning ignition switch to ON.

DIAGNOSTIC PROCEDURE

1.CHECK CAN COMMUNICATION LINE

Perform self-diagnosis. Refer to AT-77, "

CONSULT-III Function (TRANSMISSION)" .

Is a malfunction in CAN communication indicated in the results?

YES >> Check CAN communication line. Refer to AT- 8 7 .

NO >> GO TO 2.

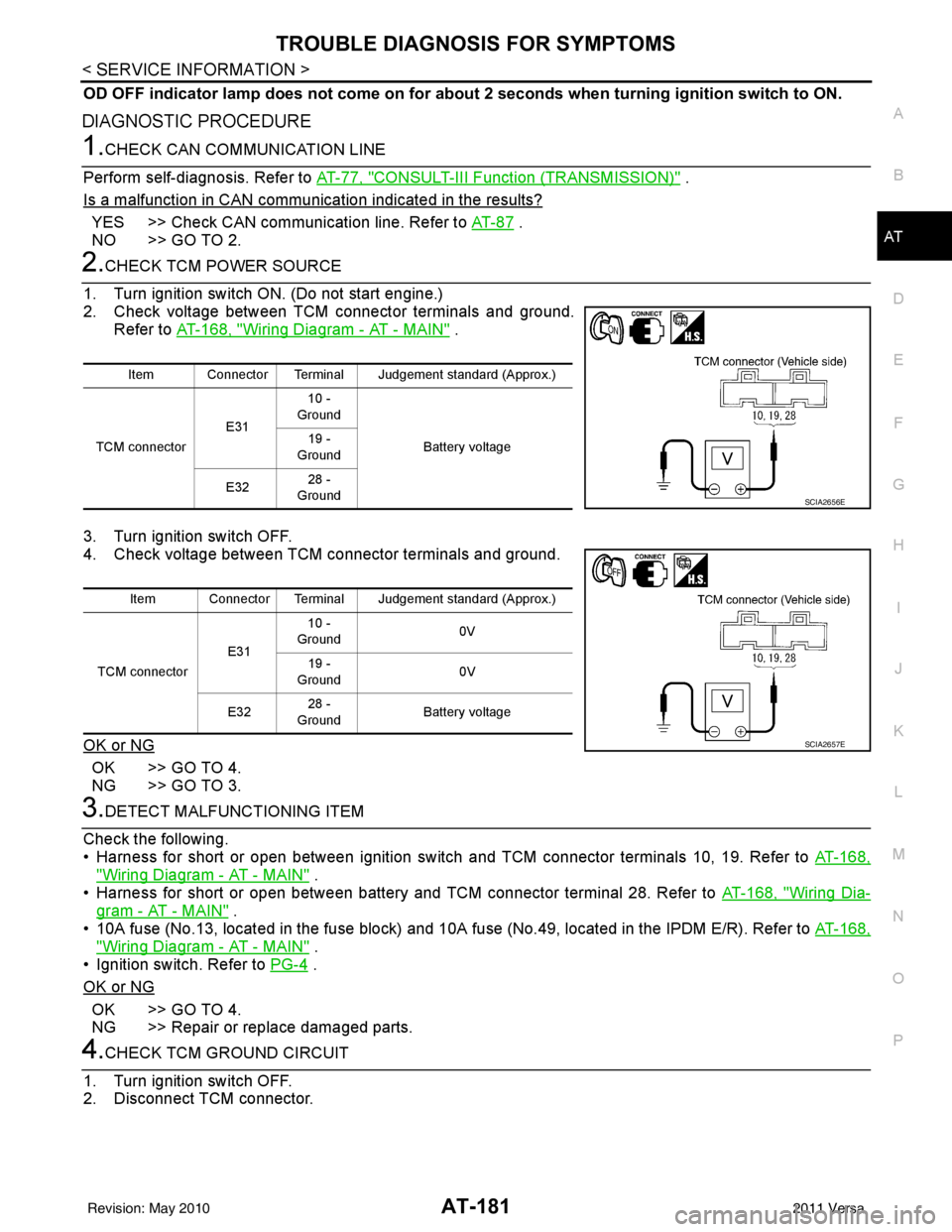

2.CHECK TCM POWER SOURCE

1. Turn ignition switch ON. (Do not start engine.)

2. Check voltage between TCM connector terminals and ground. Refer to AT-168, "

Wiring Diagram - AT - MAIN" .

3. Turn ignition switch OFF.

4. Check voltage between TCM connector terminals and ground.

OK or NG

OK >> GO TO 4.

NG >> GO TO 3.

3.DETECT MALFUNCTIONING ITEM

Check the following.

• Harness for short or open between ignition switch and TCM connector terminals 10, 19. Refer to AT-168,

"Wiring Diagram - AT - MAIN" .

• Harness for short or open between battery and TCM connector terminal 28. Refer to AT-168, "

Wiring Dia-

gram - AT - MAIN" .

• 10A fuse (No.13, located in the fuse block) and 10A fuse (No.49, located in the IPDM E/R). Refer to AT-168,

"Wiring Diagram - AT - MAIN" .

• Ignition switch. Refer to PG-4

.

OK or NG

OK >> GO TO 4.

NG >> Repair or replace damaged parts.

4.CHECK TCM GROUND CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect TCM connector.

Item Connector Terminal Judgement standard (Approx.)

TCM connector E3110 -

Ground

Battery voltage

19 -

Ground

E32 28 -

Ground

SCIA2656E

Item Connector Terminal Judgement standard (Approx.)

TCM connector E3110 -

Ground 0V

19 -

Ground 0V

E32 28 -

Ground Battery voltage

SCIA2657E

Revision: May 2010

2011 Versa

Page 495 of 3787

BCM (BODY CONTROL MODULE)BCS-5

< SERVICE INFORMATION >

C

DE

F

G H

I

J

L

M A

B

BCS

N

O P

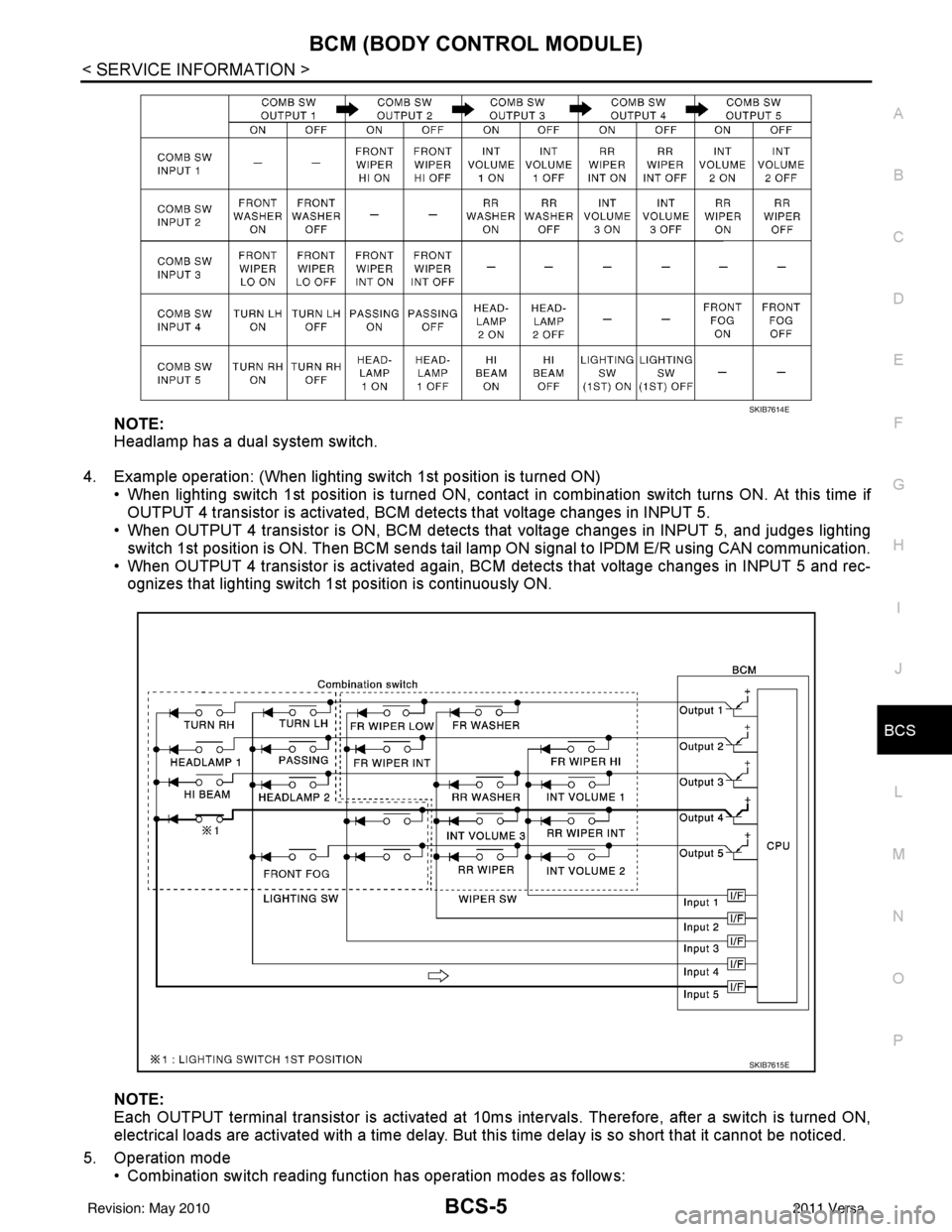

NOTE:

Headlamp has a dual system switch.

4. Example operation: (When lighting switch 1st position is turned ON) • When lighting switch 1st position is turned ON, contact in combination switch turns ON. At this time ifOUTPUT 4 transistor is activated, BCM detects that voltage changes in INPUT 5.

• When OUTPUT 4 transistor is ON, BCM detects that voltage changes in INPUT 5, and judges lighting

switch 1st position is ON. Then BCM sends tail lamp ON signal to IPDM E/R using CAN communication.

• When OUTPUT 4 transistor is activated again, BC M detects that voltage changes in INPUT 5 and rec-

ognizes that lighting switch 1st position is continuously ON.

NOTE:

Each OUTPUT terminal transistor is activated at 10ms intervals. Therefore, after a switch is turned ON,

electrical loads are activated with a time delay. But this time delay is so short that it cannot be noticed.

5. Operation mode • Combination switch reading functi on has operation modes as follows:

SKIB7614E

SKIB7615E

Revision: May 2010 2011 Versa

Page 496 of 3787

BCS-6

< SERVICE INFORMATION >

BCM (BODY CONTROL MODULE)

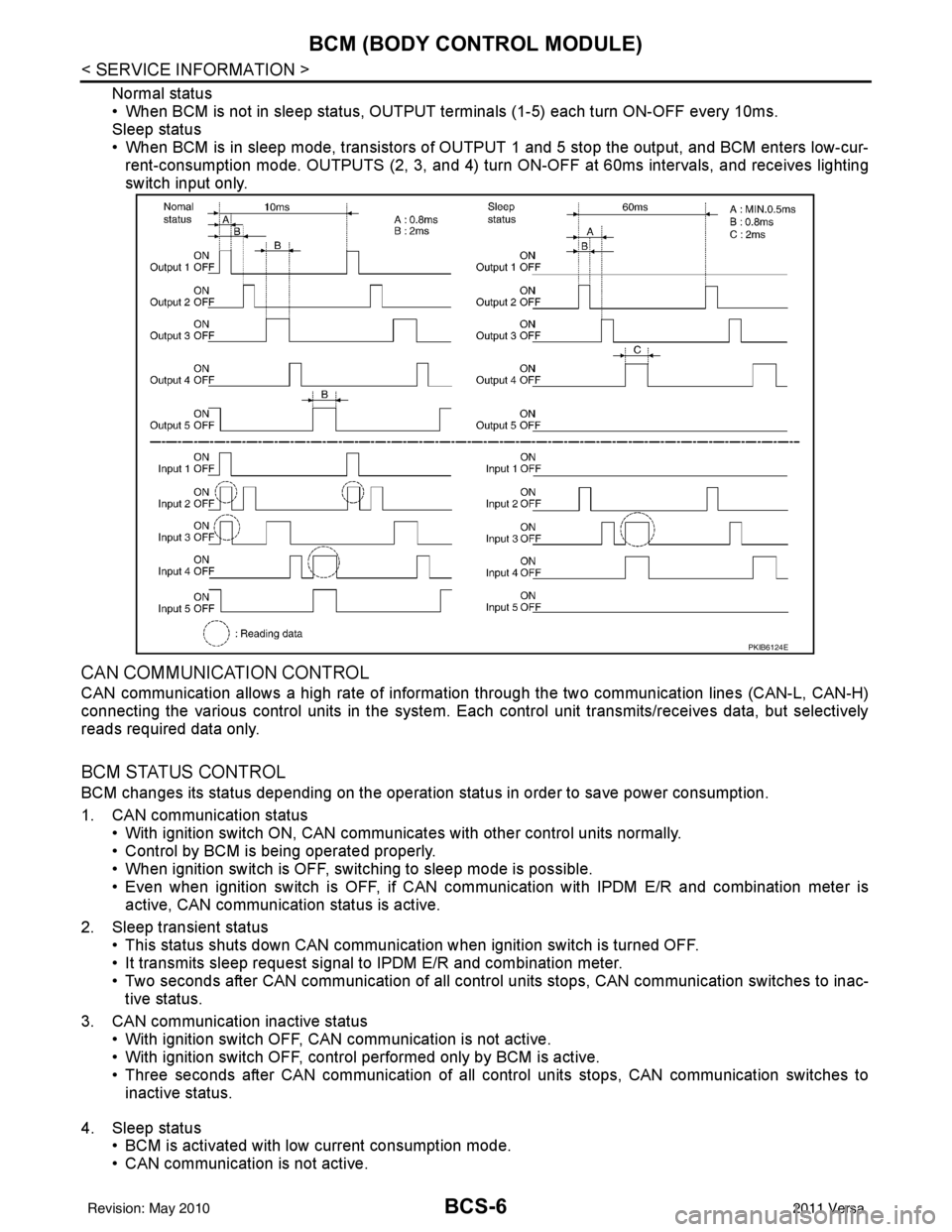

Normal status

• When BCM is not in sleep status, OUTPUT terminals (1-5) each turn ON-OFF every 10ms.

Sleep status

• When BCM is in sleep mode, transistors of OUTPUT 1 and 5 stop the output, and BCM enters low-cur-

rent-consumption mode. OUTPUTS (2, 3, and 4) turn ON-OFF at 60ms intervals, and receives lighting

switch input only.

CAN COMMUNICATION CONTROL

CAN communication allows a high rate of information through the two communication lines (CAN-L, CAN-H)

connecting the various control units in the system. Each control unit transmits/receives data, but selectively

reads required data only.

BCM STATUS CONTROL

BCM changes its status depending on the operation stat us in order to save power consumption.

1. CAN communication status • With ignition switch ON, CAN communicates with other control units normally.

• Control by BCM is being operated properly.

• When ignition switch is OFF, switching to sleep mode is possible.

• Even when ignition switch is OFF, if CAN communication with IPDM E/R and combination meter isactive, CAN communication status is active.

2. Sleep transient status • This status shuts down CAN communication when ignition switch is turned OFF.

• It transmits sleep request signal to IPDM E/R and combination meter.

• Two seconds after CAN communication of all control units stops, CAN communication switches to inac-tive status.

3. CAN communication inactive status • With ignition switch OFF, CAN communication is not active.

• With ignition switch OFF, control performed only by BCM is active.

• Three seconds after CAN communication of all control units stops, CAN communication switches to

inactive status.

4. Sleep status • BCM is activated with low current consumption mode.

• CAN communication is not active.

PKIB6124E

Revision: May 2010 2011 Versa

Page 497 of 3787

BCM (BODY CONTROL MODULE)BCS-7

< SERVICE INFORMATION >

C

DE

F

G H

I

J

L

M A

B

BCS

N

O P

• When CAN communication operation is detected, it switches to CAN communication status.

• When a state of the following switches changes , it switches to CAN communication state:

- Ignition switch

- Key switch (without Intelligent Key)

- Key switch and ignition knob switch (with Intelligent Key)

- Hazard switch

- Door lock/unlock switch (with power door locks)

- Front door switch (LH, RH)

- Rear door switch (LH, RH)

- Back door lock assembly (Hatchback)

- Trunk key cylinder switch (Sedan)

- Trunk lamp switch and trunk release solenoid (Sedan)

- Combination switch (passing, lighting switch 1st position, front fog lamp)

- Keyfob (lock/unlock signal) (with power door locks)

- Front door key cylinder switch LH

• When control performed only by BCM is required by switch, it shifts to CAN communication inactive mode.

• Status of combination switch reading function is changed.

SYSTEMS CONTROLLED BY BCM DIRECTLY

• Power door lock system (with power door locks). Refer to BL-23, "System Description" .

• Remote keyless entry system. Refer to BL-58, "

System Description" .

• Power window system (with power windows). Refer to GW-19, "

System Description" . NOTE

• Sunroof system (with sunroof). Refer to RF-11, "System Description". NOTE

• Room lamp timer. Refer to LT-93, "System Description" .

• Rear wiper and washer system (Hatchback). Refer to WW-27, "

System Description" .

NOTE:

Power supply only. No system control.

SYSTEMS CONTROLLED BY BCM AND IPDM E/R

• Panic system. Refer to BL-58, "System Description" .

• Vehicle security (theft warning) system. Refer to BL-218, "

System Description" .

• NVIS(NATS) system. Refer to BL-246, "

System Description" .

• Headlamp, tail lamp and battery saver control systems. Refer to LT-74, "

System Description", LT- 5 , "System

Description" or LT-27, "System Description" .

• Front fog lamp (with front fog lamps). Refer to LT-41, "

System Description" .

• Front wiper and washer system. Refer to WW-5, "

System Description" .

• Rear window defogger system. Refer to GW-51, "

System Description" .

SYSTEMS CONTROLLED BY BCM AND COMBINATION METER

• Warning chime. Refer to DI-43, "System Description" .

• Turn signal and hazard warning lamps. Refer to LT-50, "

System Description" .

SYSTEMS CONTROLLED BY BCM AND INTELLIGENT KEY UNIT (WITH INTELLIGENT KEY)

• Intelligent Key system. Refer to BL-88, "System Description" .

MAJOR COMPONENTS AND CONTROL SYSTEM

System Input Output

Remote keyless entry system (with

power door locks) Remote keyless entry receiver

(keyfob)• All door locking actuators

• Turn signal lamp (LH, RH)

• Combination meter (turn signal lamp)

Intelligent Key system (with Intelligent

Key) Intelligent Key unit• All door locking actuators

• Turn signal lamp (LH, RH)

• Combination meter (turn signal lamp)

Power door lock system (with power

door locks) Front power door lock/unlock

switch (LH, RH)

All door locking actuators

Power supply (IGN /RAP) to power

window (with power windows) Ignition retained power supply Power supply to power window and sunroof system

Power supply (BAT) to power window

(with power windows) Battery power supply

Power supply to power window and sunroof system

Revision: May 2010 2011 Versa